#Aerospace and defense inspection Services

Text

Witness Inspection: Quality Assurance at its Best!

Look no further! AQSS-USA's Witness Inspection services are here to uphold the utmost standards of quality and compliance.

+1 713-789-0885 | [email protected] |

#witness inspection services#oil and gas inspection services#hydrostatic & performance tests#aerospace and defense inspection services#witness inspection#gap and internal auditing services#third party industrial inspection services#welding inspection services#nuclear inspection services#first article inspection services

2 notes

·

View notes

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Quality Inspection Services#Factory Acceptance Test#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Hydrostatic & Performance Tests#Welding Inspection Services#expediting services

0 notes

Text

Government of Canada orders 4 new Airbus A330 MRTTs

Diego Alves By Diego Alves 07/26/2023 - 12:00m Military

In an effort to strengthen its continental defense capabilities, the government of Canada granted Airbus Defence and Space a contract for four newly built Airbus A330 Multi Role Tanker Transport (MRTT) aircraft and the conversion of five used A330-200s.

With an order value of approximately CAD $3 billion, this Strategic Air Transport and Refueling Capacity (STTC) initiative aims to replace the former CC-150 Polaris fleet (A310 MRTT) currently operated by the Royal Canadian Air Force (RCAF).

The A330 MRTT was considered the appropriate solution to Canada's requirements to protect its sovereignty and improve operations within the North American Aerospace Defense Command (NORAD) and NATO. “As the most advanced multi-mission tanker in the world, the A330 MRTT perfectly meets the needs of Canada,” said Mike Schoellhorn, executive director of Airbus Defence and Space. The aircraft's superior technological capabilities, combined with its interoperability with other allied client nations of the A330 MRTT, position it ahead of global competition.

The new A330-200 fleet will be set up in Toulouse, France, and will undergo a conversion at the A330 MRTT facility in Getafe, Spain, from 2025. The first MRTT is scheduled for delivery to the RCAF in 2027. The A330 MRTTs will be equipped with refueling options via hoses, drugs and booms, along with cybersecurity solutions and countermeasures. In addition, the aircraft will have the Airbus Medical Evacuation kit solution, with two Intensive Care Units and additional stretchers.

The contract includes advanced training services, featuring the Full Flight Simulator, to ensure crew readiness and modernize the air operational training infrastructure of the Canadian Armed Forces. Airbus was selected as the only qualified supplier for the replacement of the C-150 refuel after an acquisition process opened in April 2021.

With 76 requests from 15 customers and proven combat experience in theaters such as the Middle East and the Eastern Flank in Europe, the A330 MRTT has a market share of 90% outside the US and more than 270,000 flight hours. The history of interoperability, mission success and high availability rates of this mature platform highlights its remarkable performance and makes it the ideal choice for Canada's strategic defense needs.

Tags: A330 MRTTairbusMilitary AviationRCAF - Royal Canadian Air Force/Canada Air Force

Sharing

tweet

Diego Alves

Diego Alves

Related news

MILITARY

Concerns about the numbers of the RAF in the North Atlantic

26/07/2023 - 17:00

MILITARY

Poland buys Swedish early warning aircraft for $58 million

26/07/2023 - 13:00

COMMERCIAL

P&W says that "significant" number of engines of the A320neo family will have to be inspected "immediately"

25/07/2023 - 11:00

MILITARY

Delays in the delivery of the F-35 will cost Lockheed hundreds of millions in 2023

25/07/2023 - 09:00

MILITARY

Argentine Air Force awaits a "superior" proposal to choose F-16

24/07/2023 - 15:00

MILITARY

Indian Air Force considers A-400M, C-130J and C-390 to replace the average transport fleet

4 notes

·

View notes

Text

Electronic and Precision Equipment Repair and Maintenance Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The electronic and precision equipment repair and maintenance global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Electronic and Precision Equipment Repair and Maintenance Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The electronic and precision equipment repair and maintenance market size has grown strongly in recent years. It will grow from $151.23 billion in 2023 to $161.22 billion in 2024 at a compound annual growth rate (CAGR) of 6.6%. The growth in the historic period can be attributed to industrial machinery and equipment, medical devices, electronics and consumer devices, aerospace and defense equipment.

The electronic and precision equipment repair and maintenance market size is expected to see strong growth in the next few years. It will grow to $204 billion in 2028 at a compound annual growth rate (CAGR) of 6.1%. The growth in the forecast period can be attributed to advanced technologies, healthcare equipment maintenance, smart manufacturing, consumer electronics. Major trends in the forecast period include advanced technologies integration, predictive and preventive maintenance, remote maintenance and monitoring, sustainability and circular economy.

Order your report now for swift delivery @

https://www.thebusinessresearchcompany.com/report/electronic-and-precision-equipment-repair-and-maintenance-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

An increase in sales of personal computing devices (PCD’s) is expected to propel the growth of the electronic and precision equipment repair and maintenance market. Personal computing devices refer to consumer devices such as desktop computers, laptops, smartphones, and tablets. Due to the pandemic, there was an increase in the number of people working from home, leading to an increase in PCD sales. With more people using PCD’s there is an increase in the need for maintenance and repair for such devices. For example, according to a 2022 report from Singapore based technology market analyst firm, Canalys, the worldwide shipments of desktops, notebooks and workstations for the year 2021 stood at 341 million units, 15% higher than 2020. Therefore, the increase in the sale of personal computing devices is expected to drive the electronic and precision equipment repair and maintenance market going forward.

The electronic and precision equipment repair and maintenance market covered in this report is segmented –

1) By Type: Consumer Electronics Repair and Maintenance, Computer and Office Machine Repair and Maintenance, Communication Equipment Repair and Maintenance, Other Electronic and Precision Equipment Repair and Maintenance

2) By Mode: Online, Offline

3) By Service Type: Inspection, Maintenance, Repair

Get an inside scoop of the electronic and precision equipment repair and maintenance market, Request now for Sample Report @

https://www.thebusinessresearchcompany.com/sample.aspx?id=2237&type=smp

Regional Insights -

Western Europe was the largest region in the electronic and precision equipment repair and maintenance market in 2023. Asia-Pacific was the second-largest region in the electronic and precision equipment repair and maintenance market. The regions covered in the electronic and precision equipment repair and maintenance market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, and Africa.

Key Companies -

Major companies operating in the electronic and precision equipment repair and maintenance market include Juniper Networks Inc., Emcor Group, Illinois Tool Works Inc., Tsubakimoto Chain Co, Apple Inc., Electronix Services, Encompass Supply Chain Solutions Inc., Global Electronic Services Inc., iCracked Inc., Mendtronix Inc., MicroFirst Gaming Inc., Quanzhou Journey Bags Co. Ltd., Quest International Inc., OTC Industrial Technologies, Precision Electronic Repair Services, ACS Industrial Services Inc., iFixIt, ABB Ltd., Agilent Technologies Inc., Ametek Inc., Anritsu Corporation, Avnet Inc., Belden Inc., Benchmark Electronics Inc., Tech Pros, Precision Electronics Ltd., Advanced Control Solutions Inc., Microtech Services Ltd., MTAR Technologies Ltd., Techtonic Innovations Ltd., RoboTech Services Ltd.

Table of Contents

1. Executive Summary

2. Electronic and Precision Equipment Repair and Maintenance Market Report Structure

3. Electronic and Precision Equipment Repair and Maintenance Market Trends And Strategies

4. Electronic and Precision Equipment Repair and Maintenance Market – Macro Economic Scenario

5. Electronic and Precision Equipment Repair and Maintenance Market Size And Growth

…..

27. Electronic and Precision Equipment Repair and Maintenance Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

PCB Prototype: Choosing an Agile Service Provider

Understanding PCB Prototyping

As the demand for premium printed circuit board (PCB) prototypes escalates, companies confront the challenge of adhering to strict quality standards while delivering products promptly. This is particularly critical in industries such as aerospace, defense, medical, and industrial automation. Selecting the right PCB prototype provider is crucial for enhancing operational efficiency and maintaining product integrity. This article explores the benefits of choosing a nimble, smaller PCB prototype provider, known for a high ratio of engineers to assemblers, over larger, more bureaucratic organizations.

The Importance of PCB Prototyping

PCB prototyping is a fundamental phase in product development, involving the creation of a circuit board model to test and refine the design before entering mass production. This stage is essential for identifying potential defects, verifying functionality, and making necessary adjustments. Precision, meticulous attention, and the capacity for rapid iteration are essential, with smaller, agile providers often excelling in these areas.

Benefits of Agility and Dedicated Customer Service

Choosing a smaller PCB prototype provider offers numerous advantages, primarily their agility. These providers can quickly adapt to changes and specific customer requirements due to their smaller size. They manage a deliberately limited customer base, which allows for personalized service and close attention—qualities that are often missing in larger entities. This dedicated customer service ensures prototypes meet exact specifications and timelines.

Furthermore, smaller firms are generally more capable of handling urgent demands and last-minute changes. Their streamlined operations and minimal bureaucratic hurdles enable quick responses, shortening the time from design to prototype, which is vital for industries requiring fast market entry.

Superior Engineer-to-Assembler Ratio

Many smaller PCB prototype providers maintain a high ratio of engineers to assemblers, ensuring substantial technical expertise is available throughout the prototyping process. Engineers have deep knowledge of design principles, materials, and manufacturing techniques crucial for developing a high-quality PCB prototype.

With a larger contingent of engineers, smaller providers can offer more comprehensive support and problem-solving capabilities. They work closely with clients to understand specific needs, provide technical insights, and suggest design improvements that enhance the final product. This collaborative approach is often lacking in larger facilities, where the focus may be more on volume production than on the nuances of individual projects.

Addressing Quality Challenges

Maintaining a strong quality policy is critical in PCB prototyping. Smaller providers, with their focused client approach, can dedicate more resources to ensure each prototype meets stringent quality standards. They are less likely to overlook details or cut corners—a common risk in larger operations focused on output.

Additionally, these smaller entities often implement stricter quality control measures. Each prototype is thoroughly tested and inspected, with engineers actively identifying any potential issues. This proactive approach helps resolve problems early, avoids costly delays, and ensures that the final product is reliable and performs as expected.

Flexibility Over Bureaucracy

Large PCB prototype shops may suffer from bureaucratic inefficiencies, where their size and structure can hinder quick decision-making, enforce rigid procedures, and reduce flexibility in addressing unique client needs. In contrast, smaller providers are typically more adaptable, with less bureaucracy and a culture that supports innovation and prompt responses.

This flexibility allows smaller providers to experiment with new methods, swiftly incorporate advanced technologies, and customize their services to meet specific client demands. For companies requiring PCB prototypes, this means access to the latest advancements and a tailored approach to their projects.

Conclusion

Choosing the right provider is crucial for the success of any project. Smaller, agile PCB prototype providers with a higher engineer-to-assembler ratio offer significant benefits, including excellent customer service, quick turnaround times, and a dedicated focus on quality.

Their ability to overcome the challenges often faced by larger, more bureaucratic firms makes them the preferred choice for businesses ready to launch innovative products quickly and efficiently. By leveraging the strengths of these agile providers, companies can ensure their PCB prototypes adhere to the highest standards, paving the way for successful product development and market success.

For exceptional quality and personalized service in your PCB prototyping needs, consider selecting a highly agile provider. Visit our website to request a quote and explore our services.

0 notes

Text

Data Analytics in Predictive Maintenance for Aerospace

In the dynamic and technologically advanced world of aerospace engineering, the role of data analytics has emerged as a crucial component in ensuring the safety, efficiency, and cost-effectiveness of operations. From commercial airlines to defense systems, the aerospace industry relies heavily on the ability to predict and prevent mechanical failures before they occur. This proactive approach is known as predictive maintenance, and it is revolutionizing the way aircraft are maintained and serviced.

The Importance of Predictive Maintenance in Aerospace

Aircraft maintenance has traditionally been based on scheduled inspections and reactive repairs. However, these methods are not only costly but also potentially hazardous if issues are not caught in time. Predictive maintenance leverages data analytics to monitor the condition of aircraft components in real-time. By collecting and analyzing vast amounts of data from sensors and historical records, maintenance teams can predict when a part is likely to fail and take preventive action before it disrupts operations.

The integration of data analytics into predictive maintenance processes offers several advantages. Firstly, it reduces the frequency of unscheduled downtime, which can be particularly costly for airlines and detrimental to military readiness. Secondly, it enhances safety by minimizing the risk of in-flight failures. Thirdly, it optimizes maintenance schedules and resource allocation, leading to significant cost savings over time.

How Data Analytics Facilitates Predictive Maintenance

At the heart of predictive maintenance lies the ability to gather, process, and interpret large volumes of data. Sensors embedded throughout the aircraft continuously collect data on various parameters such as engine performance, temperature, pressure, vibration, and more. This data is then transmitted to ground stations where sophisticated analytics software processes it in real-time.

Data analytics algorithms play a pivotal role in identifying patterns and anomalies within the data that could indicate potential issues. Machine learning algorithms, for instance, can detect subtle changes in equipment behavior that human operators might miss. By analyzing historical data alongside real-time inputs, these algorithms can predict the remaining useful life of critical components with a high degree of accuracy.

Challenges and Considerations in Implementing Predictive Maintenance

Despite its potential benefits, implementing predictive maintenance in aerospace comes with its own set of challenges. One major challenge is the complexity of integrating data analytics systems with existing aircraft infrastructure. Retrofitting older aircraft with sensors and data transmission capabilities can be both expensive and technically demanding.

Moreover, ensuring the security and reliability of data transmissions is paramount in aerospace applications. Any compromise in data integrity or availability could have severe consequences. Thus, stringent cybersecurity measures must be in place to protect sensitive operational data from unauthorized access or manipulation.

Training and skill development also pose challenges. The aerospace industry requires skilled professionals who are proficient in both data analytics and domain-specific knowledge of aircraft systems. Training programs such as data analytics courses with job assistance tailored to aerospace applications are essential for developing a workforce capable of leveraging predictive maintenance effectively.

Data Scientist vs Data Engineer vs ML Engineer vs MLOps Engineer

youtube

Future Trends and Innovations

Looking ahead, the field of predictive maintenance in aerospace is poised for significant advancements. Rapid advancements in sensor technology, artificial intelligence, and data analytics are expected to further enhance the accuracy and efficiency of predictive maintenance systems. For example, predictive models may incorporate more diverse data sources, such as weather patterns and air traffic data, to refine predictions and optimize maintenance schedules.

Additionally, the adoption of cloud computing and edge computing solutions is enabling real-time data analytics training and decision-making directly onboard aircraft. This reduces reliance on ground-based infrastructure and facilitates faster response times to maintenance needs.

Data analytics course has become indispensable in the realm of predictive maintenance for aerospace. By harnessing the power of big data and advanced analytics, the industry can proactively address maintenance issues before they escalate, thereby improving safety, reliability, and cost-efficiency. As technology continues to evolve, so too will the capabilities of predictive maintenance systems, ensuring that aerospace operations remain at the forefront of safety and innovation.

As the demand for skilled professionals grows, training initiatives such as data analyst online certification training programs will play a crucial role in equipping the workforce with the necessary skills to drive this technological evolution forward. By investing in data analytics certification and predictive maintenance, the aerospace industry is not only safeguarding its operations but also paving the way for a more sustainable and efficient future in aviation.

Certified Data Analyst Course

youtube

0 notes

Text

Apollo Micro Systems Limited: Pioneering India's Defense Technology with Unprecedented Growth in Q1 FY25

Apollo Micro Systems Limited (AMS) has always been at the forefront of India's defense technology landscape, a position further solidified by its remarkable performance in the first quarter of FY25. As one of India's leading electronic, electro-mechanical, engineering design, and manufacturing companies, AMS has consistently demonstrated its commitment to innovation, operational excellence, and sustainable growth. Established in 1985, the company has built an impressive legacy, specializing in high-performance solutions that are crucial for mission-critical and time-sensitive operations.

AMS’s product portfolio spans a wide range of industries, including aerospace systems, ground defense, space, avionics systems, homeland security, and transportation. The company's manufacturing facility, located in Hyderabad, spans 55,000 square feet and houses a team of over 300 employees, including more than 150 dedicated to research and development (R&D). This focus on R&D has allowed AMS to remain at the cutting edge of technology, contributing to its role as a key partner in numerous defense programs.

The company’s extensive experience of over 39 years in designing, developing, and assembling custom-built electronics and electro-mechanical solutions is a testament to its expertise. AMS offers a comprehensive range of products and services, from electronic manufacturing services and PCB fabrication to embedded software design and development, circuit board assembly, and hardware design services. Its manufacturing plant is equipped with a full-fledged Environmental Stress Screening (ESS) testing facility, with inspections conducted in line with Defense Quality Assurance (DGQA) standards.

AMS’s reputation is further bolstered by its certifications and approvals, including ISO and CEMILAC certifications and recognition as a Defense Research and Development Organization (DRDO) approved partner. The company plays a key role in multiple ongoing defense programs, with a significant portion of its revenue—between 7-8%—reinvested into R&D. This investment supports the development and testing of critical components under DRDO programs, reinforcing AMS’s position as a leader in defense technology.

The company’s diverse clientele includes prominent government institutions such as the DRDO, the Indian Army, the Indian Navy, and Defense Public Sector Undertakings (DPSUs), as well as private sector giants like Adani and Larsen & Toubro. Some of the key strategic projects undertaken by AMS include the Universal Homing System for Light & Heavy Weight Torpedoes, Landing Gear Actuators for Avionic Platforms, Digital RF Seeker Signal Processor, Integrated Guidance Kit for Various Platforms, and Under Water Mines.

AMS’s capabilities extend across several sectors, including missile systems, aerospace systems, naval systems, satellite space systems, and homeland security. The company’s expertise in on-board electronic weapon systems and ground support equipment for these sectors has made it a trusted partner in the defense industry. AMS also excels in the integration of weapon and platform systems, hardware design, embedded software design and development, and electronic manufacturing services, offering a comprehensive suite of product- and service-based solutions.

The company’s financial performance in Q1 FY25 is a reflection of its robust operational capabilities and strategic vision. AMS reported a significant increase in revenue, achieving Rs. 912.02 million in Q1 FY25, up from Rs. 576.91 million in Q1 FY24. This 58.09% year-on-year growth was primarily driven by robust order execution. The company’s Earnings Before Interest, Taxes, Depreciation, and Amortization (EBITDA) also saw a substantial rise, reaching Rs. 223.71 million in Q1 FY25, a 75.57% increase from Rs. 127.42 million in Q1 FY24. This growth in EBITDA was fueled by the increased scale of operations, with the EBITDA margin improving to 24.53% in Q1 FY25 from 22.09% in the same quarter of the previous fiscal year.

Profit After Tax (PAT) for Q1 FY25 also saw an impressive increase, reaching Rs. 84.29 million, compared to Rs. 16.54 million in Q1 FY24. The PAT margin improved significantly to 9.24% in Q1 FY25, up from 2.87% in Q1 FY24. These financial achievements underscore AMS’s commitment to operational excellence and sustainable growth, positioning the company for continued success in the future.

AMS’s order book for Q1 FY25 reflects a strong and growing pipeline of projects, underscoring the company’s market leadership and the trust it has earned from its customers. The order book has expanded significantly, driven by high demand across various sectors. The diversity and quality of these orders ensure a stable revenue stream and enhanced profitability, positioning AMS to capitalize on emerging opportunities and maintain its growth momentum.

In a significant milestone, AMS has been shortlisted and awarded a prestigious Make II project by the Indian Army. This project involves the procurement of a Vehicle Mounted Counter Swarm Drone System (VMCSDS) (Version I) under the Make II category of the Defense Acquisition Procedure (DAP) 2020. The award of this project, the company’s first under the Make II category, is a testament to AMS’s capabilities and innovation. The systems developed from this project are state-of-the-art and highly futuristic, reflecting AMS’s commitment to advancing technology and supporting national defense. Importantly, as a Make II project, there will be no cost obligation involved, ensuring efficient and effective execution.

AMS is also investing in its future growth by developing two state-of-the-art modern manufacturing units, cumulatively measuring approximately 400,000 square feet. The development of these facilities is progressing on time and will significantly expand AMS’s scale of operations in the near future.

The Indian government has set an ambitious goal to export over Rs. 50,000 crore worth of defense equipment by the fiscal year 2028-2029. In the 2023-24 financial year, the value of defense production surged to Rs. 1,26,887 crore, marking a significant 16.8 percent increase compared to the previous year. This substantial growth underscores the momentum in the defense sector and reflects the government’s commitment to enhancing India’s position as a global leader in defense manufacturing. To support this vision, the government is dedicated to fostering a more favorable environment for the defense industry, implementing policies and initiatives aimed at strengthening India’s capabilities and competitiveness on the global stage. Through these efforts, India is poised to become a key player in the international defense market, contributing to both national security and economic growth.

Looking ahead, AMS is confident about its future growth prospects. The strong demand for electronic solutions in the defense sector, combined with the company’s highly specialized technology solutions, positions it well to capitalize on opportunities in this space. AMS remains committed to exploring new avenues for innovation, forging strategic partnerships, and striving for operational efficiency in its operations.

The company extends its gratitude to its employees, customers, and shareholders for their unwavering support. As AMS continues to create value, it looks forward to a successful future, driving forward the mission of strengthening defense systems for a self-reliant India.

0 notes

Text

Affordable CNC Machining Services in India | Advanced Technology.

Explore premier CNC machining suppliers in India delivering high-quality manufacturing solutions. Contact us at 9657039991.

In the realm of modern manufacturing, CNC machining stands out as a pivotal technology, driving innovation and precision. As India continues to bolster its industrial capabilities, the demand for top-notch CNC machining suppliers has surged. This article delves into the landscape of CNC machining in India, highlighting the best suppliers and the unparalleled services they offer.

Why Choose CNC Machining in India?

India has emerged as a hub for precision engineering and manufacturing. The country boasts a robust ecosystem of suppliers equipped with advanced CNC machinery, skilled workforce, and a commitment to quality. Here’s why opting for CNC machining in India is a strategic decision:

Cutting-edge Technology

Indian CNC machining suppliers leverage state-of-the-art technology to ensure precision and efficiency. From multi-axis machining centers to automated inspection systems, the technological infrastructure is designed to meet the highest standards.

Skilled Workforce

The Indian machining In India industry is supported by a highly skilled workforce. Engineers and technicians are trained to operate sophisticated CNC machines, ensuring every product meets stringent quality benchmarks.

Cost-Effective Solutions

India offers a competitive advantage in terms of cost. High-quality machining services are available at a fraction of the cost compared to other regions, without compromising on quality or precision.

Versatility and Customization

Indian suppliers offer versatile machining solutions that cater to diverse industries, including aerospace, automotive, medical, and electronics. Customization is a key strength, enabling the production of bespoke components tailored to specific requirements.

Leading CNC Machining Suppliers in India

Identifying the best CNC machining suppliers can be a daunting task. Here, we spotlight some of the top names that have established a reputation for excellence in precision manufacturing.

Supplier A: Precision Engineering Excellence

Supplier A stands as a beacon of precision engineering. With a focus on delivering high-quality components, they utilize advanced CNC machines to cater to various industries. Their commitment to innovation and quality assurance ensures customer satisfaction.

Services Offered:

Multi-axis CNC machining

Prototype development

Production machining

Quality inspection and testing

Key Industries Served:

Aerospace

Automotive

Medical devices

Supplier B: Innovative Machining Solutions

Supplier B is renowned for its innovative approach to CNC machining. By integrating cutting-edge technology and continuous improvement practices, they deliver unmatched precision and reliability.

Services Offered:

CNC milling and turning

Rapid prototyping

Custom machining

Assembly and sub-assembly

Key Industries Served:

Electronics

Industrial machinery

Consumer products

Supplier C: Comprehensive Manufacturing Services

Supplier C provides comprehensive manufacturing solutions, from concept to completion. Their expertise in CNC machining is complemented by a suite of additional services, ensuring a seamless production process.

Services Offered:

Precision CNC machining

Surface finishing

Heat treatment

Assembly services

Key Industries Served:

Defense

Telecommunications

Renewable energy

The Future of Machining in India

The future of CNC machining in India is poised for remarkable growth. With continuous advancements in technology and a focus on sustainability, Indian suppliers are well-positioned to meet the evolving demands of global markets. Here are some trends shaping the future of machining in India:

Adoption of Industry 4.0

Industry 4.0 technologies, including IoT, AI, and machine learning, are transforming CNC machining. Indian suppliers are increasingly adopting these technologies to enhance operational efficiency, predictive maintenance, and real-time quality control.

Sustainable Manufacturing Practices

Sustainability is becoming a core focus. CNC machining suppliers in India are implementing eco-friendly practices, such as energy-efficient machinery, waste reduction techniques, and sustainable sourcing of materials.

Expansion of Export Markets

Indian CNC machining suppliers are expanding their footprint in international markets. The combination of high-quality products and competitive pricing makes India an attractive sourcing destination for global companies.

Enhanced Training and Skill Development

Investment in training and skill development is paramount. Suppliers are partnering with educational institutions and industry bodies to ensure the workforce is equipped with the latest skills and knowledge.

The landscape of CNC machining in India is vibrant and dynamic. With a blend of advanced technology, skilled workforce, and cost-effective solutions, Indian CNC machining suppliers are setting new benchmarks in precision manufacturing. For businesses seeking reliable and high-quality machining services, India offers a compelling proposition.

To explore top-notch CNC machining services, contact us at 9657039991. Our team is dedicated to delivering excellence in every project, ensuring your manufacturing needs are met with precision and reliability.

Visit:- https://www.deccanew.com/cnc-machining-india.php

Contact: 9657039991

0 notes

Text

The Rise of SMS as an Attack Vector and How SMS Firewalls Protect Against It

The Rise of SMS as an Attack Vector

As mobile phones become ubiquitous communication devices, Short Message Service (SMS) has grown to become one of the most widely used messaging platforms globally. However, the open nature of SMS has also made it an attractive attack vector for cybercriminals. SMS is an inherently insecure channel that lacks end-to-end encryption and authentication. Threat actors are exploiting these weaknesses to execute large-scale SMS phishing and smishing campaigns. According to recent reports, SMS attacks increased by 700% in 2020 alone. Millions of users receive fraudulent texts each day, putting personal and financial data at risk. With nearly universal access to SMS, organizations need robust defenses to protect mobile users from this growing threat.

How SMS Firewalls Mitigate SMS-based Attacks

An SMS firewall sits between an organization's internal systems and the public telephone network to filter and monitor SMS traffic in real-time. It uses a variety of techniques to identify and block malicious or unauthorized SMS messages before they ever reach end users. SMS firewalls inspect the content, context, and patterns of incoming and outgoing text messages to identify signs of suspicious activity. They can analyze messages for malicious links, detect SMS spoofing, uncover bulk messaging patterns, and match messages against known phishing and smishing campaigns. This layered filtering approach protects users from a wide range of SMS-based attacks without disrupting legitimate business communications.

When suspicious messages are detected, the SMS firewalls is able to take automatic actions to mitigate threats. Common responses include blocking messages, redirecting URLs to warn pages, scrubbing attachments, and appending risk warnings. Administrators also receive alerts about detected threats so they can take follow-up actions like blacklisting senders or configuring new rules. For high-risk situations, the SMS firewall can even suspend entire inbound or outbound messaging on the fly. This level of real-time monitoring and control gives security teams the tools needed to proactively shut down SMS-borne attacks before any damage occurs.

A Holistic Defense Against Emerging SMS Threats

Modern SMS firewalls go beyond basic filtering to offer multilayered protections against an ever-evolving threat landscape. As attackers tweak their tactics, the latest solutions can quickly adapt defenses. Machine learning models and behavioral analytics now supplement traditional techniques, allowing SMS firewalls to more accurately detect unknown threats and anomalous activity. Deep packet inspection also examines full SMS payloads and protocols to uncover threats hidden in unusual formats, encodings or signaling messages.

Get more insights on SMS Firewall

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#SMS Firewall#Text Message Security#SMS Protection#Anti-Spam#Fraud Prevention#Message Filtering#Telecom Security#SMS Gateway#Security Protocols

0 notes

Text

Streamlining Aerospace Supply Chains: Benefits of Partnering with ISO Certified Manufacturers

In today's highly competitive aerospace industry, ensuring efficiency and reliability in the supply chain is crucial. One effective way to achieve this is by partnering with ISO certified manufacturers. These partnerships can bring numerous benefits, from enhancing quality control to improving overall supply chain performance. This blog explores the advantages of working with ISO certified defense manufacturers and how they can streamline aerospace supply chains.

What is an ISO Certified Manufacturer?

An ISO certified defense manufacturer meets the rigorous standards set by the International Organization for Standardization (ISO). These standards are designed to ensure that manufacturers adhere to quality management systems, environmental management, and other critical practices. For aerospace supply chains, this certification signifies a commitment to high standards of safety, reliability, and efficiency.

Key Benefits of Partnering with ISO Certified Manufacturers

1. Enhanced Quality Assurance

ISO certified manufacturers adhere to strict quality control measures. This commitment to quality translates into:

Consistent Product Quality: Regular audits and inspections ensure that products meet the required specifications and performance standards.

Reduced Defects: A rigorous quality management system helps in identifying and rectifying issues before they affect the final product.

2. Improved Supply Chain Efficiency

Working with an ISO certified defense manufacturer can streamline various aspects of the supply chain:

Faster Turnaround Times: Efficient processes and standardized practices lead to quicker production and delivery times.

Reliable Delivery: Consistent quality and adherence to deadlines reduce the risk of delays and disruptions.

3. Compliance with Regulatory Requirements

The aerospace industry is heavily regulated, and partnering with an ISO certified manufacturer ensures compliance with:

Aerospace Standards: Meeting industry-specific standards such as AS9100 ensures that products are built to meet aerospace requirements.

Safety Regulations: Compliance with safety standards minimizes risks and enhances the safety of the end products.

4. Cost Savings

While partnering with an ISO certified manufacturer may seem like an investment, it often leads to cost savings in the long run:

Reduced Rework and Scrap: High-quality standards reduce the need for rework and minimize waste, leading to cost savings.

Efficient Processes: Streamlined processes and reduced lead times can lower overall production costs.

5. Enhanced Customer Satisfaction

By ensuring high-quality products and reliable delivery, ISO certified defense manufacturers contribute to:

Increased Customer Trust: Consistent quality builds trust with customers and strengthens business relationships.

Better Service: Efficient processes and high standards translate to better service and support for clients.

How to Choose the Right Aerospace Supply Chain Partner

1. Verify ISO Certification

Ensure that potential partners have the relevant ISO certifications, such as ISO 9001 for quality management or AS9100 for aerospace standards. This certification indicates that they meet the necessary requirements for quality and reliability.

2. Assess Capabilities and Experience

Evaluate the manufacturer's capabilities and experience in the aerospace sector. Look for:

Relevant Expertise: Experience with aerospace components and systems is crucial.

Technological Capabilities: Advanced manufacturing technologies can enhance efficiency and quality.

3. Review Performance Metrics

Analyze the manufacturer's performance metrics, including:

Delivery Performance: Check their track record for on-time delivery.

Quality Metrics: Review defect rates and quality control measures.

Conclusion

Partnering with ISO certified manufacturers offers numerous benefits for streamlining aerospace supply chains. From enhanced quality assurance and improved efficiency to cost savings and better customer satisfaction, the advantages are significant. When selecting an aerospace supply chain partner, ensure they are ISO certified and meet the high standards required for success in the aerospace industry. By doing so, businesses can achieve greater reliability, efficiency, and overall success in their operations.

0 notes

Text

Ultrasonic Testing Market Valuation and Overview – 2024-2030

The Ultrasonic Testing Market is projected to experience significant growth from 2024 to 2030, driven by the escalating demand for non-destructive testing (NDT) techniques across various industries such as oil & gas, aerospace, automotive, and construction. Valued for its accuracy, safety, and efficiency in detecting material flaws and structural integrity issues, ultrasonic testing is increasingly being adopted to ensure compliance with stringent safety and quality standards.

Technological advancements, including the development of phased array ultrasonic testing (PAUT) and automated ultrasonic testing (AUT) systems, are expected to enhance inspection capabilities and drive market expansion. The rising focus on infrastructure maintenance, coupled with the need for extending the lifespan of aging assets, is further propelling market growth.

The global ultrasonic testing market size is projected to reach USD 4.2 billion by 2026, at a compound annual growth rate (CAGR) of 7.1% during the forecast period.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=131229239

The ultrasonic technique (UT) is likely to be the largest contributor in the market during the forecast period

The market for the UT (ultrasonic testing) technique is projected to largest contributor in Market. It is presently the most popular NDT technique due to its ability to identify defects and accurately determine their severity. Some advanced techniques such as ultrasonic immersion testing and guided-wave ultrasonic testing can be used for critical applications in the oil & gas and aerospace industries, among many others.

Inspection services to account for the largest market size by 2021

Ultrasonic testing and inspection services are likely to account for the largest share of the market in 2021. Ultrasonic testing techniques' primary purpose is to inspect objects, materials, machinery, and structures for defects so that they can be rectified in a timely and cost-effective manner. After inspection services, training services are likely to continue to gain the second-largest market share in the coming years since training NDT technicians to keep them updated with new technological trends and make them aware of the customers' changing demands is equally essential.

The Ultrasonic testing market in APAC to grow at the highest CAGR during the forecast period

Asia Pacific is likely to be the fastest-growing region in the ultrasonic testing market due to the rapid infrastructural development and automation adoption in manufacturing industries in countries such as India and China. Countries in Asia Pacific are involved in the manufacturing of defense aircraft, which is expected to increase ultrasonic testing equipment and services in the defense & aerospace industry. Many infrastructural development projects are under construction and scheduled to be constructed in the region during the forecast period. The demand for automobiles is estimated to grow substantially by 2026.

The market was dominated by ultrasonic testing companies such as Baker Hughes(US), Olympus Corporation (Japan), MISTRAS Group (US), Intertek (UK), Sonatest (UK), Zetec, Inc. (US), T.D. Williamson Inc. (US), Bosello High Technology srl (Italy), Eddyfi (Canada), and Magnaflux (US), Fischer Technology Inc. (US), Cygnus Instruments Ltd. (UK), NDT Global GmbH (Germany), Acuren (US), and LynX Inspection (Canada).

0 notes

Text

Expediting Services ,Speed Up Your Business with AQSS-USA!

Look no further than AQSS-USA's Expediting Services! We are your trusted partner in expediting solutions, ensuring your shipments reach their destinations in record time.

+1 713-789-0885 | [email protected]

#witness inspection services#hydrostatic & performance tests#welding inspection services#oil and gas inspection services#witness inspection#first article inspection services#nuclear inspection services#third party industrial inspection services#aerospace and defense inspection services#gap and internal auditing services

1 note

·

View note

Text

#Oil and gas Auditing Services#oil and gas inspection Services#Aerospace and defense inspection Services#Nuclear Inspection Services#Quality Auditing Services#Factory Acceptance Test#Quality Inspection Services#NDE Inspection Services#NDT Inspection Services#First Article Inspection Services#Heat Treatment Services#Welding Inspection Services#Third Party Industrial Inspection Services#Witness Inspection Services#Positive Material identification Services#IT Inspection Services#Cyber Security Assessment Services#Vulnerability management services#Audit and Assessments Services

0 notes

Text

The Role of First Article Inspection in Chicago

In Chicago's diverse manufacturing landscape, maintaining stringent quality standards is paramount to success. First Article Inspection (FAI) services play a crucial role in this process, ensuring that the initial products off the production line meet all specified requirements. Let's delve into how FAI supports quality assurance and compliance in Chicago, alongside the integration of advanced technologies such as 3D scanning Chicago and industrial CT scanning.At the heart of ensuring these standards are met lies the crucial process of First Article Inspection (FAI). This comprehensive quality control procedure plays a pivotal role in verifying that the initial products off the production line meet all specified requirements and standards. Moreover, the integration of advanced technologies such as 3D scanning and industrial CT scanning further enhances the accuracy, efficiency, and reliability of FAI processes, thereby bolstering quality assurance and compliance across various industries.

Understanding First Article Inspection (FAI)

First Article Inspection involves a comprehensive quality control procedure applied to the very first product manufactured according to finalized design specifications. This initial inspection verifies that the design, engineering, and manufacturing processes align seamlessly, guaranteeing that the product meets all necessary criteria before full-scale production begins. In industries where safety, reliability, and precision are critical—such as aerospace, defense, and medical device manufacturing—FAI ensures that stringent quality standards are upheld from the outset.First Article Inspection is a meticulous quality control process applied to the very first product manufactured according to finalized design specifications. It serves as a critical checkpoint to ensure that the design, engineering, and manufacturing processes align seamlessly, thereby guaranteeing that the product meets all necessary criteria before full-scale production commences. Industries where safety, reliability, and precision are paramount, such as aerospace, defense, and medical device manufacturing, heavily rely on FAI to uphold stringent quality standards from the outset.

Benefits of First Article Inspection

Quality Assurance: FAI ensures that the manufactured product meets customer and industry standards right from the start. By inspecting the first article, manufacturers can identify and rectify any deviations or issues early in the production cycle, minimizing the risk of non-conformities and ensuring consistent quality throughout subsequent production runs.

Cost Savings: Identifying and addressing manufacturing flaws or compliance issues early through FAI prevents costly rework, scrap, and potential product recalls. This proactive approach not only saves time and resources but also enhances overall production efficiency and profitability.

Baseline for Quality Testing: The first article serves as a benchmark for all subsequent quality testing and validation processes. By meticulously examining dimensions, materials, and functional features, FAI provides a thorough assessment that validates the product's ability to meet performance expectations and regulatory requirements.

Accreditation and Regulatory Compliance

In Chicago, reputable FAI service providers adhere to rigorous accreditation standards, such as those set by organizations like A2LA (American Association for Laboratory Accreditation). These accreditations ensure that inspection bodies maintain competence, operational integrity, and adherence to international standards such as ISO/IEC 17025. This commitment to accreditation underscores the reliability and credibility of FAI services, providing manufacturers with confidence in the accuracy and impartiality of inspection results.Accreditation ensures that inspection bodies demonstrate competence, maintain operational integrity, and adhere to stringent quality management practices. This commitment to accreditation underscores the reliability and credibility of FAI results, instilling confidence in manufacturers regarding the accuracy and impartiality of inspection outcomes.

Integration with Advanced Technologies

Alongside traditional inspection methods, FAI services in Chicago leverage advanced technologies to enhance accuracy and efficiency. Integration with 3D scanning and industrial CT scanning capabilities allows for more comprehensive dimensional analysis, detection of internal defects, and verification of complex geometries. These technologies not only augment FAI processes but also enable deeper insights into product quality and performance, supporting informed decision-making and continuous improvement initiatives.

3D Scanning

At the forefront of modern quality control lies 3D scanning technology, which enables manufacturers to capture precise, detailed digital representations of physical objects with exceptional accuracy. In Chicago, numerous specialized 3D scanning companies offer services tailored to the unique needs of different sectors. These companies utilize state-of-the-art equipment and software to conduct comprehensive scans of components, prototypes, and assemblies, thereby ensuring that every aspect of the product meets stringent quality standards.

Industrial CT Scan

In addition to surface scanning, industrial CT scanning has emerged as a pivotal tool for non-destructive testing and inspection. This technology allows for the internal examination of objects in 3D, revealing internal structures and detecting potential defects such as voids, cracks, or inclusions. Manufacturers in Chicago leverage industrial CT scans to ensure the integrity of complex components, particularly those used in critical applications where reliability is paramount.

Advancing Quality Assurance Through Integration

The integration of advanced inspection technologies—3D scanning, dimensional inspection, and industrial CT scanning—enables comprehensive FAI. FAI plays a crucial role in validating the initial production units against design specifications. It helps identify early-stage manufacturing issues, ensuring that products meet rigorous quality standards from the outset. This proactive approach not only minimizes the risk of costly rework and recalls but also enhances overall production efficiency and customer satisfaction.

Conclusion

In conclusion, First Article Inspection is integral to ensuring quality compliance and operational excellence in Chicago's manufacturing sector. By combining meticulous inspection protocols with advanced technological capabilities, FAI services empower manufacturers to deliver products that meet the highest standards of reliability, safety, and precision. As the manufacturing landscape continues to evolve, the integration of FAI alongside 3D scanning, dimensional inspection, and industrial CT scan positions Chicago at the forefront of innovation and quality assurance in global markets.First Article Inspection is integral to ensuring quality compliance and operational excellence in Chicago's manufacturing sector. By combining meticulous inspection protocols with advanced technological capabilities, FAI services empower manufacturers to deliver products that meet the highest standards of reliability, safety, and precision. As the manufacturing landscape continues to evolve, the integration of FAI alongside 3D scanning, dimensional inspection, and industrial CT scanning positions Chicago at the forefront of innovation and quality assurance in global markets.

By embracing these cutting-edge tools and methodologies, companies in Chicago not only uphold their commitment to quality but also strengthen their competitive edge in the global marketplace. The future of manufacturing excellence lies in leveraging advanced technologies to drive continuous improvement and meet the evolving demands of industry and consumers alike.

0 notes

Text

Flexpert Bellows is the world's leading expansion company.

The need for dependable, high-quality expansion bellows is always increasing in the quickly changing industrial scene. These necessary elements are important for many other applications, such as petrochemical plants, aeronautical and maritime engineering, and power generating. Flexpert Bellows is a trailblazer in this industry, establishing the standard for quality, innovation, and client satisfaction among the top producers and exporters worldwide.

How Do Expansion Bellows Work?

Devices known as expansion bellows, or expansion joints, are made to absorb the expansion and contraction caused by heat in ducts, vessels, and pipe systems. They prevent structural damage and preserve system integrity by making up for movement brought on by temperature fluctuations, mechanical vibration, and other stresses.

The Benefit of Flexpert Bellows

Flexpert Bellows is a well-known brand in the industry, renowned for its high-quality products and outstanding customer support. What makes Flexpert Bellows unique is as follows:

1. Quality Assurance: Flexpert Bellows makes sure that every product is put through a thorough testing and inspection process in order to meet the highest quality requirements. Their numerous industry accolades and ISO certifications attest to their unwavering commitment to quality.

2. Creative Solutions: The business makes significant investments in R&D and is always pushing the limits of technology to produce creative solutions. Flexpert Bellows is at the forefront of innovation, whether it's creating bellows specifically for unusual applications or using cutting-edge materials for improved performance.

3. Global Reach: Flexpert Bellows provides services to clients in more than 50 nations through a strong distribution network. Their extensive worldwide reach is supported by effective customer service and logistics that guarantee on-time delivery.

4. Customized Products: Flexpert Bellows is aware that every sector and use case has particular needs. They provide specialized advice from design to implementation and offer solutions that are specifically tailored to satisfy needs.

5. Sustainability Commitment: Flexpert Bellows is committed to using eco-friendly processes in a time when sustainability is crucial. When feasible, they employ environmentally friendly materials and concentrate on energy-efficient manufacturing techniques.

Important Items and Uses

To meet the needs of many sectors and applications, Flexpert Bellows provides an extensive selection of expansion bellows.

1. Metal Expansion Bellows: Used in power plants, refineries, and the chemical processing industry, metal bellows are perfect for high-temperature and high-pressure conditions.

2. Rubber Expansion Bellows: These bellows are frequently used in water treatment facilities, marine engines, HVAC systems, and other applications needing flexibility and vibration absorption.

3. Fabric Expansion Bellows: Fabric bellows are utilized in ventilation, exhaust, and ducting systems. They are made for low-temperature and low-pressure applications.

4. High-Performance Bellows: Flexpert Bellows offers high-performance bellows constructed from cutting-edge materials like Inconel, Hastelloy, and other exotic alloys for specific applications like aerospace and defense.

Case Study: The Operation of Flexpert Bellows

Flexpert Bellows's creativity and experience are demonstrated in a recent assignment. Designing and producing expansion bellows for a top petrochemical facility was the company's assignment. Making bellows resistant to corrosive environments and high temperatures was a difficulty. Flexpert Bellows provided a customized solution that included cutting-edge welding methods, extensive quality testing, and premium stainless steel. The outcome was a solid and dependable product that greatly increased the plant's operational efficiency while also exceeding the client's expectations.

Bellows Flexpert: Why Choose Them?

Selecting Flexpert Bellows is choosing to work with a business that values innovation, quality, and client happiness. Their extensive array of products, global presence, and dedication to sustainability position them as the go-to option for sectors across the globe.Finally

Flexpert Bellows is still at the forefront of the expansion bellows market, offering top-notch goods and services that help its customers succeed. Flexpert Bellows provides the knowledge and experience to satisfy your demands, whether you require standard bellows or a unique solution. For dependable, superior expansion bellows that guarantee the security and effectiveness of your operations, rely on Flexpert Bellows.

Explore Flexpert Bellows' extensive selection of goods and services at https://www.flexpertbellows.com for additional information.

0 notes

Text

Advanced Robotic Abilities to Amp Aerospace Robotics Market Growth

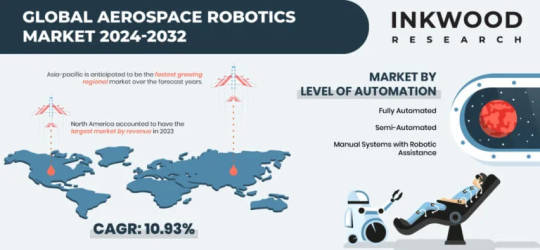

As per Inkwood Research, the Global Aerospace Robotics Market is estimated to progress at a CAGR of 10.93% in terms of revenue over the forecasting period of 2024-2032.

VIEW TABLE OF CONTENTS :https://www.inkwoodresearch.com/reports/aerospace-robotics-market/#table-of-contents

Aerospace robotics is revolutionizing aircraft manufacturing and maintenance with precision automation, enhancing efficiency and safety. These advanced systems are crucial for tasks like assembly, inspection, and repairs, driving innovation in the aerospace industry.

REQUEST FREE SAMPLE : https://inkwoodresearch.com/reports/aerospace-robotics-market/#request-free-sample

Improved Robotic Capabilities to Propel Aerospace Robotics Market Growth

Improved robotic capabilities are set to propel the aerospace robotics market growth by enhancing efficiency, precision, and safety in various applications. These advancements include sophisticated automation for assembly and inspection tasks, significantly reducing human error and operational costs. State-of-the-art robots equipped with artificial intelligence and machine learning can adapt to complex aerospace environments, performing intricate tasks with high accuracy. A key goal aligned with this progress is to achieve zero-defect manufacturing, ensuring that every component meets stringent quality standards. This development accelerates production timelines and boosts the reliability and performance of aerospace systems, fostering innovation in the industry.

Articulated Robots: Largest Robot Type in the Aerospace Robotics Market

Articulated robots, characterized by their rotary joints, dominate the aerospace robotics market due to their flexibility and precision. They are extensively used in assembly, welding, painting, and inspection tasks, enhancing efficiency and accuracy in aerospace manufacturing and maintenance. These robots' ability to mimic human arm movements allows for intricate and complex operations, making them indispensable in the industry. As technology advances, articulated robots continue to evolve, incorporating AI and machine learning to further optimize performance and adaptability in dynamic aerospace environments.

In 2023, North America was the Major Region in the Aerospace Robotics Market

North America's dominance in the aerospace robotics market is driven by a robust aerospace industry with major players like Boeing and Lockheed Martin, creating high demand for automation. Government initiatives, such as Canada’s Strategic Aerospace and Defense Initiative (SADI) and the US's National Robotics Initiative (NRI), support innovation through significant funding for R&D in the region.

The global aerospace robotics market is characterized by intense industry rivalry, pushed by major players competing for market share and technological advancements. This competition spurs innovation and fuels companies to continually enhance their offerings to meet the evolving demands of the aerospace sector. Some of the leading companies operating in the market include ABB Ltd, Aerobotix, Comau SpA, Electroimpact Inc, FANUC Corporation, etc.

Request for Customization: https://inkwoodresearch.com/request-for-custom-report/

About Inkwood Research

Inkwood Research specializes in syndicated & customized research reports and consulting services. Market intelligence studies with relevant fact-based research are customized across industry verticals such as technology, automotive, chemicals, materials, healthcare, and energy, with an objective comprehension that acknowledges the business environments. Our geographical analysis comprises North & South America, CEE, CIS, the Middle East, Europe, Asia, and Africa.

Contact Us

https://www.inkwoodresearch.com

1-(857)293-0150

Related Reports:

INDUSTRIAL ROBOTICS MARKET: https://inkwoodresearch.com/reports/industrial-robotics-market/

0 notes