#super duplex pipe specification

Explore tagged Tumblr posts

Text

Sinosteel Stainless Steel Pipe Technology (Shanxi) Co., Ltd. is well structured and possesses complete product specifications, uses exquisite techniques and produces excellent quality. We produce different steel grades of austenitic and super austenitic stainless steel pipes, ferritic stainless steel pipes, duplex steel and super duplex steel pipes. We also produce nickel-base alloy pipes, titanium alloy pipes, copper alloy pipes and clad steel pipes with an outer diameter from 8mm to 3600mm, with wall thicknesses from 0.2mm to 120mm. We are one of the nation’s largest enterprises that can produce the most complete varieties and specifications of stainless steel pipes.

Our company has successively obtained ISO9001 Quality Management System Certification, GJB9001C Military Quality Management System Certification, ISO14001 Environmental Management System Certification, ISO45001 Occupational Health And Safety Management System Certification and the Manufacture License of Special Equipment of pressure piping component, Shanxi province Hygienic License for Drinking Water Hygiene and Safety Product, PED, European Pressure Equipment Directive, API 5LC / API 5LD certification of American Petroleum Institute, CU-TR (EAC) Certification and several national classification societies such as CCS, BV, DNV and LR. We have established close technical R & D and cooperative relationship with a number of scientific research institutions, has strong R & D and innovation capabilities, has won a number of national patents, and has been identified as a provincial and municipal enterprise technology center and the Technologically Advanced “Little Giant” enterprise.

1 note

·

View note

Text

Piping Material Engineer

Responsibilities of Material Engineer:1 Preparation of Piping Material index, Piping Material classes for Process & Utilities.2 Preparation of Valve datasheets and Piping Specialty items datasheets.3 Writing Technical / Purchase specifications for Bulks, Valves etc.4 Hands on experience in handling metallic piping like Carbon / Stainless Steel /Duplex / Super Duplex Stainless Steels & Low Alloy…

0 notes

Text

ASTM A790 UNS S32750 Pipe, Duplex Steel 2507 Seamless Pipes Exporters in Mumbai, India.

In the rapidly evolving world of industrial applications, the demand for high-performance materials is more prominent than ever. One such material gaining widespread recognition is Duplex Steel 2507, classified under the ASTM A790 UNS S32750 standard. This grade is known for its superior strength, excellent corrosion resistance, and remarkable durability, making it an ideal choice for demanding environments like chemical processing, oil & gas, power generation, and marine industries.

ASTM A790 UNS S32750 is a super duplex stainless steel pipe that offers a perfect blend of austenitic and ferritic properties. The alloy consists of high levels of chromium, molybdenum, and nitrogen, which significantly improve its resistance to pitting, crevice corrosion, and chloride stress corrosion cracking. Due to its low thermal expansion and high thermal conductivity, these pipes are particularly useful in extreme pressure and temperature conditions.

As one of the leading Duplex Steel 2507 Seamless Pipe exporters in Mumbai, India, Calico Metal Alloys LLP has built a strong reputation for delivering premium-quality products across the globe. Our seamless pipes undergo rigorous quality testing and are manufactured under strict compliance with international standards. With a wide distribution network and a strong focus on customer satisfaction, we ensure timely delivery and reliable performance for every project.

These pipes are widely used in applications that demand high strength and corrosion resistance, such as offshore platforms, desalination plants, and heat exchangers. The seamless construction ensures leak-proof performance, making them a preferred choice for high-pressure fluid handling systems.

Whether you're a project engineer, procurement officer, or contractor, choosing ASTM A790 UNS S32750 Duplex 2507 Seamless Pipes from a trusted exporter like Calico Metal Alloys LLP can significantly enhance the longevity and efficiency of your infrastructure. With decades of experience in the industry, we are committed to providing cutting-edge solutions that meet your specific requirements and exceed your expectations.

0 notes

Text

How ICCL DBB Valves Optimize Offshore and High-Pressure Piping Systems

In tough industrial settings like offshore platforms and high-pressure pipeline networks, safety, space, and system integrity are absolutely vital. One key player in making sure these goals are met is the DBB valve, or Double Block and Bleed valve.

At ICCL (Industrial Components & Connectors Ltd.), we design DBB valves that are specifically built to handle the challenges of offshore and high-pressure applications. In this blog, we’ll dive into how ICCL’s DBB valves enhance system safety, streamline operations, and boost overall efficiency in some of the toughest working conditions on the planet.

What Is a DBB Valve?

A Double Block and Bleed (DBB) valve is a unique valve setup that features two sealing barriers (block valves) along with a bleed mechanism in between. This design serves a couple of important purposes:

It completely isolates a section of the pipeline.

It safely vents or bleeds off pressure or trapped fluid between the two block points.

This setup allows operators to confirm isolation, carry out maintenance safely, and avoid accidental releases of toxic or pressurized fluids.

Why Offshore and High-Pressure Systems Need DBB Valves

Offshore oil and gas platforms, as well as high-pressure processing plants, deal with extreme conditions:

Limited space for valve assemblies.

High pressure and temperature.

Exposure to seawater, corrosion, and vibration.

Strict safety and environmental compliance requirements.

In these environments, traditional isolation methods — which involve multiple individual valves, pipe fittings, and bleed lines — can:

Take up too much space.

Increase the number of potential leak points.

Require extensive maintenance.

ICCL DBB valves tackle these issues with a compact, all-in-one solution.

Here’s the text we’re diving into: How ICCL DBB Valves Optimize Offshore & High-Pressure Operations

1. Compact Design Saves Critical Space

On offshore rigs or FPSOs (Floating Production Storage and Offloading units), every bit of space counts. ICCL’s DBB valves cleverly combine two isolation valves and a bleed valve into one compact unit, which means fewer fittings and flange connections are needed.

- Lighter and more compact skids and manifolds

- Simple installation in tight spots

- Perfect for modular skid-based systems

2. Enhanced Safety with Zero-Leak Isolation

ICCL DBB valves are designed for reliable isolation — a must-have for systems dealing with flammable, toxic, or high-pressure fluids. They provide:

- Two independent sealing mechanisms

- Venting or pressure release from the cavity between seals

- Choices between soft-seated or metal-seated valves for maximum integrity

This triple-sealing feature significantly reduces the chances of:

- Pressure buildup

- Accidental fluid leaks

- Cross-contamination during maintenance or testing

3. Reduced Leak Paths & Maintenance

When compared to traditional setups that involve multiple valves, pipe runs, and fittings, ICCL’s DBB valves cut down on:

- Potential leak points

- Threaded or jointed connections

- Maintenance intervals and costs

Fewer components mean less downtime, fewer gaskets and bolts to worry about, and a more dependable system operation — especially great for remote or unmanned installations.

4. High Pressure & Corrosion-Resistant Construction

ICCL’s DBB valves are built with materials that can handle high-pressure ratings of up to 10,000 PSI and are available in:

- SS 316/316L

- Duplex and Super Duplex Steel

- Inconel and Hastelloy (upon request)

- Monel (for seawater resistance)

These materials provide excellent resistance to:

- Chloride-induced corrosion

- Stress cracking

- Sulfide stress corrosion in sour gas environments

This ensures a long lifespan for valves in both subsea and topside operations.

Offshore platforms and high-pressure industrial plants require components that are not just compact and durable, but also completely leak-proof. That’s where ICCL’s Double Block and Bleed valves come in—they not only meet these stringent demands but exceed them, providing a solid solution that blends safety, efficiency, and top-notch performance all in one.

Thanks to precision manufacturing, global certifications, and tailored support, ICCL has established itself as the go-to supplier for DBB valves in critical applications around the globe.

📧 Email: [email protected]

🌐 Website: https://icclksa.com

📞 Call: +966 133617166

📦 Shipping Worldwide | 🛠 Custom Solutions Available

0 notes

Text

Where Stainless Steel is Used in the Food Industry: Critical Applications and Ideal Materials?

Demand for corrosive atmosphere stainless steel 316

Stainless steel 316 plate supplier is a better option in processing areas where corrosive agents such as salt, acid, or other substances are used, such as in pickling or seafood production. Due to its strong rust resistance due to its molybdenum concentration, it is perfect for use in environments that are rigid. Tools such as evaporators, sterilizers, and washing units provide better security. A reliable stainless steel 316 plate supplier. These materials meet food industry standards, especially in cleaning and sterilization areas where corrosion is a significant concern.

Pressure and Strength in Dairy and Beverage Plants

In dairy and beverage plants, piping and pressure vessels are often subjected to both acidic fluid and high temperatures. For this reason, duplex 2205 plates are becoming increasingly popular. This standard doubles the strength of austenitic stainless steels and opposes the stress corrosion cracks. This makes it ideal for westernizers, heat exchanges, and fermentation tanks. The use of duplex steel ensures that the plant product maintains purity and safety while also enjoying extended service life and low maintenance costs.

High chloride applications like super duplex 2507

When food processing involves high levels of chlorides, such as in fish processing or salty production, the super duplex 2507 plate helps in this case. Super duplex materials reduce downtime due to corresponding failures and ensure that high cleaning standards are maintained.

Specialty Alloys for High-Performance Requirements

Specific procedures in the food industry, such as fatty acids, taste extracts, or essential oils, may require the use of nickel alloys. Inconel 625 plate, for example, is used in an environment where temperature and corrosion resistance must be at their highest level. In high-temperature processing or extraction systems, this alloy is stable and safe. Similarly, Hastelloy C276 plate is ideal for aggressive chemical cleaning systems, and Monel 400 plate can be found in devices that handle high-salt products such as salt-based snacks or sauces. These alloys ensure longevity even in extreme conditions.

Heat-treated steel for baking and cooking applications

High temperature is a problem for baking items as iron or other materials are not useful, but ASTM A387 Grade 11 and ASTM A387 Grade 22 are used in food industries that help them in baking or frying. These chromium-molybdenum plates are often used in thermal oil boilers due to their extraordinary heat resistance in baking tray supports and furnace components. Their ability to maintain strength under heat makes them suitable for continuous operation in high-heat food production environments, where equipment failure may result in contamination and production stops.

External Cladding and Storage with Corten Steel

Conclusion

From food connectivity tools to external applications, the food industry depends a lot on a variety of stainless and special steels. Either a Hastelloy C276 plate, duplex 2205 plate, or stainless steel 304 plate supplier. Every day does a different function in reference to chemical resistance, to use each material every day. Food production is made safer, cleaner, and more effective by knowing where and why every grade of steel is used.

0 notes

Text

Industrial fasteners with exceptional performance for demanding applications.

In the industries where electricity, temperature resistance and corrosion protection are important, the choice of correct fasteners can make or destroy the machine. High-degree alloys and stainless steel materials are important in inclusive applications of oil and fuel, strength technology, aerospace and marine operations. Manufacturers offer a variety of specialized fasteners that meet strict requirements. This article detects first-class fasteners such as Inconel Fasteners, Hastloy fasteners, Super Duplex mounting agents, and many ASTM influenza products that ensure safety, strong and performance in serious situations.

Inconel and Hasteloy Festivals: Strength under extreme conditions

Fasteners made of nickel-based alloys are required in high-temperature, corrosive environments. Their fasteners are identified for their ability to withstand intense heat and oxidation, making them ideal for aviation motor, chemical processing and marine hardware. Similarly, Hastelloy Fasteners are used in large industries, which require strong chemical resistance, including acid flora and marine exhaust structures. These excessive-performance fasteners stay solid and reliable even in exceptionally aggressive environments.

Durability Redefined with Super Duplex Fasteners

For packages wherein both power and corrosion resistance are paramount, Super Duplex Fasteners offer a advanced solution. Composed of austenitic and ferritic stainless steels, those fasteners provide awesome mechanical electricity and resistance to chloride stress corrosion cracking. They are usually utilized in subsea oil rigs, desalination plants, and offshore platforms. Their duplex structure allows them to perform beneath excessive pressure and strain with minimum hazard of failure.

ASTM A193 B Series: Bolts and Rods You Can Trust

When it involves enterprise standards, the ASTM A193 specification units a excessive benchmark. ASTM A193 B8 Bolts are made from austenitic stainless steel and are suitable for excessive-temperature service. These bolts are used considerably in pressure vessels, warmth exchangers, and boilers. On the opposite hand, ASTM A193 B6 Bolts, made from ferritic stainless steel, provide excellent corrosion resistance and are utilized in diverse mechanical programs. For greater strong structural makes use of, ASTM A193 B7 Threaded Rod and ASTM A193 B7 Hex Bolts offer the strength required for heavy-obligation engineering structures. Their warmth-treated chromium-molybdenum steel construction ensures long-lasting overall performance under high anxiety and temperature.

Superior Strength with ASTM A320 and A453 Grades

Cryogenic and occasional-temperature applications demand unique substances. ASTM A320 L7 Stud Bolts are designed for such environments and are widely utilized in LNG and petrochemical plants. These bolts keep their energy and ductility at sub-zero temperatures, making sure protection and structural integrity. For high-temperature bolting applications, ASTM A453 Grade 660 fasteners are a desired choice. Used in turbine engines and stress vessels, these fasteners are engineered to face up to thermal expansion and mechanical stress over prolonged durations.

Stainless Steel and Inconel 718 for Corrosive and High-Stress Uses

Among stainless steels, Stainless Steel 316L Fasteners are highly regarded for their resistance to chloride environments, in particular in marine and chemical programs. The low carbon content prevents carbide precipitation, ensuring incredible corrosion resistance. For even better energy wishes, Inconel 718 Fasteners stand out due to their exquisite tensile strength, fatigue resistance, and creep resistance at elevated temperatures. They are generally utilized in aerospace engines, nuclear reactors, and excessive-strain piping structures.

Conclusion

The fasteners industry maintains to evolve with the creation of high-overall performance alloys and stricter global standards. From Inconel Fasteners and Super Duplex Fasteners to ASTM-compliant bolts and rods, cutting-edge industries rely upon superior substances to preserve protection, integrity, and durability. As call for increases throughout sectors, sourcing nice fasteners like Inconel 718 Fasteners or ASTM A193 B7 Hex Bolts from reliable manufacturers ensures lengthy-time period overall performance and peace of thoughts.

1 note

·

View note

Text

Reliable Duplex Steel Anchor Bolts for Chemical Processing Plants

Chemical processing plants require fasteners that can handle extreme conditions—corrosive chemicals, high temperatures, and heavy loads. Duplex Steel Anchor Bolts are engineered for just that. Known for their exceptional strength and resistance to corrosion, these bolts provide secure anchoring of equipment and structures in demanding industrial settings.

Made from a unique blend of austenitic and ferritic stainless steels, duplex anchor bolts offer twice the strength of regular stainless steel and unmatched durability in chemical-rich environments. They're the ideal solution for maintaining structural integrity and safety in chemical plants, even under constant exposure to aggressive substances.

Introduction

In chemical processing plants, machinery and structures face harsh chemicals, high temperatures, and constant moisture. To keep everything safe and secure, you need strong, corrosion-resistant fasteners. This is where Duplex Steel Anchor Bolts come in.

These special bolts are made from duplex stainless steel — a material that is stronger than regular stainless steel and can resist chemical corrosion much better. Whether you’re anchoring heavy equipment or structural supports to concrete, duplex steel anchor bolts provide long-lasting performance in tough industrial environments.

What Are Duplex Steel Anchor Bolts?

Anchor bolts are used to securely attach machinery, equipment, or structural elements to concrete foundations, ensuring stability and safety. They make sure machinery stays in place, even when exposed to heavy loads or vibrations.

When these bolts are made from duplex stainless steel, they become even more powerful. Duplex stainless steel features a dual-phase microstructure of ferritic and austenitic stainless steels, offering superior mechanical and corrosion-resistant properties. This combination gives duplex steel:

Very high strength

Excellent corrosion resistance

Good durability in extreme environments

Common Grades of Duplex Steel Used:

UNS S31803 and S32205 – These are standard duplex stainless steel grades known for their good balance of strength and corrosion resistance.

UNS S32750 and S32760 – These are super duplex grades offering higher strength and enhanced corrosion resistance, ideal for more demanding or aggressive environments.

Why Are They Ideal for Chemical Processing Plants?

Chemical plants often deal with:

Corrosive substances like acids, alkalis, and solvents

High moisture and chloride exposure

High pressure and temperature

Duplex steel anchor bolts are a perfect choice for these settings because they:

Resist chemical attack and rust

Can handle high mechanical loads

Work well in wet, salty, or acidic environments

Last much longer than regular carbon steel or even some stainless steels

Benefits of Duplex Steel Anchor Bolts

1. High Resistance to Corrosion

Duplex steel is known for its ability to fight corrosion from chemicals and salt, making it perfect for chemical plants.

2. Very Strong and Tough

These bolts are nearly twice as strong as standard stainless steel bolts. This means you can use smaller bolts to handle the same loads.

3. Good for Harsh Conditions

They can handle shocks, vibrations, and repeated loading without cracking or failing.

4. Cost-Efficient in the Long Run

Even though they cost more upfront, their long life and low maintenance make them a smart investment.

Where Are Duplex Anchor Bolts Used in Chemical Plants?

Applications of duplex steel anchor bolts include:

Mounting heavy machines to the floor

Holding down pressure vessels, storage tanks, and reactors

Securing pumps, agitators, and pipe supports

Supporting steel structures, instrument panels, and control systems

Anywhere that needs a strong, secure, and corrosion-proof fastening system — duplex bolts are ideal.

Types of Anchor Bolts Available

Duplex anchor bolts are manufactured in a range of configurations to meet specific structural and installation requirements.

Straight bolts with nuts and washers – Easy to install and remove

Headed anchor bolts – Have a head that locks into concrete

Sleeve anchor bolts are designed to expand within pre-drilled holes, ensuring firm anchorage in concrete or masonry.

Stud bolts – Threaded on both ends, used with nuts

Each type has a specific purpose based on how and where it’s used.

Standards and Specifications

To ensure quality, duplex steel anchor bolts are made according to international standards, including:

ASTM A1082 – For duplex stainless steel fasteners

ASTM F3125 – Structural bolt specification

ISO 898-1 – For mechanical properties

DIN / EN standards – For global compatibility

Installation and Maintenance Tips

Use the correct torque during installation to avoid breaking or loosening the bolt.

Clean the surface before installation to prevent contamination or rust spots.

Use anti-seize compounds on threads to stop galling or thread damage.

Store bolts in a dry, clean area before use.

Conclusion

Duplex Steel Anchor Bolts are a powerful and reliable solution for the demanding needs of chemical processing plants. They offer high strength, long life, and excellent corrosion resistance, even in the most challenging environments. By choosing duplex steel fasteners, plant engineers and operators can avoid costly failures, reduce maintenance, and ensure safe, stable operation.

Whether it’s holding down a reactor or anchoring a large pump, duplex anchor bolts provide the strength and performance that chemical plants can count on.

Frequently Asked Questions (FAQs)

Q1. What’s the difference between Duplex and Super Duplex Anchor Bolts?

Duplex bolts (like S31803) offer strong resistance to corrosion and good strength. Super Duplex bolts, such as S32750, provide superior strength and corrosion resistance, making them perfect for highly corrosive chemical or marine environments.

Q2. Can Duplex Anchor Bolts handle high temperatures?

Yes, they can typically handle temperatures up to 250°C (480°F). For temperatures higher than this, a specialized alloy may be better.

Q3. Are these bolts good for marine or coastal chemical plants?

Absolutely. Duplex steel resists salt and moisture, making it ideal for coastal and offshore environments.

Q4. How are these bolts installed in concrete?

They can be either:

Set into wet concrete during construction, or

Inserted into holes in existing concrete using epoxy adhesives or mechanical expansion systems.

Q5. Are Duplex Steel Anchor Bolts cost-effective?

Yes. Although they may cost more initially, their long lifespan, low maintenance, and reliability make them more economical over time.

#DuplexSteelAnchorBolts#ChemicalPlantFasteners#CorrosionResistantBolts#AnchorBolts#DuplexStainlessSteel#IndustrialFasteners#SuperDuplexBolts#ChemicalIndustryFasteners#AnankaFasteners#FastenersManufacturer#Ananka#manufacturer#fasteners#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Super Duplex Stainless Steel S32760 ERW Pipe Exporters in Saudi Arabia

In the swiftly evolving industrial landscape of Saudi Arabia, the demand for terrific materials that may withstand excessive situations is ever-growing. One of the key players in assembly this call for is the use of exceptional duplex steel pipe. Known for its awesome strength and corrosion resistance, wonderful duplex stainless steel, specifically the first-rate duplex usas32760 grade, is extensively utilized in numerous industries which includes oil and gas, chemical processing, and marine packages. This blog will delve into the specifics of super duplex stainless steel, specializing in its specs, packages, and the prominent exporters, specially Vishal Tube Industries, which has set up itself as a main manufacturer and stockist in this domain.

What is Super Duplex Stainless Steel?

Super duplex stainless steel is a class of stainless steel that combines the beneficial residences of each austenitic and ferritic stainless steels. It is characterized by way of excessive chromium and molybdenum content material, which gives it more desirable mechanical energy and high-quality resistance to pitting, crevice corrosion, and stress corrosion cracking. The first-rate duplex usas32760 is a high instance of this alloy, providing superior overall performance in challenging environments.

Super duplex pipe specification

When discussing the fantastic duplex pipe specification, it is vital to highlight the unique attributes that make terrific duplex united statess32760 stand out:

Chemical Composition:

Chromium: 24-26%

Nickel: 6-eight%

Molybdenum: 3-four%

Copper: zero.Five-1%

Tungsten: 0.Five-1%

Nitrogen: 0.2-zero.3%

Carbon: Max zero.03%

Mechanical Properties:

Yield Strength: ≥550 MPa

Tensile Strength: ≥750 MPa

Elongation: ≥25%

Hardness: Max 28 HRC

Corrosion Resistance:

Excellent resistance to chloride-precipitated pressure corrosion cracking.

High resistance to pitting and crevice corrosion.

Superior preferred corrosion resistance in various acidic and saline environments.

Applications of Super Duplex UNS S32760 Pipes

The strong houses of wonderful duplex steel pipe make it appropriate for a huge variety of programs, specifically in industries wherein sturdiness and resistance to harsh situations are critical. Here are a number of the important thing applications:

Oil and Gas Industry:

Utilized in offshore platforms, subsea systems, and processing facilities.

Ideal for pipelines transporting oil and gas underneath high stress and in corrosive environments.

Chemical Processing:

Used in reactors, heat exchangers, and storage tanks managing aggressive chemical compounds.

Ensures longevity and protection in methods concerning sulfuric, phosphoric, and other sturdy acids.

Marine Applications:

Perfect for shipbuilding and repair, wherein publicity to saltwater and marine environments is a steady undertaking.

Used in desalination flora and marine engineering structures.

Desalination Plants:

Essential in the manufacturing and distribution of potable water from seawater.

Ensures durability and minimum renovation in distinctly corrosive environments.

Vishal Tube Industries: A Leading Manufacturer and Stockist When it comes to sourcing exceptional duplex steel pipe, especially the high-quality duplex United statess32760, they stand proud as a most useful manufacturer and stockist. With a dedicated staff and modern day manufacturing facilities, they ensure their merchandise's best excellence and reliability.

Manufacturing Capabilities

They are geared up with superior manufacturing technology and a pretty professional crew of technocrats, engineers, supervisors, and people. The employer specializes in generating:

Stainless Steel Seamless Tubes

Stainless Welded Tubes

Stainless Steel U-Tubes

Their centers are designed to satisfy stringent enterprise requirements and specs, making sure that every product introduced is top-notch first-class.

Quality Assurance

One of the hallmarks is its dedication to pleasantness. The corporation employs current testing equipment and rigorous nice manipulation measures to make certain that each outstanding duplex steel pipe meets the desired specs. From chemical composition evaluation to mechanical trying out, every factor of the manufacturing system is meticulously monitored.

Global Reach

They serve various shoppers across the globe, along with big and medium-scale industries. Their potential to continually deliver awesome, remarkable duplex United statess32760 pipes has earned them a reputation as a reliable supplier inside the worldwide marketplace.

Stockist and Exporter

As a leading Super Duplex S32750 pipe Stockist, they maintain an in-depth inventory of pipes and tubes, equipped to satisfy the urgent needs of their customers. Their strategic stockholding ensures that they can provide prompt transport and aid for various projects, no matter scale.

Export Expertise

Exporting tremendous super duplex steel pipe to Saudi Arabia and other regions calls for an in-intensity understanding of both technical specifications and logistical necessities. They excel in this area, supplying seamless and green export services. Their expertise ensures that customers acquire their products on time and in perfect situations, ready for immediate use of their respective applications.

Conclusion

In conclusion, the call for excessive-performance materials like incredible duplex stainless steel is on the upward push, particularly in commercial hubs like Saudi Arabia. The superb duplex united statess32760 grade, with its splendid mechanical residences and corrosion resistance, is a perfect preference for numerous hard programs. Vishal Tube Industries, with its superior production talents, stringent excellent control, and great stockholding, stands out as a leading producer and exporter of those crucial materials.

Whether you are in the oil and gas sector, chemical processing, marine applications, or any industry requiring strong and reliable materials, sourcing your remarkable duplex steel pipe from a reputable dealer ensures that you get hold of merchandise that meet the highest requirements of excellence and performance. With a dedication to excellence and an international reach, Vishal Tube Industries maintains to guide and pressure business progress with their top-quality first-rate duplex u.S.A.S32760 pipes.

#super duplex steel pipe#super duplex pipe specification#Super Duplex s32750 pipe manufacturer#Super Duplex s32750 pipe Stockist

0 notes

Text

Super Duplex Pipe Fittings Manufacturer for Industrial Use: Strength, Safety & Sustainability

In the demanding world of industrial operations, the reliability of piping systems is non-negotiable. Whether in oil refineries, chemical plants, marine environments, or desalination facilities, the infrastructure must withstand extreme pressures, corrosive substances, and high temperatures. One material that consistently meets and exceeds these challenges is Super Duplex Stainless Steel — and with it, the need for a trusted Super Duplex pipe fittings manufacturer for industrial use becomes essential.

What Makes Super Duplex Steel So Unique?

Super Duplex stainless steel offers a perfect balance of strength and corrosion resistance. Composed of a dual-phase microstructure (austenitic and ferritic), it outperforms standard stainless steels and Duplex grades in critical industrial environments. This unique composition ensures:

High mechanical strength

Superior corrosion resistance (especially to chlorides)

Excellent weldability and fatigue resistance

Cost-effectiveness through longevity and reduced maintenance

These properties make Super Duplex pipe fittings ideal for use in highly corrosive and high-pressure systems — especially in industries where failure is not an option.

Applications of Super Duplex Pipe Fittings in Industrial Sectors

Super Duplex fittings are widely used across industries including:

Oil & Gas (onshore and offshore)

Petrochemical and Chemical Processing

Marine & Shipbuilding

Desalination Plants

Power Generation

Pulp & Paper

In these settings, fittings must perform under extreme operating conditions. Super Duplex pipe fittings ensure system integrity, reducing the risk of leaks, cracks, and corrosion-related failures.

Why Choosing the Right Manufacturer Matters

Not all fittings are created equal. For performance to match specification, selecting a reputed Super Duplex pipe fittings manufacturer for industrial use is crucial. A quality-focused manufacturer ensures:

Precision machining and dimensional accuracy

Certification to international standards (ASTM, ASME, NORSOK, etc.)

Full traceability and quality documentation

Testing for pressure, corrosion, and durability

By sourcing from a reliable manufacturer, industries gain peace of mind knowing that each fitting is engineered for long-term performance and safety.

Benefits of Super Duplex Fittings in Industrial Use

Extended Service Life: Ideal for long-term operations in aggressive environments

Reduced Maintenance Costs: Thanks to high corrosion resistance

Improved System Safety: Lower risk of failure under mechanical or thermal stress

High ROI: Durable materials lead to fewer replacements and lower lifecycle costs

Conclusion

For industries operating in critical conditions, material reliability can be the difference between smooth operations and costly shutdowns. Super Duplex pipe fittings are a powerful solution that delivers unmatched strength and corrosion resistance — making them indispensable in modern industrial infrastructure. Partnering with a trusted manufacturer ensures you're not just buying components, but investing in long-term operational success.

LPF is a globally recognized manufacturer and supplier of high-performance pipe fittings made from Super Duplex and other specialized alloys. With a commitment to engineering excellence, rigorous quality control, and client-focused service, LPF continues to support some of the world's most demanding industries with reliable and efficient piping solutions.

#super duplex fittings#china#india#duplex & super duplex fittings#Super Duplex pipe fittings#Super Duplex Pipe Fittings manufacturer for Industrial use

0 notes

Text

ICCL Female Pipe Fittings – Designed for High Pressure and Harsh Environments

In today’s industrial landscape, every connection matters. When you're working in high-pressure, corrosive, or hazardous environments, the reliability of your fittings can make a huge difference in system safety, performance, and longevity. That’s where ICCL (Industrial Components & Controls Ltd.) comes in, having built a solid reputation for manufacturing female pipe fittings that are specifically designed to tackle tough conditions across various global industries.

ICCL’s female pipe fittings are crafted to ensure secure, leak-free connections for instrumentation and process piping applications. Made from top-notch materials and precision-engineered, they find their place in sectors like oil & gas, petrochemicals, power generation, and other demanding fields where durability is a must.

What Are Female Pipe Fittings?

Female pipe fittings are threaded connectors that accept male-threaded components, such as pipes, tubes, or valves. They usually come with:

- Internal threads (NPT, BSP, etc.)

- Sturdy construction for high-pressure compatibility

- Leak-tight sealing when paired with a compatible male thread

These fittings play a crucial role in:

- Connecting instrumentation to main pipelines

- Building hydraulic and pneumatic systems

- Assembling gas sampling and pressure monitoring panels

- Installing flow meters, transmitters, and gauges

Why ICCL Female Pipe Fittings Stand Out

ICCL produces high-performance female pipe fittings that meet the toughest industry standards. Here’s what makes them special:

1. Designed for High-Pressure Systems

ICCL female pipe fittings are engineered to handle pressures of up to 6,000 psi and beyond, making them perfect for:

- Oilfield instrumentation

- Gas processing units

- High-pressure steam lines

These fittings maintain their structural integrity and sealing ability, even when faced with extreme mechanical stress and temperature changes.

2. Corrosion-Resistant Materials

ICCL provides fittings in a variety of materials tailored to your service conditions:

- SS316 / SS316L – Offers standard corrosion resistance for general industry

Duplex / Super Duplex – Perfect for offshore, marine, or salty environments.

Inconel, Monel, Hastelloy – The go-to choice for dealing with tough acids, chlorides, or sour gas.

Brass or PTFE-lined – Ideal for non-corrosive or specialized low-pressure situations.

Every batch is fully traceable, guaranteeing metallurgical compliance and long-lasting durability.

3. Precision Machined Threads

Thanks to cutting-edge CNC machining technology, ICCL guarantees tight thread tolerances for a flawless seal. The compatible thread types include:

NPT (National Pipe Tapered)

BSPT (British Standard Pipe Tapered)

BSPP (British Standard Pipe Parallel)

Metric and custom threads available upon request.

This flexibility allows ICCL fittings to seamlessly fit into global systems with minimal adjustments.

4. Zero-Leakage Assurance

All ICCL female fittings undergo rigorous testing for:

Hydrostatic pressure resistance

Air leak and vacuum performance

Dimensional accuracy and gauge fit

The outcome? Leak-tight joints that perform reliably, even under fluctuating pressures or in vibration-heavy environments.

Industrial Applications of ICCL Female Pipe Fittings

ICCL’s female pipe fittings are trusted across a variety of industries and applications:

Oil & Gas

Utilized in wellhead panels, flowlines, and control systems where maintaining pressure integrity is crucial. Their corrosion resistance makes them perfect for offshore and sour gas services.

Power Generation

Found in high-pressure steam and water systems in both thermal and nuclear plants. They can handle temperature shocks and thermal cycling with ease.

Chemical & Petrochemical

Used in reactors, mixing vessels, and dosing systems where fittings need to withstand aggressive media and high-pressure flow.

Water Treatment & Desalination

Employed in pump lines, RO systems, and chemical dosing units. Duplex and Super Duplex fittings are particularly effective for seawater applications.

Pharmaceutical & Food

Used in hygienic process lines where cleanliness and contamination control are paramount. Special surface finishes and materials are available for these specific needs.

Certifications and Compliance

At ICCL, we take pride in ensuring that our female pipe fittings are crafted and rigorously tested to meet international quality and performance standards, which include:

- ISO 9001:2015 – Quality Management Systems

- NACE MR0175 / ISO 15156 – Compliance for sour gas environments

- ASTM / ASME standards for materials and dimensions

- CE / PED certification for pressure equipment

Every product comes with Material Test Certificates (MTCs), pressure test reports, and dimensional verification records, guaranteeing traceability and readiness for audits.

Custom Solutions and Global Reach

ICCL recognizes that every industry and project has its own unique needs. That’s why we offer:

- Custom thread types and lengths

- Special finishes (like electropolishing and PTFE coating)

- Quick prototyping for OEM requirements

- Bulk supply contracts with global EPCs and distributors

With a strong presence in North America, Europe, the Middle East, and Southeast Asia, ICCL is dedicated to supporting industrial operations around the globe with timely deliveries and unwavering quality.

In tough industrial settings where pressure, corrosion, and precision are critical, ICCL female pipe fittings stand as a dependable solution. They’re designed to tackle your most challenging demands and are thoroughly tested to ensure they perform under the harshest conditions.

If your project requires fittings that guarantee leak-proof connections, a long service life, and compatibility across the globe, look no further than ICCL – where engineering excellence meets practical application expertise.

0 notes

Text

How Custom Flanges Can Solve 80% of Your On-Site Compatibility Issues

Ever stood on-site with your team, staring at a pipe that just won’t fit? The specs looked right. The angle seemed okay. But the connection? Off. By a sliver.

Now multiply that by 20 pipe joints across a tight project deadline — and suddenly, that “silver” is a serious setback.

Welcome to the world of on-site compatibility issues, where mismatched pipe ends, uneven surfaces, and non-standard dimensions wreak havoc on industrial timelines. But what if we told you that 80% of these headaches could be avoided with one smart decision?

Custom flanges.

Why Standard Flanges Often Don’t Cut It

In theory, standard flanges are great. They’re readily available, budget-friendly, and follow universal specifications.

In reality?

a. That old pipe was installed years ago with custom specs. b. Your imported machinery uses a different pressure class. c. The orientation needs an angular offset. d. The required material grade isn’t available off-the-shelf.

Now you’re either spending hours modifying parts on-site (not ideal) or calling in urgent replacements (even worse).

Real-World Scenarios Where Custom Flanges Saved the Day

Scenario 1: Offshore Platform Retrofit An oil company was retrofitting pipelines on an offshore rig. Standard flanges weren’t aligning due to corroded pipe ends and mismatched bolt patterns. Solution? Custom flanges machined to match both the old and new equipment specs — saving two weeks of delay and thousands in downtime.

Scenario 2: Food Processing Plant Upgrade A food plant switching to stainless steel pipelines found that their imported equipment used DIN-standard connections while the rest of the plant used ANSI. Solution? Dual-standard custom flanges made the conversion seamless without replacing expensive machinery.

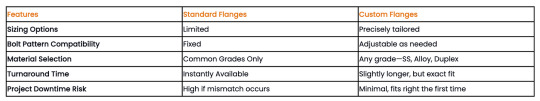

Custom v/s Standard Flanges: A Quick Comparison

How Custom Flanges Solve Compatibility Issues

1. Tailored Dimensions From OD and ID to bolt circle diameter, every spec is customized. No need to force-fit or modify pipe ends.

2. Mixed Standards? No Problem. Need to bridge JIS to ANSI or DIN to BS10? A custom flange can be your translator — engineering-wise.

3. Material Matching for Unique Environments Acidic fluids? High pressure? Extreme temperatures? Choose a custom flange in exotic materials like Inconel, Hastelloy, or Super Duplex.

4. Angular Adjustments and Tapered Ends When alignment is tricky, custom flanges with slight tapers or offset holes solve the issue with surgical precision.

But What About Cost and Time?

We get it — custom sounds expensive. But consider the full picture:

a. Cost of rework b. Labour hours wasted on poor fits c. Downtime penalties d. Delays in commissioning

A one-time custom part can eliminate cascading costs across your entire project.

Still Not Sure? Start Small

If you’re uncertain, begin with just the critical junctions. Let OnlineFittings.com help you spec out custom flanges only where needed. With CNC machining, fast delivery, and material certification — we make custom feel like standard.

Final Thought: Fit First, Fix Later or Never Fix at All?

Currently where industrial efficiency is currency, every misalignment is money lost. Custom flanges don’t just solve problems — they prevent them altogether.

So the next time your project demands precision, think beyond off-the-shelf. Think custom.

Think Online Fittings — where we don’t just deliver steel, we deliver peace of mind.

Tailored. Tested. Trusted.

0 notes

Text

Reducer for Pipe: How It Works in Industrial Piping Systems?

In industrial piping systems, achieving seamless flow transition between pipes of different diameters is critical. This is where a pipe reducer plays a key role. Whether you’re dealing with water lines, chemical systems, or HVAC piping, using the right reducer for pipe ensures efficient flow control and minimizes turbulence.This in-depth guide covers everything about types of reducers, their dimensions, functionality, and why selecting the right reducer pipe type is essential for reliable industrial plumbing.

What Is a Pipe Reducer?

A pipe reducer is a type of pipe fitting used to connect two pipes of different diameters. It reduces or increases the pipe size to meet flow requirements or to adapt to existing piping. It’s an essential component in plumbing, oil & gas, chemical, and process industries. Types of Pipe Reducers Explained Here’s a breakdown of the most common reducer types found in industrial piping: Reducer Type Shape & Centerline Applications Concentric Reducer Cone-shaped, the centerlines of both ends remain aligned Vertical piping, pump discharge, fluid systems Eccentric Reducer Flat on one side, off-centered ends Horizontal piping, to prevent air accumulation Threaded Reducer Has threads for easy screw-in pipe connection Low-pressure systems and domestic plumbing Butt-Weld Reducer Welded to pipes, offers a strong and leak-proof connection High-pressure and temperature piping systems Socket Weld Reducer Fits into pipe sockets, then welded Small-diameter, high-pressure lines Each type of reducer in piping has a specific role depending on alignment needs, flow behavior, and pressure conditions. Concentric vs Eccentric Reducer – What’s the Difference? Concentric Reducer (Reducer Pipe Concentric) Cone-shaped fitting. Used when maintaining the centerline elevation is important. Commonly used in pump discharge lines or vertical pipelines. Eccentric Reducer One side is flat, and the other side is angled. Prevents air pockets in horizontal flow. Ideal for suction lines, especially near pumps, to avoid cavitation. Where Is Super Duplex Stainless Steel Used? Materials and Standards for Pipe Reducers Reducer pipe types, including stainless steel reducers and brass reducers, are manufactured in durable materials. Carbon Steel Stainless Steel Alloy Steel PVC or Plastic Copper or Brass Common Manufacturing Standards: ASME B16.9 – Butt-welded reducers - ANSI B16.11 – Forged socket weld/threaded reducers - ASTM A234 – Steel pipe fittingsThese industry standards ensure compatibility, pressure resistance, and long-term durability for plumbing systems.

Where Are Pipe Reducers Used?

IndustryApplicationOil & GasDownstream pipelines, flow controlHVAC SystemsAir conditioning duct transitionsChemical PlantsAcid or alkali pipelinesFood ProcessingSanitary stainless steel reducersPlumbingDomestic water supply networksIn industrial piping, the selection of plumbing reducers must consider flow rate, media type, pressure rating, and alignment requirements for reliable connections.

How Does a Pipe Reducer Work?

A pipe reducer works by gradually changing the diameter of the pipe to reduce the flow area. This:Minimizes flow turbulence. Prevents cavitation in pump suction lines. Maintains laminar flow and efficient pressure handling. In a reducer in plumbing, this transition is crucial in preventing pipe damage due to abrupt changes in fluid velocity or pressure.

Summary Table – Reducer Types at a Glance

Reducer TypeBest Used InKey AdvantageConcentricVertical pipingCenterline alignmentEccentricHorizontal pipingAir pocket preventionButt-WeldHigh-pressure systemsSeamless and leak-proofThreadedLow-pressure, temporary connectionsEasy installationSocket WeldSmall pipe diametersSecure joint for pressureLook for pipe reducer manufacturers in India with global quality standards and prompt delivery.

Final Thoughts

Choosing the right reducer for pipe is more than just a sizing decision—it's about optimizing fluid dynamics, reducing stress on components, and ensuring system safety. With several types of reducer for pipe available, understanding their design, purpose, and dimension standards helps avoid costly errors in industrial systems.Partner with a trusted supplier to get reducers that are easy to install, compliant with global standards, and built to withstand demanding environments. Read the full article

0 notes

Text

Uses of Bolts for Oil & Gas Pipelines

Introduction

In the oil and gas industry, pipelines serve as the lifelines for transporting crude oil, natural gas, and refined products over long distances. These critical infrastructures demand components that ensure safety, durability, and performance under extreme conditions. Bolts, though small in size, play a vital role in the assembly, integrity, and maintenance of oil & gas pipeline systems.

This blog delves into the importance, various types, and specific applications of bolts in oil and gas pipeline systems.

Importance of Bolts in Oil & Gas Pipelines

Bolts are critical mechanical fasteners that securely connect two or more components. In oil and gas pipeline systems, they serve to:

Secure flange connections

Support valve assemblies

Withstand high pressure and temperature

Resist corrosion from harsh chemicals and environmental conditions

Enable easy maintenance and disassembly

Any failure in bolted joints could result in leaks, production downtime, or safety hazards, making bolt selection and installation critical to pipeline integrity.

Key Applications of Bolts in Oil & Gas Pipelines

1. Flanged Connections

Used to bolt two pipe ends together using gaskets.

Ensure tight sealing in high-pressure, high-temperature environments.

They typically use high-strength stud bolts and nuts in accordance with ASME B16.5 or B16.47 standards.

2. Valve Installation

Bolts attach valves to pipelines, allowing for effective regulation of flow and pressure within the system.

They must withstand frequent operation and significant mechanical stress.

3. Compressor & Pump Stations

They anchor rotating machinery like pumps and compressors to the pipeline system, ensuring stable and reliable operation.

Require vibration-resistant bolts with high tensile strength.

4. Manifolds & Headers

Bolts connect complex pipe networks for distributing or collecting fluids.

Used in both upstream and downstream systems.

5. Pipeline Supports and Anchors

Anchor bolts fix supports that carry the pipeline’s weight and thermal expansion.

Must withstand static and dynamic loads.

Types of Bolts Used in Oil & Gas Pipelines

Stud Bolts

Common in flange connections; used with two nuts

Hex Head Bolts

Used in areas requiring easy access for tightening

Anchor Bolts

Secure pipelines and equipment to concrete foundations

U-Bolts

Support pipes in hangers or saddle mounts

Heavy Hex Bolts

Provide additional contact surface for high-load applications

Material Considerations for Oil & Gas Pipeline Bolts

Pipelines are often exposed to corrosive environments, including:

Sour gas (H₂S presence)

Saline offshore environments

High-temperature fluids

Acids and hydrocarbons

Common Materials Used:

Carbon Steel (B7)

High tensile strength; cost-effective; used in non-corrosive environments

Stainless Steel (316, 304)

Good corrosion resistance; suitable for moderate environments

Duplex / Super Duplex

Excellent corrosion resistance and strength; ideal for offshore use

Inconel / Monel / Hastelloy

For extreme conditions involving acids, heat, or seawater

PTFE or Xylan Coated Bolts

Enhanced resistance against galling and corrosion

Industry Standards for Pipeline Bolts

Bolts used in oil & gas pipelines must meet stringent international standards, such as:

ASTM A193 / A194 – For high-temperature and pressure service

ASME B16.5 / B16.47 – Flange dimensions and bolting

API Standards – For pipeline construction and pressure testing

Conclusion

Though often overlooked, bolts are critical components in the oil and gas pipeline infrastructure. Their correct selection, installation, and maintenance ensure the safety, reliability, and longevity of pipeline systems in some of the world’s harshest environments. From securing flange joints to supporting heavy equipment, bolts must be engineered to withstand extreme mechanical and chemical stresses.

Ananka Group offers a wide range of high-performance bolts that meet the demanding specifications of the oil and gas industry. With precision manufacturing, premium materials, and adherence to international standards, our fasteners are trusted in pipeline projects around the world.

FAQ

Q1: What are the different types of bolts used in oil and gas pipeline systems?The most commonly used bolts include stud bolts with heavy hex nuts, hex head bolts, and anchor bolts, particularly for flange connections, valve installations, and structural support.

Q2: Why is material selection important for pipeline bolts?Pipeline environments involve high pressure, extreme temperatures, and corrosive media like H₂S or saltwater. Material selection ensures the bolts can withstand these conditions without failure, enhancing safety and reliability.

Q3: What standards govern bolts for oil & gas pipeline applications?Key standards include ASTM A193 / A194 for high-pressure and high-temperature bolting, ASME B16.5/B16.47 for flanges, and NACE MR0175/ISO 15156 for sour gas corrosion resistance.

Q4: Are stainless steel bolts suitable for all oil and gas pipeline environments?Not necessarily. While stainless steel offers good corrosion resistance, environments with sour gas or extreme salinity often require more specialized materials like Inconel, Monel, or Super Duplex.

Q5: What types of coatings are applied to pipeline bolts to enhance corrosion resistance?Common protective coatings include PTFE (Teflon), Xylan, hot-dip galvanizing, and zinc plating, which enhance corrosion resistance and ease of installation.

Q6: How are bolt failures prevented in pipeline systems?By using the correct material grade, applying proper torque during installation, following maintenance schedules, and ensuring compliance with relevant engineering standards and certifications.

Q7: What is the role of stud bolts in pipeline flange assemblies?Stud bolts provide even clamping force across the flange face when used with heavy hex nuts, ensuring a leak-proof and secure connection in high-pressure pipeline systems.

Q8: Can coated bolts be used in subsea pipeline systems? Yes, but the coating and base material must be selected carefully. In subsea applications, corrosion-resistant alloys like Super Duplex or Inconel, often coated with PTFE or Xylan, are preferred for longevity and performance.

#OilAndGas#PipelineBolts#IndustrialFasteners#HighStrengthBolts#PipelineConstruction#StudBolts#ASMEBolts#ASTMA193#HeavyHexNuts#AnankaFasteners#BoltsAndNuts#OilAndGasEngineering#Ananka#Articles#Blog#tumblr blog#tumblr

1 note

·

View note

Text

Is Super Duplex Steel Pipe the Right Choice for Your Home?

When it comes to deciding on materials for production, sturdiness, and performance, deciding on the right kind of metallic pipe is important. Super Duplex Steel Pipes have emerged as a leading choice for plenty of packages because of their advanced houses. But are they the proper desire for your own home? Let's dive into the specifics of Super Duplex Steel Pipes, together with splendid duplex pipe specs, tremendous duplex fabric houses, and different key aspects to help you make a knowledgeable decision.

Understanding Super Duplex Steel

Super Duplex Steel, acknowledged for its tremendous corrosion resistance and excessive energy, is a kind of chrome steel that mixes the exceptional attributes of each austenitic and ferritic stainless steels. This specific combination gives a material that is both sturdy and proof against the harshest environments.

Super Duplex Pipe Specifications

Super Duplex Steel Pipes are often classified through particular standards and grades, such as the ASTM A790 UNS S32760 welded pipe. This specification ensures the pipes meet stringent first-class and overall performance requirements, making them appropriate for demanding applications.

Grade: ASTM A790 UNS S32760

Type: Welded Pipe

Diameter: Varies primarily based on software

Thickness: Customizable to fulfill precise needs

Length: Available in standard and custom lengths

These specifications highlight the versatility and robustness of Super Duplex Steel Pipes, making them an exquisite preference for numerous uses.

Super Duplex Material Properties

The exquisite duplex material properties make those pipes stand out within the market. Some of the maximum tremendous houses include:

High Strength: Super Duplex Steel Pipes showcase advanced tensile power, which makes them ideal for excessive-strain applications.

Corrosion Resistance: Their resistance to pitting, crevice corrosion, and pressure corrosion cracking ensures long-lasting performance even within the most harsh environments.

Good Weldability: Despite their excessive electricity, those pipes are especially clean to weld, taking into account flexible set up.

Thermal Conductivity: The thermal conductivity of Super Duplex Steel is better than that of austenitic stainless steels, enhancing its performance in warmness exchangers and other thermal applications.

Durability: These pipes provide fantastic sturdiness, making sure they could withstand harsh situations with out substantial wear and tear.

Super Duplex Stainless Steel Price Per Kg

One of the factors that homeowners and contractors take into account is the price of substances. The excellent duplex stainless-steel charge in step with kg can vary based totally on numerous elements together with the grade, length, and dealer. However, it is essential to view this price within the context of the long-term advantages supplied through the fabric.

While Super Duplex Steel Pipes may have a better prematurely cost compared to other substances, their durability, and minimal protection requirements can lead to massive financial savings through the years. Investing in extremely good Super Duplex Steel Pipes can therefore be a cost-powerful decision in the long run.

Applications in Home Construction

Super Duplex Steel Pipes aren't just for commercial use; they also have numerous applications in home production. Here are a few scenarios in which they is probably the proper preference:

Plumbing Systems: Due to their notable corrosion resistance, those pipes are best for plumbing structures that require long lasting and leak-proof solutions.

Heating Systems: The high thermal conductivity of Super Duplex Steel makes it best for heating structures, making sure green strength switch.

Structural Applications: Their excessive electricity permits them to be used in structural applications, offering dependable support and balance.

Water Treatment: If you have a home water treatment gadget, Super Duplex Steel Pipes can make sure the gadget's toughness and overall performance due to their resistance to corrosion and chemical compounds.

Availability and Export

Vishal Tube Industries is a main manufacturer and exporter of Super Duplex Steel Pipes, ensuring that splendid substances are available to meet the needs of numerous industries and houses globally. As a Super Duplex S32750 Pipe Fittings Exporter, the company guarantees that the fittings meet international requirements and are to be had for diverse programs.

Super Duplex S32760 Pipe Fittings Stockist in Saudi Arabia

For those in Saudi Arabia, finding a reliable dealer of Super Duplex S32760 Pipe Fittings is essential. Vishal Tube Industries shares a wide range of those fittings, ensuring that local wishes are met with the identical stage of great and reliability located globally.

Advantages of Choosing Super Duplex Steel Pipes for Your Home

Longevity: The durability and corrosion resistance of Super Duplex Steel Pipes make certain a longer lifespan in comparison to traditional materials.

Safety: These pipes provide a high stage of protection because of their energy and resistance to leaks and bursts.

Low Maintenance: The advanced homes of Super Duplex Steel result in minimal maintenance necessities, saving time and money in the end.

Aesthetic Appeal: With their smooth finish and high resistance to staining and tarnishing, Super Duplex Steel Pipes also make contributions to the aesthetic enchantment of your own home.

Conclusion

Super Duplex Steel Pipes, with their awesome amazing duplex fabric residences and sturdy extraordinary duplex pipe specs, offer several blessings for home construction. While the incredible duplex stainless steel price according to kg might be higher than a few options, the long-term benefits, which include durability, protection, and coffee upkeep, make them a worthy funding.

Vishal Tube Industries, with its tremendous experience and brand new centers, ensures which you have get admission to to pinnacle-pleasant Super Duplex Steel Pipes and fittings, whether or not you are inside the local marketplace or searching for a Super Duplex S32750 Pipe Fittings Exporter or a Super Duplex S32760 Pipe Fittings Stockist in Saudi Arabia. When considering the quality substances for your house, Super Duplex Steel Pipes stand out as a dependable and efficient desire.

#super duplex pipe specification#super duplex material properties#super duplex stainless steel price per kg#Super Duplex s32750 pipe Fittings Exporter#ASTM a790 uns s32760 welded pipe#Super Duplex s32760 pipe Fittings Stockist in Saudi Arabia

0 notes

Text

Top-Quality Hub Flanges for Industrial Applications

Metallica Forging Inc. is a trusted name among Hub Flanges manufacturers in India. We provide premium-grade flanges designed for maximum efficiency and durability. Our commitment to engineering excellence ensures that each product meets international standards, making us a go-to source for clients in the oil and gas, petrochemical, power, and marine industries. As a reliable Hub Flanges manufacturer, we combine advanced manufacturing technology with high-quality materials to deliver products that perform in demanding environments.

Understanding Hub Flanges and Their Industrial Role

Hub flanges are uniquely designed components that connect pipes and facilitate secure joints in pressurized systems. Characterized by a tapered hub that gradually thickens from the pipe toward the flange face, this design is instrumental in reducing mechanical stress at the joint. When welded to piping systems, hub flanges are commonly referred to as weld neck flanges. They are ideal for high-pressure, high-temperature, and corrosive service conditions.

Their structural integrity makes them a preferred choice for industries where safety, durability, and leak-proof performance are non-negotiable. Whether transporting hazardous chemicals or operating in extreme temperatures, a properly selected and installed hub flange offers unmatched reliability.

As a prominent Hub Flanges manufacturer and supplier in India, we offer a comprehensive range of hub flanges tailored to different pressure classes and applications. These flanges are available in various face types, such as raised face, flat face, and RTJ, and are suitable for both seamless and welded pipes.

Key Materials and Application Sectors

Hub flanges are manufactured using a wide selection of materials, with the choice depending on the operational environment and fluid characteristics. Common options include:

Carbon Steel: Excellent strength and weldability, ideal for general-purpose use

Stainless Steel: Superior corrosion resistance for aggressive chemical or marine environments

Duplex and Super Duplex Steel: High resistance to stress corrosion cracking and pitting, used in offshore and high-load systems

Hub flanges are critical to many applications, especially in:

Oil and gas transportation pipelines

Refineries and chemical processing plants

Thermal, nuclear, and hydro power generation

Desalination and water treatment systems

Marine construction and shipbuilding

These flanges not only ensure operational safety but also support easy dismantling, inspection, and maintenance of connected components.

Advantages of Choosing Hub Flanges from a Trusted Manufacturer

Partnering with an experienced Hub Flanges Supplier in India ensures you receive products that are engineered for longevity, safety, and performance. Some core benefits include:

Enhanced Strength and Load Distribution: The tapered hub design minimizes stress concentration, reducing the risk of failure under pressure.

Superior Sealing Performance: They offer excellent leak prevention, especially in high-pressure applications, improving operational integrity.

Moreover, our flanges undergo stringent quality inspections and testing to maintain global standards. We also offer tailored solutions for non-standard sizes and custom material grades to meet specific industry requirements.

0 notes

Text

36 Inch Gate Valve Guide and Sourcing: NSW Big Size Supplier

The Mighty Flow Controller: Your Complete Guide to 36 Inch Gate Valves

In the world of industrial fluid control, where pipelines resemble superhighways for liquids and gases, 36 Inch Gate Valves stand as critical guardians. These massive valves are engineered for applications demanding high flow capacity, reliable shut-off, and robust performance under extreme conditions. Found in power generation, water treatment, oil & gas transmission, mining, and large-scale chemical processing, selecting the right 36 Gate Valve involves understanding key specifications. This guide dives deep into materials, pressure ratings, connection types, and the landscape of 36 Inch Gate Valve Manufacturers.

Understanding the Scale: Why 36 Inches Matters

The sheer size of a 36 Inch Gate Valve (nominal pipe size – NPS 36, actual outside diameter ~ 914mm) signifies its role in primary transmission lines, main intake/discharge points, and bypass systems for major facilities. Big size Gate Valves like these handle enormous volumes, making their reliability paramount. A failure isn’t just a leak; it can mean significant downtime, environmental risk, and costly repairs. Choosing the correct valve involves careful consideration of several factors.

1. The Backbone: Materials of Construction for 36 Inch Gate Valves

Material selection is fundamental, dictated by the fluid media, temperature, pressure, and environmental conditions (like corrosion potential). Common materials include:

* Carbon Steel (WCB, WCC, LCC): The most prevalent choice for 36 Gate Valves handling water, oil, steam, gas, and general service applications. Offers excellent strength and cost-effectiveness. ASTM A216 grades are standard.

* Stainless Steel (CF8/304, CF8M/316, CF3/304L, CF3M/316L): Essential for corrosive environments, high-purity applications (food, pharma), or elevated temperatures. Type 316/L offers superior chloride resistance. ASTM A351/A743 grades.

* Duplex & Super Duplex Stainless Steel (CD3MN/31803, CD3MWCuN/32750, etc.): Provide exceptional strength (twice that of 316 SS) and outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC), especially in seawater, chemical, and offshore oil & gas applications. Crucial for demanding Big size Gate Valves.

* Alloy Steels (WC6, WC9, C5, C12): Used for high-temperature and high-pressure steam service (power plants) or specific corrosive services where carbon steel falls short. Often conform to ASTM A217.

* Special Alloys (Monel, Inconel, Hastelloy): Employed for highly specialized, aggressive chemical services or extreme temperatures, though less common at this size due to cost.

* Trim Materials: The internal parts (seat, gate, stem) often require harder or more corrosion-resistant materials than the body. Common trims include 13% Cr, 316 SS, Stellite, Monel, or Inconel overlays/seats depending on service.

2. Containing the Force: Pressure Ratings for 36 Inch Gate Valves

Pressure rating defines the maximum allowable pressure the valve body and internals can safely withstand at a given temperature. For 36 Inch Gate Valves, common pressure classes include:

* ASME Class 150: Suitable for low to moderate pressure applications (e.g., cooling water, low-pressure steam, some process fluids).

* ASME Class 300: A very common rating for 36 Gate Valves in process industries, oil & gas pipelines (mid-stream), and power plants, handling medium pressures.

* ASME Class 600: Used for higher pressure services common in upstream oil & gas production, refining, and high-pressure steam.

* ASME Class 900 & 1500lb: Required for very high-pressure applications, such as wellheads, critical process lines, or high-pressure gas transmission. Valves at these classes and 36 Inch Gate Valve dimensions become significantly heavier and more complex.

Important Note: The actual pressure a 36 Inch Gate Valve can handle decreases as temperature increases. Always refer to the specific valve manufacturer’s pressure-temperature rating charts based on the material.

3. Joining the Line: Connection Types for 36 Inch Gate Valves

Integrating a massive valve requires robust connection methods:

* Flanged Ends (RF, RTJ): The *most common* connection for 36 Inch Gate Valves. Allows for bolting between pipeline flanges, facilitating installation, maintenance, and potential removal.

* Raised Face (RF): Uses a gasket compressed between raised faces. Standard for many applications.

* Ring Type Joint (RTJ): Uses a metal ring gasket seated in machined grooves. Essential for high-pressure and high-temperature services (Class 600 and above, common in oil & gas) as it provides a superior seal.

* Butt Weld Ends (BWE): The valve body ends are beveled to match the pipe and welded directly into the pipeline. This creates a permanent, leak-proof connection ideal for high-integrity, high-pressure, high-temperature, or hazardous fluid services where disassembly is rare. Reduces potential leak points compared to flanges. Common in critical power plant steam lines or subsea applications.

* Other Types (Less Common at 36″): Mechanical joint (MJ) or grooved ends are rarely used at this size due to pressure limitations.

4. Sourcing Giants: 36 Inch Gate Valve Manufacturers and Suppliers

Manufacturing Big Size Gate Valves requires specialized foundries, machining centers, testing facilities, and significant engineering expertise. The market includes:

* Established Global Industrial Valve Giants: Companies like Emerson (Fisher), Flowserve, Velan, KITZ, Bray, NSW Valve, Cameron/ Schlumberger, IMI Critical, Spirax Sarco, and Crane have extensive experience and global reach in producing high-quality

36 Inch Gate Valves. They offer broad material options, pressure ratings, and connection types.

* Specialized Large Valve Manufacturers: Some manufacturers focus specifically on Big size Gate Valves and specialize in bespoke solutions for extreme pressures, temperatures, or corrosive services.

* Regional/National Manufacturers: Many countries have strong regional players capable of producing reliable 36 Inch Gate Valves for standard applications, often offering competitive pricing.

* The Role of Suppliers: 36 Inch Gate Valve Suppliers (distributors, stockists, engineering procurement companies) play a vital role. They aggregate inventory from various 36 Inch Gate Valve Manufacturers, provide local sales/support, offer faster delivery on standard specs, and assist with selection and sourcing specialized valves. Look for suppliers with technical expertise and a strong logistics network capable of handling these massive components.

5. Understanding Investment: 36 Inch Gate Valve Price Factors

The 36 Inch Gate Valve Price is highly variable and depends significantly on:

* Material: Carbon steel is the most economical. Stainless steel commands a premium. Duplex/Super Duplex and exotic alloys are substantially more expensive.

* Pressure Class: Higher pressure ratings (Class 600, 900, 1500, 2500) drastically increase cost due to thicker walls, heavier components, and more complex manufacturing/testing.

* Connection Type: Butt weld valves often have a lower base cost than flanged valves (no flanges/casting), but installation welding costs must be considered. RTJ flanges add cost over RF.

* Trim: Specialized trim materials (Stellite, hard alloys) significantly increase price.

* Manufacturer Brand & Origin: Valves from major global OEMs typically cost more than those from regional manufacturers. Country of manufacture also influences price.

* Quantity & Lead Time: Single valves cost more per unit than bulk orders. Expedited manufacturing adds cost.

* Specifications & Testing: Compliance with stringent specs (API 600, API 6D, NACE MR0175/MR0103) or additional testing (Fugitive Emission testing per ISO 15848, Shell MESC SPE 77/312) increases cost.

* Actuation: Large 36 Gate Valves often require powerful electric, pneumatic, or hydraulic actuators, which can sometimes cost as much as or more than the valve itself.

*As a very rough indication,* expect a basic carbon steel, Class 150, flanged 36 Inch Gate Valve to start in the tens of thousands of US dollars. Prices escalate rapidly with higher pressure, exotic materials, special trims, and actuation, easily reaching hundreds of thousands.

Choosing the Right Partner: Beyond Just the 36 Inch Gate Valve Dimensions

Selecting a 36 Inch Gate Valve is a major capital decision. Beyond just matching the 36 Inch Gate Valve dimensions (face-to-face, flange dimensions per ASME B16.10/B16.5), consider:

* Application Criticality: How vital is absolute reliability and zero leakage?

* Total Cost of Ownership (TCO): Factor in purchase price, installation costs, maintenance requirements, potential downtime costs, and expected lifespan.

* Manufacturer/Supplier Reputation & Support: Proven track record, engineering support, quality certifications (ISO 9001, API Q1), warranty, and after-sales service are crucial.

* Compliance: Ensure the valve meets all relevant industry standards and regulatory requirements.

Conclusion: Mastering Large-Scale Flow Control

The 36 Inch Gate Valve is an engineering marvel designed for the most demanding flow control tasks. Successfully deploying these giants requires a deep understanding of material compatibility, pressure requirements, connection methodology, and the capabilities of different 36 Inch Gate Valve Manufacturers and Suppliers. While the 36 Inch Gate Valve Price represents a significant investment, selecting the optimal valve based on rigorous specifications ensures long-term reliability, safety, and operational efficiency for critical infrastructure handling massive volumes. When dealing with Big size Gate Valves, partnering with experienced engineers and reputable suppliers is not just advisable – it’s essential.

0 notes