#Medical Grade Thermocouple Wire

Text

Medical Grade Thermocouple Wire Market Overview and Regional Outlook Study 2017 – 2032

The market for medical grade thermocouple wire is witnessing steady growth due to the increasing demand for accurate and reliable temperature measurement in the medical industry. Thermocouples are widely used in various medical applications, including monitoring body temperature, laboratory testing, and medical equipment calibration.

Market Overview of Medical Grade Thermocouple Wire:

Technological Advancements: Advancements in thermocouple wire technology, such as the development of high-precision sensors and miniaturization, are driving the market growth. These advancements enable accurate temperature measurements in medical devices.

Healthcare Industry Expansion: The expanding healthcare industry, including hospitals, clinics, and research laboratories, is creating a substantial demand for medical grade thermocouple wire. These wires are widely used in medical devices, such as patient monitoring systems, incubators, and surgical equipment.

Stringent Regulations: The medical industry is subject to strict regulations regarding patient safety and product quality. Medical grade thermocouple wires comply with these regulations, ensuring reliability and accuracy in temperature measurement, which is a key factor driving their adoption.

Increasing Awareness: Growing awareness among healthcare professionals and researchers about the benefits of using thermocouple wires in medical applications is boosting the market. These wires offer advantages such as high accuracy, fast response time, and compatibility with various medical devices.

Key Factors Driving the Medical Grade Thermocouple Wire Market:

Rising Focus on Patient Safety: The healthcare industry's increasing emphasis on patient safety and comfort is driving the demand for medical grade thermocouple wires. These wires help in precise temperature monitoring, ensuring optimal patient care.

Growing Demand for Minimally Invasive Procedures: The rising preference for minimally invasive procedures requires accurate temperature sensing and monitoring during surgeries. Medical grade thermocouple wires enable real-time temperature measurements, enhancing the safety and success rates of such procedures.

Advancements in Medical Device Technologies: The continuous advancements in medical device technologies, such as wearable devices and remote patient monitoring systems, are fueling the demand for medical grade thermocouple wires. These wires play a crucial role in temperature sensing within these devices.

Increasing Research and Development Activities: The ongoing research and development activities in the medical field, including the development of new drugs, medical treatments, and diagnostic techniques, rely on accurate temperature measurements. Medical grade thermocouple wires are essential components in such research activities.

Growing Geriatric Population: The global increase in the geriatric population is driving the demand for medical devices and healthcare services. Medical grade thermocouple wires find extensive applications in temperature monitoring devices used for elderly care, such as patient monitors and wearable health trackers.

COVID-19 Impact: The COVID-19 pandemic has increased the demand for medical devices and equipment, including temperature monitoring systems. Thermocouple wires are used in various COVID-19-related applications, such as vaccine storage and transport, ICU patient monitoring, and fever detection systems.

Expansion of Home Healthcare: The rising trend of home healthcare services and the need for portable medical devices have led to an increased demand for medical grade thermocouple wires. These wires enable temperature monitoring in portable devices used for home healthcare purposes.

Increasing Adoption of Wireless Thermocouple Systems: The market is witnessing a shift towards wireless thermocouple systems, which offer convenience, ease of use, and reduced clutter. Medical grade thermocouple wires are an integral part of these wireless systems, driving their demand.

Collaborations and Partnerships: Key players in the medical device industry are entering into collaborations and partnerships to develop innovative solutions. Such collaborations involving medical grade thermocouple wire manufacturers contribute to market growth.

Growing Focus on Precision Medicine: The increasing focus on precision medicine, which involves personalized treatment based on individual characteristics, requires accurate temperature monitoring in various medical procedures. Medical grade thermocouple wires play a vital role in delivering precise temperature measurements for effective treatment outcomes.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/medical-grade-thermocouple-wire-market/3577/

Market Segmentations:

Global Medical Grade Thermocouple Wire Market: By Company

• TE Wire&Cable

• Johnson Matthey

• Heraeus

• Sandvik (Kanthal)

• BASF

• OMEGA Engineering

• Belden

• Pelican Wire

• National Instruments

• Indutrade (Pentronic)

• Pyromation

• Dwyer Instruments

• Tempco

• Durex Industries

• Marlin Manufacturing Corporation

• Multi/Cable Corporation

• Ellab

• Temprel

• Thermo-Electra

• Hayashidenko

Global Medical Grade Thermocouple Wire Market: By Type

• Type T

• Type K

• Other

Global Medical Grade Thermocouple Wire Market: By Application

• Pharmaceutical Enterprise

• Hospital

• Other

Global Medical Grade Thermocouple Wire Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Medical Grade Thermocouple Wire market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/medical-grade-thermocouple-wire-market/3577/

Reasons to Purchase Medical Grade Thermocouple Wire Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

Medical Grade Thermocouple Wire Market Research Report Contains Answers to your following Questions

Which Manufacturing Technology is Used for Medical Grade Thermocouple Wire? What Developments Are Going On in That Technology? Which Trends Are Causing These Developments?

Who Are the Global Key Players in This Medical Grade Thermocouple Wire Market? What's Their Company Profile, Their Product Information, and Contact Information?

What Was Global Market Status of Medical Grade Thermocouple Wire Market? What Was Capacity, Production Value, Cost and PROFIT of Medical Grade Thermocouple Wire Market?

What Is Current Market Status of Medical Grade Thermocouple Wire Industry? What's Market Competition in This Industry, Both Company, and Country Wise? What's Market Analysis of Medical Grade Thermocouple Wire Market by Taking Applications and Types in Consideration?

What Are Projections of Global Medical Grade Thermocouple Wire Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

What Is Medical Grade Thermocouple Wire Market Chain Analysis by Upstream Raw Materials and Downstream Industry?

What Is Economic Impact On Medical Grade Thermocouple Wire Industry?

What are Global Macroeconomic Environment Analysis Results? What Are Global Macroeconomic Environment Development Trends?

What Are Market Dynamics of Medical Grade Thermocouple Wire Market? What Are Challenges and Opportunities?

What Should Be Entry Strategies, Countermeasures to Economic Impact, Marketing Channels for Medical Grade Thermocouple Wire Industry?

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/medical-grade-thermocouple-wire-market/3577/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Medical Grade Thermocouple Wire#Thermocouple Technology#Temperature Measurement#Medical Devices#Healthcare Industry#Biomedical Applications#Thermocouple Sensors#Medical Equipment#Temperature Monitoring#Diagnostic Devices#Surgical Instruments#Patient Care#Clinical Research#Temperature Sensing#Biotechnology#Laboratory Instruments#Quality Control#Regulatory Compliance#Medical Instrumentation#Patient Monitoring#Invasive Procedures#Medical Testing#Precision Measurement#Life Sciences#Remote Monitoring#Sterilization Processes#Heat Management#Data Logging#Therapeutic Devices#Research and Development.

0 notes

Text

T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables, conductive screws, shells and various conduits, etc. T3 copper is mainly used as structural materials, such as the production of electrical switches, washers, rivets, nozzles and various conduits, etc.; it is also commonly used in some less important conductive components. components.

What Materials are Available in Copper CNC?

Copper classification and characteristics

1. Pure copper in China commonly known as 'purple copper' in Japan and Taiwan commonly known as 'red copper' a common grades: T1, T2, T3, TU1, TU2 b characteristics: conductive with c common uses: electrical switches, motor coils, electronic parts.

2. Brass with zinc a Common grades: H59, H62, H65, H68, HPb59-1 Free-cutting brass b Characteristics Higher strength, wear resistance, water vapor corrosion resistance c Common uses Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, munitions.

3. White brass: Nickel-containing Common grades: B19, B25, BFe10-1-1, BZn15-20, BA13-3 b characteristics: stable physical properties at room temperature c common use medical apparatus, precision instruments, thermocouples, watch parts, glasses frame

4. Bronze: a definition: the old name that tin bronze such as the ancient bell, tripod, wine ware New definition: purple, yellow, white copper other than the three categories of the collective name b according to the practical physical and chemical indicators such as hardness, strength, elasticity, high-temperature conductivity, thermal conductivity and so on the engineering composite index and have different formulations. c uses: tin-phosphor bronze, good elasticity, for lamps Spring piece, switch spring piece. Resistance welding electrode material roll welder, butt welder, touch welder, rivet welder. Chrome zirconium copper, beryllium cobalt copper.

About Copper CNC Machining

Using a computer-controlled machining tool, copper is shaped into a variety of components during the copper CNC machining process. Due to its precision and reproducibility, it is one of the most flexible and popular machining methods for copper objects. Both basic pieces with simple shapes and complicated parts with detailed shapes can be produced using this method. For applications requiring high levels of dimensional accuracy, close tolerances, and outstanding surface polish, copper CNC machining is appropriate.

1 note

·

View note

Text

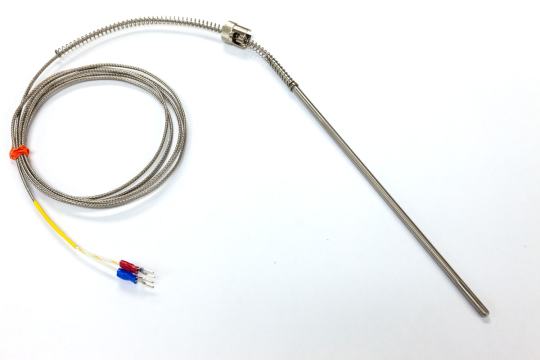

𝐑𝐞𝐬𝐢𝐬𝐭𝐚𝐧𝐜𝐞 𝐓𝐞𝐦𝐩𝐞𝐫𝐚𝐭𝐮𝐫𝐞 𝐃𝐞𝐭𝐞𝐜𝐭𝐨𝐫𝐬 (𝐑𝐓𝐃’𝐬)

RTD TYPES: PT - 50, PT- 100, PT-200, PT- 500, PT-1000

TEMPERATURE RANGE: -200 TO +600 °C

ELEMENTS: Platinum Thin RTD, Ceramic Wire Wound

CLASS OF TOLERANCE: 1/3, 1/10, CLASS A, CLASS B, CLASS C, CLASS Y &

STANDARD RTD MI PROBE SIZES: 2,3,4,5,6,8,10,12,16,19,20,21,22,25 mm

CONFIGURATION: SIMPLEX, DUPLEX, TRIPLEX and MULTIPOINT

GRADE OF PROTECTION: IP 55, IP 65, IP 67, ATEX, CCOE, FLAME PRROF

TYPE OF TERMINATION: plug and Socket, IP Rated HEAD, DIN and Explosion -Proof Connection Head

CONNECTORS: MIL STD, NYLON, PLASTIC, CERAMIC

TYPE OF MEASUREMENT: AIR, GAS, LIQUID IMMERSION, CONTACT, SURFACE

SHEATHS: SS 304, SS 316, SS 310, SS 446, INCONEL 600, INCONEL 800, INCOLY TITANIUM, INCONEL, CERAMIC, APM

STANDARDS: DIN EN 60751

𝐀𝐏𝐏𝐋𝐈𝐂𝐀𝐓𝐈𝐎𝐍𝐒

FOOD/ OIL/GAS/CHEMICAL/LAB & MEDICAL etc

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬

📷+ 𝟗𝟏 𝟗𝟖𝟒𝟒𝟐𝟑𝟑𝟐𝟒𝟒

📷 𝐢𝐧𝐟𝐨@𝐡𝐞𝐚𝐭𝐜𝐨𝐧𝐬𝐞𝐧𝐬𝐨𝐫𝐬.𝐜𝐨𝐦

📷 https://heatconsensors.com/

#heatconsensors #sensors #thermocouples #rtds

0 notes

Text

High nickel alloys for sheathing applications

The metallic sheath is used to secure the internal thermocouple wires from chemically active conditions. In few conditions, hot air can damage the thermocouple wires and result into permanent lose calibration. Selection of the suitable metal sheath material is based on the required application, the industry in which they function and the area they are established. Commonly used metal sheath materials are stainless steel 304 and Inconel 600. They are commonly used in multiple industries for example food processing. Stainless steel grade 304 is a widely used alloy that is easily available and economical to manufacture. Few industries like petroleum, medical, nuclear, aircraft and power production have their specific standards and need more complex and higher performance alloys.

Following are the commonly used alloys for sheath materials.

Stainless steel 304: A low carbon version of stainless steel 304 is called 304l, because it can be welded more easily. Normally, it is interchangeable with plain 304. Applications of 304 stainless steel are in food and beverage processing, chemical processing, dairy, hospital and pharmaceutical plants, nuclear reactor components, containers for mild corrosives. Temperature limitations are up to 1600oF for cyclic processes. Inconel 600 is widely used at temperature about or above 1650oF.

Inconel 600: High nickel and chromium alloy is costlier than varied stainless steels. It is recommended for prolong use at high temperatures and prevents corrosion by simple acids and pure water. Applications of Inconel 600 include furnace components, chemical and food processing, nuclear power production and caustic chemicals. It is used at temperatures up to 2100oF.

Stainless steel 310

It is commonly used at higher temperatures because it resists scaling up to 1900oF. The alloy is stronger and prevents air corrosion better than stainless steel 304 at these higher temperatures. It also serves well in fossil fuel gases at high temperatures.

Applications of 310 stainless steel are air heaters, baking systems, chemical processing systems, furnace components, heat exchangers and electric power system and petroleum refining. It is recommended for use up to 1900oF.

Stainless steel 316/316l

Higher corrosion resistance to most chemicals, salts and acids than various stainless steels because of presence of molybdenum. It also significantly prevents corrosion against sulfur or chlorine based liquids. This steel grade is commonly used in marine trim exteriors, chemical and food processing, petroleum refining equipment, paper and pulp and textile finishing. It should be used up to 1600oF continuously in air or in cyclic corrosive media, nominally higher in air.

Hastelloy X

Hastelloy X grade is costly because of presence of iron, chromium and molybdenum. It features high temperature strength and supreme oxidation resistance. It is comparatively old alloy, more economical and offers better performance than some new materials. Applications of Hastelloy wire made from grade X include gas turbines for power production, aerospace applications, industrial furnaces, boiler and pressure vessels. The temperature limitations of Hastelloy X are up to 2150oF.

0 notes

Text

#Global Medical Grade Thermocouple Wire Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

Medical Grade Thermocouple Wire Market

0 notes