#Ion Exchange Resins

Text

Ion Exchange Resins for Water Purification: Effective Solutions for Clean Water

Ion Exchange Resins for Water Purification are essential in achieving high-quality, contaminant-free water. At Ion Exchange Global, we offer advanced resin solutions tailored for effective water treatment in various applications. Our resins efficiently remove impurities, ensuring safe and clean water for industrial and domestic use. For more information, visit us at https://id.ionexchangeglobal.com/

#ion exchange resins#water purification#water treatment#ion exchange technology#clean water solutions#water filtration#industrial water purification

0 notes

Text

#Total dissolved solids (TDS)#Drinking water quality#TDS measurement techniques#TDS reduction methods#Water purification systems#Reverse osmosis (RO) filtration#Activated carbon filters#Water softening systems#Deionization (DI) systems#Distillation processes#Ion exchange resins#TDS meter usage#Ideal TDS levels for drinking water#Importance of TDS testing in water quality#Health effects of high TDS levels in drinking water.#commercial ro plant manufacturer#commercial ro plant

0 notes

Text

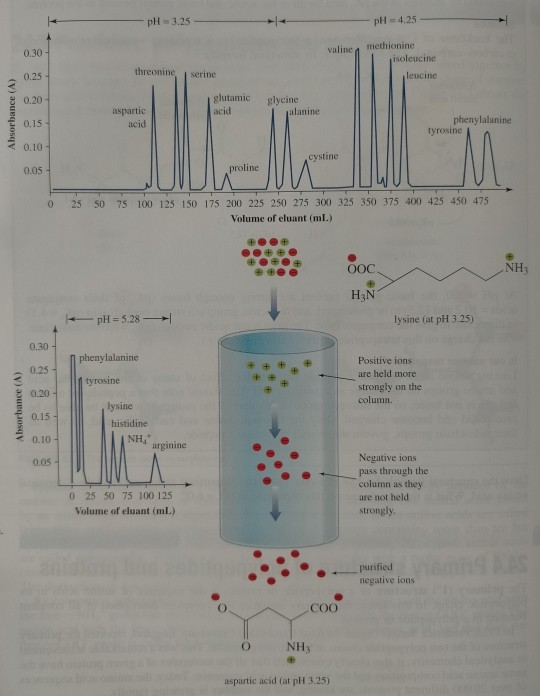

Figure 24.7 shows the analysis of a polypeptide hydrolysate by ion-exchange chromatography.

FIGURE 24.7 Analysis of a mixture of amino acids by ion-exchange chromatography using Amberlite IR-120, a sulfonated polystyrene resin. The resin contains phenyl-SO3-Na+ groups. The amino acid mixture is applied to the column at low pH (3.25), conditions under which the acidic amino acids (Asp, Glu) are weakly bound to the resin and the basic amino acids (Lys, His, Arg) are tightly bound. Sodium citrate buffers of two different concentrations and three different values of pH are used to elute the amino acids from the column. Cysteine is determined as cystine, Cy-S-S-Cys, the disulfide of cysteine.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#polypeptide#hydrolysate#ion exchange#chromatography#resin#amino acid#aspartic acid#threonine#serine#glutamic acid#proline#glycine#alanine#cystine#valine#methionine#isoleucine#leucine#tyrosine#phenylalanine#cysteine#ions#amberlite

5 notes

·

View notes

Text

[ID: four large plastic totes overflowing with large black plastic funnels. Three of the totes are placed on a cart, and the fourth is next to the cart because the cart ran out of room. The funnels are not in organized stacks but instead piled haphazardly and look rather like they’re going to fall over at any moment. In a few places plastic tubes are visible connected to the bottom of each funnel - this is why they do not stack nicely. End ID]

#this image represents the single most insane project i have ever been involved in#say hello to my 216 funels! which corresponded to 216 1 liter bottles. 216 plants. 216 different samples under different conditions.#oh and 216 tubes full of microplastic ion exchange resin#this project was nuts. it also involved 2 whole days spent in a greenhouse. one of those was in summer.#anyways. madness.#i loved it but oh my god#it wasn't my project it was one of the plant scientists but as an undergrad i did A LOT of the prep work#i and one other person assembled all those funels and resin tubes. and we acid washed the resin tubes. i wish i had photos#of every available countertop covered in plastic boxes full of resin tubes and acid.#dilute acid but still#acid. so much acid. we made it in 3 liter batches.#too many batches to count#this also involved 74 liters of potassium chloride#which is like...#almost 20 gallons#i am never happier than when lab work gets this insane#hylian does science#biogeochemistry

2 notes

·

View notes

Text

Resin for Commercial Water Treatment in Kenya: Efficient Solutions for Industrial Water Purification

Get high-quality resin for commercial water treatment in Kenya from Ion Exchange Global. Our ion exchange resins are designed for efficient industrial water purification, softening, and filtration. Trust us for reliable and sustainable water treatment solutions for your business in Kenya. For more information, visit us at https://ke.ionexchangeglobal.com/

#resin for commercial water treatment in Kenya#commercial water treatment resin#industrial water purification#water treatment solutions in Kenya#ion exchange resin for commercial use

0 notes

Text

Role of Ion Exchange Resins in Water Treatment

Water is a precious resource obtained from natural sources like rivers, streams, or wells. It can contain contaminants or pollutants that can be harmful for usage or consumption. While solid particles can be removed through filtration, soluble substances need special treatment. Ion exchange resins play a crucial selectively removing solutes from water. They are used to reduce dissolved impurities by selectively exchanging ions based on charges. This article shed light on the role of ion exchange resins in water treatment, emphasizing their importance in different industries.

What are Ion Exchange Resins?

Ion exchange resins are highly porous materials that selectively remove or exchange ions in water or other solutions. The primary role of ion exchange in water treatment is ion exchange. These are tiny beads that have charged particles known as ions. This helps remove hardness and contaminants like chromate, nitrate, and arsenic in water. Western Carbon & Chemicals is a leading ion exchange resin manufacturer in India, offering a comprehensive range of ion exchange resins for different water treatment processes. Our product is tested and approved by the power sector, fertilizers, textiles, and other industries for their need of high-quality water needs. Choose our range of high-quality ion exchange resins for your specific applications.

Role of Ion Exchange Resin in Water Treatment Process

Water Softening

Water softness involves reducing water hardness by removing magnesium and calcium ions. These components create scales in appliances and pipes. Hard water is passed through a bed of cationic ion exchange resin beads that grab calcium and magnesium ions and release sodium ions in exchange. This helps to produce softer water that reduces the chances of scale build-up.

Demineralization

This process removes specific ions like magnesium, chloride, calcium, and sulfate from water. Ion exchange resins are used in industries that need high-quality treated water. This process is a combination of anionic and cationic resins. The ion exchange resin suppliers can customize resin tailored to remove specific ions for water consisting of needed minerals.

Deionization

Deionization, a critical process in water treatment, involves the removal of all ions from water to produce the high-purity water that is indispensable in laboratories, electronics manufacturing, and various industrial processes. The use of cationic resins, followed by anionic resins, effectively removes ions from water, ensuring the high-purity water that is a necessity in these settings. This underscores the critical role of ion exchange resins in ensuring the quality and reliability of industrial processes.

In all these water treatment processes, ion exchange resins selectively remove specific ions to get the desired water quality. The versatility and effectiveness of ion exchange resins make them essential in water treatment processes in different industrial settings. Western Carbon & Chemicals is one of the most trusted ion exchange resin manufacturers in uae for water treatment. Whether you need ion exchange resins for high-purity water or water for industrial processes, we tailor our product to your application. Get in touch with us to discuss your water treatment requirements.

Also visit:- Choose the Right Garnet Abrasive for Your Waterjet Cutting

#ion exchange resin manufacturer in India#ion exchange resin suppliers#ion exchange resin manufacturers in India

0 notes

Text

What are Ion Exchange Resins? Properties, Types & Applications

Western Carbon & Chemicals is a leading ion exchange resin manufacturer in India. We offer different grades in gel micro-porous structures for water and other applications, and another popular ion exchange resins application is in the fruit beverage industry. For more information visit our blog.

#Ion Exchange Resin manufacturer in India#Ion Exchange Resin supplier in India#Ion Exchange resins materials#Ion Exchange resins applications#Ion Exchange Resin for water softener#Ion Exchange Resins water treatment#water softener Ion Exchange#high-capacity Ion Exchange Resin#Ion Exchange resin exporter

0 notes

Text

Ion Exchange Resins Market Share, Industry Trends, Forecast 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Global Ion Exchange Resins Market size at USD 1.43 billion in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Global Ion Exchange Resins Market size to expand at a CAGR of 5.64% reaching a value of USD 2.1 billion by 2030. The Global Ion Exchange Resins Market is propelled by the thriving water treatment sector driven by the rising need for ultrapure water in the electronics and pharmaceutical industries. The growing utilization of mixed bed resins in water treatment, nuclear applications, and power generation is contributing to the increased demand for ion exchange resins. The rise in electricity demand in both industrial and residential sectors is also a key factor driving market growth. Also, the escalating use of these resins in various industries such as industrial water treatment, mining, power generation, and food & beverages is expected to enhance the overall global ion exchange resins market size during the forecast period. Market players are presented with promising growth opportunities through the expansion of manufacturing capacities. Key companies in the global ion exchange resins industry are strategically focusing on partnerships and collaborations to reinforce their global presence. Hence, such aspects are expected to boost the expansion of the global ion exchange resins market during the period in analysis.

Impact of Geopolitical Tensions on Global Ion Exchange Resins Market

The Global Ion Exchange Resins Market is impacted by increasing geopolitical tensions in several ways. The conflict has generated geopolitical tensions and economic disruptions, resulting in heightened uncertainty and volatility in global trade. It has adversely affected the production, supply chain, and distribution of anion-exchange resins, potentially leading to shortages and fluctuations in market prices. Also, the slowdown in industrial activities and reduced demand for products and services globally have contributed to a decline in the demand for ion-exchange resins. Despite these challenges, the ion-exchange resins market is expected to experience moderate growth during the forecast period. It can be attributed to factors, such as increased industrialization, expanding applications in water treatment, and rising environmental concerns. However, the exact growth expectations remain uncertain due to the aforementioned geopolitical tensions and the potential for further economic repercussions from the ongoing conflicts on the Global Ion Exchange Resins Market.

Sample Request @ https://www.blueweaveconsulting.com/report/ion-exchange-resins-market/report-sample

Global Ion Exchange Resins Market

Segmental Information

Global Ion Exchange Resins Market – By End User Industry

By end user industry, the Global Ion Exchange Resins Market is divided into Healthcare, Food & Beverages, Water and Wastewater Treatment, Mining, Power, Paper & Pulp, and Chemicals segments. The power segment is expected to hold the highest share in the Global Ion Exchange Resins Market by end user industry during the forecast period. It is primarily due to the burgeoning demand for ion exchange resins in the power industry. The heightened demand is particularly noteworthy in emerging economies, such as China, India, and the UAE. Ion exchange resins play a crucial role in the sector by facilitating the removal of toxic and heavy metal ions from hard water, a process wherein magnesium and calcium ions are substituted with sodium ions. As the power industry rapidly expands in these emerging economies, the reliance on ion exchange resins for effective water treatment contributes significantly to the projected dominance of the power segment in the global market.

Global Ion Exchange Resins Market – By Region

The in-depth research report on the Global Ion Exchange Resins Market covers the market in a number of major countries across five regions: North America, Europe, Asia Pacific, Latin America, and Middle East and Africa. The Asia Pacific region is expected to hold the highest share of the Global Ion Exchange Resins Market during the forecast period. Rapid industrialization and urbanization in countries like China and India have led to an increased demand for water treatment solutions, where ion exchange resins play a significant role. The flourishing manufacturing and chemical industries in the region further amplify the need for purification and separation processes, contributing to the rising demand for ion exchange resins. Additionally, the region's large and growing population and heightened awareness of water scarcity and environmental concerns prompt investments in advanced water treatment technologies, fostering market growth. Favorable government policies supporting water conservation and environmental sustainability also contribute to the widespread adoption of ion exchange resins in the region.

Competitive Landscape

Major players operating in Global Ion Exchange Resins Market include Anhui Samsung Resin Co. Ltd, Bio-rad Laboratories Inc., Doshion Polyscience Pvt Ltd, Dupont, Ecolab, Eichrom Technologies LLC, Evoqua Water Technologies LLC, Ion Exchange (India) Ltd, Jacobi Carbons Group, Lanxess, Mitsubishi Chemical Corporation, and Novasep. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Video

youtube

all kinds of ion exchange resin & adsorption resin,Made in China.Sanxing...

#ion exchange resin#cation exchange resin#anion exchange resin#adsorption resin#watertreatment#mixed bed resin#purewater

1 note

·

View note

Text

One of the three letters written by Vlad Drăculea, Prince of Wallachia, and the historical predicate for the character Dracula, studied to diagnose his condition of hemolacria. :: [Robert Scott Horton]

+

A chemical analysis of the letters of the legendary historical figure reputed to have inspired fictional vampire Dracula has revealed Vlad Drăculea (aka Vlad the Impaler) may have cried tears of blood. Traces left behind on the paper by the 15th century ruler of Wallachia suggest he was afflicted by a condition known as hemolacria, which manifests as the presence of blood in tears. And he may have had skin and respiratory conditions besides.

"To our reckoning," writes a team led by chemist Maria Gaetana Giovanna Pittalà of the University of Catania in Italy, "this is the first time such research has been carried out and has helped to bring to the limelight the health status of Vlad Dracula the Impaler." Vlad Drăculea, also known as Vlad Țepeș, was certainly a towering figure in European history. His exploits as ruler of Wallachia are almost mythical; in particular, the extremely bloody lengths he went to in order to protect his land from multiple conflicts.

It's unknown how many deaths he is responsible for, but estimates put it at over 80,000 – and an estimated over 20,000 of those were impaled on wooden spikes. Not to mention all the other forms of torture of which he has been (disputedly) accused. Although his life and deeds have been well documented, and in many cases no doubt exaggerated, there are some details that we are likely never to know. But Pittalà and her colleagues thought there may be a way to find out – by studying objects that Drăculea is known to have touched. Namely, letters the man himself penned.

Letters are an absolute treasure trove for historians. In this case, however, it was not the contents of Drăculea's letters that interested the researchers, but what secrets may have been left behind on the paper: the molecules and proteins that may have been transferred by human touch. The letters are now over 500 years old, and extracting material from them could cause damage, which is not ideal for precious historical documents. But the recent development of a special film of ethylene-vinyl acetate, treated with ion exchangers and water-repelling resins, has been used to promising effect with ancient fabrics and papers.

When applied to any type of surface, this film is able to extract proteins and molecules without damaging the surface. The team used these films on three of the Vlad Drăculea letters, one dated 1457, the other two 1475, and used mass spectrometry to analyze the results. They found thousands of peptides and proteins. They focused on signals of human biology; and, because many people have handled the letters over the centuries, only the human material with the most advanced degradation.

[Dracula Letters]

* * * *

“How blessed are some people, whose lives have no fears, no dreads; to whom sleep is a blessing that comes nightly, and brings nothing but sweet dreams.”

― Bram Stoker, Dracula

8 notes

·

View notes

Text

Hey, science Tumblr, question.

Dishwashers have this water softening system: a special ion exchange resin, that attracts certain minerals, which prevents the buildup of limescale. It needs to be reset periodically, and that's what the dishwasher salt is for - it's mostly regular salt, just purer and bigger (for a reason!).

Water jug filtering cartridges usually contain active carbon and ion exchange resin. With the resin handling minerals responsible for limescale.

If the main reason why I'm using water filters is to handle limescale, would giving a cartridge a salt bath reset it? Can I reuse it then?!

#science tumblr#save me science tumblr#I have some old cartridges I haven't thrown out yet#so I'm gonna grab some water tests from the shop#and actually run some tests#and you know actually test it#and yes I get that mold can be an issue#but it's for science!#hag talks

4 notes

·

View notes

Text

DuPont resin AmberLite HPR4800 OH can quickly react with impurity ions in water, achieving efficient ion exchange.

0 notes

Note

*asks about job*

Anon you are my favorite.

Okay, so, I'm a laboratory and field technician in a soil and water science lab.

I love my job so goddamn much. I get to work with fancy machines like the gas chromatograph and spectrometer! (The spectrometer is actually really boring but shhh.) I get to go outside and watch birds while I collect water samples! I am getting paid for this! I get to learn data processing and engineering and wilderness safety precautions and how to explain complex science to people whose careers are Not This.

Also, research labs are chaos and I delight in it. Okay maybe not ALL research labs, I'm informed the chemistry department does not look like this. BUT this is an environmental science lab. It is full is bizarre, deeply nerdy, deeply passionate people. Who do things like eat baked potatoes like apples, improvise experimental setups with mason jars and duct tape, and nickname every instrument either a human name or a Pixar reference. I love them so much I have no words.

Crazy and fun things I've done for this job:

Freezer jenga followed by freezer tetris (had to take all the things out of a the freezer, put them in coolers to keep them cold, defrost the freezer, and put them back in except organized this time. I was delighted by this for no logical reason, my boss thought I was nuts).

Okay you know in scifi movies where they have some weird mystery substance and they put it in a box with gloves attatched so they can work with it without actually touching it? I've done that! Not because of hazardous substances, we just needed to put stuff in jars without exposing it to oxygen. But still! It was cool!

Shopping trip to get food for like half a dozen people for three days (I had weird dreams about being overwhelmed with tortilla chips afterwards, this doesn't sound that crazy but I promise you it felt like it).

Taped plastic tubing to 200+ funels until the boxes we were storing them in overflowed and there was no longer floorspace to walk (AFTER cutting the plastic tubing into 200+ equally sized pieces and stuffing it with ion exchange resin, which is like evil microplastic sand. Between all those things, this took WEEKS. It got really boring).

Dissolved like 10kg of KCl (KCl my behated, its very harmless but hell to get off glassware) in water to make 80 LITERS OF KCL SOLUTION (that's over 20 pounds of solid KCl and over 20 gallons of solution! My coworker and I were sort of laughing hysterically over this entire process because come on! 80 liters! For reference most lab protocols need like, a liter or less of whatever solution.) Fun fact about solid KCl, it tends to stick together into a giant brick. We were chiseling at it with scoops, spoons, whatever was on hand (i really wanted to attack it with a screwdriver but it would introduce dirt into the chemicals so i couldn't) and eventually we got so frustrated we went outside and dropped the thing off a second floor balcony. After wrapping it in like 3 layers of plastic bags because we knew at least one bag was gonna break. This did not actually help much but it was very cathartic.

There was a project once where we had to take sealed mason jars and replace all the air in them with nitrogen gas. Repeatedly. For over a hundred jars. My PI (principle invesitgator, means the scientist in charge of a project and usually a lab) is good at building things, so of course he assembled this manifold thing so we could pump nitrogen through a dozen jars at once. Which was great, except it involved two dozen needles, half of them attatched to flexible plastic tubing so they'd kinda bounce around when you pulled them out of the jars. It looked like a very stabby centipede-slash-octopus monster. Impressively, we only stabbed ourselves a couple times each with this thing (and changed the needles of course, we are aware of the risks of transmitting blood diseases).

Actually one of the craziest things about this job in my opinion is how many fucking needles we work with. You see, we study atmospheric gases. And to do that, we need to transfer gases between sealed containers, which means needles and septa (the rubber things they put on vials so you can poke needles through them). So. Many. Needles. Did you know you can only use a needle four times before it gets too dull? It's extremely noticeable as you're using them - not as they get dull, but when you discard an old needle and get out a new one it is a huge difference. I don't know why I find this so fascinating, but working with needles is honestly so fun. I feel like a mad scientist or something. Also, for the first couple months I kept poking myself on accident so I was just walking around with these pinpricks and papercut looking wounds. It felt a bit like a badge of honor, somehow, like a rite of passage for working in the gas lab. Another thing about needles, if you get scratched with one horizontally instead of stabbed, they look like papercuts. It's weird. Also weird is how good you get after a while at not stabbing yourself.

I think I like working with needles because they're something that used to make me nervous. Not horribly, but I have more than typical anxiety and I get nervous about everything. And yet I am now totally chill about needles, because I work with them all the time. It's... freeing I guess. Maybe empowering, even. I am scared of so many things, but I am not scared of this. Ditto large quantities of acid, once you've had to work with dozens of liters of the stuff you stop being scared of it - this was for the same project as the KCl and yes it was equally ridiculous. Dilute acid, thankfully, but to make dilute acid you have to mix the really concentrated stuff with water. It does not come as dilute acid, that would be too easy. So we spent multiple days in a row diluting acid and soaking things in it, there were plastic boxes full of the stuff on every available counter space with handmade warning labels, it was A Thing™️.

Anyways, I'm a person who's scared of everything, except weird stuff like hydrochloric acid, needles, and wasps. I can blame all three of those things on this job, which I love dearly. I love to learn new things, pretend I'm in a scifi movie, be surrounded by crazy people (affectionate), and apparently overcome my numerous fears. You absolutely did not sign up for this big puddle of feelings, anon, but thank you for inspiring it nevertheless.

#something something personal growth and overcoming fears. maybe that's part of why i love this job.#the wasp thing is because i have a field site at a bridge that's basically got wasp nests all over the underside#the wasps like to watch me work#i am genuinely having personal realizations while answering this ask#thank you anon sorry this got out of control i hope my exploits amuse you#some of it i think you just had to be there#also if anyone recognizes these stories shh you didn't see anything#my coworkers had better not see this it would be so embarassing#hylian rambles#hylian does science#anon#asks#thanks anon!#needles tw#i promise proper safety protocols were being followed in all of these stories#the acid involved so. much. ppe.

1 note

·

View note

Text

What is the 5 Benefits of Water Filtration Maintenance?

Introduction: What is Water Filtration Maintenance?

Water filtration maintenance is crucial for ensuring the consistent delivery of clean and safe drinking water. Whether you're using a home filtration system or a larger, more complex system for a commercial or industrial setting, regular maintenance is non-negotiable. Without proper care, your system can become inefficient, clogged, or worse, it could allow harmful contaminants to bypass the filter, putting your health at risk.

But what exactly does water filtration maintenance entail? Why is it necessary, and how can you keep your system in peak condition without overspending? This gadget blog will cover the causes of water filtration maintenance, proper usage guidelines, how to achieve cost efficiency, and the best practices to extend the lifespan of your system. Let’s dive in!

What is water quality for human use?

Water quality for human use refers to the characteristics of water that make it safe, clean, and suitable for consumption and other daily activities like cooking, cleaning, and bathing. High-quality water should be free from harmful contaminants, such as:

- Physical Contaminants: Dirt, sediment, and debris should be absent.

- Chemical Contaminants: Harmful chemicals like lead, pesticides, or industrial waste should be either absent or within safe levels.

- Biological Contaminants: Bacteria, viruses, and parasites must be removed or reduced to safe levels.

- Taste and Odor: Water should be free of unpleasant tastes and odors.

- pH Level: It should have a balanced pH (around 6.5-8.5), ensuring it’s neither too acidic nor too alkaline for safe use.

In essence, water quality for human use ensures that the water is not only clean and free of harmful elements but also pleasant and safe to consume or use in daily life. Source: Water Quality Index (WQI) - Quality water program

What Causes Water Filtration Maintenance?

Water filtration systems, though highly effective, are prone to several issues over time. Here are some primary reasons why Water Filtration Maintenance is needed:

1. Sediment Buildup: Water Filtration System Servicing

Sediment is a common issue in water filtration system servicing systems, especially in areas with high turbidity. Sediment includes particles such as dirt, sand, and rust, which can clog up filters and reduce their effectiveness. If not addressed, sediment buildup can lead to reduced water pressure and slow filtration rates, making your filtration system work harder than it needs to. This can cause a strain on your system and ultimately lead to premature wear and tear.

For instance, sediment pre-filters are often the first line of defense in a filtration system. They need to be regularly checked and replaced to prevent blockages from affecting the rest of the system.

2 Mineral Deposits and Scale

In areas with hard water, which contains high levels of minerals like calcium and magnesium, scale buildup is a common problem. Over time, these minerals can deposit themselves on the inside of pipes, fixtures, and filtration components, leading to reduced water flow and efficiency. This not only affects the performance of your water filtration system but can also cause damage to appliances like water heaters, dishwashers, and washing machines.

Water softeners, which are often part of a complete filtration system, help mitigate this issue. However, even they require maintenance, particularly if they rely on salt-based ion exchange systems. Regularly refilling salt or cleaning out resin beads are essential tasks to ensure they continue to function properly.

3 Organic Contaminants

Organic contaminants such as algae, bacteria, and viruses can also lead to filter clogs or contamination. If your filtration system is exposed to stagnant water or hasn’t been maintained regularly, biological growth can occur. This is particularly dangerous as it poses a direct health risk. Activated carbon filters, which are often used to remove organic compounds and improve taste and odor, need to be replaced frequently as they become saturated over time.

Additionally, reverse osmosis (RO) systems, which are highly effective at removing biological contaminants, require routine cleaning and disinfection to prevent bacterial buildup on the membrane.

4 Wear and Tear for Water treatment system upkeep

Like any mechanical system, Water treatment system upkeep experiences normal wear and tear. O-rings, seals, and connectors can degrade over time, leading to leaks and reduced efficiency. Filters themselves, whether they’re activated carbon, sediment, or reverse osmosis membranes, have a limited lifespan and must be replaced periodically to maintain optimal performance. Ignoring regular maintenance can lead to system failures and costly repairs.

Benefits of Regular Water Filtration Maintenance

Regular maintenance of your water filtration system offers numerous advantages, ensuring not only that your water remains clean and safe, but also that your system operates efficiently. Here are the key benefits:

1 Improved Water Quality after Filtration System Servicing

The primary reason for maintaining your filtration system is to ensure consistently high water quality. Clean filters effectively remove contaminants like chlorine, lead, bacteria, and other harmful substances. Without proper maintenance, your filter can become clogged and less effective, allowing these pollutants to pass through and potentially harm your health. The filtration system servicing process improves drinking water quality

Regular water filtration maintenance guarantees that your system continues to produce water that is clear, odor-free, and safe to consume.

2 Prolonged System Lifespan after water filtration maintenance

Just like any other appliance, routine care can significantly extend the life of your water filtration system. Regularly replacing filters, cleaning the system, and checking for wear and tear prevent small issues from becoming major problems. This ensures that your system doesn’t experience premature failure, saving you the cost and hassle of early replacement.

In the long run, properly servicing your water filtration system also minimizes the need for frequent repairs, helping you avoid costly service calls.

3 Better Water Pressure after maintaining your water filtration system

One of the common complaints when filters aren’t maintained is reduced water pressure. A clogged or dirty filter restricts the flow of water, making it harder for the system to deliver the desired amount of filtered water. Regular maintenance of filters ensures that water pressure remains consistent, offering convenience when using faucets, showers, and appliances like dishwashers and washing machines.

Good water pressure not only improves daily activities but also helps other connected systems and appliances operate more efficiently after water filtration maintenance.

4 Increased Energy Efficiency by filtration system servicing

When filters are clogged or not replaced on time, your water filtration system servicing has to work harder to push water through. This can increase energy usage, especially for systems connected to pumps or other energy-driven components. By keeping the system clean and filters unclogged, you ensure that the system operates at peak efficiency, potentially lowering energy bills over time.

5 Prevention of Health Risks:

A poorly serviced water filtration system can become a breeding ground for harmful bacteria, mold, and algae. If your filter is saturated or if the system isn’t cleaned regularly, these contaminants can multiply and enter your drinking water. This poses a significant health risk, particularly to individuals with weakened immune systems or sensitivities to certain microorganisms.

By water filtration maintenance your system, you reduce the likelihood of exposure to waterborne illnesses and ensure the water you and your family consume is safe and healthy.

6 Cost Savings

While regular maintenance requires an investment of time and money for replacement water filters, it saves you more in the long run. Neglecting maintenance leads to more frequent repairs, reduced system lifespan, and potentially higher energy bills. Additionally, well-maintained Filtration systems servicing doesn’t require frequent part replacements or emergency fixes, making the overall cost of ownership more affordable.

For example, spending a small amount on a new water filter every few months is far less expensive than replacing a malfunctioning water filtration unit.

7 Enhanced Taste and Odor of Water

A clean water filter is essential for removing unpleasant tastes and odors from tap water, particularly those caused by chlorine or organic materials. Over time, an unmaintained filter can become saturated and ineffective, allowing these undesirable elements to affect your water’s taste and smell.

With regular water filtration maintenance, you ensure that your water not only looks clean but also tastes fresh and appealing, making it more enjoyable to drink.

How to Properly Maintain Your Water Filtration System

Regular water filtration maintenance ensures that your water filtration system remains functional and efficient. Here’s a step-by-step guide to help you properly maintain your system:

1 Follow Manufacturer Guidelines

Every water filtration system is different, so it’s essential to follow the manufacturer’s guidelines for maintenance. The user manual will provide specific instructions on how to clean and replace filters, as well as any other system components. Failing to follow these instructions can void your warranty and cause issues down the road.

For example, some reverse osmosis systems may recommend replacing the membrane every 2-3 years, while carbon filters may need replacement every 6-12 months. Being diligent about these timelines will ensure the longevity of your system.

2 Regular Filter Replacement

The filter is the heart of any filtration system, and its regular replacement of water filters is key to maintaining water quality. Different types of filters have different lifespans:

- Sediment Filters: Usually need replacement every 6-12 months depending on the water quality and usage.

- Carbon Filters: Activated carbon filters should typically be replaced every 3-6 months, especially in high-usage households.

- Reverse Osmosis Membranes: These can last anywhere from 2 to 5 years, but they should be checked annually for performance.

A clogged filter not only reduces water pressure but can also allow contaminants to pass through, defeating the purpose of your system.

3 System Cleaning

In addition to replacing filters, it’s important to regularly clean your filtration system’s housing and other components. Over time, grime, sediment, and other residues can accumulate in the filter housing, potentially contaminating your water. Simple practices like wiping down the exterior of the system, rinsing out the filter housing, and cleaning out water lines can keep your system running smoothly.

If you’re using a reverse osmosis system RO, regular cleaning of the storage tank is essential to prevent the buildup of bacteria and algae.

4 Check Water Quality Regularly

It’s always a good idea to test your water quality periodically to ensure that your filtration system is working as it should. Home water testing kits are widely available and can help you monitor for issues like pH levels, chlorine, lead, and bacterial contamination.

Testing the water after the filter allows you to catch any performance dips early and prevent the consumption of unsafe water.

5 Inspect for Leaks and Malfunctions

A key part of a water filtration maintenance system is inspecting for leaks, cracks, or other malfunctions. Even a small leak can lead to water damage or a significant drop in efficiency. If you notice reduced water pressure, higher-than-normal water consumption, or strange noises from your filtration system, it might be time to troubleshoot and fix potential issues before they become serious.

Moderation in Water Filtration: Don’t Overdo It

While a water filtration system is crucial, it’s equally important not to overdo it. Too much maintenance can lead to unnecessary costs or even damage to the system. Here’s how to find a balanced approach to water filtration maintenance:

1 Monitor Performance

Instead of following a rigid maintenance schedule, it’s often better to monitor your water filtration maintenance system’s performance. If you notice a decrease in water pressure or a change in taste, it’s probably time to replace the filter. This way, you avoid over-replacing parts that are still functioning well, saving time and money.

2 Use Testing Kits for Drinking Water to Determine Filter Replacement

Using home testing kits to evaluate your water quality can help determine when maintenance is truly needed. For instance, if your water is still clean and free of contaminants, you might be able to extend the life of certain filters without any risk. This kind of moderation prevents over-maintenance and keeps costs manageable. Use water testing kits for drinking water.

Cost Efficiency in Water Filtration Maintenance

Maintaining your water filtration system doesn’t have to break the bank. Here are some tips for keeping costs down while ensuring that your water filtration maintenance system functions at its best:

1 Reusable Filters

Opting for filters that can be cleaned and reused rather than disposable ones can save you a significant amount of money. Many sediment filters and certain carbon filters can be rinsed and reused multiple times before needing replacement.

2 Preventive Maintenance

Regular inspections and preventive care can help you catch small issues before they become major problems. Fixing a small leak or replacing a worn-out seal is far cheaper than dealing with a full system failure that could require an expensive repair or replacement.

3 Bulk Purchases

Many manufacturers offer discounts when you buy replacement filters in bulk. If you know you’ll need several filters for a year, purchasing them all at once can save you both time and money. Keep an eye out for seasonal sales or promotions from your filter manufacturer.

Good Practices for Long-Lasting Water Filtration Systems

Here are additional tips for ensuring your water filtration system lasts as long as possible with water filtration maintenance:

1 Use Filter Protectors

Installing a sediment pre-filter or filter protector can help extend the life of more expensive filters by catching larger particles before they reach the main filtration unit. This not only improves performance but also reduces maintenance costs.

2 Keep Components Dry

When the filtration system isn’t in use for extended periods, such as during vacations, it’s best to drain and dry the system. This will prevent the growth of bacteria, mold, or algae within the filters and pipes.

3 Flushing the System

Occasionally flushing your water filtration system can help remove built-up sediment and other impurities that could clog your filters. This simple practice keeps your system functioning smoothly and prevents more significant maintenance issues down the line.

Conclusion: Ensure Clean Water for Years to Come

A water filtration maintenance system is an essential task that ensures your water supply's long-term health and safety. By understanding what causes the need for regular maintenance and adopting good practices, you can enjoy clean, healthy water for years to come without incurring unnecessary costs. Regular care is the key to extending the life of your system, improving its efficiency, and ensuring you get the best value from your investment.

Some Home Related Articles for you

What is Not a Physical Security Measure for Your Home?

Best Smart Home Gadgets 2024: Won’t Break Bank

How to Align Garage Door Sensors: 3 Expert Tips

Don’t Be a Victim: Discover the 7 Power of Spy Cameras

The Most Satisfying Bedroom Gadgets

Read the full article

0 notes

Text

Chromatography Resin Market Size, Trends, Revenue Share Analysis, Forecast, 2024–2030

The Chromatography Resin Market was valued at USD 2.6 billion in 2023-e and will surpass USD 4.4 billion by 2030; growing at a CAGR of 7.7% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market. The report also identifies the key stakeholders, their business gaps, and their purchasing behavior. This information is essential for developing effective marketing strategies and creating products or services that meet the needs of the target market.

Chromatography is a laboratory technique for the separation of a mixture into its components. Chromatography resin is a medium used in the column chromatography method, which includes ion exchange, affinity, and size exclusion chromatography. These resins are essential for purifying proteins, nucleic acids, and other biomolecules, making them indispensable in various industries.

Read More about Sample Report: https://intentmarketresearch.com/request-sample/chromatography-resin-market-3154.html

Key Drivers of Growth

Biopharmaceutical Boom: The rise in biopharmaceutical production, including monoclonal antibodies, vaccines, and recombinant proteins, has significantly boosted the demand for chromatography resins. These resins play a crucial role in the purification processes, ensuring the safety and efficacy of biopharmaceutical products.

Technological Advancements: Innovations in chromatography techniques and resin development have enhanced the efficiency and effectiveness of purification processes. Advances such as multi-modal resins, which combine different modes of interaction, have expanded the applications of chromatography.

Regulatory Compliance: Stringent regulatory requirements for drug approval and quality control in the pharmaceutical and food industries necessitate the use of reliable and efficient purification methods. Chromatography resins, known for their precision and reliability, are in high demand to meet these standards.

Environmental and Food Safety: The growing emphasis on environmental monitoring and food safety has increased the use of chromatography resins in testing and analysis. These resins help detect contaminants and ensure the quality of water, air, and food products.

Market Segmentation

The chromatography resin market can be segmented based on type, technique, application, and region.

By Type: Natural polymer, synthetic polymer, and inorganic media are the primary types of chromatography resins. Natural polymers, such as agarose and cellulose, dominate the market due to their biocompatibility and versatility.

By Technique: The market is segmented into ion exchange, affinity, size exclusion, hydrophobic interaction, and others. Ion exchange and affinity chromatography are the most widely used techniques, owing to their high selectivity and efficiency.

By Application: The applications of chromatography resins span across pharmaceuticals, biotechnology, food and beverage, water and environmental analysis, and others. The pharmaceutical and biotechnology sectors account for the largest share due to their extensive use in drug development and production.

By Region: North America holds the largest market share, followed by Europe and the Asia-Pacific region. The presence of major biopharmaceutical companies, advanced healthcare infrastructure, and significant R&D investments drive the market in these regions.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/chromatography-resin-market-3154.html

Future Prospects

The chromatography resin market is poised for continued growth, driven by several key trends:

Personalized Medicine: The shift towards personalized medicine and targeted therapies will increase the demand for chromatography resins in the purification of specific biomolecules tailored to individual patient needs.

Biosimilars and Biobetters: The rising development of biosimilars and biobetters will fuel the demand for efficient purification techniques, further driving the chromatography resin market.

Sustainability Initiatives: Increasing focus on sustainability and green chemistry will lead to the development of eco-friendly chromatography resins, reducing environmental impact and enhancing market growth.

Emerging Markets: Rapid industrialization and advancements in healthcare infrastructure in emerging markets, particularly in Asia-Pacific and Latin America, will provide significant growth opportunities for the chromatography resin market.

Conclusion

The chromatography resin market is on a trajectory of robust growth, driven by advancements in biotechnology, increasing biopharmaceutical production, and stringent regulatory requirements. With ongoing innovations and expanding applications, the future of the chromatography resin market looks promising. Stakeholders in the industry should stay abreast of these trends to capitalize on the growth opportunities and navigate the evolving landscape effectively.

#Chromatography Resin#Chromatography Resin Growth#Chromatography Resin Trends#Chromatography Resin Outlook

0 notes