#Thermocouple Sensors

Text

Medical Grade Thermocouple Wire Market Overview and Regional Outlook Study 2017 – 2032

The market for medical grade thermocouple wire is witnessing steady growth due to the increasing demand for accurate and reliable temperature measurement in the medical industry. Thermocouples are widely used in various medical applications, including monitoring body temperature, laboratory testing, and medical equipment calibration.

Market Overview of Medical Grade Thermocouple Wire:

Technological Advancements: Advancements in thermocouple wire technology, such as the development of high-precision sensors and miniaturization, are driving the market growth. These advancements enable accurate temperature measurements in medical devices.

Healthcare Industry Expansion: The expanding healthcare industry, including hospitals, clinics, and research laboratories, is creating a substantial demand for medical grade thermocouple wire. These wires are widely used in medical devices, such as patient monitoring systems, incubators, and surgical equipment.

Stringent Regulations: The medical industry is subject to strict regulations regarding patient safety and product quality. Medical grade thermocouple wires comply with these regulations, ensuring reliability and accuracy in temperature measurement, which is a key factor driving their adoption.

Increasing Awareness: Growing awareness among healthcare professionals and researchers about the benefits of using thermocouple wires in medical applications is boosting the market. These wires offer advantages such as high accuracy, fast response time, and compatibility with various medical devices.

Key Factors Driving the Medical Grade Thermocouple Wire Market:

Rising Focus on Patient Safety: The healthcare industry's increasing emphasis on patient safety and comfort is driving the demand for medical grade thermocouple wires. These wires help in precise temperature monitoring, ensuring optimal patient care.

Growing Demand for Minimally Invasive Procedures: The rising preference for minimally invasive procedures requires accurate temperature sensing and monitoring during surgeries. Medical grade thermocouple wires enable real-time temperature measurements, enhancing the safety and success rates of such procedures.

Advancements in Medical Device Technologies: The continuous advancements in medical device technologies, such as wearable devices and remote patient monitoring systems, are fueling the demand for medical grade thermocouple wires. These wires play a crucial role in temperature sensing within these devices.

Increasing Research and Development Activities: The ongoing research and development activities in the medical field, including the development of new drugs, medical treatments, and diagnostic techniques, rely on accurate temperature measurements. Medical grade thermocouple wires are essential components in such research activities.

Growing Geriatric Population: The global increase in the geriatric population is driving the demand for medical devices and healthcare services. Medical grade thermocouple wires find extensive applications in temperature monitoring devices used for elderly care, such as patient monitors and wearable health trackers.

COVID-19 Impact: The COVID-19 pandemic has increased the demand for medical devices and equipment, including temperature monitoring systems. Thermocouple wires are used in various COVID-19-related applications, such as vaccine storage and transport, ICU patient monitoring, and fever detection systems.

Expansion of Home Healthcare: The rising trend of home healthcare services and the need for portable medical devices have led to an increased demand for medical grade thermocouple wires. These wires enable temperature monitoring in portable devices used for home healthcare purposes.

Increasing Adoption of Wireless Thermocouple Systems: The market is witnessing a shift towards wireless thermocouple systems, which offer convenience, ease of use, and reduced clutter. Medical grade thermocouple wires are an integral part of these wireless systems, driving their demand.

Collaborations and Partnerships: Key players in the medical device industry are entering into collaborations and partnerships to develop innovative solutions. Such collaborations involving medical grade thermocouple wire manufacturers contribute to market growth.

Growing Focus on Precision Medicine: The increasing focus on precision medicine, which involves personalized treatment based on individual characteristics, requires accurate temperature monitoring in various medical procedures. Medical grade thermocouple wires play a vital role in delivering precise temperature measurements for effective treatment outcomes.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/medical-grade-thermocouple-wire-market/3577/

Market Segmentations:

Global Medical Grade Thermocouple Wire Market: By Company

• TE Wire&Cable

• Johnson Matthey

• Heraeus

• Sandvik (Kanthal)

• BASF

• OMEGA Engineering

• Belden

• Pelican Wire

• National Instruments

• Indutrade (Pentronic)

• Pyromation

• Dwyer Instruments

• Tempco

• Durex Industries

• Marlin Manufacturing Corporation

• Multi/Cable Corporation

• Ellab

• Temprel

• Thermo-Electra

• Hayashidenko

Global Medical Grade Thermocouple Wire Market: By Type

• Type T

• Type K

• Other

Global Medical Grade Thermocouple Wire Market: By Application

• Pharmaceutical Enterprise

• Hospital

• Other

Global Medical Grade Thermocouple Wire Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Medical Grade Thermocouple Wire market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/medical-grade-thermocouple-wire-market/3577/

Reasons to Purchase Medical Grade Thermocouple Wire Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

Medical Grade Thermocouple Wire Market Research Report Contains Answers to your following Questions

Which Manufacturing Technology is Used for Medical Grade Thermocouple Wire? What Developments Are Going On in That Technology? Which Trends Are Causing These Developments?

Who Are the Global Key Players in This Medical Grade Thermocouple Wire Market? What's Their Company Profile, Their Product Information, and Contact Information?

What Was Global Market Status of Medical Grade Thermocouple Wire Market? What Was Capacity, Production Value, Cost and PROFIT of Medical Grade Thermocouple Wire Market?

What Is Current Market Status of Medical Grade Thermocouple Wire Industry? What's Market Competition in This Industry, Both Company, and Country Wise? What's Market Analysis of Medical Grade Thermocouple Wire Market by Taking Applications and Types in Consideration?

What Are Projections of Global Medical Grade Thermocouple Wire Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

What Is Medical Grade Thermocouple Wire Market Chain Analysis by Upstream Raw Materials and Downstream Industry?

What Is Economic Impact On Medical Grade Thermocouple Wire Industry?

What are Global Macroeconomic Environment Analysis Results? What Are Global Macroeconomic Environment Development Trends?

What Are Market Dynamics of Medical Grade Thermocouple Wire Market? What Are Challenges and Opportunities?

What Should Be Entry Strategies, Countermeasures to Economic Impact, Marketing Channels for Medical Grade Thermocouple Wire Industry?

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/medical-grade-thermocouple-wire-market/3577/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Medical Grade Thermocouple Wire#Thermocouple Technology#Temperature Measurement#Medical Devices#Healthcare Industry#Biomedical Applications#Thermocouple Sensors#Medical Equipment#Temperature Monitoring#Diagnostic Devices#Surgical Instruments#Patient Care#Clinical Research#Temperature Sensing#Biotechnology#Laboratory Instruments#Quality Control#Regulatory Compliance#Medical Instrumentation#Patient Monitoring#Invasive Procedures#Medical Testing#Precision Measurement#Life Sciences#Remote Monitoring#Sterilization Processes#Heat Management#Data Logging#Therapeutic Devices#Research and Development.

0 notes

Text

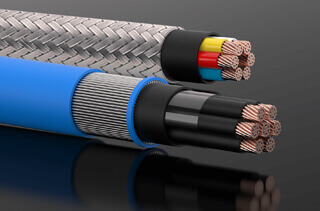

Discover India's Leading Cable Manufacturers | Top Quality Cables at Tempsens

Explore the excellence of top cable manufacturers in India at Tempsens Instruments. Elevate your connectivity with precision-engineered cables, ensuring reliability and performance. Uncover a world of trusted quality for your diverse needs.

#tempsens#cable manufacturer in india#tempsens instruments#wires and cables manufacturers in india#temperature sensor manufacturers in india#thermal solutions#tempsens india#thermocouple india

0 notes

Text

RK Temp Sensor are one of the leading thermowell manufacturers in Chennai. We offer a wide range of thermowell products and services.

1 note

·

View note

Text

Let Us Explore the Use of Thermocouples in Space

Spacecraft are marvels of engineering, designed to endure extreme conditions while exploring the cosmos. To ensure the safety and efficiency of these vehicles, precise monitoring of temperatures is essential. What more?

Read our article to know more.

Looking to purchase good quality Thermocouples for Automotive Industry?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing RTDs and Thermowells for more than 35 years.

#heatconsensorspvtltd#automotive#industrialuse#Thermocouple#sensors#temperaturemeasurement#spacecraft#engineering#monitoring#solarpanels

0 notes

Text

The IsoBlock T-1c is a high-performance isolated amplifier with built-in thermocouple cold junction compensation. It produces a low impedance isolated (6 mV/°C) output signal that can be measured with any standard ±10V DAQ

1 note

·

View note

Text

A brief note on the sensors created by the sensor manufacturers in Pune

Sensors are valuable tools that are often used in our day to day lives. They are often used in electronics and in computing technology. The sensor basically functions as a device which can detect any changes within the environment. They can also respond to some kind of output produced by another system. The role of a sensor is to convert some physical phenomenon or signal into a quantifiable digital signal or analog voltage. This is then converted into some kind of human-readable display and/or transmitted for the purpose of reading or additional processing. The input that is detected by the sensor from its immediate physical environment can vary in its form. Some of the most common forms of input here include motion, light, heat, pressure, moisture or any other type of environmental phenomena. This leads the sensor to create an output in its response. This output is mostly a signal and it can be read with the help of a human-readable display machine.

A sensor device helps to detect and read the signal from its immediate environment which is transmitted electronically. A common example of sensor is a microphone as it helps to convert the sound energy into an electrical signal which can be further amplified, recorded, transmitted and reproduced. These days when computers and computing technology is used at almost all aspects of human lives, the sensors have become an essential component for all things related to internet of things (IoT). Through the use of sensors, it is possible to give rise to a huge ecosystem of connected devices that seamlessly collect, share and process data regarding the environment in which they operate and the users that interact with these devices. This in turn helps the companies owning the devices to monitor, control and manage the devices with greater accuracy and efficiency. The IoT sensors are extensively used in automobiles, in the airplanes, in homes, in the field, in various industrial settings as well as in other locations. The use of sensors makes it possible to create a connection between the physical domain and the logical world.

Such factors really make the sensors a quintessential component for computing infrastructure which in turn can assist in analyze and act on the data that has been collected with the help of the sensors. Over the years, many different types of sensors have been designed and produced and they all have specific user cases of their own. Some of the most well known types of sensors that you can find in the market include thermocouples, thermistors and RTDs, all of which are used to measure temperature. Other types of sensors include the load cells that can help in measuring load and weight; strain gages for measuring the strain on some object, such as tension, pressure and weight; accelerometers for measuring shock and vibration; LVDT sensors for measuring the displacement in distance; Microphones to capture the sound waves; current transducers that can help in measuring the AC current or DC current; optical sensors for detecting light, replace conventional sensors and transmission of data; voltage transformers to measure the high voltage potentials; camera sensors for capturing single as well as continuous 2D images, positioning sensors for GPS purposes and digital sensors for rotary and linear encoding as well as position measurements.

When you need to get specific types of sensors for your operations, you need to contact a company of sensor manufacturers in Pune that can get you the products you are looking for. This will not only help you to ensure complete accuracy of your procedure but also ensure the best output in the process.

0 notes

Link

Quick Sense(QS-TC02): Digital AC 90V 250V Digital Temperature Controller Thermostat

Switch the modes between cool and heat; Control temperature by setting the temperature set value and the different value; Temperature collaboration; Refrigerating control output delay protection; Alarm when temperature exceeded temperature limit or when sensor error.

Specification and size

Front panel size: 75(L)x34.5(W)(mm)

product size: 75(L)x34.5(W)x85(D)(mm)

Mounting size: 71(L)x29(W)(mm)

Sensor length: 2m(Include the probe)

Technical parameters

Temperature measuring range: -50°C~90°C

Resolution: 0.1°C

Accuracy: +-1°C(-50°C~70°C)

Power supply: 220VAC 50Hz/60Hz

Power consumption: <3W

Sensor: NTC sensor (1P°C)

Relay contact capacity:Cool(10A/250VAC);Heat(10A/250VAC)

Ambient temperature: 0°C~60°C

Storage temperature: -30°C~75°C

Relative humidity: 20~85%(No condensate)

1 note

·

View note

Text

There is nothing that amuses me more than a secret inside of a secret.

Here’s an article that I wrote that my friend Dario Leone owner of Aviation Geek Club shared about the YF 12 and the secret SR 71 tail number 951.

Most people when they think of the YF 12 think of it as an experimental airplane that never really flew, but that is wrong. It did fly for many years. The last flight was in 1979 when it was flown to the Air Force Museum near Dayton, Ohio you can find it next to the XB-70.

The so-called YF-12C was really the SR-71A 61-7951, modified with a bogus tail number 06937 belonging to an A-12.

Taken in 1975, the interesting photos in this post show NASA Blackbirds carrying the ” Cold wall” heat transfer pod on a pylon beneath the forward fuselage.

The Blackbirds portrayed in these photos are usually referred to as YF-12s, but actually one of them was an SR-71 as Linda Sheffield Miller (Col Richard (Butch) Sheffield’s daughter, Col. Sheffield was an SR-71 Reconnaissance Systems Officer), who runs Born into the Wild Blue Yonder Habubrats Facebook page, told to The Aviation Geek Club: ‘In case anybody asked the pictures with the two NASA Blackbirds the one on the top is a YF-12 but the one on the bottom is an SR-71!

‘Another interesting thing about those pictures is that NASA was not allowed to have an SR-71 but they did and they passed it off as a YF-12!

In fact, the “YF-12C” was a then-secret SR-71A (serial no. 64-17951, the second production SR-71A) given the NASA tail no. 60-6937. The reason for this bit of subterfuge lay in the fact that NASA while flying the YF-12A interceptor version of the aircraft, was not allowed to possess the strategic reconnaissance version for some time. The bogus tail number actually belonged to a Lockheed A-12 (serial no. 60-6937), but the existence of the A-12 remained classified until 1982. The tail number 06937 was selected because it followed the sequence of tail numbers assigned to the three existing YF-12A aircraft: 06934, 06935, and 06936. Isn’t that amazing?’

The Coldwell project, supported by Langley Research Center, consisted of a stainless steel tube equipped with thermocouples and pressure sensors. A special insulating coating covered the tube, which was chilled with liquid nitrogen.

Given that the US Air Force (USAF) needed technical assistance to get the latest reconnaissance version of the A-12 family, the SR-71A, fully operational, the service offered NASA the use of two YF-12A aircraft, 60-6935 and 60-6936.

Eventually, with 146 flights between Dec. 11, 1969, and Nov. 7, 1979, 935 became the workhorse of the program while the second YF-12A, 936, made 62 flights. Given that this aircraft was lost in a non-fatal crash on Jun. 24, 1971, it was replaced by the so-called YF-12C SR-71A 61-7951, modified with YF-12A inlets and engines and a bogus tail number 06937.

The SR-71 differed from the YF-12A in that the YF-12A had a round nose while the SR-71 had its chine carried forward to the nose of the airplane. The SR-71 was longer, nearly 8 feet longer as it had an extra fuel tank that the YF 12 didn’t have. There were other differences in internal and external configuration, but the two aircraft shared common inlet designs, structural concepts, and subsystems. Also of note the SR 71C is really a combination of a static display of the SR 71 for the front half and the back half is the crashed YF-12!

In my study of all the Blackbirds, I have found other secrets inside of secrets. Such as the test SR-71 plane the 955. Everyone was told often that this airplane never left the United States, but that is not true.

When it comes to reconnaissance airplanes and War, even if it was a Cold War, Rearranging the facts is fair.

There will always be mystery in the SR 71 program.

Don’t believe that all of the secrets have been told.

I know that is not true.

Linda Sheffield, Daughter of a Habu

@Habubrats71 via X

Tap Title bar to view👇

42 notes

·

View notes

Text

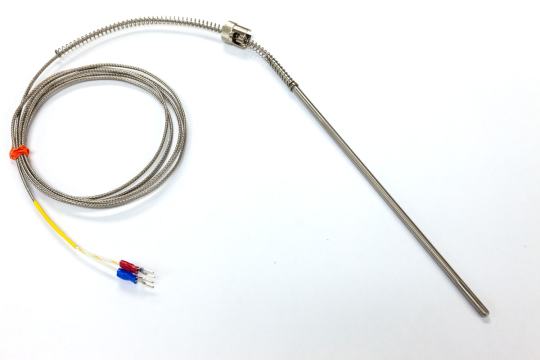

Measuring Temperature through Electrical Properties

There are three common temperature sensors that rely on the electronic properties of materials to determine temperature.

The first are thermocouples. Thermocouples measure temperature based on the Seebeck effect. When a temperature difference exists between two connected and dissimilar (electrically conductive) metals, charge will flow from the warm end to the cool end, creating a voltage that is used to calculate the temperature. There are multiple types of thermocouples, including thermocouple probes and wires, and multiple materials that are used for these sensors. Commercial thermocouples are fairly inexpensive but may not be accurate to more than a degree or so.

The term thermistors, the second type of sensor, comes from thermal resistor. These are semiconducting resistors, whereas the resistance of the material is strongly dependent on temperature. There are two general types of thermistors, negative-temperature-coefficient (NTC) thermistors and positive-temperature-coefficient (PTC) thermistors, which have either less or more resistance at higher temperatures, respectively. These sensors are typically highly accurate, but have a limited range.

Finally, resistance temperature detectors (RTDs) also use electrical resistance to measure temperature, but whereas thermistors use semiconductors, RTDs use pure metals. Platinum, copper, and nickel wires are common choices and RTDs are typically produced in 2-, 3-, or 4-wire configurations, where the 4-wire varieties have the highest accuracy.

Sources/Further Reading: (Image source - MadgeTech) Thermocouples: (Omega, Wikipedia); Thermistors: (Omega, Wikipedia); RTDs: (Electrical4U, Wikipedia)

12 notes

·

View notes

Text

Two-Body Problem

Mark Watney x reader

Grad School AU, (academic) rivals to ??????

No use of y/n

[Masterlist]

Not Beta-read, we die like Spirit and Opportunity.

CW: networking, Inaccurate depictions of organic chemistry, probably riddled with typos, but that's all I can think of. Please please please let me know if I missed anything and I'll add it to the top of the list

The reader and Mark are both PhD candidates at Northwestern and both happen to be GTAs for an o-chem/bio-chemistry class. They schedule and meet up on neutral ground(a library) to get some grading done together and some unexpected feelings creep in.

AN: This is the first fanfic I've ever written; critique is always welcome and encouraged, but, uh, perhaps manage your expectations? Idk 😅 I'm not the best when it comes to creative writing, but there's a criminally low amount of fic for The Martian and even fewer fic centered around Mark imo. I might continue this into something more, if there's demand and if I've the energy and motivation 🤷🏾

Alright, I'll stop trying to lamp-shade; Enjoy, and thanks for taking the time out of your day to read this 💚💚💚

●○●○●○●○●○●○●○●○●○●○●○●○●○●○●○●○●○●○●

Wanna meet up to put a dent in the pile of grading I know you also have?

The two of you exchanged numbers at the beginning of fall quarter out of politeness, but it was still surprising to see the notification from Mark’s text.

Leaning back in your chair, you considered your options, the soft sensor schematic in front of you now fully abandoned after an hour of rearranging thermocouples and resistors trying to alleviate a stubborn inductive noise problem.

Mark had been a thorn in your proverbial side since the day you met him; well, night, to be exact—your blood begins to boil at the memory. You were engaged in cordial and calculated banter with a researcher working in a lab you were gunning for before being interrupted by someone exclaiming “Dr. Hernandez!” to your left. You blinked and the fragile connection you just began to form had crumbled as the attention of the faculty member in question whirled to the side and greeted a stocky and stubbly man who Dr. Hernandez introduced to you as “Mark Watney, one of my PhD students!” This confused you since his name tag clearly said, Plant Bio and Conservation and this was a mixer in the electrical and computer engineering department; “I’m working with him and a faculty member in my own department on developing novel ways of monitoring soil properties in areas in Illinois hardest hit by industrial runoff” Mark says with a smile that oozes levels of confidence and hubris only considerable privilege can spawn. He gives you a quick glance before saying, “which actually reminds me-” and steering Dr. Hernandez away from you. Now, this certainly stung, but it wasn’t anything that you couldn’t get over. No, what made this a problem was Mark’s uncanny ability to draw the room’s attention to him and his work, making it a just a tad difficult to properly network without having to entertain talk and conversation surrounding the department’s charismatic new wunderkind apparent. This combined with quite publicly challenging a design of yours for a class you two shared had firmly placed Mark in your list of worst enemies. Which, admittedly, might be a bit dramatic, but after some quippy and well worded critiques and suggestions to optimize a C++ script he’d written for the same class it seemed you’d made your way onto his hit list too, if department gossip had any veracity to it—so at least the feeling was mutual.

Which brings you back to your confusion at this new development in your communication with him; Mark hadn’t exactly jumped for joy when, in some sick reversal of the infamous two-body problem, the two of you got hired as TAs for the same introductory o-chem class. You exchanged numbers, but neither reached out to the other to host joint office hours, or to work together to get through the ever-growing pile of completed homework assignments that you two need to finish grading—in fact, this is the first time either of you texted the other since the first text you sent confirming your number as yours. Staring at your phone’s screen you weighed the pros and cons of saying yes; on the one hand, it’ll help the two of you get ahead on the imposing pile of work that had accumulated just in the first 2 and a half weeks of the quarter. On the other hand, it meant that you’d have to breathe the same air as your infuriatingly handsome nemesis for longer than you were required to. Not that he was your type. Absolutely not. He just… had an objectively strong jawline…. Choosing not to think too hard about that and reasoning that getting grading done was more important than your pride, you typed out a curt sure. See you at Galter in an hour? And waited for his equally as curt sounds good before getting up to go change out of your comfy, at-home garb and head out the door with your half of the grading pile and your laptop tucked away into your backpack.

You’re chewing the last bite of a pop tart you got, realizing you unfortunately forgot to eat dinner before leaving, and scrolling through Instagram when Mark walks through the glass doors leading into the Galter Health Sciences Library. Under a mild windbreaker, he’s wearing what’s presumably a band t-shirt but with a worn-out and unrecognizable logo tucked into his cuffed light wash jeans. He"s carrying a clearly well-loved canvas satchel with a Cubs patch sewn onto the front. His hair was artfully tousled as he ran a hand through it while he looked for you in the spattering of students who occupied the library at minutes to 9 on a Friday evening. When his eyes finally land on you, he looks taken aback, the carefree look wiped off his face for a moment before he smirks at you through an obviously clenched jaw. “Glad you didn’t decide to stand me up. You reserve a conference room?” You returned his tension-filled smirk with a smile resembling a sneer and responded, “Of course. We’re on the second floor.” You stood up from your seat and started walking in the direction of the staircase, looking behind you to make sure he was following you only to find him in the middle of a light jog to position himself on your right side.

“So, how’s the dissertation writing going?” he asks over his shoulder. Scoffing, you respond with an incredulous “How’s yours?”, hoping he pics up on your clear annoyance at being asked that dreaded question yet again. Wincing at your retort of a question, he concedes with a “Fair enough” And the two of you are plunged back into the awkward silence that permeates the sparsely populated library.

after finally finding the room you reserved(the library is like a maze, capable of ensnaring even the most seasoned of academics), you shuffle into the study room together and set up your computers and piles of homework to be graded before settling into a serene flow with Mark working quietly beside you.

after about thirty minutes, you look over to Mark’s pile and notice that his “complete” pile is, unfortunately, larger than yours, which ignites a spark of competition in you. You start to try to work through your pile faster and Mark seems to pick up on your haste.“Worried about falling behind?” he scoffs with a shit-eating grin, clasping his hands together in front of his mouth. “Oh, not in the slightest; just trying to optimize my time, I've more work to get back to, you know.” you say, smirking back at him but with a glint in your eye, tacitly challenging him to try to get through his pile before you get through yours.

The two of you actually make some substantial progress in both of your piles before you encounter one of the more difficult homework assignments your students have been assigned. You’re stumped by the multi-part problem at the top of the page, trying unsuccessfully to follow the student’s work in front of you.

“... You on homework 15 yet?”

“Yep.” you nod.

“... You have any idea what Dr. C is asking them to do?”

“Absolutely not.”

“Alright, just checking.”

Mark sits back in his chair with a thud and runs a hand down his face. you stand from your seat and move to the small whiteboard on the wall opposite where you were sitting and start to list out the knowns and unknowns in the problem statement. You can feel Mark’s eyes on you the entire time, following along with your work and your movements as you draw out the reaction being described in the first part of the problem. You get stumped at the end of the problem, trying to piece together the end products of the reaction. You hear Mark shift behind you before turning around to see him walking toward the whiteboard to silently walk himself through your work, nodding at each step you took. He picks up a marker and starts adding onto where you were stumped and you watch intently, absorbing what he’s writing. As he finishes the problem, you get the chance to actually get a look at him while he’s working; he furrows his eyebrows and you notice a small crease he gets between his eyebrows as they cinch together, and the faint spattering of freckles across his nose becomes apparent with how close he is to you now. God, he is so close-"that should be it? I think?" He looks to you with an indiscernible look in his eye; first, a hint of shock as his eyes widen--looks like he noticed how close you are too-- then something else you can't quite identify. It takes more effort than your willing to admit, but you eventually tear your eyes away from his and look at his work on the board. It all makes sense, you also note how messily he draws his diagrams of the assortment of carboxyl groups created by the process at the center of the problem(and it also takes everything within you not to smile at that, thinking to yourself, when did this start feeling nice???). "It, uh, it looks all good to me. And the rest should follow from this too." you utter awkwardly and turn to face him again. "Yeah?" His state of mind is still elusive to you, and he responds with an almost dazed sounding "Yeah."

The moment doesn't last for long though, as a soft knock sounds at the door, startling you both out of your joint reverie. "Hey, you guys are the TAs for o-chem this quarter, right? Do you have time to talk about the homework due tomorrow?" The two of you exchange a glance and invite the exhausted looking undergrad into the alcove.

After helping your wayward student, the two of you start packing up your now completed piles of grading in silence, the awkward air from the beginning of the night settling back in now that the distraction from grading was gone. The two of you are about to part ways at the entrance of the library when Mark stops you with a "hey," and says,"uh, so, I know we have this…whatever this is? Between us" He gestures chaotically back and forth in the space between you, and you raise an eyebrow at him. "But this is the most work I've gotten done in one sitting in a while. Would you, uh, like to do this again? Maybe? But at more reasonable hour?" Mark takes a defensive steps back, and this throws you off for a multitude of reasons. One, Mark is acting nervous, which is something you've had the pleasure of witnessing mabe once in your time being around him. Two, he seems to be genuinely asking spend more time with you. And, to be honest, after the silence between the two of you was broken, that was also the most productive you've been in a while. And it probably wouldn't hurt to actually collaborate with him instead of trying to compete with him. Just as you began to fear you were taking too long to respond, Mark pulls his hands out of his pockets and puts them up in the universal "I'm harmless" pose, "you don't have to, I just thought I'd ask-" "sure." You cut him off before he can try to answer his question for you. He looks at you with what can only be described as gleeful shimmer in his eyes and smirked again; this time, though, it didn't have his usual venom behind it. "Yeah?" He asks hopefully. "Yeah." You smile in return, it reaching your eyes this time.

#the martian#andy weir#the martian(2015)#mark watney#mark watney x reader#mark watney x gn!reader#gn!reader#self insert#no use of y/n#this is my first fanfic#and yes#I was imagining 90's Matt Damon while imagining what Mark would've looked like in grad school#academic rivals#enemies to lovers#?#but perhaps not as intense?#idk man#i just work here#space pirate#mark watney x oc

48 notes

·

View notes

Text

When, Why and How to Change Your Transmission Fluid in Porsche

Transmission related problems have become common in most of the cars. A substance which keeps the transmission parts protected is transmission fluid. When this fluid gets older in your transmission or gearbox, it loses some of its properties and has to be replaced. In this article you will get to know why, when and how you can replace the transmission fluid in your Porsche car.

Why do you have to replace the transmission fluid?

First you need to know about the role of transmission fluid in vehicles. Transmission fluid is a transparent, red coloured fluid used in your transmission for the purpose of lubrication of moving parts, prevention of overheating and increase longevity of the gear box. It helps the gearbox to carry out its work smoothly and effortlessly. Transmission fluid is like a tonic for gear box. The transmission fluid also has validity. If it becomes too old, used or impure, then it has to be changed. As the transmission fluid flows throughout the transmission, dirt and debris may get accumulated inside it with time, also older fluids fail to carry out their work effectively. Replacing the transmission fluid makes the transmission last longer and you will not have to take your car to diagnose transmission failure. Using the same fluid for years without changing it will cause the transmission to slip, the gears will get worn out and overheat, then the transmission may fail.

When to replace the transmission fluid?

Generally in Porsche cars, the transmission fluid is to be replaced once for every 30000 miles. In some models, it is recommended to replace the fluid for every 100000 miles. But the life of the fluid also depends on how often you use your car. Here are some signs that your transmission fluid needs replacement.

The colour of the fluid becomes dark brown or light pink, opaque or becomes cloudy or dirt and debris or other residues in the fluid.

Transmission begins to slip

Unusual grinding sounds from transmission.

Transmission begins to overheat

Also note that you have to also replace the transmission fluid filter with the fluid. The filter lasts for 30000-50000 miles.

How to change your transmission fluid?

To change the fluid you need to have automatic service transmission kit for your Porsche model. This kit has all those parts that are to be installed after replacement. You must have the following tools - 240Torx, level, 17 mm hex, 10 mm socket/ratchet, torque wrench, bead thermocouple digital temperature sensor, catch tray, lint free towels, gravity oil fill. You will get these all from local auto parts stores.

Steps

1. The vehicle is raised and the under plastic shield id removed to access transmission pan

2. Level on the oil pan is placed to check if the car is level, fore and aft, side to side.

3. Then drain the fluid by opening the transmission drain plug

4. To reduce spillage and drain more fluid, pan is made to tilt down towards the drain by loosening the pan bolts.

5. Other pan bolts are also to be removed. You will see three bolts that attach filter to the valve body. You have to unbolt them to remove the filter along with seal O ring.

6. New filter is installed and bolted. Then new gasket is to be installed.

7. The transmission pan is reinstalled and use thread locker while bolting the old bolts.

8. Pour the fluid through fill hole till it drips from the fill. The fluid should be of 3-4 liters.

9. Start the engine and allow it to idle. Adding of fluid should be continued.

10. Shift the gear lever from park to D, wait for 3 seconds, then turn it to R and wait for 5 seconds.

11. Engine should idle and check the fluid temperature by the temperature sensor while adding the fluid. Pouring of fluid should continue till it drips from the hole and the temperature comes near to 40 degree C.

12. Put the hole plug with a sealing ring and torque it to 70Nm.

You should be very care full while following these steps of changing the fluid. Never work under the car if you are alone.

Conclusion

If you do not get the tools, then you can get the work done in authorized service stations for Porsche. If you take your car for transmission service then the transmission fluid change will be done in an affordable price.

2 notes

·

View notes

Text

Understanding the Use of Thermocouples and the Automotive Industry

Multi-location measurement of temperatures is quite usual in the process of automotive testing. For the measurement of thermocouples in the brakes, the wire bundle of the thermocouple could speedily attain a stage wherein the diameter starts impacting the structural integrity. What more?

Read our article to know more.

Looking to purchase good quality Thermocouples for Automotive Industry?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing RTDs and Thermowells for more than 35 years.

#heatconsensorspvtltd#automotive#industrialuse#Thermocouple#sensors#temperaturemeasurement#infraredpyrometry#environmentcontrol#bangalore

0 notes

Text

Custom Cable Manufacturers: Tailored Solutions for Complex Needs

Custom cable manufacturers offer specialized solutions for industries requiring cables beyond standard specifications. From aerospace to medical devices, these manufacturers design and produce cables that meet exacting requirements in terms of size, material, insulation, and performance. Unlike off-the-shelf cables, custom cables are engineered to address specific challenges, such as extreme temperatures, high voltage, or unique environmental conditions.

One of the primary benefits of working with custom cable manufacturers is the ability to tailor cables to match precise technical demands. This ensures that the cable not only fits the equipment perfectly but also enhances operational efficiency and safety. Custom cables can also incorporate features such as shielding, multiple conductors, and custom jacketing to ensure optimal performance in challenging environments.

Additionally, custom cable manufacturers collaborate closely with clients to develop innovative solutions for complex projects, offering flexibility in terms of design, materials, and production timelines. This allows businesses to get a product that is perfectly suited to their needs, ensuring reliable performance and reduced downtime.

For industries looking to optimize their operations, working with custom cable manufacturers ensures access to high-quality, tailor-made cables that enhance productivity and durability.

#cable manufacturers#thermocouple wire#thermocouple wire type k#wire manufacturers#k type thermocouple wire#nichrome wire#high temperature wire#wire manufacturers in florida#heat trace cable#cable manufacturers in florida

0 notes

Text

TC Calibrator: Ensuring Precision in Temperature Measurement

In industries where accurate temperature measurement is critical, the TC calibrator (Thermocouple Calibrator) is an essential tool. Designed to test and calibrate thermocouples, which are widely used temperature sensors, the TC calibrator ensures that temperature readings are precise and reliable.

What is a TC Calibrator?

A TC calibrator is a device specifically designed for the calibration of thermocouples. Thermocouples measure temperature by generating a voltage that varies with temperature changes. The TC calibrator simulates precise temperature conditions and measures the output from thermocouples to ensure their accuracy.

Key Features

The TC calibrator comes equipped with several features that enhance its functionality:

High Accuracy: Provides precise temperature simulations, which are crucial for verifying the accuracy of thermocouples.

Wide Temperature Range: Capable of covering a broad range of temperatures, making it versatile for different calibration needs.

User-Friendly Interface: Includes a digital display and intuitive controls for easy operation and clear readouts.

Multiple Thermocouple Types: Supports various types of thermocouples, such as Type K, J, T, and others, making it adaptable to different applications.

How It Works

The TC calibrator operates through a straightforward process:

Temperature Simulation: The calibrator generates and maintains stable, known temperatures. This simulated environment is used to test the thermocouple’s response.

Measurement: The output voltage from the thermocouple is measured and compared against the expected value for the simulated temperature.

Calibration: If there are discrepancies between the thermocouple’s readings and the known values, adjustments are made to ensure accurate temperature measurement.

Applications

TC calibrators are used in various industries where precise temperature measurement is crucial:

Manufacturing: Ensures that temperature sensors in production processes are accurately calibrated to maintain product quality and process control.

Pharmaceuticals: Verifies the accuracy of temperature sensors in storage and processing environments to meet strict safety and quality standards.

Energy: Calibrates temperature sensors in power plants and other energy systems to ensure efficient and safe operation.

Benefits

Using a TC calibrator offers several significant benefits:

Enhanced Accuracy: Ensures that thermocouples provide precise temperature measurements, which is essential for maintaining accurate process control.

Reduced Downtime: Regular calibration helps prevent errors and operational issues, leading to minimized downtime and improved efficiency.

Cost Efficiency: Accurate temperature measurements contribute to process optimization and can help avoid costly mistakes or inefficiencies.

Conclusion

For industries that rely on accurate temperature measurements, the TC calibrator is an indispensable tool. By providing precise temperature simulation and measurement, it ensures that thermocouples operate reliably and accurately. Investing in a TC calibrator enhances the accuracy and efficiency of temperature-sensitive applications, making it a valuable asset for maintaining high standards in industrial operations.

0 notes

Text

Everything you need to know about Thermocouples

A thermocouple is perhaps a sensor that is used for the measurement of temperature. It comprises two metal wires in which one part is welded while the other part is connected to a particular device. So, if it is configured in the right way, then measurement can be presented in different temperature ranges.

So, if you are looking out for any kind of sensor, then it is recommended that you opt for good sensor manufacturers in Chennai.

Further, in this article, we would discuss everything associated with thermocouple sensors. Let us dive in:-

Construction of the Thermocouple Sensors

Thermocouples are temperature sensors that have two metal alloys through which voltage is produced. So, the temperature difference that tends to happen between the conductors of the thermocouples is directly proportional to the temperature.

Further, each of the thermocouple sensors tends to have two parts i.e. hot junction and cold junction. So, whenever any temperature change tends to happen at the hot junction, then you will notice an emf change at the cold junction. Also, the controller is the one that tends to record the output emf. So, with the temperature increase, there is an increase in the output emf as well.

Moreover, based on the application, different metals are used such that the required voltage can be produced.

Benefits of Thermocouple Sensors

There are several benefits associated with Thermocouple sensors. Some of them include the:-

Self-Sufficient

As the temperature changes, the output temperature tends to increase. Hence, there is no requirement for an external source of power. Hence, they are self-sufficient when it comes to operations.

Robust and Simple

If you talk about the design of the thermocouple sensors, then they tend to be quite simple yet quite tough. Further, they are manufactured using metals that are of high strength which includes iron, aluminum, platinum, and copper. Hence, they tend to have very wide industrial applications.

Cost-effective

If you talk about the price, then thermocouples tend to be quite cost-effective. Moreover, they are three times less expensive as compared to RTDs.

Wide range of temperature

Thermocouples are used directly to measure an application's temperature. Thus, they offer a wide temperature range of up to 2600 degree Celsius.

What is the cost of thermocouple production?

Thermocouple production tends to be quite complex and the cost of production is based on different requirements. Also, they are available in different types of material and they can be used for low as well as high-temperature ranges. So, the cost of production boils down to some fixed and variable cost that is involved in the process.

Some of the other factors that contribute to the production cost are staff salaries, machine investment, testing speed, basic substances cost, etc.

Final Verdict

Thermocouple Sensors tend to have several benefits associated with them. Likewise, it has a wide industrial application range which includes fog machines, industrial ovens, automotive diesel engines, and gas turbines to name a few. They are also highly robust, cost-effective, and highly efficient. The best part is that they can easily last for a very long time.

0 notes