#Smart Factory Technology

Explore tagged Tumblr posts

Text

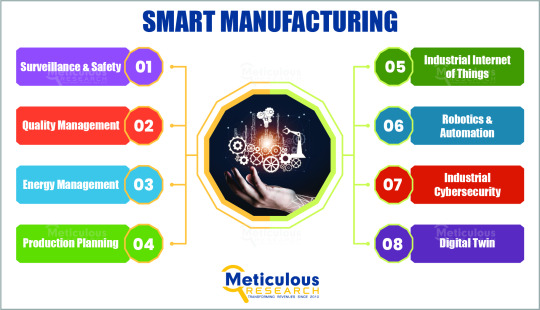

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

Using the Internet of Things (IoT) in manufacturing has totally changed how stuff gets done, making it way better. It’s like giving factories a major upgrade! This technology has made factories run quicker, smarter, and safer. In this article, we’ll chat about why IoT is so cool and how it’s making manufacturing awesome.

2 notes

·

View notes

Text

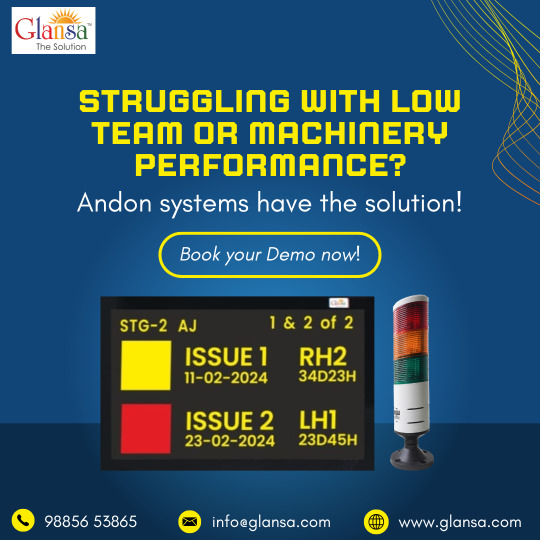

How Andon Devices Improve Manufacturing Efficiency – A Smart Factory Essential

Introduction

In today’s competitive manufacturing landscape, operational efficiency and real-time communication are critical. As factories move toward Industry 4.0, tools like the Andon device are becoming essential for lean production environments. An Andon system serves as an immediate visual and/or audible alert mechanism that highlights issues on the shop floor, enabling faster response times and reducing costly downtimes.

What is an Andon Device?

An Andon device is a signal system used in industrial settings to alert operators, supervisors, or maintenance teams about problems or abnormalities in real time. Traditionally, Andon systems were simple light signals. However, modern solutions—like those offered by Glansa Solutions—come with digital displays, IoT integration, and real-time data tracking.

Why Use an Andon Device?

Real-Time Communication: Operators can immediately alert others to issues without leaving their station.

Reduced Downtime: Early detection allows teams to resolve problems faster.

Increased Accountability: Tracks how long issues persist and who responded.

Better Decision Making: Collected data helps in analyzing production trends and implementing continuous improvements.

Key Features of Glansa’s Andon System

✔️ Visual and audible alerting

✔️ Custom-configurable signals

✔️ Web-based dashboard for real-time monitoring

✔️ Seamless integration with ERP and MES systems

✔️ IoT-enabled for smart factory use

Use Cases in Manufacturing

Glansa’s Andon devices are used in various sectors including automotive, electronics, textiles, and FMCG industries. Whether it’s to notify quality checks, machine breakdowns, or material shortages, Andon devices ensure faster responses and increased production visibility.

Why Choose Glansa Solutions?

Glansa Solutions is a trusted name in industrial automation and smart factory tools. With years of experience, we deliver scalable and intelligent Andon systems that help manufacturers meet their production goals while embracing digital transformation.

Conclusion

Investing in a robust Andon device is a smart move for manufacturers aiming to boost shop floor transparency and operational efficiency. With solutions like those from Glansa, businesses can stay ahead in the era of smart manufacturing.

📍 Learn more: https://glansa.com

#Andon Device#Manufacturing Technology#Glansa Solutions#Lean Manufacturing#Production Monitoring#Smart Factory#Industrial Automation#Shop Floor Management

0 notes

Text

Manufacturing IoT in the Automotive Industry - Key Companies and Trends to Know

Explore how top companies are using IoT in automotive manufacturing to boost efficiency and reduce costs. Learn how Theta Technolabs, a leading IoT app development company in Dallas, builds smart IoT solutions to power innovation in the automotive industry.

#IoT Solutions#IoT in automotive manufacturing#IoT app development company#smart factory solutions#industrial IoT solutions#Technology

0 notes

Text

AI in Automotive Manufacturing 2025: Driving the Future of Smart Production

Introduction

The automotive industry is undergoing a paradigm shift, with artificial intelligence (AI) playing a crucial role in transforming manufacturing processes. AI in automotive manufacturing 2025 is set to revolutionize production efficiency, quality control, and supply chain optimization. From predictive maintenance to autonomous quality inspection, AI is enhancing every aspect of car production, making factories smarter and more efficient. In this article, we explore how AI is reshaping the automotive manufacturing landscape, its benefits, and the future it holds.

The Role of AI in Automotive Manufacturing

AI is bringing unprecedented efficiency and precision to car manufacturing by enabling automation, predictive analytics, and intelligent decision-making. Key areas where AI is making a significant impact include:

1. Smart Robotics & Automation

AI-driven robotic arms are streamlining manufacturing processes by executing tasks such as welding, painting, and assembly with extreme accuracy. Unlike traditional robots, AI-powered machines adapt to new tasks through machine learning algorithms, reducing downtime and improving productivity.

2. Predictive Maintenance

Predictive maintenance powered by AI helps automotive manufacturers prevent unexpected equipment failures. By analyzing data from IoT sensors, AI can predict machinery breakdowns and recommend timely maintenance, reducing downtime and costs.

3. AI-Powered Quality Control

Traditional quality control methods are being replaced by AI-driven vision inspection systems that detect even the smallest defects in car components. AI ensures consistency and precision, minimizing recalls and warranty claims.

4. Supply Chain Optimization

AI is optimizing the automotive supply chain by predicting demand, managing inventory, and identifying disruptions before they occur. This helps manufacturers maintain a steady production flow while reducing costs and improving efficiency.

5. Autonomous Vehicles in Manufacturing Plants

Automakers are integrating AI-powered autonomous vehicles within factories to transport materials, enhancing efficiency and reducing human intervention in logistics.

Benefits of AI in Automotive Manufacturing

The integration of AI in car manufacturing offers numerous advantages, including:

• Enhanced Efficiency: AI automates repetitive tasks, reducing manual labor and increasing production speed.

• Cost Savings: Predictive analytics minimize operational costs by preventing breakdowns and optimizing resource allocation.

• Improved Product Quality: AI-driven quality control ensures defect-free components, leading to higher customer satisfaction.

• Sustainability: AI helps reduce waste and energy consumption, making manufacturing more environmentally friendly.

• Workforce Safety: AI-powered robots take over hazardous tasks, improving workplace safety for employees.

Challenges in Implementing AI in Automotive Manufacturing

Despite its benefits, AI adoption in automotive manufacturing faces several challenges:

• High Initial Investment: Implementing AI-driven systems requires significant investment in technology and infrastructure.

• Skilled Workforce: Companies need trained professionals who can manage AI systems effectively.

• Data Privacy & Security: Protecting sensitive manufacturing data from cyber threats remains a critical concern.

• Integration Complexity: AI systems must be seamlessly integrated into existing manufacturing processes, requiring careful planning.

The Future of AI in Automotive Manufacturing

By 2025, AI is expected to become an integral part of every automotive production process. Key future trends include:

• Fully Automated Factories: AI will lead to the development of smart factories with minimal human intervention.

• AI-Driven Customization: Personalized car manufacturing will be possible, allowing customers to customize vehicle features in real time.

• Sustainable Manufacturing: AI will enhance sustainability by optimizing resource usage and reducing emissions.

• Collaboration Between AI & Humans: AI will complement human workers, enabling them to focus on high-value tasks while AI handles repetitive processes.

Conclusion

The AI in automotive manufacturing 2025 revolution is transforming the industry by improving efficiency, quality, and sustainability. As automakers embrace AI-driven technologies, they will unlock new opportunities for growth and innovation. While challenges exist, the benefits of AI far outweigh the hurdles, making it a game-changer for the future of car manufacturing.

#tagbin#writers on tumblr#artificial intelligence#technology#ai trends 2025#AI in automotive manufacturing 2025#AI in car production#artificial intelligence in auto industry#AI-driven vehicle manufacturing#smart factories in automotive#AI-powered car assembly#robotics in automobile production#future of AI in automotive#AI automation in car factories#machine learning in automotive industry

0 notes

Text

AI-Driven Manufacturing: How Data and Human Intelligence Are Shaping 2025

Manufacturing is going through a major shift. By 2025, smart factories won’t just be a concept, they will define how production happens. This change isn’t just about automation; it’s about using real-time data, AI, and human expertise together to improve manufacturing processes.

The Power Behind Manufacturing

Factories today generate large amounts of data from IoT devices. But raw data isn’t enough — it must be turned into useful insights that improve production.

Better Process Control: Advanced analytics and edge computing help make real-time adjustments. For example, in metalworking, AI can analyze tool vibration and temperature, helping set the right cutting speed and feed rate. This can extend tool life by 20% and improve surface finish by 15%.

Predicting Quality Issues: AI doesn’t just find defects — it can predict when a problem might happen. In semiconductor manufacturing, AI models can spot wafer defects with over 95% accuracy, reducing waste and improving output.

AI: Working Together With People

AI is not about replacing workers — it’s about making better decisions and improving production.

Smarter Robots: AI-powered robots can adjust to different part sizes and shapes, reducing downtime and making production more flexible.

Helping Workers Solve Production Issues: AI systems gather data from various sources, allowing operators to detect and resolve production challenges more quickly.

AI in Product Design: AI-driven design tools can create and test product designs faster, making products stronger, lighter, and easier to manufacture. This is already being used in the aerospace and automotive industries.

Skilled Workers: The Backbone of Smart Factories

Even with all these advancements, experienced workers remain crucial in smart factories. AI and robotics support them, ensuring smoother operations and better results.

Working With Robots: Cobots (collaborative robots) handle repetitive tasks, allowing workers to focus on complex and skilled operations.

AI That Supports Workers: AI systems now explain their suggestions, helping operators understand and make better decisions.

Ensuring Factories Secure and Reliable

With more connected systems, cybersecurity and supply chain risks are growing. Manufacturers need to focus on security to keep operations running smoothly.

Stronger Security Measures: A ‘zero trust’ approach ensures that only authorized users and devices can access factory systems.

Protecting Machines From Cyber Threats: AI-powered monitoring systems track industrial networks to spot unusual activity before it causes problems.

Supply Chain Stability: Data analytics help manufacturers identify risks and build stronger, more flexible supply chains to avoid disruptions.

Manufacturing in 2025: Smarter, Faster, and More Reliable

By 2025, factories will be connected systems where data, AI, and skilled workers work together to improve production. Success will come from using technology wisely, investing in workers, and keeping factories secure. The future of manufacturing isn’t just about automation — it’s about making production smarter, more flexible, and ready for the challenges ahead.

#Predicting Quality Issues#AI-powered robots#Smart Factories#Manufacturing in 2025#thirdeyeai#technology#AI-Driven Manufacturing

0 notes

Text

Revolutionising Smart Factories with Digital Twin Technology

Discover how digital twin technology transforms smart factories with real-time monitoring, maintenance, & optimised workflows for efficiency and growth.

1 note

·

View note

Text

Explore how sustainable engineering is shaping a greener future! 🌱 Dive into innovative green technologies, renewable energy solutions, and eco-friendly practices driving global change. From reducing carbon footprints to creating smarter designs, sustainability is the key to progress. 🌍⚙ Let’s build a better tomorrow together!

#green technologies#sustainable engineering#renewable energy#green construction#waste-to-energy#water management#eco-friendly materials#energy efficiency#smart factories#environmental sustainability

0 notes

Text

Did you know that 75% of manufacturers struggle with operational inefficiencies due to outdated systems? What if your factory could make decisions in real-time, streamline production, and eliminate bottlenecks—all by harnessing the power of data?

Our latest blog dives into how smart factories are revolutionizing the manufacturing landscape with interconnected systems, real-time analytics, and automated processes. If you're ready to unlock new levels of productivity and efficiency, this guide will show you exactly how to transform your facility into a smart factory.

Explore the step- by-step transformation here: Link

0 notes

Text

#Smart Manufacturing Market#Smart Manufacturing#Smart Production#Smart Manufacturing Industry 4.0#Smart Manufacturing Solutions#Smart Factory Technology#Smart Factory Industry 4.0

0 notes

Text

#industrial iot#technology#iot app development#iot development company#smart manufacturing#industrial IoT#smart factories#manufacturing technology#digital transformation#Industry 4.0#IoT in manufacturing

0 notes

Link

When you sell or pass on your computer without properly erasing everything, there’s a risk that tech-savvy people could get your data back, which could lead to problems like hacking or data theft. So, it’s crucial to make sure your data is completely gone by performing factory reset to avoid any costly mistakes. Read More

#factory reset#mac#macbook#macos sonoma#macos ventura#macos monterey#technology#how to blog#tech blog#tech series#macos sonoma features#ventura#@apple#@apple news#Erase Assistant#file vault#protect your privacy#smart move#original settings#protect data#save data

1 note

·

View note

Text

Improve Production Efficiency with Glansa’s Andon Device

Looking to reduce downtime and improve real-time visibility in your manufacturing process? Glansa offers intelligent Andon device solutions that provide instant visual and audio alerts for production line issues. Enhance your shop floor communication and accelerate response times with our customizable and reliable Andon systems.

#Andon Device#Manufacturing Technology#Glansa Solutions#Lean Manufacturing#Production Monitoring#Smart Factory#Industrial Automation#Shop Floor Management

0 notes

Text

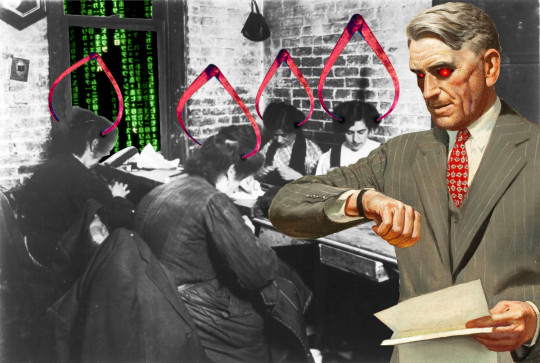

Bossware is unfair (in the legal sense, too)

You can get into a lot of trouble by assuming that rich people know what they're doing. For example, might assume that ad-tech works – bypassing peoples' critical faculties, reaching inside their minds and brainwashing them with Big Data insights, because if that's not what's happening, then why would rich people pour billions into those ads?

https://pluralistic.net/2020/12/06/surveillance-tulip-bulbs/#adtech-bubble

You might assume that private equity looters make their investors rich, because otherwise, why would rich people hand over trillions for them to play with?

https://thenextrecession.wordpress.com/2024/11/19/private-equity-vampire-capital/

The truth is, rich people are suckers like the rest of us. If anything, succeeding once or twice makes you an even bigger mark, with a sense of your own infallibility that inflates to fill the bubble your yes-men seal you inside of.

Rich people fall for scams just like you and me. Anyone can be a mark. I was:

https://pluralistic.net/2024/02/05/cyber-dunning-kruger/#swiss-cheese-security

But though rich people can fall for scams the same way you and I do, the way those scams play out is very different when the marks are wealthy. As Keynes had it, "The market can remain irrational longer than you can remain solvent." When the marks are rich (or worse, super-rich), they can be played for much longer before they go bust, creating the appearance of solidity.

Noted Keynesian John Kenneth Galbraith had his own thoughts on this. Galbraith coined the term "bezzle" to describe "the magic interval when a confidence trickster knows he has the money he has appropriated but the victim does not yet understand that he has lost it." In that magic interval, everyone feels better off: the mark thinks he's up, and the con artist knows he's up.

Rich marks have looong bezzles. Empirically incorrect ideas grounded in the most outrageous superstition and junk science can take over whole sections of your life, simply because a rich person – or rich people – are convinced that they're good for you.

Take "scientific management." In the early 20th century, the con artist Frederick Taylor convinced rich industrialists that he could increase their workers' productivity through a kind of caliper-and-stopwatch driven choreographry:

https://pluralistic.net/2022/08/21/great-taylors-ghost/#solidarity-or-bust

Taylor and his army of labcoated sadists perched at the elbows of factory workers (whom Taylor referred to as "stupid," "mentally sluggish," and as "an ox") and scripted their motions to a fare-the-well, transforming their work into a kind of kabuki of obedience. They weren't more efficient, but they looked smart, like obedient robots, and this made their bosses happy. The bosses shelled out fortunes for Taylor's services, even though the workers who followed his prescriptions were less efficient and generated fewer profits. Bosses were so dazzled by the spectacle of a factory floor of crisply moving people interfacing with crisply working machines that they failed to understand that they were losing money on the whole business.

To the extent they noticed that their revenues were declining after implementing Taylorism, they assumed that this was because they needed more scientific management. Taylor had a sweet con: the worse his advice performed, the more reasons their were to pay him for more advice.

Taylorism is a perfect con to run on the wealthy and powerful. It feeds into their prejudice and mistrust of their workers, and into their misplaced confidence in their own ability to understand their workers' jobs better than their workers do. There's always a long dollar to be made playing the "scientific management" con.

Today, there's an app for that. "Bossware" is a class of technology that monitors and disciplines workers, and it was supercharged by the pandemic and the rise of work-from-home. Combine bossware with work-from-home and your boss gets to control your life even when in your own place – "work from home" becomes "live at work":

https://pluralistic.net/2021/02/24/gwb-rumsfeld-monsters/#bossware

Gig workers are at the white-hot center of bossware. Gig work promises "be your own boss," but bossware puts a Taylorist caliper wielder into your phone, monitoring and disciplining you as you drive your wn car around delivering parcels or picking up passengers.

In automation terms, a worker hitched to an app this way is a "reverse centaur." Automation theorists call a human augmented by a machine a "centaur" – a human head supported by a machine's tireless and strong body. A "reverse centaur" is a machine augmented by a human – like the Amazon delivery driver whose app goads them to make inhuman delivery quotas while punishing them for looking in the "wrong" direction or even singing along with the radio:

https://pluralistic.net/2024/08/02/despotism-on-demand/#virtual-whips

Bossware pre-dates the current AI bubble, but AI mania has supercharged it. AI pumpers insist that AI can do things it positively cannot do – rolling out an "autonomous robot" that turns out to be a guy in a robot suit, say – and rich people are groomed to buy the services of "AI-powered" bossware:

https://pluralistic.net/2024/01/29/pay-no-attention/#to-the-little-man-behind-the-curtain

For an AI scammer like Elon Musk or Sam Altman, the fact that an AI can't do your job is irrelevant. From a business perspective, the only thing that matters is whether a salesperson can convince your boss that an AI can do your job – whether or not that's true:

https://pluralistic.net/2024/07/25/accountability-sinks/#work-harder-not-smarter

The fact that AI can't do your job, but that your boss can be convinced to fire you and replace you with the AI that can't do your job, is the central fact of the 21st century labor market. AI has created a world of "algorithmic management" where humans are demoted to reverse centaurs, monitored and bossed about by an app.

The techbro's overwhelming conceit is that nothing is a crime, so long as you do it with an app. Just as fintech is designed to be a bank that's exempt from banking regulations, the gig economy is meant to be a workplace that's exempt from labor law. But this wheeze is transparent, and easily pierced by enforcers, so long as those enforcers want to do their jobs. One such enforcer is Alvaro Bedoya, an FTC commissioner with a keen interest in antitrust's relationship to labor protection.

Bedoya understands that antitrust has a checkered history when it comes to labor. As he's written, the history of antitrust is a series of incidents in which Congress revised the law to make it clear that forming a union was not the same thing as forming a cartel, only to be ignored by boss-friendly judges:

https://pluralistic.net/2023/04/14/aiming-at-dollars/#not-men

Bedoya is no mere historian. He's an FTC Commissioner, one of the most powerful regulators in the world, and he's profoundly interested in using that power to help workers, especially gig workers, whose misery starts with systemic, wide-scale misclassification as contractors:

https://pluralistic.net/2024/02/02/upward-redistribution/

In a new speech to NYU's Wagner School of Public Service, Bedoya argues that the FTC's existing authority allows it to crack down on algorithmic management – that is, algorithmic management is illegal, even if you break the law with an app:

https://www.ftc.gov/system/files/ftc_gov/pdf/bedoya-remarks-unfairness-in-workplace-surveillance-and-automated-management.pdf

Bedoya starts with a delightful analogy to The Hawtch-Hawtch, a mythical town from a Dr Seuss poem. The Hawtch-Hawtch economy is based on beekeeping, and the Hawtchers develop an overwhelming obsession with their bee's laziness, and determine to wring more work (and more honey) out of him. So they appoint a "bee-watcher." But the bee doesn't produce any more honey, which leads the Hawtchers to suspect their bee-watcher might be sleeping on the job, so they hire a bee-watcher-watcher. When that doesn't work, they hire a bee-watcher-watcher-watcher, and so on and on.

For gig workers, it's bee-watchers all the way down. Call center workers are subjected to "AI" video monitoring, and "AI" voice monitoring that purports to measure their empathy. Another AI times their calls. Two more AIs analyze the "sentiment" of the calls and the success of workers in meeting arbitrary metrics. On average, a call-center worker is subjected to five forms of bossware, which stand at their shoulders, marking them down and brooking no debate.

For example, when an experienced call center operator fielded a call from a customer with a flooded house who wanted to know why no one from her boss's repair plan system had come out to address the flooding, the operator was punished by the AI for failing to try to sell the customer a repair plan. There was no way for the operator to protest that the customer had a repair plan already, and had called to complain about it.

Workers report being sickened by this kind of surveillance, literally – stressed to the point of nausea and insomnia. Ironically, one of the most pervasive sources of automation-driven sickness are the "AI wellness" apps that bosses are sold by AI hucksters:

https://pluralistic.net/2024/03/15/wellness-taylorism/#sick-of-spying

The FTC has broad authority to block "unfair trade practices," and Bedoya builds the case that this is an unfair trade practice. Proving an unfair trade practice is a three-part test: a practice is unfair if it causes "substantial injury," can't be "reasonably avoided," and isn't outweighed by a "countervailing benefit." In his speech, Bedoya makes the case that algorithmic management satisfies all three steps and is thus illegal.

On the question of "substantial injury," Bedoya describes the workday of warehouse workers working for ecommerce sites. He describes one worker who is monitored by an AI that requires him to pick and drop an object off a moving belt every 10 seconds, for ten hours per day. The worker's performance is tracked by a leaderboard, and supervisors punish and scold workers who don't make quota, and the algorithm auto-fires if you fail to meet it.

Under those conditions, it was only a matter of time until the worker experienced injuries to two of his discs and was permanently disabled, with the company being found 100% responsible for this injury. OSHA found a "direct connection" between the algorithm and the injury. No wonder warehouses sport vending machines that sell painkillers rather than sodas. It's clear that algorithmic management leads to "substantial injury."

What about "reasonably avoidable?" Can workers avoid the harms of algorithmic management? Bedoya describes the experience of NYC rideshare drivers who attended a round-table with him. The drivers describe logging tens of thousands of successful rides for the apps they work for, on promise of "being their own boss." But then the apps start randomly suspending them, telling them they aren't eligible to book a ride for hours at a time, sending them across town to serve an underserved area and still suspending them. Drivers who stop for coffee or a pee are locked out of the apps for hours as punishment, and so drive 12-hour shifts without a single break, in hopes of pleasing the inscrutable, high-handed app.

All this, as drivers' pay is falling and their credit card debts are mounting. No one will explain to drivers how their pay is determined, though the legal scholar Veena Dubal's work on "algorithmic wage discrimination" reveals that rideshare apps temporarily increase the pay of drivers who refuse rides, only to lower it again once they're back behind the wheel:

https://pluralistic.net/2023/04/12/algorithmic-wage-discrimination/#fishers-of-men

This is like the pit boss who gives a losing gambler some freebies to lure them back to the table, over and over, until they're broke. No wonder they call this a "casino mechanic." There's only two major rideshare apps, and they both use the same high-handed tactics. For Bedoya, this satisfies the second test for an "unfair practice" – it can't be reasonably avoided. If you drive rideshare, you're trapped by the harmful conduct.

The final prong of the "unfair practice" test is whether the conduct has "countervailing value" that makes up for this harm.

To address this, Bedoya goes back to the call center, where operators' performance is assessed by "Speech Emotion Recognition" algorithms, a psuedoscientific hoax that purports to be able to determine your emotions from your voice. These SERs don't work – for example, they might interpret a customer's laughter as anger. But they fail differently for different kinds of workers: workers with accents – from the American south, or the Philippines – attract more disapprobation from the AI. Half of all call center workers are monitored by SERs, and a quarter of workers have SERs scoring them "constantly."

Bossware AIs also produce transcripts of these workers' calls, but workers with accents find them "riddled with errors." These are consequential errors, since their bosses assess their performance based on the transcripts, and yet another AI produces automated work scores based on them.

In other words, algorithmic management is a procession of bee-watchers, bee-watcher-watchers, and bee-watcher-watcher-watchers, stretching to infinity. It's junk science. It's not producing better call center workers. It's producing arbitrary punishments, often against the best workers in the call center.

There is no "countervailing benefit" to offset the unavoidable substantial injury of life under algorithmic management. In other words, algorithmic management fails all three prongs of the "unfair practice" test, and it's illegal.

What should we do about it? Bedoya builds the case for the FTC acting on workers' behalf under its "unfair practice" authority, but he also points out that the lack of worker privacy is at the root of this hellscape of algorithmic management.

He's right. The last major update Congress made to US privacy law was in 1988, when they banned video-store clerks from telling the newspapers which VHS cassettes you rented. The US is long overdue for a new privacy regime, and workers under algorithmic management are part of a broad coalition that's closer than ever to making that happen:

https://pluralistic.net/2023/12/06/privacy-first/#but-not-just-privacy

Workers should have the right to know which of their data is being collected, who it's being shared by, and how it's being used. We all should have that right. That's what the actors' strike was partly motivated by: actors who were being ordered to wear mocap suits to produce data that could be used to produce a digital double of them, "training their replacement," but the replacement was a deepfake.

With a Trump administration on the horizon, the future of the FTC is in doubt. But the coalition for a new privacy law includes many of Trumpland's most powerful blocs – like Jan 6 rioters whose location was swept up by Google and handed over to the FBI. A strong privacy law would protect their Fourth Amendment rights – but also the rights of BLM protesters who experienced this far more often, and with far worse consequences, than the insurrectionists.

The "we do it with an app, so it's not illegal" ruse is wearing thinner by the day. When you have a boss for an app, your real boss gets an accountability sink, a convenient scapegoat that can be blamed for your misery.

The fact that this makes you worse at your job, that it loses your boss money, is no guarantee that you will be spared. Rich people make great marks, and they can remain irrational longer than you can remain solvent. Markets won't solve this one – but worker power can.

Image: Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

#pluralistic#alvaro bedoya#ftc#workers#algorithmic management#veena dubal#bossware#taylorism#neotaylorism#snake oil#dr seuss#ai#sentiment analysis#digital phrenology#speech emotion recognition#shitty technology adoption curve

2K notes

·

View notes

Text

AI in Manufacturing Innovation: Transforming the Future of Production

Artificial Intelligence (AI) is revolutionizing industries worldwide, and manufacturing is no exception. With its ability to enhance efficiency, reduce costs, and unlock unprecedented opportunities, AI is spearheading a new era of manufacturing innovation. This article delves into the profound impact of AI on manufacturing, the technologies driving the change, and the future it promises.

Understanding AI in Manufacturing

AI in manufacturing involves using advanced algorithms and machine learning to automate processes, optimize workflows, and predict outcomes. From production line automation to quality control, AI empowers manufacturers to meet rising demands with precision and speed.

Applications of AI in Manufacturing Innovation

Predictive Maintenance: AI-powered systems analyze machinery data to predict maintenance needs, reducing downtime and preventing costly breakdowns.

Quality Assurance: AI detects defects with unparalleled accuracy, ensuring high-quality output and reducing waste.

Supply Chain Optimization: By analyzing market trends and logistical data, AI enhances inventory management, supplier coordination, and delivery schedules.

Robotics in Production: Smart robots, driven by AI, perform repetitive and dangerous tasks with precision, improving safety and productivity.

Demand Forecasting: AI analyzes consumer data and market trends to anticipate product demand, optimizing production schedules and inventory.

Benefits of AI in Manufacturing

Increased Efficiency: AI-driven automation streamlines workflows, boosting productivity.

Cost Reduction: By minimizing errors and waste, AI significantly reduces operational costs.

Enhanced Flexibility: Adaptive AI systems enable manufacturers to pivot quickly to market changes.

Sustainability: AI facilitates resource optimization, promoting eco-friendly practices.

Challenges and Solutions

High Implementation Costs: While initial investment is high, ROI from increased efficiency and reduced downtime offsets the expense.

Workforce Transition: Upskilling workers to collaborate with AI systems ensures a harmonious integration of human expertise and technology.

Data Security: Robust cybersecurity measures safeguard sensitive manufacturing data from breaches.

Case Studies of AI-Driven Manufacturing Innovation

Tesla: Tesla employs AI in its Gigafactories for automation, predictive maintenance, and quality control, setting benchmarks in automotive manufacturing.

Siemens: Siemens uses AI for intelligent robotics and process optimization, leading to cost-efficient production cycles.

GE Aviation: GE leverages AI for predictive analytics, optimizing engine performance and maintenance schedules.

The Future of AI in Manufacturing

AI's integration with emerging technologies like the Internet of Things (IoT) and 5G will further revolutionize manufacturing. Smart factories, characterized by autonomous systems and real-time data exchange, are set to become the industry norm. AI will also drive sustainable manufacturing by optimizing resource use and reducing carbon footprints.

Conclusion

AI in manufacturing is not just a technological advancement; it’s a transformative force reshaping the entire industry. By integrating AI solutions like predictive maintenance, robotics, and quality assurance systems, manufacturers can achieve unmatched efficiency, cost-effectiveness, and sustainability. Despite challenges such as high implementation costs and workforce adaptation, the benefits far outweigh the hurdles. As industries continue to evolve, AI will play a pivotal role in driving innovation, fostering adaptability, and ensuring a sustainable future. Companies embracing this revolution are poised to lead the charge in setting new benchmarks for productivity and excellence in manufacturing.

#tagbin#tagbin boardroomai#writers on tumblr#artificial intelligence#technology#ai in manufacturing#Manufacturing Innovation#Smart Factories#Predictive Maintenance#Future of Manufacturing#Sustainable Manufacturing#Manufacturing Trends#Automation#Industrial AI#AI in Manufacturing Innovation

0 notes