#Liquid Adhesives Sales

Text

The market for liquid adhesives in APAC is projected to register high growth, and the trend is projected to continue during the forecast period. The increasing industrial and infrastructural development in APAC is responsible for its high share. APAC has emerged as the leading consumer and producer of liquid adhesives because of the increasing demand from India, South Korea, China, Indonesia, and others.

APAC is an emerging and potential market for liquid adhesives, in terms of both value and volume. The increasing demand from end-use industries is contributing to the demand for liquid adhesives in the APAC region. The market is also driven by increased foreign investments due to cheap labor and accessible raw materials. Government proposals to improve the manufacturing and infrastructure, and to increase cash-intensive non-residential construction activities, coupled with the increase in the manufacturing of end-use products, are other factors driving the liquid adhesives market.

#Liquid Adhesives Market#Adhesives Market#Liquid Adhesives#liquid nails for concrete#liquid stitches#liquid fusion glue#liquid nails acrylic#mastisol liquid adhesive#liquid nails use#liquid nail adhesive#Water-based Adhesive Market#liquid nails construction adhesive#COVID 19 impact on Liquid Adhesives Market#Industrial Adhesives Market#Global Liquid Adhesives Market#Liquid Adhesives Market Share#Liquid Adhesives Market Forecast#Liquid Adhesives Demand#Liquid Adhesives Sales#Liquid Adhesives Market Growth#global liquid adhesives market#Impact of COVID-19 on Liquid Adhesives Market#Water-based liquid adhesives#APAC liquid adhesives market

0 notes

Text

Pre-Columbian civilizations across the Americas developed various adhesives used in everyday applications and ceremonial contexts. These adhesives were crafted from natural materials, such as plant resins, tree gums, and animal-based glues, with their use spanning numerous cultural groups, including the Maya, Aztec, Inca, and Moche. By understanding the properties of their surrounding environment, these cultures could create adhesives suitable for tool-making, repairing objects, crafting jewelry, and producing artwork.

This article will focus on the adhesives used by these ancient cultures, how they were made, and the specific applications seen in archaeological findings.

Moche Wood Scepter c. 400-800 AD. closeup view

Moche wood scepter w/ inlaid Shell and Stones

Materials Used in Pre-Columbian Adhesives

Pre-Columbian adhesives were primarily sourced from plant resins, tree gums, and animal derivatives. Each civilization developed unique techniques to harvest and process these natural materials to suit their environmental and cultural needs.

Plant Resins and Tree Gums

Plant resin was one of pre-Columbian cultures’ most widely used adhesive materials. Resins such as copal, commonly used by the Maya and other Mesoamerican civilizations, were derived from trees in the Burseraceae family. The Maya used copal resin for both ritual and practical purposes. It was often burned as incense in religious ceremonies, but in a solid form, it was an adhesive for binding materials such as stone and wood.

The Aztecs also exploited natural resins, particularly pine resin. Pine resin was commonly mixed with natural powders like ash or powdered stone to enhance its adhesive properties. This combination was often applied to tools, pottery repairs, or affixing feathers and stones to wooden or clay artifacts.

Animal-Based Adhesives

In some pre-Columbian cultures, animal-based adhesives were also used, although these were less documented than plant resins. These adhesives were typically made by boiling animal hides, bones, or tendons to produce gelatinous substances that, when cooled, formed a strong bond. Andean civilizations, such as the Inca, likely employed these adhesives, though less direct evidence survives than their Mesoamerican counterparts.

For example, animal-based glues may have been used in textile production to attach decorative elements such as feathers to ceremonial garments or headpieces. However, animal-based adhesives’ exact prevalence and variety are not as well-documented as resin-based adhesives.

Methods of Production and Application

The production of adhesives in the pre-Columbian Americas required an understanding of local materials and their properties. Though methods varied between cultures, specific techniques were standard across regions.

Resin Extraction and Processing

Plant resins like copal were often harvested by cutting into the bark of resin-producing trees. The resin would ooze out and harden upon exposure to air, after which it could be collected and stored. When needed, the hardened resin was heated over a fire or other heat source until it became a thick liquid. Once liquefied, it could be applied to objects as an adhesive.

For specific applications, additives like powdered stone or pigments were mixed into the resin to adjust its texture or increase its durability. For example, this practice was common in affixing decorative stones to jewelry or securing blade heads to wooden shafts for tools and weapons.

Paracas Wood, Stone and Feather Club for Sale

Paracas wooden club w/inlaid Stone

Application Techniques

Adhesives were applied directly to the surfaces that needed bonding, often in thin layers. When used to repair pottery, artisans would apply the glue to the broken edges and carefully press the pieces together, holding them in place until the resin hardened. In some cases, additional adhesive was applied over the joints to reinforce the bond.

For weaponry and tools, adhesives were often used with other fastening techniques. For example, in Mesoamerican cultures, resin might have been used to help secure stone blades to wooden handles, followed by wrapping the joint with plant fibers for additional strength.

Cultural Examples of Adhesive Use

Several archaeological findings highlight the importance of adhesives in pre-Columbian material culture. Below are examples of how various civilizations across the Americas used adhesives.

Maya Copal Resin

The Maya extensively used copal resin for ceremonial incense and as an adhesive for repairing ceramics and affixing small decorative stones or shells to larger objects. For instance, archaeologists have found examples of jade and shell inlays on wooden objects in Maya tombs held in place by hardened copal resin.

Aztec Featherwork

Featherwork, a vital art form in Aztec and Maya civilizations, required adhesives to attach vibrant bird feathers to textiles, shields, and headdresses. In Aztec society, feather artisans, known as amantecas, used a combination of plant-based resins, such as pine resin, to bind the feathers in place. The featherwork pieces served decorative and religious purposes, demonstrating the adhesive’s role in crafting items of cultural significance.

Inca Wood and Stone Artifacts

In the Andean regions, particularly within the Inca Empire, adhesives were employed in various woodworking and stone-carving techniques. For example, adhesives were used to fasten metal or stone inlays into wooden objects, such as ceremonial staffs or chicha cups. Additionally, using resin-based adhesives for pottery repair has been suggested by analyzing broken and mended artifacts found in Inca archaeological sites.

Moche Metalworking

The Moche civilization of northern Peru is known for its advanced metallurgy and intricate artwork. Moche artisans likely used plant-based adhesives in their fine metalworking to affix precious stones or inlays into metal pieces. Some surviving Moche metal objects, such as ornamental plaques and jewelry, show evidence of adhered stone inlays using organic adhesives.

Moche Pututu Trumpet Shell Horn front side view

Moche Pututu Shell – Waylla Kepa w/ inlaid Silver Mouth Piece

Wari Mask Product for Sale

Wari False Head w/inlaid Shells

Conclusion

Pre-Columbian adhesives played a crucial role in the daily and ceremonial lives of the Maya, Aztecs, Inca, and other ancient civilizations. By utilizing plant resins like copal and pine and possibly animal-derived glues, these cultures produced durable and versatile adhesives for repairing ceramics, crafting tools, and creating intricate works of art. The widespread use of these adhesives, as demonstrated by surviving artifacts, provides insight into the technological sophistication of these pre-Columbian societies. Their understanding of natural resources allowed them to create functional and integral materials for their cultural and artistic practices, ensuring that these innovations would endure through the ages.

How to Determine Cotton Fabric from Camelid Fibers Accurately?

Research Academic Papers and News Articles

#ancient art#ancient history#archaeology#pre-columbian#art history#artifacts#inca#aztec#mayan#south america#ancient technology

9 notes

·

View notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

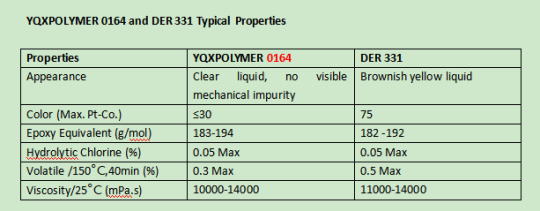

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

Supex Anaerobic threadlockers

Threadlockers are essential in ensuring the security and reliability of mechanical assemblies. Among the many brands in the market, Supex Anaerobic Threadlockers stand out for their superior performance and versatility. These adhesives are designed to prevent loosening, leakage, and corrosion in threaded fasteners. In this article, we’ll explore what makes Supex Anaerobic Threadlockers unique, how they work, their benefits, and common applications.

What Are Anaerobic Threadlockers?

Anaerobic threadlockers are liquid adhesives that cure in the absence of air and in the presence of metal. When applied to threaded fasteners (like bolts, screws, and studs), the threadlocker fills the gaps between the mating threads. Once the fasteners are tightened, the adhesive is confined between the metal surfaces, cutting off its exposure to oxygen. This creates a strong bond that locks the fastener in place, preventing it from loosening due to vibration, shock, or thermal expansion.

How Do Supex Anaerobic Threadlockers Work?

The working mechanism of Supex threadlockers is based on the anaerobic curing process. Here’s a step-by-step breakdown of how they work:

Application: The threadlocker is applied as a liquid to the threaded surface of the fastener.

Assembly: The fastener is then tightened, which forces the liquid threadlocker into the gaps between the metal threads.

Anaerobic Curing: Once the threadlocker is sealed between the metal surfaces and cut off from air exposure, the adhesive begins to cure. The curing process is catalyzed by the presence of metal ions.

Locking: As the threadlocker cures, it forms a strong, thermoset plastic bond that locks the fastener in place, preventing loosening due to vibration or other external forces.

If you want to know more information about threadlockers please visit our site https://supex.in/threadlockers/

Conclusion

Supex Anaerobic Threadlockers offer reliable solutions for securing threaded fasteners in demanding environments. Their high bonding strength, chemical resistance, and ability to prevent loosening due to vibration make them indispensable in industries like automotive, aerospace, and heavy machinery. By selecting the appropriate strength grade and following proper application techniques, Supex threadlockers can enhance the durability and performance of any mechanical assembly.

Contact Us

Phone-: +91 9699892782

Email us-: [email protected]

0 notes

Text

SRF retrofits an inline coater on its Brückner 5-layer BOPP line at Indore

Brückner Servtec, service partner for the entire film stretching lifecycle, has achieved another huge milestone in the company’s history, by celebrating its 1000th completed upgrading project. A successfully installed inline coater (ILC) on the 5-layer BOPP film stretching line of the Indian customer SRF Limited marked this pivotal moment and strongly demonstrated the upgrade capabilities of the service company, founded in 2003, according to the company’s press release.

“The whole project was completed successfully, ahead of schedule, and the advanced inline coated film was produced on the same day. Thanks to this technology, we are quite confident to be able to supply film for the circular economy in the near future,” states Dinesh Bhatt, vice president and Unit Head at SRF.

Markus Gschwandtner, managing director Brückner Servtec, says, “We are proud to reach this significant milestone with an upgrade for one of our most loyal and valued customers. It is the result of our daily efforts to continuously improve our services which have always been customized long-term solutions for ensuring maximum availability, performance and efficiency of film stretching lines.”

An upgrade contributing to circular economy

The ILC is an upgrade solution highly valued by customers since it reliably delivers a wide range of improvements and benefits that contribute to a sustainable film production. As the key component, Brückner’s Inline Coating Technology has been fully integrated into the existing film stretching line, applying a thin, wet, water-based, chemical coating before the film is stretched and dried in the transverse direction orientation (TDO). SRF Limited benefits from improved barrier properties, high metal adhesion, long-term stability, and optimized printability in their BOPP film production, and is able to extend its portfolio with high barrier inline coated films.

Sustainable solutions on the rise

Brückner’s press release states, “The 1000th upgrade not only shows technological development, it moreover demonstrates how sustainability has become a key part of today’s film production, increasingly requested by customers. In response to this demand, Brückner Servtec offers a wide range of solutions, such as heat recovery systems, line conversions to recyclable mono-material BOPE films, or direct drives for energy savings. These solutions enable customers to contribute to recyclable packaging and circularity.”

When Susanne Bluml interviewed Reinhard Priller, Brückner’s director of Sales in March 2021 for Packaging South Asia, she asked him, “Does an Indian customer have to invest more in the preparation of such an upgrade – if the upgrade is done later?”

Prillers answered, “At Brückner, numerous specialists support our customers in this decision. This can be pre-equipment so that the machine is a little longer to dry the applied coating liquid or to produce even better structures for mono-materials already in the extrusion process. Then it is up to the customer to decide whether he can already launch such innovative products in the market. The pre-equipment may well mean additional investment of 10 to 15%, depending on which options are already planned in advance. A customer being faced with price pressure will think carefully about which options to pack into the machine.”

see also

Strong Asian packaging

film business for Brückner

– despite crisis

Bluml followed up by asking, “How many customers from the Indian market bought these preparations in their machines in 2020?” Prillers clarified in the same interview, “About 10% of the lines in our new deals have pre-equipment for inline coating or options for mono-material extrusion. But our lines can be equipped with upgrades during their lifetime, adapted in performance or even in the complexity of the manufacturing process. This is a part of our business at Brückner Servtec that should not be underestimated. About 30% of the business there concerns adaptations and retrofits of existing plants.”

Brückner Servtec is a member of the family-owned Brückner Group Germany, a worldwide leading supplier of tailor-made technical solutions and services for the plastic and packaging industry, with over 2,900 employees in 18 locations worldwide. The company offers a wide range of service and upgrade solutions for film stretching lines of any type, handling their whole lifecycle.

0 notes

Link

Check out this listing I just added to my Poshmark closet: Stila Shimmer & Glow Liquid Eyeshadow ~ VIVID LABRADORITE ~ Limited Edition.

0 notes

Text

Why Phoenix Mixer Leads as a Top Gyroscopic Mixer Machine Supplier: Quality & Innovation

When it comes to finding reliable Gyroscopic Mixer Machine suppliers, the choice you make can significantly impact your business's efficiency and product quality. At Phoenix Mixer, we pride ourselves on being one of the leading names in the industry, delivering innovative, high-quality Gyroscopic Mixer Machines to meet diverse industrial needs. Whether you’re in paint manufacturing, pharmaceuticals, cosmetics, or any other industry requiring precise and efficient mixing, our advanced solutions are designed to ensure superior performance and reliability.

Why Choose Phoenix Mixer as Your Preferred Gyroscopic Mixer Machine Supplier?

Proven Expertise and Industry ExperienceWith years of experience in supplying Gyroscopic Mixer Machine suppliers, Phoenix Mixer has developed a deep understanding of various industrial mixing needs. We are committed to providing tailored solutions that cater to the specific requirements of each client. Our reputation as one of the most trusted Gyroscopic Mixer Machine suppliers is built on our consistent delivery of high-quality products and exceptional customer service.

Innovative and High-Performance Mixing SolutionsAt Phoenix Mixer, innovation is at the core of our product development. Our Gyroscopic Mixer Machines are engineered with state-of-the-art technology to deliver outstanding mixing results. They ensure uniform and thorough mixing of materials, reducing the time required and enhancing productivity. This makes them ideal for a wide range of applications, including paints, coatings, adhesives, chemicals, and more.

Quality That You Can Rely OnAs top Gyroscopic Mixer Machine suppliers, we adhere to strict quality control measures to ensure that each machine meets the highest standards of performance and durability. Built with robust materials and advanced technology, our machines are designed to withstand rigorous industrial use, providing consistent and reliable performance over time.

Your Trusted Partner for Mixing Solutions

When it comes to selecting a reliable Gyroscopic Mixer Machine supplier, Phoenix Mixer stands out for its commitment to quality, innovation, and customer satisfaction. Whether you are looking to enhance your production efficiency or need a customized mixing solution, our advanced Gyroscopic Mixer Machine suppliers are the perfect choice. Contact Phoenix Mixer today and discover why we are the preferred choice for businesses worldwide.

Frequently Asked Questions (FAQs)

What makes Phoenix Mixer the best choice among Gyroscopic Mixer Machine suppliers?Our commitment to innovation, quality, and customer satisfaction sets us apart. We provide tailored solutions that meet diverse industrial needs.

Can your Gyroscopic Mixer Machines handle different types of materials?Yes, our machines are versatile and suitable for mixing a variety of materials, from liquids to powders and viscous substances.

How do I choose the right Gyroscopic Mixer Machine for my business?Our experts will guide you in selecting the most suitable machine based on your specific needs and production requirements.

Do you offer customization options for your mixers?Absolutely! We provide customized solutions to ensure our mixers meet your unique production demands.

What kind of after-sales support does Phoenix Mixer offer?We offer comprehensive support, including installation, training, maintenance, and technical assistance to ensure your machines run smoothly.

Visit : https://www.phoenixmixer.com/products/mixer-machine/mixer/gyro525/ Contact : +91 9011958800

0 notes

Text

Annual Wellness Visits (AWV) Software Market Size, Share, Forecast [2032]

Annual Wellness Visits (AWV) Software Market provides in-depth analysis of the market state of Annual Wellness Visits (AWV) Software manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Annual Wellness Visits (AWV) Software in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Annual Wellness Visits (AWV) Software Market Report:

The report offers a comprehensive and broad perspective on the global Annual Wellness Visits (AWV) Software Market.

The market statistics represented in different Annual Wellness Visits (AWV) Software segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Annual Wellness Visits (AWV) Software are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Annual Wellness Visits (AWV) Software.

Major stakeholders, key companies Annual Wellness Visits (AWV) Software, investment feasibility and new market entrants study is offered.

Development scope of Annual Wellness Visits (AWV) Software in each market segment is covered in this report. The macro and micro-economic factors affecting the Annual Wellness Visits (AWV) Software Market

Advancement is elaborated in this report. The upstream and downstream components of Annual Wellness Visits (AWV) Software and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/annual-wellness-visits-awv-software-market-100557

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Thermal Spray Equipment MarketMarket Share

Hvac Filters MarketMarket Growth Rate

Premium Audio MarketMarket Forecast

Global Mobile Robotics MarketMarket Size

Marketing Technology MarketMarket Growth

Sodium Hydrosulfide MarketMarket Analysis

Information Technology MarketMarket Size

Global Microcapsule MarketMarket Share

Global Solar Charger MarketMarket Growth

Virtual Private Server MarketMarket

Transcatheter Heart Valves MarketMarket Share

Hard Asset Equipment Online Auction MarketMarket Growth Rate

Automotive Ag Glass MarketMarket Forecast

Global Breast Imaging Equipment MarketMarket Size

Advanced Hvac Control MarketMarket Growth

Small Articulated Loader (Wheeled Mini Loader) MarketMarket Analysis

N-Methylmorpholine N-Oxide (NMMO) MarketMarket Size

Global Liquid Metal Product MarketMarket Share

Global Airship MarketMarket Growth

Fully Depleted Silicon-On-Insulator (Fd-Soi) Technology MarketMarket

iPaaS MarketMarket Share

Oligonucleotide Library MarketMarket Growth Rate

Rehabilitation Devices/Equipment MarketMarket Forecast

Global Automotive Body Sealing Systems MarketMarket Size

Fiber Coupled Superluminescent Light Emitting Diodes (SLED) MarketMarket Growth

Action Figures and Statues MarketMarket Analysis

Online On-demand Home Services MarketMarket Size

Global Silicon Carbide (Sic) Semiconductor Materials And Devices MarketMarket Share

Global Electronics Adhesives MarketMarket Growth

Protein Characterization And Identification MarketMarket

Blockchain Software MarketMarket Share

MRI Guided & Focused Ultrasound Devices MarketMarket Growth Rate

Baby Wipes MarketMarket Forecast

Global Karaoke App MarketMarket Size

Automatic Filter Press Machine MarketMarket Growth

Big Data in E-commerce MarketMarket Analysis

Frozen Egg Tart Skin MarketMarket Size

Global Noni Juice MarketMarket Share

Global Off-grid Energy Storage Systems MarketMarket Growth

0 notes

Text

Sodium Silicate Prices Trend | Pricing | Database | Index | News | Chart

Sodium Silicate Prices, also known as water glass, is a versatile chemical compound that finds applications in various industries. It is a colorless, odorless liquid that is soluble in water and has a wide range of uses, from industrial manufacturing to household products. In this article, we will explore the factors that influence sodium silicate prices and discuss its significance in different sectors.

One of the key determinants of sodium silicate prices is the raw material cost. Sodium silicate is primarily produced by reacting silica sand and sodium carbonate in a furnace. The availability and cost of these raw materials can vary depending on factors such as geographical location, mining regulations, and market demand. Fluctuations in the cost of raw materials can directly impact the overall price of sodium silicate.

Another factor that affects sodium silicate prices is the manufacturing process. There are two main types of sodium silicate: liquid sodium silicate and solid sodium silicate. The production process for each type involves different steps and technologies, which can influence the cost of production. Additionally, the quality and purity of the final product also play a role in determining its price.

Get Real Time Prices for Sodium Silicate : https://www.chemanalyst.com/Pricing-data/sodium-silicate-1340

The demand and supply dynamics of sodium silicate also impact its pricing. The compound is widely used in industries such as construction, automotive, textiles, and water treatment. The growth of these industries and their respective demand for sodium silicate can drive up prices. Conversely, a decrease in demand or an increase in supply can lead to a decrease in prices.

Furthermore, the global market trends and competition among manufacturers can affect sodium silicate prices. The compound is produced by various companies worldwide, and their pricing strategies can vary. Factors such as production capacity, geographical reach, and brand reputation can influence the competitiveness of manufacturers and consequently impact the prices they offer.

Apart from the industrial sector, sodium silicate is also used in household products such as detergents, adhesives, and fireproofing agents. The demand for these consumer goods can indirectly influence the price of sodium silicate. Additionally, government regulations and environmental policies can also play a role in shaping the market and pricing of sodium silicate, especially in terms of safety standards and sustainability.

In conclusion, sodium silicate prices are influenced by a multitude of factors, including raw material costs, manufacturing processes, demand and supply dynamics, market trends, competition, and government regulations. Understanding these factors is crucial for businesses and consumers alike to make informed decisions regarding the purchase and use of sodium silicate. As the chemical compound continues to find new applications and expand its reach, monitoring and analyzing these factors will remain essential for navigating the sodium silicate market.

Get Real Time Prices for Sodium Silicate : https://www.chemanalyst.com/Pricing-data/sodium-silicate-1340

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Silicate#Sodium Silicate Price#Sodium Silicate Prices#Sodium Silicate Pricing#Sodium Silicate News#Sodium Silicate Database

0 notes

Link

Check out this listing I just added to my Poshmark closet: Automatic Wall Mounted Rechargeable Mouthwash Dispenser.

0 notes

Text

The paper, packaging & related products segment is expected to lead the liquid adhesives market during the forecast period. The growth of this segment can be attributed to the increased use of adhesives in a wide variety of paper bonding applications ranging from corrugated box construction and the lamination of printed sheets to packaging materials used in all types of consumer products and the production of large industrial tubes and cores. Increasing E-commerce has stimulated the growth of this industry.

#Liquid Adhesives Market#Adhesives Market#Liquid Adhesives#liquid nails for concrete#liquid stitches#liquid fusion glue#liquid nails acrylic#mastisol liquid adhesive#liquid nails use#liquid nail adhesive#Water-based Adhesive Market#liquid nails construction adhesive#COVID 19 impact on Liquid Adhesives Market#Industrial Adhesives Market#Global Liquid Adhesives Market#Liquid Adhesives Market Share#Liquid Adhesives Market Forecast#Liquid Adhesives Demand#Liquid Adhesives Sales#Liquid Adhesives Market Growth#global liquid adhesives market#Impact of COVID-19 on Liquid Adhesives Market#Water-based liquid adhesives#APAC liquid adhesives market

0 notes

Text

Painting Kitchen Cabinets Without Sanding: A Step-by-Step Guide

Painting kitchen cabinets is an effective way to refresh the look of your kitchen without the expense of replacing them. While sanding is typically recommended as part of the preparation process, it's possible to paint kitchen cabinets without sanding under certain circumstances. In this guide, we'll explore the step-by-step process for painting kitchen cabinets without sanding, along with tips for achieving professional-looking results.

Clean the Cabinets Thoroughly: Start by cleaning the cabinets thoroughly to remove dirt, grease, and grime that may affect paint adhesion. Use a gentle degreaser or a mixture of warm water and mild detergent to clean the surfaces. Rinse the cabinets with clean water and allow them to dry completely before proceeding.

Remove Hardware and Doors: Remove the cabinet doors, drawers, and hardware, such as handles and hinges, to facilitate easier painting. Label each door and hardware with its corresponding cabinet to ensure proper reassembly later. Place the hardware in labeled bags or containers for safekeeping.

Degloss the Surfaces: Instead of sanding, use a liquid deglosser to etch the surface of the cabinets and promote paint adhesion. Apply the deglosser according to the manufacturer's instructions, using a clean cloth or sponge. Allow the deglosser to dry completely before proceeding to the next step.

Apply Primer: To ensure a smooth and durable finish, apply a bonding primer designed specifically for painting kitchen cabinets. Use a high-quality synthetic brush or foam roller to apply the primer evenly to the cabinet surfaces. Allow the primer to dry according to the manufacturer's recommendations.

Paint the Cabinets: Once the primer has dried, it's time to apply the paint. Choose a high-quality paint suitable for kitchen cabinets, such as a durable enamel or acrylic-latex paint. Apply the paint in thin, even coats, using a brush or roller, working in the direction of the wood grain for a smooth finish. Allow each coat to dry completely before applying the next.

Apply Additional Coats: Depending on the desired coverage and finish, you may need to apply multiple coats of paint. Allow each coat to dry thoroughly before applying the next, lightly sanding between coats with fine-grit sandpaper to remove any imperfections or brush marks.

Reassemble and Reinstall: Once the final coat of paint has dried, reassemble the cabinet doors, drawers, and hardware, ensuring proper alignment and attachment. Reinstall the cabinets in their original location, taking care to protect the freshly painted surfaces during reinstallation.

Conclusion: Painting kitchen cabinets without sanding is possible with the right preparation and materials. By following these steps and using quality products, you can achieve a professional-looking finish that refreshes the appearance of your kitchen cabinets without the hassle of sanding. Whether you're updating the look of your kitchen or preparing your home for sale, painting cabinets can be a cost-effective and transformative solution.

0 notes

Text

YQXPOLYMER Epoxy Resin 0614/0614DL were Launched into International Market

April 9, 2024, YQXPOLYMER, a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider is pleased to launch its 0614/0614DL epoxy resin worldwide. To expand its business operations, YQXPOLYMER is now open to exploring partnerships with like-minded organizations, businesses, and individuals interested in the epoxy industry.

YQXPOLYMER 0614/0614DL are diluted liquid epoxy resins, which is manufactured from C12~C14 aliphatic glycidyl ether and bisphenol A epoxy resin.

YQXPOLYMER 0614/0614DL are special low viscosity liquid epoxy resins, which are widely used in Stone adhesive. YQXPOLYMER 0614/0614DL can be used to paste fiberglass mesh on the back of marble to enhance the strength and stability of the stone, prevent the stone from falling off and improve the impact resistance of the stone. Also they are used in Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, and so on.

A wide variety of curing agents is available to cure liquid epoxy resins at ambient conditions. The most frequently used are aliphatic polyamines, polyamides, alicyclic amines, cycloaliphatic amines and modified versions of these curing agents. Elevated temperature cures are necessary and long post-cures are required to develop full end properties if anhydrides or catalytic curing agents are employed.

YQXPOLYMER 0614/0614DL Typical Properties

YQXPOLYMER 0614/0614DL Key Features

Low viscosity and strong fluidity, good performance at room temperature, and easier to paint and construct.

It can better penetrate into the surface to be coated or bonded, improving performance stability and durability.

Widely used in Stone adhesive, Ceramic tile adhesive, Epoxy floor, Road bridge tunnel filling, etc.

Packing variety: drums, IBC container, or customization.

YQXPOLYMER 0614/0614DL Typical Applications

This product is suitable for use in applications such as:

• Stone adhesive

• Ceramic tile adhesive

• Epoxy floor

• Building repair adhesive( Road bridge tunnel filling)

• Solventless coatings

• Composite materials

• Liquid molding compounds

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally. And we provide highly cost-effective products, short lead time, in-time after-sales service, even OEM service.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy adhesive#epoxy resin supplier#epoxy floor#tile adhesive#YD-114#Kukdo YD-114E#stone adhesive

0 notes

Text

The Ultimate Guide to Choosing Waterproofing Suppliers in Qatar!

In the heart of the Arabian Peninsula lies Qatar, a country known for its towering skyscrapers, luxurious lifestyle, and, importantly, its extreme climate conditions. With temperatures that can soar above 40°C in the summer and occasional heavy rains in the winter, the need for robust waterproofing solutions cannot be overstated. Whether it’s a new construction project or a renovation, ensuring that your building is protected against water damage is paramount. This comprehensive guide aims to navigate you through the process of selecting the best waterproofing suppliers in Qatar, ensuring your project's longevity and integrity.

Understanding the Importance of Waterproofing in Qatar

Waterproofing is not just an optional addition; it’s a fundamental aspect of construction that safeguards the structural integrity of buildings. In Qatar’s harsh climate, the risk of damage caused by water ingress is significantly high. This can lead to a plethora of issues, including mold growth, structural damage, and deterioration of building materials. The right waterproofing strategy can protect your investment, extend the lifespan of your building, and ensure the safety and comfort of its occupants.

The Waterproofing Market in Qatar

The Qatari market is bustling with waterproofing suppliers and companies, each promising unparalleled products and services. However, the challenge lies in distinguishing the truly reliable and high-quality suppliers from the rest. The key is to look for companies that not only offer superior waterproofing solutions but also bring a wealth of experience, technical support, and after-sales service to the table.

Key Factors to Consider When Choosing a Waterproofing Supplier

Product Range: A reputable supplier should offer a comprehensive range of waterproofing products, from membranes and coatings to sealants and adhesives. This variety ensures that you can find all necessary solutions under one roof, tailored to different parts of your project.

Quality and Certification: Quality should never be compromised when it comes to waterproofing. Look for suppliers whose products meet international standards and come with quality certifications. This is a testament to their commitment to providing durable and effective waterproofing solutions.

Technical Expertise: The best waterproofing companies in Qatar are those that provide not just products but also valuable advice and technical support. Their expertise can guide you in selecting the right products and methods for your specific project needs.

Project Portfolio: A supplier’s past projects can offer insights into their capabilities and reliability. Companies that have supplied reputable projects in Qatar are more likely to provide quality solutions and services.

After-Sales Support: The relationship with your supplier shouldn’t end at purchase. After-sales support, including technical assistance during application and addressing any post-application issues, is crucial.

Waterproofing Solutions for Qatar’s Climate

Selecting the right waterproofing solution is critical, given Qatar's unique environmental challenges. Here are some solutions well-suited for the region:

Membrane Waterproofing: Ideal for roofs, basements, and under-tile areas, membrane waterproofing provides a robust barrier against water ingress.

Liquid Waterproofing: This versatile solution can be applied to a wide range of surfaces, offering flexibility and strong waterproofing protection.

Cementitious Waterproofing: Especially suitable for areas in direct contact with water, such as swimming pools and water tanks, cementitious waterproofing provides a durable and seamless barrier.

Navigating the Selection Process

With numerous waterproofing suppliers in Qatar, making the right choice can seem daunting. Start by conducting thorough research, both online and through industry contacts. Recommendations and reviews can provide valuable insights into a supplier’s reliability and the quality of their products and services.

Once you have shortlisted potential suppliers, engage with them directly to discuss your project requirements. This interaction can offer a deeper understanding of their expertise, customer service, and commitment to quality. Don’t hesitate to ask for product samples, technical data sheets, and case studies of previous projects.

Choosing the right waterproofing supplier in Qatar is a critical decision that can significantly impact the success and longevity of your construction project. By prioritizing quality, technical support, and a comprehensive product range, you can ensure that your building is well-protected against the harsh Qatari climate. Remember, the best waterproofing companies in Qatar are those that understand the local challenges and offer solutions tailored to meet these specific needs.

waterproofing is an investment in your building’s future. Take the time to select a supplier that not only provides high-quality products but also stands by your side throughout the project lifecycle. With the right partner, you can achieve a waterproofing solution that ensures the durability, safety, and comfort of your construction project for years to come.

0 notes

Text

Medical Dust-free Cleaning Swabs

The medical wiping rod adopts medical polyurethane sponge as raw material and purifies in the clean room, which has the characteristics of extremely low dust volume, strong liquid absorption, soft and clean. Perfect edge closure and thermal radiation technology enable the head to be successfully fixed to the polypropylene handle, avoiding contamination caused by the use of adhesives, and radiation sterilization ensures absolute safety in the medical industry. The quality of the products has reached the advanced level of similar international products. Products are generally used in: influenza detection, cell sampling, DNA testing, surgical care, etc.

Company Name:Suzhou Suyu dust-free Technology Co., Ltd.

Web:https://www.suyu-cleanroom.com/product/lint-free-cleaning-swabs/medical-dustfree-cleaning-swabs.html

ADD:1388# Ruyuan road,Xiangcheng economic developing zone,Suzhou,China.

Phone:86-13328056777

Email:[email protected]

Tip:215133

Profile:Suzhou Suyu dust-free Technology Co., Ltd. is currently the main business for two categories. The first type of main business: dust-free wiping paper series, dust-free wiping cloth series, anti-static dust-free clothing series, anti-static dust-free shoes series, dust-free gloves series, and other anti-static dust-free consumables production, research and development, sales as one of the enterprise.Also a professional OEM factory.

0 notes

Text

Revolutionize Your Mixing Process with Phoenix Mixer’s High-Speed Dispersion Mixers and Variable High-Speed Dispersers

In the world of industrial mixing, achieving consistent, high-quality results can be a challenging task. However, with Phoenix Mixer’s cutting-edge High-Speed Dispersion Mixers and Variable High speed disperser, you can streamline your production process and achieve unparalleled efficiency and quality. Here, we explore the advantages and applications of these innovative mixing solutions.

The Power of High-Speed Dispersion Mixers

Phoenix Mixer’s High speed dispersion mixers are designed to meet the demands of various industries, including paint, coatings, adhesives, cosmetics, and pharmaceuticals. These mixers operate at high speeds, ensuring rapid and thorough dispersion of materials. This results in shorter mixing times and a more uniform product, which is crucial for maintaining quality standards in production.

Key Benefits:

Efficient Mixing: The high-speed operation of our mixers ensures that materials are dispersed quickly and uniformly, reducing production time and increasing throughput.

Enhanced Product Quality: Consistent mixing results in a homogeneous product, which is essential for applications where uniformity is critical.

Cost Savings: By reducing mixing times and improving product quality, our high-speed dispersion mixers help you save on production costs and minimize waste.

Versatility with Variable High-Speed Dispersers

In addition to our high-speed mixers, Phoenix Mixer offers Variable High speed disperser that provide unmatched versatility in the mixing process. These dispersers allow you to adjust the speed according to the specific requirements of your application, ensuring optimal results for a wide range of materials.

Key Features:

Adjustable Speed: The variable speed control allows you to fine-tune the mixing process, making it suitable for both low and high-viscosity materials.

Flexibility: Whether you are mixing liquids, pastes, or powders, our variable high-speed dispersers can handle a diverse range of materials with ease.

Robust Construction: Built to withstand rigorous industrial environments, our dispersers ensure long-lasting performance and reliability.

Applications of High-Speed Dispersion Mixers and Variable High-Speed Dispersers

Phoenix Mixer’s advanced mixing solutions are ideal for a variety of applications across different industries. Some of the key applications include:

Paints and Coatings: Achieve consistent and high-quality dispersions in paint and coating formulations, ensuring smooth and even finishes.

Adhesives and Sealants: Enhance the performance of adhesives and sealants by achieving a uniform mix of components, resulting in stronger and more reliable products.

Cosmetics and Personal Care: Ensure the homogeneity of cosmetic formulations, leading to superior product quality and consistency.

Pharmaceuticals and Chemicals: Maintain strict quality standards in pharmaceutical and chemical production with precise and efficient mixing solutions.

Why Choose Phoenix Mixer?

Opting for Phoenix Mixer’s High speed dispersion mixers and Variable High-Speed Dispersers brings numerous advantages to your production process:

Expertise: With years of experience in the industry, Phoenix Mixer understands the unique challenges of industrial mixing and provides solutions tailored to meet your specific needs.

Innovation: Our commitment to innovation ensures that we offer the latest and most advanced mixing technologies to our customers.

Customer Support: From product selection to after-sales service, our team of experts is dedicated to providing comprehensive support to ensure your satisfaction.

Summary

Phoenix Mixer’s High-Speed Dispersion Mixers and Variable High speed disperser are the ultimate solutions for achieving superior mixing performance in a wide range of industrial applications. By integrating these advanced mixers into your production process, you can enhance efficiency, improve product quality, and reduce costs. Contact us today to learn more about how Phoenix Mixer can revolutionize your mixing process and help your business thrive.

This article emphasizes the benefits and applications of Phoenix Mixer’s High-Speed Dispersion Mixers and Variable High-Speed Dispersers, providing a comprehensive overview of how these products can enhance industrial mixing processes.

Visit: https://www.phoenixmixer.com/products/lab-equipments/high-speed-disperser/

Contact: +91 91452 40124

0 notes