#Lab-Scale Extruder

Explore tagged Tumblr posts

Text

Lab-Scale Extruder and Spheronizer Combo is a seamlessly integrated system poised to redefine granulation in formulation research and product development. The Extruder component, featuring four interchangeable heads, facilitates versatile low-pressure granulation techniques on a bench-top scale, accommodating batches as small as 200 grams. Its adaptability and indicative results make it a cost-effective and efficient solution for evaluating diverse formulations.

0 notes

Text

Comparative Noise Analysis of Lab Scale Twin Screw Extruder and Lab Scale Extruder

Noise level is an important consideration in laboratory equipment, especially for devices like lab scale extruders used in research and small-scale production. Among the popular types are the Lab Scale Twin Screw Extruder and the Lab Scale Single Screw Extruder. Understanding their noise characteristics can help users choose the right equipment to maintain a safer and more comfortable working environment without compromising performance.

Factors Influencing Noise in Lab Scale Extruders

The noise generated by extruders primarily comes from mechanical components such as motors, gearboxes, screws, and bearings, as well as from the material processing itself, including melting and conveying. The design and configuration of the extruder strongly affect these noise levels.

Twin screw extruders typically have two intermeshing screws rotating simultaneously, which can cause more mechanical complexity and potential noise sources compared to single screw extruders. However, advanced engineering and sound insulation can mitigate much of this noise.

Noise Characteristics of Lab Scale Twin Screw Extruders

Lab Scale Twin Screw Extruders are favored for their good mixing and processing capabilities, especially for complex or multi-component materials. However, the engagement of two screws and their synchronized rotation may introduce higher mechanical noise due to the interaction between screws and increased number of moving parts.

The motors powering twin screw extruders are usually designed to handle higher torque, which can also contribute to noise. Yet, manufacturers often incorporate vibration-damping materials, precision bearings, and optimized gearboxes to reduce operational noise.

Additionally, since twin screw extruders often operate at varying speeds depending on the application, noise levels may fluctuate. At lower speeds, noise tends to be quieter, while higher speeds may generate more audible sound due to increased mechanical activity and material shear.

Noise Characteristics of Lab Scale Single Screw Extruders

Lab Scale Single Screw Extruders, in contrast, generally produce less mechanical noise due to their simpler design. With only one rotating screw, there are fewer moving components interacting, causing reduced vibration and sound emissions.

The motor and drive systems for single screw extruders tend to be smaller and less complex, which typically results in quieter operation. However, single screw extruders may produce some noise from the material melting and conveying process, but this is usually less pronounced.

Applications that do not require extensive mixing or compounding often prefer single screw extruders due to their quieter operation and simpler maintenance.

Comparison and Considerations for Laboratory Settings

When noise is a critical factor in laboratory environments, single screw extruders may be advantageous due to their inherently lower mechanical noise. However, if processing complexity demands a twin screw extruder, selecting models with noise reduction features and implementing external soundproofing can help manage sound levels.

Operators should also consider the placement of the extruder in rooms with adequate acoustic treatments and the use of personal protective equipment if necessary. Regular maintenance ensures that bearings and gears remain lubricated and aligned, preventing excess noise caused by wear or damage.

Noise level measurements, often expressed in decibels (dB), vary between different extruder models and brands. Prospective users should request noise specifications and, if possible, observe operational demonstrations to assess suitability.

Conclusion

Both Lab Scale Twin Screw Extruders and Lab Scale Single Screw Extruders have distinct noise profiles influenced by their mechanical designs and operating conditions. While twin screw extruders may generate higher noise due to their complexity, modern engineering solutions can effectively reduce this. Single screw extruders generally offer quieter operation and are suitable for less demanding processes.

Understanding these differences allows laboratory managers and researchers to select extruder equipment that balances processing needs with noise considerations, promoting a productive and comfortable working environment.

0 notes

Text

High pressure homogenizer

There are a lot of homogenizers out there, and magnitudes more applications in which homogenization is required. Highpressurehomogenizer.com makes it simple for you to find and purchase the best homogenizer for your application High-pressure homogenizers are most commonly used for creating emulsions and for cell lysis when relatively large volumes are being processed.

#extruder homogenizer#highpressurehomogenizer#pressure homogenizer#extruder#small production homogenizer#inline homogenizer#homogenizer in chennai#homogenizer manufacturers in india#homogenizer lab scale

0 notes

Text

There are a lot of homogenizers out there, and magnitudes more applications in which homogenization is required. Highpressurehomogenizer.com makes it simple for you to find and purchase the best homogenizer for your application High-pressure homogenizers are most commonly used for creating emulsions and for cell lysis when relatively large volumes are being processed.

#highpressure homogenizer#pressure homogenizer#extruder homogenizer#small production homogenizer#homogenizer in chennai#homogenizer in india#homogenizer mechanism#homogenizer lab scale#inline homogenizer

0 notes

Text

youtube

With a puffy and prickly body, the spiny star (Hippasteria sp.) is easy to spot on the deep seafloor.

These stars roam the seafloor searching for a delicious dinner, and a hungry Hippasteria can be quite particular when it comes to feeding. For some, sea pens or anemones are their sole preference. Here in our backyard, spiny stars seek out prey that is particularly prevalent in the Monterey Bay and beyond: deep-sea corals.

While some corals have evolved protective stinging sweeper tentacles to deter hungry predators, spiny stars are determined in their quest for a nutritious feast. They use tiny tube feet to scale a towering coral. When they find a good spot to stop, they wrap their arms around the stalk to hang on tight, then extrude their stomach out of their mouth to devour the juicy coral polyps.

Hippasteria are important in restructuring the habitats where they live. As they leave dead coral skeletons behind, homes for new animals are created. This natural turnover keeps the community healthy and helps foster diversity among the fishes and invertebrates that live there.

Animals that live deep in the ocean thrive in cold water and high salinity. Changes in climate at the surface ripple down to the depths below. Warmer and more acidic waters put deep-sea corals—and the animals that depend on them for food and shelter—at risk.

Studying the animals of the deep is increasingly urgent. Overfishing, pollution, and climate change all threaten the deep ocean. What we learn in the field and in the lab improves our baseline understanding of deep-sea communities so we can assess and track ongoing human impacts on the animals and habitats far beneath the ocean’s surface.

Learn more about the spiny star and other fascinating animals of the deep at our Animals of the Deep gallery.

65 notes

·

View notes

Text

The Best Venue For Private Events Mumbai: La Panthera

Selecting the best venue for private events in Mumbai can make all the difference when throwing an unforgettable celebration. There are plenty of chic and adaptable locations in Mumbai to pick from, whether you're looking for the best pasta in Mumbai, top restaurants, a bridal shower, or simply a get-together with your closest friends at the best bars. La Panthera provides all. What if the ideal combination of setting, food, and drinks is what your party deserves

Best Venue For Private Events Mumbai Designed For festivities

Just one year has passed since La Panthera debuted in the Bandra Kurla Complex, yet it already has the respect that is typically given to historic dining rooms, which are the best venue for private events in Mumbai. The 100-seat venue, which was designed by Rohit Bhoite to resemble the drawing room of a European manor with its velvet couches, Corinthian columns, and brass frond chandeliers, is a combination of salon and stage. The tone is theatrical as you enter, with a gilded panther sculpture skulking next to the hostess's desk.

Event planners from all across the city are drawn to this location because of its unique combination of intimacy and spectacle. Whether it's a CEO's fireside talk, a trendy mehendi, a milestone birthday, or the after-party for a magazine launch, La Panthera effortlessly scales up or down.

Access to a private, many-cover dining salon with a marble bar is available for private bookings.

Modern AV concealed in ornate cabinetry ensures that the décor never appears businesslike.

A central hall that can hold many people for a cocktail party or plated dinner.

Committed butler service, valet parking, and floral design in association with the best venue for private events in Mumbai

Although those pragmatic considerations are important, visitors frequently recall the unique ambiance that lends even business gatherings a little of The Gatsby.

Classical-inspired The Best Venue For Private Events Mumbai

Although Chef Manuel Olveira's menu varies from Spain to Greece to the Amalfi coast, his "ingredient-first" attitude is evident in every dish. Elle Décor claims that Oliveira plates with haute elegance while "letting the ingredients shine." That translates into four customizable menu tracks for private events:

Tapas to share include ruby-red beetroot tartare cones, tuna escabeche on cassava crackers, and Manchego croquetas.

New Zealand lamb chops sitting on morel-rich sauce, lobster risotto, and burrata with basil oil are all part of a grand European feast.

Mediterranean vegetarian odyssey: Aegean-style mushroom dolmas, slow-roasted heirloom tomatoes in gazpacho consommé, and charred leek agnolotti.

Importantly, La Panthera has already established itself as the best pasta in Mumbai thanks to its freshly extruded tagliatelle with sea urchin cream and confit garlic, which has already become a cult favorite among fans of Italian food with the best bars in Bandra.

One of The Best bars in Bandra is Liquid Theatre.

The eight-meter marble bar that serves as the focal point of the west wall is rarely left Instagrammed by visitors. Behind it, mixologists whisk and toss drinks that are a nod to the European aperitivo culture, such as the mezcal-forward Raison d'Être, the watermelon-gin Wildlings, and the sherry-washed Negronis. For event evenings, bartenders prepare specialty drinks in advance at the best venues for private events in Mumbai where 140 cocktails can be served in a matter of minutes. The bar's technical program, which includes clarified citrus, fast infusions, and lab-grade carbonation, combines showmanship with speedy service to confirm its standing as one of Bandra's top bars.

What Mumbai's best venue for private events Should Have

After discussing food and beverages, let's move on to logistics. When selecting a location for the best venue for private events in Mumbai, keep the following points in mind:

Layout and Capacity

Make sure the best venues for private events in Mumbai can accommodate the number of people you intend to invite. While some venues can easily hold 100+ attendees, others are better suited for intimate gatherings of 20–30 people. Seek out locations that offer open spaces for dancing, adjustable seating, and quiet alcoves for more private discussions.

Ambience and Design

Each gathering has its vibe. Which would you prefer—casual, contemporary, and urban, or warm? There are best venues for private events in Mumbai to suit every mood. While some venues allow you to bring your décor and entertainment, others are already stylishly furnished.

Packages of food and beverages

The best venues for private events in Mumbai provide specialized meal and drink packages to fit your tastes and price range. Make sure your location is adaptable, with top restaurants in Bandra, a variety of international cuisines, or an open bar with the best bars in Bandra.

Entertainment and Music Choices

Verify whether live bands or DJs are permitted at the location. Certain best venues for private events in Mumbai have specially designed lighting and sound systems.

Conclusion

Mumbai's restaurant industry is changing quickly, yet certain establishments instantly become classics by fusing atmosphere, creativity, and business acumen. One such unicorn is La Panthera. It delights plate and palate lovers, appeases spreadsheet stewards of budgets and BOQs, and provides photographers with an infinite supply of opulent moments.

The hunt is over for hosts looking for the best venue for private events in Mumbai, which is surrounded by the top restaurants , serves the best pasta, and has cocktails from one of the best bars. Book a table Today!

Article source- https://medium.com/@gayatrihd99/the-best-venue-for-private-events-mumbai-la-panthera-4d9e8a7b948e

0 notes

Text

7 Aluminium Ingots for Electrical Industry: The Role of A7 Aluminium Ingots for Electrical Industry in Powering Modern Infrastructure

Introduction A7 Aluminium Ingots for Electrical Industry

In the ever-evolving world of energy and electrical systems, the demand for high-conductivity, corrosion-resistant, and cost-effective materials has never been higher. Aluminium, known for its lightweight, conductive, and recyclable nature, is one of the most used metals in the electrical industry. Within this domain, A7 aluminium ingots for electrical industry hold a place of prominence due to their high purity (99.7%) and superior electrical properties. To meet the growing demand, choosing a reliable A7 aluminium ingots for electrical industry supplier has become critical for manufacturers and contractors in the electrical sector.

What are A7 Aluminium Ingots for Electrical Industry?

A7 aluminium ingots for electrical industry are high-purity aluminium blocks, generally with a minimum of 99.7% aluminium content. These ingots are categorized based on the purity levels and elemental composition defined by global standards such as the International Aluminium Institute (IAI).

Key Properties of A7 Aluminium Ingots for Electrical Industry:

High electrical and thermal conductivity

Excellent corrosion resistance

Lightweight

Non-toxic and environmentally friendly

Easily recyclable

These properties make A7 aluminium ingots for electrical industry ideal for applications in power transmission, distribution networks, and high-efficiency electrical devices.

Importance of A7 Aluminium in the Electrical Industry

The electrical industry relies heavily on conductive materials that can withstand various environmental and operational challenges. A7 aluminium has emerged as an economical and efficient alternative to copper for many applications, primarily because of its cost-effectiveness and similar conductivity performance.

Advantages of Aluminium Over Copper:

Lower weight (about one-third of copper)

More abundant and less expensive

Easier to fabricate and handle

Lower thermal expansion

Applications of A7 Aluminium Ingots for Electrical Industry:

Power transmission lines

Electrical busbars

Transformer windings

Overhead conductors (ACSR and AAC cables)

Electrical wiring in buildings and infrastructure

Energy storage components (battery casings)

Technical Standards for A7 Aluminium Ingots for Electrical Industry

To ensure consistency and quality, A7 aluminium ingots for electrical industry must comply with several international standards:

ASTM B221 – Standard for aluminium and aluminium-alloy extruded bars, rods, wires

ISO 209 – International specifications for ingot production

EN 573-3 – European standard for aluminium chemical composition

RoHS and REACH – Compliance with environmental safety

A trustworthy A7 aluminium ingots for electrical industry supplier will always provide certificates of analysis, third-party lab reports, and compliance documentation to meet these regulatory requirements.

How A7 Aluminium Enhances Electrical Conductivity

The high-purity aluminium in A7 aluminium ingots for electrical industry reduces resistivity, enhancing the performance of electrical applications:

Electrical Resistivity: Lower impurities ensure minimal resistance.

Thermal Conductivity: Better heat dissipation prevents component overheating.

Oxidation Resistance: A7 grade naturally forms a protective oxide layer that resists further corrosion, critical for overhead and exposed electrical systems.

These benefits are especially vital in large-scale installations such as substations, urban transmission grids, and renewable energy systems.

The Role of A7 Aluminium Ingots for Electrical Industry Supplier

A7 aluminium ingots for electrical industry are not a commodity to be procured casually. Choosing the right A7 aluminium ingots for electrical industry supplier impacts production schedules, product quality, regulatory compliance, and ultimately, business profitability.

What to Expect from a Reliable Supplier when buying A7 Aluminium Ingots for Electrical Industry

Consistent supply of high-purity ingots

Global logistics capability

Certifications and quality assurance

Technical documentation and test certificates

Custom sizes and packaging options

Responsive customer support

Suppliers streamline procurement processes for electrical component manufacturers, EPC (Engineering, Procurement, Construction) contractors, and energy infrastructure developers.

Leading Global A7 Aluminium Ingots for Electrical Industry Suppliers

Here are a few globally recognized suppliers specializing in high-purity aluminium for electrical use:

AWF Global Trading Co. (Hong Kong)

Shandong Yien Import & Export Co. (China)

Asif Metals Pvt. Ltd. (India)

DE-Two Trading (USA)

These companies offer competitive pricing, international shipping, and compliance with regional standards for A7 aluminium ingots for electrical industry.

Logistics and Sourcing Considerations for A7 Aluminium Ingots for Electrical Industry

A well-established A7 aluminium ingots for electrical industry supplier will offer end-to-end logistics support, including:

Freight forwarding and cargo consolidation

Export documentation: COO, BL, packing list, invoice, etc.

Insurance against transit damage

Port-to-door delivery

Things to Confirm During Sourcing of A7 Aluminium Ingots for Electrical Industry:

Country of origin

Lead time

Minimum order quantity (MOQ)

Incoterms (FOB, CIF, DDP)

Quality control processes

Case Study: Power Transmission Project Using A7 Aluminium Ingots for Electrical Industry

A power transmission company in the UAE needed high-conductivity materials for a desert-based overhead grid expansion. By partnering with a trusted A7 aluminium ingots for electrical industry supplier in China, they:

Reduced project costs by 15%

Improved cable conductivity by 20%

Received material within 18 days, meeting critical deadlines

Achieved environmental compliance with recyclable ingots

The right supplier not only met material requirements but also enhanced overall project performance.

Sustainability and Environmental Impact

The electrical industry is under pressure to reduce carbon emissions and promote sustainability. A7 aluminium ingots for electrical industry align with this trend:

Recyclable: 100% recyclable without losing quality

Energy Efficient: Aluminium smelting technology continues to evolve, lowering energy usage

Lightweighting: Reduces energy demand in transportation and handling

Suppliers offering “green aluminium”—produced using renewable energy—are becoming increasingly important for eco-conscious buyers in the electrical sector.

Future Outlook: Smart Grids and Aluminium Demand

As smart grid technology and decentralized energy systems become mainstream, demand for high-performance conductive materials will rise. A7 aluminium ingots for electrical industry are poised to play a central role in:

IoT-integrated smart meters and panels

Electrification of rural zones

EV charging infrastructure

Battery storage systems

Global energy transition goals will necessitate strategic partnerships with top-tier A7 aluminium ingots for electrical industry suppliers.

Tips for Selecting the Best A7 Aluminium Ingots for Electrical Industry Supplier

Check References: Ask for client lists and project examples.

Visit Facilities: Virtual tours or in-person audits.

Test Samples: Small batch orders to verify performance.

Assess Responsiveness: Communication is key to long-term partnerships.

Evaluate Pricing Models: Understand what’s included and what’s not.

Common Challenges and Solutions in Bulk Procurement

ChallengeSolutionQuality inconsistencyWork with certified suppliers, ask for third-party lab reportsDelayed deliveriesPartner with suppliers having proven logistics experienceHigh freight costConsolidate shipments, use FOB/CIF depending on project needsRegulatory hurdlesEnsure supplier provides complete documentation

A competent A7 aluminium ingots for electrical industry supplier will anticipate these issues and proactively offer solutions.

Conclusion of A7 Aluminium Ingots for Electrical Industry

A7 aluminium ingots for electrical industry are indispensable due to their unique combination of high conductivity, corrosion resistance, and lightweight properties. Their applications span from simple wiring to complex energy infrastructure and smart grid systems.

Securing a dependable A7 aluminium ingots for electrical industry supplier ensures uninterrupted production, quality compliance, and long-term profitability. As the global demand for energy-efficient, sustainable materials increases, sourcing A7 aluminium ingots for electrical industry from reliable suppliers becomes more than a procurement choice—it becomes a strategic necessity.

If your organization is involved in electrical manufacturing or infrastructure development, now is the time to evaluate your aluminium sourcing strategy. Choose a supplier who aligns with your technical needs, regulatory expectations, and growth aspirations.

LME Price of Aluminium

0 notes

Text

At VJ Instruments, we specialise in providing advanced mixing and granulation equipment designed for optimal performance in pharmaceutical, chemical, and food industries. Our top-quality cone blender, cube mixer, die roller extruder, and double cone blender are engineered for precision blending, consistent granule formation, and ease of use. With a focus on innovation and reliability, VJ Instruments ensures that every product meets global standards for quality and efficiency, making us a trusted name for lab and pilot-scale equipment worldwide.

FAQs:

1. What is a cone blender and where is it used? A cone blender is used for homogeneous mixing of dry powders and granules. It is commonly used in the pharmaceutical and chemical industries for uniform mixing without particle degradation.

2. How does a cube mixer work? A cube mixer operates by rotating a cube-shaped container to thoroughly blend ingredients. Its unique tumbling action ensures even mixing of dry materials, making it ideal for sensitive formulations.

3. What is the function of a die roller extruder? A die roller extruder shapes wet mass into uniform extrudates using a rotating die. It is widely used in pharmaceutical granulation and pelletisation processes.

0 notes

Text

Melt Flow Index Tester to Measure the Melt Volume Rate

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-to-measure-the-melt-volume-rate

Introduction

An accurate device to measure the melt volume rate of thermoplastic materials under special conditions is the Melt Flow Index Tester. It is an important equipment for quality control and product development because it helps manufacturers to identify how a polymer will behave during processing. This device calculates the amount of material flowing through a die over a set time by offering valuable data for comparing material levels. It allows consistent product performance and reliable manufacturing and is very accurate and simple to use. For industries searching to improve their testing capabilities with advanced, user-friendly equipment Perfect Group India provides trusted solutions.

Why Use a Melt Flow Index Tester? An instrument used in labs to measure the flow properties of thermoplastic polymers is called a Melt Flow Index Tester. It monitors how quickly molten plastic moves through a die at a given temperature and pressure. Depending on the measurement unit this flow rate is referred to as the Melt Volume Rate (MVR) or Melt Flow Index (MFI).

The test results which show how much material extruded from the instrument in that time, are given in grams per 10 minutes (for MFI) or cubic meters per 10 minutes (for MVR). These results help manufacturers in creating the behavior of the material during actual processing, such as blow molding, extrusion or injection molding.

Why Measuring Melt Volume Rate is Important The Melt Volume Rate of a material is important for these reasons:

Quality Control A Melt Flow Index Tester can be used by businesses to test polymers on a regular basis to make sure the materials meet demands before going into manufacturing. Defects, waste and expensive rework are decreased as a result.

Material Comparison Industries often require to compare various batches or suppliers of polymer materials. Measuring the MVR guarantees reliability across batches which is important for large-scale manufacturing.

Process Optimization By adjusting processing parameters like temperature and pressure based on the flow characteristics, engineers can improve product quality as well as productivity.

Regulatory Compliance International standards (like ASTM D1238 or ISO 1133) must be followed in many industries, especially the packaging and automotive sectors. Reliable data for records and certification is provided by Perfect Group India.

How Does a Melt Flow Index Tester Work? The way a Melt Flow Index Tester works is simple but accurate:

Preparation: A pre weighed amount of thermoplastic granules is loaded into a heated barrel.

Melting: The material is allowed to melt and stabilize at the specified temperature.

Extrusion: A standard load is applied through a piston, pushing the molten polymer through a die.

Measurement: The extruded material is collected over a 10-minute interval and weighed or its volume is measured to calculate the MVR.

Advanced testers offer digital displays, automated cutting mechanisms and load controls to increase accuracy and ease of use.

Industries that Choose on Melt Flow Index Tester The device is used across a variety of industries where plastics play a key role:

Packaging Industry: Guarntee film consistency and uniformity

Automotive: Testing thermoplastics for performance important features

Medical Devices: Quality assurance of polymers for hygienic and durable use

Consumer Goods: Verifying material strength and moldability

Construction: Provide PVC pipes and profiles meet strength and flow specs

No matter the sector, the equipment provides high-quality manufuring with less downtime and better product performance.

Why Choose Perfect Group India for Your Melt Flow Index Tester? At Perfect Group India we understand the important function that testing instruments play in manufacturing success. For this reason we provide accurate, reliable and reasonably priced products that are suited to your industrial requirements.

High Accuracy Our testers are engineered for consistency and accuracy helping your lab meet global standards like ASTM and ISO.

User-Friendly Interface Designed for ease of use our testers come with digital displays, programmable settings and automated features.

After-Sales Support Perfect Group India provides full technical support, calibration services and training to guratee your team gets the best out of your investment.

Competitive Pricing We believe quality doesn’t have to come at a premium. Get industry-leading equipment at affordable rates with Perfect Group India.

Tips for Getting the Most Out of Your Melt Flow Index Tester

Calibrate Regularly: Provide accurate results by following a regular calibration schedule.

Use Consistent Sample Sizes: This reduces variability in results.

Maintain Clean Equipment: Residue buildup can affect flow and measurements.

Train Operators: Skilled users provide more consistent, reliable results.

Conclusion In quality control a Melt Flow Index Tester is an important device for accurately measuring the melt volume rate of thermoplastic materials. In order to maintain manufacturing quality and follow industry standards it helps manufacturers to identify the flow characteristics of polymers. It is used in the polymer, plastic and packaging industries because of its simple functioning and reliable results. This equipment improves the testing processes, increasing productivity and saving time. It is important in material testing labs and is trusted by experts in many different fields. Perfect Group India provides trustworthy options for polymer testing instruments that are accurate and durable.

0 notes

Text

Melt Flow Index Tester to Measure the Melt Volume Rate

Source of Info: https://www.perfectgroupindia.co.in/blog/melt-flow-index-tester-to-measure-the-melt-volume-rate

Introduction

An accurate device to measure the melt volume rate of thermoplastic materials under special conditions is the Melt Flow Index Tester. It is an important equipment for quality control and product development because it helps manufacturers to identify how a polymer will behave during processing. This device calculates the amount of material flowing through a die over a set time by offering valuable data for comparing material levels. It allows consistent product performance and reliable manufacturing and is very accurate and simple to use. For industries searching to improve their testing capabilities with advanced, user-friendly equipment Perfect Group India provides trusted solutions.

Why Use a Melt Flow Index Tester?

An instrument used in labs to measure the flow properties of thermoplastic polymers is called a Melt Flow Index Tester. It monitors how quickly molten plastic moves through a die at a given temperature and pressure. Depending on the measurement unit this flow rate is referred to as the Melt Volume Rate (MVR) or Melt Flow Index (MFI).

The test results which show how much material extruded from the instrument in that time, are given in grams per 10 minutes (for MFI) or cubic meters per 10 minutes (for MVR). These results help manufacturers in creating the behavior of the material during actual processing, such as blow molding, extrusion or injection molding.

Why Measuring Melt Volume Rate is Important

The Melt Volume Rate of a material is important for these reasons:

1. Quality Control

A Melt Flow Index Tester can be used by businesses to test polymers on a regular basis to make sure the materials meet demands before going into manufacturing. Defects, waste and expensive rework are decreased as a result.

2. Material Comparison

Industries often require to compare various batches or suppliers of polymer materials. Measuring the MVR guarantees reliability across batches which is important for large-scale manufacturing.

3. Process Optimization

By adjusting processing parameters like temperature and pressure based on the flow characteristics, engineers can improve product quality as well as productivity.

4. Regulatory Compliance

International standards (like ASTM D1238 or ISO 1133) must be followed in many industries, especially the packaging and automotive sectors. Reliable data for records and certification is provided by Perfect Group India.

How Does a Melt Flow Index Tester Work?

The way a Melt Flow Index Tester works is simple but accurate:

• Preparation: A pre weighed amount of thermoplastic granules is loaded into a heated barrel.

• Melting: The material is allowed to melt and stabilize at the specified temperature.

• Extrusion: A standard load is applied through a piston, pushing the molten polymer through a die.

• Measurement: The extruded material is collected over a 10-minute interval and weighed or its volume is measured to calculate the MVR.

Advanced testers offer digital displays, automated cutting mechanisms and load controls to increase accuracy and ease of use.

Industries that Choose on Melt Flow Index Tester

The device is used across a variety of industries where plastics play a key role:

• Packaging Industry: Guarntee film consistency and uniformity

• Automotive: Testing thermoplastics for performance important features

• Medical Devices: Quality assurance of polymers for hygienic and durable use

• Consumer Goods: Verifying material strength and moldability

• Construction: Provide PVC pipes and profiles meet strength and flow specs

No matter the sector, the equipment provides high-quality manufuring with less downtime and better product performance.

Why Choose Perfect Group India for Your Melt Flow Index Tester?

At Perfect Group India we understand the important function that testing instruments play in manufacturing success. For this reason we provide accurate, reliable and reasonably priced products that are suited to your industrial requirements.

High Accuracy

Our testers are engineered for consistency and accuracy helping your lab meet global standards like ASTM and ISO.

User-Friendly Interface

Designed for ease of use our testers come with digital displays, programmable settings and automated features.

After-Sales Support

Perfect Group India provides full technical support, calibration services and training to guratee your team gets the best out of your investment.

Competitive Pricing

We believe quality doesn’t have to come at a premium. Get industry-leading equipment at affordable rates with Perfect Group India.

Tips for Getting the Most Out of Your Melt Flow Index Tester

• Calibrate Regularly: Provide accurate results by following a regular calibration schedule.

• Use Consistent Sample Sizes: This reduces variability in results.

• Maintain Clean Equipment: Residue buildup can affect flow and measurements.

• Train Operators: Skilled users provide more consistent, reliable results.

Conclusion

In quality control a Melt Flow Index Tester is an important device for accurately measuring the melt volume rate of thermoplastic materials. In order to maintain manufacturing quality and follow industry standards it helps manufacturers to identify the flow characteristics of polymers. It is used in the polymer, plastic and packaging industries because of its simple functioning and reliable results. This equipment improves the testing processes, increasing productivity and saving time. It is important in material testing labs and is trusted by experts in many different fields. Perfect Group India provides trustworthy options for polymer testing instruments that are accurate and durable.

0 notes

Text

Lab-Scale Extruder and Spheronizer Combo is a seamlessly integrated system poised to redefine granulation in formulation research and product development. The Extruder component, featuring four interchangeable heads, facilitates versatile low-pressure granulation techniques on a bench-top scale, accommodating batches as small as 200 grams. Its adaptability and indicative results make it a cost-effective and efficient solution for evaluating diverse formulations.

0 notes

Text

The Role of Lab Extruder Machine Factory and Lab Scale Twin Screw Extruder

In the realm of material science and engineering, precision is paramount, especially when dealing with sensitive materials. The Lab Extruder Machine Factory, renowned for its high-quality Lab Scale Twin Screw Extruder, plays a pivotal role in ensuring that these materials are processed with accuracy. The Lab Scale Twin Screw Extruder, a product of the Lab Extruder Machine Factory, is designed to meet the stringent demands of research and development in various industries, including pharmaceuticals, food processing, and polymer compounding.

The Lab Extruder Machine Factory's Lab Scale Twin Screw Extruder is engineered to provide precise control over the extrusion process, which is critical when handling sensitive materials. These materials often require specific temperature, pressure, and flow rate conditions to maintain their integrity and achieve the desired outcome. The Lab Scale Twin Screw Extruder from the Lab Extruder Machine Factory is equipped with advanced control systems that allow for fine-tuning of these parameters, ensuring that the material's properties are preserved throughout the extrusion process.

One of the key features of the Lab Scale Twin Screw Extruder from the Lab Extruder Machine Factory is its ability to handle a wide range of materials with varying viscosities and rheological properties. This versatility is crucial in research environments where experiments often involve the testing of new materials or the optimization of existing ones. The Lab Extruder Machine Factory's Lab Scale Twin Screw Extruder is designed with a modular approach, allowing researchers to customize the extruder's configuration to suit the specific needs of their project.

The precision of the Lab Scale Twin Screw Extruder from the Lab Extruder Machine Factory is not only limited to the physical processing of materials but also extends to the data it generates. The Lab Extruder Machine Factory's extruders are often equipped with sensors and data acquisition systems that provide real-time feedback on the extrusion process. This data is invaluable for researchers who need to analyze the performance of the Lab Scale Twin Screw Extruder and make adjustments as necessary to achieve the desired results.

The Lab Extruder Machine Factory also places a strong emphasis on the reliability and durability of its Lab Scale Twin Screw Extruder. In industries where sensitive materials are processed, downtime due to equipment failure can be costly. The Lab Extruder Machine Factory's extruders are built with robust components and are designed to withstand the rigors of continuous operation, ensuring that the processing of sensitive materials is not interrupted.

Maintenance and cleaning are also critical aspects of precision in the context of sensitive materials. The Lab Extruder Machine Factory's Lab Scale Twin Screw Extruder is designed for easy disassembly and cleaning, which is essential for maintaining the purity and consistency of the materials being processed. The Lab Extruder Machine Factory provides comprehensive maintenance guidelines and support to ensure that users can keep their Lab Scale Twin Screw Extruder in suitable condition.

In conclusion, the Lab Extruder Machine Factory's Lab Scale Twin Screw Extruder is a testament to the importance of precision in the processing of sensitive materials. Its advanced control systems, modular design, data acquisition capabilities, and robust construction make it an indispensable tool in the arsenal of researchers and engineers working with sensitive materials. The Lab Extruder Machine Factory continues to set the standard for precision and reliability in the field of extrusion technology.

0 notes

Text

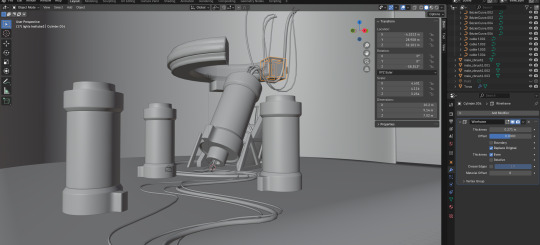

Assignment 5 - Work with 3D

Hard surface modeling

Fig.1 Resident evil 4 Remake gameplay

As a person who is deeply influenced by sci-fi and horror, particular apocalyptic chaos of zombie outbreaks like the game, Biohazard, I wanted to create a Sci-fi scenery for human experiment In this assignment.

I decided to give 3D hard surface modeling a try, and began to model the experiment chamber with a cylinder with 32 divisions. I extruded and scaled up the top and bottom part to be the cap and receptacle base respectively. Then, I selected and applied a solidify modifier on the middle part to create the thickness of the glass. I added the 2 torus mesh, scaling them to a reasonable size, and placed them on the cap to be the lighting. The same method was applied to the top circular light, whose shape design was inspired by surgical lighting, creating a peculiar and eerie atmosphere for the scene. I used triangular meshes with the frame modifier to create the metallic frames beside the largest chamber. Finally, I used the bezier curve to create wires connected to the main chamber. Bam! The modeling of the scene was done!

Node Shader

I decided to use a blueish colour to render the entire scene because I wanted to create an aquatic theme relating to deep sea creatures. I wanted to use colour to depict the scene into a human experiment lab of combining human and sea creatures. I turned the colour node, which is located in the scenery attribute section, to be dark blue, and applied scenery particles to elevate the eerie atmosphere. I used the colour ramp node on the glass to create some gradient colours, and finally, turned all the light sources’ material into emission attributes.

Zbrush sculpting

Since this is a human experiment lab, it must contain some live test subjects. I tried to explore my ideas on the test subject design using Zbrush. In the competitive and fast-paced gaming industry, efficiency is the key, and I am no exception. Instead of building a model from scratch, I sculpted on top of a default human base mesh in Zbrush to efficiently bring my concept idea to life. I used the Move tool to stretch the human mesh and created an unusual body shape on the left side. I kept the human shape on the right side and created some thorns on his back, shoulders and elbow to emphasise that his mutation is still in progress inside the cultivation chamber. After I finished the sculpting, I polypainted it in Zbrush, exporting it as .fbx and imported it to blender. I scaled the models and placed them in the chambers.

Overall, this was a very interesting assignment that helped me to understand certain operations in blender. I am satisfied with the result, and I have learned a lot about 3D modeling through this little project. In the future, I would love to explore more about topology and hard surface modeling techniques to improve the smoothness of my model, and save time.

Reference:

Fig.1: Neoseeker.com. Available at:

https://www.neoseeker.com/resident-evil-4-2023/walkthrough/Chapter_13

(Accessed: January 13, 2025)

0 notes

Text

We have five products available. There are Lab Scale, Pilot Scale, Small Production, Production Model, Extruder. The offer scientists the largest selection of laboratory High pressure homogenizer of any laboratory equipment supplier, the tools to make finding the right homogenizer easy, and expert support to assist you whenever you need help. We enable you to readily compare between a multitude of brands, models, and homogenization methods as well as review customer feedback.

#extruder homogenizer#highpressurehomogenizer#inlinehomogenizer#small production homogenizer#inline homogenizer#homogenizer in chennai#homogenizer in chennai#high pressure homogenizer#types of homogenizer#homogenizer lab scale#homogenizer manufacturers in india#homogenizer mechanism

0 notes

Text

The advantage of Genizer liposome extruders

Genizer offers a comprehensive range of extruders suitable for researchers and manufacturers across all scales, from lab-scale HandExtruder and GJE-10mL/100mL models for small-scale research and development, to pilot-scale GJE-800mL/3000mL models for larger experiments and production runs, and the GOE-8L/25L extruder for large-scale commercial production. This means that regardless of the scale of the project, Genizer has an extruder that can meet the requirements.

Genizer extruders can be easily connected to its own high-pressure homogenizers to create a powerful, integrated system. The intelligent control system of the homogenizers allows researchers and manufacturers to effortlessly set and adjust parameters, which enables precise control over critical factors such as temperature, pressure, and flow rate. By ensuring that the processes are efficient and accurate, the intelligent control system of the homogenizers results in consistent, high-quality liposomes. This integration also saves time, reduces the risk of contamination, and enables greater control over the final product.

Genizer extruders are designed to meet strict pharmaceutical requirements and have been adopted by leading pharmaceutical companies worldwide, including Sanofi, Teva Pharma, GP Pharma and so on. These industry leaders have put Genizer's extruders to the test, and the results have been overwhelmingly positive. Genizer's extruders have received unanimous acclaim from these industry leaders for their reliability, precision, and efficiency and have become the go-to choice for pharmaceutical researchers and manufacturers worldwide.

0 notes

Text

Why PP Spunbond Nonwoven Fabric is Essential for Cleanroom Environments

Cleanroom environments are crucial in various industries, including pharmaceuticals, electronics, and biotechnology. These controlled spaces require stringent cleanliness standards to prevent contamination and ensure the quality and safety of products. One material that plays a significant role in maintaining these standards is PP spunbond nonwoven fabric. In this blog, we’ll explore why this fabric is essential for cleanroom environments and how it contributes to maintaining a sterile and safe workspace.

What is PP Spunbond Nonwoven Fabric?

PP spunbond nonwoven fabric is a type of fabric made from polypropylene (PP) fibers. PP non woven fabric manufacturer is produced through a spunbonding process, where polypropylene fibers are extruded and then bonded together using heat and pressure. This process creates a durable, lightweight, and flexible fabric that does not unravel, making it ideal for various applications, including cleanroom environments.

Key Properties of PP Spunbond Nonwoven Fabric

High Filtration Efficiency: PP spunbond nonwoven fabric has excellent filtration properties. It can effectively trap dust, particles, and microorganisms, which is crucial in maintaining the cleanliness of a cleanroom.

Breathability: Despite its filtration capabilities, the fabric remains breathable. This ensures comfort for individuals working in cleanrooms while preventing the buildup of heat and moisture.

Chemical Resistance: The fabric is resistant to many chemicals, making it suitable for environments where exposure to harsh substances is common. This durability ensures that the fabric remains intact and continues to perform well over time.

Cost-Effective: Compared to other materials, PP spunbond nonwoven fabric is relatively inexpensive. This cost-effectiveness makes it a practical choice for large-scale applications in cleanrooms.

Lightweight and Flexible: The fabric is lightweight, which makes it easy to handle and install. Its flexibility allows it to conform to various shapes and surfaces, enhancing its usability in different cleanroom applications.

Applications in Cleanroom Environments

Protective Clothing: PP spun bond non woven fabric is commonly used to manufacture protective clothing such as gowns, coveralls, and lab coats. These garments provide a barrier against contaminants and help maintain the sterile conditions required in cleanrooms.

Surface Covers: The fabric is also used for surface covers and drapes in cleanrooms. These covers protect equipment and surfaces from dust and contaminants, ensuring that the environment remains clean and uncontaminated.

Air Filters: In cleanroom HVAC systems, PP spunbond nonwoven fabric is used in air filters to trap airborne particles and prevent them from circulating within the cleanroom. This helps maintain the required air quality and cleanliness levels.

Cleaning Cloths and Wipes: The fabric is used to make cleaning cloths and wipes that are essential for regular cleaning and maintenance of cleanroom surfaces and equipment. These wipes are effective in removing dust, dirt, and other contaminants without leaving residues.

Floor Mats: PP spunbond nonwoven fabric is used in floor mats that help control the amount of dirt and dust brought into cleanroom environments. These mats can be placed at entry points to reduce the risk of contamination from foot traffic.

Benefits of Choosing PP Spunbond Nonwoven Fabric

Enhanced Cleanliness: By using PP spunbond nonwoven fabric in cleanroom environments, you can significantly enhance the level of cleanliness. Its filtration and barrier properties help prevent contamination and maintain the required cleanroom standards.

Durability and Longevity: The fabric’s durability ensures that it remains effective over time, reducing the need for frequent replacements. This longevity contributes to cost savings and operational efficiency.

Customizability: PP spunbond nonwoven fabric can be customized to meet specific requirements, such as different thicknesses, colors, and sizes. This flexibility allows for tailored solutions that fit various cleanroom needs.

Ease of Maintenance: The fabric is easy to clean and maintain, making it a practical choice for environments where regular cleaning is essential. Its resistance to chemicals and abrasion ensures that it retains its properties even with frequent use.

Eco-Friendly Options: Some manufacturers offer eco-friendly versions of PP spunbond nonwoven fabric, which can be an excellent choice for organizations looking to reduce their environmental impact. These options provide the same benefits while supporting sustainable practices.

Choosing a Reliable Manufacturer

When selecting PP spunbond nonwoven fabric for your cleanroom, it is crucial to choose a reliable manufacturer. Look for a PP non woven fabric manufacturer with a proven track record in providing high-quality products. If you are in India, consider choosing a PP nonwoven fabric Manufacturer in Ahmedabad known for its commitment to quality and customer satisfaction. A reputable manufacturer will ensure that you receive fabric that meets industry standards and performs effectively in your cleanroom environment.

FAQs

What is the difference between PP spunbond nonwoven fabric and other nonwoven fabrics?

PP spunbond nonwoven fabric is made from polypropylene and is produced through a spunbonding process. It differs from other nonwoven fabrics in terms of its filtration efficiency, chemical resistance, and cost-effectiveness.

Can PP spunbond nonwoven fabric be used in all types of cleanrooms?

Yes, PP spunbond nonwoven fabric is versatile and can be used in various types of cleanrooms. It is suitable for environments requiring high cleanliness and protection against contaminants.

How do I choose the right PP spunbond nonwoven fabric for my cleanroom?

Consider factors such as filtration efficiency, breathability, chemical resistance, and cost. Additionally, choose a fabric from a reputable PP nonwoven fabric manufacturer to ensure quality and performance.

Is PP spunbond nonwoven fabric eco-friendly?

Some manufacturers offer eco-friendly versions of PP spunbond nonwoven fabric. These options are designed to be more sustainable while still providing the same benefits as standard fabric.

How often should PP spunbond nonwoven fabric be replaced in cleanroom environments?

The replacement frequency depends on factors such as usage, contamination levels, and maintenance practices. Regular inspections and adherence to cleanroom protocols will help determine when replacement is necessary. In conclusion, PP spunbond nonwoven fabric is a valuable material for cleanroom environments due to its excellent filtration, breathability, and chemical resistance. By choosing the right fabric and working with a reliable manufacturer, you can ensure that your cleanroom maintains the highest standards of cleanliness and safety.

0 notes