#NDT Inspection Services

Text

Enhance Safety with Professional Penetrant Inspection Services

Protect your equipment and components with MyNDT’s professional Penetrant Inspection. Our non-destructive testing method efficiently identifies surface defects, such as cracks and leaks, in non-porous materials. Trust our certified technicians to provide clear, accurate results that help you stay ahead of potential failures.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndttraining#ndt#non destructive entry#business#services#Penetrant Inspection

0 notes

Text

Unmatched NDT Inspection Services in Dubai by Falcon Laboratory LLC

Falcon Laboratory LLC offers the best NDT inspection services in Dubai, ensuring precise and reliable testing for various industries. Our advanced non-destructive testing methods guarantee safety, quality, and compliance, making them a trusted partner for all your inspection needs in the UAE.

Know More: https://www.falconlabuae.com/ndt-services/

0 notes

Text

Understanding Ferrite Testing in Pune: A Comprehensive Guide

Ferrite testing, a critical aspect of non-destructive testing (NDT), plays a pivotal role in ensuring the integrity and quality of welds, particularly in stainless steel components. In Pune, a hub of industrial activity, the demand for accurate and reliable ferrite testing services is paramount to maintaining safety standards and operational efficiency across various sectors.

Ferrite Testing Services in Pune

Ferrite testing services in Pune are essential for industries ranging from manufacturing to construction, where the properties of stainless steel must meet stringent specifications. These services involve the measurement of ferrite content within welds, which directly impacts their mechanical and corrosion-resistant properties. Integrated NDE offers comprehensive ferrite testing services in Pune, utilizing advanced NDT techniques to provide precise and reliable results.

Importance of Non Destructive Testing (NDT) in Pune

Non-destructive testing (NDT) in Pune is integral to ensuring the structural integrity and safety of industrial components without causing damage. Ferrite testing, as part of NDT, assesses the ferrite content in stainless steel welds to determine their susceptibility to corrosion, cracking, and mechanical failure over time. This proactive approach helps industries in Pune mitigate risks and enhance the longevity of their assets.

Ferrite Testing: Methodology and Applications

The methodology of ferrite testing involves using electromagnetic induction to measure the ferrite content in stainless steel welds. This process is non-invasive and provides immediate results, making it ideal for on-site inspections and quality control in Pune's industrial settings. Integrated NDE employs trained technicians and state-of-the-art equipment to conduct ferrite inspections accurately and efficiently.

Ferrite Testing of Welds in Pune

In Pune, ferrite testing of welds is crucial for verifying weld quality and compliance with industry standards such as ASME, AWS, and API. By assessing the ferrite content, engineers and inspectors can determine the weld's structural integrity, its ability to withstand environmental conditions, and its performance under stress. This meticulous testing process ensures that welds meet the specified ferrite range, thereby enhancing reliability and safety.

Ferrite Testing in Stainless Steel: Ensuring Durability and Performance

Stainless steel's corrosion resistance and mechanical strength depend significantly on its ferrite content. Ferrite testing in Pune's stainless steel applications ensures that components meet design specifications and regulatory requirements. Whether for aerospace, automotive, or infrastructure projects, accurate ferrite testing by Integrated NDE helps businesses in Pune deliver products that are durable, safe, and cost-effective.

Choosing Integrated NDE for Ferrite Testing Services

Integrated NDE stands out in Pune's NDT landscape for its commitment to excellence and client satisfaction. With years of experience and a team of certified professionals, Integrated NDE offers tailored ferrite testing solutions that meet the unique needs of Pune's diverse industries. Their expertise spans across various sectors, including oil and gas, manufacturing, and power generation, ensuring comprehensive support for quality assurance and regulatory compliance.

Conclusion

In conclusion, ferrite testing services in Pune, provided by Integrated NDE, are indispensable for industries seeking reliable NDT solutions. By conducting thorough ferrite inspections, businesses can enhance product quality, extend asset lifespan, and maintain operational efficiency. For companies in Pune looking to optimize their welding processes and ensure compliance with international standards, partnering with Integrated NDE ensures peace of mind and superior outcomes.

#ferrite testing in pune#ferrite testing services#non destructive testing in Pune#ndt testing#ferrite testing#ferrite inspection#ferrite testing of welds#ferrite testing stainless steel#destructive testing#non destructive testing#ndt inspection services

0 notes

Text

Why Do Engineering Safety Inspection Services Matter in Management and Supervision?

In today’s competitive industrial world, safety is no longer a luxury; it’s a fundamental cornerstone of successful operations. Accidents not only have devastating human consequences, but they also lead to costly downtime, production delays, and potential legal ramifications. This is where engineering safety inspection services come into play — acting as a critical partner for management and supervision in ensuring a safe and productive work environment.

Proactive Risk Mitigation:

One of the most significant advantages of employing engineering safety inspection services is their focus on proactive risk mitigation. Unlike reactive approaches that address issues only after an incident occurs, these services utilize a proactive strategy to identify potential hazards and safety concerns before they develop into accidents. Through comprehensive inspections conducted by qualified professionals, these services can uncover:

Equipment malfunctions: Regular inspections can detect potential equipment failures before they happen, allowing for timely maintenance and repairs. This not only prevents accidents but also extends the lifespan of valuable equipment.

Process safety hazards: Improper procedures or deviations from safety protocols can create unseen dangers. Engineering safety inspections scrutinize existing processes and procedures, recommending modifications to eliminate these hazards.

Environmental concerns: Leaks, spills, and hazardous materials pose a significant threat to both personnel and the environment. Inspection services can identify these issues and recommend corrective actions to ensure a safe and sustainable work environment.

Improved Compliance:

Safety regulations and standards are constantly changing, and keeping pace with these changes can be a challenge for management teams. Engineering safety inspection services possess in-depth knowledge of relevant regulations and standards. Their inspections ensure your operations adhere to these requirements, minimizing the risk of compliance violations and potential legal consequences.

Enhanced Employee Morale and Productivity:

When employees feel safe and confident in their work environment, their morale and productivity naturally increase. Regular safety inspections demonstrate a commitment to worker safety, fostering an atmosphere of trust and well-being. Employees feel valued and are more likely to be engaged in their work, leading to improved efficiency and overall performance.

Reduced Operational Costs:

While the cost of engineering safety inspection services might seem like an additional expense at first glance, in the long run, it is a valuable investment. By preventing accidents, injuries, and downtime, these services lead to significant cost savings. Additionally, reduced repair costs, improved equipment lifespan, and lower insurance premiums contribute to a healthier bottom line.

Data-Driven Decision Making:

Engineering safety inspections yield valuable data and insights that empower management and supervision to make informed decisions regarding safety protocols and resource allocation. These reports can identify trends and patterns, allowing for targeted interventions and resource allocation to address priority areas.

Continuous Improvement:

The safety inspection process is not a one-time event. Regular inspections create a culture of continuous improvement within your organisation. By identifying and addressing safety concerns proactively, management can demonstrate a commitment to creating and maintaining a safe work environment. This fosters a proactive safety culture where employees feel empowered to report potential hazards, leading to ongoing improvement in safety practices.

Choosing the Right Inspection Service Provider:

When selecting an engineering safety inspection service provider, it’s crucial to choose a company with qualified professionals who have experience and expertise in your specific industry. Look for a provider that offers comprehensive inspection, use of relevant standards and regulations, and can translate complex findings into actionable recommendations.

Conclusion:

In conclusion, engineering safety and ndt inspection services are not just a tick-the-box exercise but a crucial investment in the safety, well-being, and overall success of your organization. By partnering with a reputable inspection service provider, management and supervision gain valuable insights, proactive risk mitigation strategies, and improved compliance, fostering a safe, productive, and cost-effective work environment for everyone.

To learn more contact the experts at RiskCON today.

#non destructive evaluation

#non-destructive testing

#engineering services

#welding engineer

#visual inspection

#ndt certification

#welding engineering

#mag particle testing

#ndt inspector

#testing and inspections

#ultrasonic test

#ndt inspection services

#ultrasonic inspection

#visual testing

#inspection engineer

#engineering and inspection services

#construction engineering and inspection services

#engineering & inspection services

#engineering safety inspection services

#welding engineering inspection services

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#ultrasonic test#ndt inspection services#visual testing#non destructive evaluation#non-destructive testing#engineering services

0 notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Quality Inspection Services#Factory Acceptance Test#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Hydrostatic & Performance Tests#Welding Inspection Services#expediting services

0 notes

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development,Total quality management.Vendor pre evaluation, Inspection and Expediting Services,Pre-Shipment Inspection,NDT inspection and testing like Radiography and many more.

For more details please visit our website-

https://avengineersefp.com/service/third-party-inspection-ndt-services/

0 notes

Text

AG Price Fabrication Shop | Experienced Metal Fabrication in New Zealand

AG Price Fabrication Shop offers a wide range of metal fabrication services for various industries. Their experienced fitters can weld, stress relieve, and perform NDT inspections on-site. They have a long history and a variety of equipment to meet your needs.to know more please visit us for more details: https://www.agprice.co.nz/fabrication-shop

#mining industry#foundry#metal fabrication New Zealand#fabrication shop Auckland#welding services New Zealand#NDT inspection#metal fabrication#custom metal fabrication#metal fabrication company#fabrication workshop#stainless steel fabrication#steel fabrication#aluminum fabrication

0 notes

Text

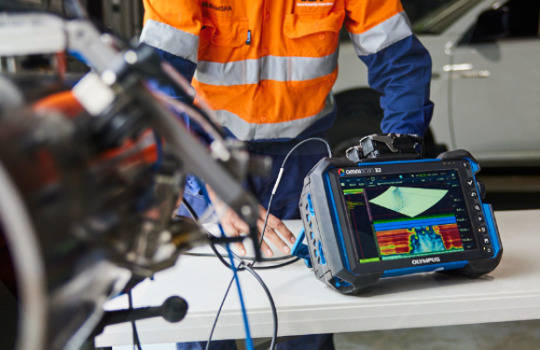

The Value of Advanced NDT Techniques in Tube Inspection

Ensuring the optimal performance and safety of industrial equipment is a top priority across various sectors. One critical aspect of maintaining such performance is through Tube Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services are indispensable for industries that rely on the efficient functioning of tubes, such as in heat exchangers, boilers, and condensers. Here, we explore the importance of Inspection Services and how they contribute to the overall health of industrial systems.

Preventive Maintenance e Precision

Inspection Services are fundamental to preventive maintenance strategies. By regularly inspecting tubes, potential issues can be identified before they lead to significant failures or costly downtime. This proactive approach not only enhances the longevity of the equipment but also ensures that it operates at peak efficiency. Regular inspections help detect early signs of wear and tear, corrosion, and other forms of degradation, allowing for timely interventions that can prevent more severe damage.

Advanced Inspection Techniques

The effectiveness of Inspection Services is greatly enhanced by advanced non-destructive testing (NDT) methods. Techniques such as eddy current testing, ultrasonic testing, and remote visual inspection are commonly employed to assess the condition of tubes without causing any damage. Inspectors with NDT Level 2 Certification Courses from RVS QUALITY CERTIFICATIONS PVT LTD are trained to use these advanced methods to accurately identify defects, including cracks, pitting, and wall thinning. This high level of precision ensures that even the smallest issues are detected, enabling precise maintenance planning and execution.

Optimizing System Efficiency

The performance of systems that rely on tubes, such as heat exchangers and boilers, directly impacts the overall efficiency of industrial operations. Any compromise in the integrity of these tubes can lead to reduced heat transfer efficiency, increased energy consumption, and higher operational costs. By employing comprehensive Inspection Services, organizations can maintain optimal system performance. These inspections help ensure that the tubes are free from blockages, corrosion, and other issues that could impede their functionality, thereby sustaining efficient and cost-effective operations.

Safety and Compliance

Ensuring the safety of industrial operations is paramount, and Inspection Services play a crucial role in this regard. Faulty tubes can lead to catastrophic failures, posing serious risks to personnel and equipment. Regular inspections help mitigate these risks by identifying and addressing potential issues before they escalate. Furthermore, industries are often required to comply with stringent safety and regulatory standards. Third-party Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD provide an additional layer of assurance, validating that the equipment meets all necessary compliance requirements. This external validation not only enhances safety but also boosts the organization's credibility and reliability.

Cost-Effective Maintenance

While some may view Inspection Services as an added expense, they are, in fact, a cost-effective maintenance strategy. Early detection of issues through regular inspections can prevent costly repairs, extensive downtime, and loss of productivity. The ability to plan maintenance activities based on accurate inspection data allows organizations to allocate resources more efficiently and avoid unexpected breakdowns. In the long run, the investment in Inspection Services pays off by reducing the total cost of ownership and maximizing the return on investment for industrial equipment.

Training and Expertise

The effectiveness of Inspection Services is highly dependent on the expertise of the inspectors. Professionals trained through NDT Certification Courses possess the necessary skills and knowledge to perform thorough and accurate inspections. Their expertise ensures that all potential issues are identified and appropriately addressed. Continuous training and certification updates are essential to keep inspectors abreast of the latest advancements in inspection technologies and methodologies, thereby maintaining high standards of service quality.

In conclusion, Inspection Services are essential for ensuring the optimal performance, safety, and efficiency of industrial systems. By incorporating advanced non-destructive testing techniques and leveraging the expertise of certified professionals, organizations can proactively manage the health of their equipment. Regular inspections help prevent costly failures, ensure compliance with safety standards, and enhance overall operational efficiency. For industries striving to maintain high-performance standards and minimize risks, investing in Inspection Services is a prudent and necessary decision.

0 notes

Text

CMM Inspection Services For Precision and Quality Assurance

Nel PreTech specializes in providing comprehensive CMM inspection services for precision and quality assurance. Leveraging cutting-edge technology, our team ensures meticulous dimensional measuring to prevent errors and uphold the highest standards of quality. From first article inspection to part validation, gage R&R, and capability studies, we assist manufacturers in various industries, including automotive, aerospace, and medical devices. Trust Nel PreTech for accurate measurements, efficient inspections, and cost-effective solutions to enhance your product quality and reduce manufacturing costs. Contact us at 708-429-4887 to learn more about our services.

#cmm inspection services#3d scanning chicago#industrial ct scan#dimensional inspection#ndt x-ray#3d scanning

0 notes

Link

0 notes

Text

Revolutionizing Inspection Processes with Nondestructive Testing

Nondestructive Testing (NDT) has transformed how industries approach inspection and maintenance. At MyNDT, we specialize in delivering precise and reliable NDT services that minimize downtime and maximize efficiency. Delve into our range of NDT techniques, from advanced digital radiography to sophisticated ultrasonic testing.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndt#ndttraining#non destructive entry

0 notes

Text

Top-Quality NDT Inspection Services in Dubai by Falcon Laboratory LLC

Falcon Laboratory LLC offers the best NDT inspection services in Dubai, ensuring top-notch quality and safety standards. Using advanced non-destructive testing techniques, we provide accurate and reliable results for various industries. Trust Falcon Laboratory for comprehensive inspection solutions that guarantee structural integrity and operational efficiency.

Know More: https://www.falconlabuae.com/ndt-services/

0 notes

Text

Certified Dye Penetrant Inspection Services in Pune

Here at Integrated NDE, we take great pride in offering the best Dye Penetrant Inspection (DPI) services in Pune. Consider DPI as a material detective, able to uncover hidden fissures and defects that are not apparent to the unaided eye. From metals to ceramics, this non-destructive testing technique works flawlessly on a variety of materials.

Our DPI Process:1) Surface washing: To make sure the surface is clear of any impurities that could conceal flaws, we begin by carefully washing it.

Using Penetrant: After that, a dye that is visible or fluorescent is applied. This dye uses capillary action to infiltrate into surface-breaking defects.

3) Dwell Time: The penetrant is allowed to fully permeate any flaws by remaining on the surface for a predetermined amount of time.

4) Removing Extra Penetrant: To ensure that the dye inside the flaws remains in situ, excess dye is carefully removed.

5) Developer Application: To extract the penetrant from the defects and produce visible signs, a developer is applied.

6) Inspection: After that, our knowledgeable inspectors look over the surface in the right lighting to look for any flaws.

Why Opt for DPI?

Why Choose DPI?

DPI is a flexible, affordable, and extremely sensitive method of detecting surface-breaking faults, even at the tiniest ones. It is a dependable option for regular inspections in a number of sectors, such as industrial, automotive, and aerospace.

Our Expertise: Our staff at Integrated NDE has received the greatest certifications and training available. We guarantee the integrity and safety of your components by using the most up-to-date methods and tools to deliver accurate and trustworthy findings.

Applications: DPI is perfect for checking machined items, castings, forgings, and welds. Our services are made to satisfy the demanding needs of many sectors, whether they be for automotive or aerospace components.

Get in touch with us:

Go to Integrated NDE for reliable Dye Penetrant Inspection services in Pune. In each inspection, we promise to provide quality and dependability. For additional information, see our article on dye penetrant inspection.

At Integrated NDE, we take the highest care to ensure the safety and soundness of your components, treating them like a detective uncovering buried secrets.

#dye penetrate inspection#dye penetrate testing#dye penetrate inspection services in pune#non destructive testing#destructive testing#non destructive weld testing#ndt inspection services#"non destructive inspection#non destructive testing radiography#ndt testing

0 notes

Text

How Mag Particle Testing Protects Your Critical Assets?

Our world relies on a vast network of critical assets. From the towering wind turbines that harvest clean energy to the intricate pipelines that transport vital resources, these structures form the backbone of modern civilization. However, hidden beneath the surface of these assets can lurk a silent threat: cracks. These imperfections, often invisible to the naked eye, can pose a significant risk to safety, functionality, and operational efficiency. To read more visit

#welding engineering inspection services#engineering safety inspection services#engineering & inspection services#construction engineering and inspection services#engineering and inspection services#inspection engineer#visual testing#ultrasonic inspection#ndt inspection services#ultrasonic test#testing and inspections#ndt inspector#mag particle testing#welding engineering#ndt certification#visual inspection#welding engineer#engineering services#non-destructive testing#non destructive evaluation

0 notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Factory Acceptance Test#Quality Inspection Services#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Welding Inspection Services#Third Party Industrial Inspection Services#Witness Inspection Services#Positive Material identification Services#IT Inspection Services#Cyber Security Assessment Services#Vulnerability management services#Audit and Assessments Services

0 notes

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development,Total quality management.Vendor pre evaluation, Inspection and Expediting Services,Pre-Shipment Inspection,NDT inspection and testing like Radiography and many more.

For more details please visit our website-

0 notes