#MaintenanceScheduling

Explore tagged Tumblr posts

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#MaintenancePlanning#AssetManagement#ReliabilityEngineering#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization#OperationsManagement

1 note

·

View note

Text

#maintenancescheduling#tips#benefitsofeam#mobileeam#eam#enterpriseassetmanagement#propelapps#sap#oracle#effectivemaintenancescheduling

0 notes

Text

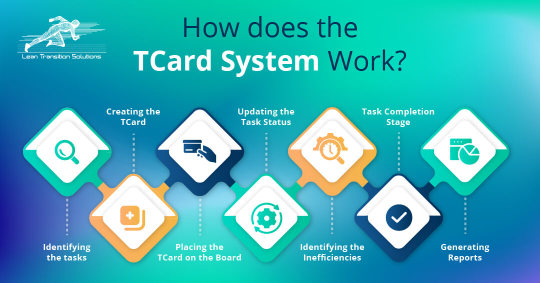

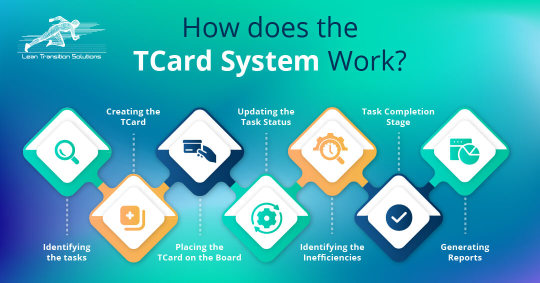

How does the TCard System Work?

The T-card system visually manages tasks, represented through T cards, moved across the columns on the T card boards to track progress & workflow.

Read More: https://www.linkedin.com/pulse/how-does-tcard-system-work-lean-transition-solution-l7caf/

#tcardssoftware#electronictcardsystem#digitaltcardsystem#tcardsonline#tcardboards#digitaltcardsboard#tcards#tcardsystem#kamishibai#Scheduletasks#teamscheduling#trackprogress#managingtasks#schedulingsystem#schedulingtasks#Workflowmanagement#MaintenanceScheduling#TaskAllocation#ProjectPlanning#InventoryManagement#LeanManufacturing#KanbanSystem#TaskTracking#Lean#lts#Industry4.0#Leantransitionsolutions#projectmanagement#kanban#kanbanboards

0 notes

Text

Maintenance Woes: Proactive Maintenance that Prevent Breakdowns and Extend your Forklift's Lifespan While Keeping Costs in Check.

Introduction: Hey there, fellow forklift owners in Malaysia! 🇲🇾 Let’s talk about something we all know too well: maintenance struggles. But don’t let those maintenance blues get you down! Today, we’re diving into the world of proactive maintenance – the secret sauce to keeping your forklifts in top shape and your wallet happy. Let’s roll up those sleeves and tackle this challenge head-on! 🔧💪 Why…

View On WordPress

#documentation#EGAN#eganseries#forkliftmalaysia#forkliftnation#forklifts#lovelaughlift#MaintenanceSchedule#proactivemaintenance#qualityparts#training

0 notes

Text

Top 7 John Deere 2640 Problems: Critical Issues Farmers Need to Know

https://autorepairlebanontn.com/?p=3728 Top 7 John Deere 2640 Problems: Critical Issues Farmers Need to Know The John Deere 2640 tractor has earned its place in agricultural history as a workhorse, but even reliable machines encounter issues over time. We’ve noticed an increasing number of farmers searching for answers to common 2640 problems, from transmission troubles to hydraulic headaches that can bring fieldwork to a frustrating halt. With many of these tractors now decades old, understanding their potential weak points isn’t just helpful—it’s essential for keeping your operation running smoothly. We’ll jump into the most frequent John Deere 2640 issues and provide the practical answers you need. Whether you’re currently dealing with a breakdown or want to prevent future problems, this comprehensive guide has you covered. Table of Contents Toggle Common John Deere 2640 Problems: An OverviewHydraulic System FailuresClogged Screens and FiltersInternal LeaksHydraulic Pump FailuresLeaking Hydraulic PumpsPower Steering IssuesTransmission ProblemsShifting DifficultiesClutch Failure PointsElectrical System WeaknessesStarting ProblemsAlternator and Charging IssuesEngine-Related ConcernsCompression and Starting IssuesOverheating TendenciesFuel System ComplicationsMaintenance Tips to Prevent John Deere 2640 IssuesHydraulic System MaintenanceTransmission CareEngine UpkeepSteering System InspectionCooling System AttentionPTO MaintenanceScheduled Maintenance PlanningFinding Parts and Service for Aging 2640 TractorsCost Analysis: Repairing vs. Replacing Your John Deere 2640Common Repair ExpensesReplacement ConsiderationsMaking the DecisionConclusionFrequently Asked QuestionsWhat are the most common problems with the John Deere 2640 tractor?How can I fix hydraulic system issues in my John Deere 2640?What causes transmission problems in the John Deere 2640?Are electrical problems common in the John Deere 2640?What engine issues should I watch for in my John Deere 2640?What maintenance should I perform regularly on my John Deere 2640?How difficult is it to find parts for the John Deere 2640?Is it better to repair or replace a problematic John Deere 2640?What should I check before buying a used John Deere 2640?How can I prevent fuel system problems in my John Deere 2640? Common John Deere 2640 Problems: An Overview The John Deere 2640 tractor presents several recurring issues that owners frequently encounter. Manufactured between 1975 and 1982, these tractors have developed predictable failure points that become more pronounced with age. Transmission problems top the list of concerns, with many operators reporting difficulty shifting gears and unexpected slippage during operation. Hydraulic system failures follow closely behind, often manifesting as slow response times and inadequate lifting power. Engine troubles plague many 2640 models, particularly those with higher operating hours. Oil leaks commonly appear around the rear main seal and valve cover gaskets, compromising engine performance and requiring regular monitoring. Electrical system faults create starting problems and intermittent instrument panel functionality, especially in tractors stored in damp environments. Steering components wear down over time, creating excessive play in the wheel and reduced control precision. Cooling system inefficiencies lead to overheating during extended operation, particularly in hot weather conditions. Brake performance deterioration presents safety concerns that shouldn’t be ignored, with many units displaying uneven stopping power between left and right sides. Fuel system contamination affects many 2640 tractors still in service, causing power loss and rough running conditions. PTO engagement issues frustrate farmers attempting to use implements, with clutch problems being the typical underlying cause. Understanding these common failure points helps owners develop effective maintenance strategies and anticipate repairs before they cause important downtime. Hydraulic System Failures Hydraulic system issues rank among the most frustrating problems affecting John Deere 2640 tractors. These failures often appear gradually, with symptoms worsening over time until the system becomes completely compromised. Understanding the common hydraulic failure points helps owners identify problems early before they lead to costly repairs. Clogged Screens and Filters Clogged suction screens and dirty hydraulic filters frequently cause hydraulic performance problems in the 2640 model. Debris accumulation, particularly brake material, creates restricted flow that manifests as jerky movements in the loader, power steering, and 3-point hitch operations. Regular maintenance requires cleaning or replacing the suction screen located inside the transmission housing. Hydraulic filters need replacement at recommended intervals based on operating hours rather than calendar time. Many owners report immediate improvement in hydraulic response after addressing these filtration components. Internal Leaks Internal hydraulic leaks create performance issues that aren’t always immediately visible. These hidden leaks occur inside the transmission case or involve broken internal lines and connections that lead to cavitation and reduced hydraulic performance. Symptoms include sluggish carry out response, difficulty lifting heavy loads, and inconsistent hydraulic pressure. Proper diagnosis involves pressure testing the system to identify where fluid is bypassing rather than flowing through intended pathways. The charge pump commonly develops internal leaks after extended service, especially in tractors exceeding 8,000 operating hours. Hydraulic Pump Failures Hydraulic pump deterioration represents a important concern for aging 2640 tractors. Pumps experiencing wear typically show early warning signs including unusual noise, excessive heat generation, and jerky hydraulic movements. Complete pump failure leaves implements inoperable and prevents essential functions. Tractors with approximately 8,300 hours commonly develop pump issues requiring either rebuild or replacement. Pump failure rarely happens suddenly without warning signs, giving attentive operators opportunity to address problems before complete system breakdown. Leaking Hydraulic Pumps Shaft seal deterioration accounts for most external hydraulic pump leaks on the 2640 model. These leaks appear as fluid trails running down from the pump mounting area and often worsen during operation. Replacing worn or damaged seals resolves most external leakage, though this repair requires important disassembly. Front hydraulic pump drive couplers sometimes fail, preventing proper power transmission from the engine crankshaft to the pump shaft. Coupler inspection involves checking for excessive play or misalignment when the engine runs. Addressing underlying issues proves essential for preventing repeat failures after seal replacement. Power Steering Issues Power steering problems frequently stem from the same hydraulic system that services implements on the 2640. Hydraulic fluid quality plays a crucial role in steering performance, with dirty or degraded fluid causing jerky wheel movement and inconsistent response. Changing hydraulic fluid and filters while ensuring clean suction screens improves steering function substantially. Low system pressure caused by internal leaks or pump wear affects steering response, making the wheel difficult to turn particularly at low engine RPMs. Comprehensive hydraulic system evaluation remains necessary when diagnosing steering issues since individual components rarely fail in isolation within this integrated system. Transmission Problems Transmission issues rank among the most common problems affecting John Deere 2640 tractors, especially in units with important operating hours. These problems can render a tractor virtually unusable in the field and often require immediate attention to prevent further damage. Shifting Difficulties Shifting difficulties plague many John Deere 2640 owners, with some reporting complete inability to engage forward gears while reverse functions normally. This frustrating problem sometimes resolves after repeated shifting attempts, suggesting potential issues with the clutch mechanism or transmission linkage adjustment. Even tractors with recently replaced clutches can experience persistent shifting problems, indicating improper adjustment or underlying transmission issues that weren’t addressed during clutch service. Forward gear engagement failures particularly impact productivity as operators can’t perform most field operations effectively without reliable forward movement. Clutch Failure Points Clutch components represent critical failure points in the 2640’s drivetrain system, even after replacement work has been completed. Normal wear patterns develop over time, especially in tractors approaching or exceeding 8,000 operating hours, leading to increasingly difficult gear engagement and frequent adjustment needs. Incorrect clutch adjustment following replacement often causes persistent shifting issues, creating additional work and expense for owners. Internal hydraulic tubes within the transmission can develop cracks or damage, compromising the clutch’s hydraulic operation and contributing to overall transmission failure. Weak transmission pumps further complicate clutch operation as they fail to generate sufficient pressure for smooth engagement, resulting in jerky movements and inconsistent power transfer when shifting between gears. Electrical System Weaknesses The John Deere 2640 tractor’s electrical system, though relatively simple compared to modern equipment, presents several vulnerability points that owners frequently encounter. Electrical issues often manifest through poor connections, corroded terminals, and aging wiring that deteriorates over decades of use. Starting Problems Starting difficulties rank among the most common electrical complaints for the John Deere 2640. Many owners experience intermittent starting issues caused by corroded battery terminals or poor ground connections. Relocating the battery ground cable from a rusty battery box to a cleaner connection point, such as the starter mounting bolt or engine block, significantly improves electrical reliability and starting performance. Cold weather exacerbates these problems, with many tractors requiring additional maintenance during winter months. The starter solenoid can also develop faulty contacts over time, resulting in clicking sounds but no engine cranking when the key is turned. Alternator and Charging Issues Charging system failures create frustrating operational problems for 2640 owners, particularly during extended work sessions. The charging circuit components, including the alternator, voltage regulator, and connecting wires, become susceptible to damage as these tractors age. Regular inspection of the alternator belt tension prevents slippage that reduces charging capability. Corrosion at connection points between the alternator and battery disrupts proper current flow, leading to undercharged batteries even when the engine runs normally. Monitoring battery voltage during operation provides early warning signs of alternator issues, with healthy systems maintaining approximately 13.5-14.5 volts while running. Agricultural environments with dust, moisture, and temperature fluctuations accelerate wear on electrical components, making preventative maintenance essential for maintaining reliable operation. Engine-Related Concerns The John Deere 2640 tractor frequently experiences engine problems that can significantly impact performance and reliability. These issues often become more pronounced as these machines age, requiring owners to be vigilant about maintenance and troubleshooting. Compression and Starting Issues Low compression stands out as a primary concern for John Deere 2640 owners, particularly affecting cold weather operation. Many tractors struggle to start in cooler temperatures because inadequate compression fails to generate sufficient heat for proper fuel ignition. The starting system components, including the solenoid, starter, and associated wiring, can deteriorate over time, further complicating the starting process. Regular compression testing helps identify potential problems before they lead to complete starting failure. Blue smoke emission from the exhaust typically indicates worn internal engine components that require attention. This telltale sign suggests oil is burning within the combustion chamber, pointing to worn piston rings, valve guides, or cylinder walls. Tractors exhibiting this symptom often need a comprehensive engine rebuild to restore proper functionality and prevent additional damage to related systems. Overheating Tendencies While not specifically documented as a prevalent issue with the 2640 model, maintaining the cooling system remains essential for preventing overheating problems. The cooling system efficiency diminishes over time due to scale buildup, radiator fin damage, and thermostat malfunctions. Regular inspection of coolant levels and quality provides protection against potential overheating scenarios that could cause severe engine damage. Cooling system maintenance should include periodic radiator cleaning to remove debris that restricts airflow through the cooling fins. Damaged or bent fins reduce heat dissipation capability, potentially leading to elevated operating temperatures during extended work periods. Coolant replacement according to manufacturer specifications helps prevent corrosion and maintains optimal cooling efficiency. Fuel System Complications Fuel delivery problems frequently plague the John Deere 2640, with clogged or deteriorated fuel filters emerging as common culprits behind poor engine performance. These filters gradually accumulate contaminants, restricting fuel flow and causing power loss, rough idling, and starting difficulties. Replacing fuel filters during regular service intervals prevents many of these issues from developing. Electrical connections within the fuel system require regular inspection for security and corrosion. Loose wires on the solenoid can interrupt starting functionality, while corroded connections limit current flow to critical components. The fuel system’s overall condition directly impacts engine performance, with even minor issues potentially causing important operational problems if left unaddressed. The injection pump reliability affects both power output and fuel efficiency. Worn pumps deliver inconsistent fuel quantities, resulting in rough running conditions and reduced performance under load. Signs of injection pump problems include black smoke, power loss during operation, and uneven engine performance across different RPM ranges. Maintenance Tips to Prevent John Deere 2640 Issues Hydraulic System Maintenance Regular hydraulic fluid level checks prevent jerky movements in the loader, power steering, and 3-point hitch. Inspect the system for leaks that could lead to unexpected performance issues during critical fieldwork. Clean the hydraulic screen periodically to remove debris that restricts proper fluid flow. Using only John Deere specified hydraulic fluid ensures optimal system performance and longevity. Replacing both hydraulic fluid and filters resolves many common problems before they escalate into major repairs. Transmission Care Monitoring transmission fluid levels and condition helps maintain smooth shifting and consistent power transfer. Contaminated fluid accelerates wear on internal components and leads to premature transmission failures. Perform regular transmission service according to the manufacturer’s schedule to prevent the shifting difficulties that plague many high-hour 2640 tractors. Engine Upkeep Air filter inspections should occur regularly since dirt accumulation restricts airflow and reduces engine efficiency. Replace clogged fuel filters to maintain proper fuel delivery and prevent poor engine performance. Examine spark plugs for proper gapping and good condition to ensure reliable ignition and smooth engine operation. Check the exhaust system for damage or leaks that affect backpressure and engine performance. Verifying correct engine timing improves fuel economy and power output during demanding field operations. Steering System Inspection The bell crank above the axle pivot represents a common wear point in 2640 steering systems. This component typically wears down over time, causing jittery front wheels especially at road speeds. Regular inspection of all steering components prevents dangerous handling issues and improves operator comfort during extended use. Cooling System Attention Coolant level and condition checks prevent overheating issues that can cause catastrophic engine damage. Flush the cooling system according to maintenance schedules to remove scale and deposits that reduce cooling efficiency. Inspect radiator fins for debris that might block airflow through the cooling system. PTO Maintenance PTO component inspection ensures reliable power transfer to implements. Worn PTO components can affect hydraulic performance and create unexpected operational issues. Lubricate PTO bearings and inspect seals to prevent premature failure of these critical driveline components. Scheduled Maintenance Planning High-hour tractors (like those exceeding 8,300 hours) require more frequent maintenance checks to address wear issues before they lead to breakdowns. Creating and following a detailed maintenance calendar based on operating hours helps prevent most common John Deere 2640 problems. Documenting service history provides valuable information for troubleshooting intermittent issues and planning future maintenance needs. Finding Parts and Service for Aging 2640 Tractors Locating parts for John Deere 2640 tractors becomes increasingly challenging as these machines age, but several reliable options exist for owners. OEM parts remain available through John Deere dealerships, where staff can often order components even for older models. Aftermarket suppliers specializing in vintage tractor parts provide cost-effective alternatives that match or exceed original specifications. Online communities serve as invaluable resources for 2640 owners seeking hard-to-find components. Forums like TractorByNet and Yesterday’s Tractors connect experienced operators who share parts sources, maintenance tips, and troubleshooting advice. Members frequently post about successful repairs and identify reliable suppliers for exact components. Local repair shops with experience servicing older John Deere models offer another avenue for parts acquisition. These specialized mechanics often maintain networks of salvage contacts and can fabricate custom parts when necessary. Their practical knowledge of common 2640 issues like hydraulic failures and transmission problems proves especially valuable when dealing with high-hour tractors. Preventative maintenance significantly reduces the need for emergency parts sourcing. Regular hydraulic fluid changes, filter replacements, and suction screen cleaning help avoid the contamination issues that commonly plague aging 2640s. Addressing minor problems promptly prevents the cascading failures that can leave tractors inoperable and owners scrambling for rare components. Cost Analysis: Repairing vs. Replacing Your John Deere 2640 Common Repair Expenses Hydraulic system repairs rank among the most frequent expenses for John Deere 2640 owners. These costs typically range from $100-$500 for basic fluid and filter replacements to $2,000-$5,000 for a complete hydraulic pump replacement. Many tractors experience jerky motions of the loader, power steering issues, and 3-point hitch problems due to clogged suction screens or internal leaks within the hydraulic system. PTO and clutch problems create another important repair category, with replacement costs varying from $500-$2,000 depending on whether you’re replacing seals, clutch packs, or the entire assembly. Fluid leaks from the hydraulic pump shaft often require seal replacements that cost between $50-$200 for parts and labor. Brake debris accumulation can lead to pump cavitation and costly repairs if not addressed promptly. This repair involves cleaning or replacing the suction screen and potentially the hydraulic pump itself. Fuel tank rust, common due to the tank’s location, may necessitate replacement or extensive cleaning at a cost of $500-$1,500. Replacement Considerations Purchasing a new John Deere tractor represents a substantial investment, with prices typically ranging from $20,000 to over $50,000 depending on the model’s specifications and features. Used John Deere 2640 tractors vary widely in price based on condition and hours of operation, with models showing around 4,000 hours generally selling between $10,000-$20,000. Tractors with excessive operating hours (over 8,000) often reach a tipping point where multiple systems begin failing simultaneously. At this stage, the cumulative repair costs can quickly approach or exceed the value of a replacement unit. Labor costs compound these expenses, especially when dealing with complex hydraulic or transmission repairs that require important disassembly. Making the Decision Conducting a thorough mechanical assessment provides the foundation for an informed repair-versus-replace decision. Tractors with good compression readings, functional hydraulics, and manageable wear patterns often justify repair investments, particularly if the issues are isolated to one system. Multiple simultaneous failures across hydraulic, transmission, and engine systems typically signal the end of cost-effective repairs. For example, combining a hydraulic pump replacement ($2,000-$5,000) with clutch repairs ($500-$2,000) and fuel tank replacement ($500-$1,500) quickly approaches the lower range of replacement costs. Parts availability factors heavily into this equation, as older John Deere 2640 components become increasingly scarce. Consultation with an experienced mechanic helps identify potential cascading failures that might not be immediately apparent but could significantly increase your total repair investment. Conclusion The John Deere 2640 remains a valuable workhorse even though its aging design and common problems. With proper maintenance and timely repairs we’ve outlined the most critical issues with hydraulic systems transmission components and electrical systems that owners should monitor. Understanding these vulnerabilities isn’t just about troubleshooting—it’s about making informed decisions on repair investments versus replacement options. By implementing our recommended maintenance schedule and knowing where to source parts you’ll maximize your 2640’s service life. Even tractors with high hours can continue delivering reliable performance when owners stay proactive. Whether you’re addressing current issues or preventing future breakdowns the key is consistent attention to these well-documented problem areas. Frequently Asked Questions What are the most common problems with the John Deere 2640 tractor? The most common problems with the John Deere 2640 include transmission issues (difficulty shifting gears, slippage), hydraulic system failures (slow response, inadequate lifting power), engine troubles (oil leaks), electrical system faults, worn steering components, cooling system inefficiencies, brake deterioration, fuel system contamination, and PTO engagement problems. Most issues result from age, as many of these tractors are several decades old. How can I fix hydraulic system issues in my John Deere 2640? Start by checking for clogged suction screens and dirty hydraulic filters, which often cause jerky movements in loader and steering operations. Regular maintenance, including fluid changes and filter replacements, can prevent most hydraulic problems. Listen for unusual noises that might indicate pump failure. A comprehensive evaluation of the entire hydraulic system is recommended for persistent issues. What causes transmission problems in the John Deere 2640? Transmission problems typically stem from clutch mechanism issues, improper transmission linkage adjustments, or wear in tractors with high operating hours. Common symptoms include difficulty engaging forward gears while reverse functions normally. Weak transmission pumps can cause jerky movements and inconsistent power transfer. Regular maintenance and proper adjustments can prevent many transmission failures. Are electrical problems common in the John Deere 2640? Yes, electrical issues are common despite the relatively simple system. Problems typically include poor connections, corroded terminals, and aging wiring. Starting problems often result from corroded battery terminals or poor ground connections. Relocating the battery ground cable can improve reliability. Alternator and voltage regulator failures may lead to undercharged batteries, especially in challenging agricultural environments. What engine issues should I watch for in my John Deere 2640? Monitor for low compression (especially affecting cold-weather operation), blue smoke from the exhaust (indicating worn internal components), and cooling system issues. While overheating isn’t common, regular cooling system maintenance is essential. Check for clogged fuel filters, which can cause poor performance, and inspect the injection pump for signs of wear like black smoke and uneven engine performance. What maintenance should I perform regularly on my John Deere 2640? Regularly check hydraulic and transmission fluid levels and conditions. Inspect air and fuel filters, steering system components, the cooling system, and PTO components. Create a detailed maintenance calendar for high-hour tractors, addressing wear issues proactively. Prompt attention to minor issues helps avoid major failures. Regular compression testing and cooling system inspections are also recommended. How difficult is it to find parts for the John Deere 2640? Finding parts for aging John Deere 2640 tractors can be challenging but not impossible. Options include OEM parts from John Deere dealerships, aftermarket suppliers, and online communities dedicated to vintage equipment. Local repair shops experienced with older models can also be valuable resources. Preventative maintenance reduces the need for emergency parts sourcing. Is it better to repair or replace a problematic John Deere 2640? This depends on the tractor’s condition and the extent of problems. Hydraulic system repairs can range from $100-$500 for basic maintenance to $2,000-$5,000 for pump replacements. When repair costs approach or exceed replacement value, especially in tractors with excessive operating hours, replacement may be more economical. A thorough mechanical assessment should guide this decision. What should I check before buying a used John Deere 2640? Inspect the transmission for smooth shifting, test the hydraulic system for proper lifting power and response time, check for engine oil leaks (especially around the rear main seal), verify electrical system functionality, examine steering components for wear, test the cooling system, and evaluate brake performance. Also check the PTO engagement and fuel system for contamination. How can I prevent fuel system problems in my John Deere 2640? Replace fuel filters regularly according to maintenance schedules. Inspect electrical connections within the fuel system to ensure proper functionality. Keep fuel clean and free from contamination by using quality fuel sources and proper storage practices. Monitor the injection pump for signs of wear such as black smoke or uneven engine performance, addressing issues promptly. https://autorepairlebanontn.com/?p=3728 Absolute Auto Repair

0 notes

Text

Heating vs. Air Conditioning in Kansas City: Seasonal Maintenance Tips for Both

Your HVAC system works year-round to keep your home comfortable, adjusting to the demands of each season. Whether it’s winter or summer, proper maintenance ensures your heating and air conditioning systems perform efficiently when you need them most. In this guide, we’ll explore key seasonal maintenance tips for heating and air conditioning in Kansas City to help you maximize comfort and energy efficiency.

1. Why Seasonal HVAC Maintenance Is Essential

Seasonal maintenance keeps your HVAC systems in Kansas City running smoothly by:

Preventing unexpected breakdowns during peak weather.

Lowering energy bills through improved efficiency.

Extending the lifespan of your heating and cooling systems.

2. Preparing Your Heating System for Winter

Schedule a Heating Tune-Up in Kansas CityRegular tune-ups identify potential issues before the cold sets in, ensuring your system is ready to handle freezing temperatures.

Check Your ThermostatCalibrate your thermostat for accurate readings. If it’s outdated, consider thermostat repair or thermostat installation in Kansas City for better temperature control.

Inspect and Clean the DuctsDuct cleaning in Kansas City, MO, removes debris that restricts airflow, enhancing efficiency and improving indoor air quality.

Replace FiltersDirty filters make your system work harder. Replace them regularly for optimal performance.

3. Maintaining Your Air Conditioning System for Summer

Inspect and Clean the UnitRemove debris from the outdoor condenser unit to ensure proper airflow.

Schedule a Maintenance CheckRoutine HVAC maintenance in Kansas City ensures your air conditioning system is prepared for the heat.

Check Refrigerant LevelsLow refrigerant can cause your air conditioner to lose efficiency. A professional can inspect and recharge your system if needed.

Upgrade Your ThermostatInstall a smart thermostat to save on cooling costs and maintain consistent temperatures during hot days.

4. Key Differences Between Heating and Air Conditioning Maintenance

Seasonal FocusHeating systems require tune-ups before winter, while air conditioning systems need servicing in spring.

Component ChecksHeating systems involve checking furnaces or heat pumps, whereas air conditioning maintenance focuses on coils, refrigerants, and compressors.

Energy UsageEach system has unique energy demands, making tailored maintenance essential for reducing costs.

5. Emergency HVAC Services in Kansas City: Be Prepared for the Unexpected

Even with regular maintenance, unexpected issues can arise. Emergency HVAC services in Kansas City provide:

Fast repairs for heating or air conditioning breakdowns.

Professional expertise to diagnose and fix problems promptly.

Peace of mind knowing help is available when you need it most.

6. Tips for Year-Round HVAC Care

Combine Seasonal MaintenanceSchedule heating tune-ups and air conditioning checks together to save time and ensure year-round performance.

Inspect Your System RegularlyLook for signs of wear, such as unusual noises or inconsistent temperatures, and address them promptly with HVAC repair in Kansas City.

Invest in Energy EfficiencyUpgrade to energy-efficient HVAC systems in Kansas City to reduce costs and improve comfort.

Conclusion

Maintaining your heating and air conditioning systems in Kansas City with seasonal care ensures they work efficiently year-round. Regular tune-ups, duct cleaning, and thermostat checks keep your home comfortable while lowering energy costs. By staying proactive, you’ll enjoy reliable performance no matter the season. Priorities seasonal HVAC maintenance today for peace of mind and long-term savings.

1 note

·

View note

Text

Your Complete Guide To Garage Door Repairs In Parramatta: Common Issues And Solutions

Introduction

Garage doors are integral to home security and convenience in Parramatta. Over time, various problems may arise that require repair or maintenance. Understanding these common issues and their solutions will help you keep your garage door functioning optimally. This comprehensive guide delves into typical problems and how to tackle them effectively, ensuring your garage door repairs in Parramatta are straightforward and efficient.

Common Garage Door Problems

Several issues commonly affect garage doors. Recognising these can help you act promptly.

1. Noisy OperationUnusual sounds can indicate issues with rollers, tracks, or other components. Regular lubrication and cleaning can often resolve noise problems.

2. Door Won’t Open or CloseThis can be caused by a faulty remote, misaligned tracks, or broken springs. Troubleshooting each component systematically can help identify the issue.

3. Weather Stripping DamageWorn-out weather stripping can lead to drafts and energy loss. Replacing this is a simple DIY task that can enhance insulation.

4. Sensor MalfunctionThe safety sensors at the base of the door can sometimes misalign or become obstructed, preventing the door from closing. Cleaning and realigning these sensors can often resolve the problem.

Solutions to Common Issues

Once you've identified the issue, the next step is to find effective solutions.

1. Fixing Noisy DoorsRegular lubrication of hinges, rollers, and tracks can significantly reduce noise. If noise persists, inspect the components for wear and consider replacement if necessary.

2. Addressing Opening/Closing IssuesStart by checking the power supply to the opener. If the problem lies with the springs or tracks, consider consulting a professional for repairs.

3. Replacing Weather StrippingTo replace weather stripping, remove the old material and clean the surface. Measure and cut new stripping to size, ensuring a snug fit to prevent drafts.

4. Sensor RealignmentIf the door isn’t closing, check the sensors for obstructions or misalignment. Cleaning the sensors and ensuring they are level can often solve the problem.

Prevention and Maintenance Tips

Regular maintenance can prevent many common problems and extend the life of your garage door.

1. Regular InspectionsConduct regular inspections of your garage door to identify any potential issues early on. Look for wear on cables, springs, and other components.

2. Professional MaintenanceSchedule professional maintenance at least once a year to ensure all components are in good working order. This proactive approach can help catch issues before they escalate.

3. LubricationRegularly lubricate all moving parts, including rollers, hinges, and tracks. This not only reduces noise but also ensures smooth operation.

4. Keeping the Area ClearEnsure that the area around your garage door is free of debris and obstacles. This allows for smooth operation and reduces the risk of damage.

Conclusion

Understanding the common issues associated with garage door repairs in Parramatta is essential for homeowners looking to maintain their properties. By identifying problems early and knowing when to tackle them yourself or call a professional, you can ensure your garage door remains functional and secure. With regular maintenance and a proactive approach, your garage door can serve you well for years to come.

0 notes

Text

Avoid additional heavy-duty truck axle repair services by covering routine axle maintenance steps. After carefully inspecting, repairing, and testing your truck axle, we provide you with a recommended maintenance schedule for essential tasks. These tasks can improve the lifetime of your spindle and avoid another emergency repair situation.

🌐 https://unitedaxleofnm.com . . . .

axlemaintenance #truckaxlecare #preventivemaintenance #spindlecare #truckmaintenance #avoidemergencyrepairs #routineaxleinspection #extendaxlelifetime #fleetmanagement #maintenanceschedule #truckingtips #proactiverepairs #roadsafety #truckspindlemaintenance #heavydutytrucks

0 notes

Link

#facilitymaintenancesoftware#buildingmaintenancesoftware#maintenancescheduling#teamwork#workmanagement#collaboration#preventive maintenance

0 notes

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#Maintenance#AssetManagement#ReliabilityEngineering#MaintenancePlanning#OperationsManagement#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization

0 notes

Text

#physicalassets#eamsolutions#eamoffers#maintenanceschedules#assetmanagement solutions#computerizedmaintenancemanagementsystemcmms#criticalasset#predictivemaintenance#preventivemaintenance#assetlifecyclemanagement#assetperformance#workorders#assetmaintenance#maintenanceactivities#enterpriseassetmanagementeam#enterpriseassetmanagementsoftware#maintenancestrategies#realtime#workordermanagement

0 notes

Text

How does the TCard System Work?

The T-card system visually manages tasks, represented through T cards, moved across the columns on the T card boards to track progress & workflow.

Read More: https://www.linkedin.com/pulse/how-does-tcard-system-work-lean-transition-solution-l7caf/

#tcardssoftware#electronictcardsystem#digitaltcardsystem#tcardsonline#tcardboards#digitaltcardsboard#tcards#tcardsystem#kamishibai#Scheduletasks#teamscheduling#trackprogress#managingtasks#schedulingsystem#schedulingtasks#Workflowmanagement#MaintenanceScheduling#TaskAllocation#ProjectPlanning#InventoryManagement#LeanManufacturing#KanbanSystem#TaskTracking#Lean#lts#Industry4.0#Leantransitionsolutions#projectmanagement#kanban#kanbanboards

0 notes

Text

Forklift Maintenance: Ensuring Safe and Reliable Equipment

Forklifts are vital tools for warehouses, manufacturing facilities, and construction sites, helping to move heavy loads with ease. However, like any piece of machinery, forklifts require regular maintenance to operate safely and reliably. In this episode, we will discuss the importance of regular maintenance for forklifts, how to create a maintenance schedule, and some best practices for forklift…

View On WordPress

#EGAN#EquipmentLongevity#EquipmentMaintenance#EquipmentReliability#ForkliftInspection#ForkliftMaintenance#forkliftmalaysia#forkliftnation#forklifts#ForkliftSafety#ForkliftService#forklifttips#HeavyEquipment#IndustrialEquipment#lovelaughlift#MaintenanceSchedule#ManufacturingMaintenance#PreventiveMaintenance#RoutineMaintenance#SafeForkliftOperation#WarehouseMaintenance#WorkplaceSafety

0 notes

Photo

What do the Certified Repair and Maintenance Services do?

The certified repair maintenance services keep vehicles operational and running and reduce the overall maintenance cost. They work with the motive of offering preventing measures by checking the fleet for every minute defect. Repairing vehicles for every problem and replacing the damaged parts beforehand keeps them away from sudden breakdowns.

#Certified Fleet#Certified Fleet Services#COMPLETE PROCESS MANAGEMENT#Diesel Fleet Solution#EMERGENCY ROADSIDE ASSISTANCE#Roadside Assistance Services#PREVENTIVE MAINTENANCESCHEDULED & PREVENTIVE MAINTENANCESCHEDULED#TOWING & ACCIDENT MANAGEMENT#TOWING#ACCIDENT MANAGEMENT#Fleet Solution Cars#Fleet Solutions Near Me#How To Call For Roadside Assistance#Roadside Assistance Emergency#Roadside Assistance Near Me#Roadside Assistance Number#Roadside Assistance Plans#24 hour roadside tire service near me#24 hour semi truck road service near me#24 hour tire assistance near me#24 hour tire change near me#24 hour tire change

0 notes

Text

There is no use getting a bike and not use it

Being a motorcycle rider, you are probably plagued by a lotof motorcycle maintenance and mechanic problems. It is one thing you can’tavoid once you’re a rider and a cautious rider for that matter. Why? Themaintenance of China Custom Trike motorcycle Factory your motorcycle and its parts is one way of ensuring that youwon’t get into a messy road accident or crash. By having enough knowledge aboutthe most common motorcycle problems, you will be able to avoid getting into accidents.One of the most common reasons why you are faced with a lotof motorcycle maintenance and mechanic problem is your lack of proper maintenanceschedule.

Upon buying your motorcycle, you are given a motorcycle manual thathas all the instruction on the kind of maintenance you’re going to do and whenyou’re going to do it. In short, read your manual and follow the maintenanceschedule for your motorcycle. Aside from knowing the right schedule for your maintenance,a motorcycle manual can help get you familiar with the most common motorcycleproblems such as fuel contamination, premature tire wear, poorly lubricatedchains, uncharged batteries, dirt and debris collection. 1. Fuel contamination. This usually happen whenyour motorcycle wasn’t used often. If you let your bike sit on the corner for along period of time, the gas will go stale which will result to a clog on yourfuel system. The best way to avoid this problem is to use your motorcycle asoften as you can.

There is no use getting a bike and not use it. However, thereis a fuel stabilizing additive that you can use to prevent clogs in case you can’tuse your motorcycle often.2. Uncharged batteries. This common problem is aresult also of not using the motorcycle often. Once you have a neglectedbattery, the best remedy to this problem is to purchase a battery charger whereyou can hook up your battery every time you’re finish riding it. 3. Premature tire wear. It is best to change yourtires every three years. However, premature tire wear is such a common motorcycleproblem and you can avoid it by having a regular tire check up and by havingthe proper tire pressure.4. Poorly lubricated chains. This is one commonmotorcycle problem that could cause a serious road accident. If you seldom useand maintain your motorcycle, the chains could break or slip causing a skid tooccur. That is why you are advised to regularly check and lubricate the chainsof your bike to avoid getting into accidents.

0 notes