#Industrial Safety Harnesses Belts

Text

A lanyard is traditional with small electronics

A lanyard is definitely an attachment used to require keys, badges, and various items to a specific thing. They are generally Industrial Safety Harnesses Belts used for collection or restraint, so are sometimes made with different materials, as well as nylon, polyester, silk, silk, and polyethylene terephthalate (PET). That name 'lanyard' appeared to be coined by Wedgwood, Hensleigh in 1855, when he / she published a book on false etymologies.

A lanyard is traditional with small electronics, such as mobile devices and other convenient electronic devices, to help keep them safe coming from dropping or becoming dropped. Most lanyards are attached with the device via a hole on the conclusion, called the cow hinderance. In some conditions, the strand can also be used as any headphone cord, and several earphones incorporate the actual audio signal to the ring. A popular example may be the Wii Remote wrist strap, which keeps it in place even during vigorous work out plans.

Many lanyards will be custom-printed with art logos of businesses in addition to events. You could print these logos with screen-printing, Jacquard loom weaving, or offset printing. Luckily they are used to attach keys and other small objects into a lanyard for single handed access. However, you must order 10 pieces or more to purchase this product or service. There is simply no minimum order number. In addition, lanyards work extremely well as key chains.

A lanyard can be a versatile attachment for a device. It can be used to pick up serious objects, hold gear, and secure other gear. It is additionally helpful for obtaining objects, so you should use it to make your wellbeing easier. It is a handy accessory for every purpose. You might attach a badge to it utilizing a lanyard. You might buy a lanyard to install an earphone.

A lanyard is commonly used to showcase ID cards, tickets, and badges. Its design is usually a woven or braided stuff. The lanyard will be divided at one end which includes a clip that is that come with the holder. A name badge is often attached to the actual linch-style hat by just a lanyard. They also serve like a keychain. If you happen to be a member of the Royal Navy, you ought to wear a light linch-style sleeved lanyard.

ANY lanyard suspension method uses a twine or strap for you to suspend a prosthesis. It feeds by means of an opening inside bottom of the actual socket. It makes it easy to draw the stump in the socket, and it makes it possible to don the prosthesis even though seated. It is likewise useful for seated users. If you are unable to reach the socket from the standing position, you possibly can still use a new lanyard-strap-style attachment.

10 notes

·

View notes

Text

We are the manufacture, export and supply of a wide range of good quality Road Safety Equipment. We offer safety cones, spring posts, delineator’s posts, barriers, studs, reflectors, speed bumpers and numerous other essential equipment. Metro Safety Products manufacturers in India, Metro Moulding Industries, Peeragarhi, safety boots manufacturers, safety gloves suppliers, safety life jackets manufacturers, safety helmets suppliers, India. Visit website https://www.metrosafetypro.com Business Enquiries: - Email: [email protected]

#metro safety products#metro safety#Industrial safety harness#Safety belts manufacturer#Safety helmets#Safety jackets

1 note

·

View note

Text

Could airlines do a better job of making their planes fire-safe? You bet they could. They could install more emergency exits, but they won’t, because that means taking out seats and losing revenue. They could install sprinkler systems or build crashworthy fuel systems of the type used on military helicopters. But they won’t, because both these options would add too much weight. More weight means higher fuel costs.

Who decides when it’s okay to sacrifice human lives to save money? Ostensibly, the Federal Aviation Administration. The problem is that most airline safety improvements are assessed from a cost-benefit viewpoint. To quantify the “benefit” side of the equation, a dollar amount is assigned to each saved human life. As calculated by the Urban Institute in 1991, you are worth $2.7 million. “That’s the economic value of the cost of somebody dying and the effects it has on society,” said Van Goudy, the FAA man I spoke with.

...

Goudy used the example of shoulder harnesses ... “The agency would say, ‘All right, if you’re going to save fifteen lives over the next twenty years by putting in shoulder straps, that’s fifteen times two million dollars; that’s thirty million.’ The industry comes back and says, ‘It’s gonna cost us six hundred and sixty-nine million to put the things in.’” So long, shoulder straps. Why doesn’t the FAA then come back and say, “Tough tiddlywinks. You’re putting them in anyway”? For the same reason it took fifteen years for the government to begin requiring air bags in cars. The regulatory agencies have no teeth.

“If the FAA wants to promulgate a regulation, they have to provide the industry with a cost-benefit analysis and send it out for comment,” says Shanahan. “If the industry doesn’t like what they see, they go to their congressmen. If you’re Boeing, you have a tremendous influence in Congress.”*

*This is no doubt why planes today are not equipped with air bags. Believe it or not, someone actually designed an airplane air-bag system, called the Airstop Restraint System, which combined underfoot, underseat, and chest air bags. The FAA even tested the system on dummies on a DC-7 that it crashed into a hill outside of Phoenix, Arizona, in 1964. While a control dummy in a lap belt fastened low and tight about it jackknifed violently and lost its head, the Airstop-protected dummy fared just fine. The designers were inspired by stories of World War II fighter pilots who would inflate their life vests just before a crash.

Stiff, Mary Roach

48 notes

·

View notes

Text

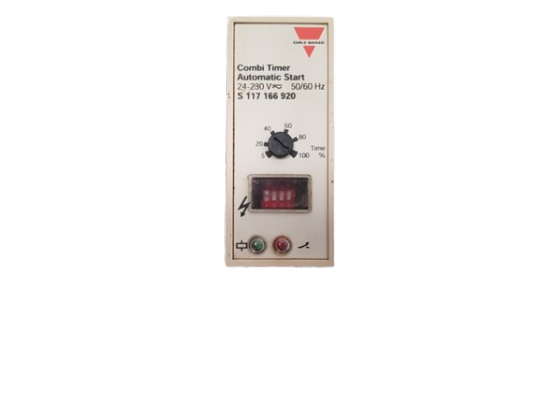

Timer Tactics: Enhancing Performance in Industrial Automation Systems

In the realm of industrial automation, efficiency is king. Every second counts, and every process must be optimized to ensure maximum output. One often-overlooked tool in achieving this optimization is the humble timer. Timers play a crucial role in orchestrating tasks, synchronizing operations, and enhancing overall performance in industrial automation systems. In this blog, we will look into the strategic use of timers and explore how they can be leveraged to boost productivity, minimize downtime, and streamline operations in industrial settings.

The Role of Timers in Industrial Automation

To lay a solid foundation, let's begin by understanding what timers are and how they function within industrial automation systems. Timers are essentially devices or software components that count time intervals. They can trigger actions based on predefined time criteria, such as initiating a process, controlling the duration of an operation, or signaling the completion of a task. In industrial automation, timers are deployed across a wide range of applications, from simple time-delay circuits to complex scheduling systems.

Optimizing Production Processes with Timers

One of the primary objectives of industrial automation is to optimize production processes for efficiency and reliability. Timers play a pivotal role in achieving this objective by synchronizing tasks, coordinating sequences, and minimizing idle time. For instance, in a manufacturing environment, timers can regulate the timing of conveyor belts, control the duration of heating or cooling cycles, and sequence the operation of robotic arms. By fine-tuning these parameters with timers, manufacturers can streamline their workflows and maximize output.

Minimizing Downtime through Scheduled Maintenance

Downtime is the bother of industrial operations, leading to lost productivity, increased costs, and customer dissatisfaction. Timely maintenance is essential to prevent equipment breakdowns and prolong the lifespan of machinery. Timers can be programmed to schedule routine maintenance tasks, such as lubrication, inspections, and part replacements. By proactively addressing maintenance needs based on predefined intervals, companies can minimize unplanned downtime and ensure the smooth operation of their facilities.

Enhancing Safety with Timer-Based Control Systems

Safety is dominant in any industrial environment, where machinery and processes pose inherent risks to workers and equipment. Timer-based control systems can play a crucial role in enhancing safety by implementing time-delayed interlocks, emergency shutdowns, and alarm triggers. For instance, in a chemical processing plant, timers can activate emergency showers or ventilation systems in the event of a leak or spill, mitigating potential hazards and protecting personnel and assets.

Real-Time Monitoring and Adaptive Control

In today's interconnected world, real-time monitoring and adaptive control are essential for maintaining agility and responsiveness in industrial automation systems. Timers can be integrated into supervisory control and data acquisition (SCADA) systems to track process variables, analyze performance metrics, and dynamically adjust parameters in response to changing conditions. By harnessing the power of timers for real-time control, companies can optimize their operations, adapt to market demands, and stay ahead of the competition.

Future Trends and Innovations in Timer Technology

As technology continues to evolve, so too does the landscape of industrial automation. In the realm of timer technology, advancements such as digital timers, programmable logic controllers (PLCs), and cloud-based timer management systems are driving new possibilities for efficiency and optimization. Moreover, the emergence of artificial intelligence (AI) and machine learning (ML) is poised to revolutionize how timers are utilized, enabling predictive maintenance, adaptive scheduling, and autonomous decision-making.

Conclusion

In conclusion, timers are essentials tools for enhancing performance in industrial automation systems. By strategically deploying timers across various applications, companies can optimize production processes, minimize downtime, enhance safety, and achieve new levels of efficiency. As technology continues to advance, the potential for innovation in timer technology is limitless, offering exciting opportunities for companies to stay competitive and succeed in the digital age of automation.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial automation equipment#industrial and marine automation equipment#industrial and marine automation#industrial#timer

0 notes

Text

Sealing Solutions Redefined- Harnessing the Power of Silicone Rubber Sheets

In the intricate machinery of modern industry, where precision meets performance, the importance of reliable sealing solutions cannot be overstated. Among the diverse array of sealing materials available, silicone rubber sheets stand out as a versatile and indispensable option. This article embarks on an exploration of silicone rubber sheets and , delving into their composition, applications, and the unique benefits they bring to a wide range of industries.

Unveiling Silicone Rubber Sheets:

Silicone rubber sheets represent a pinnacle of sealing technology, offering a combination of flexibility, durability, and thermal stability. Composed of silicone elastomers, these sheets boast properties that make them well-suited for a multitude of sealing applications across diverse industries.

Composition and Properties:

Temperature Resistance: Silicone rubber sheets exhibit exceptional thermal stability, withstanding a wide range of temperatures from extreme cold to high heat without losing their elasticity or mechanical properties.

Flexibility and Resilience: Silicone rubber sheets are highly flexible and resilient, allowing them to conform to irregular surfaces and maintain a tight seal even under dynamic conditions.

Chemical Resistance: Silicone rubber is inherently resistant to many chemicals, oils, and solvents, making silicone rubber sheets suitable for use in applications where exposure to harsh chemicals is common.

Applications Across Industries:

Silicone rubber sheets find widespread use across various industries and applications, owing to their versatility and reliability:

Industrial Sealing: Silicone rubber sheets are commonly used for sealing applications in industrial machinery, equipment, and components. They create tight seals in gaskets, O-rings, and flange connections, preventing leaks and ensuring the integrity of systems.

Food and Beverage: Silicone rubber sheets are FDA-approved for use in food and beverage processing applications, where hygiene and product purity are paramount. They seal equipment such as conveyor belts, seals, and gaskets, providing a safe and sanitary environment for food production.

Medical Devices: Silicone rubber sheets are utilized in medical devices and equipment, where biocompatibility, sterilizability, and reliability are critical. They seal components such as tubing, valves, and connectors, ensuring the safety and effectiveness of medical devices.

Electrical Insulation: Silicone rubber sheets provide excellent electrical insulation properties, making them ideal for use in electrical enclosures, wire and cable insulation, and electronic components where protection against electrical shock and short circuits is required.

Innovations and Advancements:

The evolution of silicone rubber sheets continues to be driven by innovations aimed at enhancing performance, durability, and sustainability. Recent advancements include:

Enhanced Tear Strength: New formulations of silicone rubber sheets offer improved tear strength, allowing them to withstand higher levels of mechanical stress and prolonging their lifespan in demanding applications.

Low Volatile Organic Compound (VOC) Formulations: Manufacturers are developing silicone rubber sheets with reduced VOC content, promoting environmental sustainability and compliance with regulatory standards.

Antimicrobial Properties: Some silicone rubber sheets are engineered with antimicrobial additives to inhibit the growth of bacteria and fungi, making them suitable for use in medical and food processing environments where cleanliness is paramount.

Conclusion:

Gasket & Materials offer high quality silicone rubber sheets. Silicone rubber sheets stand as a testament to the ingenuity and innovation driving sealing technology forward. From industrial machinery to medical devices, these versatile components play a vital role in ensuring the reliability, safety, and performance of systems across diverse industries. As industries continue to evolve, the evolution of silicone rubber sheets will undoubtedly remain at the forefront, reshaping the landscape of sealing solutions and reaffirming their status as indispensable components in the machinery of modern industry.

Original Source: Silicone Sheets

0 notes

Text

Pet Collar Chronicles: Stories from Furry Friends and Their Humans

Introduction:

Pet collars are more than just accessories; they’re symbolic of the bond between humans and their furry companions. Each collar carries with it a story, a connection, and a myriad of memories. In this blog post, we delve into the fascinating world of "Pet Collar Chronicles: Stories from Furry Friends and Their Humans." Join us as we explore heartwarming anecdotes, adventures, and the profound significance behind these simple yet meaningful adornments.

Inseparable Bonds: The Essence of Pet Collars

Pet collars serve as tangible reminders of the unbreakable bond between pets and their humans. From the moment a collar is placed around a pet's neck, it signifies a commitment to care, love, and companionship. Whether adorned with a name tag, a special charm, or vibrant colors, each collar tells a unique tale of devotion and loyalty. Through thick and thin, these collars remain steadfast symbols of the enduring connection shared between pets and their adoring owners.

A Walk Through Time: Pet Collars Through History

The history of pet collars dates back centuries, evolving from simple leather straps to intricately designed accessories. In ancient times, collars were primarily used for identification and control, reflecting the utilitarian relationship between humans and their working animals. However, as pets became cherished members of the family, collars transitioned into expressions of personal style and affection. Today, the pet collar industry boasts a diverse array of designs, materials, and functionalities, catering to the unique preferences of pet owners around the globe.

Fashion Forward: The Style Evolution of Pet Collars

Gone are the days of mundane, utilitarian collars. In today's world, pet collars have become a fashion statement, reflecting the personality and taste of both pet and owner. From chic leather designs to whimsical patterns and vibrant colors, the options are limitless. Pet owners take pride in selecting collars that not only complement their pet's appearance but also showcase their individuality. Whether it's a sleek and sophisticated look or a playful and colorful ensemble, there's a pet collar to suit every taste and occasion.

Click here to know more : -

Tales of Adventure: Pet Collars on the Go

Pet collars are more than just accessories; they're essential gear for adventures both near and far. Whether it's a leisurely stroll through the neighborhood or an exhilarating hike in the great outdoors, collars provide a sense of security and safety for pets and their owners alike. With features such as reflective strips, GPS tracking, and built-in LED lights, modern pet collars ensure that furry friends stay visible and protected during any escapade. These collars serve as silent companions, accompanying pets on their journeys and adding an extra layer of assurance for their human counterparts.

Memories Etched in Leather: Personalized Pet Collars

For many pet owners, a personalized collar is more than just a fashion statement; it's a cherished keepsake filled with memories and sentiment. Whether engraved with a pet's name, a special date, or a heartfelt message, personalized collars serve as enduring tokens of love and affection. Each time a pet dons their custom-made collar, it serves as a reminder of the special bond shared with their human companion. These collars become part of the family story, passed down through generations as a testament to the enduring love between pets and their devoted owners.

Conclusion:

In the world of pets, collars are not just accessories; they're symbols of love, companionship, and adventure. From the humble beginnings of leather straps to the personalized, high-tech designs of today, pet collars have evolved into much more than mere adornments. They are storytellers, weaving tales of loyalty, friendship, and unforgettable moments shared between pets and their humans. As we continue to cherish these beloved companions, let us never forget the profound significance of the simple yet powerful pet collar.

Read more : - Wagging Wellness: How Dog Food Affects Overall Health

0 notes

Text

How Fall Protection Airbags Can Help With Workplace Safety

The occupational safety industry keeps evolving advanced solutions preventing workplace accidents. Especially with working from heights risks causing thousands of injuries annually, fall protection gear sees many impactful improvements lately. Here are five of the most promising fall protection equipment breakthroughs protecting employees now.

1. Smart Harnesses

While harnesses traditionally focused solely on catching falls, new models provide additional safeguarding advantages. Modern smart harnesses integrate sensors monitoring suspension time, tug thresholds and ambient conditions during rescues. The data analytics better inform safer work planning and training updates.

Other intelligent harness systems feature built-in tag alarms. Warning notifications activate automatically if nearing unprotected edges or landing in non-upright positions. The audible and vibrating alerts nudge workers away from precarious positioning before falling.

2. Innovative Inflatable Stunt Bag Designs

The Inflatable Stunt Bag has been a game-changer for the film and entertainment industry, providing safer environments for stunts and high-fall scenes. This year's innovations have made them even more versatile and safer:

Improved materials increase durability and impact resistance.

New designs allow for quicker setup and more precise positioning.

They now come in various sizes and shapes, accommodating a wide range of stunts and falls.

These advancements make stunt bags essential for any production or activity where falls are a risk, ensuring safety without hindering performance.

3. Ladder Safety Systems

Extensions ladders comprise over half of falling deaths across occupations as portable ladders see heavy use accessing heights. New ladder safety systems integrate fall prevention and fall arrest technologies, keeping climbers protected.

The systems attach protective sleeves deploying pod airbags alongside rails during loses of balance. Stabilizer mechanisms also prevent ladder bases from kicking out. Sensor-triggered alarms now also alert ground spotters of tipping activity for quicker interventions.

4. Active Warning Wearables

Wearable safety gadgets safeguard workers when distracted or accidentally stepping into danger. Sensor-integrated boots, hats, badges and belts actively warn before nearing unprotected edges. Detecting proximity to openings or markings denoting boundaries, the wearables provide personal alerts through buzzes, flashes or beeps.

These devices provide extra responsive precautions beyond safety officers’ eyes and whistles directing people back to safe positioning.

5. Automated Suspension Recovery

Speedy responses for rescuing fallen workers have also become automated now. Instead of relying on seen accidents or vague check-ins, new harness models detect suspensions themselves. Integrated sensors trigger descent braking and transmit geo-tagged alerts to response teams.

Self-rescue mechanisms also now reposition harness victims to upright postures automatically. This allows moving out of further dangers while awaiting assistance.

The latest fall protection equipment incorporates technological enhancements to prevent more falls while expediting rescue response. To equip your team with the most advanced safety gear, check out i2K’s full range at i2kairpad.com.

Conclusion

The developments in the fall protection equipment this year are major advances in safety at work and during leisure activities. These innovations offer improved safety and comfort in different surroundings, from sophisticated airbag systems to full safety kits. With the changing safety standards, businesses and facilities must be updated on the most recent developments. For those striving to enhance their fall protection systems, i2k AirPad provides a variety of state-of-the-art systems designed to meet the specific requirements of various industries and activities. Through the incorporation of such revolutionary products into your safety measures, you will guarantee a safer environment for all.

0 notes

Text

The Role of Polyester Technical Yarns in Advanced Textile Applications

Introduction

Polyester technical yarns are revolutionizing the landscape of advanced textile applications, offering unparalleled versatility, durability, and performance. As a leading producer of spun polyester yarns in India, SD Polytech is at the forefront of this innovation, driving advancements in various industries and applications. Let's delve into the pivotal role of polyester technical yarns and the contributions of SD Polytech in shaping the future of advanced textiles.

1. Versatility in Applications:

Technical yarns in polyester offer unmatched versatility, making them suitable for a wide range of advanced textile applications. From automotive fabrics and industrial ropes to geotextiles and protective clothing, polyester technical yarns find application in diverse sectors where strength, durability, and reliability are paramount. SD Polytech's extensive range of spun polyester yarns caters to the unique requirements of each industry, providing tailored solutions for specialized applications.

2. Strength and Durability:

One of the key advantages of technical yarns in polyester is their exceptional strength and durability. Engineered to withstand high tensile loads and harsh environmental conditions, these yarns ensure longevity and reliability in demanding applications. Whether used in safety harnesses, conveyor belts, or reinforcement fabrics, polyester technical yarns from SD Polytech offer unmatched strength and durability, enhancing the performance and lifespan of textile products.

3. Performance Enhancement:

Polyester technical yarns play a crucial role in enhancing the performance of textile products across various industries. With their superior mechanical properties and resistance to abrasion, moisture, and chemicals, these yarns improve the functionality and effectiveness of end-use applications. Whether providing structural support in composite materials or enhancing the tear resistance of upholstery fabrics, polyester technical yarns contribute to superior performance and functionality.

4. Innovation in Textile Technology:

The continuous development of polyester technical yarns drives innovation in textile technology, enabling the creation of advanced fabrics and materials with enhanced properties and functionalities. SD Polytech invests in research and development to push the boundaries of textile innovation, exploring new materials, processes, and applications to meet evolving industry demands. By collaborating with customers and industry partners, SD Polytech pioneers breakthroughs in textile technology that pave the way for new possibilities and applications.

5. Sustainable Solutions:

In addition to their performance benefits, technical yarns in polyester offer sustainable solutions for various industries. By optimizing material usage, reducing waste, and improving energy efficiency, these yarns contribute to environmental conservation and resource efficiency. SD Polytech is committed to sustainability across its operations, implementing eco-friendly practices and offering recycled and eco-friendly yarn options to meet the growing demand for sustainable textiles.

Conclusion

In conclusion, polyester technical yarns play a pivotal role in advancing textile applications across industries, offering unparalleled versatility, strength, durability, and performance. As a leading producer of spun polyester yarn producers in India, SD Polytech is committed to driving innovation and excellence in advanced textiles. Through continuous research, development, and collaboration, SD Polytech continues to push the boundaries of textile technology, providing tailored solutions to meet the evolving needs of customers and industries worldwide.

Also Read:

Exploring the Future of Sustainable Textiles: SD Polytech's Role in Eco-Friendly Yarn Production

Exploring Different Types of Yarn Produced in Delhi: From Natural to Synthetic

Originally published at https://sdpolytech.blogspot.com

0 notes

Text

Industrial Automation Solutions – The Dawn of New Industrial Era

In today's rapidly evolving industrial landscape, the demand for increased efficiency, productivity, and safety has led to the widespread adoption of industrial automation solutions. From manufacturing plants to logistics centers, businesses are integrating automation technologies to streamline operations and gain a competitive edge in the market.

Importance of Industrial Automation

The concept of industrial automation revolves around using advanced technologies to automate tasks traditionally performed by humans. This not only reduces human intervention but also minimizes errors and improves overall operational efficiency. With automation, businesses can achieve consistent output quality, lower production costs, and optimize resource utilization.

Evolution of Automation in Industries

Initially, automation was limited to simple mechanical systems, such as conveyor belts and assembly lines. However, with advancements in technology, automation solutions have become more sophisticated, incorporating robotics, artificial intelligence, and data analytics to perform complex tasks with precision and accuracy.

Types of Industrial Automation Solutions

Robotics

Robots play a crucial role in industrial automation, performing tasks ranging from material handling and welding to assembly and packaging. With advancements in robotic technology, modern robots are becoming more versatile, agile, and collaborative, allowing them to work alongside humans in a variety of applications.

Programmable Logic Controllers (PLCs)

PLCs are specialized computers used to control and monitor industrial processes. These programmable devices are designed to withstand harsh industrial environments and can be programmed to execute specific tasks based on input from sensors and other control devices.

Industrial Internet of Things (IIoT)

The IIoT refers to the network of interconnected devices, sensors, and systems used in industrial settings to collect, analyze, and exchange data. By harnessing the power of IIoT, businesses can gain real-time insights into their operations, optimize performance, and proactively address maintenance issues.

Benefits of Industrial Automation Solutions

Increased Productivity

One of the primary benefits of industrial automation is its ability to significantly boost productivity. By automating repetitive and time-consuming tasks, businesses can accelerate production cycles, reduce lead times, and meet customer demands more efficiently.

Cost Reduction

Automation helps businesses minimize operational costs by optimizing resource utilization, reducing labor expenses, and minimizing material wastage. Additionally, automation can lead to energy savings and lower maintenance costs, further contributing to overall cost reduction.

Improved Safety

By replacing manual labor with automated systems, businesses can enhance workplace safety and mitigate the risk of accidents and injuries. Automation solutions are equipped with built-in safety features and protocols to ensure compliance with industry regulations and standards.

Key Components of Industrial Automation Solutions

Sensors and Actuators

Sensors and actuators are essential components of industrial automation systems, enabling machines to interact with their environment and perform specific actions. Sensors gather data from the physical world, while actuators translate control signals into mechanical movement.

Human Machine Interface (HMI)

HMI systems provide operators with a user-friendly interface to monitor and control industrial processes. These interfaces typically consist of touchscreen displays, buttons, and indicators, allowing users to interact with automation systems in real-time.

Control Systems

Control systems play a vital role in regulating and optimizing industrial processes. These systems receive input from sensors, analyze data, and execute control actions to maintain desired operating conditions and achieve performance objectives.

Applications of Industrial Automation Solutions

Industrial automation finds applications across various industries, revolutionizing traditional manufacturing and production processes. Some common applications include:

Manufacturing: Automation streamlines assembly, machining, and packaging processes, improving efficiency and quality.

Automotive Industry: Automation is integral to automotive manufacturing, facilitating tasks such as welding, painting, and assembly.

Food Processing: Automation ensures compliance with food safety standards and enhances product consistency and quality.

Challenges and Considerations

While the benefits of industrial automation are undeniable, businesses must overcome several challenges when implementing automation solutions. These include:

Initial Investment: Automation requires significant upfront investment in equipment, software, and infrastructure.

Workforce Upskilling: Employees need to be trained to operate and maintain automation systems effectively.

Cybersecurity Risks: With increased connectivity comes the risk of cyber threats and data breaches, necessitating robust security measures.

Future Trends in Industrial Automation

As technology continues to advance, the future of industrial automation looks promising, with several emerging trends shaping the landscape:

Artificial Intelligence (AI) Integration: AI-powered automation solutions can analyze vast amounts of data and make intelligent decisions in real-time.

Collaborative Robots (Cobots): Cobots work alongside humans in a shared workspace, enhancing flexibility and productivity.

Edge Computing: Edge computing enables data processing and analysis to be performed closer to the source, reducing latency and improving system responsiveness.

Case Studies of Successful Implementations

Tesla's Automated Manufacturing

Tesla's Gigafactories employ advanced automation solutions to produce electric vehicles and batteries at scale, optimizing production efficiency and quality control.

Amazon's Fulfillment Centers

Amazon utilizes robotics and AI-driven automation in its fulfillment centers to automate order picking, packing, and shipping processes, enabling fast and reliable order fulfillment.

Siemens' Automation Solutions

Siemens offers a comprehensive range of automation solutions for various industries, leveraging IoT, AI, and digital twins to optimize production processes and drive innovation.

Choosing the Right Industrial Automation Solution

When selecting an industrial automation solution, businesses should consider their specific needs, goals, and operational requirements. Key factors to consider include:

Assessing Needs and Goals: Identify areas where automation can bring the most significant benefits and align automation initiatives with strategic objectives.

Integration Capabilities: Ensure compatibility and seamless integration with existing systems and workflows.

Scalability: Choose automation solutions that can scale with growing business demands and adapt to evolving technologies and market trends.

Conclusion

Industrial automation solutions have transformed the way businesses operate, enabling them to achieve higher levels of efficiency, productivity, and competitiveness. By embracing automation, businesses can streamline processes, reduce costs, and unlock new opportunities for innovation and growth.

#automation#labview#technology#software development#industrial automation#robotics#machinery#labviewsoftware

0 notes

Text

Maximizing Efficiency and Safety with Vertex Standard Radio Holster

At its core, the Vertex Standard Radio Holster is more than just a carrying accessory; it's a tool designed to enhance workflow and facilitate seamless communication. Crafted with durable materials and meticulous attention to detail, this holster offers a snug fit for Vertex Standard radios, ensuring they remain securely in place throughout the busiest of shifts.

One of the standout features of the Vertex Standard Radio Holster is its versatility. Engineered to accommodate various wearing preferences, it can be conveniently attached to belts, harnesses, or vests, providing users with flexibility in how they carry their communication device. Whether worn on the hip, chest, or shoulder, the holster allows for quick and easy access to the radio, enabling swift response times in critical situations.

Moreover, the holster's ergonomic design prioritizes both comfort and functionality. Its lightweight construction minimizes strain during extended wear, while strategically placed openings and adjustments ensure a tailored fit for every user. This ergonomic approach not only enhances wearer satisfaction but also contributes to overall productivity by reducing fatigue and discomfort.

Safety is a paramount concern in any professional setting, particularly those characterized by high-risk activities or hazardous environments. The Vertex Standard Radio Holster incorporates several features designed to enhance user safety. Its secure fastening mechanism prevents accidental dislodgment of the radio, even in fast-paced or physically demanding situations. Additionally, reflective accents enhance visibility in low-light conditions, promoting worker safety during night shifts or outdoor operations.

In addition to its practical benefits, the Vertex Standard Radio Holster is built to withstand the rigors of daily use. Engineered with rugged materials and reinforced stitching, it boasts exceptional durability, capable of enduring the bumps, scrapes, and exposure to the elements commonly encountered in industrial settings. This durability translates into long-term cost savings for organizations, as the holster remains reliable and functional over extended periods, reducing the need for frequent replacements.

Furthermore, the Two Way Radio Holster is designed with user convenience in mind. Thoughtful details, such as integrated storage compartments for spare batteries or small tools, add value by providing a designated space for essential accessories. This organizational feature not only streamlines workflow but also ensures that users have everything they need within arm's reach, minimizing disruptions and maximizing efficiency.

0 notes

Text

How To Choose The Right Ladder

When you are working at a certain height, a ladder is the most important thing you should think about as it is your foundation. Choosing the right ladder for the work will ensure the safety of you and the crew on the site. Height must be the first consideration when choosing an aluminum ladder, but you should also pay attention to the type of material used and its rating.

There were 724,000 injuries reported on the site related to the ladder in the year 2010. Ladder safety and training must be enforced on the worksite in order to maintain crew safety.

Choosing The Right Type & Size Of Ladder

While considering whether a ladder can support your weight or not, don’t forget to add the weight of the tools and equipment you will be hauling up there with you. Always check the instructions to determine the maximum working range of each product. For example, a 17-foot aluminum ladder has an approximate standing level of 14 feet.

The top material choices for industrial ladders are aluminum and fiberglass. Aluminum ladders are light in weight so they can be carried very easily. Aluminum ladders can be hazardous near electrical equipment or wire so fiberglass is a better option here.

Light-duty household: 90 kg

Medium-duty commercial: 100 kg

Heavy-duty industrial: 120 kg

Extra-heavy-duty: 135 kg

Super-heavy-duty: 150 kg

Ladder Safety Guide

There are some safety tips, you should keep in mind while working on a ladder

Do not go over-reach when working on a ladder. Come down and move it and be sure to use the right ladder for the work.

Always maintain three points of contact while working on a ladder; usually, both hands and one foot when climbing up and down, and two feet and one hand when working on site.

Always stay two steps down from the top of a step ladder. With an extension ladders, stay four rungs down from the top. The top of your ladder should reach three ft. past the top of your working surface.

Ladders should always maintain a 75 ½ degree angle to the ground surface. The base of the ladder should be 1 ft. away from the job site.

When working with portable or extension ladders, make sure that a minimum of 1 m extends above the platform and always tie off the top at support points.

Working above 3 meters requires workers to wear safety belts or harnesses.

Regularly inspect your ladder for any wear and tear and repair if necessary.

#Ladder Safety#Compact Design#Portable Ladders#Space Saving#Easy Storage#Aluminum Ladders#Lightweight Design#Telescopic Extension#Foldable Ladders#Multi Purpose Ladders#Construction Tools#Safety First#High Quality Ladders#Adjustable Height#Extendable Ladder#Professional Tools#Ergonomic Design#Sturdy Construction#Versatile Ladders#Light duty household#Medium duty commercial#Heavy duty industrial#Extra heavy duty#Super heavy duty

0 notes

Text

Hands-Free Safety Tools: Ensuring Workplace Safety in Houston

Introduction: In the bustling industrial landscape of Houston, Texas, safety is a top priority across workplaces, construction sites, and industrial facilities. With the demand for efficiency and productivity, workers often find themselves juggling multiple tasks simultaneously, increasing the risk of accidents and injuries. Hands-free safety tools emerge as invaluable assets in this environment, offering innovative solutions to mitigate risks and promote a culture of safety. In this blog, we explore the importance of hands-free safety tools in Houston, highlighting their features, benefits, and applications in ensuring workplace safety.

The Significance of Hands-Free Safety Tools: Hands-free safety tools are designed to enable workers to perform tasks without the need for manual intervention, reducing the risk of accidents associated with distractions or compromised balance. These tools offer several key benefits:

Enhanced Safety: By allowing workers to keep their hands free while performing tasks, hands-free safety tools minimize the risk of accidents caused by manual distractions or loss of balance.

Increased Productivity: Hands-free tools streamline workflow processes, enabling workers to complete tasks more efficiently without compromising safety, ultimately boosting productivity.

Improved Ergonomics: Many hands-free tools are ergonomically designed to reduce strain and fatigue on the body, promoting comfort and reducing the risk of musculoskeletal injuries.

Versatility: From wearable devices to automated equipment, hands-free safety tools come in various forms to suit different industries and applications, offering versatility and adaptability.

Applications Across Industries: Hands-free safety tools find applications across a wide range of industries in Houston, including:

Construction: Workers can use hands-free harnesses and tool belts to secure equipment and materials while working at heights or in confined spaces.

Oil and Gas: Hands-free headlamps, communication devices, and personal protective equipment (PPE) enhance safety for workers in offshore rigs, refineries, and drilling sites.

Manufacturing: Automated machinery and robotics enable hands-free operation in manufacturing facilities, reducing the risk of accidents during production processes.

Healthcare: Hands-free medical devices and assistive technologies help healthcare professionals perform procedures and tasks safely and efficiently.

Key Hands-Free Safety Tools:

Wearable Harnesses and Belts: Designed to secure tools, equipment, and materials, allowing workers to keep their hands free while working at heights or in hazardous environments.

Headlamps and Lighting Solutions: Hands-free lighting solutions enable workers to illuminate work areas without the need for handheld flashlights or lamps, enhancing visibility and safety.

Communication Devices: Hands-free communication devices such as headsets and earpieces enable workers to maintain communication with colleagues or supervisors while performing tasks.

Automated Equipment: Robotics and automated machinery enable hands-free operation in manufacturing and industrial settings, reducing the need for manual intervention and minimizing risks.

Conclusion: Hands-free safety tools play a pivotal role in promoting workplace safety and productivity in Houston's dynamic industrial landscape. By equipping workers with innovative solutions that enable them to perform tasks safely and efficiently, organizations can create safer work environments, prevent accidents, and uphold the highest standards of safety and compliance.

Final Call to Action: Explore our comprehensive range of hands-free safety tools and discover the solutions that can enhance safety and productivity in your workplace. Contact us today to learn more about how hands-free tools can help you achieve your safety goals and protect your workforce in Houston and beyond.

0 notes

Text

Pet Accessories: Enhancing Comfort, Style, and Well-being

Pet accessories play a crucial role in providing comfort, style, and well-being to our beloved animal companions. From collars and leashes to grooming tools and travel accessories, these items are essential for ensuring the health and happiness of our pets. In this article, we'll explore the world of pet accessories, discussing their types, benefits, trends, and even DIY options.

Types of Pet Accessories:

Collars and Leashes:

Collars serve as identification and can be fashionable.

Leashes ensure control and safety during walks.

Beds and Blankets:

Provide a cozy spot for resting and sleeping.

Offer warmth and comfort, especially during colder months.

Toys and Chewables:

Keep pets entertained and mentally stimulated.

Aid in dental health by promoting chewing.

Clothing and Costumes:

Protect pets from the elements.

Allow for style expression and fun during special occasions.

Grooming Tools:

Brushes, combs, and nail clippers help maintain hygiene.

Ensure the pet's coat and skin remain healthy and clean.

Travel Accessories:

Carriers and crates ensure safe transportation.

Travel bowls and water bottles keep pets hydrated on the go.

Feeding Accessories:

Bowls and feeders come in various sizes and designs.

Elevated feeders promote better posture during meals.

Safety Gear:

Reflective vests and LED collars enhance visibility during nighttime walks.

Seat belts and harnesses secure pets during car rides.

Choosing the Right Pet Accessories:

When selecting pet accessories, it's essential to consider factors such as the pet's breed, size, preferences, quality, durability, and budget. Assessing these aspects ensures that the chosen accessories meet the pet's needs and provide long-term value.

Benefits of Using Pet Accessories:

Using pet accessories offers numerous benefits, including enhancing comfort and well-being, promoting physical and mental stimulation, facilitating training and behavior management, and strengthening the bond between pet and owner. Investing in high-quality accessories contributes to the overall happiness and health of our furry friends.

Trends in Pet Accessories:

The pet accessory industry is constantly evolving, with emerging trends such as sustainable and eco-friendly options, tech-enabled accessories for tracking and monitoring, personalized and customizable products tailored to individual pets, and fashion-forward designs inspired by human trends.

DIY Pet Accessories:

For pet owners who enjoy crafting and DIY projects, creating homemade toys and treats, crafting pet clothing, and even making grooming tools can be rewarding and cost-effective alternatives to store-bought options. DIY pet accessories allow for customization and creativity while catering to the specific needs and preferences of the pet.

Caring for Pet Accessories:

To prolong the lifespan of pet accessories, regular cleaning and maintenance are essential. Proper storage helps prevent damage from moisture, sunlight, and pests, while timely replacement of worn-out items ensures continued comfort and safety for the pet.

1 note

·

View note

Text

Safety Harnesses With lanyards Manufacturers

A safety harness is a personal protective equipment that is worn by a worker to help prevent falls from heights. It consists of a harness that is worn around the torso and a lanyard that is attached to the harness and is used to anchor the worker to a fixed point. The lanyard is a flexible line of rope, wire, or webbing that is used to secure the worker to the anchor point. Safety harnesses with lanyards are commonly used in construction, utility work, and other industries where there is a risk of falling from heights. They are an important part of fall protection systems and are designed to help protect workers from serious injury or death in the event of a fall.

Our safety harnesses are made of premium webbing and have a hook-and-loop adjustment system for quick, easy adjustment. The quick-connect buckles make it easy to put on and take off so you can stay safe and at work quickly.

Safety harnesses are used to secure employees working above or below ground level on construction projects. It is vital that these safety belts be properly used, inspected and maintained. It is often a requirement of OSHA (Occupational Safety and Health Administration) that all workers wear safety harnesses at all times.

0 notes

Text

Reaching New Heights Safely: Australian Standards for Working at Heights

In Australia, where numerous industries involve tasks conducted at elevated positions, the significance of adhering to strict safety standards for working at heights cannot be overstated. Committed to ensuring the well-being of workers and minimizing occupational hazards, Australian Standards have been established to govern practices in various workplaces where employees are exposed to elevated work environments.

AS/NZS 1891 Series: A Comprehensive Framework for Height Safety

The primary standard governing working at heights in Australia is the AS/NZS 1891 series, developed jointly by Standards Australia and Standards New Zealand. This series comprises several standards, each addressing specific aspects of height safety, equipment, and practices.

1. AS/NZS 1891.4: Selection, Use, and Maintenance of Industrial Fall Arrest Systems and Devices:

This standard outlines the criteria for selecting, using, and maintaining fall arrest systems. It covers aspects such as anchorages, connectors, and full-body harnesses, providing guidelines for ensuring the reliability and effectiveness of equipment designed to prevent falls.

2. AS/NZS 1891.1: Industrial Fall Arrest Systems and Devices - Safety Belts and Harnesses:

Focusing specifically on safety belts and harnesses, this standard details the design, construction, and performance requirements for these critical pieces of personal protective equipment. Compliance with this standard ensures that workers are equipped with gear that meets rigorous safety criteria.

3. AS/NZS 1891.2: Horizontal Lifeline and Rail Systems:

For situations where a horizontal lifeline or rail system is employed for fall arrest, this standard provides guidelines for their selection, installation, use, and maintenance. It ensures that these systems are configured to provide reliable protection for workers across horizontal surfaces.

4. AS/NZS 1891.3: Fall Arrest Devices:

This standard delves into fall arrest devices, offering specifications for their design, construction, and performance. It covers a range of devices, including energy absorbers, lanyards, and self-retracting devices, providing a comprehensive guide for their proper use.

5. AS/NZS 1891.4: Industrial Fall-Arrest Systems and Devices - Selection, Use, and Maintenance:

Addressing the broader spectrum of fall-arrest systems and devices, this standard provides a framework for their selection, usage, and maintenance. It serves as a comprehensive guide for employers and workers to ensure that the entire system is in compliance with safety requirements.

Compliance and Implementation in the Workplace:

Australian businesses and organizations conducting work at heights are legally obligated to comply with the AS/NZS 1891 series. By adhering to these standards, employers not only prioritize the safety of their workers but also demonstrate their commitment to meeting regulatory requirements.

Employers must ensure that workers are adequately trained in working at heights and the proper use of associated equipment. Periodic inspections, maintenance, and record-keeping are integral components of compliance, guaranteeing that safety measures are consistently upheld.

Benefits of Adherence to Standards:

Adhering to Australian Standards for working at heights brings about several benefits, including:

Enhanced Safety: Compliance with these standards directly contributes to a safer working environment, reducing the risk of accidents and injuries.

Legal Compliance: Businesses that adhere to the standards meet legal obligations, protecting themselves from regulatory penalties and legal consequences.

Worker Confidence: Employees working at heights with compliant equipment and practices have increased confidence in their safety, leading to improved morale and productivity.

Reduced Liability: Following safety standards reduces the risk of workplace incidents, subsequently minimizing liability for employers.

In conclusion, working at heights in Australia is governed by a comprehensive set of standards designed to ensure the safety of workers. Adhering to these standards not only guarantees legal compliance but also fosters a culture of safety and responsibility, creating a workplace where employees can carry out their tasks with confidence and security.

0 notes

Text

Global Fall Protection Equipment Market Analysis 2024 – Estimated Market Size And Key Drivers

The Fall Protection Equipment Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Fall Protection Equipment Market:

https://www.thebusinessresearchcompany.com/report/fall-protection-equipment-global-market-report

According to The Business Research Company’s Fall Protection Equipment Global Market Report 2024, The fall protection equipment market size has grown strongly in recent years. It will grow from $3.12 billion in 2023 to $3.35 billion in 2024 at a compound annual growth rate (CAGR) of 7.4%. The growth in the historic period can be attributed to economic development, risk management strategies, workplace safety regulations, industrialization and construction boom, urbanization and infrastructure projects..

The fall protection equipment market size is expected to see strong growth in the next few years. It will grow to $4.52 billion in 2028 at a compound annual growth rate (CAGR) of 7.8%. The growth in the forecast period can be attributed to expanding market opportunities, emphasis on comfort and usability, shift towards prevention, industry-specific requirements, environmental and sustainability concerns.. Major trends in the forecast period include industry digitization and automation, remote monitoring and management, worker-centric approach, global health and safety standards, sustainability and eco-friendly solutions.

Rising construction and renovation activities are expected to boost the growth of the fall protection equipment market going forward. Construction is the process of building, altering, improving, repairing, remodeling, or demolishing an infrastructure facility. The construction industry in general is struggling with an extensive number of accidents and a high fatality rate. Fall protection and prevention systems are crucial for worker security, particularly in the construction sector. It is the employer's responsibility to avoid falls in the construction sector. The surge in construction and renovation activities is driving the fall protection equipment market. For instance, in February 2022, according to the report published by the Office for National Statistics, a UK-based administrative office of the United Kingdom Statistics Authority, the annual construction sector rose by a record 12.7% in 2021 compared to the previous year. In December 2021, the volume of monthly construction output climbed by 2.0%; this was entirely due to a rise in new work (3.5%). In addition to the monthly rise, the construction industry's quarterly production climbed by 1.0% in Q4 2021 compared to Q3. This increase was driven by both new work (1.1%) and repair and maintenance (0.8%). Therefore, the rising construction and renovation activities are driving the growth of the fall protection equipment market.

Get A Free Sample Of The Report (Includes Graphs And Tables):

https://www.thebusinessresearchcompany.com/sample.aspx?id=8495&type=smp

The fall protection equipment market covered in this report is segmented –

1) By Type: Soft Goods, Hard Goods, Rescue Kits, Body Belts, Full Body Harness, Other Types

2) By Product: Anchors And Connectors, Bodywear, Devices, Other Products

3) By End-Use Industry: Construction, Telecom, Energy And Utility, Transportation, Mining, Marine, Other End-Use Industries

Major companies operating in the fall protection equipment market are developing innovative products such as self-retracting lifelines to meet larger customer bases, more sales, and increase revenue. A self-retracting lifeline (SRL) refers to a safety device used in fall protection systems to prevent or arrest falls from heights. For instance, in January 2023, Guardian, a US-based height safety specialist, launched fall protection products consisting of a new customization station, self-retracting lifelines, anchor additions, and the B7 comfort harness. The innovative online tool for product customization and request processing empowers customers to personalize full-body harnesses for workers, incorporating their company's colors and logo. This customization not only supports branding but also enhances safety, visibility, and control on job sites. Guardian's self-retracting lifelines (SRLs) surpass forthcoming compliance standards with features such as increased static and dynamic strength, thicker cables, and robust shock packs. Additionally, three new anchor products expand Guardian's height safety offerings. The B7-Comfort Harness, born from over a year of end-user research and trials, boasts patented features, a heavy-duty industrial design, precision adjustment, breathable padding, and 360-degree hip mobility hardware, making it exceptionally suitable for demanding conditions.

The fall protection equipment market report table of contents includes:

Executive Summary

Market Characteristics

Market Trends And Strategies

Impact Of COVID-19

Market Size And Growth

Segmentation

Regional And Country Analysis

.

.

.

Competitive Landscape And Company Profiles

Key Mergers And Acquisitions

Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes