#Modbus Display

Explore tagged Tumblr posts

Text

Controllers, Flowmeters, and Signal Converters

In today's highly automated industrial environments, maintaining control, accuracy, and safety is essential. From process manufacturing to water treatment, a range of instrumentation ensures that systems operate efficiently and reliably. Among the critical components used across industries are Temperature Controllers, Open Channel Flowmeters, and Signal Isolators. These devices not only optimise operations but also contribute to long-term cost savings, welfare, and regulatory compliance.

Temperature Controllers

A Temperature Controller is an indispensable device in any process where temperature needs to be accurately maintained. Whether it's a furnace, a chemical reactor, or a food processing unit, the stability of temperature directly impacts & quality and structural efficiency.

How It Labours

Temperature controllers function by receiving input from a temperature sensor, comparing it to a desired setpoint, and issuing a control signal to a heating or cooling element to right any deviation.

Kinds of Temperature Controllers

ON/Away Controllers –

Best for simple applications. They switch heating/cooling on or away.

PID Controllers –

Use complex algorithms to deliver more correct and stable control.

Programmable Controllers –

Allow multiple setpoints and hour-based operations.

Requests

HVAC structures

Plastic moulding apparatuses

Pharmaceutical procedures

Nourishment and beverage equipment

Open Channel Flowmeters

For industries that manage water or wastewater, Open Channel Flowmeters are essential tools. Unlike closed-pipe systems, open channels present unique measurement challenges due to surface current, variable flow levels, and environmental factors.

How It Labours

Most open channel flowmeters use ultrasonic or radar level sensors to measure the height of the liquid above a known geometry. The flow rate is then calculated based on this quantity and the known characteristics of the channel.

Key Goods

Non-contact Quantification –

Minimises in and contamination.

Actual-time Monitoring –

Ideal for faraway or outdoor locations.

Environmental Compliance –

Ensures correct data for regulatory reporting.

Requests

Sewage and wastewater towards

Irrigation waterways

Manufacturing effluent monitoring

Stormwater structures

Gesture Isolators

Modern industrial systems rely heavily on data from field instruments, making Signal Isolators critical for maintaining signal quality and electrical safety. These devices serve as intermediaries between sensors and controllers, conditioning and isolating the gesture.

Purposes of Signal Isolators

Separation –

Prevents ground bends and electrical interference.

Change –

Translates signals from one format to more.

Amplification –

Strengthens weak signals for reliable transference.

Why They Material

Without signal isolators, noise and electrical disturbances can lead to inaccurate readings, control errors, or even equipment failure. Isolators ensure that only clean, correct data reaches your control system.

Requests

Process control consoles

DCS and PLC structures

Hazardous district instrumentation

Remote sensor webs

End

As industries continue to automate and optimise, devices like Temperature Controllers, Open Channel Flowmeters, and Signal Isolators are more important than ever. These components not only enhance precision and efficiency but also ensure the longevity and safety of industrial operations. Investing in quality instrumentation is a strategic decision that delivers operational flexibility, regulatory compliance, and improved productivity.

#Alarm Annunciator#Modbus Display#Flameproof Indicator#Flow Indicator Totalizer#Jumbo Display#Temperature Controller#Loop Powered Indicator#IOT data logger#IOT Energy Monitoring#Open Channel Flowmeter#Temperature Transmitter#Signal Isolator

0 notes

Text

Buy Modbus Display

Electromed Engineer is offering a complete range of Modbus Display which is designed by using high-grade materials and advance techniques. Modbus Display is the most popular protocol used in the Automation industry. Modbus Displays have built in Modbus protocol. Our offered Display is known for its sustainability to harsh industrial environments, low maintenance, accuracy and reliability.

Visit Here :- https://www.electromed.co.in/modbus-display/

0 notes

Text

Analog vs. Digital Meters: Understanding the Differences and Applications

In today’s increasingly connected and technologically advanced world, precise electrical measurement is critical for efficient power management and system monitoring. Two primary tools dominate the field of electrical measurement: analog meters and digital meters. While both serve the same fundamental purpose — measuring electrical quantities like voltage, current, and frequency — their technology, design, readability, and application differ significantly.

This article explores the key differences between analog and digital meters, their respective advantages, disadvantages, and common use cases to help you make an informed decision when selecting the right meter for your needs.

What Are Analog Meters?

Analog meters are traditional instruments that display measurement readings through a mechanical needle moving over a graduated scale. They have been widely used for decades in industries, commercial applications, and even residential setups.

Key Features of Analog Meters:

· Use of moving coil or iron vane mechanisms

· Continuous scale display

· Passive operation (no power required in many types)

· Simple, durable construction

Common Types:

· Analog Voltmeters

· Analog Ammeters

· Analog Frequency Meters

· Analog Power Factor Meters

Advantages of Analog Meters:

· Easy to interpret trends and fluctuations

· Cost-effective for basic applications

· Operate without auxiliary power

· Better tolerance to transient spikes and overloads

Limitations:

· Lower accuracy compared to digital meters

· Manual reading required

· Parallax error due to needle reading

· Limited data logging or interfacing capabilities

What Are Digital Meters?

Digital meters represent a more modern approach to electrical measurement. These devices convert analog signals into digital values, displaying results on an LCD or LED screen. They are widely used in automation, smart grids, and precision engineering environments.

Key Features of Digital Meters:

· High-resolution digital display

· Advanced microprocessor control

· MODBUS communication (RS-485 interface)

· Programmable settings and alarms

Common Types:

· Digital Voltmeters

· Digital Ammeters

· Digital Frequency Meters

· Digital Multifunction Meters (VAF, kWh, Power Factor, etc.)

Advantages of Digital Meters:

· High accuracy and readability

· Remote monitoring capabilities

· Compact and modern design

· Enhanced functionalities like data logging, alarms, and networking

Limitations:

· Higher initial cost

· Requires auxiliary power

· More complex installation in some cases

Applications of Analog and Digital Meters

Where Analog Meters Excel:

· Educational institutions for teaching fundamentals

· Industrial environments where ruggedness is key

· Backup or emergency systems where power is limited

· Low-budget installations

Where Digital Meters Lead:

· Smart panels and industrial automation

· Energy monitoring systems

· Commercial buildings and infrastructure

· Remote power distribution networks

Choosing the Right Meter: Factors to Consider

When deciding between analog and digital meters, consider the following:

1. Accuracy Requirements — For precision tasks, digital meters are the preferred choice.

2. Budget Constraints — Analog meters offer a cost-effective solution for basic needs.

3. Environment — Analog meters can be more tolerant in high-temperature or high-vibration areas.

4. Communication Needs — If integration with SCADA or monitoring systems is needed, go digital.

5. Data Analysis — For trend tracking and analytics, digital meters with memory and communication ports are ideal.

Enza Electric: Your Trusted Source for Analog and Digital Meters in the UAE

At Enza Electric, we provide a comprehensive range of analog and digital panel meters tailored to meet diverse electrical monitoring needs. Our digital meters support RS-485 MODBUS, enabling seamless integration into modern automation systems. Whether you’re looking for reliable analog meters for legacy systems or advanced digital meters for new installations, Enza Electric has the expertise and inventory to deliver.

We offer:

· Voltmeter, Ammeter, and Frequency meters in both analog and digital forms

· Multifunction VAF meters

· Panel meter sizes: 72x72mm and 96x96mm

· Customizable CT and PT ratios

Conclusion

Both analog and digital meters play important roles in today’s electrical systems. While analog meters offer simplicity and durability, digital meters bring precision, connectivity, and intelligence. Understanding their differences and applications is key to choosing the right tool for your project.

For expert guidance and high-quality meters, contact Enza Electric — one of the leading electrical measurement solution providers in the UAE.

#AnalogMeters#DigitalMeters#PanelMeters#ElectricalMeasurement#PowerMonitoring#ElectricalEngineering#EnergyMeters#IndustrialAutomation#MeteringSolutions#Instrumentation#electrical#switchgear#dubai#low voltage#uae

4 notes

·

View notes

Text

How to Install and Set Up a Digital Water Flow Meter with Telemetry

A digital water flow meter with telemetry is a smart, efficient, and reliable solution for industries and utilities that require real-time flow monitoring, accurate data logging, and remote accessibility. Whether you’re working in water distribution, wastewater management, or industrial processing, installing this system properly is crucial for getting accurate readings and maximum performance.

In this step-by-step guide, we’ll explain how to install and set up a digital water flow meter with telemetry, with easy-to-follow instructions and expert tips.

✅ Step 1: Choose the Right Flow Meter Model

Before installation, identify:

The type of fluid (clean water, wastewater, chemicals, etc.)

The pipe diameter and material

Required flow rate range and accuracy

Environmental conditions (indoor, outdoor, high-temp, etc.)

📌 Tip: For most water infrastructure and industrial applications, an electromagnetic digital water flow meter with telemetry is ideal due to its accuracy and no-moving-parts design.

✅ Step 2: Select a Proper Installation Location

The performance of your digital water flow meter with telemetry heavily depends on correct placement.

Key guidelines:

Install on horizontal pipes with a full pipe condition

Maintain straight pipe lengths upstream (minimum 5×D) and downstream (3×D)

Avoid installing near valves, pumps, or elbows

Ensure the location is free from electrical interference

📌 Tip: If installing outdoors, use weatherproof enclosures and secure cable management for telemetry systems.

✅ Step 3: Mount the Flow Meter

Now it’s time to physically install the meter.

🔧 Installation Steps:

Shut off the water supply before cutting into the pipe.

Position the flow meter using flange or threaded fittings, based on the model.

Make sure the flow direction arrow on the meter aligns with actual flow.

Tighten bolts evenly to prevent leaks.

Ensure proper grounding, especially for electromagnetic flow meters.

📌 Tip: Always follow the manufacturer’s installation manual for model-specific instructions.

✅ Step 4: Connect the Telemetry System

Telemetry enables remote monitoring of flow data via GSM, GPRS, or IoT platforms.

📡 Telemetry Setup:

Connect the telemetry transmitter to the signal output of the flow meter.

Insert SIM card or configure Wi-Fi/Ethernet, depending on model.

Set parameters like data transmission intervals, reporting format, and alert triggers.

Test the signal strength and connectivity to ensure stable communication.

📌 Tip: Use a secure, cloud-based telemetry platform to view data from anywhere in real-time.

✅ Step 5: Configure and Calibrate the Flow Meter

Once physically installed, configure the meter through its digital display or remote dashboard.

⚙️ Configuration Includes:

Setting the pipe diameter and fluid type

Zeroing the meter (zero-flow calibration)

Configuring pulse output, 4–20mA analog signals, or MODBUS/RTU output

Checking and confirming flow accuracy

📌 Tip: Many advanced digital water flow meters with telemetry allow remote calibration and diagnostics, reducing the need for site visits.

✅ Step 6: Test and Validate the System

After setup, run a few test cycles to verify system performance:

Check live flow readings against manual measurements

Ensure telemetry data is being received on the cloud dashboard

Validate alarms and alert triggers

Document settings and baseline flow conditions

📌 Tip: Keep a record of all setup parameters for future reference and servicing.

🌟 Benefits of Using a Digital Water Flow Meter with Telemetry

📊 Real-time monitoring from remote locations

⚠️ Instant alerts for abnormal flow or system issues

🧠 Smart data logging and reporting

🛠️ Reduced maintenance with predictive insights

🌍 Ideal for smart cities, water boards, and industrial plants

🧾 Conclusion

Installing a digital water flow meter with telemetry may seem technical, but following the right steps ensures precise monitoring and hassle-free operation. It’s a game-changer for industries looking to embrace automation, efficiency, and smart water management.

For trusted and high-performance flow meters, Atlantech offers cutting-edge solutions backed by 30+ years of industry experience.

#digital flow meters#digital water flow meter#digital water flow meter manufacturer in india#electromagnetic flow meter manufacturers in india#digital water flow meter india#digital water meter#flow meters#electromagnetic water meter#electromagnetic flow meter suppliers in india

0 notes

Text

ARM Embedded Controllers ARMxy in Building Fire Protection Systems

Main Application Scenarios

Fire Detection and Alarming: ARM controllers integrate sensors (e.g., smoke, temperature, gas sensors) to monitor environmental data in real-time, using algorithms to assess fire risks and trigger alarms.

Fire Equipment Control: Manage fire pumps, sprinkler systems, fire doors, smoke exhaust fans, etc., ensuring rapid response during a fire.

Communication and Networking: Support multiple communication protocols (e.g., Modbus, CAN, Ethernet, 4G, Wifi) for connectivity with fire control centers, cloud platforms, or other smart devices.

Data Processing and Storage: Process large amounts of sensor data and log events for post-incident analysis and system optimization.

Human-Machine Interaction: Drive displays or touchscreens to provide status monitoring and operation interfaces for fire protection systems.

Emergency Power Management: Manage backup power sources (e.g., UPS or batteries) to ensure system operation during power outages.

Advantages of ARM Embedded Controllers ARMxy series

High Performance and Low Power Consumption: ARM Cortex-M series (e.g., Cortex-M4, M7) or Cortex-A series offer strong computing power while maintaining low energy consumption, ideal for continuous operation in fire systems.

Rich Peripheral Support: ARMxy series Integrated RS485, GPIO, DI, DO, AI, AO. RS232, CAN, RTD, etc., facilitate connections to various sensors and actuators.

Real-Time Capability: Support real-time operating systems (RTOS, e.g., FreeRTOS, uC/OS) to ensure low-latency fire detection and response.

Scalability: ARMxy series supports modular design, enabling easy system upgrades or feature expansions.

Cost-Effectiveness: ARM chips are relatively affordable, suitable for large-scale deployment in building fire systems.

Security: Support encryption modules and secure boot to prevent malicious tampering, ensuring system reliability.

Typical Implementation Cases

Smoke Alarm System: Use ARM Cortex-A7 controllers BL330 with smoke sensors, collecting data via DI/AI to trigger buzzers or networked alarms.

Smart Fire Hydrant Monitoring: ARM controllers monitor hydrant water pressure and status, uploading data to the cloud via Ethernet, 4G or WiFi.

Building Fire System Integration: Cortex-A55 controllers BL410 running Linux integrate video surveillance, fire alarms, and evacuation guidance for comprehensive management.

Development Considerations

Reliability: Fire systems require 24/7 operation; select industrial-grade ARM chips to ensure high temperature resistance and anti-interference.

Redundancy Design: Include backup controllers or communication channels to prevent single-point failures.

Certification Standards: Ensure compliance with fire protection standards.

Power Optimization: Use sleep modes or dynamic frequency scaling to reduce energy consumption and extend device lifespan.

Software Security: Regularly update firmware to mitigate potential cyberattacks.

Summary

ARM embedded controllers, with their high performance, low power consumption, and flexibility, have become core components of building fire protection systems. Through proper chip selection and design, they enable efficient and reliable fire detection, equipment control, and emergency response, significantly enhancing building fire safety.

0 notes

Text

Inline Compressed Air Flow Meter with Output Interface - PCD Flowmeter

This compact air flow meter for compressed air is designed for seamless installation in existing pipes.It supports Modbus RS485, has a clear display & offers stable readings for small to mid-scale industries.Ideal as a cfm meter for compressed air in workshops & local manufacturing units.Developed by compressed air flow meter manufacturers who focus on practical, space-saving & efficient monitoring tools to manage compressed air usage accurately.

#compressed air flow meter#cfm meter for compressed air#air flow meter for compressed air#air flow meter manufacturers in india#flowmeter

0 notes

Text

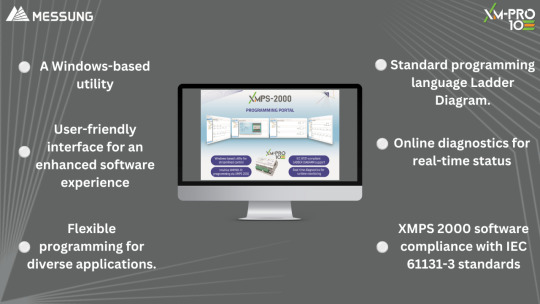

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

Enhancing Industrial Safety and Control Systems with Fire Annunciators and Signal Converters

In the fast-paced world of industrial automation, reliability and safety are non-negotiable. As facilities strive to optimize their operations, devices like alarm annunciators and signal isolators play a pivotal role in ensuring process control, monitoring, and protection. These components serve as silent guardians, safeguarding both equipment and personnel from unexpected events and structural failures.

What is a Fire Annunciator?

An Alarm Annunciator is an essential device used in industrial control systems to monitor various process parameters and alert operators in case of abnormal conditions. It provides a visual and audible indication when any of the monitored signals go beyond the pre-set limits. Whether in a power plant, chemical factory, or manufacturing line, annunciators help reduce downtime by ensuring that faults are quickly recognized and resolved.

Key benefits of using fear annunciators:

Real-time alerts to prevent accidents or equipment harm

Customizable logic to match complex plant functioning

Multi-tip monitoring, improving overall situational awareness

Compliance with welfare and regulatory standards

Modern annunciators are equipped with LED displays, integrated communication agreements, and even remote notification capabilities, making them indispensable in smart facilities.

Comprehension Signal Isolators

A Signal Isolator is a device that electrically isolates the input signal from the output, preventing ground loops and minimizing noise in signal transmission. Signal isolators are vital for ensuring accurate quantification and data logging, especially in sensitive environments where multiple control systems are interconnected.

Why signal isolators material:

Prevents ground loop matters, which can lead to inaccurate readings

Protects control structures from voltage spikes and surges

Improves signal quality over long transmission intervals

Enables safe interfacing between incompatible structures

Signal isolators are widely used in automation systems, PLC/DCS integration, and data acquisition units. They are designed to work with a diversity of input types, including thermocouple and RTD signals.

When used together, alarm annunciators and signal isolators offer a robust solution for monitoring and control. While annunciators ensure prompt operator response to faults, isolators maintain signal fidelity and protect equipment from electrical disturbances. Their integration enhances operational transparency and system reliability across diverse industries like oil & gas, energy, pharmaceuticals, and aqua treatment.

Last Thoughts

As industries move toward greater automation and digitalization, foundational elements like alarm annunciators and signal isolators remain vital for operational safety and efficiency. Investing in quality devices ensures uninterrupted monitoring, accurate control, and long-term system integrity. Whether upgrading legacy structures or building new infrastructure, these tools form the backbone of any effective industrial control solution.

#Alarm Annunciator#Modbus Display#Flameproof Indicator#Flow Indicator Totalizer#Jumbo Display#Temperature Controller#Loop Powered Indicator#IOT data logger#IOT Energy Monitoring#Open Channel Flowmeter#Temperature Transmitter#Signal Isolator

0 notes

Text

ATZ2000 series multi-function power instruments: the right-hand assistant for industrial power monitoring

In modern industrial production and complex power systems, accurate power monitoring is crucial to ensuring stable operation of equipment, improving energy utilization efficiency, and ensuring production safety. With its excellent performance, a wide range of application scenarios and reliable quality, the ATZ2000 series multi-function power instrument has become an ideal choice for many companies in the field of power management.

1. Functional characteristics - comprehensive monitoring and accurate control

The ATZ2000 series multi-function power meter is very powerful and can display the power, voltage and current values of each phase in real time. Whether it is a three-phase and four-wire (3P 4W) system or other common power system types, it can be accurately monitored. Operators can intuitively obtain these key power parameters on the instrument screen with just a simple press of the buttons, providing strong data support for the stable operation of the power system.

This instrument also has electrical energy metering function, which can accurately measure total and phase separation power. Its measurement accuracy is as high as 0.5S level of active power and 2nd level of reactive power. It can accurately record the power consumption of enterprises and provide a reliable basis for energy management and cost accounting. In today's environment of advocating energy conservation and emission reduction, accurate electricity measurement will help companies better understand their own electricity usage and formulate targeted energy-saving measures.

In addition, the ATZ2000 series instrument can measure power factor, frequency and other parameters. The power factor reflects the effective utilization of electricity in the power system. By monitoring the power factor, enterprises can promptly detect the problem of excessive reactive power and take corresponding compensation measures to improve the quality of electricity. Monitoring of frequency parameters is also crucial to ensuring the stability of the power system. Once the frequency fluctuates abnormally, the instrument can issue an alarm in time to remind the staff to handle it.

2. Technical parameters - Stable and reliable, widely adapted

Judging from the technical parameters, the ATZ2000 series multi-function power instruments show strong adaptability and stability. Its operating power supply range is AC/DC85 - 265V, which means it can work properly in a variety of power supply environments. Whether it is an AC power supply common in industrial sites or a DC power supply used in some special occasions, it can provide stable power support for the instrument. At the same time, the instrument has a low power consumption, and the power consumption design of ≤5W is not only energy-saving and environmentally friendly, but also effectively reduces long-term use costs.

In terms of input voltage, the instrument supports AC100V, 220V, 400V and other rated voltages, and has a certain overload capacity, which can withstand continuous overload of 1.2 times the rated voltage and short-term overload of 2 times the rated voltage for 10 seconds. For input current, its measurement range is 1 - 9999A, which can meet the monitoring needs of power systems of different sizes. Whether it is low-voltage distribution systems in small factories or high-voltage transmission lines in large industrial enterprises, the ATZ2000 series instruments can accurately measure current.

In terms of communication, the instrument is equipped with an RS485 interface and uses the Modbus RTU communication protocol, and the communication rate can reach 2400 - 38400bps. This high-speed and stable communication method allows the instrument to efficiently transmit data with the upper computer control system, making it easier for enterprises to realize remote monitoring and centralized management of the power system. Through the computer software, staff can view the measurement data of the instrument in real time, set the instrument parameters, and even realize remote control functions, greatly improving the convenience and intelligence of power management.

3. Application scenarios——Multiple-field coverage to meet diverse needs

The ATZ2000 series multi-function power meters have a wide range of application scenarios and play an important role in the power supply and distribution systems of industrial enterprises. For example, in the power distribution room of the factory, by installing this series of instruments, the power parameters of the incoming lines, busbars and various important feeders can be monitored in real time, and abnormal situations in the power system can be discovered in a timely manner, such as voltage fluctuations, current overloads, etc., to provide guarantees for the safe operation of the equipment. Once a failure occurs, the instrument can quickly issue an alarm and notify the staff to handle it, effectively reducing production interruptions caused by power failure and reducing economic losses to the company.

In the field of building automation, this instrument also plays an indispensable role. In large commercial buildings or office buildings, electricity consumption is huge and equipment is numerous, so refined management of electricity is required. The ATZ2000 series instruments can be installed in floor distribution boxes, equipment computer rooms, etc., to monitor the electricity consumption in each area in real time, help property management personnel understand the electricity distribution of buildings, formulate reasonable electricity consumption plans, and achieve the goal of energy conservation and emission reduction. At the same time, through integration with building automation systems, instruments can also automatically adjust the operating status of equipment according to actual electricity consumption, and improve energy utilization efficiency.

In the energy management system, the ATZ2000 series of multi-function power meters provide enterprises with accurate energy data. Enterprises can use this data to conduct energy audits, cost analysis, and energy efficiency assessments. Through in-depth analysis of energy data, enterprises can find out the key links of energy consumption, take targeted energy-saving transformation measures, reduce energy costs, and improve the economic benefits and competitiveness of enterprises.

With its powerful functions, reliable technical parameters and a wide range of application scenarios, the ATZ2000 series multi-function power instrument has become a leader in the field of power monitoring. Whether it is industrial enterprises, construction industry or energy management departments, they can obtain accurate power data and efficient management support from this instrument, protecting the stable operation of the power system and the rational use of energy.

0 notes

Text

A Complete Guide to Digital Flow Meters: Accurate Measurement in the Digital Age

In today's data-driven world, precise measurement and control of liquid flow is crucial across industries—from automotive and aviation to agriculture and manufacturing. One innovative solution revolutionizing the way fluids are monitored is the Digital Flow Meter.

These compact, tech-enhanced devices are quickly replacing traditional analog systems. Offering greater accuracy, digital displays, and seamless integration with smart monitoring systems, digital fuel flow meters have become the backbone of modern fuel management.

What is a Digital Flow Meter?

A Digital Flow Meter is an electronic device that measures the volume or mass of a fluid (typically liquids like water or fuel) as it passes through a system. Unlike mechanical meters, digital models utilize sensors and microprocessors to provide precise, real-time data displayed on easy-to-read screens.

These meters are used in:

Fuel dispensing systems

Industrial fluid management

Agricultural irrigation systems

Water treatment plants

By minimizing human error and offering data logging capabilities, they help streamline operations and reduce waste.

Why Use a Digital Fuel Flow Meter?

When it comes to tracking fuel consumption, Digital Fuel Flow Meters offer unmatched benefits:

High Accuracy: They offer precise measurement within ±0.5%, which is essential for cost control.

Real-Time Monitoring: Display screens and connectivity options allow for instant feedback.

Low Maintenance: With fewer moving parts than mechanical meters, maintenance needs are drastically reduced.

Data Integration: Advanced models can connect to IoT systems for remote monitoring and automated reporting.

These features make them ideal for use in fleet management, construction, logistics, and marine industries.

Real User Experiences

"After switching to a digital fuel flow meter, our fleet's fuel tracking became incredibly streamlined. No more manual logs—just plug and play." — James T., Logistics Manager

"We saved thousands by detecting small leaks early, thanks to real-time data from our digital flow meters." — Priya R., Operations Head, Water Treatment Facility

Key Features to Look For

When selecting a digital fuel flow meter, consider the following:

Flow Range Compatibility: Ensure it supports the specific volume of fluid your system handles.

Material Durability: Stainless steel and corrosion-resistant polymers are best for long-term use.

Display Type: Look for large, backlit LCDs for readability in low-light environments.

Communication Protocols: Choose meters with Bluetooth, RS-485, or Modbus for system integration.

Battery Life: Industrial versions often run for years on a single set of batteries.

Frequently Asked Questions

Q1: Are digital flow meters only for industrial use? Not at all. While widely used in industries, they’re also suitable for residential and agricultural applications, especially where precision and automation are required.

Q2: Can I install a digital flow meter myself? Many models are designed for easy, inline installation. However, professional setup is recommended for large-scale systems or where integration with software is needed.

Q3: How long do digital fuel flow meters last? With proper maintenance and quality materials, they can last up to 10 years, depending on usage and environmental conditions.

Q4: Do these meters require calibration? Yes, periodic calibration ensures continued accuracy. Many digital meters include automatic calibration prompts or alerts.

The Future of Fluid Measurement

With increasing demand for data transparency and operational efficiency, Air Operated Diaphragm Pump are poised to become standard in all sectors involving fluid transfer. From improving environmental compliance to enhancing fuel economy, these devices are shaping a smarter, more efficient future.

Whether you're overseeing an industrial plant, managing a vehicle fleet, or optimizing a farm irrigation system, investing in a digital fuel flow meter can bring you one step closer to operational excellence.

0 notes

Video

youtube

✅ Real-Time Gas Monitoring Made Visible We’ve just completed a project integrating our Custronics 4” LED Display with the Bebur AS525 VOC Gas Detector—making gas readings instantly visible across the factory floor! 💨 From tiny 0.5" LCD to a large, high-brightness display 🔌 RS485 Modbus integration 📏 DOE-compliant, real-time visibility 📍 Perfect for: Hazardous gas areas, Gas pipe zones, DOE inspections, Smart factories

1 note

·

View note

Text

FU2200A RTU_modbus_digital_panel_power_meter_data_logger

The FU2200A RTU Modbus Digital Panel Power Meter Data Logger is a versatile and high-performance device designed for accurate monitoring and recording of electrical parameters in power systems. Featuring RTU Modbus communication, it enables seamless integration with supervisory control and data acquisition (SCADA) systems, providing real-time data for energy management and system analysis. The FU2200A is ideal for use in commercial, industrial, and utility environments where reliable power measurement and logging are essential for operational efficiency and compliance. Key Features:

RTU Modbus Communication: The FU2200A supports RTU Modbus communication, allowing it to easily integrate with existing SCADA systems for real-time data acquisition. This feature enables remote monitoring and control, making it ideal for power distribution systems, substations, and industrial applications where centralized monitoring is essential. 2. Digital Panel Power Meter: The FU2200A acts as a digital panel power meter, providing accurate readings of critical electrical parameters, including voltage, current, power, energy, frequency, and power factor. This enables users to monitor and analyze power consumption, efficiency, and system performance. 3. Data Logger Functionality: Equipped with data logging capabilities, the FU2200A can store historical data for later analysis. This feature helps track energy usage trends, identify inefficiencies, and maintain detailed records for reporting, compliance, and optimization purposes. 4. Wide Application: The FU2200A is suitable for a wide range of applications, including power monitoring, energy management, and load analysis in commercial buildings, industrial facilities, and utility companies. It helps users optimize energy consumption, reduce costs, and improve system reliability. 5. High Accuracy and Precision: The FU2200A offers high accuracy in measuring electrical parameters, ensuring reliable and precise data for energy metering and system diagnostics. This is critical for identifying power quality issues, preventing system failures, and ensuring optimal energy usage. 6. User-Friendly Interface: The FU2200A features an intuitive digital display for easy readout of measured values and system parameters. The user-friendly interface simplifies setup, configuration, and monitoring, allowing operators to quickly assess the status of the power system. 7. Compact Design: Designed for ease of installation, the FU2200A features a compact and robust design, suitable for mounting on standard panels in electrical cabinets. Its space-saving form factor makes it ideal for environments with limited space. Applications:

Energy Monitoring: Helps track energy usage and optimize consumption in commercial and industrial settings. Load Management: Provides insights into load distribution, helping prevent overloads and enhance system efficiency.

System Diagnostics: Monitors system parameters, aiding in the detection of faults, power quality issues, and other inefficiencies.

SCADA Integration: Offers seamless integration with SCADA systems for remote monitoring and control of power systems.

In summary, the FU2200A RTU Modbus Digital Panel Power Meter Data Logger is a powerful and reliable solution for real-time power monitoring and data logging. With its RTU Modbus communication, data logging capabilities, and high-accuracy measurements, the FU2200A is ideal for optimizing energy usage, improving system performance, and ensuring operational efficiency in commercial, industrial, and utility environments.

For detailed information, please refer to the relevant links on the official website:https://www.gfuvegroup.com/ethernet-power-meter/ethernet-digital-power-meter-with-2m-data-logger.html

1 note

·

View note

Text

Electromagnetic Flowmeter Principle and Features

Introduction

Water metering technology has evolved significantly, and Electromagnetic Water Meters have become one of the most reliable solutions for accurate flow measurement. These meters are widely used in industries such as water treatment, chemical processing, and agriculture due to their non-invasive operation and high precision. In this blog, we will explore the working principle and key features of electromagnetic flowmeters.

Principle of Electromagnetic Flowmeters

Electromagnetic flowmeters operate based on Faraday’s Law of Electromagnetic Induction. According to this principle, when a conductive liquid passes through a magnetic field, it induces a voltage that is directly proportional to the velocity of the liquid. This voltage is then measured by electrodes placed on the inner surface of the meter. The signal is processed and converted into flow rate readings.

Key Aspects of the Principle:

Magnetic Field Generation — The flowmeter generates a magnetic field using coils positioned around the pipe.

Induced Voltage Measurement — Electrodes detect the voltage induced as the conductive liquid flows through the magnetic field.

Signal Processing — The meter’s transmitter processes the signal and displays the accurate flow rate.

Since Electromagnetic Water Meters do not have moving parts, they provide high reliability and require minimal maintenance.

Features of Electromagnetic Flowmeters

Electromagnetic flowmeters offer several advantages over traditional mechanical meters. Some of their key features include:

High Accuracy — These meters deliver precise measurements, with accuracy levels as high as ±0.5% of the actual flow rate.

No Moving Parts — The absence of mechanical components reduces wear and tear, increasing the lifespan of the meter.

Wide Applicability — Suitable for measuring conductive liquids such as water, chemicals, and slurries.

Minimal Pressure Loss — Since there are no obstructions inside the meter, the pressure drop is negligible.

Bidirectional Measurement — They can measure flow in both directions, making them highly versatile.

Digital Communication — Many modern Electromagnetic Water Meters come with smart communication interfaces like Modbus, HART, or Profibus for remote monitoring and integration with SCADA systems.

Applications of Electromagnetic Water Meters

Water Supply and Distribution — Municipal corporations use these meters for accurate billing and monitoring.

Wastewater Treatment — Ideal for measuring treated and untreated sewage without clogging issues.

Chemical and Pharmaceutical Industry — Used for precise fluid monitoring in production processes.

Agriculture and Irrigation — Helps in efficient water management for farming applications.

Conclusion

Electromagnetic Water Meters have revolutionized flow measurement by offering high accuracy, low maintenance, and durability. Their ability to measure flow without direct contact with the liquid makes them suitable for a wide range of applications. Industries and municipalities adopting these meters can expect improved efficiency, cost savings, and better resource management.

For more insights on water metering technologies, check out our related articles on Digital Water Flow Meters and Ultrasonic Flow Meters.

#flow meters#digital water flow meter#digital water meter#electromagnetic flow meter suppliers in india#digital flow meters#electromagnetic flow meter manufacturers in india#digital water flow meter india#digital water flow meter manufacturer in india#electromagnetic water meter#electromagnetic flow meters

0 notes

Text

Numerical Relays - Adlite Electricals

The Future of Electrical Protection: Numerical Relays by Adlite Electricals

In today’s fast-evolving power systems, ensuring the safety and reliability of electrical networks is more important than ever. With increasing demand for precision, efficiency, and smart automation, traditional protection systems are being replaced by advanced numerical relays. Adlite Electricals, a leading provider of electrical solutions, offers a range of high-performance numerical relays designed to meet the modern industry's needs.

What Are Numerical Relays?

Numerical relays are microprocessor-based protection devices that replace conventional electromechanical and static relays. Unlike their predecessors, they incorporate multiple protection functions within a single unit, reducing equipment costs and simplifying system design. These relays use advanced algorithms and digital signal processing to ensure faster, more accurate fault detection and isolation.

Advantages of Numerical Relays

Numerical relays offer several benefits over traditional relay systems, including:

Multifunctionality: A single numerical relay can perform various protection tasks, eliminating the need for multiple separate relays.

Enhanced Accuracy: Digital technology ensures precise measurement and fault identification, minimizing false tripping and improving response time.

Compact & Space-Saving Design: These relays have a smaller footprint, making them ideal for modern electrical installations.

Advanced Communication Capabilities: Equipped with protocols such as Modbus RS485 and IEC61850, numerical relays enable seamless integration into smart grids and automation systems.

Low Maintenance & High Reliability: With no moving parts, numerical relays experience minimal wear and tear, reducing maintenance costs and enhancing longevity.

Numerical Relays by Adlite Electricals

Adlite Electricals offers a comprehensive selection of numerical relays tailored for different protection applications. Some of the standout products include:

CGI 110VDC Master Trip Relay – A reliable contact multiplication relay designed for effective trip command execution.

CGI 14C 18-52VDC Relay & CGI 14C 75-250VDC Relay – Fully digital protection relays available in various voltage ranges for diverse applications.

CGI 14N 18-52VDC Relay & CGI 14N 75-250VDC Relay – Designed for enhanced protection, ensuring safe electrical operations.

CGI 14S 230VAC Relay – A specialized relay for AC applications, providing robust performance.

CGI 24C 18-52VDC Relay & CGI 24C 75-250VDC Relay – Offering high-precision fault detection and system reliability.

CGI 24VDC Master Trip Relay – Ensures efficient contact multiplication for trip commands.

CGXH1 3 Element Aux 110 VDC Relay & CGXH1 3 Element Aux 24 VDC Relay – Under-voltage and neutral display relays, ensuring continuous monitoring and protection.

Crompton TCSR Unit 110 VDC 1 Relay & Crompton TCSR Unit 110 VDC Relay – Designed for monitoring the health of trip circuits, enhancing overall system safety.

Crompton TCSR Unit 24 VDC Relay – Adds reliability to trip circuit supervision.

Megawin M140c Relay – A robust numerical relay for various power applications.

Megawin MB 140c (Breaker Manager Relay) – Ensures precise breaker management and protection.

Megawin Auxiliary Relays – Provides essential support for complex electrical protection systems.

Megawin MF 790C (Feeder Manager Relay) – A high-performance device ensuring complete feeder protection and management.

Why Choose Adlite Electricals?

With years of experience in providing cutting-edge electrical solutions, Adlite Electricals ensures top-notch quality, innovation, and reliability in all its products. Their numerical relays are built to withstand the rigorous demands of industrial, commercial, and power utility applications, offering best-in-class protection and performance.

Conclusion

As the electrical industry continues to modernize, numerical relays are becoming the gold standard for protection and automation. Adlite Electricals’ advanced numerical relays provide the perfect combination of efficiency, accuracy, and smart communication, making them the ideal choice for safeguarding electrical systems. Explore Adlite Electricals’ range of numerical relays today and step into the future of electrical protection!

For more details, visit Adlite Electricals Numerical Relays.

#CGI 110VDC Master Trip Relay#CGI 14C 18-52VDC Relay#CGI 14C 75-250VDC Relay#CGI 14N 18-52VDC Relay#CGI 14N 75-250VDC Relay#CGI 14S 230VAC Relay#CGI 24C 18-52VDC Relay#CGI 24C 75-250VDC Relay#CGI 24VDC Master Trip Relay#CGXH1 3 Element Aux 110 VDC Relay#CGXH1 3 Element Aux 24 VDC Relay#Crompton TCSR Unit 110 VDC 1 Relay#Crompton TCSR Unit 110 VDC Relay#Crompton TCSR Unit 24 VDC Relay#Megawin M140c Relay#Megawin MB 140c (Breaker Manager Relay)#Megawin- Auxiliary Relays#Megawin- MF 790C (Feeder Manager Relay)

0 notes

Text

ARMxy Ubuntu Gateway BL370 and Rapid SCADA for Diesel Generator Monitoring System

Case Details

Combining the ARMxy series Ubuntu Gateway BL370 and Rapid SCADA to implement a diesel generator monitoring system is a great choice. This combination offers an efficient, flexible, and scalable monitoring solution. Below are some possible technical solutions and architectural designs:

1. Hardware Platform (ARM Ubuntu Gateway)

The ARM Ubuntu Gateway BL370 running Ubuntu provides powerful computing capabilities and stable support, allowing it to receive sensor data from the diesel generator and perform real-time processing. You can interface with the generator hardware in the following ways:

Digital and Analog Inputs: Connect the sensors of the diesel generator (e.g., temperature, pressure, voltage, current, etc.) through the gateway, often using the MODBUS RTU or TCP protocol to communicate with the SCADA system.

Remote Data Acquisition: The gateway can connect to the remote SCADA system via wireless (Wi-Fi/4G/5G) or wired networks (Ethernet), enabling data transmission and remote control.

2. SCADA System (Rapid SCADA)

Rapid SCADA is an open-source industrial automation platform that works well for monitoring generator operations. It supports a wide range of communication protocols (e.g., Modbus, OPC, SNMP) and integrates smoothly with ARM Ubuntu Gateway BL370.

Main features:

Real-time Monitoring: Display critical parameters like generator status, load, fuel consumption, temperature, pressure, etc.

Data Storage and Historical Queries: Rapid SCADA stores real-time data and allows querying and analysis through a database (like MySQL), generating reports.

Alarming and Event Management: When monitored data exceeds preset thresholds, the system can automatically trigger alarms and log events for troubleshooting and maintenance.

Remote Control: Users can remotely control the generator’s start/stop operations and adjust the load through the SCADA system.

3. System Architecture Example

Sensors and Controllers: Install various sensors (e.g., temperature, pressure, oil level) on the diesel generator, transmitting data to the ARM Ubuntu Gateway BL370 via Modbus RTU/TCP protocol.

Gateway Device (BL370): This gateway runs Ubuntu OS and handles receiving sensor data from the generator and transmitting it to the SCADA system over the network.

SCADA Server: Rapid SCADA runs on a server, processing and displaying data from the gateway, generating real-time data views, alarms, and reports.

User Interface: Users can access the SCADA system through a web interface or desktop client to view the generator's status, historical data, and alarm information.

4. Data Transmission and Protocols

Modbus Protocol: In industrial environments, Modbus is a commonly used protocol for communication between the diesel generator and the SCADA system. Modbus TCP or Modbus RTU can be used, depending on the system design and needs.

MQTT Protocol: For remote communication, MQTT can be used to transmit sensor data, especially when using 4G or wireless networks.

HTTP/HTTPS API: If Rapid SCADA supports it, the gateway can send data to the SCADA system via HTTP or HTTPS APIs.

5. Data Analysis and Prediction

Using historical data accumulated by the SCADA system, deeper data analysis can be conducted. For example, algorithms can predict maintenance needs for the diesel generator or optimize its workload based on performance data, thus reducing downtime.

6. Security Considerations

Data Encryption: To protect data security during communication, it’s recommended to use TLS/SSL encryption protocols.

User Authentication and Access Control: Set proper permissions and roles within the SCADA system to ensure that only authorized users can operate critical equipment.

Summary

Using an ARMxy Ubuntu Gateway BL370 in conjunction with Rapid SCADA to set up generator monitoring system is a flexible and efficient solution. The ARM gateway provides reliable data acquisition and processing capabilities, while Rapid SCADA offers powerful data visualization, alarming, and historical data storage features. Together, they can significantly enhance the monitoring, management, and maintenance of the diesel generator.

0 notes