#IMDG Code classifications

Explore tagged Tumblr posts

Text

IMDG code for shipping containers

The International Maritime Dangerous Goods Code (IMDG Code) sets standards for the shipments of hazardous materials across the sea. This code encompasses guidelines for packaging, container handling, and storing these substances. Different classes cover explosives, gases, flammable goods, oxidizing and radioactive substances. Contact LOTUS Containers for container types supporting the transportation of unique and hazardous cargo.

0 notes

Text

International Cargo Handling Services in India

Overview

The effective transport of products across borders depends on international cargo handling, allowing companies to quickly and easily satisfy requires all over the world. It guarantees products arrive at the proper location safely by including everything from loading and packing to customs clearance. Good cargo handling services are now crucial in sectors like electronics, chemicals, and pharmaceuticals because to the growing demand for international commerce. Selecting trustworthy cargo handling firms helps businesses cut down on delays, save losses, and boost supply chain effectiveness—all of these are important for being competitive in the global market.

Knowing About Cargo for Dangerous Goods (DG)

Materials that might harm people's health, safety, assets, or the environment are classified as dangerous goods (DG), and therefore require to be handled carefully when being transported. These products, which are classified according to their physical and chemical characteristics, might include things like acids, harmful compounds, and explosive liquids. Selecting the right packing, labeling, and shipping processes requires proper classification. Logistics companies like Bluewave Logistics can reduce risks and guarantee the safe and legal transportation of dangerous goods by correctly identifying DG cargo.

Safety Procedures for DG Cargo Handling

Complete conformity to international safety standards, such as those set out by the International Marine Dangerous commodities (IMDG) Code and the International Air Transport Association (IATA), is required and transporting dangerous commodities. In order to reduce the hazards connected with dangerous goods, these rules require proper paperwork, labeling, and handling practices. Logistics firms must stick to these guidelines in order to guarantee the secure transportation of DG goods. By following these guidelines, Bluewave Logistics shows its dedication to social logistics and reduces hazards to the environment and public safety.

Bluewave Logistics' Method for Handling DG Cargo

A wide variety of specialist services customized to the requirements of transporting dangerous goods are provided by Bluewave Logistics. Bluewave's solutions, varying from labeling and packing to temperature-controlled storage and customs clearance, are made to handle DG goods successfully and safely. To handle complicated shipments, the team they employ adheres to stringent processes, guaranteeing compliance to national and international regulations. Bluewave is a valued partner for companies with demanding logistical requirements because of its unique strategy.

Conclusion

It is vital to handle dangerous substances safely in order to safeguard public safety and avoid environmental risks. Logistics firms like Bluewave are critical because they make sure that DG cargo is handled in a way that complies with regulations, protecting corporations, workers, and the general public. This strategy improves the security and validity of logistics services while minimizing risks. For safe and effective shipment, companies handling dangerous goods must work with a logistics company like Bluewave Logistics. Businesses can preserve regulation, safeguard their assets, and build consumer trust by giving safe logistics solutions first priority. Having Bluewave Logistics as a partner gives you piece of mind understanding that shipments are handled with skill and dedication.

Visit our site for more information or contact us at +918690887751 or email us at [email protected].

#Cargo Handling Services#International Cargo Handling Services#International Cargo Handling Services in India#International Cargo Handling Services in Ahmedabad

0 notes

Text

The Chemical Logistics Market is projected to grow from USD 282365 million in 2024 to an estimated USD 433340.99 million by 2032, with a compound annual growth rate (CAGR) of 5.5% from 2024 to 2032.The chemical logistics market plays a crucial role in supporting various industries, including manufacturing, agriculture, pharmaceuticals, and energy. As one of the most regulated and specialized sectors, chemical logistics requires highly specialized services, including the safe and timely transportation, handling, storage, and distribution of chemicals. The global market for chemical logistics has seen substantial growth over the past few years and is projected to expand further, driven by rising demand from end-use industries, globalization, and advancements in transportation infrastructure.

Browse the full report at https://www.credenceresearch.com/report/chemical-logistics-market

Overview of the Chemical Logistics Market

Chemical logistics refers to the process of transporting chemicals and related materials, whether raw materials or finished products, through different modes such as road, rail, sea, and air. This market encompasses a range of services, including packaging, warehousing, inventory management, and distribution. Safety regulations, environmental concerns, and the need for specialized equipment define the market's operation.

According to recent market reports, the global chemical logistics market is expected to grow at a compound annual growth rate (CAGR) of approximately 4.3% between 2023 and 2030. The growing demand for chemicals in industrial processes, agriculture, pharmaceuticals, and consumer goods is a significant driver of this growth. Additionally, the globalization of trade and increasing exports of chemicals have further strengthened the market.

Key Market Drivers

1. Growth in the Chemical Industry The chemical industry is one of the largest and most diverse sectors globally, contributing to the demand for effective logistics solutions. Chemicals are essential in manufacturing plastics, fertilizers, pharmaceuticals, and other key products, driving the need for efficient supply chains. The global chemical industry's growth has been accelerated by the rising demand from emerging economies, particularly in Asia-Pacific, which has become a hub for chemical production and export. Consequently, the demand for chemical logistics services has surged, especially in regions like China, India, and Southeast Asia.

2. Stringent Safety and Environmental Regulations Transporting chemicals poses inherent risks due to the hazardous nature of many chemical products. The logistics sector must adhere to strict safety and environmental regulations to mitigate the risks of accidents, spills, and contamination. International standards such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) and the International Maritime Dangerous Goods (IMDG) Code play a pivotal role in ensuring the safe handling and transportation of chemicals. Compliance with these regulations requires specialized training, packaging, and equipment, which has led to increased demand for professional logistics companies that are equipped to handle the unique challenges of chemical transportation.

3. Advancements in Technology and Digitalization Digitalization has brought significant improvements to the chemical logistics market. Technologies such as GPS tracking, Internet of Things (IoT) devices, blockchain, and cloud-based systems have enhanced supply chain visibility, improving operational efficiency and safety. These technologies allow companies to track shipments in real-time, manage inventory more effectively, and ensure regulatory compliance. For example, IoT sensors are used to monitor temperature, pressure, and other environmental factors in chemical transportation, ensuring that conditions remain optimal and compliant with safety standards. Digitalization also enhances the ability to manage risks, as data analytics can help predict potential disruptions in the supply chain.

4. Sustainability and Green Logistics Increasing awareness about environmental sustainability has prompted logistics providers to focus on reducing the carbon footprint of chemical transportation. Green logistics, which includes using fuel-efficient vehicles, optimizing routes to reduce emissions, and adopting eco-friendly packaging materials, has gained momentum. As chemical companies themselves are pressured to reduce their environmental impact, they are demanding more sustainable logistics solutions. This has led to innovation in the market, including the development of more energy-efficient modes of transportation and the use of alternative fuels such as biofuels and electric trucks.

Challenges in the Chemical Logistics Market

Despite its growth potential, the chemical logistics market faces several challenges:

1. High Operating Costs The cost of adhering to safety regulations, maintaining specialized equipment, and ensuring proper training for staff can be prohibitive. Additionally, chemical transportation requires investments in temperature-controlled vehicles and tanks, which adds to operational costs.

2. Supply Chain Disruptions The COVID-19 pandemic exposed vulnerabilities in global supply chains, including the chemical logistics market. Border closures, transportation restrictions, and labor shortages led to delays and increased costs. As global economies recover, companies in the chemical logistics space must focus on building resilient supply chains that can withstand future disruptions.

3. Lack of Skilled Workforce Handling hazardous chemicals requires highly skilled labor. However, there is a shortage of trained personnel capable of managing chemical logistics operations, particularly in emerging markets. Addressing this shortage is crucial to the market's long-term growth.

Key Player Analysis:

A&R Logistics

Agility

BASF

BDP International

BDtrans

Robinson Worldwide Inc.

Deutsche Bahn (DB) Schenker

Deutsche Post AG (DHL)

Kuehne + Nagel

Rhenus Logistics

Ryder System Inc

Segmentation:

By Mode of Transportation

Roadways

Railways

Airways

Waterways

Pipelines

By Services

Transportation & Distribution

Storage & Warehousing

Customs & Security

Green Logistics

Consulting & Management Services

Others

By End User

Chemical industry

Pharmaceutical Industry

Cosmetic Industry

Oil & Gas Industry

Specialty Chemicals Industry

Food

Others

By Region

North America

US

Canada

Latin America

Brazil

Argentina

Mexico

Rest of Latin America

Europe

Germany

UK

Spain

France

Italy

Russia

Rest of Europe

Asia Pacific

China

India

Japan

Australia

South Korea

ASEAN

Rest of Asia Pacific

Middle East

GCC

Israel

Rest of Middle East

Africa

South Africa

North Africa

Central Africa

Browse the full report at https://www.credenceresearch.com/report/chemical-logistics-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Understanding The Regulatory Environment For Hazardous Chemical Transporters

Transporting hazardous chemicals is a complex and highly regulated task due to the potential risks to public health, safety, and the environment. The regulatory environment surrounding the Hazardous Chemical Transporter is designed to mitigate these risks through stringent guidelines and compliance requirements. This article delves into the key aspects of this regulatory framework, highlighting the main regulations, agencies involved, and best practices for compliance.

Key Regulations Governing Hazardous Chemical Transport

The Hazardous Materials Regulations (HMR)

The primary regulations for hazardous chemical transportation in the United States are the Hazardous Materials Regulations (HMR), administered by the Pipeline and Hazardous Materials Safety Administration (PHMSA). The HMR outlines specific requirements for the classification, packaging, labelling, and documentation of hazardous materials during transportation. These regulations are crucial for ensuring that hazardous chemicals are handled safely and efficiently.

International Regulations

For international transport, the United Nations has established the Model Regulations on the Transport of Dangerous Goods, which serve as a basis for the regulations adopted by various countries. Additionally, the International Maritime Dangerous Goods (IMDG) Code and the International Air Transport Association (IATA) Dangerous Goods Regulations are critical for maritime and air transport, respectively. These international regulations ensure a consistent and safe approach to hazardous materials transportation across borders.

The Environmental Protection Agency (Epa) Regulations

The EPA plays a significant role in regulating the transportation of hazardous chemicals to prevent environmental contamination. The Resource Conservation and Recovery Act (RCRA) is a key regulation that governs the management of hazardous waste, including its transportation. The EPA sets forth standards for transporters of hazardous waste, focusing on tracking, handling, and disposal to safeguard environmental health.

Agencies Overseeing Hazardous Chemical Transport

Pipeline And Hazardous Materials Safety Administration (Phmsa)

PHMSA, under the U.S. Department of Transportation (DOT), is the primary federal agency responsible for enforcing HMR. PHMSA’s role includes issuing regulations, conducting inspections, and providing training and resources to ensure compliance with hazardous materials transportation standards.

Federal Motor Carrier Safety Administration (Fmcsa)

FMCSA oversees the safe operation of commercial motor vehicles, including those transporting hazardous materials. The FMCSA enforces regulations related to driver qualifications, vehicle standards, and hours of service to minimize the risk of accidents involving hazardous chemicals.

Occupational Safety And Health Administration (Osha)

OSHA regulates the safety of workers involved in hazardous chemical transportation. OSHA's Hazard Communication Standard (HCS) ensures that workers are informed about the hazards they might encounter and the measures needed to protect themselves. Proper training and communication are essential components of OSHA’s regulatory framework.

Best Practices For Compliance

Proper Classification And Labeling

One of the critical steps in hazardous chemical transportation is accurate classification and labelling. Chemicals must be classified according to their hazard class, and appropriate labels must be affixed to containers to communicate the risks effectively. This ensures that all parties involved in the transportation process are aware of the potential dangers.

Adequate Training And Certification

Transporters of hazardous chemicals must receive proper training to handle these materials safely. Training programs should cover regulatory requirements, emergency response procedures, and safe handling practices. Certification ensures that personnel are qualified to manage hazardous chemicals, reducing the risk of accidents and regulatory violations.

Comprehensive Documentation

To ensure compliance with regulations, it is imperative to maintain accurate and comprehensive documentation. Shipping papers, safety data sheets (SDS), and emergency response information must be meticulously prepared and kept up-to-date. Proper documentation ensures traceability and facilitates swift action in case of incidents during transport.

Emergency Preparedness And Response

Having a robust emergency response plan is vital for dealing with potential incidents involving hazardous chemicals. Transporters should be equipped with the necessary resources and trained personnel to handle spills, leaks, or accidents. Coordination with local emergency services and regular drills can enhance preparedness and mitigate the impact of emergencies.

Conclusion

Understanding and adhering to the regulatory environment for hazardous chemical transporters is crucial for ensuring safety and compliance. By following established regulations, engaging with overseeing agencies, and implementing best practices, transporters can minimize risks and contribute to the safe and efficient transport of hazardous chemicals. Compliance not only protects public health and the environment but also fosters trust and reliability in the hazardous materials transportation industry.

0 notes

Text

Best Practices for Transporting Hazardous Materials Safely

Transporting hazardous materials requires meticulous planning, stringent adherence to regulations, and the implementation of best practices to ensure the safety of people, property, and the environment. Hazardous materials (hazmat) include chemicals, explosives, flammable liquids and gases, toxic substances, and radioactive materials. Here are some best practices for transporting hazardous materials safely:

1. Understand and Comply with Regulations

Compliance with international, national, and local regulations is paramount. Key regulatory bodies and guidelines include:

International Air Transport Association (IATA) Dangerous Goods Regulations for air transport.

International Maritime Dangerous Goods (IMDG) Code for sea transport.

European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) for road transport in Europe.

49 CFR regulations in the United States, which cover the transportation of hazardous materials by all modes.

Ensuring compliance with these regulations helps prevent legal issues and enhances safety.

2. Classify and Label Materials Properly

Proper classification and labeling of hazardous materials are essential. This involves:

Identifying Hazard Classes: Each hazardous material must be classified according to its primary hazard (e.g., flammable, toxic, corrosive).

Using Correct Labels and Placards: Ensure that all containers are marked with appropriate labels and that transport vehicles display the correct placards to indicate the presence of hazardous materials.

Material Safety Data Sheets (MSDS): Include MSDS with shipments to provide detailed information about the materials and their handling procedures.

3. Use Suitable Packaging

Packaging plays a critical role in the safe transport of hazardous materials. Best practices include:

Selecting Appropriate Containers: Use containers that are designed and tested to withstand the physical and chemical properties of the materials being transported.

Sealing and Securing: Ensure that all containers are properly sealed and secured to prevent leaks and spills during transit.

Secondary Containment: Use secondary containment methods for additional protection, particularly for liquids and gases.

4. Implement Robust Training Programs

Training is vital for everyone involved in the transportation of hazardous materials. Training programs should cover:

General Awareness and Familiarization: Employees should understand the basic principles of hazardous materials transportation.

Function-Specific Training: Tailored training for specific roles and responsibilities.

Safety Training: Instructions on the use of personal protective equipment (PPE), emergency response procedures, and safe handling practices.

Security Training: Awareness of security risks and measures to prevent unauthorized access to hazardous materials.

Regular refresher training ensures that employees stay updated with the latest regulations and best practices.

5. Plan and Optimize Routes

Careful route planning can mitigate risks associated with transporting hazardous materials. Best practices include:

Avoiding High-Risk Areas: Whenever possible, avoid densely populated areas, schools, hospitals, and environmentally sensitive regions.

Using Safe Parking and Rest Areas: Plan for secure and safe stopping points to minimize the risk of accidents or theft.

Monitoring and Tracking: Utilize GPS and other tracking technologies to monitor the shipment in real-time, ensuring timely response in case of incidents.

6. Ensure Vehicle and Equipment Readiness

The condition of vehicles and equipment used in the transportation of hazardous materials is critical. Best practices include:

Regular Maintenance and Inspections: Conduct regular maintenance checks and inspections to ensure that vehicles and equipment are in good working order.

Specialized Equipment: Use equipment designed for transporting specific types of hazardous materials, such as pressure tanks for gases or refrigerated units for temperature-sensitive substances.

Emergency Equipment: Equip vehicles with emergency kits, including spill containment materials, fire extinguishers, and first-aid supplies.

7. Develop Emergency Response Plans

Preparation for emergencies is crucial. Best practices include:

Emergency Response Plans: Develop and regularly update comprehensive emergency response plans that outline procedures for dealing with spills, leaks, fires, and other incidents.

Training and Drills: Conduct regular emergency drills to ensure that all personnel are familiar with response procedures and can act swiftly in case of an incident.

Coordination with Authorities: Establish communication channels with local emergency responders and regulatory agencies to ensure prompt and coordinated responses.

8. Document and Communicate

Accurate documentation and effective communication are essential for the safe transport of hazardous materials. Best practices include:

Shipping Papers and Manifests: Ensure that all shipments are accompanied by the required documentation, including shipping papers, manifests, and MSDS.

Clear Communication: Maintain clear communication channels between all parties involved in the transportation process, including shippers, carriers, and receivers.

Incident Reporting: Implement procedures for reporting and documenting any incidents or near-misses, as this information is valuable for improving safety practices.

9. Implement Security Measures

Security is a critical concern in the transportation of hazardous materials. Best practices include:

Access Control: Restrict access to hazardous materials to authorized personnel only.

Security Training: Train employees to recognize and respond to security threats.

Tracking and Monitoring: Use technology to track shipments and detect any unauthorized access or tampering.

Incident Response: Develop and implement procedures for responding to security breaches.

10. Continuous Improvement

The field of hazardous materials transportation is constantly evolving. Best practices include:

Staying Informed: Keep up-to-date with changes in regulations, technology advancements, and industry best practices.

Review and Audit: Conduct regular reviews and audits of transportation practices to identify areas for improvement.

Feedback and Improvement: Encourage feedback from employees and stakeholders to continually enhance safety procedures and protocols.

In conclusion, transporting hazardous materials safely requires a comprehensive approach that includes understanding and complying with regulations, proper classification and packaging, thorough training, meticulous planning, and continuous improvement. By adhering to these best practices, companies can ensure the safe and efficient transport of hazardous materials, protecting their employees, the public, and the environment.

0 notes

Text

Navigate the Chemical Seas: A Guide to CHEMCO Course in Mumbai

Mumbai, the heart of India's maritime industry, is a hub for seafarers seeking to upskill and advance their careers. For those interested in specializing in chemical tankers, the CHEMCO (Chemical Tanker Officer – Limited Certificate) course becomes an essential stepping stone. This blog delves into the world of CHEMCO courses in Mumbai, equipping you with the knowledge to make informed decisions about this critical training program.

What is a CHEMCO Course?

The CHEMCO course equips officers with the specialized knowledge and skills required for safe and efficient cargo operations on chemical tankers. Chemical tankers carry a diverse range of hazardous chemicals, and navigating the intricacies of handling these substances demands a unique skillset. The International Maritime Organization (IMO) mandates the STCW (Standards of Training, Certification and Watchkeeping for Seafarers) Convention, which includes the CHEMCO course as a requirement for officers holding a level-2 Chemical Tanker Endorsement (DCE).

Who Should Take a CHEMCO Course?

The CHEMCO course caters to a specific audience within the maritime community. It's ideal for:

Deck Officers: Masters, Chief Officers, and Second Mates seeking to expand their career options and work on chemical tankers.

Engine Officers: Chief Engineers and Second Engineers who will be responsible for the safe operation and maintenance of machinery related to cargo handling on chemical tankers.

Anyone with immediate responsibility for chemical cargo: This could include personnel involved in loading, discharging, and caring for chemical cargo during transit.

If you aspire to work on chemical tankers and deal with these specialized cargoes, successfully completing a CHEMCO course becomes a prerequisite.

What to Expect in a CHEMCO Course

A standard CHEMCO course typically spans 10 days and covers a comprehensive range of topics. Here's a glimpse into the curriculum:

Chemical tanker familiarization: This section dives deep into the design, construction, and operational characteristics of chemical tankers. You'll gain insights into various types of chemical tankers, cargo handling systems, and safety equipment specific to these vessels.

Physico-chemical properties of chemicals: Understanding the behavior of different chemicals is crucial for safe handling. The course delves into the classification of chemicals, their physical and chemical properties, and potential hazards associated with each type.

Cargo handling procedures: Loading, discharging, and caring for chemical cargo in transit all require specialized procedures. The course equips you with the knowledge and skills to handle these operations safely and efficiently. This includes familiarization with cargo piping systems, pumps, valves, and various safety precautions needed during cargo transfer.

Emergency procedures: Chemical tankers carry hazardous materials, and the potential for emergencies is ever-present. The course equips participants with the knowledge and skills to respond effectively to emergencies such as fires, leaks, spills, and pollution incidents.

Regulations and conventions: A crucial aspect of safe chemical tanker operations is adhering to international regulations and conventions like MARPOL (International Convention for the Prevention of Pollution from Ships) and the IMDG Code (International Maritime Dangerous Goods Code). The course ensures a thorough understanding of these regulations and their practical application.

In addition to theoretical knowledge, most CHEMCO courses incorporate practical exercises and simulations. This allows participants to apply their learnings in realistic scenarios, enhancing their preparedness for real-world situations on board chemical tankers.

Benefits of Taking a CHEMCO Course in Mumbai

Mumbai offers a plethora of advantages for pursuing a CHEMCO course:

Renowned Training Institutes: The city boasts several well-established and Directorate General of Shipping (DGS) approved institutes offering CHEMCO courses. These institutes have a proven track record of delivering high-quality training programs.

Experienced Faculty: The courses are led by experienced instructors with extensive knowledge of the chemical tanker industry. They provide valuable insights and practical guidance to the participants.

Focus on Practical Training: Mumbai's training institutes often have access to sophisticated simulators and training facilities. This allows participants to gain hands-on experience in a controlled environment.

Industry Recognition: A DGS-approved CHEMCO course certificate from a reputed Mumbai institute holds significant value within the maritime industry. It demonstrates your commitment to professional development and enhances your employability on chemical tankers.

Finding the Right CHEMCO Course Provider in Mumbai

With numerous institutes offering CHEMCO course in Mumbai, choosing the right one becomes crucial. Here are some key factors to consider:

Institute Reputation: Research the institute's track record, accreditations, and faculty qualifications. Opt for institutes with a proven reputation for delivering high-quality CHEMCO training programs.

Course Content and Structure: Ensure the course curriculum aligns with the STCW requirements and covers all the essential topics mentioned earlier.

0 notes

Text

𝗪𝗲𝗶𝘁𝗲𝗿𝗯𝗶𝗹𝗱𝘂𝗻𝗴𝘀𝘁𝗲𝗿𝗺𝗶𝗻𝗲 𝗠𝗮̈𝗿𝘇

𝘞𝘦𝘪𝘵𝘦𝘳𝘦 𝘛𝘦𝘳𝘮𝘪𝘯𝘦 𝘧𝘪𝘯𝘥𝘦𝘯 𝘚𝘪𝘦 𝘢𝘶𝘧 𝘶𝘯𝘴𝘦𝘳𝘦𝘳 𝘏𝘰𝘮𝘦𝘱𝘢𝘨𝘦

𝟬𝟰.𝟬𝟯.𝟮𝟬𝟮𝟰 - 𝟬𝟱.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦 𝘓𝘪𝘵𝘩𝘪𝘶𝘮𝘣𝘢𝘵𝘵𝘦𝘳𝘪𝘦-𝘝𝘦𝘳𝘴𝘢𝘯𝘥 𝘧𝘶̈𝘳 𝘥𝘪𝘦 𝘝𝘦𝘳𝘬𝘦𝘩𝘳𝘴𝘵𝘳𝘢̈𝘨𝘦𝘳: 𝘚𝘵𝘳𝘢ß𝘦 (𝘈𝘋𝘙), 𝘚𝘤𝘩𝘪𝘦𝘯𝘦 (𝘙𝘐𝘋), 𝘚𝘦𝘦 (𝘐𝘔𝘋𝘎 𝘊𝘰𝘥𝘦), 𝘓𝘶𝘧𝘵 (𝘐𝘈𝘛𝘈 𝘋𝘎𝘙/𝘐𝘊𝘈𝘖 𝘛𝘐)

Trainer: Robert Wenske

Ort: Virtuelles Klassenzimmer

𝟭𝟰.𝟬𝟯.𝟮𝟬𝟮𝟰 - 𝟭𝟱.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦 𝘝𝘦𝘳𝘴𝘦𝘯𝘥𝘦𝘳 𝘈2/𝘈3 𝘶𝘯𝘥 𝘝𝘦𝘳𝘱𝘢𝘤𝘬𝘦𝘳 𝘉2/𝘉3 | 𝘴𝘱𝘦𝘻𝘪𝘦𝘭𝘭 𝘧𝘶̈𝘳 𝘓𝘪𝘵𝘩𝘪𝘶𝘮-𝘉𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘯 – 𝘒𝘭𝘢𝘴𝘴𝘦 9 (𝘦𝘩𝘦𝘮. 𝘗𝘒1/𝘗𝘒2 𝘒𝘭.9) 𝘎𝘳𝘶𝘯𝘥- 𝘶𝘯𝘥 𝘙𝘦𝘧𝘳𝘦𝘴𝘩𝘦𝘳𝘭𝘦𝘩𝘳𝘨𝘢𝘯𝘨

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟮.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦 𝘚𝘦𝘮𝘪𝘯𝘢𝘳 𝘕𝘦𝘶𝘦𝘳𝘶𝘯𝘨𝘦𝘯 𝘶𝘯𝘥 𝘈̈𝘯𝘥𝘦𝘳𝘶𝘯𝘨𝘦𝘯 𝘣𝘦𝘪𝘮 𝘝𝘦𝘳𝘴𝘢𝘯𝘥 𝘷𝘰𝘯 𝘓𝘪𝘵𝘩𝘪𝘶𝘮-𝘡𝘦𝘭𝘭𝘦𝘯 𝘶𝘯𝘥 -𝘉𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘯 𝘢𝘶𝘧 𝘢𝘭𝘭𝘦𝘯 𝘝𝘦𝘳𝘬𝘦𝘩𝘳𝘴𝘵𝘳𝘢̈𝘨𝘦𝘳𝘯 2024-2026

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟮.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘌𝘕𝘎𝘓𝘐𝘚𝘏: 𝘖𝘯𝘭𝘪𝘯𝘦 𝘚𝘦𝘮𝘪𝘯𝘢𝘳 𝘕𝘦𝘸 𝘢𝘯𝘥 𝘤𝘩𝘢𝘯𝘨𝘦𝘥 𝘳𝘦𝘨𝘶𝘭𝘢𝘵𝘪𝘰𝘯𝘴 𝘧𝘰𝘳 𝘴𝘩𝘪𝘱𝘱𝘪𝘯𝘨 𝘭𝘪𝘵𝘩𝘪𝘶𝘮 𝘤𝘦𝘭𝘭𝘴 𝘢𝘯𝘥 𝘣𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘴 𝘰𝘯 𝘢𝘭𝘭 𝘵𝘳𝘢𝘯𝘴𝘱𝘰𝘳𝘵 𝘮𝘰𝘥𝘦𝘴 2024 𝘵𝘰 2026

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟱.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦-𝘚𝘱𝘦𝘻𝘪𝘢𝘭𝘴𝘦𝘮𝘪𝘯𝘢𝘳 𝘻𝘶𝘳 𝘒𝘭𝘢𝘴𝘴𝘪𝘧𝘪𝘻𝘪𝘦𝘳𝘶𝘯𝘨 𝘷𝘰𝘯 𝘓𝘪𝘵𝘩𝘪𝘶𝘮-𝘡𝘦𝘭𝘭𝘦𝘯 𝘶𝘯𝘥 -𝘉𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘯

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟱.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘌𝘕𝘎𝘓𝘐𝘚𝘏: 𝘖𝘯𝘭𝘪𝘯𝘦 𝘚𝘦𝘮𝘪𝘯𝘢𝘳 𝘚𝘱𝘦𝘤𝘪𝘢𝘭 𝘰𝘯 𝘵𝘩𝘦 𝘤𝘭𝘢𝘴𝘴𝘪𝘧𝘪𝘤𝘢𝘵𝘪𝘰𝘯 𝘰𝘧 𝘭𝘪𝘵𝘩𝘪𝘶𝘮 𝘤𝘦𝘭𝘭𝘴 𝘢𝘯𝘥 𝘣𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘴

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟲.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦-𝘚𝘱𝘦𝘻𝘪𝘢𝘭𝘴𝘦𝘮𝘪𝘯𝘢𝘳 𝘻𝘶𝘮 𝘛𝘩𝘦𝘮𝘢 𝘥𝘦𝘧𝘦𝘬𝘵/𝘣𝘦𝘴𝘤𝘩𝘢̈𝘥𝘪𝘨𝘵𝘦 𝘓𝘪𝘵𝘩𝘪𝘶𝘮-𝘡𝘦𝘭𝘭𝘦𝘯 𝘶𝘯𝘥 -𝘉𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘯

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟲.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘌𝘕𝘎𝘓𝘐𝘚𝘏: 𝘖𝘯𝘭𝘪𝘯𝘦 𝘚𝘦𝘮𝘪𝘯𝘢𝘳 𝘚𝘱𝘦𝘤𝘪𝘢𝘭 𝘰𝘯 𝘥𝘢𝘮𝘢𝘨𝘦𝘥/𝘥𝘦𝘧𝘦𝘤𝘵𝘪𝘷𝘦 𝘭𝘪𝘵𝘩𝘪𝘶𝘮 𝘤𝘦𝘭𝘭𝘴 𝘢𝘯𝘥 𝘣𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘴

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟳.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘖𝘯𝘭𝘪𝘯𝘦-𝘚𝘱𝘦𝘻𝘪𝘢𝘭𝘴𝘦𝘮𝘪𝘯𝘢𝘳 𝘻𝘶𝘮 𝘛𝘩𝘦𝘮𝘢 𝘌𝘯𝘵𝘴𝘰𝘳𝘨𝘶𝘯𝘨/𝘙𝘦𝘤𝘺𝘤𝘭𝘪𝘯𝘨 𝘷𝘰𝘯 𝘓𝘪𝘵𝘩𝘪𝘶𝘮-𝘡𝘦𝘭𝘭𝘦𝘯 𝘶𝘯𝘥 -𝘉𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘯

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

𝟮𝟳.𝟬𝟯.𝟮𝟬𝟮𝟰

𝘌𝘕𝘎𝘓𝘐𝘚𝘏: 𝘖𝘯𝘭𝘪𝘯𝘦 𝘚𝘦𝘮𝘪𝘯𝘢𝘳 𝘚𝘱𝘦𝘤𝘪𝘢𝘭 𝘰𝘯 ��𝘩𝘦 𝘳𝘦𝘤𝘺𝘤𝘭𝘪𝘯𝘨/𝘥𝘪𝘴𝘱𝘰𝘴𝘢𝘭 𝘰𝘧 𝘭𝘪𝘵𝘩𝘪𝘶𝘮 𝘤𝘦𝘭𝘭𝘴 𝘢𝘯𝘥 𝘣𝘢𝘵𝘵𝘦𝘳𝘪𝘦𝘴

Trainerin: Eva Glimsche

Ort: Virtuelles Klassenzimmer

#gefahrgutvorschriften#transportvorschriften#lithiumbatterien#lithiumzellen#transport#versand#lithiumbatteryservice#weiterbildung#schulung#networking#konferenz

#lithiumbatterien#lithiumzellen#transport#verpacken#versand#gefahrgut#lithiumbatteryservice#logistik#transportvorschriften#schulungen#weiterbildung#training#networking

0 notes

Text

How Dangerous Goods are Shipped from China

China is one of the world’s largest exporters of goods, including those that are classified as dangerous or hazardous. Dangerous goods are any materials that pose a risk to health, safety, property, or the environment when transported. Examples of dangerous goods include explosives, flammable liquids, corrosive substances, radioactive materials, and infectious substances.

Shipping dangerous goods from China to any destination in the world requires careful planning and compliance with various regulations and requirements. In this article, we will cover the following aspects of shipping dangerous goods from China:

Understanding the regulations and requirements for shipping dangerous goods

Packaging and labeling requirements for dangerous goods

Choosing the right shipping method for dangerous goods

Documentation needed for shipping dangerous goods

Ensuring the safety of dangerous goods during transit

Common challenges and solutions for shipping dangerous goods

Compliance and legal considerations for shipping dangerous goods

Working with freight forwarders and logistics providers for shipping dangerous goods

Understanding the regulations and requirements for shipping dangerous goods

The first step to shipping dangerous goods from China is to understand the regulations and requirements that apply to your shipment. Depending on the type, quantity, and destination of your dangerous goods, you may need to follow different rules and standards.

The main sources of regulations and requirements for shipping dangerous goods are:

The United Nations Recommendations on the Transport of Dangerous Goods (UNRTDG), which provide a global framework for the classification, identification, packaging, labeling, documentation, and handling of dangerous goods.

The International Maritime Dangerous Goods Code (IMDG Code), which applies to the sea transport of dangerous goods.

The International Air Transport Association Dangerous Goods Regulations (IATA DGR), which apply to the air transport of dangerous goods.

The Chinese Dangerous Goods Transport Regulations (CDGTR), which apply to the domestic transport of dangerous goods within China by road, rail, or inland waterways.

These regulations and requirements are updated regularly to reflect the latest scientific and technical developments, as well as the best practices for ensuring the safety and security of dangerous goods transport. Therefore, it is important to check the latest versions of these regulations and requirements before shipping dangerous goods from China.

Packaging and labeling requirements for dangerous goods

One of the most important aspects of shipping dangerous goods from China is to ensure that they are properly packaged and labeled. Packaging and labeling requirements for dangerous goods are designed to prevent leakage, damage, or contamination of the goods, as well as to provide clear and accurate information about the contents and hazards of the goods.

Packaging requirements for dangerous goods vary depending on the type and quantity of the goods, as well as the mode of transport. Generally, packaging for dangerous goods must meet the following criteria:

Be of good quality, strong enough to withstand the normal conditions of transport, and compatible with the goods.

Be tested and certified by an approved authority, and marked with the UN specification number, the manufacturer’s name or symbol, and the date of manufacture.

Be closed and secured in a way that prevents any loss of contents.

Be fitted with appropriate devices, such as vents, valves, or pressure relief devices, if necessary.

Labeling requirements for dangerous goods also vary depending on the type and quantity of the goods, as well as the mode of transport. Generally, labeling for dangerous goods must include the following elements:

The UN number, which is a four-digit code that identifies the type of dangerous goods.

The proper shipping name, which is the official name of the dangerous goods, as specified in the regulations and requirements.

The hazard class and division, which indicate the nature and degree of the hazard posed by the dangerous goods. There are nine hazard classes and several subdivisions, each with a specific symbol and color.

The packing group, which indicates the degree of danger within a hazard class. There are three packing groups: I (high danger), II (medium danger), and III (low danger).

The subsidiary risk label, which indicates any additional hazards that may be present in the dangerous goods, such as toxicity, corrosivity, or radioactivity.

The marine pollutant mark, which indicates that the dangerous goods may cause harm to the marine environment if released.

The orientation arrows, which indicate the correct upright position of the package.

The emergency contact information, which provides the name and phone number of a person or organization that can provide information or assistance in case of an emergency involving the dangerous goods.

Choosing the right shipping method for dangerous goods

Another important aspect of shipping dangerous goods from China is to choose the right shipping method for your shipment. The shipping method you choose will depend on several factors, such as the type, quantity, and destination of your dangerous goods, as well as the cost, speed, and reliability of the service.

The main shipping methods for dangerous goods are:

Sea freight, which is the most common and economical shipping method for dangerous goods, especially for large volumes and long distances. Sea freight offers a wide range of options, such as full container load (FCL), less than container load (LCL), roll-on/roll-off (RoRo), or break bulk. However, sea freight also has some disadvantages, such as longer transit times, higher risk of damage or loss, and more complex documentation and customs clearance procedures.

Air freight, which is the fastest and most convenient shipping method for dangerous goods, especially for small volumes and urgent deliveries. Air freight offers a high level of security and traceability, as well as lower insurance costs and fewer restrictions on the destination. However, air freight also has some disadvantages, such as higher costs, stricter regulations and requirements, and limited capacity and availability.

Road freight, which is the most flexible and accessible shipping method for dangerous goods, especially for short distances and door-to-door deliveries. Road freight offers a high degree of control and customization, as well as lower packaging and handling costs and fewer intermediaries. However, road freight also has some disadvantages, such as higher fuel costs, traffic congestion, environmental impact, and safety risks.

Rail freight, which is a reliable and efficient shipping method for dangerous goods, especially for long distances and inland destinations. Rail freight offers a high capacity and frequency, as well as lower emissions and noise levels. However, rail freight also has some disadvantages, such as higher infrastructure costs, limited network coverage, and dependence on other modes of transport for the first and last mile.

Documentation needed for shipping dangerous goods

Another essential aspect of shipping dangerous goods from China is to prepare and provide the necessary documentation for your shipment. Documentation for dangerous goods is required to comply with the regulations and requirements, as well as to facilitate the identification, inspection, and clearance of the goods.

The main documents needed for shipping dangerous goods are:

The dangerous goods declaration, which is a document that provides detailed information about the nature, quantity, and packaging of the dangerous goods, as well as the shipper’s and consignee’s details, the mode of transport, and the emergency contact information. The dangerous goods declaration must be signed by the shipper or an authorized representative, and must accompany the shipment at all times.

The bill of lading, which is a document that serves as a contract of carriage and a receipt of goods between the shipper and the carrier. The bill of lading must include the information from the dangerous goods declaration, as well as the terms and conditions of the service, the freight charges, and the delivery instructions. The bill of lading must be issued by the carrier or an agent, and must be presented for the release of the goods.

The air waybill, which is a document that serves as a contract of carriage and a receipt of goods between the shipper and the airline. The air waybill must include the information from the dangerous goods declaration, as well as the flight details, the weight and dimensions of the goods, and the charges and fees. The air waybill must be issued by the airline or an agent, and must be attached to the package or the container.

The packing list, which is a document that provides a detailed description of the contents and the packaging of the goods. The packing list must include the information from the dangerous goods declaration, as well as the number and type of packages, the marks and numbers, and the gross and net weights. The packing list must be prepared by the shipper or an agent, and must be enclosed in the package or the container.

The certificate of origin, which is a document that certifies the origin of the goods. The certificate of origin may be required by the destination country for customs purposes, or by the importer for tariff or preferential treatment. The certificate of origin must be prepared by the shipper or an agent, and must be authenticated by a chamber of commerce or a government authority.

The commercial invoice, which is a document that provides the value and the terms of sale of the goods. The commercial invoice may be required by the destination country for customs purposes, or by the importer for payment or taxation. The commercial invoice must be prepared by the shipper or an agent, and must include the information from the dangerous goods declaration, as well as the price, the currency, the incoterms, and the payment method.

Ensuring the safety of dangerous goods during transit

Another crucial aspect of shipping dangerous goods from China is to ensure the safety of the goods during transit. Safety measures for dangerous goods are designed to prevent or minimize the risk of accidents, incidents, or emergencies involving the goods, as well as to protect the health and safety of the people and the environment involved in the transport.

Segregation and compatibility, which means keeping different types of dangerous goods separate from each other, and from other goods that may react with them, during transport. Segregation and compatibility rules are based on the hazard class and division, the packing group, and the UN number of the dangerous goods, and may vary depending on the mode of transport. Segregation and compatibility measures may include using different containers, compartments, vehicles, or vessels, or maintaining a minimum distance or a barrier between the goods.

Training and awareness, which means providing adequate information and instruction to the personnel involved in the transport of dangerous goods, such as the shipper, the carrier, the driver, the loader, the handler, and the receiver. Training and awareness programs are based on the roles and responsibilities of the personnel, as well as the type and quantity of the dangerous goods. Training and awareness measures may include providing manuals, guides, posters, labels, placards, or signs, as well as conducting courses, workshops, drills, or exercises.

Emergency response and preparedness, which means having a plan and a procedure to deal with any accidents, incidents, or emergencies involving the transport of dangerous goods, such as spills, leaks, fires, explosions, or exposures. Emergency response and preparedness plans are based on the type and quantity of the dangerous goods, as well as the mode of transport and the route of the shipment. Emergency response and preparedness measures may include providing emergency equipment, such as fire extinguishers, spill kits, or personal protective equipment, as well as notifying and coordinating with the relevant authorities, such as the police, the fire department, or the environmental agency.

Inspection and verification, which means checking and confirming that the transport of dangerous goods complies with the regulations and requirements, as well as the standards and specifications of the packaging, labeling, documentation, and safety measures. Inspection and verification activities are performed by the personnel involved in the transport of dangerous goods, as well as by the competent authorities, such as the customs, the port, or the airport. Inspection and verification measures may include using instruments, such as scanners, detectors, or testers, as well as conducting audits, surveys, or investigations.

Compliance and legal considerations for shipping dangerous goods

Another important aspect of shipping dangerous goods from China is to comply with the legal obligations and responsibilities that apply to your shipment. Compliance and legal considerations for shipping dangerous goods are designed to ensure that the transport of dangerous goods follows the applicable laws and regulations, as well as to protect the rights and interests of the parties involved in the transport.

Compliance and legal considerations for shipping dangerous goods include the following:

Liability and insurance, which means being accountable and liable for any damages, injuries, or losses that may result from the transport of dangerous goods, as well as having adequate insurance coverage to compensate for such events. Liability and insurance rules are based on the type and quantity of the dangerous goods, as well as the mode of transport and the terms of the contract. Liability and insurance measures may include obtaining a certificate of insurance, declaring the value of the goods, or paying a premium or a deductible.

Customs and duties, which means following the customs procedures and paying the duties and taxes that may apply to the import or export of dangerous goods. Customs and duties rules are based on the origin, destination, and value of the dangerous goods, as well as the type of trade agreement or preferential treatment. Customs and duties measures may include submitting a customs declaration, providing a certificate of origin, or applying for a duty exemption or a refund.

Sanctions and restrictions, which means complying with the sanctions and restrictions that may prohibit or limit the trade or transport of dangerous goods to or from certain countries, regions, entities, or individuals. Sanctions and restrictions rules are based on the nature and purpose of the dangerous goods, as well as the foreign policy and national security interests of the countries involved. Sanctions and restrictions measures may include obtaining a license, a permit, or an authorization, or avoiding or reporting any violations or breaches.

Working with freight forwarders and logistics providers

Another helpful aspect of shipping dangerous goods from China is to work with freight forwarders and logistics providers who specialize in the transport of dangerous goods. Freight forwarders and logistics providers are intermediaries who offer various services and solutions for the transport of goods, such as booking, consolidation, warehousing, distribution, and customs clearance.

Working with freight forwarders and logistics providers for shipping dangerous goods can offer the following benefits:

Expertise and experience, which means having access to the knowledge and skills of professionals who are familiar with the regulations and requirements, as well as the best practices and standards, for shipping dangerous goods.

Convenience and efficiency, which means saving time and effort by outsourcing the complex and tedious tasks and processes involved in shipping dangerous goods, such as packaging, labeling, documentation, and safety measures.

Cost-effectiveness and competitiveness, which means reducing the costs and risks associated with shipping dangerous goods, as well as increasing the opportunities and options for the transport of goods, such as using different modes of transport, routes, or carriers.

Reliability and security, which means ensuring the quality and safety of the transport of dangerous goods, as well as the compliance and legal obligations, by working with reputable and trustworthy partners who have the necessary licenses, certifications, and insurance.

GET A CHEAP FREIGHT FOWARDER IN CHINA

0 notes

Text

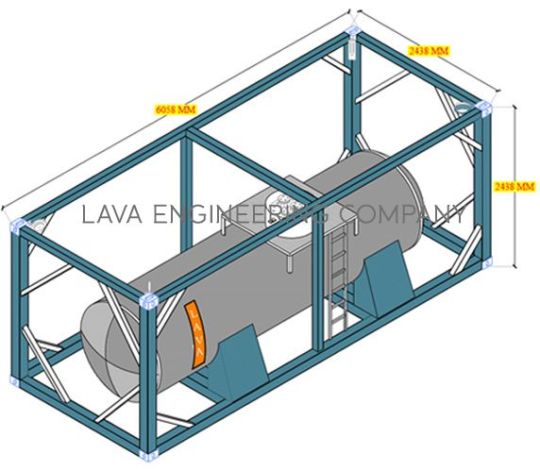

ISO TANK CONTAINER SPECIALIST

ISO TANK CONTAINER LAVA Engineering Company designs and builds UN portable ISO tank containers with ASME VIII / ISO668 design standards for storage and transport of all edible Liquids, chemicals, Oils and Gases. LAVA ISO Tank Containers conforms to the International Maritime Organization Standards (IMO) which allows LAVA Containers to be used for imports/exports in for countries like INDIA, Middle East, AFRICA, USA, CANADA, EUROPE,US and other parts of the world through Sea, Rail and Road transport.

KNOW MORE

Some Of Our Approved Model ISO Tank Containers

T1 ISO tank container for Wine / Juices and Light liquids T3 ISO tank container for Petrol, Diesel, Jet Fuel, Crude Oil (ATF), Bitumen T4 ISO tank container for Edible / Non Edible Oils T11 ISO tank container for Non hazardous chemicals T14 ISO tank container For Hazardous Chemicals and Acids like HCL / Caustic / sulfuric acid/ Ferric Chloride) with Rubber lining / FRP lining Inner / PE lining T20 ISO tank container for Bromine T50 ISO tank container for LPG / Ammonia Gas / Propane SWAP Tank container for cargo above 28,000 Litres to 35,000 Litres We have the facility and experts in the design and fabrication of DV Box Container and Tank containers to serve the worldwide Food industries, Chemical Industry, Oil Drilling & exploration companies, Oil field Equipment service companies, Pharmaceutical companies, Nuclear and Defense Industries. We apply the same precision and engineering excellence throughout the whole of our extensive range of Containers with International design standards of ASME / ISO/ API /DNV.

T1 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T1 – ISO Tank Containers in exclusivity for Juice and Wine manufacturers as per ISO 668 design code.

KNOW MORE

T1 – UN Portable ISO Tank Container Technical Specification

Size–20ft / 40ft ISO tank container Capacity–26,000 Litres / 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–-40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T3 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T3 ISO Tank Containers & Airport storage tanks for Diesel, Jet Fuel (ATF) as per IS 7667 standards.

KNOW MORE

T3 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T4 ISO TANK CONTAINER LAVA Engineering is a UN portable T4 ISO Tank Container manufacturers India. These tanks are for food grade liquids and edible and inedible Oils. Specific customer Design requirement for food grade liquid handling are also undertaken to suit individual industries.

KNOW MORE

T4 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 BarTest Pressure–2.90 Bar

T11 ISO TANK CONTAINER LAVA Engineering is the only Indian company to have Prototype approved and fully certified UN T11 ISO Tanks for storage and transport of Non Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T11 ISO tanks are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

T11 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, ISO 668 MOC–CS / SS Gross Weight–30,000 Kgs Temperature–+65 deg C Operating Pressure–4 Bar Test Pressure–6 Bar

T14 ISO TANK CONTAINER LAVA Engineering is the only T14 HCL ISO Tank Container manufacturer in India to have Prototype approved and fully certified UN T14 ISO Tank Container for storage and transport of Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T14 ISO tank containers are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

LAVA T14 tanks are made of Carbon Steel or Stainless Steel with Rubber lining / FRP lining / PE lining inners for storage and transport of Hazardous Chemicals like Hydrochloric Acid (HCL), Caustic Soda, Sulfuric Acid, Ferric Chloride etc. As an ISO Tank Containers Manufacturer India, Lava Engineering supplies T14 ISO Tank containers, which are tested as per ISO 1496 /3 and are prominent with customers in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands.

T14 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerCapacity-20 M3Design Code-ASME VIII, EN 12972 ,ISO 668Lining-Rubber Lining / FRP lining / PE liningGross Weight-30,000 KgsTemperature-+65 deg COperating Pressure-4 BarTest Pressure-6 Bar

T22 ISO TANK CONTAINER T22 – ISO Tank Container Technical Specification

KNOW MORE

Lava engineering company manufacturing ISO tank container for bromine liquid (UN no. 1744) storage & transport with all required international certification like ASME SEC VIII DIV -I, ISO (T22), IMDG-T22,CSC,RID/ADR,US DOT – CFR,TIR,TC,UIC

The ISO tank container liner with Lead lining inner suitable for storage of bromine liquid.

Offshore Chemical tanks Norway

T50 ISO TANK CONTAINER LAVA Engineering manufacture T50 - ISO tank containers and Gas storage tanks for LPG Propane, and other gaseous liquids. We supply LPG storage bullets and LPG transport trailers with CCOE / PESO for Indian operations of Road & Rail and with IMDG & ADR certifications for overseas customers.

KNOW MORE

T50 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerL / W / H-6058 X 2438 X 2591 mmCapacity-24,000 LitresDesign Code-ASME VIII, ISO 668Gross Weight-30,000 KgsTemperature-- 40 to +60 deg COperating Pressure-22 BarDesign Pressure-25 Bar

SWAP TANK LAVA Engineering Company also manufactures SWAP tank containers for customers interested to carry Bulk cargo with capacity of 30,000 to 35,000 Litres

KNOW MORE

The frame Dimension varies from 7150 – 7820L X 2550W X 2670H mm depending on the capacity requirement of the customer

The SWAP tank container is ideal for Storage and Road transport application in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands and African countries where the road restrictions are minimal

The SWAP tank container comes with UN classification of T1, T4 and T11 Containers. Special modifications are also provided for T14 containers for Rubber or PE lined inner for Acid chemicals.

The SWAP tank can be customized as specialty containers as per client requirements and shall carry certifications of ASME, IMDG and ISO for specific chemicals.

0 notes

Text

Imdg Code Volume 1

THE PURPOSE OF THIS CODE IS TO FACILITATE SAFE TRANSPORT OF DANGEROUS GOODS AND AT THE SAME TIME TO ALLOW FOR THEIR UNRESTRICTED MOVEMENT.

IMDG Contents. The Code comprises 7 parts. It is presented in two books; Volume 1 and Volume 2. It is necessary to use both books to obtain the required information when shipping dangerous goods by sea.The Code also contains a Supplement. Volume 1 (Parts 1-2 & 4-7 of the Code) comprises: Part 1 General provisions, definitions.

CMate-IMDG Code contains: 1. IMDG Code (Volume 1 and Volume 2) Amendment 39-18 2.

IMDG Code Vol 1 & 2, 2018 Edition The IMDG Code is accepted as an international guide to the transport of dangerous goods by sea and is recommended to governments for adoption or for use as the basis for national regulations.

IMO: IMDG Code – Volume 1. The International Maritime Dangerous Goods (IMDG) Code lays out the regulatory framework for all aspects of handling dangerous goods and marine pollutants in sea transport. Since its was first published in 1965, the Code has undergone many changes, in both format and content, in order to keep up with the rapid. In the event of any dangerous goods or harmful substances being carried aboard the general cargo ship, reference to ‘The International Maritime Dangerous Goods (IMDG)’ code (volume 1, 2 and suppliment) should be consulted.

THIS CODE IS THERE TO COMPLY WITH SOLAS CH 7, PART 8 AND MARPOL ANNEX III.

THE CODE HAS 2 VOLUMES AND 1 SUPPLEMENT.

VOLUME 1: CONSISTS OF PART 1, 2, 4, 5, 6 AND 7.

PART 1 – GENERAL DEFINITIONS, PROVISIONS AND TRAINING,

PART 2 – CLASSIFICATION,

PART 4 – PACKING AND TANK PROVISIONS,

PART 5 – CONSIGNMENT PROCEDURE,

PART 6 – CONSTRUCTION AND TESTING OF PACKAGING, INTERMEDIATE BULK

CONTAINER, LARGE PACKAGINGS ETC,

Imdg Code Volume 1 And 2

PART 7 – PROVISIONS CONCERNING TRANSPORT OPERATIONS.

VOLUME 2: CONSISTS OF PART 3

3.1 – GENERAL

3.2 – DANGEROUS GOODS LIST

3.3 – SPECIAL PROVISIONS

3.4 – LIMITED QUANTITIES

DANGEROUS GOODS LIST CONSISTS OF 18 COLUMNS:

1. U.N. No.

2. PROPER SHIPPING NAME,

3. CLASS,

4. SUBSIDIARY RISK,

5. PACKING GROUP,

6. SPECIAL PROVISIONS,

7. LIMITED QUANTITY,

8 & 9. PACKING REQUIREMENTS

10 & 11. IBC (INTERMEDIATE BULK CONTAINER

12, 13 & 14. TANK INSTRUCTIONS,

15. EmS

16. STOWAGE AND SEGREGATION,

17. PROPERTIES AND OBSERVATIONS,

18. UN No.

COLUMN NUMBER 1, 2, 3, 4, 5, 6, 15, 16, 17 ARE IMPORTANT FOR US TO KNOW.

SUBSIDIARY RISK: MEANS ANY OTHER RISK WHICH THE CARGO MAY POSSES OTHER THAN THE ONE SPECIFIED BY ITS CLASS. IT IS A SECONDARY RISK. IF A CARGO HAS TWO RISKS INVOLVED, THEN IT SHOULD BE MARKED WITH 2 LABELS STATING BOTH THE RISKS. IF A PACKAGE HAS MORE THAN ONE CLASS OF DANGEROUS GOODS INSIDE IT, THEN IT SHOULD BE MARKED WITH BOTH THE CLASSES.

STOWAGE CATEGORY: STATED IN VOL 1, PART 7.1.

CLASS 1 HAS 15 CATEGORIES

CLASS 2-9 HAS 5 CATEGORIES (A~E).

THIS WILL DECIDE WHERE THE CARGO HAS TO BE STOWED, ON DECK OR UNDER DECK.

SEGREGATION: STATED IN VOL 1, PART 7.2

THIS SECTION HAS TABLES FOR FOLLOWING:

SEGREGATION FOR DANGEROUS GOODS CARRIED IN PACKAGED FORM: THIS IS GIVEN IN THE FORM OF A TABLE. STATING THE TYPE OF SEGREGATION REQUIRED BETWEEN CLASSES OF CARGO, EXCLUDING CLASS 1, WHICH HAS AN ALTOGETHER SEPARATE TABLE. THE TERMS USED FOR SEGREGATION ARE:

AWAY FROM: MAY BE CARRIED IN THE SAME COMPARTMENT OR ON DECK PROVIDED A MINIMUM HORIZONTAL SEPARATION OF 3M PROJECTED VERTICALLY IS MAINTAINED.

SEPARATED FROM: CAN BE CARRIED IN THE SAME COMPARTMENT IF THE INTERVENING DECK IS RESISTANT TO FIRE AND LIQUIDS OTHERWISE IN SEPARATE HOLDS. ON DECK A MINIMUM HORIZONTAL SEPARATION OF 6 METERS.

SEPARATED BY A COMPLETE COMPARTMENT FROM: THERE MUST BE EITHER A VERTICAL OR LONGITUDINAL SEPARATION BY A COMPLETE COMPARTMENT OR HOLD, AND TWO BULKHEADS WHICH ARE RESISTANT TO FIRE AND LIQUIDS. FOR ON DECK, A HORIZONTAL SEPARATION OF AT LEAST 12 METRES EVEN IF THE PACKAGE IS STOWED UNDER DECK.

SEPARATED LONGITUDINALLY BY A COMPLETE COMPARTMENT OR HOLD FROM: A VERTICAL SEPARATION IS NOT ALLOWED, THE PACKAGE MUST BE HORIZONTALLY SEPARATED BY A COMPLETE COMPARTMENT. ON DECK A HORIZONTAL SEPARATION OF 24 METERS IS REQUIRED. BETWEEN ON DECK AND UNDER DECK CARGO A HORIZONTAL SEPARATION OF 24 METERS + INTERVENING COMPARTMENT.

FOR CONTAINERS THE TABLE IS THE SAME AS ABOVE BUT THE MEANING OF THE ABOVE SEGREGATION TERMS IS DIFFERENT.

FOR HATCH COVERLESS TYPE CONTAINER VESSEL, THE TABLE IS AGAIN THE SAME BUT THE MEANINGS OF THE ABOVE SEGRETATION TERMS IS DIFFERENT.

THERE IS A SEPARATE TABLE FOR RO-RO VESSEL.

SEPARATE TABLE FOR SEGREGATION BETWEEN CARGO IN BULK AND CARGO IN PACKAGED FORM.

SEGREGATION TABLE FOR CLASS 1 CARGO WHICH IS BY COMPATIBILITY CODES. WHICH ARE A TO L, N AND S.

IMDG SUPPLEMENT: CONSISTS OF

EMERGENCY PROCEDURES (EmS)

MEDICAL FIRST AID GUIDE,

REPORTING PROCEDURES,

PACKING CARGO TRANSPORT UNIT,

USE OF PESTICIDES ON SHIP,

INF CODE

Imdg Code Volume 1 2014 Edition

AND APPENDIX

EMERGENCY PROCEDURES (Ems): GUIDELINES TO BE FOLLOWED IN CASE OF A DANGEROUS CARGO EMERGENCY (FIRE AND SPILLAGE). IN THE D.G. LIST COLUMN 15, IT IS STATED AS FA, SA IN FRONT OF A PARTICAL DANGEROUS CARGO, WHICH MEANS IN CASE OF A FIRE TABLE NO FA HAS TO BE FOLLOWED AND IN CASE OF SPILLAGE TABLE NO SA TO BE FOLLOWED. IF IT IS UNDERLINED IT MEANS THE CARGO HAS SOME SPECIAL RISK WHICH IS STATED SEPARATELY IN THE RESPECTIVE TABLE INFRONT OF THE SPECIFIC UN No.

Imdg Code Volume 1

FOR FIRE THERE ARE 10 TABLE (FA ~ FJ)

FOR SPILL THERE ARE 26 TABLES (SA ~ SZ).

MEDICAL FIRST AID GUIDE: THIS PART OF THE SUPPLEMENT WITH THE MEDICAL FIRST AID TO BE GIVEN TO A PERSON WHO HAS COME IN CONTACT WITH THE DANGEROUS CARGO EITHER BY INHALATION, INJESTION, SKIN CONTACT, EYE CONTACT ETC. THIS IS IN THE FORM OF A TABLE (QUESTANAIRE), ASKING VARIOUS QUESTIONS ABOUT THE MEDICAL EMERGENCY. THE RESPECTIVE TABLE IN THE FLOWCHART HAS TO BE REFFERED. IN ANY CASE THE COMPLETE FLOWCHART HAS TO BE COMPLETED FOR ANY MEDICAL EMERGENCY.

REPORTING PROCEDURES: REPORTINGS SUCH AS AMVER, AUSREP, MAREP, JASREP WHICH CONTAINS ITEMS FROM A~Z. IT HAS GOT VARIOUS REPORT SUCH AS DANGEROUS GOODS REPORT, MARINE POLLUTANT REPORT ETC. WHICH STATES THE ITEMS FROM A~Z WHICH HAVE TO BE SENT.

DANGEROUS CARGO MANIFEST: IT IS A MANIFEST PREPARED BY THE VESSEL OR THE OWNER’S AGENT ON BEHALF OF THE VESSEL, FOR CUSTOM PURPOSES.

THIS MANIFEST GIVES DETAILS LIKE:

NAME OF THE SHIP,

IMO NUMBER,

NATINALITY OF THE SHIP,

MASTER’S NAME,

VOYAGE NUMBER,

PORT OF LOADING,

PORT OF DISCHARGE,

AGENT’S NAME.

DETAILS OF THE DANGEROUS GOODS ONBOARD:

BOOKING REFERANCE NUMBER,

MARKS AND NUMBER OR CONTAINER NUMBER,

NUMBER AND KIND OF PACKAGES,

CLASS OF CARGO,

UN NO,

PACKAGING GROUP,

SUBSIDIARY RISK,

FLASHPOINT,

MARINE POLLUTANT,

WEIGHT OF THE CARGO,

EMS,

STOWAGE POSITION.

AGENT’S SIGNATURE AND MASTER’S SIGNATURE WITH PLACE AND DATE.

Imdg Code Volume 1 Contents

A VESSEL SHOULD ALSO HAVE A SHIPPER’S DECLARATION FOR EVERY PACKAGE THAT THE CARGO HAS BEEN PACKED, MARKED, LABELLED AND PLACARDED PROPERLY WITH THE REQUIREMENTS. GENERALLY THIS CERTIFICATE IS GIVEN TO THE SHIPPER BY THE PACKING AGENCY.

MAGAZINE STOWAGE FOR EXPLOSIVES:

MAGAZINE IS THE NAME GIVEN TO THE ENCLOSURE DESIGNED TO PROTECT CARGO FROM DAMAGE BY ANY OTHER CARGO DURING LOADING AND UNLOADING, AGAINST ADVERSE WEATHER CONDITIONS AND TO PREVENT UNAUTHORISED ACCESS. A MAGAZINE MAY BE A FIXED STRUCTURE ON SHIP, A CLOSED FREIGHT CONTAINER, THE LOADED COMPARTMENT OF A FREIGHT CONTAINER OR A PORTABLE MAGAZINE.

Contents Of Imdg Code Volume 1

MAGAZINE A: IT IS BASICALLY FOR THOSE SUBSTANCES WHICH HAVE TO BE KEPT CLEAR OF SHIP’S STEELWORK. THIS SORT OF MAGAZINE SPECIALLY GUARDS AGAINST FRICTION BETWEEN CARGO AND STEELWORK. THE INNER SIDES AND FLOOR SHOULD BE CLOSE BOARDED WITH WOOD. THE ROOF NEED NOT BE FLATTENED BUT SHOULD BE FREE OF LOOSE RUST AND SCALES. THE CARGO MUST BE AT A MINIMUM DEPTH OF 300mm FROM THE DECKHEAD.

MAGAZINE C: A CLOSED CARGO UNIT PLACED AS CLOSE AS POSSIBLE TO THE CENTRELINE OF THE SHIP. IF NOT THEN AT A DISTANCE B/8 OR 2.4 METERS, WHICHEVER IS LESS, FROM THE SHIP SIDE.

SPECIAL: THE GOODS MUST BE STOWED AS FAR AS POSSIBLE AWAY FROM THE LIVING QUARTERS OF THE CREW. GENERALLY GIVEN THE TOP MOST STOWAGE.

PRECAUTIONS WHEN LOADING / UNLOADING DANGEROUS GOODS

DOCUMENTATION IN ORDER (SHIPPER’S DECLARATION, CONTAINER PACKING CERTIFICATE, EMERGENCY INFORMATION) EMERGENCY INFORMATION),

ALL CARGO OPERATIONS SUPPORTED BY A RESPONSIBLE OFFICER WHO SHOULD BE IN POSSESION OF OPERATIONAL AND EMERGENCY INFORMATION (INCLUDING STABILITY INFORMATION),

NO INTOXICATED PERSON TO BE ALLOWED CHARGE OF OPERATION,

NO UNAUTHORIZED PERSON ALLOWEN IN VICINITY OF CARGO BEING HANDLED,

COMPARTMENT DRY AND SUITABLE FOR CARGO,

CARGO HANDLING EQUIPMENT CHECKED BEFORE USE,

NO CARGO HANDLING UNDER ADVERSE WEATHER CONDITIONS,

PACKAGING AND SEGREGATION AS PER IMDG CODE,

ALL CARGO PROPERLY LABELLED, NO LABELS DEFACED OR REMOVED,

CARGO HANDLED CAREFULLY, HANDLING KEPT TO MINIMUM,

TANKS NOT OVERFILLED,

PORT AUTHORITY INFORMED,

FIRE WIRES RIGGED AS NECESSARY,

EMERGENCY EQUIPMENT AVAILABLE FOR FIRE / SPILLAGE,

SUITABLE PRECAUTIONS AGAINST FIRE AND EXPLOSION,

PACKAGES TO BE STOWED AS PLANNED IN ACCORDANCE WITH THE IMDG CODE,

CARGO SPACE TO BE PROPERLY VENTILATED,

‘B’ FLAG DISPLAYED,

THERE IS A SAFE ACCESS TO THE PACKAGES, SO THAT IN CASE OF FIRE THEY CAN BE REMOVED,

ELECTRICAL FITTING IN GOOD CONDITION.

THE PACKAGE IS PROPERLY LABELLED / MARKED AND PLACARDED.

IF CARGO IN DRUMS, THEY SHOULD BE STOWED VERTICALLY,

THE CARGO SHOULD BE PLACED IN SUCH A MANNER THAT THERE IS SAFE AND CLEAR ACCESS TO ALL LSA / FFA,

PACKAGES SHOULD BE STOWED AWAY FROM SUNLIGHT OR OTHER HEAT SOURCES,

NO CARGO SHOULD BE STOWED ON TOP OF PORTABLE TANKS,

DG’S WITH GIVE OF VAPOUR TO BE STOWED ON DECK OR IN MECHANICALLY VENTILATED SPACES,

CARGO SECURING MANUAL TO BE COMPLIED WITH,

SEGREGATION AS PER THE IMDG CODE.

1 note

·

View note

Photo

#Dangerousgoods- A commodity that is determined by the Department of Transportation to be capable of posing an unreasonable risk to health, safety and property, when transported in commerce. DG goods are also called as Hazardous cargo. These commodities may endanger the safety of a Ship / aircraft or persons on board. The air / sea transportation of these dangerous materials can either be forbidden or restricted. The Transport of Dangerous Goods and Marine Pollutants in sea going ships is regulated by the International Convention for the “Safety of The Life At Sea (SOLAS)” and the International Convention for the Prevention of Pollution from Ships (MARPOL). Terms of both (SOLAS) And (MARPOL) have been worked-out in detail, and are included in the International Maritime Dangerous Goods (IMDG) Codes. IMDG code representing the classification of dangerous goods as defined by the International Maritime Organization (IMO) in compliance with international legal requirements. http://fresatechnologies.com/ #fresa #fresatechnologies #freightsoftware #freighterp #freightmanagement

2 notes

·

View notes

Text

There are mainly the following international laws and regulations concerning the transportation of dangerous chemicals and dangerous goods:

The United Nations:

Model Regulation on the Proposed Transport of Dangerous Goods (TDG)

Uniform Global Classification and Labelling System for Chemicals (GHS)

Manual of Recommended Tests and Criteria for the Transport of Dangerous Goods

International Agreement on the Carriage of Dangerous Goods by Road (ADR)

International Agreement on the Carriage of Dangerous Goods by Inland Waterways (ADN)

Intergovernmental Organization for International Railway Transport:

Rules for the International Carriage of Dangerous Goods by Rail (RID)

International Maritime Organization:

International Maritime Dangerous Goods Code (IMDG Code)

International Civil Aviation Organization:

Technical Guide for the Safe Transport of Dangerous Goods by Air (ICAO-TI)

0 notes

Text

Dangerous Goods Shipping: Top Tips

There are several hazards and risks when it comes to shipping dangerous goods (DG). Thankfully, there are also companies that offer special DG shipping services and packaging options.

DG shipping strictly adheres to specific guidelines. In this article, we’ll cover some of the best tips for dangerous good shipping. These tips can come in handy for individuals who handle dangerous goods frequently and organizations who want to get into the business as well.

What are hazardous goods?

First and foremost, it is crucial to familiarise yourself with the different dangerous goods classification. By doing so, you can identify which items or materials belong to a specific group and you’ll have a better idea how it is best dealt with.

Below is the dangerous good classification:

1. Explosives

2. Flammable Gases

2.1 Flammable gases i.e. acetylene and most Aerosols.

2.2 Non-flammable, non-toxic gases i.e. helium and oxygen.

2.3 Toxic gases i.e. chlorine.

3. Flammable Liquids

4. Flammable solids

4.1 Flammable solids i.e. phosphorous (red).

4.2 Substances liable to (white) spontaneous combustion i.e. phosphorus.

4.3 Substances that, when they come in contact, emit

5. Oxidizing

5.1 Oxidizing agents i.e. ammonium dichromate.

5.2 Organic peroxides i.e. ethyl methyl ketone peroxide.

6. Toxic and Infectious

6.1 Toxic substances i.e. cyanides, arsenic compounds, and lead acetate.

6.2 Infectious substances i.e. vaccines and pathology specimens.

7. Radioactive

8. Corrosives

9. Miscellaneous

Following the dangerous goods regulation

Shipping dangerous goods can pose a threat to human life when not done right. That being said, laws and regulations need to be in place to warrant the proper handling, packaging, and shipping of dangerous goods. There are specific regulations set for the shipper and/or the carrier of dangerous goods. However, these restrictions, regulations, and processes can vary from country to country.

Transporting dangerous goods by sea is internationally regulated by the International Maritime Dangerous Goods Code or IMDG Code. The code also ensures protection of the ship carrier’s crew at the same time. In addition, they also put guidelines in place so dangerous goods are transported safely from one destination to another.

On the other hand, air freight is governed internationally by the International Air Transport Association (IATA) International Dangerous Goods Regulations. They are the main source of information or help for those who want to process documents for the shipment of dangerous goods.

Moreover, they are also recognised by many of the world’s best airlines for 60 years now (and counting). They are also known to be the comprehensive, most recent, and user-friendly reference in the DG shipping industry.

Ensure proper and suitable packaging

With proper packaging comes suitable packaging as well. Proper packaging is vital for any type of cargo, much more when handling and shipping dangerous goods as they pose a threat to human health and safety. You must ensure that you use appropriate packing materials for a specific type of dangerous goods.

However, this is not a one-rule-fits-all type of situation. Some of the hazardous goods may be affected by a change in temperature, friction, or pressure when not packaged right. If anything, packaging can be the source of serious and extreme situations when not done accordingly.

Train and Educate Workers

Last but definitely not the least, it is crucial that those responsible for the packing and shipping of dangerous goods are properly aware of the dangers and guidelines that have been set.

Since they will be involved firsthand in the chain of shipment, they should know what to do in case something untoward happens. This is key so they can readily protect themselves and others when the need calls for it.

This applies to everyone in the shipment chain such as cargo handlers, packers, equipment operators, documentary staff, truckers, hazardous goods approvers, and more.

0 notes

Text

How to Choose the Best Shipping Option (Sea, Air or Road) for Different Types of Dangerous Goods and Destinations

Shipping dangerous goods is a challenging task that requires careful planning and execution. Dangerous goods are articles or substances that can pose a hazard to health, safety, property or the environment, such as explosives, flammable liquids, corrosives, radioactive materials, etc1

Depending on the type, class and quantity of dangerous goods that you need to ship, and the destination that you need to ship them to, you may have different shipping options available. These options include sea, air and road transportation, each with its own advantages and disadvantages.

In this article, we will help you understand how to choose the best shipping option for your dangerous goods shipments by considering the following factors:

The regulations and requirements for shipping dangerous goods

The characteristics and classification of your dangerous goods

The cost and time of each shipping option

The availability and accessibility of each shipping option

The risks and challenges of each shipping option

The Regulations and Requirements for Shipping Dangerous Goods

One of the most important factors to consider when choosing a shipping option for dangerous goods is the regulations and requirements that apply to your shipment. Shipping dangerous goods is subject to strict international and national standards and regulations that aim to ensure the safety and security of people, property and the environment.

Some of the main regulations and requirements that you need to be aware of are:

The International Air Transport Association (IATA) Dangerous Goods Regulations (DGR) for air transportation

The International Maritime Dangerous Goods (IMDG) Code for sea transportation

The Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR) for road transportation

The U.S. Department of Transportation (DOT) Hazardous Materials Regulations (HMR) for domestic transportation in the U.S.

The regulations and requirements of the countries or territories of origin, transit and destination of your shipment

These regulations and requirements specify how to identify, classify, pack, mark, label, document and handle dangerous goods shipments according to their type and class. They also specify which dangerous goods are prohibited or restricted for each mode of transportation, and which ones require special permits or approvals.

As a shipper of dangerous goods, you are responsible for complying with all the applicable regulations and requirements for your shipment. You should consult with the manufacturer or supplier of your dangerous goods for a Safety Data Sheet (SDS) that contains information about their classification and characteristics. You should also consult with a reliable and experienced freight forwarder that can help you prepare your shipment according to the standards and regulations.

The Characteristics and Classification of Your Dangerous Goods

Another factor to consider when choosing a shipping option for dangerous goods is the characteristics and classification of your dangerous goods. Depending on their physical state, properties, and potential hazards, dangerous goods are classified into nine classes by the UN system: Class Description Examples 1. Explosives Fireworks flares 2. Gases Aerosols, camping gas3Flammable liquids Solvents, paints4Flammable solids; substances liable to spontaneous combustion; substances which emit flammable gases when in contact with water Matches, phosphorus 5. Oxidizing substances; organic peroxides Fertilizers, fiberglass repair kits 6. Toxic substances; infectious substances Pesticides, blood tests 7. Radioactive material Smoke detectors 8. Corrosives Bleach, drain cleaner 9. Miscellaneous dangerous goods Airbags, magnets

Some classes are further divided into divisions or sub-divisions based on their degree of hazard. For example, class 1 explosives are divided into six divisions based on their compatibility group.

The classification of your dangerous goods determines which shipping options are available or suitable for your shipment. For example:

Some classes or divisions of dangerous goods are prohibited or restricted for air transportation due to their high risk of explosion or fire. These include class 1 explosives (except division 1.4S), class 2.3 toxic gases, class 4.2 substances liable to spontaneous combustion, class 5.2 organic peroxides (except type E), class 6.2 infectious substances (except category B), class 7 radioactive material (except low specific activity material), etc2

Some classes or divisions of dangerous goods are prohibited or restricted for sea transportation due to their high risk of pollution or corrosion. These include class 1 explosives (except division 1.4S), class 6.1 toxic substances (except packing group III), class 6.2 infectious substances (except category B), class 7 radioactive material (except low specific activity material), etc3