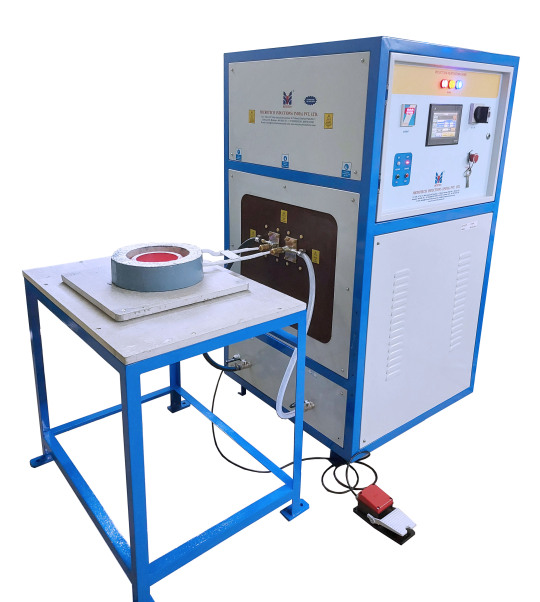

#Manufacture of Induction Forging Machine

Explore tagged Tumblr posts

Video

youtube

Head Forging Process #inductionheating #metaltreatment # inductionheating...

Malhotra Technologies looks forward to cooperating with you to create a bright future. Manufacturing and Sales Induction Heating Machine.

Contact no - 8199000995

website - https://malhotratechnologies.com/ , https://inductionmaster.com/

0 notes

Text

Induction Heating Machine Manufacturers

With induction heating, industrial heating technology has gained a new player. Providing maximum reliability and efficiency for precision heating applications and energy-efficient processes, induction hardening machine manufacturers are there for the end-user to rely on. When selecting equipment, it would thus be wise to choose the right induction heating machine manufacturer based on your industrial needs. The following article delves into the basics of these machines, their usage, and finding the right manufacturing partner.

What is Induction Heating?

Induction heating is a non-contact heating process that uses electromagnetic fields to heat electrically conductive materials. This method provides accurate, rapid, and efficient heating solutions for a wide range of applications, including metalworking, automotive, aerospace, and electronics industries.

How Does Induction Heating Work?

The process includes:

Induction Coil: An alternating current flows through a coil to produce a magnetic field.

Eddy Currents: When a conductive material is placed within the field, eddy currents are induced in the material.

Heat Generation: The resistance to these currents within the material produces heat.

Key Advantages of Induction Heating

Energy Efficiency: Minimizes energy waste compared to traditional heating methods.

Speed: Heats materials in seconds.

Precision: Targets specific areas without affecting surrounding materials.

Safety: No open flames or harmful emissions.

Induction Heating Machines: An Overview

The key technology at the heart of this is an induction heating machine. These machines are versatile and capable of meeting diverse industrial demands. The topmost manufacturers of induction heating machines constantly innovate and provide machines that are quite efficient, durable, and versatile.

Types of Induction Heating Machines

Induction Brazing Machines

Joining metals using filler materials.

Frequently used in the automotive and HVAC industries.

Induction Forging Machines

Prepare metals for forging by heating the metals to specific temperatures.

High-Quality Forging of uniform heating.

Induction Hardening Machines

Specialised in the surface hardening of metallic parts.

Widely applied in manufacturing gear, shaft, and car auto parts.

Knowing Induction Hardening Machines

An induction hardening machine is an induction heating machine type specialising in the process of surface hardening. Surface hardening makes a metal component tough at its outer portion and softer core, for pliability.

Usage of Induction Hardening Machines

Automotive Industry: Hardens gears, camshafts, and drive shafts.

Aerospace: Hardens turbine blades and parts of landing gear.

Tool Manufacturing: Hardens cutting tools, dies, and molds

Heavy Machinery: Hardens rollers and tracks

Advantages of Induction Hardening Machine

Long-lasting: Resists wear and tear, thus enhances long-term life.

Accurate: Only those specific areas are affected that would not otherwise affect the entire structure

Efficient: Reduced time for manufacturing due to rapid heating and cooling

Environment-friendly: No emissions or toxic wastes

Selecting the Best Induction Heating Machine Manufacturer

The reliability of a manufacturer when investing in an induction heating system stands first and foremost. Some factors to note include:

1. Experience and Expertise

An experienced induction heating machine manufacturer ought to have several years of experience with a proven track record. Look for companies that are skilled in the following areas:

Coming up with customized solutions

Customizing to different requirements by various industries

Technical support and after-sales service

2. Range of Products

It is important that the manufacturer offers a comprehensive range of products, among them including:

Induction brazing machines.

Induction forging machines.

Induction hardening machines.

This means that you can get all your heating requirements from a single supplier.

3. Quality Standards

An excellent manufacturer has very stringent quality standards. Look out for accreditation such as ISO 9001, which guarantee uniformity and quality.

4. Customization Options

Industrial processes have different requirements. Consider a manufacturer who has:

Custom machine configurations

Flexible power ratings

Adaptable coil designs

5. Technical Support

A good manufacturer will give you installation assistance and operator training.

Provide prompt technical support and maintenance services.

Best Features of Induction Hardening Machine Manufacturers

A professional induction hardening machine manufacturer should be able to provide solutions that meet the requirements of surface hardening. Here is what makes them stand out:

Advanced Technology

The best manufacturers invest in:

High-frequency induction technology.

The latest control systems for accurate heating.

Energy-efficient designs.

Application Expertise

The leading manufacturers know the exact requirements of various industries, such as automotive, aerospace, and tooling. They provide machines capable of handling different materials and sizes of components.

R&D Capabilities

Research and development are key to innovation. Manufacturers with strong R&D teams can:

Develop new technologies.

Improve machine efficiency.

Stay ahead of industry trends.

Why Choose an Induction Heating Solution?

Induction heating machines offer a host of benefits that make them the go-to choice for modern industries:

Cost Savings: Lower energy consumption and faster heating reduce operational costs.

Product Quality: Precise heating ensures consistent and reliable results.

Sustainability: Environmentally friendly operations with zero emissions.

Flexibility: It can work on different materials and applications.

Future of Induction Heating Technology

The future of induction heating is bright with constant innovations to transform the industry. Some of the trends include:

IoT Integration

Smart machines with real-time monitoring and control.

Increased data collection for predictive maintenance.

Energy Optimization

Ultra-efficient systems in development.

Renewable energy sources used to power the machines.

Compact Designs

Space-saving machines for small and medium-sized enterprises.

AI-Driven Automation

Machines that self-adjust to optimize performance.

Conclusion

The choice of induction heating machine manufacturer or the induction hardening machine manufacturer is a step to success for your industrial activities. Based on expertise, the range of products, and support, you could find a business partner that serves your specific requirements. The development of induction heating technology and innovative developments will be exciting but sustainable in the future.

Useful Links

induction heating machine manufacturer

Induction Hardening Machine manufacturer

0 notes

Text

Complete Guide to Drum Heating Machine and High-Frequency Induction Heating Machine

Properly utilized technology will make all the difference in matters of operational efficiency and cost effectiveness in industrial heating. Of the two main options, which meet the requirements of virtually every industry are the Drum Heating Machine and the High-Frequency Induction Heating Machine. What these machines are, their benefits, and how they're applied will be outlined within this guide.

What is a Drum Heating Machine?

A drum heating machine is an apparatus used for heating materials kept in drums or barrels. It ensures that temperature-sensitive substances, such as oils, chemicals, and food-grade materials, are kept within their optimal viscosity or consistency.

How Does a Drum Heating Machine Work?

There are several mechanisms of heating with drum heaters, such as:

Electric Band Heaters: These are placed around the drum to heat evenly.

Induction Heating: A non-contact method, wherein the electromagnetic fields are used directly to heat the metal drum.

Hot Air Blowers: Heated air is blown around the drum.

The mechanism to be adopted depends on the application and type of material to be heated.

Benefits of Using a Drum Heating Machine

Increased Efficiency: Provides uniform heating without any risk of overheating.

Material Preservation: Avoids thermal degradation of sensitive materials.

Customizable Options: Available in varied sizes and configuration to cater for the types of drums.

Safety: Prevent spillage or accident, as the heating is controlled.

Applications of Drum Heating Machines

The application of drum heating machines spans into various sectors. Some of the sectors where this machine has gained its utilization in include;

Food and Beverages: They apply the syrups, honey, or the viscous fluids.

Chemical Manufacturers: Maintains chemical flow when it is under process.

Pharmaceuticals: For Raw materials' good consistency

Petroleum: Warm oils or lubricants so as to become pumpable.

High-Frequency Induction Heating Machines utilize electromagnetic induction to heat conductive materials at a rapid and efficient rate. It is an advanced technology that will revolutionize industries with the need for precise and fast heating solutions.

How Does High-Frequency Induction Heating Work?

The process produces an alternating current, with high frequency, through the coil. When a conducting material is put inside that coil, electromagnetic fields induce an eddy in the material by heating it. This technique has the following advantages:

Advantages of Induction Heating Machines High Frequency

Speed : Heating takes just seconds.

Accuracy: Suitable for localized heating of the material.

Energy Efficiency: Consumes lesser energy as compared to conventional methods.

Durability: Non-contact process reduces abrasion on machinery.

Environmentally Friendly: Does not produce any open flames or pollutants harmful to the environment.

Applications of High-Frequency Induction Heating Machines

These machines can be used extensively in various industries such as:

• Metalworking: Heat-treatment, brazing, and forging metals.

• Automotive: Hardening gear, shafts, and other parts.

• Electronics: Soldering and bonding of fragile parts

• Medical Devices: Sterilization and precise joining of materials.

Future Trends in Industrial Heating Technology

Industrial heating landscape is continuously changing. Here, innovations have a focus either on efficiency or sustainability, and it can be noticed through the following key trends:

Smart Heating Systems: Integration of IoT to provide real-time monitoring and control.

Eco-Friendly Solutions: Energy-efficient designs to minimize carbon footprints.

Customization: Machines developed as per the requirement of the respective industry.

Conclusion

Both the Drum Heating Machine and the High-Frequency Induction Heating Machine are found in modern industries. Whether it's to maintain viscosity in a drum for materials or to apply precise heating in metal components, these machines will provide unmatched efficiency and reliability. Knowing their functionalities and benefits helps businesses make proper decisions in the optimization of operations.

0 notes

Text

Supplier of Industrial Induction Heating Systems: AB Induction

AB Induction is a global leader in the design, manufacturing, and supply of advanced industrial induction heating systems. With decades of expertise and a commitment to innovation, AB Induction provides cutting-edge solutions tailored to meet the needs of diverse industries, including automotive, aerospace, metallurgy, and energy.

Key Offerings:

Induction Hardening Machines: Designed for precision surface hardening of gears, shafts, and other components, ensuring durability and wear resistance.

Induction Brazing Systems: Provides efficient and clean bonding of metal parts for applications in HVAC, electrical, and automotive sectors.

Induction Melting Furnaces: High-performance systems for melting ferrous and non-ferrous metals, ideal for foundries and casting applications.

Custom Induction Heating Solutions: Tailored systems for specialized industrial processes, including annealing, forging, and shrink fitting.

Energy-Efficient IGBT Technology: Leveraging advanced solid-state inverters for precise temperature control and reduced energy consumption.

Why Choose AB Induction?

Advanced Technology: Cutting-edge solutions integrating automation, PLC controls, and real-time monitoring for superior performance.

Customization: Systems designed to meet specific requirements, ensuring maximum efficiency and reliability.

Global Presence: A trusted partner serving industries worldwide with local support and service.

Sustainability: Focus on energy efficiency and environmentally friendly heating solutions.

Comprehensive Support: End-to-end services including design, installation, training, and maintenance.

Applications Across Industries:

Automotive: Induction hardening of crankshafts, camshafts, and gears for enhanced durability.

Aerospace: Heat treatment and brazing of critical turbine and structural components.

Foundries: Efficient melting and forging systems for rapid production cycles.

Electronics: Soldering and brazing of electrical connectors and components.

AB Induction’s commitment to quality, innovation, and customer satisfaction has established it as a preferred supplier of industrial induction heating systems worldwide. Whether you need a standard solution or a customized system, AB Induction delivers reliable performance and unmatched precision for all your heating requirements.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Plot No. 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

1 note

·

View note

Text

Continuous Cast Billets | Mangalam Worldwide

Mangalam Worldwide is a leading Continuous Cast Billets manufacturer and supplier in India, offering high-quality billets produced through advanced processes for rolling and forging applications

Scrape metal is melted in technologically advanced Electric Induction Furnace with AOD Converter, Concasted and electronically controlled and monitored, to control & optimize the chemistry for consistent process parameters, to achieve high quality in all grades.

Continuously Casted Square Billets are produced through Double Strand Continuous Casting machine. They are used in rolling & forging applications in various industries.

Supply Conditions

Length up to 12 Meters.

Spot Ground or Fully Ground condition.

Free from Radioactive elements, Mercury and Lead contamination.

Marked with Heat Number, Colour Code, Grade Size & Weight.

100% mix up test through XRF Analyser (Portable Spectrometer). We are a multi location Fully Integrated Specialty Stainless Steel Mill. A LEADER in Continuous Cast Billets Manufacturers and Supplier In India, we are A Fully Integrated Specialty Stainless Steel Mill. Based out of Ahmedabad, Gujarat, India, our production facilities are located at Halol, Changodar and Kapadvanj. Our modern and technologically advanced production plants with European technology are powered by highly skilled and experienced team of Development, Production & Quality engineers, who believe in being “A Step Ahead”. This helps them to adopt quickly to market needs & requirements and offer a right solution to customers requirements in shortest possible times, besides ensuring that our products meet the stringent specifications of our global customers.

0 notes

Text

Stainless Steel Recycling: Methods, Benefits, and Industrial Solutions

Stainless metal recycling is a important difficulty of sustainable commercial practices and environment stewardship. As industries and clients are trying to find methods to lessen waste and enhance the circular financial machine, stainless-steel recycling stands out as a key answer. Vardhaman Ferro Alloys, a leading name within the enterprise, gives whole insights into the strategies, advantages, and industrial solutions related to stainless-steel recycling. In this blog, we’ll discover how recycling stainless-steel can contribute to sustainability and financial overall performance, collectively with the placement of scrap companies and pricing within the recycling technique.

Methods of Stainless Steel Recycling

Collection and Sorting:

The first step in stainless steel recycling involves the gathering and sorting of scrap stainless steel. This scrap can come from numerous belongings, which consist of manufacturing procedures, antique home equipment, and production substances. Efficient sorting is crucial because it guarantees that the price for scrap stainless steel is separated from distinct metals and contaminants, facilitating a smoother recycling procedure.

Shredding and Size Reduction:

After sorting, the stainless-steel scrap supplier is shredded into smaller quantities. This length bargain makes it plenty less hard to deal with and method in subsequent stages. Shredding also increases the ground area of the metallic, which permits in carrying out a greater uniform softening at some stage in the recycling phase.

Melting and Refining:

The shredded stainless-steel is then melted in electric arc furnaces (EAF) or induction furnaces. The melting device entails heating the metallic to immoderate temperatures to advantage a liquid united states. During refining, impurities are removed, and alloying elements are added to accumulate the favored composition. This step is important in making sure that the recycled stainless steel meets the excellent requirements required for reuse in new products.

Casting and Forming:

Once sensitive, the molten chrome steel is cast into numerous shapes along with ingots, billets, or slabs. These solid merchandise are then in addition processed into completed items via strategies like rolling, forging, or extrusion. The resulting stainless-steel merchandise are ready for use in diverse applications, collectively with manufacturing, automobile, and customer gadgets.

Quality Control and Testing:

Recycled chrome steel undergoes rigorous terrific management and checking to make certain it meets industry requirements. This consists of checking the chemical composition, mechanical properties, and normal integrity of the metal. Quality guarantee is critical to make sure that recycled stainless steel plays comparably to virgin stainless-steel in cease-use programs.

Benefits of Stainless Steel Recycling

Environmental Impact:

Recycling stainless-steel considerably reduces the want for uncooked fabric extraction and minimizes environmental pollution. By recycling, we keep natural sources, lessen energy consumption, and decrease greenhouse gasoline emissions. Stainless metallic is inherently recyclable, making it a green preference for sustainable commercial enterprise practices.

Energy Efficiency:

The recycling technique makes use of less electricity in comparison to producing stainless-steel from raw substances. Melting scrap stainless steel requires notably an awful lot much less electricity than the producing of the latest stainless steel from ore. This cut price in power consumption results in decreased operational prices and reduced carbon footprint.

Economic Advantages:

Stainless steel recycling is economically useful because it reduces the charge of raw substances. The availability of recycled chrome steel often results in lower costs in assessment of virgin stainless-steel. For agencies, this translates into value monetary savings and superior profitability. Additionally, the recycling enterprise creates task opportunities and allows economic growth.

Resource Conservation:

Recycling allows preserving treasured natural property via reusing gift substances. Stainless metal is durable and lengthy-lasting, and recycling extends its lifecycle. This technique supports a circular economic system in which materials are continuously reused and recycled, decreasing waste and promoting sustainability.

Reduced Landfill Waste:

Recycling stainless-steel permits lessen the amount of waste sent to landfills. By diverting scrap stainless-steel from landfills, we decrease environmental impact and reduce the stress on waste manipulate structures.

Industrial Solutions and Vardhaman Ferro Alloys

Our company plays a critical feature inside the chrome steel recycling company with the aid of the use of performing as a dependable scrap issuer. Our determination to be satisfactory and sustainable ensures that we offer high-quality scrap stainless steel to numerous industries. As a major scrap dealer, we facilitate the recycling technique with the aid of offering aggressive charges for scrap stainless steel and ensuring a regular supply of recyclable material.

Key Services Offered:

Scrap Stainless Steel Supply: We offer various chrome steel scrap types appropriate for recycling, along with 304, 316, and special grades.

Competitive Pricing: Our pricing for scrap stainless-steel is aggressive and displays current marketplace conditions, offering rate for each provider and customers.

Efficient Logistics: We make sure properly timed series and shipping of stainless steel scrap, assisting easy operations and lowering downtime for recycling centers.

Conclusion

Stainless steel recycling is a crucial issue of sustainable organization practices, presenting several advantages for the surroundings and the financial machine. By know-how the techniques and benefits of recycling, organizations and clients could make knowledgeable choices that make a contribution to a more sustainable destiny. Vardhaman Ferro Alloys is dedicated to assisting the recycling industry with first-rate scrap chrome steel and aggressive pricing, riding ahead the spherical monetary device and promoting beneficial resource conservation.

0 notes

Text

What is super duplex Steel Pipe

In the realm of stainless-steel piping, where durability, corrosion resistance, and power are paramount, tremendous duplex steel pipes stand out as a powerful option. Super duplex steel pipes provide a unique aggregate of residences that lead them to be fantastically sought-after in various industries, from oil and fuel to chemical processing. In this comprehensive manual, we delve into the intricacies of terrific duplex steel pipes, exploring their specs, production methods, and various programs.

What is Super Duplex Steel Pipe?

Super duplex steel pipe is a form of chrome steel pipe famous for its exquisite corrosion resistance, high electricity, and outstanding mechanical residences. It belongs to the duplex stainless-steel circle of relatives, which includes a --phase microstructure comprising each austenitic and ferritic grains. What sets splendid duplex steel apart is its expanded stages of chromium, molybdenum, and nitrogen, which make a contribution to its advanced overall performance in harsh environments.

Super Duplex Pipe Specifications

Super duplex steel pipes are engineered to meet stringent specifications to make sure ultimate performance in stressful applications. Here are a few key specifications commonly related to super duplex steel pipes:

Chemical Composition: Super duplex steel usually contains chromium content starting from 24% to 26%, along side substantial quantities of molybdenum (3% to five%), nitrogen (0.2% to 0.3%), and on occasion small quantities of different alloying elements like nickel and copper.

Mechanical Properties: Super duplex steel exhibits incredible mechanical houses, including high tensile strength, yield power, and impact sturdiness. These homes make it suitable for withstanding extreme pressures and temperatures encountered in various commercial settings.

Dimensions and Sizes: Super duplex steel pipes are available in a wide variety of sizes and dimensions to accommodate various packages. They are generally available in seamless and welded forms, with diameters starting from some millimeters to several inches.

Corrosion Resistance: One of the most distinguishing functions of awesome duplex steel is its incredible corrosion resistance, particularly in competitive environments containing chlorides, acids, and other corrosive substances. This resistance makes it perfect for offshore oil and fuel systems, chemical processing vegetation, and marine packages.

Standards Compliance: Super duplex steel pipes adhere to enterprise requirements inclusive of ASTM, ASME, and API, ensuring consistency in exceptional and overall performance throughout distinct producers and suppliers.

Manufacturing Process of Super Duplex Pipes

The manufacturing method of extraordinary duplex steel pipes includes numerous ranges, each vital for achieving the preferred residences and quality requirements. Here's an overview of the typical manufacturing technique:

Raw Material Selection: The manner starts with the cautious selection of raw substances, along with outstanding stainless steel alloys with the vital composition for the remarkable duplex steel.

Melting and Casting: The selected alloys are melted in electric arc or vacuum induction furnaces, observed by casting into billets or ingots.

Forming: The billets are then hot or cold worked using procedures together with extrusion, forging, or rolling to achieve the desired form and dimensions of the pipe.

Heat Treatment: Heat treatment is executed to refine the microstructure and enhance the mechanical houses of the brilliant duplex steel, inclusive of its energy and longevity.

Finishing: The pipes go through finishing approaches together with slicing, machining, and surface treatment to meet unique patron necessities and requirements.

Testing and Quality Assurance: Throughout the production manner, rigorous testing and high-quality assurance measures are carried out to make sure that the notable duplex steel pipes meet the desired specifications and standards.

Applications of Super Duplex Steel Pipes

Super duplex steel pipes discover sizable programs across various industries wherein corrosion resistance, electricity, and reliability are essential. Some commonplace applications consist of:

Oil and Gas Industry: Super duplex metal pipes are used in offshore drilling platforms, subsea pipelines, and petrochemical centers due to their ability to resist corrosive seawater and cruel operating situations.

Chemical Processing: Super duplex steel pipes are employed in chemical processing plant life for transporting corrosive chemicals, acids, and solvents safely and successfully.

Marine Engineering: Super duplex steel is favored in marine engineering for its resistance to saltwater corrosion, making it appropriate for shipbuilding, desalination flora, and different marine systems.

Power Generation: Super duplex steel pipes are applied in strength generation facilities, which includes nuclear, thermal, and renewable energy flowers, in which they bear high temperatures and corrosive environments.

Desalination: Super duplex steel plays a essential role in desalination plant life, wherein it's far used in piping systems for changing seawater into freshwater through reverse osmosis and different strategies.

Conclusion

Super duplex steel pipes represent a top of engineering excellence, offering extraordinary corrosion resistance, energy, and reliability in stressful business applications. As globalization drives the want for super materials and advanced technologies, the prominence of high-quality duplex metal keeps developing. With Vishal Tube Industries at the vanguard of producing top-fine stainless steel pipes, the destiny seems promising for the great adoption of terrific duplex metal in numerous sectors globally.

0 notes

Text

Made in China Expansion Indicator HPSQ150-150*150 for thermal power plant

Made in China Expansion Indicator HPSQ150-150*150 for thermal power plant Deyang YOYIK skill is strong, the production of strict accordance with national standards. With the power station forging, mining metallurgy, rolling, cement and spare parts spare parts, metallurgy, rolling and other products improve the production and operation system. For hundreds of water technology change, hydropower, thermal power plant overhaul supply of high-quality equipment selection, equipment commissioning, construction plans, spare parts, after-sales service, such as through-train service. The company to undertake hydropower stations, thermal power plant unit capacity transformation, technical transformation and overhaul projects. Look forward to the major manufacturers to inquire. Yoyik can offer many spare parts for power plants as below: #DF-Expansion Indicator HPSQ150-150*150-DF Cable Type RTD Sensor WZPM-201 5000MM M6 thread WRNK2-291 φ5 Tacho RPM sensor CS-3-M16-L120 Pressure Sensor Z1201420 lvdt displacement sensor ZD-5000TDB speed sensor location CS-1-D-060-05-01 displacement inductive sensor TDZ-1E-13 lvdt full form HL-6-150-15 lvdt displacement sensor LVDT-900-3 sensor rpm TM0793V-M temperature gauge sensor WZP2-221 rtd cable WZP2M-201 displacement sensor sany LVDT-20-3 TC Sensor WRNK2-221 temperature transmitter pt100 WZPK-646 industrial displacement sensor 5000TDGN-80-01-01 inductive displacement sensor TDZ-1-33 lvdt transducer TDZ-1E-25 furnace thermocouple WRN2-630 LX1=225*76 pt100 temperature controller WZRK-105 Φ5 Shaft Speed Sensors CS-1-G-100-03-01 lvdt-sensor B151.36.09G03 rpm meter digital speed HZQW-O3E tachometer price SQSD-3B temperature transmitter pt100 DZ3.1.2.7-1992 shaft rotation sensor SZXB-01-B01 LVDT Position Sensors 186.33.31.02 pt100 thermocouple machine WRN-332NM temperature thermometers WK-P2T(TH) lvdt linear position sensor ZDET-600B sensor pt100 WZP2-230 pt100 sensor WZP-190 Shaft Speed Sensors G-065-05-01 lvdt 0-300 ZD-3000TDA full form of lvdt FRD.WJA2.301H Thermocouple Type-K TE-303 Expansion Indicator HPSQ150-150*150 Shaft Speed Sensors ZS-03 L=65 Frequency Inverter ACS800-01-0005-3+P901 5000 rpm torque sensor E6B2-CWZ6C lvdt displacement sensor inductive sensor 4000TDZ-A rotation sensor D-090-02-01 displacement sensor sany 4000TDGN-100-01-01 rpm meter for generator HZQW-03A rotation sensor G-065-05-01 dial pipe thermometer WSS-481 PT100 lvdt linear position sensor C9231122 Digital display AC ammeter PA194I-5S4 lvdt 20mm sensor DET-350A LVDT Displacement Transducer Sensors TDZ-1D-05 displacement transducer ZDET-350B pt100 thermocouple WREK2-191 turbine speed sensor D-065-02-01 stainless steel electric tubular heater ZJ-22-3(R) linear displacement transducer A181.36.06G02 linear displacement transducer TDZ-1E-12 output speed sensor DF6202-005-050-04-00-01-000 thermocouple range WREKD2-04 LVDT Position Sensors TDZ-1 LVDT Displacement Transducer Sensors B151.36.09.04-008 lvdt full form 181.36.06G03 rpm tachometer WZ-1D-C digital tachometer rpm SZC-04 cable pt100 WZPM-201 φ6 rpm sensor indicator CS-1(G-100-02-01) sensor de rpm K-SV01 Rotary Torque Sensor CS-1-065-02 angular displacement sensor TD-1-100 pt100 thermal resistance WZPK2-336 thermal resistance unit WZP2-035 lvdt 0-300 B151.36.09.04-010 non-contact displacement sensor FRD.WJA2.308H thermocouple k TE-304 Expansion Indicator HPSQ150-150*150 DFYLSYC-2024-5-8-A

0 notes

Text

Microtech Inductions - India's Best Induction Brazing, Annealing, Heating, Melting machine manufacturers and suppliers.

INTRODUCTION

MICROTECH INDUCTIONS PVT. LTD. stands out as a leader in the design and production of advanced Solid State Inverter Technology-based Induction machines catering to a wide range of applications including Heating, Melting, Annealing, Hardening, Brazing, Cap Sealing, and Shrink Fitting.

With over 1000 successful Induction Machines in operation worldwide, MICROTECH has achieved several notable industries first such as:

First to introduce Utensil Annealing Machine in Steel Industry.

First to introduce double frequency inverter in Melting with efficiency as high as 95%.

First to introduce hybrid control strategy for induction power control (patent pending).

First to introduce multi-stacking of voltage source inverter for capacity enhancement (Patent pending).

The company also boasts a state-of-the-art Setup, Testing, and Manufacturing facility dedicated to ensuring adherence to quality standards in line with ISO and CE guidelines.

Brazing Excellence

Microtech Inductions' induction brazing machines are renowned for their precision and consistency. Whether it's joining intricate components in the automotive industry or creating strong bonds in the aerospace sector, their brazing machines deliver exceptional results every time

Annealing Solutions

For heat treatment processes such as annealing, MicrotechInductions offers specialized machines that provide uniform heating and controlled cooling, ensuring optimal material properties. This is crucial for industries like metallurgy, where precise annealing processes are essential.

Heating Capabilities

In applications requiring rapid and localized heating, Microtech Inductions' induction heating machines excel. From forging to hardening, their machines provide fast, efficient, and energy-saving heating solutions, enhancing productivity and reducing operational costs.

Melting Expertise

Induction melting is another area where Microtech Inductions shines. Their melting machines offer precise temperature control and unmatched purity, making them ideal for industries like foundries, where high-quality molten metal is critical for production processes.

CONCLUSION

In conclusion, MICROTECH INDUCTIONS is well-equipped to tackle any challenge that comes its way by a dynamic and forward-thinking management and Business Administration team. As one of the leading manufacturers and suppliers of Induction Brazing ,Heating, Melting, and Annealing machines, MICROTECH continues to drive innovation and excellence in the industry.

1 note

·

View note

Text

Empowering Industry Efficiency: Oritech Solutions' Revolutionary Induction Furnace Technology

Introduction:

In today's rapidly evolving industrial landscape, efficiency isn't just a goal—it's a necessity. Oritech Solutions stands at the forefront of innovation, pioneering cutting-edge technologies that redefine efficiency and sustainability in industrial processes. In this blog, we delve into Oritech's ground breaking advancements in energy-saving induction furnaces, induction hardening machines, and the transformative role of IGBT inverters.

Energy-Saving Induction Furnaces: Redefining Efficiency Oritech Solutions leads the charge in energy-saving induction furnace technology. Our furnaces are engineered with a focus on maximizing energy efficiency without compromising performance. By leveraging advanced insulation materials, optimized heating mechanisms, and intelligent control systems, Oritech's energy saving induction furnaces minimize energy consumption while delivering superior results. With reduced operating costs and environmental impact, Oritech's furnaces pave the way for a sustainable future in industrial heating processes.

Precision and Performance: Induction Hardening Machines Precision is paramount in modern manufacturing, and Oritech Solutions delivers with its state-of-the-art induction hardening machines. These machines offer unparalleled precision and control, ensuring consistent and uniform hardening of metal components. Whether in automotive, aerospace, or heavy machinery applications, Oritech's induction hardening machines deliver exceptional results, enhancing durability and performance while minimizing distortion and waste.

The Role of IGBT Inverters: Driving Innovation in Induction Furnaces At the heart of Oritech Solutions' induction furnace technology lies the innovative IGBT inverter. These inverters serve as the backbone of our furnaces, providing precise control over power and frequency modulation. By harnessing the efficiency and reliability of IGBT technology, Oritech's induction furnaces achieve optimal performance, versatility, and durability. From brass melting to steel forging, our furnaces equipped with IGBT inverters deliver unmatched efficiency and productivity.

Conclusion:

Oritech Solutions is dedicated to empowering industries with state-of-the-art induction furnace technology. Through our energy-saving induction furnaces, precision induction hardening machines, and innovative IGBT inverters, we redefine efficiency, performance, and sustainability in industrial heating processes. As industries continue to evolve, Oritech remains committed to driving innovation and delivering solutions that set new standards for excellence. Join us in shaping the future of industrial heating with Oritech Solutions.

1 note

·

View note

Text

Forge Success: A Comprehensive Guide to Setting Up and Operating an Efficient Iron Casting Plant

Setting up and operating an iron casting plant requires careful planning, precise execution, and a deep understanding of the industry. This guide aims to provide a step-by-step approach to help entrepreneurs and industry professionals establish and run a successful iron casting plant.

Step 1: Feasibility Study Begin with a thorough feasibility study to assess the market demand, competition, and potential profitability. Analyze raw material availability, transportation logistics, and regulatory requirements to identify the ideal location for your iron casting plant.

Step 2: Designing the Layout Collaborate with experienced engineers to design an efficient layout that optimizes workflow and minimizes waste. Consider factors such as furnace placement, mold preparation areas, and storage for raw materials and finished products.

Step 3: Procuring Equipment and Technology Invest in high-quality casting equipment, such as induction furnaces, molding machines, and casting molds. Adopt the latest technologies to enhance efficiency and reduce energy consumption. Additionally, implement robust quality control measures to ensure the production of top-notch castings.

Step 4: Environmental Considerations Address environmental concerns by implementing sustainable practices. Explore options for recycling and reusing waste materials, and invest in eco-friendly technologies to minimize the plant's environmental footprint.

Step 5: Workforce Training Train your workforce extensively on safety protocols, casting techniques, and equipment operation. Create a culture of continuous learning to keep your team updated on the latest industry trends and advancements.

Step 6: Regulatory Compliance Navigate the regulatory landscape by obtaining all necessary permits and certifications. Comply with environmental, health, and safety regulations to maintain a secure and legally sound operation.

Step 7: Supply Chain Management Establish strong relationships with suppliers for consistent and reliable access to raw materials. Implement an effective supply chain management system to streamline procurement and reduce production delays.

Step 8: Quality Assurance Implement a stringent quality assurance program to ensure that the produced iron castings meet or exceed industry standards. Regular inspections, testing, and feedback loops are essential to maintaining the highest quality throughout the manufacturing process.

Step 9: Marketing and Sales Develop a comprehensive marketing strategy to promote your iron casting plant. Highlight your commitment to quality, efficiency, and environmental sustainability to attract clients in various industries requiring iron castings.

Conclusion: By following this comprehensive guide, entrepreneurs can navigate the complexities of establishing and operating a successful iron casting plant. With careful planning, strategic investments, and a commitment to excellence, your plant can become a key player in the iron casting industry.

1 note

·

View note

Text

The Power of Precision: Understanding Induction Heating Machines

In the rapidly evolving manufacturing and metal processing landscape, induction heating machines have become indispensable tools for delivering fast, efficient, and controlled heating. Leveraging the principles of electromagnetism, these machines offer a clean and contactless method for heating conductive materials, primarily metals, making them a preferred solution across industries such as automotive, aerospace, electronics, and metallurgy.

What is Induction Heating?

High-frequency alternating current (AC) is used in the non-contact heating method known as induction heating to produce heat inside a conductive substance. This is accomplished by inserting the material—referred to as the workpiece—into a coil that conducts AC. Eddy currents are created in the material by the alternating magnetic field, and because of electrical resistance, these currents produce heat. The procedure is accurate, economical, and highly controllable, allowing for consistent outcomes and little thermal distortion - attributes that are difficult to obtain with standard heating methods.

How Induction Heating Machines Work

The following essential parts are commonly found in an induction heating machine: Power Supply: Generates high-frequency AC power from the mains.

The magnetic field produced by the work coil (inductor) causes current to flow through the workpiece.

Cooling System: Maintains optimal temperatures in the coil and electronic components.

Control Interface: Allows operators to manage different applications' temperature, time, and frequency parameters.

By adjusting the frequency and power levels, induction heating systems can be fine-tuned for various applications, from surface hardening to deep metal penetration. Advantages of Induction Heating Machines

Speed and Efficiency Induction heating delivers heat directly to the workpiece without relying on external conduction or radiation, leading to extremely rapid heating cycles. This translates to improved production speeds and energy efficiency.

Precision and Control Heat can be localized to very small areas with millimeter accuracy. Digital controls allow for programmable heating cycles tailored to specific materials and requirements.

Clean and Safe Operation As there is no open flame, induction heating is safer and cleaner than gas or oil-fired furnaces. It also reduces oxidation, improving the quality of the finished product.

Repeatability and Automation Induction heating machines are highly compatible with automated production lines, ensuring consistent and repeatable results over thousands of cycles

Common Applications of Induction Heating Machines

Hardening of steel parts (e.g., gears, shafts, and rollers)

Brazing and soldering of metals without the use of torches

Annealing to improve ductility and relieve internal stresses

Shrink fitting for assembling components with tight tolerances

Melting and forging of metals in foundries and metalworking industries

These machines can be customized for handheld use in small-scale operations or fully integrated into high-capacity industrial production lines.

Choosing the Right Induction Heating Machine

Selecting the right induction heating machine involves considering factors such as:

Type and size of the material

Required heating depth and temperature

Cycle time and production volume

Frequency range and power output

Automation and integration capabilities

Reputable manufacturers offer machines tailored to specific needs — from compact benchtop units for research labs to high-power industrial systems for heavy-duty manufacturing.

Future of Induction Heating

With ongoing advancements in power electronics and control systems, induction heating technology is becoming smarter and more energy-efficient. Integration with Industry 4.0 technologies such as IoT and AI is enabling predictive maintenance, real-time monitoring, and data-driven process optimization.

As sustainability and precision become top priorities across industries, the adoption of induction heating is set to grow. It represents not just a heating method, but a strategic tool for competitive and environmentally responsible manufacturing.

Conclusion

Induction heating machines offer a cutting-edge solution for precise, fast, and clean heating across a wide range of industrial applications. Their versatility, efficiency, and ability to integrate into automated systems make them a cornerstone of modern metalworking and thermal processing.

Whether you’re looking to improve productivity, reduce energy costs, or achieve unparalleled control over your heating processes, induction heating technology is a powerful investment for the future.

#induction heating machine#induction hardening machine#induction annealing machine#induction forging machine#marketing#youtube

0 notes

Text

Structural Metal Plate

Similarly, marine-grade aluminum, such as the alloys, provides an excellent balance between strength, corrosion resistance, and workability. Before buying a light metal plate, it's important to contemplate some properties. These properties embody conductivity, corrosion resistance, density, hardness, and impression resistance. Therefore, sheets with low conductivity are best for insulation, whereas these with high conductivity are utilized in purposes like refrigeration. Secondly, it is important to consider the density of the steel plate as an outcome of it'll decide how a lot a part of a specific measurement will weigh. This property is significant in the aerospace and automotive business, the place weight matters - steel plate.

Stainless steel bolts are also appropriate for connecting galvanized steel and aluminum members. They can be made in a variety of sizes and weights, the upper limits being ruled by the actual casting process used, and the required mechanical properties and surface finish. It is possible to realize high strength, high ductility, and excessive toughness within the forged kind. Castings can have wonderful surface finish and good welding and machining traits - stainless steel.

Steel strip is uncoiled and guided, cold, through units of forming rolls to supply the cylindrical form. At the purpose where the perimeters meet, a high frequency present is introduced into the edges of the strip, either by induction utilizing an encircling coil or by contacts sliding on the surface of the strip. The electric present produces sufficient native heat to melt the strip edges as they're cast collectively.

This signifies that every metal base plate or fan plate we manufacture is repeatable to your specs and is completed to the best potential requirements throughout the entire process. Since the envelope types have a serious seen function, colored coating techniques are provided. The commonest form of strip steel used in development is a hot-dip galvanized coil. These work rolls that contact the recent steel are sometimes supported by larger diameter rolls to stop them bending underneath the rolling loads to make sure a uniform thickness product. For more information, please visit our site https://www.rebrebarandsteel.com/

0 notes

Text

Forged Pocket Teeth Sprocket Supplied by SCIC

As a manufacturer and supplier of industrial sprockets, we understand the importance of providing quality products that meet the performance and safety standards required by our customers. In this blog post we take a closer look at our 14x50mm grade 100 round link chain sprockets, which are designed and manufactured using the latest technology and the highest quality materials to ensure superior performance and durability. Round link chain sprocket 14x50mm is with 8 pocket teeth. This design results in a stronger, tighter fit between the sprocket and chain, helping to reduce the risk of slippage and improve overall efficiency. The tooth surface is hardened by induction heat treatment, which improves the wear resistance of the chain during operation and prolongs the service life of the sprocket. A critical aspect of the manufacturing process is sprocket tooth hardness testing. This test measures the wear resistance of the sprocket teeth and ensures that the teeth are within the required hardness range. Our sprockets are rigorously tested to ensure optimum performance and reliability in even the harshest industrial environments. Additionally, we employ strict dimensional control inspections during production to ensure that each sprocket is precisely machined to the required specifications. This includes carefully measuring the chain link diameter, pitch & width, to ensure a perfect fit between the chain links and sprockets. Finally, the Fitting Compliance Guide is used to ensure that each sprocket is properly fitted and ready for use. We understand the importance of getting things right the first time, which is why we place so much emphasis on assembly and quality control processes. In summary, our 14x50mm round link chain sprocket is a top performing industrial sprocket designed for heavy duty applications. With their pocket teeth, case hardened surfaces and stringent quality control measures, our sprockets provide exceptional performance, reliability and longevity. Contact us today to learn more about our sprocket products and services. Read the full article

0 notes

Text

ABInduction: Revolutionizing Industrial Heating Solutions with Advanced Technology

ABInduction has established itself as a trailblazer in the field of induction heating solutions, offering cutting-edge technology designed to meet the demands of modern industries. With a strong focus on precision, efficiency, and sustainability, ABInduction provides tailored solutions to a wide range of applications, including automotive, aerospace, construction, and manufacturing.

Innovative Induction Heating Solutions

At the core of ABInduction's success is its advanced induction heating technology, which utilizes electromagnetic fields to heat metals precisely and efficiently. Their machines are known for:

Energy Efficiency: Reduced power consumption without compromising performance.

Customization: Tailor-made solutions that adapt to client-specific requirements.

Environmental Friendliness: A clean and eco-friendly alternative to traditional heating methods.

Key Product Offerings

ABInduction's product line includes:

Induction Hardening Machines: Designed for surface hardening of automotive parts, heavy machinery components, and tools.

Vertical & Horizontal Scanners: High-precision machines for hardening applications with automated PLC controls.

Billet Heaters: Efficient solutions for pre-heating billets and bars in forging and extrusion processes.

Electroplating Rectifiers: Reliable power supply systems for electroplating industries.

Commitment to Quality and Innovation

ABInduction combines over two decades of experience with continuous R&D to develop state-of-the-art machines that meet global standards. Their equipment is built to deliver high performance, durability, and consistent results, empowering industries to achieve greater productivity.

Global Impact

Operating out of Faridabad, India, ABInduction serves clients worldwide, earning a reputation for excellence and reliability. Their commitment to customer satisfaction and technological innovation has made them a trusted partner for businesses across various industrial sectors.

With a vision for transforming the future of industrial heating, ABInduction continues to lead the way by providing advanced, sustainable, and efficient heating solutions that cater to the ever-evolving needs of the industry.

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/induction-heating-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Continuous Cast Billets Manufacturers and Supplier

Mangalam Worldwide is a leading Continuous Cast Billets manufacturer and supplier in India, offering high-quality billets produced through advanced processes for rolling and forging applications

Scrape metal is melted in technologically advanced Electric Induction Furnace with AOD Converter, Concasted and electronically controlled and monitored, to control & optimize the chemistry for consistent process parameters, to achieve high quality in all grades.

Continuous Cast Billets Manufacturers and Supplier in India

Continuously Casted Square Billets are produced through Double Strand Continuous Casting machine. They are used in rolling & forging applications in various industries.

0 notes