#Liquid Adhesives Market

Text

The market for liquid adhesives in APAC is projected to register high growth, and the trend is projected to continue during the forecast period. The increasing industrial and infrastructural development in APAC is responsible for its high share. APAC has emerged as the leading consumer and producer of liquid adhesives because of the increasing demand from India, South Korea, China, Indonesia, and others.

APAC is an emerging and potential market for liquid adhesives, in terms of both value and volume. The increasing demand from end-use industries is contributing to the demand for liquid adhesives in the APAC region. The market is also driven by increased foreign investments due to cheap labor and accessible raw materials. Government proposals to improve the manufacturing and infrastructure, and to increase cash-intensive non-residential construction activities, coupled with the increase in the manufacturing of end-use products, are other factors driving the liquid adhesives market.

#Liquid Adhesives Market#Adhesives Market#Liquid Adhesives#liquid nails for concrete#liquid stitches#liquid fusion glue#liquid nails acrylic#mastisol liquid adhesive#liquid nails use#liquid nail adhesive#Water-based Adhesive Market#liquid nails construction adhesive#COVID 19 impact on Liquid Adhesives Market#Industrial Adhesives Market#Global Liquid Adhesives Market#Liquid Adhesives Market Share#Liquid Adhesives Market Forecast#Liquid Adhesives Demand#Liquid Adhesives Sales#Liquid Adhesives Market Growth#global liquid adhesives market#Impact of COVID-19 on Liquid Adhesives Market#Water-based liquid adhesives#APAC liquid adhesives market

0 notes

Photo

Researchers develop 100% biodegradable paper straws that do not become soggy

The paper straws that are currently available are not entirely made of paper alone. Straws made with 100% paper become too soggy when they come in contact with liquids and cannot function as straws. Accordingly, their surfaces should be coated.

The most commonly used coating materials for paper straws are polyethylene (PE) or acrylic resin—the same materials used for making plastic bags and adhesives. Paper cups are also coated with the same materials as paper straws. A large number of previous studies have reported that polyethylene coating on discarded paper cups can disintegrate into small particles without being fully decomposed and become microplastics. Moreover, these paper products are made with paper and plastics (two very different materials) and thus it is difficult to recycle them.

Conventional paper straws are inconvenient to use. Upon prolonged contact with a liquid, they become soggy. And when these straws are used to drink carbonated beverages, many bubbles form due to their surface properties. Currently, polylactic acid (PLA) straws and rice straws are available in the market as alternatives to paper straws. However, PLA straws—also known as corn plastic straws—do not decompose well in the ocean. While rice straws decompose well in the environment, they have disadvantages, including higher prices due to difficulties in their mass-production and their sharp cross-sections.

Read more.

72 notes

·

View notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

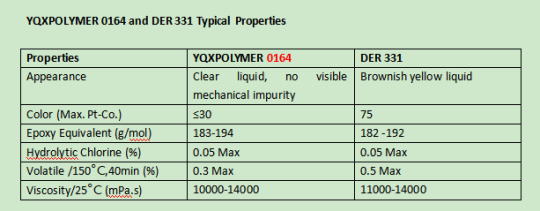

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

Soft-Touch Polyurethane Coatings Market: Exploring Growth Opportunities and Challenges

Introduction

Soft touch polyurethane coatings are a type of clear protective finish that provides a smooth, matte surface. These coatings are created through a chemical process that bonds polyurethane resin to the substrate material. They derive their soft feel from microscopic irregularities in the coating's surface structure that diffuse light and reduce shine.

Composition and Application

At the molecular level, soft touch polyurethane coatings consist of polyols and diisocyanates that crosslink during curing. This chemical reaction forms a tough, elastic polymer network bonded strongly to the underlying object. These coatings can be applied through various conventional methods such as spray painting, dip coating, flow coating and curtain coating.

Proper surface preparation including cleaning and priming is important for optimum adhesion. Multiple thin coats are usually needed, with enough time allowed between coats for proper curing. Curing speeds and properties can be modified by adjusting catalysts, temperature and humidity controls during application and drying.

Aesthetic and Tactile Benefits

Soft touch polyurethane coatings enhance the visual and tactile qualities of coated surfaces. Their matte, low-gloss finish provides an understated elegance as it diffuses reflections and minimizes fingerprint smudges. The coating's microscopic surface texture creates a smooth, silky feeling under the touch.

This improves handling comfort and ergonomics for devices that come into regular contact with human skin, such as automotive interior trim, medical and consumer electronics. The soft finish also provides an upscale, premium impression. A wide range of special effect pigments and modifiers can be incorporated into these coatings to impart additional visual characteristics.

Mechanical Properties

In addition to aesthetic attributes, soft touch polyurethane coatings offer robust mechanical performance. They form a hard, abrasion-resistant surface that protects the substrate from scuffs, scratches and wear. Coated components maintain their like-new appearance longer.

The coatings also impart some flexibility and impact resistance. Cured films withstand flexing and minor impacts without cracking or delaminating. This durability makes them well-suited for applications involving handling, assembly operations and occasional drops or bumps. Their chemical resistance protects coated surfaces from exposure to common liquids and environmental factors.

Additional Advantages

Soft touch polyurethane coatings provide certain functional advantages beyond appearance and handling characteristics. Their low-gloss finish makes surfaces less susceptible to fingerprints and smudges. This ease of cleanability is advantageous for sanitary applications.

Anti-microbial coatings can also be formulated by incorporating silver or other agents. The coating's lack of shine and pores hinders microbial habitation and growth. Coatings may offer benefits like static dissipation for electronic devices. In automotive uses, their insulating effect assists with thermal management and noise reduction.

Versatility in Many Industries

Thanks to their wide-ranging positive attributes, soft touch polyurethane coatings see application across diverse industries. In consumer electronics and medical devices, they enhance user experience and equipment longevity. For automotive interior and exterior trim components, the coatings boost tactile appeal and durability.

Their subtle elegance and easy maintenance make these finishes suitable for sanitary surfaces in food processing and other industrial settings. Other uses include coatings for recreational and sports equipment, cosmetic and perfume packaging, and specialty household items. Engineers and designers continue utilizing the technology in innovative new applications.

#Soft-Touch Polyurethane Coatings Growth#Soft-Touch Polyurethane Coatings Size#Soft-Touch Polyurethane Coatings Share

0 notes

Text

Global Top 7 Companies Accounted for 83% of total Anisotropic Conductive Film market (QYResearch, 2021)

Anisotropic conductive film (ACF) is a lead-free and environmentally friendly adhesive interconnect system that is commonly used in liquid crystal display manufacturing to make the electrical and mechanical connections from the driver electronics to the glass substrates of the LCD.

Anisotropic conductive adhesives are prepared in two forms: films and pastes. In the film form, Anisotropic conductive adhesives are called Anisotropic conductive film (ACF), while they are known as anisotropic conductive pest (ACP) in the paste form. This report studies the Anisotropic conductive film (ACF) market, from angles of Company, regions, product types and end industries, to analyze the status and the future.

According to the new market research report “Global Anisotropic Conductive Film Market Report 2023-2029”, published by QYResearch, the global Anisotropic Conductive Film market size is projected to reach USD 0.8 billion by 2029, at a CAGR of 4.8% during the forecast period.

Figure. Global Anisotropic Conductive Film Market Size (US$ Million), 2018-2029

Figure. Global Anisotropic Conductive Film Top 7 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Anisotropic Conductive Film include Showa Denko Materials, Dexerials, etc. In 2021, the global top three players had a share approximately 83.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Wet Granulation Equipment Market Regional Analysis, Investment Opportunities and Landscape 2024 - 2031

The "Wet Granulation Equipment Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Wet Granulation Equipment Market?

Market Analysis and Size

In recent years, the wet granulation equipment market is anticipated to proliferate during the forecast period. Granulation improves the flow characteristics of powdered active substances, making compression easier during tablet production. It also prevents the powdered material from segregating. There are two types of granulation: wet granulation and dry granulation. The process chosen is determined on the powder's properties and the goal of tablet production. It refers to the procedure of enlarging pharmaceutical substances to prevent constituent segregation in the powder mix. Granulation is a process that is often used to make oral medication formulations including tablets, pills, and capsules.

Data Bridge Market Research analyses that the wet granulation equipment market was valued at USD 3,867.75 million in 2021 and is expected to reach USD 6,211.29 million by 2029, registering a CAGR of 6.10% during the forecast period of 2022 to 2029. The rapid mixer granulator segment by product type is anticipated to hold the largest market share due to its ease of installation, simple operational process, and availability in various sizes suitable for research, pilot scale, and production. The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, patient epidemiology, pipeline analysis, pricing analysis, and regulatory framework.

Market Definition

The process of binding powder materials together with a liquid and adhesive material is known as wet granulation. Preparing material for granulation, soaking the powder/adding granulation solution, agglomeration process, and drying process are all part of the wet granulation process. Some of the benefits include improved material flow qualities, reduced air pollution, improved material compression and densification characteristics, and the ease of generating a homogeneous combination.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Wet Granulation Equipment market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Wet Granulation Equipment Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-wet-granulation-equipment-market

Which are the driving factors of the Wet Granulation Equipment market?

The driving factors of the Wet Granulation Equipment market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Wet Granulation Equipment across various industries further propel market expansion.

Wet Granulation Equipment Market - Competitive and Segmentation Analysis:

Global Wet Granulation Equipment Market, By Product Type (Rapid Mixer Granulator, Fluidized Bed Granulator, Others), Application (Laboratory Experiments, Pilot Batches Scaling, Commercial Scale Manufacturing, Others), End-Users (Pharmaceutical Research Laboratories, Pharmaceutical Production Plants, Contract Research and Manufacturing Organizations, Academic and Research Institutes, Others) – Industry Trends and Forecast to 2029

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Wet Granulation Equipment market?

Some of the major players operating in the wet granulation equipment market are:

SaintyCo. (China)

Nicomac Srl (Italy)

Alexanderwerk AG (Germany)

Romaco Group (Germany)

Fluid Air Systems (India)

Vanguard Pharmaceutical Machinery (US)

L.B. Bohle (India)

Karnavati Engineering (India)

CCS GROUP (US)

Syntegon Technology GmbH (Germany)

FREWITT SWITZERLAND (Switzerland)

LINXIS Group (France)

Anchor Mark Pvt Ltd. (India)

DIOSNA Dierks & Söhne GmbH. (Germany)

Spraying Systems Co. (US)

GEBRÜDER LÖDIGE MASCHINENBAU GMBH (Germany)

Glatt GmbH (Germany)

GEA Group Aktiengesellschaft (Germany)

ERWEKA GmbH (Germany)

Senieer (China)

Short Description About Wet Granulation Equipment Market:

The Global Wet Granulation Equipment market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Wet Granulation Equipment. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Wet Granulation Equipment Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Wet Granulation Equipment in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Wet Granulation Equipment Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Wet Granulation Equipment market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Wet Granulation Equipment Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Wet Granulation Equipment market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Wet Granulation Equipment?

What are the upcoming industry applications and trends for Wet Granulation Equipment market?

What Are Projections of Global Wet Granulation Equipment Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Wet Granulation Equipment?

What are the raw materials used for Wet Granulation Equipment manufacturing?

How big is the opportunity for the Wet Granulation Equipment market?

How will the increasing adoption of Wet Granulation Equipment for mining impact the growth rate of the overall market?

How much is the global Wet Granulation Equipment market worth? What was the value of the market In 2020?

Who are the major players operating in the Wet Granulation Equipment market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Wet Granulation Equipment Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-wet-granulation-equipment-market

Detailed TOC of Global Wet Granulation Equipment Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Wet Granulation Equipment Market By Type

Wet Granulation Equipment Market By Function

Wet Granulation Equipment Market By Material

Wet Granulation Equipment Market By End User

Wet Granulation Equipment Market By Region

Wet Granulation Equipment Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-wet-granulation-equipment-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Pharmacy Automation Market – Industry Trends and Forecast to 2030

Global Wet Granulation Equipment Market – Industry Trends and Forecast to 2029

Global Feed Modifiers Market - Industry Trends and Forecast to 2029

Global Automotive Brake Valve Market – Industry Trends and Forecast to 2028

Global Teak Wood Packaging Market – Industry Trends and Forecast to 2029

0 notes

Text

N-Propyl Acetate Prices Trend, Pricing, Database, Index, News, Chart, Forecast

N-Propyl Acetate Prices, a colorless liquid with a pleasant odor, is a widely used solvent in various industries including coatings, inks, adhesives, and pharmaceuticals. The pricing of n-propyl acetate is influenced by several factors such as raw material costs, production processes, demand-supply dynamics, and market trends. In recent years, the price of n-propyl acetate has experienced fluctuations due to changes in these underlying factors. Understanding these influences can provide insight into current and future price movements.

The primary raw materials for producing n-propyl acetate are acetic acid and propanol. Any fluctuation in the prices of these inputs directly affects the cost of n-propyl acetate. Acetic acid, being a key component, is subject to price volatility driven by feedstock availability, production levels, and global demand. Similarly, the price of propanol can vary based on the availability of propylene, from which it is derived. These raw material costs are often influenced by crude oil prices, as oil is a significant input for petrochemicals. Thus, a rise in crude oil prices can lead to an increase in the cost of producing n-propyl acetate.

Another significant factor impacting n-propyl acetate prices is the production process. Manufacturing efficiency, technological advancements, and the scale of production all play crucial roles. Companies with more advanced production facilities and economies of scale can produce n-propyl acetate at a lower cost, which can translate to competitive pricing in the market. Conversely, any disruptions in the production process, such as plant shutdowns or maintenance activities, can reduce supply and drive up prices.

Get Real Time Prices of N-Propyl Acetate: https://www.chemanalyst.com/Pricing-data/n-propyl-acetate-1133

Demand and supply dynamics are also crucial in determining the market price of n-propyl acetate. Industries such as automotive, construction, and consumer goods are major consumers of n-propyl acetate due to its solvent properties. Therefore, economic conditions affecting these sectors can influence demand. For instance, a booming automotive industry typically leads to higher demand for coatings and adhesives, subsequently increasing the need for n-propyl acetate. Conversely, an economic downturn can reduce demand and put downward pressure on prices. Additionally, seasonal variations and cyclical market trends can also impact demand.

On the supply side, factors such as production capacity, geopolitical issues, and trade policies can affect the availability of n-propyl acetate in the market. An increase in production capacity or the entry of new producers can boost supply and potentially lower prices. However, geopolitical tensions and trade restrictions can disrupt supply chains, leading to shortages and higher prices. For example, tariffs on chemical imports or exports can alter trade flows and impact the pricing of n-propyl acetate.

Market trends and regional differences also play a role in price determination. Different regions may experience varying levels of demand and supply, leading to price disparities. For instance, Asia-Pacific, being a major manufacturing hub, often shows higher demand for solvents like n-propyl acetate compared to other regions. This regional demand can influence global prices. Furthermore, market trends such as the shift towards environmentally friendly products and sustainable practices can affect demand patterns. N-propyl acetate, being a relatively low-toxicity solvent, may see increased demand as industries move towards greener alternatives, potentially impacting its price.

In recent times, the COVID-19 pandemic has significantly influenced the chemical markets, including n-propyl acetate. The pandemic caused disruptions in manufacturing activities, supply chain constraints, and fluctuations in demand across various sectors. Initially, the lockdowns and reduced industrial activities led to a decrease in demand and a drop in prices. However, as industries began to recover and adapt to the new normal, demand picked up, and prices started to stabilize. The pandemic highlighted the importance of resilient supply chains and the need for flexibility in production processes.

In conclusion, the prices of n-propyl acetate are shaped by a complex interplay of raw material costs, production efficiencies, demand-supply dynamics, and market trends. Understanding these factors can help stakeholders make informed decisions in procurement, production planning, and market strategy. As the global economy continues to evolve, staying attuned to these influences will be crucial for navigating the n-propyl acetate market effectively. With the potential for further technological advancements and a continued emphasis on sustainability, the market for n-propyl acetate may see new trends emerging, further shaping its pricing landscape.

Get Real Time Prices of N-Propyl Acetate: https://www.chemanalyst.com/Pricing-data/n-propyl-acetate-1133

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#N-Propyl Acetate#N-Propyl Acetate Price#N-Propyl Acetate Prices#N-Propyl Acetate Pricing#N-Propyl Acetate News

0 notes

Text

Acrylic Acid Market: Trends, Growth Drivers, and Future Prospects

The acrylic acid market has witnessed significant growth over the past few decades, driven by its extensive application across various industries. As a key component in the production of polymers, acrylic acid plays a crucial role in the manufacture of adhesives, paints, coatings, textiles, and superabsorbent polymers. This article explores the current trends, growth drivers, and future prospects of the acrylic acid market.

Overview of Acrylic Acid

Acrylic acid market is a colorless, corrosive liquid with a characteristic acrid odor. It is primarily used as a raw material in the production of acrylate esters such as methyl acrylate, ethyl acrylate, and butyl acrylate, which are then used in the production of adhesives, sealants, and coatings. Additionally, acrylic acid is a vital ingredient in the manufacture of superabsorbent polymers (SAPs), which are used in products like diapers and adult incontinence products due to their high absorption capacity.

Market Trends

1. Growing Demand in Adhesives and Sealants: The increasing use of acrylic acid in the production of adhesives and sealants is one of the primary factors driving market growth. These products are essential in the construction, automotive, and packaging industries, contributing to the rising demand for acrylic acid.

2. Expansion of the Paints and Coatings Industry: Acrylic acid is a critical component in water-based paints and coatings, which are favored for their environmental benefits and low volatile organic compound (VOC) emissions. The growing construction activities and infrastructure development worldwide are fueling the demand for paints and coatings, thereby boosting the acrylic acid market.

3. Rising Use in Personal Care Products: The superabsorbent polymers made from acrylic acid are extensively used in personal care products such as diapers, sanitary napkins, and adult incontinence products. With increasing awareness of hygiene and rising disposable incomes, the demand for these products is escalating, further propelling the acrylic acid market.

4. Sustainability Initiatives: The industry is witnessing a shift towards sustainable and bio-based acrylic acid production. Companies are investing in research and development to produce bio-acrylic acid from renewable resources, reducing the carbon footprint and dependence on fossil fuels. This trend is expected to create new growth opportunities in the market.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/acrylic-acid-market/

Growth Drivers

1. Industrial Growth in Emerging Economies: Rapid industrialization and urbanization in emerging economies such as China, India, and Brazil are major drivers of the acrylic acid market. The increasing demand for adhesives, sealants, paints, and coatings in these regions is bolstering market growth.

2. Technological Advancements: Innovations in production processes and the development of new applications for acrylic acid are enhancing its market potential. Advanced manufacturing techniques are improving yield and efficiency, making acrylic acid more cost-effective and accessible for various industrial applications.

3. Rising Consumer Awareness: Growing consumer awareness about hygiene and sanitation is driving the demand for personal care products, which, in turn, is boosting the demand for superabsorbent polymers made from acrylic acid. This trend is particularly prominent in developing regions where improving living standards are increasing the adoption of such products.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=44289

Future Prospects

The future of the acrylic acid market looks promising, with several factors poised to drive its growth. The continued expansion of the construction and automotive industries, particularly in developing economies, will sustain the demand for adhesives, sealants, and coatings. Furthermore, the increasing focus on sustainability and the development of bio-based acrylic acid are expected to open new avenues for market growth.

However, the market also faces challenges such as fluctuating raw material prices and environmental concerns related to acrylic acid production. Addressing these challenges through technological advancements and sustainable practices will be crucial for the market's long-term growth.

Conclusion

The acrylic acid market is on a robust growth trajectory, driven by its diverse applications and the increasing demand across various industries. As manufacturers continue to innovate and adopt sustainable practices, the market is expected to witness significant advancements. With the ongoing industrial growth and rising consumer awareness, the future of the acrylic acid market holds immense potential.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

#Acrylic Acid Market#Acrylic Acid Market Growth#Acrylic Acid Market Share#Acrylic Acid Market Trends

0 notes

Text

The paper, packaging & related products segment is expected to lead the liquid adhesives market during the forecast period. The growth of this segment can be attributed to the increased use of adhesives in a wide variety of paper bonding applications ranging from corrugated box construction and the lamination of printed sheets to packaging materials used in all types of consumer products and the production of large industrial tubes and cores. Increasing E-commerce has stimulated the growth of this industry.

#Liquid Adhesives Market#Adhesives Market#Liquid Adhesives#liquid nails for concrete#liquid stitches#liquid fusion glue#liquid nails acrylic#mastisol liquid adhesive#liquid nails use#liquid nail adhesive#Water-based Adhesive Market#liquid nails construction adhesive#COVID 19 impact on Liquid Adhesives Market#Industrial Adhesives Market#Global Liquid Adhesives Market#Liquid Adhesives Market Share#Liquid Adhesives Market Forecast#Liquid Adhesives Demand#Liquid Adhesives Sales#Liquid Adhesives Market Growth#global liquid adhesives market#Impact of COVID-19 on Liquid Adhesives Market#Water-based liquid adhesives#APAC liquid adhesives market

0 notes

Text

With Our Pail Filling Machine, Revolutionize Your Production Line

In the current, hectic production environment, precision and efficiency are critical factors that can either save or destroy a company. The packaging of liquids and semi-liquids can be entirely changed with the right equipment. This is when using our cutting edge pail filling machine comes in handy.

Machine for Filling Pails: Efficiency Redefined

Through the simplification of the filling procedure, our pail filling machine is intended to transform your production line. Its automated features allow it to fill a range of pail sizes with reliable accuracy, lowering labor expenses and product waste. No more spills or manual filling mistakes since our machine makes sure every pail is filled to the precise volume needed.

When Versatility Works Best

Paints, chemicals, adhesives, and food ingredients are all handled by our pail filling machine. Easy modification to fit your particular product needs is made possible by its adaptable design. Its strong design guarantees longevity as well, making it a dependable addition to your manufacturing floor.

Accuracy and dependability

Preciseness in filling procedures is essential, particularly for companies where even a little difference might have major consequences. Our pail filling machine has cutting edge technology built in to guarantee precise and dependable filling every time. Happy customers, less quality control issues, and a healthier bottom line follow from this.

Put Money Towards Quality

It is an investment in quality to buy our pail filling equipment. It is a prudent move that can help your business remain competitive and meet market demands. Inefficiencies, errors, and bottlenecks in your production line will be replaced with a reliable, efficient, and streamlined filling process.

To sum up, upgrading your production line is made possible by our Pail Filling Machine. See the change and higher production it offers, and see how your business thrives in the modern market.

0 notes

Text

Propylene Oxide Market Dynamics: A Comprehensive Overview

Introduction

Propylene oxide is an organic compound with the chemical formula C3H6O. It is a colorless volatile liquid that is miscible with water, most common organic solvents and has a faint ethereal odor. C3H6O is an epoxide, meaning it contains an oxide group bonded to two carbon atoms forming a three-membered cyclic ether. It is formed through the oxidation of propylene.

Production of Propylene Oxide

Industrially, propylene oxide is produced on a large scale through the chlorohydrin process or hydroperoxide process. In the chlorohydrin process, propylene is oxidized with chlorine in the presence of a chloride catalyst to form propylene chlorohydrin which is then hydrolyzed to yield C3H6O and hydrochloric acid. This process allows for greater selectivity in product formation.

The hydroperoxide process involves three steps - first hydroperoxide is formed by oxidizing propylene with an oxygen containing gas like air or oxygen over a silver catalyst. This is followed by decomposition of hydroperoxide to form C3H6O and water. The final step recovers and purifies the C3H6O product. This process affords higher atom efficiency and lower energy consumption.

Properties and Applications

Due to its versatile functionality of forming additional bonds through ring opening, C3H6O has a wide range of applications. It is mainly used for producing polyether polyols which are building blocks for polyurethane products like rigid and flexible foams for insulation and cushioning. C3H6O is also used to produce propylene glycols that are commonly used as heat transfer fluids and manufacturing solvents.

As an intermediate chemical, C3H6O is converted to propylene glycol ethers which are used in industrial and automotive antifreeze formulations as well as paints, coatings and cleaning agents due to their good solvent properties. Epoxy resins formed from reacting C3H6O with epichlorohydrin are used to produce protective and durable coatings, adhesives, composites and encapsulation of electronics.

C3H6O acts as a intermediate in producing other chemical compounds like propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate which are solvents for inks, coatings and electronics packaging. It can also react with amines to form amine oxide surfactants that are used in personal care, home care and industrial cleaning products.

Health and Environmental Effects

While C3H6O is useful industrially, it also poses certain health risks. It is a volatile flammable liquid and contact with eyes and skin can cause irritation. Inhalation may cause respiratory issues. Studies have shown it to be possibly carcinogenic to humans and its vapors are harmful if inhaled in large quantities.

Organizations like the EPA have classified C3H6O as a hazardous air pollutant and possible human carcinogen. Manufacturing sites emitting this chemical are subject to regulations regarding its release into the environment. Proper handling and storage in a well-ventilated area along with use of protective equipment is important when working with propylene oxide. Spills contaminating soil and water need remediation to minimize environmental damage.

Conclusion

In summary, C3H6O is a versatile chemical building block found in many industrial and commercial products. While serving important applications, its adverse health effects require careful production and usage practices, transportation, storage and disposal according to safety guidelines. Ongoing research explores safer production technologies for this valuable oxirane compound supporting many modern industries. With proper risk management measures, propylene oxide will continue meeting manufacturing needs sustainably.

0 notes

Text

Global Market Analysis Of Precipitated Calcium Carbonate

Originally published by Technavio : Precipitated Calcium Carbonate Market Analysis APAC, Europe, North America, Middle East and Africa, South America - US, China, India, UK, Germany - Size and Forecast 2023-2027

The global Precipitated Calcium Carbonate (PCC) market is poised for significant growth from 2023 to 2027, with the market size projected to increase by USD 2.51 billion, reflecting a CAGR of 4.75%. This growth is driven by PCC's essential role in various industries, including paper manufacturing, paints and coatings, and as an industrial filler. PCC's unique properties, such as superior surface finish, enhanced impact and electrical resistance, and precise control over manufacturing processes, make it a preferred choice over other fillers.

Click here for sample report

Market Size and Segmentation

The PCC market's expansion is detailed in the following segments:

By Type:

Pharmaceutical Grade: This segment is anticipated to see significant growth. Pharmaceutical-grade PCC is rigorously tested for purity and quality, making it suitable for pharmaceutical formulations and healthcare applications. It is widely used in calcium supplements, antacid formulations, and for pH regulation in liquid or semi-solid preparations.

Industrial Grade

By End-User:

Paper: PCC is crucial in the paper industry for enhancing paper properties such as brightness and opacity.

Plastic

Paint

Adhesive and Sealant

Others

By Geography:

North America: Expected to contribute 36% to the global market growth, driven by diverse industrial applications.

APAC: Significant growth due to increasing industrial activities, particularly in China and India, supported by government infrastructure investments.

Europe

Middle East and Africa

South America

Key Market Drivers

Versatility as an Industrial Filler: PCC is widely adopted across various applications due to its affordability and superior properties compared to alternatives like clay, kaolin, and talc. Its role in enhancing product performance and maintaining cost-effectiveness drives market growth.

Pharmaceutical Industry Demand: The pharmaceutical sector significantly contributes to the PCC market due to its use in calcium supplements, antacids, and as a non-toxic ingredient according to FDA standards.

Construction and Automotive Sectors: Ongoing infrastructure development and automotive production expansion bolster the demand for PCC in these industries.

Significant Market Trends

Pharmaceutical and Personal Care Applications: Growing demand for PCC in these sectors, driven by its non-toxic nature and regulatory approvals, is a key market trend.

Eco-Friendly Products: Increasing awareness and preference for eco-friendly products fuel the adoption of PCC in green applications.

Major Market Challenges

Health Hazards: Overconsumption of PCC can lead to adverse health effects like kidney stones and other symptoms. This can negatively impact market growth.

Price Volatility and Substitutes: Fluctuations in raw material prices and the availability of alternative materials pose challenges to market stability.

Competitive Landscape

Key companies in the PCC market employ strategies such as mergers, acquisitions, partnerships, and product innovations to maintain and enhance their market positions. Some of the prominent players include:

Blue Mountain Minerals

Cales de Llierca SA

Carmeuse Coordination Center SA

FIMATEC Ltd.

Imerys S.A.

Omya International AG

SCHAEFER KALK GmbH & Co. KG

Market Dynamics and Customer Landscape

The PCC market serves diverse industries, enhancing product properties and meeting stringent regulatory standards. Despite challenges like price volatility and health concerns, the market benefits from innovations in manufacturing and raw material sourcing. The emphasis on eco-friendly solutions and sustainability further drives PCC adoption across various sectors.

In conclusion, the Precipitated Calcium Carbonate market is set for robust growth, driven by its versatile applications and the increasing demand across industries like pharmaceuticals, construction, and automotive. Addressing challenges related to health risks and price stability will be crucial for sustained market expansion.

Contact us for more information

0 notes

Text

Unraveling the Growth Trajectory: The Fibrin Sealant Market

Introduction: In the realm of modern medicine, fibrin sealants have emerged as invaluable tools in surgical procedures and wound management. Fibrin sealants, also known as fibrin glues or fibrin tissue adhesives, are biocompatible compounds that mimic the final stage of the body's natural clotting cascade, promoting hemostasis and tissue sealing. As surgical techniques continue to advance and the demand for minimally invasive procedures rises, the fibrin sealant market is experiencing robust growth. This article delves into the multifaceted landscape of the fibrin sealant market, exploring its key drivers, applications, innovations, and future prospects.

Understanding Fibrin Sealants: Fibrin sealants are composed of two main components: fibrinogen and thrombin. When combined, these components initiate a cascade of biochemical reactions, culminating in the formation of a stable fibrin clot at the site of application. This clot acts as a sealant, adhering tissue surfaces together and promoting wound healing. Fibrin sealants are available in various formulations, including liquid, spray, and patch forms, catering to diverse surgical and clinical needs.

Market Dynamics:

Rising Surgical Volumes: The growing prevalence of chronic diseases and age-related conditions necessitates an increase in surgical interventions, driving the demand for fibrin sealants in various surgical specialties such as cardiovascular, orthopedic, and general surgery.

Shift towards Minimally Invasive Procedures: With a focus on reducing patient morbidity and healthcare costs, there is a notable shift towards minimally invasive surgical techniques, wherein fibrin sealants play a pivotal role in achieving hemostasis and tissue sealing.

Advancements in Product Development: Continuous innovation in fibrin sealant formulations, delivery systems, and adjunctive technologies is expanding the applicability and efficacy of these products, further fueling market growth.

Expanding Clinical Indications: Fibrin sealants are increasingly being utilized across a spectrum of clinical scenarios, including wound closure, tissue repair, hemostasis in vascular surgery, and augmentation of surgical procedures, broadening their market reach.

Growing Regulatory Approvals: Regulatory agencies are increasingly recognizing the safety and efficacy of fibrin sealants, leading to expedited approvals and market penetrations in both developed and emerging markets.

Applications Across Specialties:

Cardiovascular Surgery: Fibrin sealants are used to achieve hemostasis and seal vascular anastomoses, reducing the risk of postoperative bleeding and complications in cardiac and vascular surgeries.

Orthopedic Surgery: In orthopedic procedures such as total joint replacement and spinal surgery, fibrin sealants aid in tissue adherence, reducing the risk of postoperative leakage and promoting bone and soft tissue healing.

General Surgery: Fibrin sealants find extensive use in various general surgical procedures, including gastrointestinal surgery, hepatic resections, and organ transplantation, facilitating hemostasis and tissue approximation.

Plastic and Reconstructive Surgery: Fibrin sealants play a crucial role in plastic and reconstructive procedures, promoting tissue adherence and enhancing aesthetic outcomes in tissue flaps, grafts, and microsurgery.

Future Outlook: The future of the fibrin sealant market is promising, driven by ongoing technological advancements, expanding clinical indications, and the growing adoption of minimally invasive surgical techniques. With an aging population and increasing healthcare expenditure worldwide, the demand for fibrin sealants is expected to surge further. Additionally, advancements in biomaterials, tissue engineering, and regenerative medicine are poised to unlock new opportunities for fibrin sealants in tissue repair and regeneration.

Conclusion: The fibrin sealant market is witnessing unprecedented growth, propelled by the burgeoning demand for effective hemostatic agents and tissue adhesives across diverse surgical specialties. As healthcare providers and medical device manufacturers continue to innovate and collaborate, the landscape of fibrin sealants is poised for continuous evolution, offering novel solutions for complex surgical challenges and improving patient outcomes worldwide. By leveraging cutting-edge technologies and embracing a multidisciplinary approach, stakeholders in the fibrin sealant market can capitalize on emerging opportunities and contribute to the advancement of modern surgical practice.

Related Reports:

U.S. Pharmacy Market 2024 Key Drivers, Industry Size & Trends and Forecasts to 2032

Defibrillators Market 2024 Key Drivers, Industry Size & Trends and Forecasts to 2032

Defibrillators Market 2024 Data Current and Future Trends, Revenue, Business Growth Forecast to 2032

Defibrillators Market 2024 Latest Industry Size, Growth, Demand, Trends Forecasts to 2032

Defibrillators Market 2024 Size, Trends Outlook, Geographical Segmentation Forecasts to 2032

Defibrillators Market 2024 Size, Gross Margin, Trends, Future Demand, Analysis by Top Leading Players and Forecast till 2032

Defibrillators Market 2024 Key Drivers, Industry Size & Trends and Forecasts to 2032

0 notes

Text

Diethyl Phthalate Manufacturers. Crafting a Key Component in Modern Industry

Introduction

Diethyl phthalate (DEP) is a versatile organic compound widely used as a plasticizer and solvent in various industrial applications. This colorless, odorless liquid has found its way into numerous products ranging from personal care items to plastics and pharmaceuticals. As the demand for DEP continues to grow, manufacturers play a critical role in ensuring its availability and quality. This article explores the landscape of diethyl phthalate manufacturing, highlighting key players, production processes, market trends, and the challenges and opportunities in this essential industry.

The Significance of Diethyl Phthalate

Diethyl phthalate, with the chemical formula C12H14O4, is primarily used as a plasticizer—a substance added to plastics to increase their flexibility, transparency, and durability. Its primary applications include:

Plastics and Polymers: DEP is extensively used in the production of flexible plastics, including packaging materials, toys, and medical devices.

Personal Care Products: It is a common ingredient in cosmetics, perfumes, and lotions, where it acts as a solvent and fixative.

Pharmaceuticals: DEP serves as a coating agent for tablets and capsules, ensuring their stability and controlled release.

Industrial Solvent: Its properties as a solvent make it valuable in the manufacturing of coatings, inks, and adhesives.

Given its widespread applications, the production and supply of high-quality diethyl phthalate are vital to many industries.

Leading Manufacturers

The market for diethyl phthalate is dominated by several key manufacturers known for their commitment to quality and innovation. These companies are often large chemical corporations with extensive production capabilities and global reach.

TKM Pharma

Head to TKM Pharma for the most quality-focused diethyl phthalate manufacturer in India. Founded on the bedrock of hard work, innovation, and customer-centricity, we have become the most sought-after brand when it comes to high-efficacy chemicals for a wide assortment of industrial applications. Since our inception in 2000, we have grown in strength owing to our unwavering commitment to quality chemical products and customer engagement. Some of the industries we offer our expertise to include pharmaceuticals, chemicals, additives, paints, and perfumes.

Production Processes

The production of diethyl phthalate involves the esterification of phthalic anhydride with ethanol. This process can be carried out using different methods, but the most common involves acid catalysis:

Acid-Catalyzed Esterification: Phthalic anhydride is reacted with ethanol in the presence of an acid catalyst, such as sulfuric acid.

Purification: The crude DEP produced is then purified through distillation to remove any unreacted ethanol, water, and other impurities, ensuring the final product meets the required quality standards.

Quality Control: Rigorous quality control measures are implemented to ensure that the DEP produced meets industry-specific purity and performance criteria.

Market Dynamics

The diethyl phthalate market is influenced by various factors, including technological advancements, regulatory frameworks, and economic conditions:

Technological Innovations: Advances in production technologies enhance the efficiency, safety, and environmental sustainability of DEP manufacturing. Innovations in catalytic processes and purification techniques are particularly significant.

Regulatory Compliance: DEP manufacturers must adhere to stringent regulations regarding its production, use, and disposal. Regulatory bodies like the Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) oversee these standards to protect human health and the environment.

Growing Demand from End-Use Industries: The increasing demand for flexible plastics, personal care products, and pharmaceuticals drives the market for DEP.

Sustainability Initiatives: The chemical industry faces increasing pressure to adopt sustainable practices. Manufacturers are investing in green chemistry and renewable raw materials to produce DEP more sustainably, reducing their environmental footprint.

Economic Fluctuations: The demand for DEP is sensitive to broader economic conditions. Industrial slowdowns or booms can significantly impact production volumes and pricing.

Challenges Facing Manufacturers

Manufacturers of diethyl phthalate face several challenges that require strategic management and innovation:

Regulatory Pressures: Compliance with environmental and safety regulations is critical. Manufacturers must ensure that their production processes minimize emissions and waste, adhering to local and international standards.

Market Competition: The DEP market is competitive, with numerous players vying for market share. Manufacturers must continuously innovate and optimize their operations to maintain a competitive edge.

Raw Material Availability: The availability and cost of raw materials, such as phthalic anhydride and ethanol, can impact production efficiency and profitability. Effective supply chain management is essential.

Environmental Concerns: Public and regulatory scrutiny regarding the environmental impact of plasticizers necessitates the development of more sustainable and less harmful alternatives.

Consumer Awareness: Increasing consumer awareness about the potential health effects of phthalates, particularly in personal care products, can influence market dynamics. Manufacturers must address these concerns through transparency and product safety assurances.

Future Outlook

The future of diethyl phthalate manufacturing looks promising, with continuous advancements in production technologies and increasing demand from various industrial sectors. The focus on sustainability and environmental responsibility is likely to drive innovation, leading to greener production methods and more efficient processes. As industries such as plastics, personal care, and pharmaceuticals continue to grow, the demand for DEP will rise, ensuring a steady market for manufacturers.

Conclusion

Diethyl phthalate manufacturers play a crucial role in supplying a versatile and essential chemical to various industries worldwide. Despite facing numerous challenges, these manufacturers continue to innovate and adapt to meet the evolving demands of the market. With a focus on quality, safety, and sustainability, the diethyl phthalate industry is poised for growth, driven by technological advancements and expanding applications in emerging markets. As the industry evolves, manufacturers will need to navigate regulatory landscapes, manage economic fluctuations, and prioritize environmental concerns to sustain their crucial role in the global chemical sector.

0 notes

Text

Coating Materials Market Growth, Advanced, Trends, Revenue Analysis 2024-32

The Reports and Insights, a leading market research company, has recently releases report titled “Coating Materials Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Coating Materials Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Coating Materials Market?

The global coating materials market was US$ 157.2 Billion in 2022. The market to register a revenue CAGR of 3.6% over the forecast period and account for a market size of US$ 216.1 Bn in 2031.

What are Coating Materials?

Coating materials refer to substances applied to surfaces to enhance or protect them. They come in various forms such as liquids, powders, or solids and find applications across industries like automotive, aerospace, construction, and electronics. Coatings can enhance durability, resist corrosion, improve aesthetics, provide insulation, or impart specific functions like non-stick or anti-microbial properties. Paints, varnishes, sealants, and adhesives are among the common types of coating materials, each designed for specific surfaces and purposes.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2061

What are the growth prospects and trends in the Coating Materials industry?

The coating materials market growth is driven by various factors and trends. The coating material market is a substantial component of the chemicals industry worldwide, fueled by the need for protective and decorative coatings in industries like automotive, construction, aerospace, and industrial manufacturing. It encompasses diverse coating materials such as acrylics, polyurethanes, epoxies, and more, each serving distinct purposes and possessing unique properties. Market dynamics are shaped by factors such as advancements in technology, environmental directives, and the increasing demand for sustainable and environmentally friendly coatings. Emerging trends in the market include the innovation of smart coatings and the integration of nanotechnology to enhance coating functionalities. Hence, all these factors contribute to coating materials market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Material Type

Pure Metals

Alloys

Ceramic (Oxide)

Pseudo Alloys

By Coating Type

Organic Coatings

Inorganic Coatings

By Thinner Type

Mineral Spirits

Aromatics

Ketones

Alcohols

Water

By End-Use

Automotive

Architectural

Electronic

Food and Beverage

Marine

By Region

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

AkzoNobel N.V.

PPG Industries Inc.

BASF

The Sherwin Williams Company

Axalta Coating Systems

KANSAI PAINT CO., LTD

Nippon Paint Holdings Co. Ltd.

JOTUN

RPM International Inc.

Tiger Drylac U.S.A

View Full Report: https://www.reportsandinsights.com/report/Coating Materials-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Sodium Silicate Market Insights, Status And Forecast to 2030

Global Sodium Silicate Market Report from Market Research Forecast highlights deep analysis on market characteristics, sizing, estimates and growth by segmentation, regional breakdowns & country along with competitive landscape, player’s market shares, and strategies that are key in the market. The exploration provides a 360° view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improved profitability. In addition, the study helps venture or private players in understanding the companies in more detail to make better informed decisions.

Major Players in This Report Include:

Occidental Petroleum Corporation (U.S.), Evonik Industries (Germany), CIECH Group (Poland), Silmaco NV (Belgium), Oriental Silicas Corporation (Taiwan), PQ Corporation (U.S.), Nippon Chemical Industrial CO.LTD (Japan), Kiran Global Chem Limited (India), Ankit Silicates (India), BASF SE (Germany).

Free Sample Report + All Related Graphs & Charts @: https://marketresearchforecast.com/report/sodium-silicate-market-1401/sample-report

The Sodium Silicate Marketsize was valued at USD 6.25 USD Billion in 2023 and is projected to reach USD 8.85 USD Billion by 2032, exhibiting a CAGR of 5.1 % during the forecast period.

Market Drivers:

Growing Demand for the Product from Various Application Areas to Drive the Market Growth

Market Trend:

Restrains:

Toxic Nature of the Product to Impede Market Growth

Enquire for customization in Report @: https://marketresearchforecast.com/report/sodium-silicate-market-1401/enquiry-before-buy

In this research study, the prime factors that are impelling the growth of the Global Sodium Silicate market report have been studied thoroughly in a bid to estimate the overall value and the size of this market by the end of the forecast period. The impact of the driving forces, limitations, challenges, and opportunities has been examined extensively. The key trends that manage the interest of the customers have also been interpreted accurately for the benefit of the readers.

The Sodium Silicate market study is being classified Type: Solid and Liquid","Application: Detergents, Pulp & Paper, Derivative Silicates, Construction, Water Treatment, Adhesives, and Others

The report concludes with in-depth details on the business operations and financial structure of leading vendors in the Global Sodium Silicate market report, Overview of Key trends in the past and present are in reports that are reported to be beneficial for companies looking for venture businesses in this market. Information about the various marketing channels and well-known distributors in this market was also provided here. This study serves as a rich guide for established players and new players in this market.

Get Reasonable Discount on This Premium Report @ https://marketresearchforecast.com/report/sodium-silicate-market-1401/request-discount

Extracts from Table of Contents

Sodium Silicate Market Research Report

Chapter 1 Sodium Silicate Market Overview

Chapter 2 Global Economic Impact on Industry

Chapter 3 Global Market Competition by Manufacturers

Chapter 4 Global Revenue (Value, Volume*) by Region

Chapter 5 Global Supplies (Production), Consumption, Export, Import by Regions

Chapter 6 Global Revenue (Value, Volume*), Price* Trend by Type

Chapter 7 Global Market Analysis by Application

………………….continued

This report also analyses the regulatory framework of the Global Markets Sodium Silicate Market Report to inform stakeholders about the various norms, regulations, this can have an impact. It also collects in-depth information from the detailed primary and secondary research techniques analysed using the most efficient analysis tools. Based on the statistics gained from this systematic study, market research provides estimates for market participants and readers.

Contact US :

Craig Francis (PR & Marketing Manager)

Market Research Forecast

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: (+1 201 565 3262, +44 161 818 8166)

[email protected]

#Global Sodium Silicate Market#Sodium Silicate Market Demand#Sodium Silicate Market Trends#Sodium Silicate Market Analysis#Sodium Silicate Market Growth#Sodium Silicate Market Share#Sodium Silicate Market Forecast#Sodium Silicate Market Challenges

0 notes