#LinearMotionGuide

Explore tagged Tumblr posts

Text

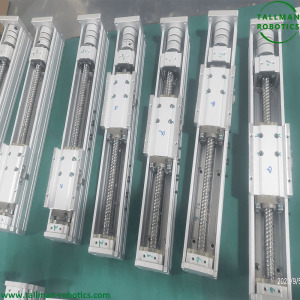

Linear Guide Way Modules are finished for Clients from India

Linear Guide Way Modules are ready for delivery to Clients from India. Linear guide way modules are mechanical components used in various applications to provide linear motion and support. They consist of a linear guide rail and a carriage or slider that moves along the rail. The guide rail typically has precision-machined surfaces, such as grooves or tracks, that allow the carriage to slide smoothly and accurately. Linear guide way modules offer several benefits, including: 1. Precise and smooth motion: The design of linear guide way modules ensures accurate and smooth linear motion, making them suitable for applications that require precise positioning and high repeatability. 2. Load-bearing capacity: Linear guide way modules can support significant loads, making them suitable for applications that involve heavy equipment or machinery. 3. Rigidity and stiffness: These modules are designed to provide high rigidity and stiffness, which helps minimize deflection and ensure stability during operation. 4. Low friction and wear: Linear guide way modules often incorporate rolling elements, such as balls or rollers, to reduce friction and wear. This design choice improves efficiency and prolongs the lifespan of the module. 5. Configuration flexibility: Linear guide way modules are available in various sizes, lengths, and configurations, allowing for flexibility in design and integration into different applications. Linear modules find applications in numerous industries, including manufacturing, automation, robotics, machine tools, semiconductor equipment, and more. They are commonly used in CNC machines, linear motion systems, industrial robots, and other precision equipment that require controlled linear motion. It's worth noting that there are different types of linear actuators available, such as ball guides, roller guides, and magnetic guides. Each type has its own advantages and is suitable for specific applications based on factors like load capacity, speed, precision requirements, and environmental conditions. Overall, linear modules play a crucial role in providing reliable and precise linear motion in a wide range of industrial and automation applications. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#1-axislinearmodule#DustproofLinearGuide#LinearCarriagesAndSlides#LinearMotionGuide#LinearSlidingGuide#SingleAxisGuideArm#SingleAxisRobot

0 notes

Text

LM Guide Actuator KR Type with Ball Screw.

Today we are discussing about the new industry application which are being used in Railway sectors to inspect Wheel with the help of LM Guide Actuator KR Type with Ball Screw.

Unique features and property of LM Guide Actuator KR type with Ball screw:

1. 4-way Equal Load & it can be used in any mounting orientation

2. High Rigidity

3. High Accuracy

4. Space Saving

5. It is equipped with end seals and side seals for dust prevention

https://youtu.be/XlJIlv6pOeg

#seimitsu#seimitsufactoryautomation#seimitsufactoryautomationpvtltd#factoryautomation#industrialautomation#distributor#linearmotionguide#LMguideactuator#actuator#lmguide#ballscrew#bearing#block#highrigidity#highaccuracy#rail#automation#automotive#railwaysector#aerospace#defence#machinetool#packaging#pharma#wheelinspector

0 notes

Link

The primary purpose of linear guides is to make sure that the machine moves along a straight line smoothly. Usually, this is only possible through linear motion bearings, which are made of plastic or ceramic bushes.

Let’s have a look mistakes to avoid When Choosing Linear Guide:

1. Avoid Adding Mounting Features for Alignment

2. Not Defining Preload Accurately

3. Ignore to Test Full Run of Travel

4. Not Forming Mounting Surfaces to Tolerance

5. Mechanical Components

6. Avoid Examining the Impact of Materials and Plating on Cost and Lead Time

After considering all these points, it help you to understand the requirements when choosing linear guide.

0 notes

Link

Seimitsu offers wide range of THK Make linear motion products such as Lm guide, Caged Type LM Guide, Caged roller guide, Cross LM Guide Model SCR, LM Guide with Rack & Pinion Model GSR, LM Guide HCR etc at best price in all over India.

0 notes

Text

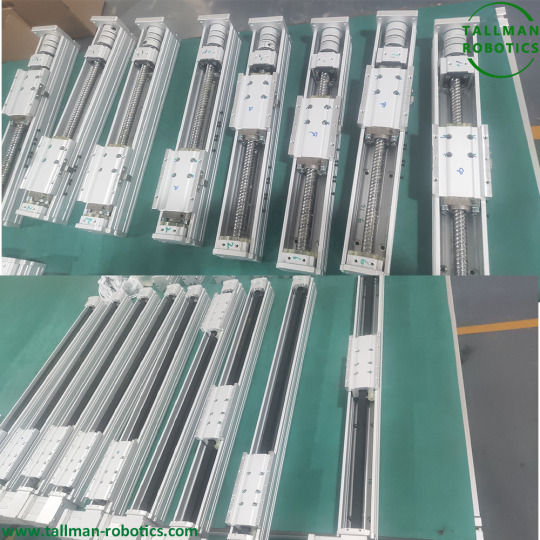

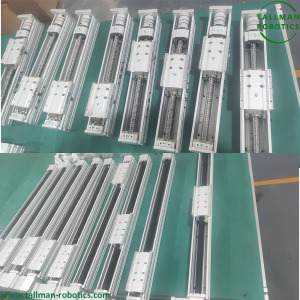

Single Axis Guide Arms are Under Test for Clients from Germany

Single Axis Guide Arms for Clients from Germany are under test, and will be delivered. Single axis guide arms are mechanical components used in various applications, such as industrial automation and robotics, to provide linear guidance and support for moving parts. They are typically used when a single degree of freedom or linear motion is required.

These guide arms consist of a rigid structure or frame that houses a linear guide system. The linear guide system usually consists of a rail and a carriage, where the rail provides a smooth and precise path for the carriage to move along. The carriage is attached to the moving component or load, allowing it to travel along the rail in a linear direction. Single axis guide arms are often used in applications where there is a need for controlled and accurate linear motion. They can be found in assembly lines, pick-and-place systems, packaging machinery, CNC machines, and other automated systems. These guide arms help to ensure precise positioning, smooth movement, and reduced friction between moving parts. The design of single axis guide arms can vary depending on the specific application and load requirements. They may incorporate different types of linear guides, such as ball bearing guides or roller guides, to accommodate different load capacities and operating conditions. The guide arms may also include additional features like adjustable stops, damping mechanisms, or lubrication systems to enhance performance and longevity. Overall, single axis guide arms play a crucial role in providing linear guidance and support in various industrial and robotic applications, enabling precise and controlled movement of components or loads along a single axis. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearCarriagesAndSlides#LinearGuideSystems#LinearMotionGuide#LinearMotionGuideActuators#LinearMotionStages#LinearMotionSystems#LinearSlideSystem#SingleAxislinearmotion

0 notes

Text

Linear Motion Blocks

Linear Motion Blocks from Tallman Robotics Limited SNTC/SNW Linear Motion Blocks. 1. The slider and guide rail are made of stainless steel and carbon steel respectively. Including sliders, rails, and other metal accessories such as steel balls, retainers, etc., all made of stainless steel material with anti rust properties. 2. Adopting a Gothic four point contact design. Capable of withstanding loads in all directions, with strong rigidity and high accuracy. 3. Rolling cycle system. Sliders, rails, steel balls, retainers 4. Reserve oil injection holes on the cover side to inject oil or grease into the interior of the slider for lubrication. 5. Product specifications, models, and characteristics of interchangeability and non interchangeability Two types of linear slide rails, non interchangeable and interchangeable, have the same specifications and dimensions. The difference is that interchangeable slide rails can be used interchangeably for single shipments, which is more convenient. However, their combination accuracy cannot meet the customized accuracy requirements of non interchangeable slide rails However, SNT has good size control and strict quality requirements in manufacturing, and interchangeability can also meet the needs.

Linear motion blocks are a type of mechanical component used in engineering and construction projects. They are commonly used in systems that require straight and precise movement, such as conveyor belts, robotic arms, and sliding doors. Linear motion blocks consist of a stationary base and a moving carriage. The carriage is mounted on ball bearings or rollers, allowing it to slide smoothly along the base. The motion can be controlled manually or automated using motors and control systems. These blocks are typically made from durable materials such as steel or aluminum to withstand heavy loads and ensure long-lasting performance. They are designed with precision to minimize friction and increase efficiency. Linear motion blocks are available in various sizes and load capacities, allowing engineers to select the appropriate block for their specific application. They can be easily integrated into existing systems or used as a standalone component. their use in industrial settings, linear motion are also common in DIY projects, such as building CNC machines or 3D printers. Their versatility and ease of use make them a popular choice for both professional engineers and hobbyists. Overall, linear motion blocks play a crucial role in creating smooth and controlled linear movement in a wide range applications. They provide a reliable and efficient solution for achieving precise motion in diverse engineering projects. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearBearingLinearBearingBlocks#Linearguiderailsandlinearblocks#LinearGuides#LinearGuideways#LinearMotionBlocks#LinearMotionGuideBlocks#LinearMotionGuides&Blocks#LinearMotionSlideBlocks#StandardLinearMotionBlock

0 notes

Text

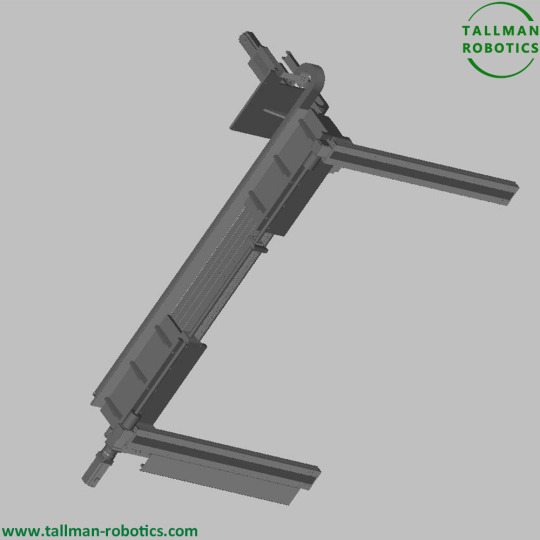

XYZ Linear Motion System Will be Delivered to Russia

XYZ Linear Motion System from Tallman Robotics Limited Will be Delivered to Russia.

XYZ Linear Motion refers to a type of motion in which an object moves along three perpendicular axes: the X-axis, Y-axis, and Z-axis. This type of motion is commonly used in engineering and manufacturing, where precise linear movement is required for positioning and alignment of tools and components. XYZ Linear Motion systems typically use linear guides, bearings, and motors to control the movement of the object along each axis. XYZ linear motion refers to a type of linear motion that occurs in three perpendicular directions, namely the X-axis, Y-axis, and Z-axis. This type of motion is often used in various mechanical and engineering applications, including 3D printing, CNC machining, robotics, and automated manufacturing systems. XYZ linear motion systems typically rely on various components, such as linear guides, lead screws, ball screws, stepper motors, and linear actuators, to move objects or tools in a precise and controlled manner along any combination of the three axes. XYZ Linear Motion refers to a system of motion in three dimensions, where the motion is restricted to linear (straight-line) motion along the X, Y, and Z axes. This type of motion is often used in manufacturing and automation, where precise movements are required for tasks such as assembling parts or moving materials. XYZ Linear Motion systems may use various types of mechanisms, such as linear guides or ball screws, to achieve accurate and repeatable motion. XYZ Linear Motion System is a device used for precise movement of objects along the X, Y and Z axes. It consists of a platform or carriage that can move in three directions along linear rails or stages. This system is widely used in various industries such as manufacturing, robotics, and automation, where accurate positioning and movement of objects are required. It is controlled by a motor or a stepper motor that enables precise movement, making it useful in applications that require high precision and accuracy. XYZ Linear Motion System is a type of motion control system that allows for precise and controlled movement in three directions - X, Y, and Z axes. It is commonly used in manufacturing and industrial applications, such as CNC machines, 3D printers, and robotic systems. The system typically includes a combination of motors, control software, and linear bearings, guide rails, or ball screws for smooth and accurate movement. XYZ Linear Motion System is a type of motion control system used in manufacturing and industrial automation. It consists of three linear motion stages that move in the X, Y, and Z directions, respectively. These stages are often driven by stepper motors or servo motors and are controlled by a motion controller or programmable logic controller (PLC). The system is commonly used in applications such as CNC machining, pick and place operations, and automated assembly lines. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#3-AxisXYZMotionSystemwithLinearStagesandController#HeavydutylinearmotionsystemXYZtable#LinearMotionGuide#LinearMotorManufacturer#Linearpositioningstage#MotorizedLinearStageXyz#XYandXYZLinearStagesforMulti-DirectionalMotion#XYandXYZSystems#XYZ3AxisLinearStage#XYZAxisLinearStage#XYZaxisMovementSystem#XYZGantry#XYZPrecisionStage

0 notes

Text

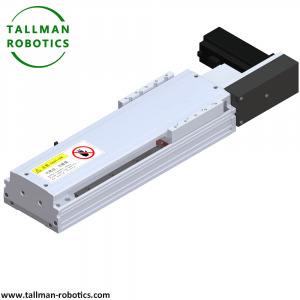

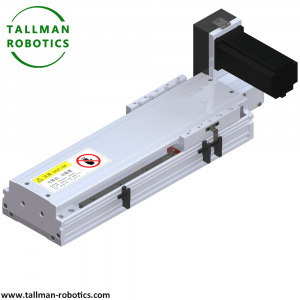

Single Axis Linear Actuator

Single Axis Linear Actuator You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Single Axis Linear Actuators, also named as Modular Linear Actuator, Linear Motion Module, Industrial Linear Motion, Linear Axis Actuator etc. TM by Tallman Robotics, as a famous producer to produce linear modules, supplies diverse TM Linear modules such as screw linear modules, belt linear modules, and semi closed and fully closed respectively for different environment application. TM Linear Modular Actuator Modules can run with world famous band motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 stepping motors in quality aluminum frame system to guarantee precise and speed requirement of various precision and common application projects. You can choose linear modules with brake or without brake. Tallman Robotics’s Single Axis Linear Actuator type TM135 with body with by 135mm have 5 series. Respectively,TM135 can be classified into screw driven semi closed, screw driven fully closed, and belt driven semi closed, belt driven fully closed. These Linear modules perform strokes from 0 mm up to 3500 mm, and payload from 6kg up to 110kgs. It could applied in laser marking, connection insert and pull test, components can be stitched by a condition of a certain thrust, parts from automobile undergo the second picking and positing.

Basic Specification of TM135 series Model No TMS135-CM TMS135CR Drive solution Ball screw Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 95/110/110 75/110/110 44/68/90 35/50/80 13/30/60 10/15/25 Vertical 0.3G 27/35/35 18/25/35 7/18/25 6/14/20 -/8/10 - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/528 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMS135S-CM Drive solution Ball screw Sealed or not Semi closed Motor power AC (W) 200/400W/750 Repeatability (mm) ±0.01/±0.005 Ball screw outer diameter (mm) 16/20 16/20 16 16/20 16 20 lead (mm) 5 10 16 20 32 40 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 2000 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 70/70/70 47/70/70 30/48/70 24/45/70 13/25/50 10/15/25 Vertical 0.3G 17/17/25 12/12/18 6/8/15 4/6/10 - - Rate Thrust (N) 683/1388/2100 341/694/1050 213/432/840 174/347/840 108/216/380 42/174/320 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Model No TMB135-CM TMB135-CR Drive solution Timing Belt Timing Belt Sealed or not Semi closed Fully closed Motor power AC (W) 200/400W Repeatability (mm) ±0.04 Reduction Ratio 1:1 1:2 lead (mm) 90 45 Fastest speed Motor speed 3000 (rpm) 4500 2250 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 10/21 22/42 Vertical 0.3G - - Rate Thrust (N) 45/91 90/182 Linear guide (mm) 15*12.5-2 Origin sensor: Plug-in EE-SX672(NPN)EE-SX672P(PNP) Inside EE-SX951(NPN)EE-SX951P(PNP) Related knowledge:Which industries are linear modules used for? How should it be classified? 1. Painting The linear module can be accurately positioned and stable operation 2. Image visual inspection device Utilizing the characteristics of high positioning accuracy and telling running stability of the linear slide module, it can be used to perform AOI inspection of appearance 3. Surface treatment Using the sliding table's constant speed and stable movement characteristics, the workpiece can be hung on the sliding table and immersed in the solvent, which can smoothly perform the surface treatment 4. Substrate printing Utilizing the sliding table's constant speed and stable movement characteristics, the substrate can be fixed on the sliding table's moving seat to perform the printing operation 5. Circuit board cutting Use the sliding table to move at a constant speed and stable, with the cutter mechanism to perform the cutting operation 6. Part assembly operations Utilize the characteristics of multi-point positioning and accurate positioning of the servo slide, which can smoothly perform the assembly of parts 7. Production line handling operations Utilize the module's high load and tellable running characteristics, it can be used to carry out the goods handling operation on the conveyor belt 8. Packing entire operation Utilizing the characteristics of high positioning accuracy of single-axis robots, it can be used for the entire movement on the conveyor belt 9. Large items pick and place operation Using the characteristics of high load and high positioning accuracy of the robot, it can be used to replace the manual execution of large items. 10. Machine tool processing pick and place operation Using the high positioning accuracy and high-speed stability of the linear module, it can be used with a machine tool to execute the pick-and-place mechanism for loading and unloading of processed parts 11. Print job Use the feature that the slide can move at the same speed and at the same distance to perform laser printing 12. Pick and place entire columns The linear module can be accurately moved, using a two-axis module sliding table, with a fixture or suction cup can be assembled into a pick and place mechanism 13. Automatic soldering operation Utilizing the characteristics of high positioning accuracy and high stability of the servo slide, it is possible to perform the soldering operation of complex circuit board parts 14. Large LCD glass substrate coating equipment Using the design method of gantry connection, the glue gun is fixed on the Z axis and can be used for high-speed glue application 15. Winding device The characteristics of sliding table can be moved with high precision and accurate and fixed speed operation Main products---electric slide (manipulator, actuator, linear module, electric cylinder) The electric slide table is widely used in precise positioning and moving animal materials, and can be basically used in the automation industry involved. Commonly used in the following industries: Electronics industry equipment: dispensers, placement machines, etc.: Battery equipment: power battery laminator, etc.; Laser equipment: laser welding machine, laser cutting machine, laser marking machine, etc.; Spraying equipment: spraying manipulator, etc.; Cutting equipment; plasma cutting machine, flame cutting machine, etc.; Die-casting machine, injection molding machine reclaiming manipulator, etc. Read the full article

#CurvedRailSystems#Electricaxes#LinearGuideRail#LinearGuideSystems#LinearmotionGuide#LinearMotionGuideModule#LinearMotionGuideRail#linearmotionsystems;linearslidesandcylindersandactuators#Linearmotorsingleaxisrobots#MiniatureLinearGuide#SingleAxis#SingleAxisLinearActuator#SmallLinearActuators

0 notes

Photo

Seimitsu has model HRX roller type LM Guide for ultra-highrigidity and ultra-heavyloads readily in stock

For more Detail about product information please visit our website: www.seimitsu.in

Please reach on below details for further clarifications:

Email Id: [email protected]

Phone no.: +91 (20) - 46212700

Mobile No.: +919028121211

#seimitsu#seimitsufactoryautomationpvtltd#factoryautomation#industrialautomation#distributor#standardlinearguides#linearguides#linearmotion#linearmotionguide#Thkdistributor#lmguidesystem#lmguide#linearmotionsystem#linearbearings#linearshaft#THKdealer#railguides#fullball#linearguiderails#blockssuppilers

0 notes

Text

THK Precision Ball Screw Supplier in India | SEIMITSU

youtube

THK products are commonly used in CNC machine tools to provide precise and smooth motion control.

THK products that might be used in a CNC machine include:

Linear motion guides: These are used to guide the movement of machine tool components, such as slides and tables, in a straight line. They consist of a stationary rail and a movable block that rides on the rail.

Ball screws: These are used to translate rotary motion into linear motion, and are often used in CNC machine tools to move the spindle or other parts of the machine. Actuators: These are mechanical devices that convert energy into motion, and are often used to move machine tool components in a precise and controlled manner. Other mechanical components: THK also manufactures a variety of other components used in machine tools, such as cross-roller bearings and linear bushings, which are used to support and guide moving parts.

SEIMITSU Factory Automation is an authorized distributor of THK Products

To Know More: https://www.seimitsu.in/thk-linear-motion-system-distributor-india.html

Email Id: [email protected]

Contact: +91 9028121211

Reference Link- https://youtu.be/WSongKvf858

#thk#cncmachinetools#linearmotionguides#ballscrews#actuators#machinecomponents#precisionengineering#manfacturingtechnology#machinetollindustry#seimitsu#seimitsufactoryautomation#thklinearguides#thkballscrew#thklmguide

0 notes

Link

Seimitsu offers wide range of THK Make linear motion products such as Lm guide, Caged Type LM Guide, Caged roller guide, Cross LM Guide Model SCR, LM Guide with Rack & Pinion Model GSR, LM Guide HCR etc at best price in all over India.

0 notes

Text

THK LM Guide Supplier in India | Seimitsu

The THK Linear Guideway (Linear Motion) is a highly advanced system that enables linear motion through the integration of rolling components between a rail and a block. This system is capable of creating high-precision, energy-efficient, high-rigidity, and high-speed machines with extended lifespans, and is used in a variety of industries, used in Machine Tools, Semiconductor and LCD Manufacturing equipment, Industrial Robots, Automobile Industry, Aerospace, Medical, and Assistive industries, among many others.

# # # # #slideguide #cagedballllmguide #cagedrollerlmguide #fullrollerlmguide #lmguidefullballtype #rail #block # # #industrialautomation #factoryautomation #distributor #supplier # # #india #linearmotionguideways #linearmotionguide #linearmotionguiderail #typesoflinearmotionguideways #maintenance

#linearguideways#linearguides#lmguides#linearmotion#seimitsufactoryautomation#seimitsu#channelpartner#pune

0 notes