#Manufacturing Line Optimization Tools

Explore tagged Tumblr posts

Text

⚙️ Tool Balancer Market Forecast to Reach $762.8 Million by 2035 Amid Growing Demand in Manufacturing & Automotive Sectors

The global Tool Balancer market is poised to grow from $358.7 million in 2024 to $762.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/tool-balancer-market-research-report

Tool balancers are vital in reducing operator fatigue and improving workflow efficiency across applications such as manufacturing assembly lines, automotive maintenance, warehouse operations, and biomedical equipment handling. The report explores market expansion across dimensions like Product Type, Application, Technology Integration, and Load Capacity.

🔍 Competitive Landscape & Industry Trends

The Tool Balancer market is highly competitive, with top players focusing on innovation, durability, and ergonomic safety. Leading companies include:

Ingersoll Rand

Carl Stahl

Gleason Reel (Hubbell)

Conductix-Wampfler

Tractel

Aero-Motive (Woodhead, A Molex Company)

Hangzhou Tangcheng

POWERMASTER

James Walker

Fasten Enterprises

NAC-InterCom

TE Connectivity

Key drivers fueling market expansion include the evolution of Industry 4.0, growing automation needs, and heightened emphasis on operator safety and fatigue reduction.

🌍 Global Outlook & Demand Hubs

Major growth opportunities lie in:

Rapid industrialization in emerging economies

Technological innovations in smart lifting systems

Strategic partnerships for equipment standardization

Demand is particularly strong in the U.S., Germany, China, Japan, and the UK, with Indonesia, Chile, and South Africa emerging as attractive markets for Total Addressable Market (TAM) expansion.

🔄 Supply Chain Evolution

With North America and Asia-Pacific leading in adoption, the Tool Balancer market’s supply chain—ranging from raw material procurement and precision manufacturing to global distribution—is expected to grow in complexity and resilience.

Challenges such as limited awareness in smaller markets and high upfront costs are being addressed through educational outreach, cost-competitive innovation, and after-sales support strategies.

🧠 About DataString Consulting

DataString Consulting delivers actionable market intelligence through tailored B2B and B2C research projects. With over 30 years of combined experience, our experts track and analyze fast-evolving segments across 15+ industries worldwide to help clients navigate strategic decisions with precision and confidence.

#Tool Balancer Market Forecast#Industrial Tool Balancers#Manufacturing Line Optimization Tools#Automotive Assembly Equipment#Ergonomic Lifting Solutions#Load Handling Equipment#Industrial Safety Tools#Assembly Line Support Devices#Warehouse Equipment Market#Smart Balancing Systems#DataString Market Insights#Global Manufacturing Tools Trends

1 note

·

View note

Text

Common Electrical Issues That a High-Quality Current Transformer Can Prevent

In today’s fast-paced industrial world, electrical reliability is more crucial than ever. A small error in current measurement can lead to serious system failures, downtime, and costly repairs. This is where high-quality current transformers (CTs) make a huge difference. But what exactly can a superior CT prevent? Let’s dive in.

What Is a Current Transformer?

A current transformer (CT) is an essential device used to measure alternating current (AC) by producing a scaled-down, manageable current for meters, relays, and other instruments. It enables safe monitoring and accurate metering in high-voltage environments, protecting both equipment and personnel.

Common Electrical Problems a High-Quality CT Can Prevent

1. Overloading and Equipment Failure

Problem: Without accurate current measurement, systems can easily become overloaded, causing motors, transformers, and cables to overheat.

How a CT Helps: A precision CT ensures real-time, reliable current monitoring. It detects overcurrent conditions immediately, allowing protective relays to trip and prevent expensive equipment damage.

2. Inaccurate Energy Billing

Problem: Incorrect current readings can lead to wrong billing, causing businesses to either overpay for energy or face disputes with utilities.

How a CT Helps: High-accuracy CTs provide precise energy data for billing and cost allocation, especially critical in commercial complexes, factories, and power plants.

3. Protection Relay Malfunction

Problem: If a CT delivers incorrect signals, protection relays may not operate during faults, leading to extended damage and system blackouts.

How a CT Helps: Reliable CTs ensure protection relays receive the correct fault current levels, enabling fast and accurate circuit isolation.

4. Short Circuits Going Undetected

Problem: A minor fault can escalate into a full-blown short circuit if the protection system doesn’t detect it early.

How a CT Helps: Quality CTs capture even small fault currents, triggering alarms or shutdowns before damage spirals out of control.

5. Phase Imbalance Issues

Problem: Imbalanced phases cause excessive heating, motor inefficiency, and damage to sensitive equipment.

How a CT Helps: High-precision CTs monitor each phase accurately, enabling detection of phase unbalance conditions early and preventing system inefficiencies.

6. Harmonic Distortions and Power Quality Problems

Problem: Harmonic distortions interfere with the performance of sensitive equipment and reduce the overall power quality.

How a CT Helps: Specialized CTs can detect abnormal waveform distortions, enabling corrective action through harmonic filtering or load balancing.

Why Invest in a High-Quality Current Transformer?

Accuracy: Achieve metering-class precision essential for both billing and protection. Durability: Longer lifespan even in harsh industrial environments. Safety: Better insulation, thermal stability, and overload capacity. Compliance: Meets international standards like IEC and ANSI.

How Enza Electric Ensures CT Excellence

At Enza Electric, we specialize in manufacturing current transformers built with precision, reliability, and global standards compliance. Whether you need CTs for commercial metering, industrial protection, or utility-scale power distribution, our solutions guarantee unmatched performance.

Customizable options for various ratings High dielectric strength for safety Long service life even in extreme conditions

Explore our Current Transformer Range

Final Thoughts

A high-quality current transformer isn’t just a tool — it’s a first line of defense for your electrical system. Investing in precision-engineered CTs prevents common electrical issues, boosts system longevity, ensures accurate billing, and improves overall operational safety.

If you’re serious about protecting your infrastructure and optimizing performance, choosing Enza Electric’s current transformers is a smart move.

7 notes

·

View notes

Text

fundamentally you need to understand that the internet-scraping text generative AI (like ChatGPT) is not the point of the AI tech boom. the only way people are making money off that is through making nonsense articles that have great search engine optimization. essentially they make a webpage that’s worded perfectly to show up as the top result on google, which generates clicks, which generates ads. text generative ai is basically a machine that creates a host page for ad space right now.

and yeah, that sucks. but I don’t think the commercialized internet is ever going away, so here we are. tbh, I think finding information on the internet, in books, or through anything is a skill that requires critical thinking and cross checking your sources. people printed bullshit in books before the internet was ever invented. misinformation is never going away. I don’t think text generative AI is going to really change the landscape that much on misinformation because people are becoming educated about it. the text generative AI isn’t a genius supercomputer, but rather a time-saving tool to get a head start on identifying key points of information to further research.

anyway. the point of the AI tech boom is leveraging big data to improve customer relationship management (CRM) to streamline manufacturing. businesses collect a ridiculous amount of data from your internet browsing and purchases, but much of that data is stored in different places with different access points. where you make money with AI isn’t in the Wild West internet, it’s in a structured environment where you know the data its scraping is accurate. companies like nvidia are getting huge because along with the new computer chips, they sell a customizable ecosystem along with it.

so let’s say you spent 10 minutes browsing a clothing retailer’s website. you navigated directly to the clothing > pants tab and filtered for black pants only. you added one pair of pants to your cart, and then spent your last minute or two browsing some shirts. you check out with just the pants, spending $40. you select standard shipping.

with AI for CRM, that company can SIGNIFICANTLY more easily analyze information about that sale. maybe the website developers see the time you spent on the site, but only the warehouse knows your shipping preferences, and sales audit knows the amount you spent, but they can’t see what color pants you bought. whereas a person would have to connect a HUGE amount of data to compile EVERY customer’s preferences across all of these things, AI can do it easily.

this allows the company to make better broad decisions, like what clothing lines to renew, in which colors, and in what quantities. but it ALSO allows them to better customize their advertising directly to you. through your browsing, they can use AI to fill a pre-made template with products you specifically may be interested in, and email it directly to you. the money is in cutting waste through better manufacturing decisions, CRM on an individual and large advertising scale, and reducing the need for human labor to collect all this information manually.

(also, AI is great for developing new computer code. where a developer would have to trawl for hours on GitHUB to find some sample code to mess with to try to solve a problem, the AI can spit out 10 possible solutions to play around with. thats big, but not the point right now.)

so I think it’s concerning how many people are sooo focused on ChatGPT as the face of AI when it’s the least profitable thing out there rn. there is money in the CRM and the manufacturing and reduced labor. corporations WILL develop the technology for those profits. frankly I think the bigger concern is how AI will affect big data in a government ecosystem. internet surveillance is real in the sense that everything you do on the internet is stored in little bits of information across a million different places. AI will significantly impact the government’s ability to scrape and compile information across the internet without having to slog through mountains of junk data.

#which isn’t meant to like. scare you or be doomerism or whatever#but every take I’ve seen about AI on here has just been very ignorant of the actual industry#like everything is abt AI vs artists and it’s like. that’s not why they’re developing this shit#that’s not where the money is. that’s a side effect.#ai#generative ai

9 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

20 notes

·

View notes

Text

Understanding the Difference Between a Welding Jig and a Welding Fixture

In manufacturing and fabrication, welding is a critical process that joins materials to create structures, components, and products. Specialized tools like welding jigs and fixtures are often employed to ensure precision, efficiency, and consistency in welding. While these terms are sometimes used interchangeably, they serve distinct purposes and have unique characteristics. Understanding the difference between a welding jig and a welding fixture is essential for optimizing production processes and achieving high-quality results.

What is a Welding Jig? A welding jig is a specialized tool designed to hold and position workpieces in a specific orientation during the welding process. Its primary function is to ensure that the parts being welded are aligned correctly, reducing the risk of errors and improving accuracy. Jigs are often customized for a particular workpiece or assembly, making them ideal for repetitive tasks where consistency is key.

One of the defining features of a welding jig is its ability to guide the welding tool, such as a torch or electrode, along a predetermined path. This guidance ensures that the weld is applied precisely where it is needed, minimizing deviations and enhancing the overall quality of the weld. Jigs are commonly used in applications where tight tolerances and exact alignment are critical, such as in the aerospace or automotive industries.

What is a Welding Fixture? A welding fixture, on the other hand, is a device used to securely hold and support workpieces during the welding process. Unlike a jig, a fixture does not typically guide the welding tool. Instead, its primary role is to stabilize the workpiece, preventing movement or distortion caused by heat or mechanical forces during welding. Fixtures are often designed to accommodate a range of similar workpieces, making them more versatile than jigs in some cases.

Fixtures are particularly useful in high-volume production environments where speed and efficiency are prioritized. By holding the workpiece in place, fixtures allow welders to focus on the welding process itself, reducing the likelihood of errors and improving productivity. Additionally, fixtures can help manage thermal expansion and contraction, which are common challenges in welding.

Key Differences Between Jigs and Fixtures Functionality: The most significant difference between a welding jig and a welding fixture lies in their functionality. A jig is designed to guide the welding tool and ensure precise alignment of the workpiece, while a fixture is focused on holding the workpiece securely in place.

Customization: Jigs are often highly customized for specific tasks or workpieces, making them ideal for specialized applications. Fixtures, while still customizable, are generally more adaptable and can be used for a broader range of similar workpieces.

Complexity: Jigs tend to be more complex in design due to their dual role of positioning and guiding. Fixtures, by contrast, are typically simpler, as their primary purpose is to provide stability.

Application: Jigs are commonly used in industries where precision is paramount, such as aerospace or medical device manufacturing. Fixtures are more prevalent in high-volume production settings, such as automotive assembly lines.

Cost: Because of their specialized nature, jigs are often more expensive to design and produce than fixtures. Fixtures, being more versatile and less complex, are generally more cost-effective for large-scale operations.

Choosing the Right Tool for the Job The choice between a welding jig and a welding fixture depends on the project’s specific requirements. If precision and alignment are critical, a jig is likely the better choice. However, if the primary need is to stabilize the workpiece and improve efficiency, a fixture may be more appropriate. In some cases, a combination of both tools may be used to achieve the desired results.

In conclusion, while welding jigs and fixtures share the common goal of improving the welding process, they serve distinct roles and offer unique benefits. By understanding their differences, manufacturers can make informed decisions that enhance productivity, quality, and overall success in their welding operations.

2 notes

·

View notes

Text

Nike Pegasus Premium

Nike continues to push the boundaries of performance technology with the Nike Pegasus Premium, featuring the brand’s first sculpted, visible Air Zoom unit. As the company’s most versatile cushioning technology, Nike Air has always aimed to enhance athletes’ performance, and with this new release, Nike raises the bar even higher.

Designed with the same ambition behind Nike’s most innovative Air creations, the Pegasus Premium redefines Air Zoom cushioning. The sculpted Air Zoom unit spans from the forefoot to the heel, creating a seamless transition from heel strike to toe-off. This cutting-edge design allows for a smooth, efficient run by providing responsive cushioning that propels runners forward.

For decades, Nike has built on flat Air Zoom units to offer full energy return. But with advances in computational design, AI, and rapid prototyping, Nike designers can now shape Air units to mirror the contours of the foot. This results in greater energy efficiency and performance, offering an entirely new running experience.

The Pegasus Premium also features Nike’s proprietary ZoomX foam in the midsole and ReactX foam in the heel. This combination creates a dynamic cushioning system that delivers a smooth, propulsive ride, optimizing energy return over long distances. In fact, the unique Air Zoom unit and foam placement in the Pegasus Premium provide more energy return than any previous model in the Pegasus line.

For Kathy Gomez, Nike’s VP of NXT Footwear, the Pegasus Premium represents more than just a technological breakthrough—it’s a way to make world-class cushioning accessible to all runners, unlocking the full potential of Air Zoom.

“Air is Nike’s differentiator in the footwear industry—no one else can create cushioning innovations like we do,” says Gomez. “By combining Air with midfoot plates and proprietary foams, we’ve created a performance system that’s second to none. With the Pegasus Premium, we want runners to maximize energy return from the sculpted Air Zoom unit, which not only functions as a spring-like mechanism but engages the entire foot, regardless of gait or stride.”

Nike’s design, engineering, and science teams, including those at Nike Air Manufacturing Innovation, the Nike Running team, and the Nike Sport Research Lab, collaborated to develop this new underfoot sensation. Tools like finite element analysis helped predict the sculpted Air unit’s response to the repeated impact of running, ensuring it would perform at the highest level.

The upper of the Pegasus Premium is engineered with a circular knit for a secure fit, with additional reinforcements in the forefoot to provide targeted support during runs. The same dynamic midfoot system from the Pegasus line ensures stability and comfort throughout.

A true reflection of Nike’s ongoing innovation, the Pegasus Premium showcases the power of its Air technology and its ability to serve athletes at all levels.

The Nike Pegasus Premium is now available globally at nike.com and select retail partners.

4 notes

·

View notes

Text

Northrop Grumman releases update on the program and progress of the B-21 Raider

Fernando Valduga By Fernando Valduga 09/192023 - 6:00 p.m. in Military

At last week's Air, Space and Cyber Conference of the Association of Air and Space Forces, the leadership of the U.S. Air Force and the Department of Defense discussed the B-21 program in terms of effective program management, production readiness, and early integration of support elements as fundamental to the effective delivery of operational capacity.

In addition, the U.S. Air Force announced that Northrop Grumman has driven the B-21 engines, a significant milestone in the aircraft's ground testing program. Although the first flight of the B-21 is a data-driven event closely monitored by Northrop Grumman and the U.S. Air Force, key decisions and programmatic strategies are putting the program in a positive position in the future.

Production representative aircraft

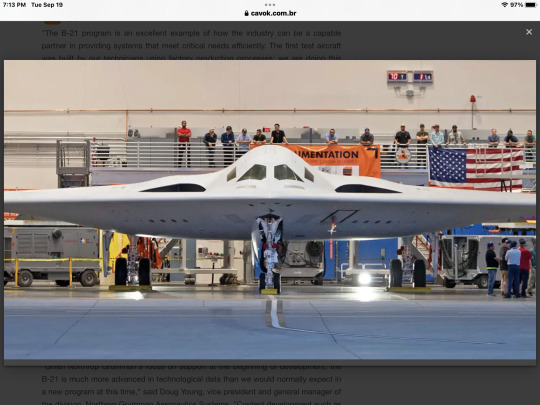

A key to the overall program strategy established from the beginning was to build a first test article representative of production. Instead of a prototype, the first test article of the B-21 Raider was built with rigorous production processes on the same manufacturing line with the same tools that will be used to continue to shape the B-21 fleet. Exclusive to aircraft development programs, the first test article of the B-21 is equipped with its primary mission systems, such as communication and navigation systems.

The decision to build a highly representative test vehicle will allow Northrop Grumman and USAF to conduct a robust flight test campaign and discover what is necessary, in alignment with the program's execution strategy from the beginning.

"The B-21 program is an excellent example of how the industry can be a capable partner in providing systems that meet critical needs efficiently. The first test aircraft was built by our technicians using factory production processes; we are doing this learning and refinement in parallel, which will allow us to reach a stable and constant production more quickly," said Tom Jones, president of the sector of Northrop Grumman Aeronautics Systems.

Support influencing design

In addition to focusing on production in the early stages of the program, the B-21 program took into account the support during the design phase. In addition to boosting long-term efficiency, this approach also produces more short-term benefits.

“Given Northrop Grumman's focus on support at the beginning of development, the B-21 is much more advanced in technological data than we would normally expect in a new program at this time,” said Doug Young, vice president and general manager of the division, Northrop Grumman Aeronautics Systems. "Content development such as product support, material preparation and training is well underway, giving the B-21 an initial advantage in support and support operations before delivery to the user community."

Proven fidelity of the digital model

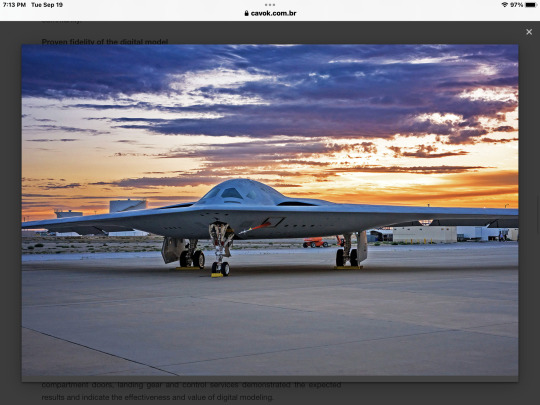

Developed with a digital line throughout the life cycle of the program, the B-21 Raider uses the latest in digital tools and resources, from design to development and testing and, finally, in support. This focus on the B-21 digital ecosystem, along with investment in laboratories and testing facilities, allowed the Northrop Grumman team to digitally model the B-21's performance before physical movements or needs.

As the B-21 undergoes several ground tests, digital models are surpassing industry standards with twice the accuracy. This is evident in the initial tests, with the first test article presenting the expected performance; the tests of the engines, weapon compartment doors, landing gear and control services demonstrated the expected results and indicate the effectiveness and value of digital modeling.

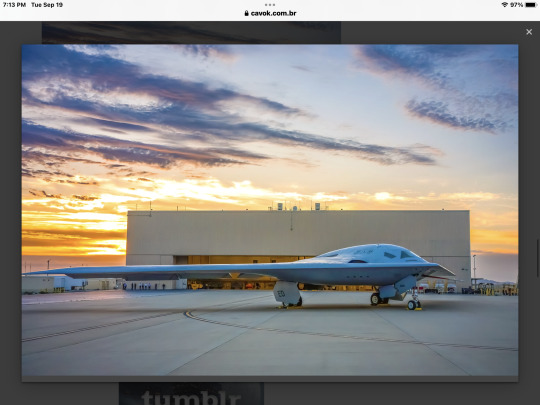

Defining the capacity of the sixth generation

The B-21 Raider is the world's first sixth-generation aircraft, supported by decades of experience in stealth technology and optimized for cutting-edge threat environments. With its open architecture and cloud technology application, the B-21 Raider was built for seamless incorporation of software updates and new features. Northrop Grumman has already demonstrated that the B-21 will be able to integrate third-party technology, supporting the maximum focus of the program on modernization and the need to keep the weapons system at the forefront of future threats.

The new approach of the program to the execution of the program, together with the effective application of digital technologies, demonstrates a focus on delivering exceptional capacity, effectively and efficiently.

Tags: Military AviationB-21 RaiderNorthrop GrummanUSAF - United States Air Force / U.S. Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work throughout the world of aviation.

Related news

MILITARY

Philippine Air Force introduces Cessna C-208B surveillance aircraft donated by the U.S.

19/09/2023 - 14:00

HELICOPTERS

IMAGES: Bell presents the Czech AH-1Z and UH-1Y combat helicopters

19/09/2023 - 12:00

MILITARY

Paramount declares first Mwari operational and reveals additional sales for two operators

19/09/2023 - 09:00

MILITARY

Australia will upgrade the P-8A Poseidon fleet and acquire the fourth MQ-4C Triton

19/09/2023 - 08:14

AIRCRAFT ACCIDENTS

Wreckage of the U.S. Marine Corps F-35B jet is found in South Carolina

18/09/2023 - 23:26

MILITARY

VIDEO: USAF receives the first T-7A Red Hawk in the production standard

09/18/2023 - 19:30

21 notes

·

View notes

Text

Why Poly Bags Are Essential for Retail and Industrial Packaging

In the world of packaging, few tools can compare to the versatility and utility of poly bags. From retail businesses to industrial sectors, these unassuming plastic sacks are essential for modern packaging solutions. But beyond their common use, poly bags offer a multitude of benefits across various industries. Whether you’re in retail, manufacturing, food, healthcare, agriculture, or event planning, understanding the importance of poly bags—and why they’re crucial—can optimize your operations and improve your bottom line.

Understanding Poly Bags

Poly bags, short for polyethylene bags, are made from a type of plastic known for its durability and flexibility. They come in various sizes, thicknesses, and designs, including open flat bags, gusseted bags, zipper bags, and more. Their adaptability to different packaging needs makes them an ideal choice for a wide range of applications.

The Benefits of Using Poly Bags

1. Versatility Across Industries

Poly bags cater to diverse needs, making them a staple in industries like retail, food, and healthcare. In retail, they serve as an economical packaging option for clothes, electronics, and hardware. In the food sector, their food-safe properties make them ideal for storing perishables safely. Healthcare sectors utilize them for sterile packaging of medical supplies, ensuring contamination-free storage.

2. Cost-Effective Solution

One of the main advantages of poly bags is their cost-effectiveness. Their lightweight nature reduces shipping costs, while their affordability makes them a budget-friendly option for businesses looking to optimize their packaging expenses without compromising quality.

3. Durability and Protection

Poly bags provide an unsurpassed level of protection for products against dirt, moisture, and damage during transportation and storage. The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags, for instance, boast extra strength and durability. Their 1 mil thickness ensures that even delicate items remain intact and protected.

4. Customization Options

Businesses can customize poly bags with logos, designs, and branding, offering a unique marketing opportunity. Custom-printed poly bags help reinforce brand identity and enhance the customer experience by adding a professional touch to packaging.

5. Eco-Friendly Options

In response to growing environmental concerns, many manufacturers now offer eco-friendly poly bag options made from biodegradable or recyclable materials. These alternatives allow businesses to maintain their commitment to sustainability while still enjoying the benefits of traditional poly bags.

Applications of Poly Bags in Key Industries

Retail Businesses

Retailers benefit from poly bags' affordability and convenience, using them for packaging clothing, accessories, and other merchandise. Their transparency allows customers to view products easily, enhancing the shopping experience.

Manufacturers and Distributors

For manufacturers and distributors, poly bags streamline the packaging process with their versatile application in bulk storage, transportation, and protection against environmental elements.

Food Industry

Poly bags play a critical role in the food industry, meeting all food safety requirements. The food-grade quality of bags like the InfinitePack ensures safe storage of perishables, snacks, or prepared meals.

Healthcare and Pharmaceutical Industry

In healthcare, sterile packaging is crucial. Poly bags provide a hygienic solution for storing medical instruments, supplies, and pharmaceuticals, reducing the risk of contamination.

Agriculture and Landscaping

Farmers and landscapers use poly bags for seed storage, plant protection, and packaging fertilizers. Their durability withstands the rigors of outdoor conditions, ensuring the integrity of agricultural products.

Event Planners and Marketers

For event planners and marketers, poly bags offer a convenient way to package promotional materials, giveaways, and event supplies. Customizable options also allow for branded packaging that enhances event visibility.

Highlighting InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags

The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags serve as an excellent example of the versatility and efficiency of poly bags. Here are some key features and benefits:

Exceptional Value & Quality: Made from high-quality materials, providing extra strength and durability.

Stock Up for Any Occasion: Perfect for a variety of uses, from holiday treats to small item storage.

Perfectly Sized & Durable: Measuring 18" x 24" with a sturdy 1 mil thickness, they cater to multiple needs.

Food-Grade & Safe: Certified food-safe to meet all storage requirements, with options for heat sealing or twist tie closure.

Multi-Purpose Utility: Suitable for storing food, organizing supplies, and protecting items from dust and damage.

2 notes

·

View notes

Text

Factory Management Software (F-VAPP) for Valves Maintenance & Manufacturing Factories and Workshops. 🖥 ------ Revolutionize your valve production and maintenance with F-VAPP—a comprehensive factory management software designed by industry experts who understand the specific needs of the valves manufacturing world. F-VAPP is not just a tool, it's a fully integrated solution that enhances every aspect of your factory’s operations. 📈 ------ Hosted securely on your internal server, F-VAPP provides role-based access for every department, ensuring seamless workflows. It’s more than just software—it’s a complete management system that knows how to prioritize and automate daily operations for each machine and section. F-VAPP deeply understands the intricate processes of valve manufacturing and maintenance, making sure every task is executed efficiently with priorities clearly in place. ---- Why F-VAPP? ---- 1- Tailor-made for the valves industry, considering every detail in production and maintenance. 2- Automated daily operations for machines and departments, prioritizing workflows for maximum efficiency. 3- Real-time production line monitoring and machine load management to optimize operations. 4- Full control over inventory management and cost automation for smart financial planning. 5- User-friendly yet powerful interface that’s simple to navigate and efficient for everyday use. 6- Comprehensive reporting tools for actionable insights and informed decision-making. 7- Streamlined processes through custom roles and permissions, helping you build a clear organizational chart and strong operational workflows. 8- Enhanced collaboration between departments, improving overall productivity and quality management. ---- With F-VAPP, your factory’s operations aren’t just managed—they’re optimized. From inventory control to production management, every function is fine-tuned for efficiency and performance. ---- Key Benefits: ---- 1- Boost productivity by ensuring smooth, prioritized workflows for machines and workers. 2- Gain real-time insights into machine performance, production schedules, and factory output. 3- Automate complex processes like costing, pricing, and inventory management. 4- Seamlessly integrate departments, improving quality control and production planning. 5- Build the perfect organizational structure with clear roles and responsibilities. 6- Generate detailed reports to guide smarter business decisions. ---- F-VAPP goes beyond software. It’s a full-scale factory management system built to meet the specific needs of the valves manufacturing and maintenance industry. Take your operations to the next level with a system designed by professionals, for professionals. 🛠

2 notes

·

View notes

Text

Discover the Best Commercial Kitchen Equipment Dealers in Delhi

When it comes to setting up or upgrading a commercial kitchen, finding the right equipment is crucial for ensuring efficiency, safety, and quality. As one of the leading commercial kitchen equipment dealers in Delhi, Swastik Professionals is dedicated to providing top-of-the-line kitchen solutions that cater to a wide array of culinary needs. Our extensive selection of high-quality kitchen equipment guarantees that your business will run smoothly and efficiently, allowing you to focus on what you do best—creating delicious meals.

Why Choose Swastik Professionals for Your Commercial Kitchen Needs?

Comprehensive Range of Products

At Swastik Professionals, we offer an extensive range of commercial kitchen equipment designed to meet the diverse requirements of our clients. Whether you are running a restaurant, a catering service, a hotel kitchen, or a food processing unit, our products are tailored to suit every need. Our inventory includes:

Commercial Ovens: From convection ovens to combi ovens, we provide advanced baking solutions.

Refrigeration Units: Our range includes walk-in coolers, freezers, and under-counter refrigerators.

Cooking Equipment: We offer high-performance ranges, fryers, griddles, and charbroilers.

Food Preparation Equipment: Find mixers, slicers, food processors, and blenders in our collection.

Dishwashing Equipment: Ensure spotless cleanliness with our efficient dishwashers and glass washers.

Quality and Durability

The quality and durability of our equipment are paramount. Each product is sourced from reputable manufacturers known for their innovation and reliability. By choosing Swastik Professionals, you invest in equipment that withstands the rigorous demands of a commercial kitchen, ensuring longevity and consistent performance.

Customization and Installation Services

Understanding that every kitchen has unique requirements, we offer customization options to ensure our equipment fits perfectly into your space and workflow. Our expert team provides professional installation services, ensuring that your kitchen is set up efficiently and correctly from the start.

Our Commitment to Customer Satisfaction

Expert Consultation

Navigating the myriad options for commercial kitchen equipment can be overwhelming. Our experienced consultants are here to guide you through the selection process, offering personalized advice based on your specific needs and budget. We help you make informed decisions that enhance your kitchen's functionality and efficiency.

After-Sales Support

Our relationship with our clients extends beyond the initial purchase. We provide comprehensive after-sales support, including maintenance services and technical assistance, ensuring your equipment remains in optimal condition. Our dedicated support team is always ready to address any issues or concerns you may have, providing prompt and effective solutions.

Competitive Pricing

At Swastik Professionals, we believe that top-quality kitchen equipment should be accessible to all businesses. We offer competitive pricing on all our products without compromising on quality. Our flexible financing options make it easier for you to equip your kitchen with the best tools available.

Understanding the Importance of Choosing the Right Equipment

Enhancing Efficiency

The right equipment can significantly enhance the efficiency of your kitchen operations. High-quality appliances reduce cooking times, streamline food preparation processes, and ensure consistent results, allowing you to serve your customers faster and more effectively.

Ensuring Food Safety and Hygiene

Commercial kitchen equipment plays a crucial role in maintaining food safety and hygiene standards. Proper refrigeration, storage, and cooking equipment help prevent contamination, ensure proper food handling, and comply with health regulations, safeguarding your customers' health and your business's reputation.

Reducing Operational Costs

Investing in durable and energy-efficient equipment can lead to substantial cost savings in the long run. Reliable appliances reduce the need for frequent repairs and replacements, while energy-efficient models lower utility bills, contributing to overall operational cost reduction.

Spotlight on Our Popular Products

Commercial Ovens

Our range of commercial ovens is designed to meet the high demands of any professional kitchen. From versatile combi ovens that offer multiple cooking functions in one unit to powerful convection ovens that ensure even cooking, our products guarantee superior performance and efficiency.

Refrigeration Units

Proper refrigeration is essential for any commercial kitchen. Our refrigeration units, including walk-in coolers and freezers, are designed to keep your ingredients fresh and safe. Advanced temperature control features and robust construction ensure reliable performance, even in the busiest kitchens.

Cooking Equipment

Efficiency and precision are key in any kitchen, and our cooking equipment delivers both. High-performance ranges, fryers, and griddles allow you to cook a variety of dishes simultaneously, while our charbroilers provide the perfect solution for grilling and broiling needs.

Food Preparation Equipment

Streamline your food preparation processes with our range of mixers, slicers, food processors, and blenders. These appliances are designed for speed and accuracy, helping you prepare ingredients quickly and consistently, saving time and labor costs.

Dishwashing Equipment

Maintaining cleanliness and hygiene is crucial in any kitchen. Our dishwashing equipment, including efficient dishwashers and glass washers, ensures that your dishes, utensils, and glassware are spotless and sanitized, meeting the highest standards of cleanliness.

Our Installation and Maintenance Services

Professional Installation

Our team of experts ensures that all equipment is installed correctly and efficiently, minimizing downtime and disruptions to your operations. We handle everything from setup to testing, ensuring that your kitchen is ready for use as quickly as possible.

Regular Maintenance

To keep your equipment in top condition, we offer regular maintenance services. Scheduled maintenance helps prevent unexpected breakdowns, extends the lifespan of your appliances, and ensures they continue to operate at peak efficiency.

Emergency Repairs

In the event of equipment failure, our rapid response team is available to provide emergency repair services. We understand the impact that equipment downtime can have on your business, and we are committed to getting you back up and running as soon as possible.

Conclusion

Swastik Professionals is your trusted partner for all your commercial kitchen equipment needs in Delhi. Our extensive product range, commitment to quality, and exceptional customer service make us the go-to choice for businesses looking to enhance their kitchen operations. Contact us today to learn more about how we can help you achieve your culinary goals with the best equipment available.

#commercial kitchen equipment suppliers in delhi#Best Commercial Kitchen Equipment Manufacturers in Delhi NCR#Commercial Kitchen Equipment Manufacturers in Delhi NCR#commercial kitchen equipments in delhi

2 notes

·

View notes

Text

Integrating CNC Grinding, Gundrilling, and Steering Machines for Maximum Efficiency

When you run a workshop, your goal is to be as efficient as possible. This means making sure all your machines, like CNC grinding machines, gundrilling machines, and steering machines, work well together. This blog will guide you on how to integrate these machines to maximize workshop efficiency.

Understanding Your Machines

CNC Grinding Machine:

A CNC grinding machine uses a rotating wheel to smooth surfaces. This machine is perfect for creating precise shapes and smooth finishes on metal pieces. It’s controlled by a computer, which means it can produce parts that are consistent and of high quality.

Gundrilling Machine:

Gundrilling machines are designed to drill deep holes with a high degree of accuracy. These machines are key in industries where precision is crucial, such as in the making of molds, dies, and various engineering components.

Steering Machine:

Steering machines shape and finish steering components, ensuring they meet specific design requirements. This is critical in automotive manufacturing, where the precision of steering components can affect vehicle performance and safety.

Steps to Integrate Your Machines

Layout Planning:

Start by planning the layout of your workshop. Place machines that are part of a similar processing line close to each other. For example, materials that are first processed in a CNC grinding machine should have easy access to the gundrilling machine if the next step involves drilling.

Scheduling Software:

Use scheduling software to manage each machine's operation times. This software can help prevent bottlenecks where one machine is waiting for another to finish. It ensures that each machine starts its task at the right time, keeping the workflow smooth and continuous.

Regular Maintenance:

Keep all machines in top condition. Regular maintenance checks can prevent unexpected breakdowns that could slow down the whole production line. Each machine, from the CNC grinder to the steering machine, should have a clear maintenance schedule.

Feedback Loop:

Create a feedback loop where data from the machines' operation is regularly analyzed to find areas for improvement. For example, if the data shows that parts from the CNC grinding machine often need adjustments before gundrilling, it might be time to recalibrate the machine.

Leveraging WIDMA's Expertise

As a final point, consider partnering with technology providers like WIDMA, a renowned leader in manufacturing precision tooling solutions. WIDMA offers a range of CNC grinding machines, gundrilling machines, and other specialized equipment tailored to enhance manufacturing efficiency.

WIDMA’s machines are built with the latest technology to ensure they deliver high performance and reliability. Moreover, WIDMA provides comprehensive support and training, which can be invaluable for workshops looking to integrate new machinery or optimize existing setups.

Using WIDMA’s advanced equipment and expert services, you can achieve a streamlined workflow that maximizes productivity and reduces downtime. Their commitment to innovation and quality makes them a smart choice for any workshop serious about staying competitive in today’s fast-paced market.

Conclusion

Integrating your CNC grinding machine, gundrilling machine, and steering machine efficiently requires thoughtful planning and the use of advanced technologies. By optimizing the workflow, maintaining machines properly, and leveraging expert solutions like those from WIDMA, your workshop can achieve the high efficiency and productivity needed to succeed in the manufacturing industry.

2 notes

·

View notes

Text

Step-by-Step Installation Guide for Your Samsung Refrigerator Ice Maker Kit

A refrigerator without an ice maker can be inconvenient, especially during hot summer days or when hosting gatherings. Installing an ice maker kit in your Samsung refrigerator can solve this problem, providing you with a steady supply of ice whenever you need it. In this detailed guide, we will lead you through the steps of installing your Samsung refrigerator ice maker kit, assuring a hassle-free experience.

Pre-Installation Preparations

Before beginning the installation procedure, it's critical to take several basic actions to ensure a seamless installation:

Safety Precautions: Safety is the first priority when using appliances and tools. Read the safety instructions included with the ice maker kit and only begin installation. Use the required protective equipment, gloves, and safety glasses.

Tools and Materials Required: Get the assembly tool and material. This usually consists of a wrench, screwdriver, water supply line, tubing cutter (if needed), Teflon tape, and either a drill (if you need to drill holes your new line needs to pass through) or in some cases, no drill required at all.

Checking Compatibility: Before ordering a new ice maker kit, make sure it is compatible with your refrigerator model. If you’re not sure, follow the manufacturer’s directions or ask a specialist.

Clearing Space: Everything in the area surrounding the ice maker installation should be removed. This will offer you plenty of space to work without causing damage to your refrigerator or other close things.

Unboxing and Inspection

Once you've completed the pre-installation preparations, it's time to unbox the ice maker kit and inspect its contents:

Unboxing: Carefully unpack the Samsung Refrigerator Ice Maker Assembly Kit, taking care not to damage any components or packaging materials. Keep track of all the parts and pieces to ensure nothing is missing.

Inspection: Check every part of the ice maker kit carefully for any indications of wear or flaws. Particularly, pay special attention to the electrical connections and the water supply line. Get support from the manufacturer if you find any problems.

Familiarization: Take a little time getting to know the ice maker assembly, water supply line, electrical harness, and intake valve, among the other parts of the kit. It'll be lot simpler to install if you know how each component goes together.

Installation Process

Now that you're familiar with the ice maker kit, it's time to proceed with the installation:

Shutting off the Water Supply: Before you begin any installation work, shut off your refrigerator’s water supply. Any unintentional spills or leaks during installation will be stopped by this.

Finding the Optimal Location: Discover where you should put the ice maker in your refrigerator. It should be put in a good location near the side or top of the freezer compartment so it is handy to get to the ice. Consult the user handbook of your refrigerator to know where to install your refrigerator.

Connecting the Water Supply Line: Cut the water supply line to the refrigerator to the proper length with a tubing cutter so the refrigerator will fit the proper water source. The water supply line is connected one end to the refrigerator’s water input valve and the other end to the water supply source with compression fittings.

Mounting the Ice Maker Assembly: Insert the ice maker assembly into the freezer compartment as it should on the proper mounting brackets. According to the manufacturer, Setting Allocate the right ice maker position and placement; Ascertain a secure attachment using the screws or mounting hardware on the kit.

Connecting the Electrical Components: Care is needed when attaching the electrical wiring to the matching outlet in the freezer compartment. Check that all connections are pretty tight (but clear so the ice maker can function).

Securing the Ice Maker in Place: Once connected, line it up and position the ice machine assembly so that it’s in place. Place everything level and stable and then use the right mounting hardware to secure it into place.

Testing for Leaks and Functionality: In accordance with the manufacturer's instructions, activate the ice maker then turn on the water supply and the refrigerator's power. Keep a watch on the installation, as well as any leaks or malfunctions you discover, and act quickly to fix any problem. You can move on to the last stages of the installation procedure when the ice maker works and is making ice.

Final Steps

With the ice maker installed and operational, it's time to complete the final steps and address any potential issues:

Turning on the Water Supply: Fully open the water supply valve to let water enter the ice maker. Look for the connections and examine them for leaks, if necessary, tighten them.

Setting up the Ice Maker: According to the manufacturer's instructions, this will also configure the ice maker to the size of the ice cubes making, and the rate at which the ice is created. Turn the settings to your liking for usage.

Following this comprehensive installation guide, you will be able to install your Samsung refrigerator ice maker kit with ease and success. That means you can have a simple and hassle-free installation process and take advantage of the convenience of always having ice on hand if you follow each step as it is described.

2 notes

·

View notes

Text

Uses and Functions of Non Woven Bag Printing Machine

Introduction

In recent years, the global movement towards sustainability and eco-consciousness has spurred a significant shift in consumer behavior and industrial practices. As businesses strive to reduce their environmental footprint, the demand for eco-friendly alternatives to traditional plastic bags has surged. Enter non-woven bags — lightweight, durable, and reusable alternatives that have gained widespread popularity. At the heart of this eco-friendly revolution lies the non-woven bag printing machine, a marvel of modern engineering that enables the mass production of customized, environmentally responsible bags. Let’s delve deeper into the efficiency and functionality of these innovative machines.

The Rise of Non-Woven Bags

Non-woven bags are crafted from synthetic or natural fibers bonded together through a mechanical, thermal, or chemical process — without the need for weaving. This manufacturing method results in bags that are strong, tear-resistant, and capable of carrying heavy loads. Moreover, non-woven bags are reusable, recyclable, and biodegradable, making them a sustainable choice for environmentally conscious consumers and businesses alike.

Advantages of Non-Woven Bag Printing Machines

Customization: Non-woven bag printing machines offer unparalleled flexibility, allowing businesses to create bespoke designs and branding solutions tailored to their unique requirements.

Speed and Efficiency: With rapid printing capabilities and automated processes, these machines enable high-volume production without compromising on quality or accuracy.

Cost-Effectiveness: By streamlining production workflows and minimizing material waste, non-woven bag printing machines help businesses optimize their operational costs and maximize profitability.

Environmental Sustainability: By facilitating the production of reusable and recyclable non-woven bags, these machines support sustainability initiatives and contribute to the reduction of plastic waste.

Non-woven bag printing machines are the unsung heroes of modern manufacturing, offering a multitude of uses and functions in various industries.

Functions of Non Woven Bag Printing Machine

Customization Made Easy

These machines empower businesses to personalize non-woven bags with logos, designs, and messages, enhancing brand visibility and communication.

Promotional Powerhouses

Ideal for creating branded merchandise, custom-printed non-woven bags serve as effective promotional tools at trade shows, events, and marketing campaigns.

Sustainable Packaging Solutions

In retail, these machines help elevate packaging by customizing non-woven bags with brand aesthetics, product showcases, and eco-friendly messaging.

Memorable Event Souvenirs

From conferences to weddings, custom-printed non-woven bags make practical and memorable giveaways, leaving a lasting impression on attendees.

Environmental Advocacy

By enabling the production of reusable and recyclable bags, these machines contribute to environmental sustainability efforts, promoting eco-conscious consumption.

In essence, non-woven bag printing machines are more than just production tools — they’re enablers of creativity, sustainability, and brand empowerment in a rapidly evolving world.

Best Non Woven Bag Printing Machine Companies in India

If you are looking for a Best Non Woven Bag Printing Machine in India, then look no further than Decent Print Line. Decent prinline is a leading manufacturer and supplier of non woven bag printing machine in India.

For more details, please contact us!

Website — https://www.decentprintline.com/

Contact — +91–9911433180

Email — [email protected]

Address — Plot №4, Gali №1, Rao Colony, Sihi Gate, Faridabad, Ballabgarh — 121004, Haryana, India

#Non Woven Bag Printing Machine#Non Woven Bag Printing Machine manufacturer#Non Woven Bag Printing Machine supplier#Non Woven Bag Printing Machine manufacturer in India#Non Woven Bag Printing Machine supplier in India#Decent printline

2 notes

·

View notes

Text

Every now and then I am reminded that we spend the vast majority of our time indoors: at home, at school, at the office, in shops and retail spaces, in bars, clubs and restaurants, in the apartments of friends and relatives, in train stations and moving vehicles, in hotels, venues and theaters, in museums, churches and hospitals – big boxes and little boxes with varying ratios of functionality to ornament.

Every now and then I am also reminded that we live in an air-conditioned dream/nightmare. In standard hotel rooms, split AC units are now as common as bedside bibles used to be. In most cases, these units are fixed to the wall above the entrance door, so that upon entering the room, guests can briefly enjoy a view unencumbered by the sight of the bulky appliance – a sort of icon corner in reverse, since an icon corner is usually located to be visible when you first enter. Once you lay down on the bed and gaze up at the familiar yet bewildering piece of engineering, you might begin to wonder: what’s the optimal temperature? Will I get sick if I sleep with the AC on? Is this thing more ugly than it is convenient? Would natality rates suddenly drop if these machines didn’t exist? Is this a tool that “brings energy home” as Ursula K. Le Guin would have it, or one that “forces energy outward?” How does it work? What’s inside the box? Is it good, is it bad? Where is the remote control for this thing?!

Although the overhead placement of these split units is clearly a matter of practicality, I can’t help but overthink and ask myself if we also tend to place them at such heights, along with other physical objects including speakers, curtains, wall reliefs and friezes, because they pertain to immaterial realms such as temperature, sound, light and narration. As a “unit,” this compact object is at once whole and dependent upon an unseen network, which suggests a hidden elsewhere beyond the confine of the room. While its boxiness could bring to mind minimalism’s so-called “specific objects” (objects that can be apprehended on a phenomenological level), the idea that it contains unseen parts and is linked to an unseen system constitutes a conceptual or even metaphoric opening. Philip Seibel’s quietly baroque Gehäuse sculptures consciously play with this dichotomy.

In borrowing some of the formal qualities of these units, Seibel paradoxically empties them out, thereby turning what first appears to be an enclosure into a container or a vessel where other ideas can get on board like stowaways. Looking up at his Gehäuse makes us aware of the many other vessels and boxes that create and sustain the conditions for our lives, those that shield us and our belongings, or again, those which act as receptacles for our fears and aspirations. Like ships made of reeds, there is something sensible but absurd about Seibel’s encasements. Their sleek finish seems to conceal something that is beyond our reach; or at least, it blurs the line between the manufactured and the handcrafted, the real and the fake, the readymade and the not already made, the functional and the decorative, the office, the hotel and the gallery.

Emile Rubino

3 notes

·

View notes

Text

The Versatility of Fiber Laser Cutting Machines in Steel Structure Processing

Versatile Fiber Laser Cutting Machines

The adaptability of fiber laser cutting machines, like the Lh 12012 00 12000w Steel Structure Production Line Tube Laser Cutting Machine, provides exceptional precision and efficiency in processing steel structures.

These machines offer high precision cutting for steel structures, ensuring accurate and clean edges.

Their advanced technology allows for intricate designs and detailed cuts, meeting the demands of various steel structure processing projects.

Precision and Efficiency

High Precision Cutting

When it comes to steel structure processing, the pipe laser cutting machine excels in providing high precision cutting. This ensures that the steel structures have accurate and clean edges, meeting the strict quality standards of the industry. The advanced technology integrated into these machines allows for the execution of intricate designs and detailed cuts, catering to the diverse requirements of various steel structure processing projects.

Efficient Production

The pipe laser cutting machine's efficient cutting process is designed to minimize material waste and enhance overall production efficiency. By incorporating zero tail material cutting, it optimizes resource utilization while minimizing operational costs. This not only contributes to cost savings but also aligns with sustainable manufacturing practices by reducing material wastage in metal materials cutting operations.

Industry Applications

In the construction industry, the tube laser cutting machine is a valuable asset for fabricating steel components with precision and efficiency. Its versatility enables the seamless processing of steel materials, contributing to the timely completion of construction projects. The machine's ability to handle various cross-section sizes makes it an ideal tool for meeting the diverse requirements of steel fabrication in construction.

In the automotive and manufacturing sectors, the tube laser cutting machine plays a crucial role in producing high-quality metal components and parts. Its precision cutting capabilities and efficient production process ensure that metal materials are processed accurately and efficiently. This contributes to enhancing overall productivity and meeting the stringent quality standards of these industries. The machine's adaptability to handle different cross-section sizes further solidifies its position as a valuable asset in meeting the diverse needs of automotive and manufacturing applications.

Automated Operations

Automatic Loading and Unloading

The integration of automatic loading and unloading capabilities in the tube laser cutting machine streamlines the entire production process. This advanced feature significantly reduces the need for manual labor, leading to a more efficient and cost-effective solution for large-scale steel structure processing. By automating the material handling aspect, this machine minimizes human intervention, thereby enhancing safety and operational efficiency.

Enhanced Productivity

The automated operations of the tube laser cutting machine contribute to a substantial increase in productivity while simultaneously reducing turnaround times. With minimal manual intervention required, the machine ensures consistent and reliable performance in metal materials cutting operations. This not only improves overall productivity but also allows for better resource allocation and optimized production scheduling.

Enhancing Steel Structure Processing

Fiber laser cutting machines play a pivotal role in enhancing the processing of steel structures across various industries. Their adaptability and precision offer efficient solutions for metal materials cutting operations, contributing to the seamless fabrication of steel components. The integration of automated operations further elevates productivity and reduces manual intervention, ensuring consistent and reliable performance. This advanced technology not only enhances the overall efficiency of steel structure processing but also aligns with sustainable manufacturing practices, making it an ideal choice for the construction industry and manufacturing sectors.

See Also

Top-notch Pipe Laser Cutting Machine Suppliers: A Comprehensive Guide

2 notes

·

View notes