#MaintenanceOptimization

Explore tagged Tumblr posts

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#MaintenancePlanning#AssetManagement#ReliabilityEngineering#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization#OperationsManagement

1 note

·

View note

Text

Implement TPM: Step-by-Step Guide to Boost Efficiency

#tpm#totalproductivemaintenance#tpmimplementation#efficiencyboost#stepbystepguide#maintenanceoptimization#industrybestpractices#continuousimprovement#manufacturingefficiency#zerodowntime#preventivemaintenance#leanmanufacturing#equipmentmaintenance#workplaceproductivity#factorymanagement

1 note

·

View note

Text

How tracet asset management software uses for construction business and what are the benefits of using:

Feeling frustrated by the inefficiencies and obstacles in your construction business? Finding it tough to track your important assets, manage resources well, and meet regulatory standards? Then it’s the perfect moment to consider Tracet Asset management software. It’s a groundbreaking solution that can transform how you operate, Let’s talk about how Tracet helps construction companies and why it’s so good.

Tracet Asset management software is specifically designed to address the unique needs and challenges of the construction industry. Whether you’re dealing with heavy machinery, tools, or materials, Tracet offers a centralized platform to streamline asset tracking and management. No more manual record-keeping or guesswork — Tracet provides real-time visibility into your assets’ location, condition, and usage history, empowering you to make informed decisions and optimize resource allocation.

Benefits of Tracet Asset management software:

Equipment Tracking:

Tracet allows construction companies to track their equipment efficiently. This includes monitoring the location of equipment, usage history, maintenance schedules, and any associated costs. This ensures that equipment is properly utilized and maintained, reducing downtime and unnecessary expenses.

Inventory Management:

Construction projects need lots of different materials and supplies. Tracet helps by managing inventory. It keeps an eye on how much stock there is, when to reorder, and how everything gets used. This makes sure that construction projects always have the right materials ready, cutting down on delays and avoiding having too much stock.

Enhanced Project Visibility:

Tracet Asset management software improves project visibility by providing real-time updates on asset status and project progress. Team members can access pertinent information remotely, facilitating collaboration and informed decision-making. Whether it’s tracking equipment movement on-site or monitoring material availability, Tracet ensures that everyone is on the same page, leading to smoother project execution.

Data-Driven Decision Making:

Tracet uses data analytics to give useful information about how assets are doing, how much they’re being used, and how well things are running. By looking at past data and trends, construction companies can find ways to do things better, make their work smoother, and get ready for what’s coming next. This helps them make smart decisions based on facts, which helps them get more done and make more money.

Cost Savings:

By streamlining asset tracking, optimizing resource allocation, ensuring compliance, and enabling data-driven decision-making, Tracet ultimately leads to cost savings for construction businesses. Whether it’s through reduced downtime, minimized equipment maintenance costs, or optimized procurement processes, Tracet helps construction companies operate more efficiently and effectively, resulting in improved bottom-line performance.

Imagine the peace of mind knowing that your construction equipment is always well-maintained and operating at peak performance. With Tracet Asset management software you can schedule routine maintenance tasks based on usage patterns, manufacturer recommendations, or regulatory requirements. By staying ahead of maintenance needs, you can minimize the risk of unexpected breakdowns, reduce costly repairs, and extend the lifespan of your assets. With Tracet, maintenance scheduling becomes a proactive strategy rather than a reactive response.

Don’t let problems with scheduling maintenance slow down your construction projects anymore. Act now and get Tracet Asset management software. See the benefits of easier maintenance planning, less downtime, assets that work better, and projects that run smoother. Many construction companies are using Tracet to make maintenance better and succeed in their projects. With Tracet, your assets will always be ready for any construction job.

#TracetAssetManagement#ConstructionTech#AssetTracking#AssetVisibility#MaintenanceOptimization#InventoryManagement#CostEfficiency#ComplianceAssurance#ProjectManagement#DataAnalytics#EfficiencyBoost

0 notes

Text

#cmms#cmmssystem#MaintenancePlanning#PreventiveMaintenance#AssetManagement#MaintenanceStrategy#EquipmentMaintenance#CMMSSoftware#ReliabilityEngineering#WorkOrderManagement#MaintenanceScheduling#MaintenanceBestPractices#MaintenanceOptimization#ConditionBasedMaintenance#MaintenanceEfficiency#MaintenanceManagement#MaintenanceAutomation#FacilityManagement#PredictiveMaintenance#MaintenanceMetrics#MaintenanceAnalytics#lts#lean#leantransitionsolutions

1 note

·

View note

Text

Java Developer with SQL Data Solutions

The position listed below is not with New York Interviews but with SQL Data SolutionsNew York Interviews is a private organization that works in collaboration with government agencies to promote emerging careers. Our goal is to connect you with supportive resources to supplement your skills in order to attain your dream career. New York Interviews has also partnered with industry leading consultants & training providers that can assist during your career transition. We look forward to helping you reach your career goals! If you any questions please visit our contact page to connect with us directlyPosition: Java Developer Location: New York, NY Experience:6+ Years Job Description:Client s Banking Technology unit is looking for expert in Java, angular who canStrong Object Oriented Development experience building distributed applicationsExperience in developing distributed software systems using NOSQL technologies such as CassandraExtensive hands-on experience with Web development stacks (Java / J2EE, Spring, JavaScript, HTML & CSS)Analyze existing models written in RPerform testing of modelsMake changes in the models / do model maintenanceOptimize / Tune the modelCreate Document and presentationsThis is for the Lending Business done by banking.Hence,Exposure to Banking would be of great helpUnderstanding of Credit Risk, CCAR, Dodd Frank Act, etc. will be an added advantageOnce these models are understood, they have plans to scale them up using Java / Scala and create a 3 tier application which would use the output produced by these models - provided by DiceNOSQL,Java / J2EE, Spring, JavaScript, HTML & CSS,Credit Risk, CCAR, Dodd Frank Act, etc. Associated topics: application, backend, back end, matlab, python, sde, sdet, software developer, software development engineer, sw JavaDeveloperwithSQLDataSolutions from Job Portal http://www.jobisite.com/extrJobView.htm?id=72704

0 notes

Text

Java Developer with SQL Data Solutions

The position listed below is not with New York Interviews but with SQL Data SolutionsNew York Interviews is a private organization that works in collaboration with government agencies to promote emerging careers. Our goal is to connect you with supportive resources to supplement your skills in order to attain your dream career. New York Interviews has also partnered with industry leading consultants & training providers that can assist during your career transition. We look forward to helping you reach your career goals! If you any questions please visit our contact page to connect with us directlyPosition: Java Developer Location: New York, NY Experience:6+ Years Job Description:Client s Banking Technology unit is looking for expert in Java, angular who canStrong Object Oriented Development experience building distributed applicationsExperience in developing distributed software systems using NOSQL technologies such as CassandraExtensive hands-on experience with Web development stacks (Java / J2EE, Spring, JavaScript, HTML & CSS)Analyze existing models written in RPerform testing of modelsMake changes in the models / do model maintenanceOptimize / Tune the modelCreate Document and presentationsThis is for the Lending Business done by banking.Hence,Exposure to Banking would be of great helpUnderstanding of Credit Risk, CCAR, Dodd Frank Act, etc. will be an added advantageOnce these models are understood, they have plans to scale them up using Java / Scala and create a 3 tier application which would use the output produced by these models - provided by DiceNOSQL,Java / J2EE, Spring, JavaScript, HTML & CSS,Credit Risk, CCAR, Dodd Frank Act, etc. Associated topics: application, backend, back end, matlab, python, sde, sdet, software developer, software development engineer, sw JavaDeveloperwithSQLDataSolutions from Job Portal http://www.jobisite.com/extrJobView.htm?id=72704

0 notes

Text

Java Developer with SQL Data Solutions

The position listed below is not with New York Interviews but with SQL Data SolutionsNew York Interviews is a private organization that works in collaboration with government agencies to promote emerging careers. Our goal is to connect you with supportive resources to supplement your skills in order to attain your dream career. New York Interviews has also partnered with industry leading consultants & training providers that can assist during your career transition. We look forward to helping you reach your career goals! If you any questions please visit our contact page to connect with us directlyPosition: Java Developer Location: New York, NY Experience:6+ Years Job Description:Client s Banking Technology unit is looking for expert in Java, angular who canStrong Object Oriented Development experience building distributed applicationsExperience in developing distributed software systems using NOSQL technologies such as CassandraExtensive hands-on experience with Web development stacks (Java / J2EE, Spring, JavaScript, HTML & CSS)Analyze existing models written in RPerform testing of modelsMake changes in the models / do model maintenanceOptimize / Tune the modelCreate Document and presentationsThis is for the Lending Business done by banking.Hence,Exposure to Banking would be of great helpUnderstanding of Credit Risk, CCAR, Dodd Frank Act, etc. will be an added advantageOnce these models are understood, they have plans to scale them up using Java / Scala and create a 3 tier application which would use the output produced by these models - provided by DiceNOSQL,Java / J2EE, Spring, JavaScript, HTML & CSS,Credit Risk, CCAR, Dodd Frank Act, etc. Associated topics: application, backend, back end, matlab, python, sde, sdet, software developer, software development engineer, sw JavaDeveloperwithSQLDataSolutions from Job Portal http://www.jobisite.com/extrJobView.htm?id=72704

0 notes

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#Maintenance#AssetManagement#ReliabilityEngineering#MaintenancePlanning#OperationsManagement#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization

0 notes

Text

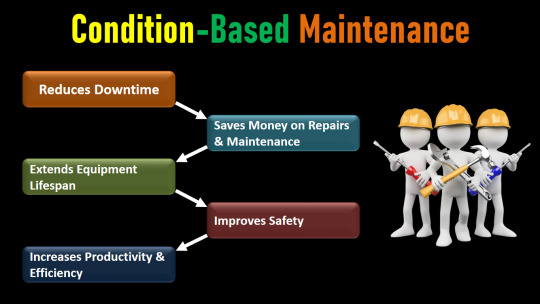

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

TPM Best Practices: Achieve Peak Efficiency & Zero Downtime

In today’s competitive industrial landscape, keeping machines running efficiently is critical to maintaining productivity and reducing costs. Equipment failures and unexpected breakdowns lead to costly downtime, delayed production, and increased maintenance expenses. This is where Total Productive Maintenance (TPM) comes in a structured approach to improving equipment reliability, reducing downtime, and maximizing operational efficiency.

➥ What is Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM) is a proactive maintenance strategy designed to keep machinery and equipment in optimal condition by involving every employee in maintenance activities. Unlike traditional maintenance, which is often reactive (fixing equipment after it breaks), TPM focuses on preventing breakdowns, minimizing defects, and increasing overall efficiency.

TPM is built on the principle that equipment operators should take ownership of routine maintenance tasks, such as cleaning, lubrication, and minor repairs, while maintenance teams focus on more complex issues. This helps improve machine longevity and ensures that maintenance issues are addressed before they cause failures.

➲ Key Objectives of TPM

✔️ Reduce unplanned downtime

✔️ Improve equipment reliability

✔️ Enhance production efficiency

✔️ Reduce maintenance costs

✔️ Minimize defects and waste

✔️ Improve workplace safety

➥ The 8 Pillars of TPM

Total Productive Maintenance (TPM) is a structured approach to maintaining equipment and improving efficiency in manufacturing and industrial settings. The goal is simple: reduce downtime, prevent failures, and keep machines running at peak performance. TPM is built around 8 key pillars to achieve this, each focusing on maintenance and productivity. Let’s dive into them one by one in a detailed and easy-to-understand manner.

1. Autonomous Maintenance (Jishu Hozen) – Empowering Operators

In many industries, only the maintenance team handles equipment servicing. This often leads to delays, as minor issues go unnoticed or are not fixed on time. Autonomous maintenance gives machine operators the responsibility of performing basic maintenance tasks such as:

✅ Cleaning equipment regularly

✅ Lubricating moving parts

✅ Checking for minor wear and tear

✅ Detecting unusual sounds, vibrations, or leaks

Read more: https://www.knowledgewale.com/2025/03/tpm-best-practices.html

#tpmbestpractices#totalproductivemaintenance#zerodowntime#peakefficiency#tpmimplementation#tpmstrategy#tpmpillars#preventivemaintenance#predictivemaintenance#equipmentreliability#industrialmaintenance#continuousimprovement#leanmanufacturing#maintenanceoptimization#tpmbenefits#tpmtraining#autonomousmaintenance#proactivemaintenance#maintenanceefficiency#reducingdowntime

0 notes

Text

Implement TPM: Step-by-Step Guide to Boost Efficiency

Total Productive Maintenance (TPM) is a powerful strategy that helps industries reduce downtime, improve equipment efficiency, and create a culture of continuous improvement. However, implementing TPM is not just about fixing machines; it’s about changing how people work, think, and take ownership of equipment maintenance.

If you want to successfully implement TPM in your industry, follow these detailed and practical steps.

➥ Step 1: Get Management Buy-In and Commitment

➲ Why is this important?

TPM requires a major shift in how maintenance and operations are handled. Without strong leadership support, it will be difficult to get employees to follow through.

➲ How to do it?

✅ Educate top management about the benefits of TPM (reduced downtime, cost savings, increased productivity).

✅ Assign a TPM Coordinator who will lead the implementation.

✅ Allocate a budget and resources for training, equipment upgrades, and maintenance improvements.

➥ Step 2: Build a Cross-Functional TPM Team

➲ Why is this important?

TPM is not just for the maintenance team—it involves operators, supervisors, quality control, and management working together.

➲ How to do it?

✅ Create a TPM team with members from different departments.

✅ Define clear roles and responsibilities for each team member.

✅ Set up a regular meeting schedule to discuss TPM progress and challenges.

➥ Step 3: Conduct a TPM Awareness Program for Employees

➲ Why is this important?

Many employees may not understand TPM or may resist change. A proper training program helps them see how TPM benefits them and makes their work easier.

How to do it?

✅ Organize workshops and training to explain TPM concepts.

✅ Use real-world examples to show how TPM has improved other industries.

✅ Encourage employees to share their concerns and ask questions.

➥ Step 4: Identify Critical Machines and Set TPM Goals

Why is this important?

Not all machines are equally important. Some machines are more critical to production, and failures can cause huge losses.

Read More: https://www.knowledgewale.com/2025/03/implement-tpm.html

#tpm#totalproductivemaintenance#tpmimplementation#efficiencyboost#stepbystepguide#maintenanceoptimization#industrybestpractices#continuousimprovement#manufacturingefficiency#zerodowntime#preventivemaintenance#leanmanufacturing#equipmentmaintenance#workplaceproductivity#factorymanagement

0 notes