#Industry 4.0 & Smart Factory

Explore tagged Tumblr posts

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

Industry 4.0: Powering the Next Industrial Revolution with Intelligence, Connectivity, and Automation

The world is undergoing a radical transformation. As we move deeper into the 21st century, the fusion of digital, physical, and biological systems is reshaping how we manufacture, operate, and innovate. This revolution has a name: Industry 4.0—the fourth industrial revolution. It represents a new era where smart technology, real-time data, automation, and interconnected networks converge to…

#5G Connectivity#Additive Manufacturing#advanced robotics#Artificial intelligence#Automation#Big Data Analytics#Blockchain#Cloud Computing#connected industry#Cyber-physical systems#data-driven operations#Digital Transformation#Digital twin#Edge computing#fourth industrial revolution#IIoT#Industrial Networking#Industry 4.0#intelligent systems#manufacturing innovation#next-gen industry#Predictive maintenance#Real-time analytics#Robotics#smart factory#Smart Grid#Smart logistics#Smart manufacturing#SolveForce#Supply Chain Visibility

0 notes

Text

0 notes

Text

Transform with SAP Industry 4.0 Solutions for Smart Factories

Explore SAP Industry 4.0 Solutions' impact on manufacturing. Unlock intelligent products, and factories with Web Synergies' expertise in SAP technologies.

1 note

·

View note

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

Interwork Software Solutions provides comprehensive Industry 4.0 solutions, integrating advanced technologies like IoT, AI, blockchain, and data analytics to enhance operational efficiency, drive automation, and support digital transformation across industries, fostering sustainable, smart, and connected business ecosystems.

0 notes

Text

#industrial iot#technology#iot app development#iot development company#smart manufacturing#industrial IoT#smart factories#manufacturing technology#digital transformation#Industry 4.0#IoT in manufacturing

0 notes

Text

How do we define Smart Factory?

How do we define Smart Factory? #SmartFactory #Industry4 #digitalization #SmartProducts #SmartMobility #SmartGrid

Smart Factory and Industry 4.0 are the two sides of the same coin. Let’s look at how Smart Factory operates, Definition of Smart Factory “At the heart of Industry 4.0 is the real-time capable, intelligent, horizontal and vertical networking of people, machines, objects, and ICT systems for the dynamic management of complex systems.”, according to BITKOM, Fraunhofer IAO, Industrie 4.0 –…

View On WordPress

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

Smart Manufacturing In the Digital Age

In today’s age of industrial automation, the buzz around digital transformation (DX) is undeniable. According to Gartner, 80% of manufacturing CEOs are increasing investments in digital technologies such as AI, machine learning, IoT, and data analytics, aiming to navigate economic challenges and propel growth. Yet, only 8% claim success in their digital endeavors. What’s the missing link? It’s not technology but organizational readiness that often falters.

Manufacturers embarking on this digital transformational journey must heed vital principles. Cross-functional digital transformation teams, spearheaded by smart manufacturing operations, blend expertise from engineering, supply chain, and material operations. IT becomes the linchpin, ensuring data’s reliability and security, essential to fuelling data-driven manufacturing.

Data demands strategic handling. Centralization ensures a singular truth source, while targeted collection tailored to specific manufacturing challenges optimizes resources. Equally crucial is democratizing data, delivering pertinent information to individuals — from operators to maintenance leaders — empowering precise decision-making.

However, technology’s human element cannot be ignored. HR plays a pivotal role, bridging generational gaps and ensuring everyone understands the purpose and benefits of digital transformation. Financial realism is equally paramount; ongoing costs, often underestimated, necessitate meticulous accounting to prevent implementation hurdles.

Above all, leadership must champion this shift, preserving the company’s ethos. By fostering a culture of decentralized, data-driven decision-making, organizations can harmonize tradition with technology. As we tread the path to digitalization, JR Automation, a Hitachi Group company stands as a beacon, guiding industries worldwide toward a future where innovation and tradition coexist seamlessly.

In summary, cross-functional teams, IT partnerships, HR support, and visionary leadership are critical to achieving a seamless and culturally aligned transition and ensuring the success of digital transformation initiatives in manufacturing.

Explore the surprising factors that drive successful digital transformation in manufacturing and best practices for overcoming organizational hurdles and harnessing cross-functional teamwork to maximize data-driven decision-making.

Discover how Hitachi is enabling data-driven manufacturing automation to achieve sustainability and profitability

#smart manufacturing#smart factory#industry 4.0#industrial digitalization#digital transformation#sustainable manufacturing#manufacturing digitalization#sustainability

0 notes

Text

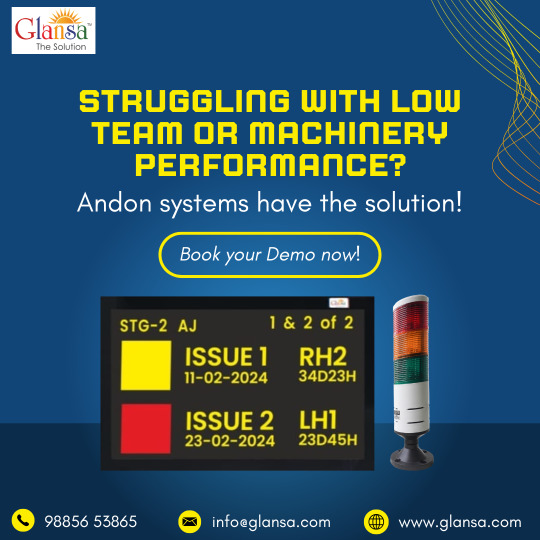

https://glansa.com/andon/

Discover how Industry Automation in India is revolutionizing manufacturing with smart solutions like Andon systems. Glansa Solutions offers a real-time alert and monitoring system to reduce downtime, improve efficiency, and support Industry 4.0 implementation. Explore how Indian industries are leveraging automation to stay globally competitive.

#Industry Automation in India#Andon System#Manufacturing Automation#Industrial Solutions India#Smart Factory#Glansa Andon#Industry 4.0 India#Real-time Production Monitoring

0 notes

Text

hiotron : Top IoT Solution Providers in Pune

Build end-to-end IoT eco-system with multiple wireless sensor nodes connected to the IoT Gateway as a Hardware client, Front end custom mobile App/Dashboard as a Front end client & Custom platform as an IoT platform including implementation of top 5 Industrial IoT case studies. hiotron is Top IoT Solution Providers in Pune

View More at: https://www.hiotron.com/

#industry 4.0 solution for smart manufacturing#iot solution for smart factory pune#iot training in pune

0 notes

Text

0 notes

Text

Transform with SAP Industry 4.0 Solutions for Smart Factories

Explore SAP Industry 4.0 Solutions' impact on manufacturing. Unlock intelligent products, and factories with Web Synergies' expertise in SAP technologies.

1 note

·

View note

Text

Smart factory industry 4.0 with Advanced Technology - Evolute

Evolute leads the smart factory industry 4.0 with advanced technology. By integrating intelligent systems, data analytics, and automation, Evolute enhances manufacturing efficiency and productivity. Its solutions leverage IIoT devices, real-time monitoring, and analytics to optimize processes and drive actionable insights for manufacturers.

0 notes