#Ladder Safety

Text

#Somewhere an OSHA handbook just burst into flames#Workplace Safety#Ladder Safety#Funny#construction#Construction Safety

14 notes

·

View notes

Text

How A Ladder Can Make Your Work Easier

A ladder is a set of rungs or steps. There are two variants of the ladder: rigid ladders which are self-supporting and that may be leaned against a vertical surface such as a wall, and aluminum which may be hung from the top. Rigid ladders are generally moveable, but some types are permanently fixed to a building. They are usually made up of metal, wood, and fiberglass, but they have been known to be made of tough plastic.

Ladders are the most wanted love of every housewife. Either it is to clean spider houses or to make your child like a monkey. Every housewife loves it. And for men, it plays the role of lifesaver to climb it and find their long-lost files. The ladder plays a very crucial role in every house. Not just only in the houses but also in shops too. Ladders have all the capacity to make you go from zero to hero.

Aluminum Ladders

Aluminum is the most well-liked choice for ladders used in households because the leading features of aluminium ladders are that they have a high strength-to-weight ratio which makes an aluminum model easy to transport and store as well as less expensive to produce than ladders which made from other materials. Aluminum products, such as ladders, may weigh up as much as 50% less.

Folding Ladders

A folding ladder is a ladder that is in the form of the step ladder style with one or more but generally not more than three that’s one-way hinges. For this ladder, Storage is not a problem as it is packed together once folded and be able to be easily stowed away. You can use this on rough surfaces such as a flight of stairs. As this type of ladder is lightweight, this is extremely moveable and suitable to use.

Telescopic Ladder

Telescoping ladders are a more versatile, moveable, and convenient form of the traditional ladder. As opposed to a typical adjustable ladder and extension ladder, this ladder used patented technology to extend and lock by the foot to a user's desired height, making them enormously versatile. This is convenient to store which is due to their compact nature. This is less vulnerable to the elements which are partially due to storage, and partially due to their makeup. This is lightweight because of that it is easily carried and transported. This is highly versatile which is appropriate for several jobs. This has high safety standards which are due to the sturdy build.

Multipurpose ladder

Multipurpose ladders are versatile and can be used for any purpose. It can be changeable and adjustable into a variety of positions according to how users want to use it. Users can use them as a step ladder, low platform, workbench, and an extension ladder with standoff (L-shaped bend), and that’s all in one single ladder which is an easily stored package. We can use it as the single solution for all our ladder requirements as it is very easily adjustable to any type of ladder. It is cost-effective as it eliminates the need to buy a variety of ladders for different purposes. It reduces space requirements for storage as you can buy only a single ladder and as well as you can fold multi-purpose ladders, make them compact and convenient to move at the same time.

The most common household ladders that are used for home purposes are step-ladders in which aluminum ladders are very strong and that’s why the most preferred choice for home purposes. Ladders made up of aluminum are lightweight and non-corrosive

Different kinds of industrial ladders are used for various applications. Most industrial ladders are made up of metal because they are required to be durable. Aluminum ladders become very popular because they are lighter in weight as compared to steel ladders and that is also not affected by corrosion. Some of the commonly used industrial ladders are step ladders, extension ladders, folding ladders, and platform ladders.

In my opinion, ladders are the most useful, sensible, and most importantly motivational things a person could ask for. It gives you a light, a light of path for your journey.

Quality that we all desire and it can become from those who are experienced in their work. So here for you EQUAL in which the name itself expresses the right one. EQUAL is a solution provider based in Jaipur, Rajasthan. It is one of the leading manufacturers in India. With Experience of 20+ years, EQUAL provides high-quality Ladders all over India at the best price. It designs ladders that are made from stainless steel and aluminum. Its ladders are durable and cost effective and they meet all the safety regulations.

#Equal#Ladder Safety#Compact Design#Portable Ladders#Space Saving#Easy Storage#Aluminum Ladders#Lightweight Design#Telescopic Extension#Foldable Ladders#Multi Purpose Ladders#Construction Tools#Safety First#High Quality Ladders#Adjustable Height#Extendable Ladder#Professional Tools#Ergonomic Design#Sturdy Construction#Versatile Ladders

2 notes

·

View notes

Text

Ladder Safety

Ladder safety is a crucial topic for both professionals and DIY enthusiasts. This article will delve into the best practices for ladder use and why adhering to these guidelines is vital for preventing accidents and ensuring safety.

The Basics of Ladder Safety

When it comes to ladder safety, the importance of selecting the right ladder for your specific task cannot be overstated. The first step…

View On WordPress

#Accident Prevention#fall prevention#health and safety#home safety#ladder inspection#ladder maintenance#ladder safety#ladder types#Personal Protective Equipment#safe ladder use#safety equipment#safety guidelines#safety protocols#Safety Training#Workplace Safety

2 notes

·

View notes

Text

Discover new requirenent for new lorry crane to be installed with stability control system here http://wshsingapore.blogspot.com/2024/07/new-lorry-crane-stability-system.html?m=1

#fyp#safety wsh#workplace safety#electrical safety#safety#youtube#ladder safety#workplace fire safety#risk#lorry crane

0 notes

Text

Beginner Guide to Roof Safety Systems:

There is a wealth of information on roof safety systems, varying in quality, from articles produced by AI to beautifully written articles from experts in the field. Ensuring your safety and the safety of your employees is of the utmost importance. So, from the myriad of articles, how do you know how to trust? While we provide some critical points on roof safety, it's crucial to remember that your safety is best ensured by reaching out to professionals in the field of roof safety systems. Most will provide free consultations and are available to answer any questions you may have, guiding you towards the best safety solutions for your specific needs.

So, without further ado, let's dive in!

Introduction to Height Safety Systems

Height safety systems are essential for workers' safety. These mechanisms and procedures are designed to prevent falls and ensure the safety of workers operating at elevated heights. Height safety systems are crucial across various industries, including construction, maintenance, roofing, and any sector where tasks are performed above ground level.

Importance in Various Settings:

Construction: Construction workers frequently operate at significant heights, making them vulnerable to falls. Height safety systems like roof anchor points, ladder brackets, guardrails, safety nets, and personal fall protection equipment (PFPE) are critical to prevent accidents and fatalities.

Maintenance and Roofing: Regular maintenance and roofing tasks often require workers to access high areas. Roof anchor points, lifelines, and ladder brackets help ensure these workers are secure and can perform their duties safely.

Industrial and Warehousing: In industrial settings, platforms, elevated walkways, and storage areas pose fall risks. Implementing height safety systems, such as guardrails and harnesses, helps protect workers in these environments.

Types of Height Safety Systems:

Personal Fall Protection Equipment (PFPE): This includes a wide range of gear, such as harnesses, lanyards, and lifelines, that workers wear to prevent falls, catering to different work environments and tasks.

Collective Protection: Systems like guardrails and safety nets that protect multiple workers simultaneously without requiring personal gear.

Access Equipment: Ladders, scaffolding, and roof access hatches provide a safe way to reach elevated work areas.

To understand how they work, let's examine each main component of height safety systems more closely.

Personal Fall Protection Equipment (PFPE)

Personal Fall Protection Equipment (PFPE) includes essential gear such as harnesses, lanyards, and lifelines that workers wear to prevent falls. These items are designed to secure an individual directly, providing critical support and minimising the risk of injury during a fall. Remember, properly using PFPE is not just a requirement; it's a responsibility. Maintaining safety standards and ensuring workers can securely perform their duties at elevated heights is vital.

Guardrails

Guardrails are collective protection systems designed to prevent falls by creating physical barriers at the edges of roofs, platforms, and walkways. They are crucial for protecting multiple workers simultaneously without needing individual gear. By installing guardrails, employers can significantly reduce the risk of falls and enhance overall safety in areas where workers are frequently exposed to height-related hazards.

Safety Nets

Safety nets are another form of collective protection designed to catch workers in the event of a fall. These nets are typically installed below the working area and provide a crucial safety measure, especially in construction and maintenance scenarios where the risk of falling is high. Safety nets help to prevent severe injuries by absorbing the impact of a fall, ensuring that workers have an additional layer of protection while performing their tasks at height.

Ladder Brackets

Working with ladders is a dangerous task. In Australia, on average, 30 people lose their lives each year from falling from a ladder. Falls from ladders account for the highest number of fatalities in height safety-related incidents, with half of the falls from less than 3 meters, resulting in death. This stark reality should be a powerful reminder of the potential risks involved when working at heights, the underscoring urgency and importance of professional consultation and proper safety systems.

Ladder brackets reduce the risk of working with ladders by preventing slippage and movement, thus eliminating the need for a second person to stabilise the ladder's base. They also allow workers to access a roof safely.

Roof Access Hatches

Roof access hatches provide a secure and easy access point to the roof from inside the building, especially for tall buildings where ladder access is difficult or impossible. They are generally the safest way to access a roof, significantly reducing the risk of falling by removing the need to climb ladders, as they can usually be accessed via a staircase. This reassurance of safety should alleviate any concerns about roof access.

These hatches are typically found in non-residential buildings such as hospitals, office buildings, warehouses, commercial centres, and larger apartment buildings.

For optimal safety, a roof anchor point should be placed within one meter of the access hatch so workers can securely connect their harnesses before stepping onto the roof.

Roof Anchor Point

A roof anchor point is precisely what the name suggests: a point on a roof to which you can attach yourself with a lifeline or lanyard. There are multiple types, but generally, they fall into two types:

Fall restraints: Prevent the user from getting close enough to the edge to fall, removing the possibility of falling.

Fall arrest: Minimise injury during a fall, stopping the user from hitting the ground.

A wide range of roof anchor points are available to suit every type of roof, whether it's tiles, terracotta, concrete, slate, iron, Colorbond® steel, or metal sheeting. This variety lets you choose the most suitable anchor point for your specific roof type, ensuring the user's safety.

Roof anchor points are divided into two main groups: temporary and permanent. Of course, both have their specific uses. Each group includes various types of anchor points, such as concrete-mounted, rafter-mounted, steel-fit, eye bolts, rail systems, I-beam, metal decking, parapet, and speciality anchors. Understanding these categories and types helps you decide on the most suitable anchor point for your needs.

However, temporary roof anchor points should be used in particular circumstances, such as a building site where walls are being placed, and they will no longer be needed in the short term.

A key feature of modern anchor points is energy absorption. These are designed to cushion a fall, reducing the risk of injury and preventing roof damage from the kinetic force of a fall. An example of this would be the Froglink roof anchor from SafetyLink, whose unique design slows you down before coming to a complete stop.

Froglink by SafetyLink

How many anchor points should I have on my roof?

Finding the correct installation points on a roof is vital to creating a height safety system that complies with all necessary legislation and offers an easy-to-use system.

Roof anchor points guidelines provide an idea of how many anchor points you will need:

Distance from Roof Edge: Never place an anchor over 10 meters from the roof edge. Otherwise, the user will require a rope line longer than the standard 15 meters, which will be overly cumbersome.

Spacing Between Anchors: Never leave more than 6 meters between anchor points. Greater distances create dead zones at the roof edge, increasing the fall risk.

Main Anchor Point Placement: The main anchor point should always be placed at the midpoint between the gutter edge and the gable end of the roof.

Every roof is different and requires a unique safety system to ensure all workers are safe and legally compliant. While it's good to know about roof anchor points, under Australian legislation, roof anchor points must be certified and recertified by professionals yearly. To avoid issues in the future, it is best to consult a professional installer. A good installer will also know how and where to install anchor points, achieving full coverage with minimal anchors.

When Must Height Safety Systems Be Used?

The Work Health & Safety (WHS) legislation (act 2011, compilation 15) requires employers to provide a safe working environment. Therefore, as far as is practical, they must implement a safety system for everyone on the worksite.

Who Can Install Height Safety Systems?

The Australian Standards AS/NZS 1891.4 states that anchor points, horizontal and vertical static lines, lifelines, and rails used for fall protection or when working at heights must be inspected and certified every 12 months. This requirement ensures the equipment remains in good working order and compliant with safety regulations. Regular inspections help prevent equipment failure and ensure the safety of workers using these systems.

Only qualified installers can install, inspect, and certify height safety systems. But if you are working on a high roof, wouldn't you be more comfortable knowing that a professional rather than a DIYer has installed the safety system?

Training & Competency

Proper training is also essential for workers who use height safety systems; if the tools are there but no one knows how to use them, they are worthless. Training programs should cover the correct use of personal fall protection equipment (PFPE), emergency procedures, and the specific safety protocols relevant to the work environment. Accredited training providers offer courses tailored to various industries and work scenarios. This is not a one-time thing; training should be refreshed regularly, typically every 12 months, to ensure that workers remain competent and up-to-date with the latest safety practices and regulations. It also helps workers not to be complacent; when people work at heights for a long time, they tend not to see the dangers anymore. Continuous training helps to reinforce safety awareness and skills, reducing the risk of accidents and ensuring compliance with legal requirements.

Summary & Key Takeaways

Height safety systems protect workers from falls in various industries. Key components include personal fall protection equipment (PFPE), guardrails, safety nets, ladder brackets, roof anchor points and roof access hatches. It is essential to understand the importance of regular maintenance and inspections, which should be conducted annually to ensure compliance and safety. Proper training and competency are crucial, with training programs needing regular refreshments to maintain high safety standards. Adhering to these practices ensures a safe working environment and aligns with legal requirements and best practices in height safety management. Always consult professional installers and safety experts to achieve optimal coverage and compliance with all necessary legislation.

#health and safety#working at heights#sydney#anchor points#roof anchor points#ladder safety#safety tips#informative

0 notes

Text

How To Inspect Your Ladder Before You Use It

Have you ever climbed a ladder only to realize it wasn't as sturdy as you thought? We've all been there, but fear not! We've all heard the advice: inspect your ladder before use. But let's be honest, how often do we really know what that means? We never delve deep into understanding what and how we should inspect it in the right way before giving it a go.

In this article, we're going to deep dive into the important steps you need to take before using your ladder. Whether you're using it for home repairs or in professional settings, such as industrial environments, checking your ladder before use is non-negotiable. But ensuring the correct method of inspection is far more critical than anything else. Let's explore together and ensure your climb is as safe as can be!

Contents:

Introduction: How right inspection can minimize the risk of accidents

A pre-use ladder check should be carried out

Essential Inspection Points

Introduction

Before you begin any task involving a ladder, make sure you have the manufacturer's user instructions handy for reference. These instructions are essential if you need guidance on how to use the ladder correctly.

Next, do a quick "pre-use" check to ensure the ladder is safe to use. Look for any obvious visual defects like cracks, bends, or missing parts. Pay attention to the rungs, rails, and locking mechanisms for signs of damage.

Also, check for dirt, debris, or anything that could cause slipping. It's important to keep the ladder clean and free from obstructions.

By following these steps, you can minimize the risk of accidents and create a safer working environment. Always prioritize safety when using ladders.

Article: Your Guide to Ladder Safety: Dos and Don'ts You Should Know

A Pre-use Ladder Check Should Be Carried Out:

• By the user; It's important that the user takes the initiative to conduct the pre-use check. After all, they're the ones who will be relying on the ladder for support and safety during their work tasks.

• At the beginning of the working day; Performing the check at the beginning of the working day sets a proactive tone for safety. It ensures that any issues or concerns with the ladder are addressed before it's put into use, reducing the risk of accidents or injuries later on.

Article: How to Prevent Falls From Ladders

• After something has changed, eg a ladder has been dropped or moved from a dirty area: Anytime something changes in the environment surrounding the ladder, a reevaluation is necessary. Whether the ladder has been dropped, moved from one area to another, or exposed to different conditions, it's essential to inspect it for any potential damage or hazards.

For example, if the ladder has been moved from a dirty area to a clean one, checking the condition of the feet becomes particularly important as they may have picked up debris or become compromised in some way during the transfer. By adhering to these points and making pre-use ladder checks a standard practice, users can significantly enhance workplace safety and minimize the risk of accidents or injuries while working at height.

Article: Which Standard to be Followed for Ladder Safety

Essential Inspection Points:

In your ladder inspection checklist, it's crucial to pay close attention to several key areas. Here's a breakdown of what you should be looking for:

1. Stiles: Check that the ladder's side rails, known as stiles, are straight and free from any bends or damage. Bent or damaged stiles could lead to the ladder buckling or collapsing under your weight.

2. Feet: Inspect the ladder's feet to ensure they are present, not worn, and undamaged. If the feet are missing or in poor condition, the ladder may slip, leading to accidents. Pay particular attention when transitioning from soft or dirty ground to a smooth, solid surface to ensure proper footing.

3. Rungs: Examine each rung of the ladder for signs of bending, wear, or damage. Bent, worn, missing, or loose rungs can compromise the ladder's integrity, increasing the risk of failure.

Article: Top Guidelines for Safely Using an Extension Ladder

4. Locking Mechanism: Test the locking mechanism to verify its functionality. Look for any signs of bent, worn, or damaged components or fixings. A faulty locking mechanism could result in the ladder collapsing, so ensure all locking bars are fully engaged before use.

5. Stepladder Platform: If you're using a stepladder, carefully inspect the platform for any signs of splitting or buckling. A compromised platform could make the ladder unstable or prone to collapse.

Article: Why FRP Ladder is Better Than Aluminium Ladder?

6. Steps or Treads on Stepladders: Check the steps or treads on Stepladders for contamination that could make them slippery. Additionally, ensure that the fixings securing the steps are tight to prevent collapse.

Remember, if you identify any of these defects during your inspection, do not use the ladder and promptly inform your employer. Prioritizing safety during ladder checks is essential for preventing accidents and injuries.

Get Your FREE Ladder Safety Checklist -> Download

Conclusion

In a nutshell, guaranteeing the safety of ladder use starts with a detailed inspection. Users can significantly lower the risk of accidents and injuries by identifying the key things to consider before usage. From testing for structural integrity to analyzing stability, each stage in the pre-use ladder inspection is critical to maintaining safety requirements.

Article: 5 Points to Consider Before Buying Telescopic Ladders

Neglecting these inspection points might lead to unsafe conditions with serious repercussions. As a result, users must include this crucial activity in their daily routine before using a ladder. Finally, prioritizing ladder inspection not only protects individuals but also builds a culture of safety in the workplace and beyond. Remember, a few minutes of review can save a lifetime of regret.

Buy Youngman Ladders

If you are looking for a ladder to prioritize safety, then check Youngman Manufacturing's range of ladders. Our products are designed to provide superior protection while ensuring maximum durability and longevity. Don't compromise on safety, choose Youngman Manufacturing for all your ladder needs. Reach out to us at: [email protected] or call: +91-9015964626

#ladder#youngman manufacturing#work at height safety#youngman india#safety#ladder safety#ladder inspection#ladder inspection guide

0 notes

Text

Step Up to Safety: A Comprehensive Guide to Step Ladder Use

Step ladders are a household staple, offering a quick and easy way to reach those out-of-reach areas. However, their seemingly simple design can mask potential hazards. Every year, thousands of people visit emergency rooms due to step ladder-related falls. This guide delves into the safe use of step ladders, empowering you to tackle tasks confidently and safely.

Understanding Your Step Ladder

Types of Step Ladders:

Single Step Ladder: A basic design with a narrow profile, ideal for minor height increases.

Double Step Ladder: Features two platforms, providing more height access.

Step Ladder with Platform: Includes a wider platform at the top for increased stability when working for extended periods.

Multi-Position Ladder: Offers multiple configurations, including step ladder and leaning ladder options. Ensure all locking mechanisms are secure before use in any configuration.

Anatomy of a Step Ladder:

Steps: The flat surfaces you stand on to ascend and descend. Look for slip-resistant treads.

Rails: Vertical supports you grasp for balance while climbing.

Spreaders: Horizontal bars at the base that stabilize the ladder when open. Ensure they are fully locked before use.

Top Cap/Platform: The uppermost flat surface of some step ladders. Not all step ladders are designed for standing on the top cap.

Weight Capacity: Every step ladder has a maximum weight limit. Never exceed this limit for your safety. The weight capacity is typically labelled on the spreader or rails of the ladder.

Safe Set-Up and Use

Setting Up Your Step Ladder:

Choose the Right Ladder: Select a step ladder with the appropriate height to reach your desired work area. Avoid overreaching.

Find Level Ground: Place the ladder on a flat, stable, and slip-resistant surface. Uneven surfaces can cause the ladder to wobble and tip over. Avoid using the ladder on carpets or rugs, as they can bunch up and compromise stability.

Open the Spreader Locks: Ensure the spreader bars at the base are fully extended and locked securely. A loose or unlocked spreader can cause the ladder to collapse.

Inspect the Ladder: Before each use, check the ladder for any cracks, loose parts, or damaged steps. A compromised ladder can be a serious safety hazard.

Safe Climbing Practices:

Maintain Three Points of Contact: Always maintain three points of contact with the ladder – two hands and a foot, or two feet and a hand. This provides better balance and reduces the risk of falls.

Face the Ladder: Ascend and descend the ladder while facing it. This allows you to see where you are placing your feet and maintain a firm grip on the rails.

Use the Rails: Keep a firm grasp on the rails while climbing or descending. Never climb with tools or materials in your hands. Use a tool belt or hoist materials separately.

Center Your Body: Stay close to the center of the ladder to avoid tipping it over.

Don't Climb Too High: Most importantly, never stand on the top two steps of a step ladder unless it's specifically designed for that purpose. These steps are often smaller and less stable than the lower steps. If you need more height, consider using a different type of ladder or scaffolding.

Additional Safety Tips:

Don't Lean the Ladder: Step ladders are designed to be free-standing. Never lean a step ladder against a wall or other object for support. This can cause the ladder to slip and collapse.

Secure the Work Area: If working near a doorway or walkway, barricade the area to prevent others from bumping into the ladder.

Be Aware of Electrical Hazards: Avoid using a metal step ladder near power lines or electrical equipment.

No Buddy Boosting: Don't use a step ladder as a platform for two people. The ladder's weight capacity is designed for a single person.

Step Ladder Maintenance

Regular Inspections: Inspect your step ladder regularly for any signs of damage, such as cracks, loose rivets, or bent parts. Discard a damaged ladder and replace it with a safe one.

Cleaning: Keep your step ladder clean by wiping it down with a damp cloth. Avoid using harsh chemicals or abrasive cleaners.

Proper Storage: When not in use, store your step ladder in a dry, protected location away from extreme temperatures.

When to Replace Your Step Ladder

Here are some signs that your step ladder may need to be replaced:

Cracks or splits in the rails or steps

Loose rivets or bolts: Over time, the connections on a step ladder can loosen. Check for any loose rivets, bolts, or screws at the connection points between the steps, rails, and spreaders. A loose connection can compromise the ladder's sturdiness.

Bent or deformed parts: Even a minor bend in a step or rail can significantly weaken the ladder's integrity. Inspect the ladder for any bent, warped, or dented parts.

Missing or damaged feet: The slip-resistant pads on the bottom of the legs are crucial for stability. Replace any missing or worn-down feet to prevent the ladder from slipping.

Difficulty locking or unlocking the spreaders: The spreaders need to lock securely to keep the ladder stable. If you have trouble locking or unlocking the spreaders, it's a sign that the mechanism may be damaged and the ladder should not be used.

Corroded or rusted metal components (for metal ladders): Metal ladders can develop rust over time, especially if stored in humid conditions. Rust weakens the metal and can lead to cracks or breaks. Inspect for any signs of corrosion and replace the ladder if necessary.

Worn or damaged treads: The steps (treads) should be slip-resistant and in good condition. Replace any treads that are cracked, grooved, or worn smooth, as they can increase the risk of slipping.

Paint or stickers (excluding warning labels): Thick layers of paint or added stickers can obscure cracks or other damage on the ladder. Avoid painting your ladder and remove any non-essential stickers.

If you notice any of these signs, it's best to err on the side of caution and replace your step ladder. A damaged ladder is a safety hazard and can lead to serious injuries.

Advanced Step Ladder Techniques (For Specific Ladder Types)

While the core safety principles apply to all step ladders, some advanced techniques come into play with specific ladder types:

Step Ladders with Platforms:

Platform Use: These ladders feature a wider platform at the top, designed for standing and working for extended periods.

Exiting the Platform: When exiting the platform, always face the ladder and use a three-point contact to descend safely. Never step off the back of the platform.

Multi-Position Ladders:

Locking Mechanisms: Double-check that all locking mechanisms are secure before using the ladder in any configuration, whether as a step ladder or a leaning ladder.

Leaning Ladder Configuration: When using the leaning ladder function, ensure the ladder is securely angled against a stable wall and tied off at the top according to the manufacturer's instructions.

Specialized Step Ladders

Extra-Wide Step Ladders: These ladders offer increased stability due to the wider base and steps. They are ideal for users who require additional stability or who plan on carrying tools or materials while climbing.

Fiberglass Step Ladders: Fiberglass ladders are non-conductive and can be used safely near electrical hazards. However, they can be heavier than aluminum ladders and require extra care to avoid damaging the fiberglass rails.

Step Ladder Safety and Common Misconceptions

Misconception 1: Step Ladders are One-Size-Fits-All

Not all step ladders are created equal. Choose the right ladder for the job by considering the height you need to reach, and the weight capacity required for yourself and any tools or materials you might be carrying.

Misconception 2: A Step Ladder Can Replace a Scaffold

Step ladders are designed for temporary, short-duration tasks. For extended projects or working at significant heights, consider using scaffolding, which offers a more secure and stable platform.

Misconception 3: Step Ladders with Wide Bases Eliminate the Need for Proper Set-Up

Even with a wide base, proper set-up procedures remain essential. Always ensure the ladder is on level ground, the spreaders are locked, and you maintain three points of contact while climbing.

Conclusion

Step ladders, when used correctly, can be a valuable tool for household tasks and reaching those out-of-the-way places. By following the safety guidelines outlined above, you can minimize the risk of falls and ensure a safe and productive work experience.

Remember, prioritizing safety is paramount. If a task requires a level of stability or height that a step ladder cannot provide comfortably, don't hesitate to use a more appropriate tool, such as a scaffold or a different type of ladder.

#ladder safety#stepladder safety#workplace safety#homesafety#fallprevention#DIYsafety#construction safety#accidents#injuryprevention

0 notes

Text

youtube

In this video tutorial, you will learn How To Secure Ladder with RoofSmart Pads and Ladder Brace.

#ladder safety#ladder brace#roofingsolution#roofingequipment#roofrepair#bestroofingequipment#roofingsafety#roofsmartpads#roofsmartpad#Youtube

0 notes

Text

What the fuck.

I have thought about Gale endlessly since September and I can count on one hand how many dreams I've had with him.

One... It was one, and it was... Well it was interesting.

But I start having dreams about my very short, outpatient surgery while I take a nap... The first nap I've taken in months.

#fuck you brain#mira rants#the Gale dream was hot though#still unusual#but hot#the surgery dream though?#i was doing intake paperwork#and laughing about it#and trying to tell the hospital to just give my bff all of the instructions bc she works in a cath lab#and then i started obsessing about this guy being on a ladder in the rain#and worrying about his safety#gale dekarios#gale of waterdeep#bg3#bg3 gale#baldur's gate 3#gale#baldur's gate gale#baldurs gate

26 notes

·

View notes

Text

Since I can't knit for a few days because of the hand-burning-thing, here's a(n extremely blurry) progress update. I have about 22 more stockinette rows before decreases and ribbing.

#Knitting#Boswellia tag#I got stitch markers but they are kind of useless and I regret the 50 rs I spent on them#Safety pins + spare yarn for the win for real#Also no one told me I'm supposed to stagger my floats to avoid laddering#My yoke colourwork has so much laddering. that portion is actually supposed to be knit with 2 size smaller needles so it was already loose#The bottom one is nice because it's actually in the appropriate size (though the gauge is off)#My crafts#I have so many tags I forget#ID in alt#Fiber art

76 notes

·

View notes

Text

After dick passed out on the fire escape, Alfred went out to find him then smacked him awake. He then carried him down the ladder to their car.

In the present, Alfred says that with just the three of them it feels like old times. Bruce argues that too much has changed for that (Batman #634)

#war games#dick and Alfred#THATS HIS BABY#HE CARRIED HIM TO SAFETY BITCH#HE WENT OUT IN A VITY WIDE FUCKINV GANG WAR FOR DICK#AND CARRIED HIM ON HIS BACK DOWN A FUCKING LADDER AND TO THE CAR#alfred pennyworth#dc#dick grayson#nightwing#dick and Bruce#Bruce Wayne#Bruce and Alfred#old times babes

12 notes

·

View notes

Text

Equal 18 FT. Aluminium Folding Telescopic Ladder for Home & Outdoor

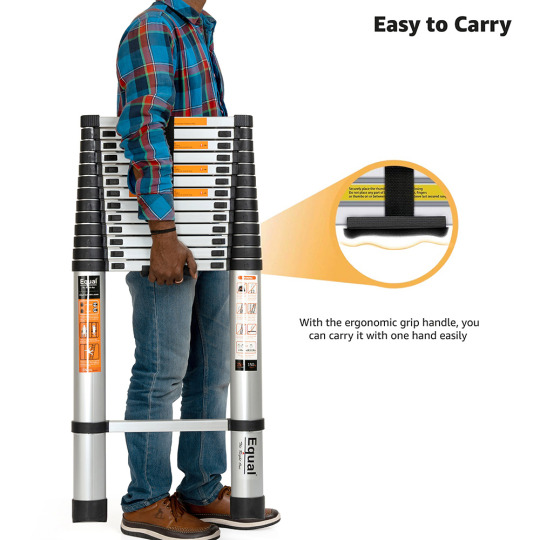

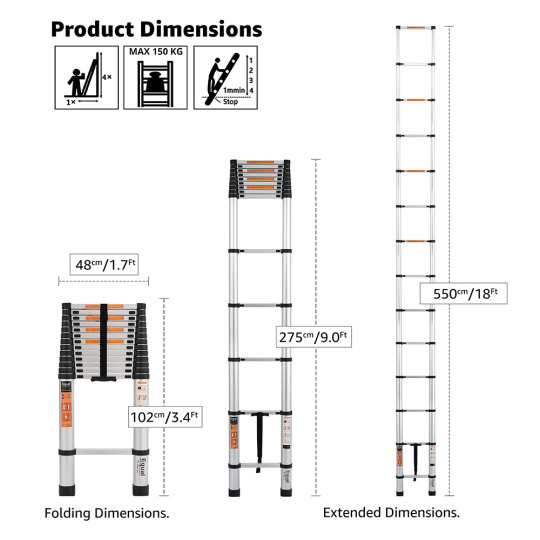

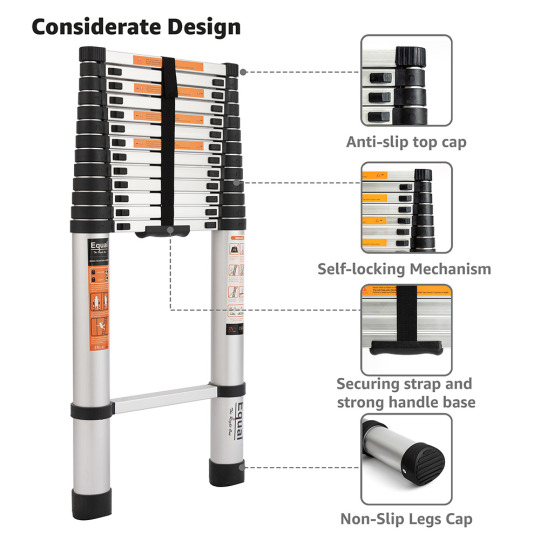

Introducing the Equal 18 FT. Aluminium Folding Telescopic Ladder, is the perfect tool for any home or outdoor project. With its heavy-duty 6063 T5-Grade aluminum construction and stable square rungs, this ladder is built to last. The sleek silver color adds a touch of sophistication to any workspace. Its impressive open size of 18 feet(48L x 9W x 594H Cm) and folding size of 3.7 Feet(48L x 9W x 113H Cm) make it easy to store and transport, while the 150-weight capacity ensures safety and stability. Plus, the ladder features a self-locking mechanism that keeps your fingers safe and speeds up retraction time. Get yours today and make any project a breeze!

Product details

Material & Color: Heavy-Duty 6063 T5-Grade Aluminum Construction; Square Rungs For Supporting, Make This Folding Ladder Stable And Durable with Sliver Color.

Size & Capacity: Open-Size: 18 Feet(48L x 9W x 594H Cm), Folding-Size: 3.7 Feet(48L x 9W x 113H Cm), Item-Weight: 15Kg., Capacity: 150Kg.

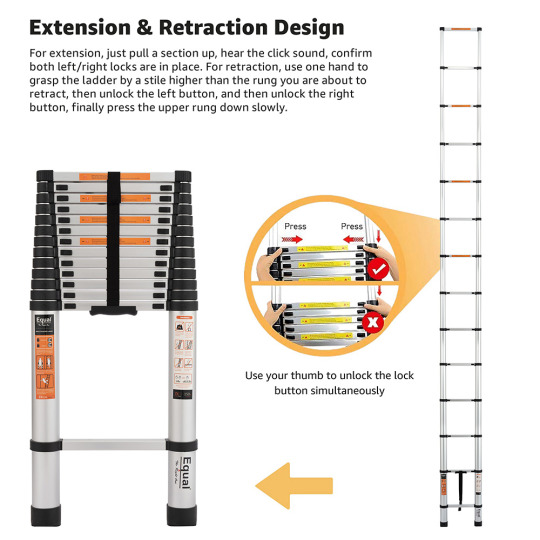

Self-Locking Feature: While Guaranteeing Quality, Our Telescoping Aluminum Ladder Also Has a One-Button Retraction Function. Simply Press The Thumb Buttons, and This Ladder Will Descending Smoothly From Its Unfolded Condition To Compact Size, So Convenient.

EN131 Safety Standard: Meets `EN131` Safety Standard Certificate with Satisfaction Guaranteed with Non-Slip Square Rungs And Supporting Tubes, Contact Professional Customer Service Before And After Purchase If You Have Any Issues Or Concerns. Customer Friendly 1-Year Warranty Against Manufacturing Defects.

Assembly Instruction: No Assembly Required. Which Can Be Opened And Locked For Changing The Height Of Ladder Easily While Guaranteeing Security.

#Ladder Safety#Compact Design#Portable Ladders#Space Saving#Easy Storage#Aluminum Ladders#Lightweight Design#Telescopic Extension#Foldable Ladders#Multi Purpose Ladders#Construction Tools#Safety First#High Quality Ladders#Adjustable Height#Extendable Ladder#Professional Tools#Ergonomic Design#Sturdy Construction#Versatile Ladders

0 notes

Note

Domain dedicated to trying to screw in a lightbulb. “How many ____ does it take to screw in a lightbulb?” Find out. Try. Nothing works.

The Dark with hints of The Buried and/or The Vast

#the hopelessness of trying and trying to escape a darkness with safety just within reach but it just doesnt work not matter what you do#could also be the vast/dark if its on a ladder with no way of knowing where the floor is#the vast#the dark#the buried#domains

15 notes

·

View notes

Text

0 notes

Text

idk what the construction workers outside my window are doing but it definitely sounds like the opposite of construction

#destruction#how many pots are they dropping in succession?#it is almost impressive#that is the sound of not progress#*Looney toons vase smashing sound* Hey man stop *more vases are smashed* what did you say? *metal ladder mildy swinged against a wall*#It just sounded like someone threw a brick at something#Are they robbing my neighbours?#But they are wearing safety hats and visibility vests#I guess they are staying safe during robbery at least#Oh the sound of a window smashed in#♧other#now they're yelling at each other

4 notes

·

View notes