#IOT data logger

Explore tagged Tumblr posts

Text

Enhancing Industrial Safety and Control Systems with Fire Annunciators and Signal Converters

In the fast-paced world of industrial automation, reliability and safety are non-negotiable. As facilities strive to optimize their operations, devices like alarm annunciators and signal isolators play a pivotal role in ensuring process control, monitoring, and protection. These components serve as silent guardians, safeguarding both equipment and personnel from unexpected events and structural failures.

What is a Fire Annunciator?

An Alarm Annunciator is an essential device used in industrial control systems to monitor various process parameters and alert operators in case of abnormal conditions. It provides a visual and audible indication when any of the monitored signals go beyond the pre-set limits. Whether in a power plant, chemical factory, or manufacturing line, annunciators help reduce downtime by ensuring that faults are quickly recognized and resolved.

Key benefits of using fear annunciators:

Real-time alerts to prevent accidents or equipment harm

Customizable logic to match complex plant functioning

Multi-tip monitoring, improving overall situational awareness

Compliance with welfare and regulatory standards

Modern annunciators are equipped with LED displays, integrated communication agreements, and even remote notification capabilities, making them indispensable in smart facilities.

Comprehension Signal Isolators

A Signal Isolator is a device that electrically isolates the input signal from the output, preventing ground loops and minimizing noise in signal transmission. Signal isolators are vital for ensuring accurate quantification and data logging, especially in sensitive environments where multiple control systems are interconnected.

Why signal isolators material:

Prevents ground loop matters, which can lead to inaccurate readings

Protects control structures from voltage spikes and surges

Improves signal quality over long transmission intervals

Enables safe interfacing between incompatible structures

Signal isolators are widely used in automation systems, PLC/DCS integration, and data acquisition units. They are designed to work with a diversity of input types, including thermocouple and RTD signals.

When used together, alarm annunciators and signal isolators offer a robust solution for monitoring and control. While annunciators ensure prompt operator response to faults, isolators maintain signal fidelity and protect equipment from electrical disturbances. Their integration enhances operational transparency and system reliability across diverse industries like oil & gas, energy, pharmaceuticals, and aqua treatment.

Last Thoughts

As industries move toward greater automation and digitalization, foundational elements like alarm annunciators and signal isolators remain vital for operational safety and efficiency. Investing in quality devices ensures uninterrupted monitoring, accurate control, and long-term system integrity. Whether upgrading legacy structures or building new infrastructure, these tools form the backbone of any effective industrial control solution.

#Alarm Annunciator#Modbus Display#Flameproof Indicator#Flow Indicator Totalizer#Jumbo Display#Temperature Controller#Loop Powered Indicator#IOT data logger#IOT Energy Monitoring#Open Channel Flowmeter#Temperature Transmitter#Signal Isolator

0 notes

Text

Data logging technologies have evolved to match the ever-growing demand for precision, efficiency, and real-time access. Whether it’s the connectivity of an IoT data logger, the reliability of a digital data logger, or the power and complexity of DAQ data acquisition systems, these tools empower industries to make smarter, faster, and more informed decisions. As technology continues to advance, the future of data logging promises even greater integration, automation, and intelligence.

0 notes

Text

In the world of Industrial IoT (IIoT), the ability to efficiently monitor, store, and analyze large volumes of time-stamped data is essential. From environmental sensors in smart factories to energy meters in power systems, time-series data forms the backbone of real-time insight and historical analysis.

InfluxDB, an open-source time-series database, is designed specifically for these use cases. Combined with the industrial-grade ARMxy Edge Gateway, it creates a robust edge solution for reliable data acquisition, storage, and visualization—all without depending on cloud availability.

🧠 Why InfluxDB on ARMxy?

InfluxDB is lightweight, high-performance, and optimized for time-series workloads. It supports powerful query languages, retention policies, and integrations with monitoring tools such as Grafana. When deployed directly on an ARMxy (RK3568J/RK3568B2) gateway, it becomes a local data engine with key advantages:

Minimal latency: Store and query data at the edge

Offline reliability: Operate without cloud or internet connection

Flexible integration: Compatible with Modbus, OPC UA, MQTT, and more

🏭 Real-World Use Case Example

Imagine a factory floor with multiple PLCs controlling machinery. Each PLC sends temperature, vibration, and power consumption data every few seconds. Instead of sending that data to a remote server, it can be ingested directly into InfluxDB running on the ARMxy device.

You can then use:

Telegraf for parsing and collecting metrics

Grafana for local visualization dashboards

Node-RED to add logic and alarms

The result? A self-contained edge monitoring system capable of showing trends, detecting anomalies, and buffering data even during connectivity drops.

🔗 Integration Workflow Overview

Install InfluxDB on ARMxy via Docker or native ARM64 package

Connect data sources: Modbus devices, MQTT brokers, etc.

Configure retention policies to manage local storage

Use Grafana (also installable on ARMxy) to build dashboards

(Optional) Forward selected metrics to cloud or central server for backup

✅ Benefits of Edge Time-Series Monitoring

Faster Insights: No need to wait for data to hit the cloud

Bandwidth Optimization: Only send essential data upstream

Improved System Resilience: Data remains accessible during downtime

Security & Compliance: Sensitive data can stay on-premises

🔚 Conclusion

Deploying InfluxDB on ARMxy Edge Gateways transforms traditional data loggers into intelligent local data hubs. With flexible integration options, support for real-time applications, and a compact industrial design, ARMxy with InfluxDB is a perfect fit for smart manufacturing, energy monitoring, and any IIoT scenario that demands fast, local decision-making.

Let the data stay close—and smart.

0 notes

Text

Enhancing Efficiency: Key Components in Industrial Automation

In today's dynamic industrial landscape, automation serves as the bedrock for efficiency, safety, and sustainable progress. At Dropship Automation, we specialize in delivering premier automation components crucial for optimizing operations across diverse industries. In this blog, we delve into three essential components vital for any automation setup: pressure gauges, recorders, and electronic components. Whether you're upgrading existing systems or initiating new installations, understanding these components is essential for achieving peak operational performance.

1. Pressure Gauges: Precision Monitoring for Operational Control

What are Pressure Gauges in Automation? Pressure gauges are instruments designed to measure and display pressure levels within industrial processes. They provide critical data for monitoring and controlling operational parameters.

Key Types and Applications:

Types: Mechanical gauges, digital gauges

Applications: Hydraulic systems, pneumatic machinery, gas pipelines

Benefits: Accurate pressure measurement, real-time monitoring, system diagnostics

Why Pressure Gauges Matter: Accurate pressure monitoring is crucial for maintaining operational efficiency and safety in industrial environments. Pressure gauges enable proactive maintenance, prevent equipment failures, and optimize process control, contributing to overall system reliability and performance.

2. Recorders: Essential Tools for Data Acquisition

What are Recorders in Automation? Recorders are devices used to capture and store data from various sensors and instruments within automation systems. They facilitate detailed analysis and decision-making processes.

Key Features and Importance:

Types: Data loggers, chart recorders

Functions: Continuous data acquisition, historical trend analysis

Applications: Environmental monitoring, quality control, process optimization

Why Recorders Matter: Recorders play a pivotal role in gathering and analyzing operational data, enabling informed decisions and predictive maintenance. They enhance operational visibility and efficiency by providing comprehensive insights into system performance over time.

3. Electronic Components: Building Blocks of Automation Systems

What are Electronic Components in Automation? Electronic components are fundamental units that form the backbone of automation systems, enabling seamless integration and functionality.

Key Components and Applications:

Types: Sensors, actuators, relays

Functions: Signal processing, control logic, interface connectivity

Applications: Control panels, robotic systems, industrial IoT

Why Electronic Components Matter: Electronic components facilitate precise control and communication within automation setups. They enable efficient signal processing, automation logic implementation, and interface connectivity, thereby optimizing system performance and reliability.

How These Components Collaborate for Seamless Automation

Imagine an industrial scenario:

Pressure gauges ensure optimal operational conditions by monitoring critical parameters.

Recorders capture data from sensors, enabling detailed analysis and proactive maintenance.

Electronic components integrate seamlessly to control processes and enhance system efficiency.

Conclusion

Automation revolutionizes industrial processes by boosting efficiency, ensuring safety, and fostering sustainable growth. By integrating essential components like pressure gauges, recorders, and electronic units, industries can achieve heightened productivity, minimized downtime, and elevated safety standards.

At Dropship Automation, we are committed to delivering cutting-edge automation solutions tailored to your specific needs. Explore our extensive range of automation parts or contact us for personalized consultation and support on your automation journey.

0 notes

Text

Temperature Data Logger Market: Growth Driven by Cold Chain Expansion and Regulatory Compliance Demands

The temperature data logger market has witnessed significant growth in recent years, driven by a confluence of technological advancements, increasing regulatory standards, and rising demand across diverse industry verticals. A temperature data logger is a compact, self-contained device used to record temperature readings over time, which can then be analyzed for a variety of applications. These tools are crucial in ensuring product quality, maintaining regulatory compliance, and optimizing supply chain operations.

1. Growing Demand for Cold Chain Monitoring

One of the primary drivers of the temperature data logger market is the expanding global cold chain logistics sector. Industries such as pharmaceuticals, food and beverages, and chemicals require precise temperature control during storage and transportation to ensure product efficacy and safety. Vaccines, in particular, need to be maintained within strict temperature thresholds. The COVID-19 pandemic further amplified this demand as global vaccine distribution relied heavily on robust cold chain systems, accelerating the adoption of temperature monitoring solutions like data loggers.

2. Regulatory Compliance and Quality Assurance

Governments and industry regulatory bodies worldwide have established stringent guidelines for temperature-sensitive goods. Compliance with standards such as Good Distribution Practice (GDP), Good Manufacturing Practice (GMP), and the U.S. FDA’s 21 CFR Part 11 necessitates the use of temperature data logging equipment. These regulations ensure that proper storage conditions are met and that any temperature excursions are documented and analyzed. The growing pressure to meet these regulatory requirements is a strong driver for market growth.

3. Advancements in IoT and Wireless Technology

The integration of Internet of Things (IoT) and wireless technologies has revolutionized the temperature data logger landscape. Modern loggers now feature real-time monitoring, wireless data transmission, cloud storage, and mobile app integration. These innovations provide greater visibility and control over environmental conditions, enabling proactive responses to potential issues. The convenience and efficiency offered by connected devices have attracted a broader range of users, further propelling market expansion.

4. Increasing Use in Healthcare and Pharmaceuticals

The healthcare and pharmaceutical industries are among the largest users of temperature data loggers. These devices are used in hospitals, laboratories, and during the transportation of temperature-sensitive drugs and biological samples. The global rise in personalized medicine, biotechnology products, and biologics—many of which require strict temperature control—has contributed to increased demand. As the pharmaceutical industry continues to grow and innovate, so too does the need for reliable monitoring tools.

5. Rising Adoption in the Food and Beverage Sector

Ensuring food safety and maintaining product quality from farm to fork is critical in the food and beverage industry. Temperature data loggers are used extensively during food processing, packaging, storage, and distribution to ensure perishable goods remain within required temperature ranges. Consumer awareness and regulatory scrutiny regarding food safety have also heightened demand for temperature monitoring solutions, especially as global trade of perishable goods increases.

6. Cost Reduction and Product Innovation

Technological developments have enabled manufacturers to produce more cost-effective and compact temperature data loggers without compromising on features. Today’s models offer improved battery life, enhanced accuracy, increased memory capacity, and user-friendly interfaces. This has made them accessible to a wider range of businesses, including small and medium enterprises. The competitive landscape has also led to product differentiation, with some companies offering specialized loggers for unique applications, such as ultra-low temperature logging for cryogenic environments.

7. Environmental Monitoring and Sustainability Goals

Temperature data loggers are also gaining traction in environmental monitoring, agriculture, and climate research. As climate change continues to impact weather patterns and ecological systems, there is a growing need for accurate and long-term temperature data. Additionally, companies focused on sustainability are using these devices to monitor energy efficiency in facilities, ensuring HVAC systems are optimized and reducing overall carbon footprints.

8. Expansion of E-commerce and Global Trade

The global e-commerce boom has driven a need for enhanced logistics and delivery infrastructure. Temperature-sensitive products, including gourmet foods, cosmetics, and pharmaceuticals, are increasingly sold online and shipped across long distances. Data loggers play a crucial role in preserving product integrity during last-mile delivery. As cross-border e-commerce continues to expand, especially in emerging markets, so does the need for reliable temperature monitoring.

Conclusion

The temperature data logger market is poised for robust growth, fueled by the convergence of technological innovation, regulatory demands, and the need for precision in modern logistics. As industries become more reliant on data-driven decision-making and real-time monitoring, temperature data loggers are no longer a luxury but a necessity. Whether for ensuring the safety of a life-saving drug or maintaining the freshness of perishable goods, these devices are playing a pivotal role in modern supply chain and quality assurance systems. Continued investment in R&D and evolving customer needs are expected to further drive market innovation and adoption in the years to come.

0 notes

Text

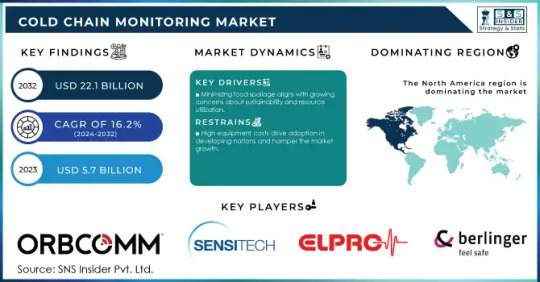

Cold Chain Monitoring Market Analysis: Key Players and Competitive Landscape

Rising Demand for Temperature-Sensitive Logistics Drives Growth in the Cold Chain Monitoring Market.

The Cold Chain Monitoring Market Size was USD 5.7 Billion in 2023 and is expected to reach USD 22.1 Billion by 2032 and grow at a CAGR of 16.2% over the forecast period of 2024-2032.

The Cold Chain Monitoring Market is driven by the increasing need for temperature-sensitive logistics solutions across industries such as pharmaceuticals, food & beverages, and chemicals. Cold chain monitoring systems ensure that perishable goods and temperature-sensitive products maintain their required storage conditions throughout the supply chain. The rising demand for biopharmaceuticals, vaccines, and fresh food products, coupled with stringent regulations on storage and transportation, is fueling the adoption of advanced cold chain monitoring solutions.

Key Players

ORBCOMM (US) – (IoT-based cold chain monitoring solutions, Fleet Management Systems)

Sensitech (US) – (TempTale Data Loggers, Cold Chain Monitoring Software)

Elpro-buchs (Switzerland) – (ELPRO Monitoring Solutions, e-Transcript System)

Berlinger & Co. (Switzerland) – (ThermoTrack Temperature Monitoring, ActiveSense Monitoring System)

Monnit (US) – (Monnit Wireless Sensors, Monnit Cloud Platform)

Controlant (Iceland) – (Controlant Smart Cold Chain, Real-time Monitoring Solutions)

Lineage Logistics Holding – (Cold Storage Solutions, Lineage Link Digital Platform)

Tagbox – (Cold Chain IoT Sensors, Tagbox Data Analytics Platform)

DAIKIN Industries – (Refrigeration Solutions, Remote Monitoring Systems)

Savi Technology – (SaviTrack RFID Solutions, SaviSense Sensor Platform)

Future Scope

The Cold Chain Monitoring Market is set for substantial expansion as supply chain digitization, IoT-based tracking systems, and AI-driven predictive analytics enhance real-time monitoring capabilities. Government regulations and quality control mandates for pharmaceutical and food safety are pushing businesses to integrate automated and cloud-based monitoring systems. Innovations in blockchain technology for supply chain transparency and the integration of smart sensors with predictive maintenance capabilities are expected to revolutionize cold chain management, reducing spoilage and ensuring compliance.

Emerging Trends

The industry is shifting toward real-time and AI-powered cold chain monitoring solutions, ensuring greater accuracy and efficiency in tracking temperature-sensitive shipments. The demand for wireless and cloud-based monitoring systems is rising, offering 24/7 remote access to temperature data and ensuring compliance with regulatory standards. Additionally, blockchain technology is being explored to enhance supply chain transparency and prevent counterfeiting in pharmaceuticals. The rise of automated alert systems, GPS tracking, and energy-efficient refrigeration technologies is also contributing to market growth.

Key Points

Rising demand for temperature-sensitive logistics in pharmaceuticals and food industries.

Increased adoption of IoT, AI, and blockchain for real-time supply chain monitoring.

Stringent regulatory requirements driving investments in advanced cold chain technologies.

Growing use of cloud-based and wireless temperature monitoring systems.

Expansion of automated alert systems and GPS tracking for improved shipment security.

Conclusion

The Cold Chain Monitoring Market is poised for significant growth, fueled by technological advancements, regulatory compliance requirements, and increasing demand for perishable goods logistics. As smart monitoring solutions, blockchain integration, and predictive analytics continue to evolve, the industry is set to enhance supply chain efficiency, reduce product wastage, and ensure the safe delivery of temperature-sensitive goods worldwide.

Read Full Report: https://www.snsinsider.com/reports/cold-chain-monitoring-market-1974

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Cold Chain Monitoring Market#Cold Chain Monitoring Market Size#Cold Chain Monitoring Market Share#Cold Chain Monitoring Market Report#Cold Chain Monitoring Market Forecast

0 notes

Text

(2025-03-23 image ©ofcom) Currently EE, Vodafone and Three have switched off their 3G networks, (with the odd pocket of 3G left) and currently O2 is doing the same. One surprise is that some of the press are highlighting the O2 switch off as a problem but as the switch off from the other networks did not cause major issues, I am not sure why they are focussing on O2 causing problems. Unless there is something special about the O2 3G network that I am not aware of.

But also EE and O2 have begun investigations about switching off 2G. When they do, there is no fall back for 2G Phones nor 3G phones that are now using 2G. Anyone with such a phone will have to upgrade to a basic 4G phone, which are not expensive, Tesco sell the Nokia 110 4G phone for £30. The 2G switch off in 5 years will be a lesser issue than the 3G switch. It will affect a few people but the solution is not significant.

BUT, the 2G switch off will affect many many devices and services. Currently there are many devices that use 2G to send data to a cloud data store be that trackers, health monitors, data loggers, traffic management, etc. An obvious solution would be to switch to 4G. They use 2G because they do not need the complexity of 4G. A switch to 4G would involve the wholesale swapping of devices which would be expensive. It is this area that EE / O2 are currently looking into. The providers of some of these 2G devices have known about the switch off for 5+ years and have not done anything about a swap, now the deadline is looming and they do need to move at a significant cost. A less obvious solution, which is cheaper, is to move to NB_IoT or LTE-M protocols designed for IoT devices. I suspect that this would need a bigger re-write of the software and again a large expense.

0 notes

Text

USB Temperature Data Logger Market Future Trends: Growth, Innovation, and Emerging Industry Opportunities Worldwide

The USB temperature data logger market is undergoing significant transformation due to technological advancements, increasing demand for real-time monitoring, and regulatory requirements across various industries. These devices play a crucial role in maintaining temperature-sensitive products such as pharmaceuticals, food, and chemicals. With the rising adoption of IoT-enabled solutions and cloud connectivity, the market is set for substantial growth.

Market Growth Drivers1. Rising Demand in Pharmaceutical and Healthcare IndustryThe pharmaceutical and healthcare sectors heavily rely on USB temperature data loggers for maintaining the integrity of vaccines, drugs, and other temperature-sensitive products. The global COVID-19 pandemic has further accelerated the adoption of advanced monitoring devices to ensure proper storage conditions.

Stringent Government RegulationsGovernments and regulatory bodies worldwide have imposed strict guidelines on temperature monitoring to ensure product safety and quality. Compliance with Good Distribution Practice (GDP) and Food Safety Modernization Act (FSMA) is boosting the demand for accurate and reliable data logging solutions.

Advancements in IoT and Cloud IntegrationModern USB temperature data loggers are now integrated with IoT and cloud-based platforms, allowing real-time data monitoring, automatic alerts, and remote access. These technological enhancements improve efficiency and reduce the risk of data loss. Emerging Market Trends1. Wireless and Bluetooth-Enabled Data LoggersThe integration of wireless connectivity features, including Bluetooth and Wi-Fi, is becoming a dominant trend. These loggers enable seamless data transfer and remote monitoring, reducing manual intervention and enhancing operational efficiency.

Increased Adoption in Cold Chain LogisticsCold chain logistics require precise temperature monitoring for the transportation and storage of perishable goods. The expansion of global supply chains, especially in the food and pharmaceutical industries, is driving the demand for USB temperature data loggers with real-time tracking capabilities.

AI and Machine Learning for Predictive AnalyticsArtificial intelligence (AI) and machine learning (ML) are being integrated into data loggers to provide predictive analytics. These smart devices can analyze historical data, predict temperature deviations, and suggest corrective actions, thereby improving decision-making. Challenges in the MarketDespite strong growth potential, the USB temperature data logger market faces several challenges: High Initial Costs: Advanced models with IoT and AI features come at a premium price. Data Security Concerns: Cloud-based systems require robust cybersecurity measures to prevent unauthorized access. Limited Awareness in Developing Markets: Many businesses in emerging economies are still unaware of the benefits of real-time data logging. Future Outlook and OpportunitiesThe future of the USB temperature data logger market looks promising with continued advancements in technology. The introduction of disposable loggers, multi-use devices, and longer battery life solutions will further enhance market penetration. Companies are focusing on providing more user-friendly and cost-effective solutions to attract a wider customer base. Moreover, as the demand for automation and precision increases, businesses will increasingly adopt data loggers with real-time alerts and cloud connectivity. This shift will further streamline operations and ensure compliance with stringent industry standards. Conclusion The USB temperature data logger market is poised for significant growth, driven by innovations in IoT, AI, and cloud computing. As industries emphasize better compliance, efficiency, and real-time monitoring, the demand for these devices will continue to rise. Companies investing in smarter, more connected, and cost-effective solutions will emerge as leaders in the evolving landscape of temperature monitoring technology.

0 notes

Text

VEGA IoT WTH50 Realtime Temperature And Humidity Data Logger (WIFI) Brand : VEGA Model : WTH50 Temperature Range :°C to +50C Temperature Accuracy :± 0.5C Resolution : 0.1 Humidity Range : 0 to 100% Humidity Accuracy : ± 3% Warranty : 1 Year Buy : https://vegabazaar.com/product/buy-vega-iot-wth50-realtime-temperature-humidity-data-logger-wifi/

0 notes

Text

Temperature Data Logger Market Insights Technological Advancements Driving Market Growth

The temperature data logger market is witnessing rapid growth due to increased demand for real-time temperature monitoring and enhanced product safety across various industries. These devices play a critical role in ensuring the integrity of temperature-sensitive products, especially in pharmaceuticals, food and beverages, and logistics. As technological advancements continue to shape this sector, the market is evolving to meet the increasing need for precision, efficiency, and regulatory compliance. The global temperature data logger market is expected to expand significantly, driven by advancements in sensor technology, the rise of the Internet of Things (IoT), and the increasing need for traceability in supply chains.

Temperature data loggers are devices that continuously measure and record temperature over time. These devices are used to monitor products in transit or storage, ensuring that they remain within optimal temperature ranges. This technology is vital for maintaining the safety and quality of temperature-sensitive goods, such as pharmaceuticals, vaccines, food, and beverages.

Temperature Data Logger Market Insights: Technological Advancements and Innovations

Technological innovation is a key driver of growth in the temperature data logger market. Recent advancements in sensor technology, connectivity, and cloud computing have enhanced the capabilities of temperature data loggers. Modern loggers feature more accurate sensors, longer battery life, and wireless communication, enabling real-time monitoring and alert systems. These innovations make it easier for industries to ensure compliance with temperature-sensitive product regulations and streamline operations.

Temperature Data Logger Market Insights: The Role of IoT in Temperature Monitoring

The integration of the Internet of Things (IoT) into temperature data loggers is transforming the market. IoT-enabled devices allow for remote temperature monitoring, enabling businesses to access data from anywhere in real time. With cloud-based platforms, companies can track temperature fluctuations, receive alerts, and generate detailed reports, improving operational efficiency and reducing the risk of product spoilage. This shift toward IoT-enabled solutions is expected to drive the market's expansion, particularly in industries requiring constant temperature monitoring, such as pharmaceuticals and food.

Temperature Data Logger Market Insights: Key Industries Driving Growth

Several industries are fueling the demand for temperature data loggers. The pharmaceutical sector is one of the biggest contributors, as it requires strict temperature control for the storage and transportation of drugs, particularly biologics and vaccines. The food and beverage industry also drives growth, as temperature monitoring is crucial to ensure food safety and prevent spoilage. Additionally, the logistics and transportation sectors require temperature data loggers to monitor shipments, especially for perishable goods. The increasing focus on cold chain logistics is expected to further propel the market.

Temperature Data Logger Market Insights: Wireless Solutions Gaining Popularity

Wireless temperature data loggers are becoming increasingly popular due to their ease of use and ability to connect to cloud platforms. Unlike traditional wired systems, wireless loggers do not require physical connections, making them more flexible and scalable. These devices can be deployed across large storage facilities or transportation networks, enabling companies to monitor temperatures remotely and receive instant alerts when temperature thresholds are exceeded. As wireless solutions continue to evolve, they are expected to play a pivotal role in the growth of the market.

Temperature Data Logger Market Insights: Expanding Adoption in Emerging Markets

As industries in emerging economies continue to grow, the adoption of temperature data loggers is expanding. Countries in regions like Asia-Pacific, Latin America, and the Middle East are witnessing increased demand for temperature monitoring solutions, driven by growing pharmaceutical, food, and logistics sectors. Emerging markets are experiencing significant investments in cold chain logistics, healthcare infrastructure, and regulatory compliance, further fueling the adoption of temperature data loggers. This trend is expected to create new opportunities for market players in these regions.

Temperature Data Logger Market Insights: Regulatory Compliance and Industry Standards

Regulatory compliance plays a crucial role in driving the temperature data logger market. In industries like pharmaceuticals and food, stringent regulations require companies to ensure that products are stored and transported under the correct temperature conditions. Non-compliance can lead to product spoilage, safety risks, and legal consequences. As regulations continue to tighten globally, temperature data loggers are becoming essential tools for ensuring compliance and meeting industry standards. This focus on regulatory compliance will continue to influence market growth.

Temperature Data Logger Market Insights: Challenges and Barriers to Adoption

Despite the promising growth of the temperature data logger market, several challenges remain. High initial costs, particularly for advanced temperature monitoring systems, may deter small and medium-sized enterprises (SMEs) from adopting these solutions. Additionally, limited access to reliable internet connectivity in remote areas may hinder the use of IoT-enabled devices in some regions. Companies will need to address these barriers to adoption in order to unlock the full potential of the market.

Temperature Data Logger Market Insights: Advancements in Sensor Accuracy

Improved sensor accuracy is a key trend in the temperature data logger market. Modern temperature data loggers are equipped with high-precision sensors that provide real-time and accurate temperature measurements. This accuracy is particularly important in industries such as pharmaceuticals, where even small temperature fluctuations can compromise product quality. Advancements in sensor technology are expected to drive further innovation in the market, improving the reliability and performance of temperature monitoring systems.

Temperature Data Logger Market Insights: Future Outlook and Market Projections

The future of the temperature data logger market looks promising, with strong growth projected across various industries. As technology continues to improve, the demand for more sophisticated temperature monitoring solutions will rise. The adoption of IoT-enabled devices, wireless solutions, and cloud-based platforms will continue to shape the market, providing businesses with more efficient, cost-effective ways to ensure the safety and quality of their products. With increasing regulatory pressure and the need for enhanced supply chain visibility, the temperature data logger market is poised for continued expansion.

Conclusion

The temperature data logger market is evolving rapidly, driven by technological innovations, increasing demand for real-time temperature monitoring, and the need for regulatory compliance across various industries. As advancements in sensor technology, IoT integration, and wireless solutions continue to reshape the market, businesses in sectors such as pharmaceuticals, food, and logistics are increasingly adopting temperature data loggers to ensure product safety and quality. While challenges such as high costs and limited connectivity persist, the market's growth prospects remain strong, with significant opportunities for innovation and expansion in emerging markets.

#Temperature Data Logger Market#Temperature Data Logger Market trends#Temperature Data Logger#Temperature Data Logger measures#Temperature Data#Temperature

0 notes

Text

Loop-Powered Indicator is A Reliable Solution for Industrial Procedure Monitoring

A Loop-Powered Indicator is a highly efficient device widely used in industrial settings to provide real-time display and monitoring of process variables such as flow, temperature, pressure, and level. Unlike traditional, loop-powered indicators draw power directly from the current loop, eliminating the need for external power supplies. This makes them an ideal choice for hazardous or faraway locations where power availability is limited.

These indicators are valued for their simplicity, reliability, and low power consumption. They are commonly installed in control panels or directly in the field, offering easy readability and seamless integration with existing systems. Whether used in oil and gas, chemical processing, water treatment, or manufacturing industries, loop-powered indicators ensure precise and consistent performance, enhancing welfare and efficiency.

When selecting a Open Channel Flowmeter, look for features such as high visibility displays, robust construction, and compatibility with your specific application needs. These devices not only streamline operations but also contribute to maintaining optimal process controller, reducing downtime, and ensuring compliance with safety qualities.

Modern loop-powered indicators often come with advanced features such as digital displays, programmable scaling, and hazardous area certifications, making them suitable for a wide range of applications. They can handle extreme environmental conditions, including high humidity, temperature variations, and exposure to corrosive elements. Additionally, these indicators offer minimal wiring requirements, which simplifies installation and reduces maintenance costs. Whether integrated into a new system or retrofitted into an existing setup, loop-powered indicators provide a cost-effective and reliable solution for maintaining precise process controllers and enhancing operational organization.

Many loop-powered indicators also offer customizable display options, including digital readouts, bar graphs, and alarm indicators, allowing operators to monitor critical parameters at a glance. Their ability to function solely on the power provided by the loop not only ensures consistent performance but also enhances safety in hazardous environments by minimizing wiring complexity. These devices are especially useful in applications where process variables need to be monitored in real-time without relying on external power sources, making them a trusted choice for industries such as oil and gas, water, and chemical procedures.

In addition to their practical benefits, loop-powered indicators contribute to enhanced process transparency by providing immediate feedback on system performance. Many models are equipped with backlit displays and wide viewing angles, ensuring visibility even in low-light or challenging environments. These indicators are also designed to withstand harsh industrial conditions, offering robust protection against dust, moisture, and mechanical impacts. By delivering accurate and real-time data, loop-powered indicators empower operators to make informed decisions quickly, ultimately improving safety, productivity, and overall process organization.

#Alarm Annunciator#Modbus Display#Flameproof Indicator#Flow Indicator Totalizer#Jumbo Display#Temperature Controller#Loop Powered Indicator#IOT data logger#IOT Energy Monitoring#Open Channel Flowmeter#Temperature Transmitter#Signal Isolator

0 notes

Text

How Do IoT Data Loggers Enhance Data Collection?

In the age of digital transformation, collecting and analyzing data has become the backbone of efficient operations across industries. Whether monitoring temperature in a cold storage facility, analyzing vibrations in machinery, or measuring electrical signals in research labs, data loggers play a vital role in recording and preserving data. Among the most commonly used tools in this field are the IoT data logger, digital data logger, and DAQ data acquisition systems.

What is a Data Logger?

A data logger is an electronic instrument designed to record various types of data over time. It typically includes sensors, microcontrollers, memory storage, and software to collect and store information for later use. Data loggers are used in diverse applications—from environmental monitoring and industrial control to logistics and scientific research.

The key benefit of a data logger is its ability to operate autonomously once configured. Users can deploy these devices in remote or hard-to-reach locations where constant human supervision is impractical. They are engineered to log everything from temperature, humidity, and pressure to voltage, current, and vibration.

Understanding the IoT Data Logger

One of the most innovative developments in the world of data logging is the IoT data logger. These devices leverage the power of the Internet of Things to transmit real-time data to cloud-based platforms. Unlike traditional loggers that require manual data retrieval, IoT data loggers provide instant remote access to critical metrics.

This functionality is particularly useful in industries like agriculture, manufacturing, smart cities, and utilities. For example, a smart farm may use IoT data loggers to monitor soil moisture, temperature, and rainfall—enabling automated irrigation systems and real-time alerts. Similarly, in industrial plants, these loggers help monitor equipment conditions and detect anomalies before they lead to costly breakdowns.

IoT data loggers often come with wireless communication features like Wi-Fi, cellular (4G/5G), or LoRaWAN. They are integrated with GPS for location tracking and equipped with dashboards or mobile apps for easy data visualization.

Digital Data Logger: A Reliable Workhorse

A digital data logger is one of the most widely used types of data loggers. These compact devices are designed to measure and store data in digital form, ensuring high accuracy and ease of integration with computers and management systems. Unlike analog data recorders, digital data loggers minimize the chances of human error and offer improved precision.

They are commonly employed in industries where continuous monitoring is crucial—such as pharmaceuticals, food processing, and transportation. For example, in cold chain logistics, digital data loggers are used to monitor the temperature of perishable goods during transit. If the temperature deviates from the allowed range, the logger stores the event and alerts the operator.

Modern digital data loggers come with LCD screens, USB or Bluetooth connectivity, long battery life, and configurable sampling intervals. Their plug-and-play functionality makes them ideal for non-technical users who still require dependable data.

DAQ Data Acquisition Systems: For Complex Data Needs

While digital and IoT data loggers are great for general-purpose monitoring, DAQ data acquisition systems are used for more advanced and high-speed data recording applications. These systems consist of sensors, signal conditioning hardware, analog-to-digital converters, and specialized software that works in tandem to gather, process, and analyze large volumes of data in real time.

DAQ data acquisition systems are frequently used in laboratories, engineering research, aerospace, automotive testing, and energy sectors. For instance, during crash tests in the automotive industry, DAQ systems capture a wide range of sensor data—force, acceleration, pressure, and more—at extremely high speeds.

What sets DAQ systems apart is their ability to handle multiple input channels simultaneously and offer highly customizable configurations. They are typically connected to a PC or an industrial controller, allowing users to visualize and manipulate data through sophisticated software tools like LabVIEW or MATLAB.

Choosing the Right Tool

Choosing between an IoT data logger, digital data logger, and DAQ data acquisition system depends on your specific application needs:

IoT data logger: Best for remote, real-time monitoring where wireless communication is key.

Digital data logger: Ideal for routine environmental or process monitoring with accuracy and ease of use.

DAQ data acquisition: Suited for research and engineering environments where complex, high-speed, multi-signal data is required.

Conclusion

Data logging technologies have evolved to match the ever-growing demand for precision, efficiency, and real-time access. Whether it’s the connectivity of an IoT data logger, the reliability of a digital data logger, or the power and complexity of DAQ data acquisition systems, these tools empower industries to make smarter, faster, and more informed decisions. As technology continues to advance, the future of data logging promises even greater integration, automation, and intelligence.

0 notes

Text

Real-time Monitoring Solutions For Cold Chain Market Outlook, Competitive Strategies And Forecast

The global real-time monitoring solutions for cold chain market size was valued at USD 12,427.8 million in 2023 and is expected to grow at a CAGR of 23.1% from 2024 to 2030. The rising demand for global real-time monitoring solutions in the cold chain market is driven by the need for greater control and efficiency in temperature-sensitive supply chains, particularly in industries such as pharmaceuticals, food and beverages, and chemicals. With stricter regulations on product safety, companies are increasingly adopting these solutions to ensure compliance with international standards.

Additionally, the growing trend of online retail, particularly for groceries and pharmaceuticals, is amplifying the need for precise cold chain management. Companies delivering fresh food, dairy, frozen products, and medicines must guarantee that their goods remain within ideal temperature conditions from dispatch to doorstep. Real-time monitoring solutions allow companies to provide end-to-end visibility into cold chain logistics, helping mitigate the risks of spoilage, reducing waste, and enhancing customer satisfaction through reliable delivery of fresh goods.

The integration of IoT (Internet of Things) devices in cold chain logistics is further driving demand for real-time monitoring solutions. IoT sensors placed within storage units and transport vehicles can continuously track environmental conditions and transmit data in real-time to centralized monitoring platforms. This ensures uninterrupted monitoring and reporting, providing companies with the ability to act immediately if parameters deviate from safe levels. The advent of AI and machine learning is also helping companies predict potential risks in the cold chain, optimize routes, and manage fleet operations more efficiently.

Gather more insights about the market drivers, restrains and growth of the Real-time Monitoring Solutions For Cold Chain Market

Key Real-time Monitoring Solutions for Cold Chain Company Insights

Some of the key companies operating in the market include Carrier (Sensitech), among others.

• Carrier (Sensitech) is a prominent player in real-time monitoring solutions for cold chain logistics, specializing in temperature monitoring and data logging technologies. Sensitech is a subsidiary of Carrier Global Corporation, a leading global provider of heating, ventilation, air conditioning, refrigeration, and fire and security solutions. It offers a range of temperature monitoring solutions designed to ensure the integrity of temperature-sensitive products throughout the cold chain. Their products include data loggers, wireless monitoring systems, and integrated software platforms that provide real-time tracking and data management.

• Accent Advanced Systems, SLU is a technology company specializing in advanced solutions for real-time monitoring in various industries, including cold chain logistics. Their offerings include advanced monitoring systems that track temperature and humidity, utilizing Internet of Things (IoT) technology for seamless data collection and transmission. These solutions provide stakeholders with real-time access to critical environmental data and alerts, supported by analytics software that helps optimize logistics operations and ensure compliance with regulatory standards.

Recent Developments

• In August 2024, Carrier (Sensitech) announced that it had completed the acquisition of Berlinger & Co. AG, a provider of temperature monitoring solutions for the cold chain logistics industry. This strategic acquisition aims to enhance Sensitech's product offerings and strengthen its position in the pharmaceutical and food sectors. This move aligns with Sensitech's commitment to delivering comprehensive solutions that meet the evolving demands of customers in global supply chains.

• In June 2024, ELPRO-BUCHS AG and Cold Chain Technologies announced a partnership to enhance cold chain monitoring solutions. This collaboration aims to integrate ELPRO's advanced temperature monitoring technology with Cold Chain Technologies' logistics expertise. Together, they will provide comprehensive solutions for temperature-sensitive products, ensuring compliance with regulatory standards and maintaining product integrity throughout the supply chain.

Global Real-time Monitoring Solutions For Cold Chain Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global real-time monitoring solutions for cold chain market report based on component, application, and region:

Component Outlook (Revenue, USD Million, 2017 - 2030)

• Hardware

o Sensors

o RFID Devices

o Telematics

o Networking Devices

o Others

• Software

o On-premise

o Cloud

Application Outlook (Revenue, USD Million, 2017 - 2030)

o Food & Beverages

o Pharmaceuticals

o Others

Regional Outlook (Revenue, USD Million, 2017 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

• Latin America

o Brazil

• Middle East and Africa (MEA)

o KSA

o UAE

o South Africa

Order a free sample PDF of the Real-time Monitoring Solutions For Cold Chain Market Intelligence Study, published by Grand View Research.

#Real-time Monitoring Solutions For Cold Chain Market#Real-time Monitoring Solutions For Cold Chain Market Size#Real-time Monitoring Solutions For Cold Chain Market Share#Real-time Monitoring Solutions For Cold Chain Market Analysis#Real-time Monitoring Solutions For Cold Chain Market Growth

0 notes

Text

Solar SCADA

Suryalog Solar SCADA is a reliable and sustainable IoT bases system for solar power plants. It has ground mount products like SCADA and RTU loggers, WMS, PPC, and ground mount Accessories. Suryalog Solar SCADA is leading with cutting-edge technologies in Ground mount solar power plants. Suryalog has a highly solar-experienced team in Hardware, Software, and Service. Solar SCADA has functionalities for monitoring, management, and maintenance activity. Solar SCADA is working with all types of input, and output ports to collect data from various types of devices in solar. Suryalog SCADA is compatible with All types of communication systems it works with wired as well as wireless solutions over a long distance.

0 notes

Text

Connected Logistics Market Poised for Significant Growth, Projected to Reach $73.4 Billion by 2033

The linked Connected logistics industry is expected to reach a valuation of $24.6 billion in 2023 and $73.4 billion in 2033. Over the projected period, connected logistics sales are expected to grow at an 11.5% CAGR.

IoT-enabled linked logistics solutions are expected to replace conventional transportation techniques, according to the connected logistics industry trend.Rising fuel prices and related environmental problems like pollution and carbon emissions shape the market trend.

The use of sensors, cloud computing, and automated procedures is common for the remote monitoring and management of supply chain operations. It also provides thorough comprehension of network issues, enabling quick and efficient decision-making.

Improved supply chain visibility leads to long-term cost savings, necessitating the use of IoT-enabled solutions in a variety of industries, including manufacturing, transportation, and automotive.

It is expected that the target market will benefit from the increased adoption of Logistics 4.0 and ongoing work on improving autonomous logistics trucks.

One of the factors fueling the market growth is the decreasing cost of loT sensors and connected logistics hardware. However, rising security and safety concerns in the logistics sector limit the market’s growth to some extent.

Key Takeaways:

Asset tracking is the top priority for the players which is leading the devices segment towards a strong growth of 12.5%. Organizations can collect massive amounts of data during the shipping and transit processes by incorporating RFID chips and IoT devices.

In terms of mode of transportation, roadways hold the majority of the market share and is showing a substantial growth of 12.2%. This is due to the increasing demand for road-based transportation to transport retail goods over long distances.

The usage of cutting-edge technologies like machine learning, the Internet of Things, cloud computing, big data, analytics, and deep learning is leading United States towards a revenue share of US$ 16.5 billion by 2033.

Rising public and private investment in the transportation sector is enhancing market expansion in the area is driving the United Kingdom regional market towards an impressive growth of 12.5%

Japan is the most lucrative region of all growing at an impressive rate of 15.7%. Japan began transforming logistics in order to strengthen its position in the Asia Pacific logistics industry by integrating new technologies with existing processes.

Manufacturers Eying Opportunities through Aggressive Strategies

The competitive landscape of this market is split moderately because of the presence of several developing and established companies in the industry. Moreover, it is forecasted that the technological developments in logistic sectors is anticipated to quicken the product development as well as investment growth.

In the market, there are different competitors aiming at addressing the problems aggressively by framing plans which are going to leave an overall impact on the market development. The growth prospects of this market have a lot of room to flourish during the forecast period.

Recent Development:

A top cloud-based logistics execution platform, BluJay Solutions was acquired by E2open Parent Holdings, Inc. for almost US$ 1.7 billion in May 2020. It is a foremost network-based provider of mission-critical, 100% cloud-based, and end-to-end supply chain management platforms.

Key Players:

AT&T Inc., IBM Corporation, Intel Corporation, SAP SE, Infosys Limited, Cisco Systems Inc., HCL Technologies Limited, Eurotech S.P.A., Microsoft, Oracle, Cloud Logistics, Zebra technologies, ORBCOMM, and GT Nexus.

Key Segments Covered in the Connected Logistics Market Report

By Component:

Connected Logistics Devices

Vehicle Telematics

Data Loggers

GPS Tracking Devices

RFID Tags

Connected Logistics Software

Fleet Management

Asset Tracking

Security Solutions

Connected Logistics Services

Consulting

Integration & Deployment

Support & Maintenance

By Transportation:

Connected Logistics for Roadways

Connected Logistics for Railways

Connected Logistics for Airways

Connected Logistics for Seaways

By Vertical:

Connected Logistics in Manufacturing

Connected Logistics in IT & Telecom

Connected Logistics in Automotive

Connected Logistics in Retail & Consumer Goods

Connected Logistics in Food & Beverages

Connected Logistics in Healthcare

Connected Logistics in Energy & Utilities

Others

By Region:

North America

Latin America

Western Europe

Eastern Europe

Asia Pacific excluding Japan (APEJ)

Japan

The Middle East & Africa (MEA)

0 notes

Text

Global GPS Equipment Market Growth Analysis 2024 – Forecast Market Size And Key Factors Driving Growth

Overview and Scope The GPS equipment refers to various devices and tools required for the functioning of the satellite navigation system. A GPS is a satellite navigation system that determines an object's location on the ground. Sizing and Forecast The gps equipment market size has grown steadily in recent years. It will grow from $2.39 billion in 2023 to $2.47 billion in 2024 at a compound annual growth rate (CAGR) of 3.3%. The gps equipment market size is expected to see steady growth in the next few years. It will grow to $2.88 billion in 2028 at a compound annual growth rate (CAGR) of 3.9%. Order your report now for swift delivery, visit the link: https://www.thebusinessresearchcompany.com/report/gps-equipments-global-market-report Segmentation & Regional Insights The gps equipment market covered in this report is segmented – 1) By Product Type: Data loggers, Data pushers, Data pullers, Covert GPS Trackers 2) By End-Use Industry: Transportation And Logistics, Construction, Oil And Gas, Metals And Mining, Government, Other End-Use Industries (Hospitality, Education, Retail, Agriculture, and Healthcare) 3) By Application: Road, Aviation, Marine, Location-based services, Surveying and Mapping, Other Applications The Asia-Pacific was the largest region in the GPS equipment market in 2023. Asia-Pacific is expected to be the fastest-growing region in the global GPS equipment market share during the forecast period. The regions covered in the gps equipment market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa. Intrigued to explore the contents? Secure your hands-on a free sample copy of the report: https://www.thebusinessresearchcompany.com/sample.aspx?id=2793&type=smp Major Driver Impacting Market Growth The increased use of GPS tracking devices in commercial vehicles contributed to the growth of the GPS equipment market. GPS tracking devices help in monitoring commercial vehicles such as trucks, buses, heavy commercial vehicles, and construction vehicles. Through monitoring and handling these vehicles in real-time with GPS trackers, companies can get real-time updates, optimize routes, increase efficiency, and improve fuel efficiency, among others. Businesses are increasingly using GPS for tracking vehicles and will have an edge over their competitors in providing a better customer experience. Therefore, the use of GPS equipment in commercial vehicles is a key factor leading to the growth of the GPS equipment market. Key Industry Players Major companies operating in the gps equipment market report are Schlumberger Limited, Texas Instruments Inc., Garmin Ltd., Sensata Technologies Inc., Trimble Navigation Limited, Ramboll Group A/S, Jimi IoT, MiTAC Digital Technology Corporation (Navman), Suntech Power Holdings Co. Ltd. The gps equipment market report table of contents includes: 1. Executive Summary 2. Market Characteristics 3. Market Trends And Strategies 4. Impact Of COVID-19 5. Market Size And Growth 6. Segmentation 7. Regional And Country Analysis . . . 27. Competitive Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected] Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes