#Maufacturer

Text

Understanding Calibrator Uses: Ensuring Accuracy in Instrumentation

Instrument calibration happens to be quite a critical process used across various industries, that tends to ensure the accuracy & reliability of measuring instruments. What more?

Read our article to know more.

Looking to procure different types of calibrated thermocouples ?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing reliable, accurate and long lasting thermocouples, RTD & Cartridge Heaters with customizations to suit a particular business' needs for more than 35 years.

#heatconsensorspvtltd#cartridgeheater#maufacturer#industrialpurpose#heatingelement#mithermocouple#manufacturing#industrial#design#calibration#types#bangalore

0 notes

Text

Top 10 Tips for Maximizing Efficiency with Your CNC Press Brake

In the realm of manufacturing, efficiency is the golden standard for success. When it comes to CNC press brake machines, achieving maximum efficiency isn't just about speeding up production; it's about optimizing processes, minimizing waste, and ensuring consistent, high-quality output. Here are ten actionable tips to elevate the efficiency of your CNC press brake operations:

1. Understanding Machine Capabilities:

Your CNC press brake is a powerhouse, but understanding its capabilities is crucial. Dive deep into its specifications - load capacity, bending speed, and precision thresholds. This knowledge forms the foundation for precise planning, preventing overloading or underutilizing its potential.

2. Effective Tool Selection:

Tools are the unsung heroes of precision bending. Different materials and bend types demand specific tools. Regular maintenance and proper tooling setups not only ensure efficiency but also extend the lifespan of your equipment, reducing downtime and ensuring consistent quality.

3. Pre-Production Preparation:

Prepare before production kicks off. Streamline setup processes, organize materials, and ensure all required tools are readily available. An organized workspace and efficient material handling significantly cut downtime between jobs, enabling faster production starts.

4. Optimal Programming Practices:

The key to efficiency lies in accurate programming. Techniques like nesting and tooling setups can significantly enhance your CNC press brake's performance. Leveraging software features for quicker programming saves time and minimizes errors.

5. Implementing Standard Operating Procedures (SOPs):

SOPs are the backbone of consistent and efficient operations. They ensure uniformity and quality across processes. By creating and implementing standardized procedures for various tasks, you not only enhance efficiency but also simplify training for new operators.

6. Operator Training and Skill Development:

Invest in your operators. Skilled operators maximize machine capabilities, reduce errors, and troubleshoot effectively. Continuous skill development and fostering a learning culture among your team are essential for sustained efficiency gains.

7. Maintenance and Calibration:

Regular maintenance and calibration are the lifelines of your CNC press brake's optimal performance. Scheduled maintenance prevents unexpected breakdowns, ensuring uninterrupted workflow. Addressing issues promptly maintains product quality and reduces downtime.

8. Workflow Optimization:

Optimize your workflows to minimize idle time between jobs. Strategies like batch processing, efficient tool changeovers, and smart job scheduling significantly reduce downtime and maximize machine uptime.

9. Quality Control and Inspection Processes:

Integrating quality checks into your workflow is essential. Implementing in-process inspections ensures that errors are caught early, preventing rework and maintaining a seamless workflow without compromising on quality.

10. Data Analysis for Continuous Improvement:

Data is your ally in efficiency. Analyze data from your CNC press brake to identify bottlenecks and inefficiencies. Embrace a culture of continuous improvement, making decisions based on data-driven insights for sustained efficiency gains.

Efficiency in CNC press brake operations is an ongoing journey rather than a one-time achievement. Implementing these ten tips can substantially boost productivity and quality while minimizing errors and downtime. By prioritizing efficiency and constantly seeking improvement, your business can thrive in the competitive manufacturing landscape.

Remember, efficiency isn't just about doing things faster; it's about doing things smarter. With these tips as your guide, harness the full potential of your CNC press brake for unparalleled efficiency and success.

1 note

·

View note

Text

How do ammonia crackers work?

Ammonia crackers work by utilizing a process known as cracking, which involves passing ammonia gas through a catalytic bed. The catalytic bed contains a catalyst that facilitates the decomposition of ammonia into its constituent elements.

When the ammonia gas comes into contact with the catalyst, it undergoes a controlled decomposition reaction. The catalyst provides a surface for the reaction to occur, allowing the ammonia molecules to break apart and form nitrogen and hydrogen gases.

This process of cracking ammonia is highly efficient and reliable, providing a sustainable solution for the production of nitrogen and hydrogen gases.

Applications of ammonia crackers

The versatility of ammonia crackers makes them indispensable in various industries. One of the primary applications of these devices is in the chemical industry, where they are used to produce nitrogen and hydrogen gases for a wide range of processes.

Nitrogen gas produced by ammonia crackers is commonly used in metal heat treatment, petroleum refining, and semiconductors. It acts as a protective atmosphere, preventing oxidation and ensuring high-quality end products. Hydrogen gas, on the other hand, finds applications in the production of ammonia-based fertilizers, fuel cells, and various chemical reactions.

Ammonia crackers also play a vital role in the food processing industry. They are used to create nitrogen-rich atmospheres for packaging perishable goods. By replacing oxygen with nitrogen, ammonia crackers help extend the shelf life of products, preventing spoilage and inhibiting microbial growth. This process is particularly beneficial for preserving the freshness of fruits, vegetables, and meat products.

In addition to their use in chemical manufacturing and food processing, ammonia crackers are also employed in industrial air pollution control systems. They are crucial in converting harmful ammonia emissions into harmless nitrogen and hydrogen gases, reducing the environmental impact of industrial activities.

Benefits of using ammonia crackers

The use of ammonia crackers offers several benefits across different industries. One of the primary advantages is their ability to produce nitrogen and hydrogen gases on-site, eliminating the need for transportation and storage of these gases. This not only saves costs but also ensures a continuous supply of gases as per the requirements of the industry.

Furthermore, ammonia crackers provide a sustainable solution for gas production. Ammonia, which is abundantly available and easily obtained, serves as the feedstock for cracking. By utilizing ammonia as a raw material, these devices contribute to the efficient utilization of resources and reduce reliance on fossil fuels.

Ammonia crackers are also highly efficient in converting ammonia gas into nitrogen and hydrogen gases. The controlled decomposition process ensures a high yield of the desired gases, minimizing wastage and maximizing productivity.

Moreover, the use of ammonia crackers enhances safety in various industries. By converting ammonia emissions into harmless gases, these devices help mitigate the health and environmental risks associated with ammonia exposure. They play a crucial role in maintaining workplace safety and ensuring compliance with environmental regulations.

Safety precautions when using ammonia crackers

While ammonia crackers provide numerous benefits, it is essential to follow safety precautions when using these devices. Ammonia gas is toxic and can be hazardous if not handled properly. Here are some safety measures to consider:

1. Adequate ventilation: Ensure proper ventilation in the area where the ammonia cracker is installed to prevent the accumulation of ammonia gas.

2. Personal protective equipment (PPE): Use appropriate PPE, including gloves, goggles, and respiratory protection, when working with ammonia crackers.

3. Regular maintenance: Conduct regular maintenance of the ammonia cracker to ensure its proper functioning and prevent any leaks or malfunctions.

4. Emergency response plan: Develop an emergency response plan in case of accidental release or exposure to ammonia gas. This plan should include evacuation procedures, first aid measures, and contact information for emergency services.

By following these safety precautions, the risks associated with using ammonia crackers can be minimized, ensuring a safe working environment.

Choosing the right ammonia cracker for your needs

When selecting an ammonia cracker for your specific requirements, several factors need to be considered. These factors include:

1. Gas production capacity: Determine the required production capacity of nitrogen and hydrogen gases to meet your industry’s demands.

2. Catalyst type: Different catalysts can be used in ammonia crackers, each with its own advantages and limitations. Consider the catalyst type that best suits your application.

3. Operating conditions: Evaluate the operating conditions, including temperature and pressure, to ensure the ammonia cracker can perform optimally under the specified conditions.

4. Safety features: Look for ammonia crackers that have built-in safety features such as leak detection systems and automatic shutdown mechanisms to enhance safety.

By carefully considering these factors, you can choose the right ammonia cracker that meets your specific needs and ensures efficient gas production.

Maintenance and troubleshooting of ammonia crackers

Proper maintenance is essential to ensure the optimal performance of ammonia crackers. Regular inspections and maintenance checks can help identify any potential issues and prevent costly breakdowns. Here are some maintenance tips for ammonia crackers:

1. Regular cleaning: Clean the catalytic bed periodically to remove any deposits or contaminants that may hinder the cracking process.

2. Catalyst replacement: Monitor the catalyst’s performance and replace it when necessary to maintain efficient gas production.

3. Leak detection: Implement a system for monitoring and detecting any ammonia leaks to prevent safety hazards.

In the event of a problem with the ammonia cracker, troubleshooting steps can be taken to identify and resolve the issue. It is advisable to consult the manufacturer’s guidelines or seek professional assistance for troubleshooting and repairs.

Common misconceptions about ammonia crackers

There are some common misconceptions about ammonia crackers that need to be clarified. One such misconception is that ammonia crackers produce harmful emissions. In reality, ammonia crackers play a crucial role in converting harmful ammonia emissions into harmless nitrogen and hydrogen gases, thereby reducing environmental impact.

Another misconception is that ammonia crackers are complex and difficult to operate. While ammonia cracking is a technical process, modern ammonia crackers are designed to be user-friendly, with automated controls and safety features that simplify operation.

It is important to dispel these misconceptions and educate individuals about the benefits and safety measures associated with ammonia crackers.

Where to buy ammonia crackers

Ammonia crackers can be purchased from various suppliers and manufacturers specializing in gas processing equipment. It is advisable to choose a reputable supplier who offers high-quality ammonia crackers that meet industry standards and requirements. Conduct thorough research and consider factors such as product quality, customer reviews, and after-sales support when selecting a supplier.

You can also read read this :

Conclusion: The importance of ammonia crackers in various industries

In conclusion, ammonia crackers are essential devices used in a wide range of industries for their ability to break down ammonia molecules into nitrogen and hydrogen gases. These devices find applications in chemical manufacturing, food processing, and environmental monitoring, offering sustainable and effective solutions.

Ammonia crackers provide numerous benefits, including on-site gas production, resource utilization, and enhanced safety. By choosing the right ammonia cracker, following safety precautions, and conducting regular maintenance, industries can maximize the efficiency and productivity of their operations.

As the demand for nitrogen and hydrogen gases continues to grow, ammonia crackers will remain indispensable in supporting various industrial processes and contributing to a more sustainable future.

#hydrogen electrolyzer#hydrogen plant manufacturer#hydrogen#best service in delhi#hydrogen cracker unit#bussiness#Maufacturer

0 notes

Text

Welcome to SP Colour & Chemicals - Your Trusted Pigments Manufacturer in India

At SP Colour & Chemicals, we are proud to be at the forefront of the pigment manufacturing industry in India. With our commitment to innovation, quality, and sustainability, we have established ourselves as a trusted partner for businesses in various sectors, both nationally and internationally.

Key Features and Benefits:

High-Quality Pigments: Our state-of-the-art production facilities are equipped with cutting-edge technology to ensure that we deliver the highest quality pigments that meet and exceed industry standards.

Wide Range of Pigments: We offer an extensive range of pigments to cater to the diverse needs of our customers. Whether you require organic pigments, inorganic pigments, or special effect pigments, we have the perfect solution for your application.

Customised Solutions: We understand that each customer's needs are unique. Our team of experienced professionals can work closely with you to develop customised pigment solutions that precisely meet your requirements.

Environmentally Friendly: SP Colour & Chemicals is committed to sustainability. Our processes are designed to minimise environmental impact, and we continuously explore eco-friendly options in our manufacturing.

Global Reach: While we are based in India, our reach extends worldwide. We export our pigments to numerous countries, making us a global player in the pigment manufacturing industry.

Competitive Pricing: We strive to offer competitive pricing without compromising on quality. Our cost-effective solutions help our clients maintain a competitive edge in their markets.

Our Pigment Categories:

Organic Pigments: These are high-performance pigments used in various industries, including plastics, coatings, inks, and textiles.

Inorganic Pigments: Our inorganic pigments are known for their durability and versatility, making them ideal for applications such as ceramics, concrete, and more.

Special Effect Pigments: These unique pigments create stunning visual effects, adding a touch of magic to your products. They are often used in cosmetics, automotive finishes, and other high-end applications.

Pigments Manufacturer India

High-Quality Pigments

Customised Pigment Solutions

Environmentally Friendly Pigments

Organic Pigments

Inorganic Pigments

Special Effect Pigments

Pigment Exporter

Competitive Pricing

Sustainable Pigment Manufacturing

For inquiries, collaborations, or to discuss your pigment needs, please don't hesitate to get in touch with us. At SP Colour & Chemicals, we are dedicated to providing you with the best pigment solutions to enhance your products and market presence.

Feel free to adapt and expand upon this content to suit your specific needs and goals. It's important to regularly update your website and marketing materials with fresh and relevant content to keep your audience engaged and informed about your company's products and services.

To know more visit our website -https://spcolour.in/

0 notes

Text

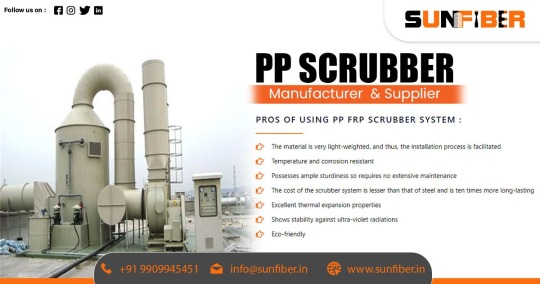

PP Scrubber Supplier in Maharashtra

PP Scrubber Supplier in Maharashtra:

Sunfiber:

"Sunfiber" is your one-stop shop for all requirements in industrial customization.

PP Scrubbers are cleaning tools made from polypropylene, a durable and chemical-resistant thermoplastic material. Designers typically create them as handheld or attachable scrubbing pads or brushes with bristles or abrasive surfaces. Engineers engineer these scrubbers to withstand harsh chemicals, high temperatures, and vigorous scrubbing actions without deteriorating, making them suitable for industrial cleaning tasks.

Applications of PP Scrubbers

PP Scrubbers have a wide range of applications in various industries, including:

Manufacturing and Processing Plants

In manufacturing facilities, they use PP Scrubbers for cleaning equipment, machinery, and production surfaces contaminated with oils, grease, chemicals, or residues.

Food Processing

In the food industry, they employ PP Scrubbers to clean food processing equipment, conveyor belts, and production areas, ensuring hygiene and compliance with food safety standards.

Automotive and Aerospace

They use PP Scrubbers to remove contaminants, such as paint overspray or adhesive residues, from vehicle surfaces and aerospace components.

Pharmaceuticals

In pharmaceutical manufacturing, these scrubbers help maintain clean and sterile conditions by cleaning tanks, vessels, and production areas.

Petrochemical Industry

PP Scrubbers are crucial for cleaning and maintaining equipment and pipelines in the petrochemical industry, where chemical resistance is paramount.

Construction

In construction, these scrubbers aid in cleaning construction equipment, and removing concrete, mortar, and construction debris.

We Provide PP Scrubber Supplier in Maharashtra like Mumbai, Pune, Nagpur, Nashik, Vasai-Virar, Solapur, Bhiwandi, Amravati, Kolhapur, Akola, Latur, Jalna, Panvel, Navi Mumbai, Parbhani, Dhule, Nanded, Jalgaon, Ahmadnagar, Chandrapur.

Read the full article

0 notes

Text

Storage Equipment Supplier in Karnataka

Storage Equipment Supplier in Karnataka:

Invoit Plast Machinery Pvt. Ltd.:

Ahmedabad serves as the hub for various significant Indian plastic industries, and it is where Invoit Plast Machinery Pvt. Ltd. is headquartered.

Manufacturer, supplier, and exporter of plastic processing equipment is Invoit Plast Machinery Pvt Ltd. For the plastic and roto molding sectors, this entails manufacturing in Ahmedabad, India, serving Indian cities like Hyderabad, Nasik, Chennai, Baroda, Bangalore, and Rajkot, as well as exporting to South Africa, Dubai, UAE, Nepal, Bangladesh, and Qatar. Invoit Plast Gear Pvt. Ltd. produces, supplies, and exports equipment for processing and recycling plastic raw materials.

Among the storage devices we produce are material storage bins, flexible silos, circular silos, bolted silos, square silos, and silos made of MS, SS, and aluminum.

Silos, which are buildings, store grains and other bulk or powdered goods, including components like cement, calcium oxide, calcium hydroxide, activated carbon, and plastic resins.

Although square and rectangular storage silos are available, cylinder silos with metal bases are more typical. Made of materials such as metal, stainless steel, reinforced concrete, wood, reinforced plastic, fiberglass, and others, they resemble towers.

We Provide Storage Equipment Supplier in Karnataka Including Bangalore, Hubli-Dharwad, Mysore, Kalaburagi, Mangalore, Belgaum, Davanagere, Bellar, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassa, Bhadravati, Chitradurga , Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru.

Read the full article

#Bagalkot#Bangalore#Belgaum#Bellar#Bhadravati#Bidar#Chikmagalur#Chitradurga#Davanagere#Gadag-Betageri#Gangavati#Hassa#Hospet#Hubli-Dharwad#Kalaburagi#Karnataka#Kolar#Mandya#Mangalore#Maufacturer#Mysore#Raichur#Ranebennuru#Robertsonpet#Shimoga#StorageEquipment#Supplier#Tumkur#Udupi#Vijayapura

0 notes

Text

Face to Face

#exhibition#cantonfair#sanitarypad#sanitarynapkin#periodpad#menstrualpad#oem#maufacturer#personalcare

0 notes

Photo

We at Bezares Alpha Drives are committed to attain and maintain technological leadership in the market it serves by :

Continuously developing and empowering employees to have total involvement and commitment

Delighting customers by providing best in class, reliable PTOs and technical support on-time

Increasing Value Addition by continual improvement in all our products & processes

see more:https://www.alphadrives.co.in/

Contact us:7538874333

#pto#ptogearbox#gearbox#powertakeoff#tatapto#truck#bharatbenz#ashokleyland#eicher#maufacturer#supplier#india

0 notes

Text

Cycle Simplex

CycleSimplex manufactures and sells trike and bike racks that are USA made. Our racks are all steel construction with powder coat paint. We pride ourselves in the quality, simplicity of design and pricing. Our racks are suitable for cars, trucks, vans, SUV's and RV's.

0 notes

Photo

https://www.laboteck.com/sieve-shaker/

0 notes

Text

not the most amazing pictures on the planet, but i'm going to be tabling a big convention for the first time ever in a few weeks and all my acrylic stuff is finally here from the manufacturer!

#i also have some prints hand-drawn paintmarker illustrations and other bits and bobs#i do resin crafting so some of that's gonna be there too#for anyone wondering why those two keychains and the bill pin are in the shame corner... they were the first things i produced#and i had been uing a different maufacturer which frankly stunk#so they're gonna be super heavily reduced pricewise so i can get rid of 'em#anyway super excited it's a pretty large convention and i'm still shocked i got in#also i need to fill out that keychain board lmao... i'll probably list prices there

21 notes

·

View notes

Text

थर्मोकपल के विफल होने के विभिन्न कारण क्या हैं?

ट्यूबलर हीटर एक प्रकार के प्रतिरोध हीटर हैं। वे एक धातु ट्यूब से बने होते हैं जो एक सर्पिल में कुंडलित या घाव होता है। फिर धातु ट्यूब को नाइक्रोम या कंथल जैसे प्रतिरोधी पदार्थ से भर दिया जाता है।

और अधिक पढ़ने के लिए लिंक पर क्लिक करें

अधिक जानकारी के लिए, कृपया मेल से संपर्क करें: [email protected]

फ़ोन: +91 9164833027 / 098442 33244

#heatconsensorspvtltd#cartridgeheater#maufacturer#industrialpurpose#heatingelement#mithermocouple#manufacturing#industrial#design#types#bangalore#thermowell#thermocoupleconnectors

0 notes

Text

If you're eager to delve deeper into the world of bookbinding, adhesive technologies, and creative solutions, follow us to stay updated on the latest content.

#book binding#chemical industry#artificial leather#gravure ink#adhesive#resin#flexo ink#offset ink#chemical maufacturer

2 notes

·

View notes

Text

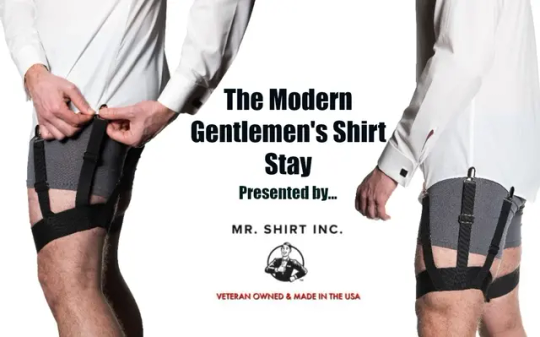

You know what, since I'm thinking about it anyways, let's talk formalwear accessories. Most of these are traditionally menswear but a bit of gender fuckery is good for the soul, and frankly most of these are about making your mass-produced clothing fit and lay properly without having to go to the tailor.

Shirt stays: these go around your thighs to hold your shirt down, so that it stays smooth and tucked in. They're usually elastic, with 1-3 clips, and if you wear skirts frequently this is a GREAT way to make sure your top doesn't ride up. The clips will be visible if you're wearing something tight, so loose pants or skirts are where these do best. There's also an insane version that clips to your socks, but that is for lunatics. If you wanted, you could also use one of these clips to hold up thigh-highs.

These do a great job of smoothing and narrowing the waist area by keeping your shirt from bunching there.

Sleeve garters: usually metal, leather, elastic, or silk. These are usually worn with button-down shirts to adjust where your cuff falls on the wrist or hand. They're properly worn on the upper arm, and you pull the fabric of the sleeve above the garter until you cuff is where you want it. Because this creates a puff of sleeve at the bicep, it also broadens the appearance of the shoulders. It's great if you're working with your hands or if your sleeves are often too long for your preference.

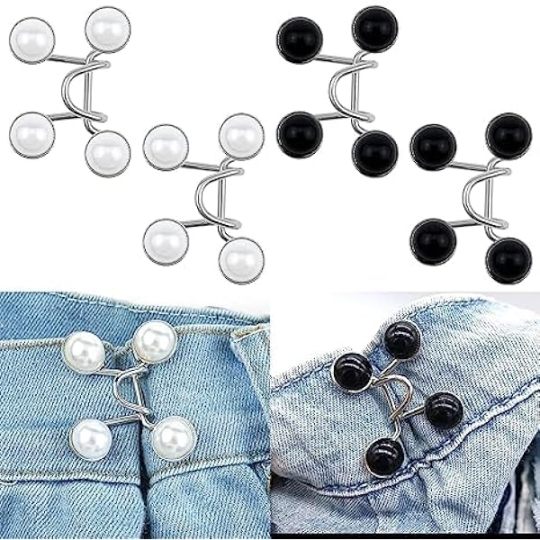

Waistband clip or belt adjustment clip/buttons: Three different ways of tightening the waistband of a pair of pants or a skirt. You're not going to get more than an inch or so tighter without weird bunching, and for most of these you'd want them to be hidden under a shirt or jacket, but they do the job if that's something you're having issues with.

Collar pins: There are so many fun ones out there, both with and without chains. They're not terribly practical, though the slight weight may help keep your collar where you want it. Also consider collar tips, which pin (surprise) to the very tips of your collar points.

Sweater clips/guards: meant to hold your sweater or cardigan mostly closed. Great if your cardigan doesn't button, or if you don't like it to be buttoned all the way.

There's tons of other stuff out there like this--etsy is a great place to find this stuff. A lot of these are old solutions to the very modern problem of mass-maufactured clothes not being as one-size-fits-all as advertised, but they're also a fun way to put a bit of personality into businesswear.

29K notes

·

View notes

Text

India’s Path to a $10 Trillion Economy: Unlocking Growth Through Financial Inclusion, Innovation, and Sustainability 🇮🇳💡🌱

India’s ambitious goal of becoming a $10 trillion economy by 2032 reflects its immense potential and aspirations. I view this target as both challenging and achievable, provided that strategic improvements are made across multiple sectors. Let’s explore the key areas that demand attention and assess their potential impact on India’s economic trajectory.

1. Financial Inclusion: The Catalyst for…

#AI in Finance#Business Growth#clean tech#Digital India#Ease of doing business#Economic Growth#Economic Vision 2032#Education Reform#Financial Inclusion#Foreign Investment#Global Powerhouse#Green Economy#Human Capital#India Rising#Infrastructure Development#Innovation#Logistics Efficiency#Make in India#Maufacturing Growth#Productivity Boost#Regulatory Reforms#Skill Development#Sustainable Growth#Tech Adoption

0 notes

Text

FRP Blower Supplier in Rajasthan

FRP Blower Supplier in Rajasthan:

Sunfiber is Manufacturer and Supplier of FRP Blower in Rajasthan, India.

An FRP blower operates by utilizing the energy from a motor to generate airflow or gas movement. It consists of a fan or impeller that rotates within a casing, creating a pressure difference that forces air or gas through the system. The use of FRP in blower construction ensures that the equipment can handle corrosive, aggressive, and chemically laden environments without deteriorating over time.

Advantages of Using FRP Blower:

Corrosion Resistance: The primary advantage of FRP blowers lies in their exceptional resistance to corrosion. FRP is inherently resistant to a wide range of chemicals, making the blowers ideal for applications in corrosive atmospheres or when handling corrosive gases.

Durability: FRP blowers exhibit excellent durability, ensuring a longer lifespan even in harsh operating conditions. The material's resistance to degradation, rust, and erosion contributes to the equipment's longevity.

Lightweight: In comparison to traditional metal materials, people recognize FRP for its lightweight nature. This feature simplifies the transportation, installation, and maintenance of the blower.

High Strength-to-Weight Ratio: Despite being lightweight, FRP has a high strength-to-weight ratio, making FRP blowers robust and able to withstand mechanical stress and pressure variations.

Thermal Insulation: FRP naturally provides thermal insulation, reducing the impact of temperature fluctuations on the blower's performance and structural integrity.

Low Maintenance: The corrosion-resistant nature of FRP blowers reduces the need for frequent maintenance, resulting in cost savings and increased operational efficiency.

Versatility: Designing FRP blowers for specific applications and requirements highlights the material's adaptability and versatility.

We Provide FRP Blower Supplier in Rajasthan Including Rajasthan like Jaipur, Jodhpur, Kota, Bhiwadi, Bikaner, Udaipur, Ajmer, Bhilwara, Alwar, Sikar, Bharatpur, Pali, Sri Ganganagar, Kishangarh, Baran, Dhaulpur, Tonk, Beawar, Hanumangarh.

Read the full article

0 notes