#LinearMotionGuideActuators

Explore tagged Tumblr posts

Text

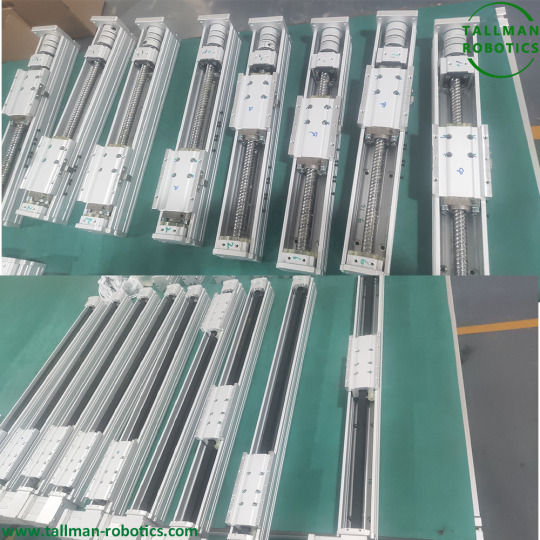

Screw Linear Motion Modules Will Be Delivered To USA

Screw Linear motion modules are mechanical systems designed to provide controlled linear movement in various applications. They are commonly used in industrial automation, robotics, and other fields where precise linear motion is required.

If you're experiencing issues or challenges with linear motion modules, it's important to identify the specific problems you're facing in order to determine the appropriate solutions. Here are a few common issues and some possible suggestions to overcome them: 1. Lack of precision: If your linear motion module is not providing the desired accuracy or precision, you may need to check if the mechanical components are properly aligned and lubricated. Additionally, consider the quality and condition of the module itself, as well as the control system used to drive it. 2. Mechanical failures: Linear motion modules consist of various mechanical components such as rails, bearings, screws, and belts. If you're experiencing frequent failures, it could be due to worn-out or damaged components. Regular maintenance and inspection can help identify and replace any faulty parts. 3. Insufficient load capacity: If you're trying to move loads that exceed the specified capacity of the linear motion module, it can lead to performance issues or even damage. Make sure you're using a module that is suitable for the intended load and consider upgrading to a higher capacity module if necessary. 4. Compatibility issues: Linear motion modules often need to be integrated into larger systems or work alongside other components. Compatibility issues can arise if the module is not properly matched with other parts of the system. Double-check the specifications and requirements of all components involved to ensure they are compatible. 5. Control and programming challenges: If you're struggling with controlling the linear motion module or programming it to perform specific tasks, it may be helpful to consult the documentation or seek support from the manufacturer. They can provide guidance on the programming interface, control signals, and troubleshooting techniques. Remember, linear motion modules are complex systems, and resolving issues might require a combination of mechanical, electrical, and software-related solutions. If you're still having difficulties, it may be beneficial to consult with experts or professionals in the field who have experience with linear motion modules. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#AcmeScrewsandLinearActuators#BallScrewandLinearMotionComponent#Ballscrewlinearmodule#LeadScrewDrivenLinearStagesModule#LeadScrews#LinearmodulesSmallModulesScrewDriven#LinearMotionGuideActuators#LinearMotionModule#PrecisionSlidingTableBallScrew#Screwdrivenmodules#ScrewLinearModules#StainlessSteelLinearModuleHighSpeedBallScrewRail

0 notes

Text

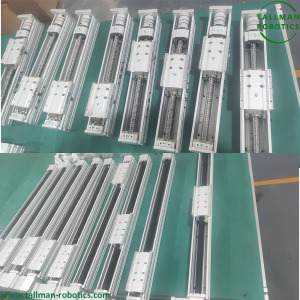

Single Axis Guide Arms are Under Test for Clients from Germany

Single Axis Guide Arms for Clients from Germany are under test, and will be delivered. Single axis guide arms are mechanical components used in various applications, such as industrial automation and robotics, to provide linear guidance and support for moving parts. They are typically used when a single degree of freedom or linear motion is required.

These guide arms consist of a rigid structure or frame that houses a linear guide system. The linear guide system usually consists of a rail and a carriage, where the rail provides a smooth and precise path for the carriage to move along. The carriage is attached to the moving component or load, allowing it to travel along the rail in a linear direction. Single axis guide arms are often used in applications where there is a need for controlled and accurate linear motion. They can be found in assembly lines, pick-and-place systems, packaging machinery, CNC machines, and other automated systems. These guide arms help to ensure precise positioning, smooth movement, and reduced friction between moving parts. The design of single axis guide arms can vary depending on the specific application and load requirements. They may incorporate different types of linear guides, such as ball bearing guides or roller guides, to accommodate different load capacities and operating conditions. The guide arms may also include additional features like adjustable stops, damping mechanisms, or lubrication systems to enhance performance and longevity. Overall, single axis guide arms play a crucial role in providing linear guidance and support in various industrial and robotic applications, enabling precise and controlled movement of components or loads along a single axis. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#LinearCarriagesAndSlides#LinearGuideSystems#LinearMotionGuide#LinearMotionGuideActuators#LinearMotionStages#LinearMotionSystems#LinearSlideSystem#SingleAxislinearmotion

0 notes

Text

Modular Linear Axis with Belt Drive Delivered to Australia

Modular Linear Axis with Belt Drive also named as Belt drive linear modules from Tallman Robotics has been delivered to client from Australia. You are welcome to visit Modular Linear Axis with Belt Drive or Belt drive linear modules for further tech data.

As a mechanical product, linear module will inevitably present some large and small problems in the application process, such as mechanical wear, mechanical defects, etc. when linear module and other mechanical products show defects, if the problems are not handled in time, it may be a big trouble. There is no doubt that the use of mechanical products can greatly improve work efficiency. Once the mechanical equipment shows defects, it will affect the production progress, and in serious cases, it will affect the delivery date, which will lead to breach of contract; Therefore, in general, if the problems of mechanical products can be handled in time, it is certainly the best. https://youtube.com/shorts/zEjllNfwtMk?feature=share Today, let's introduce how to deal with the heating phenomenon of linear module in the process of application. In general, the linear module will generate heat more or less in the process of application. For example, when doing high-speed reciprocating linear motion, heat energy will be generated in the friction process, which will cause the linear module to generate heat. This kind of heat generation belongs to the normal field, and there is no need to worry too much; If you can, stop the linear module for a few minutes and restart it. In addition to normal heating, linear modules may have abnormal heating. For example, when water drops fall on the linear module, they will vaporize immediately, which is accompanied by the problem of jitter; In this case, we should pay attention to it. If it is not handled in time, the linear module may be damaged due to heating. Wear the screw and guide rail. Thus, the service life of the linear module is affected. https://youtube.com/shorts/ctaMxDnmOC8?feature=share If the linear module presents this abnormal heating phenomenon, and it is also accompanied by jitter, according to the market response test and the research of Machinists and engineers, it is generally caused by the slider in the table fixed rod motor, that is, the slider is the root cause of this abnormal heating phenomenon, so the user should consider checking whether there is an abnormality in the slider, or directly replacing the slider. If there is a heating problem in the application process of linear module, it is generally the two phenomena mentioned in the above article. We can judge according to the heating situation of linear module we use, and then analyze and deal with the specific problems. The above is the answer about how to deal with the problem of heating in the process of using linear modules. I hope it can help us. Read the full article

#BeltDriveLinearModules#BeltDrivenActuators#BeltDrivenLinearActuators#BeltDrivenLinearGuideRail#BeltDrivenModularLinearActuators#LinearBelt-DrivenSystem#LinearModuleswithBeltDrive#LinearModuleswithtoothedbeltdrive#LinearMotionGuideActuators#MiniatureSizedLinearMotion

0 notes