#Large automobile air conditioner shell mold design

Text

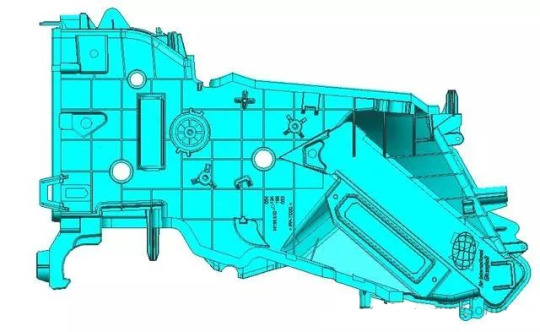

Large automobile air conditioner shell mold design ideas

Among automobile structural parts, air-conditioning housing is a representative product of relatively complex products. Today we will take air conditioner shell as an example to analyze design of its mold structure, which is of great practical reference value for everyone.

1. Product analysis

Car air conditioner shell is core component of car air conditioner, and product material is PP-TD20.…

View On WordPress

#air conditioner shell mold design#Large automobile air conditioner shell mold design#mold design#mold structure#oil cylinder#Product analysis#product design

0 notes

Video

youtube

What is automotive lightweighting

What is automotive lightweighting

The lightweight of the car is to reduce the curb weight of the car as much as possible on the premise of ensuring the strength and safety performance of the car, thereby improving the power of the car, reducing fuel consumption and reducing exhaust pollution. Experiments have shown that if the quality of the car is reduced by half, the fuel consumption will also be reduced by nearly half. Due to the needs of environmental protection and energy saving, the lightweight of automobiles has become the trend of automobile development in the world.

Experiments have shown that if the weight of the vehicle is reduced by 10%, the fuel efficiency can be increased by 6%-8%; the fuel consumption per 100 kilometers can be reduced by 0.3-0.6 liters for every 100 kg of vehicle curb weight; the fuel consumption can be reduced by 0.7 liters when the vehicle weight is reduced by 1% %. At present, due to the needs of environmental protection and energy saving, the lightweight of automobiles has become the trend of automobile development in the world.

main method

① The mainstream specifications of automobiles are continuously optimized. On the premise of retaining the main parameters of the specifications, the structural strength of the whole vehicle is improved and the consumption of consumables is reduced;

② Lightweight materials are used. Such as aluminum, magnesium, ceramics, plastics, glass fiber or carbon fiber composite materials;

③ Use computer for structural design. Such as the use of finite element analysis, local strengthening design, etc.;

④ Adopt the load-bearing body to reduce the thickness of the body sheet.

Among them, the current major automotive lightweight measures are mainly the use of lightweight materials.

Both theoretical analysis and experimental results show that lightweighting is an effective way to improve vehicle fuel economy. In order to meet the requirements of lightweight automobiles, some new materials came into being and expanded the scope of application. The rapid growth of the application of non-ferrous alloys in automobiles is a major trend in the development of automobile materials, especially aluminum alloys.

(1) Cast aluminum alloy

The automotive industry is the main market for aluminum castings. For example, in Japan, 76% of aluminum castings and 77% of aluminum die castings are automotive castings. Aluminum alloy castings are mainly used in engine cylinder blocks, cylinder heads, pistons, intake manifolds, rocker arms, engine mount brackets, air compressor connecting rods, transmission housings, clutch housings, wheels, brake parts, handles and Cover shell parts, etc.

(2) Deformed aluminum alloy

Deformed aluminum alloys refer to aluminum alloy sheets, extruded profiles and forged materials, which are mainly used in automobile body panels, body frames, engine radiators, air conditioner condensers, evaporators, wheels, decorative parts and suspension system parts, etc. .

(3) Aluminum matrix composite materials

Aluminum matrix composites have low density, high specific strength and specific modulus, and good thermal fatigue resistance, but their application in automobiles is restricted by price and production quality control, and has not yet formed a large scale. At present, the test or use of aluminum matrix composites on parts such as connecting rods, pistons, cylinder bores, brake discs, brake calipers and drive shaft tubes has shown excellent performance

One-piece die casting is a revolution in the production process of automobiles. The integrated die-casting process adopted by Tesla Model Y can be regarded as the beginning of the integration of auto parts, and the application parts are mainly on the rear floor of the car. The original more than 70 parts were integrated into 1-2 parts, so that the number of molds and presses was greatly reduced, and the production efficiency was also rapidly improved, which also brought about a significant reduction in costs. It is estimated that the aluminum consumption of the integrated die-casting process is about 100kg. The promotion of this process will greatly increase the penetration rate of aluminum in automobiles. However, although the one-piece body brings convenience to manufacturing, the follow-up maintenance has also become a problem. It is hoped that in the near future, with the development of science and technology, this problem can also be solved.

Fenan Aluminum also produces some lightweight products for automobiles, such as Aluminium auto pedal; anti-collision beam; Aluminium Battery Enclosures; Aluminium battery base,etc.If you have any need,be free to contact us.

Thanks for reading today's sharing

#aluminiummanufacturing #aluminiumprofilesupplier #fenanaluminum #foenaluminum#automotivelightweighting#lightweighting

https://www.foenalu.com/

0 notes