#Modbus TCP

Explore tagged Tumblr posts

Text

Modbus RTU & TCP Çözümleri - GelecekBT

1 note

·

View note

Text

Ensuring data integrity with the MOXA MGate MB3180

The MB3180, MB3280, and MB3480 are standard Modbus gateways that convert between Modbus TCP and Modbus RTU/ASCII protocols. Up to 16 simultaneous Modbus TCP masters are supported, with up to 31 RTU/ASCII slaves per serial port. For RTU/ASCII masters, up to 32 TCP slaves are supported.

#trending#automation#tumblr trends#viral#viralpost#bestdeals#trendingnow#moxa#MGateMB3180#today on tumblr#artists on tumblr#artist

2 notes

·

View notes

Text

AC drive ATV930D55N4

AEC switchgear provided AC drive ATV930D75N4 This Altivar Process ATV900 variable speed drive can feed 3-phase synchronous and asynchronous power motors. It is suitable for motors with power rating up to 55kW/75hp for applications requiring slight overload (up to 120%). It is suitable for motors with power rating up to 45kW/60hp for applications requiring significant overload (up to 150%). It works at a rated supply voltage from 380V to 480V AC. This variable speed / frequency drive (VSD / VFD) is specifically designed for industrial processes. In the following market segments, oil and gas, mining, minerals and metals, food and beverage water and wastewater. It offers high motor performance on any motor and total control of any kind of coupling in master/slave applications. Network services help ensure operation continuity even in case of connection breakdown. Web server and data logging help reduce downtime through fast troubleshooting and preventive maintenance. Its advanced connectivity, including EtherNet/IP and Modbus TCP, allows deep integration into automation architectures. It is designed to be mounted in vertical position (+/- 10 °) on a wall

0 notes

Text

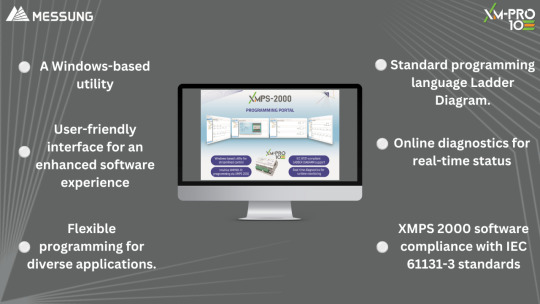

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

Siber suçlarda yapay zeka ve otomasyon patlaması!

https://pazaryerigundem.com/haber/223569/siber-suclarda-yapay-zeka-ve-otomasyon-patlamasi/ -

Siber suçlarda yapay zeka ve otomasyon patlaması!

Fortinet Tehdit Raporu’na göre saldırganların yapay zeka ve yeni teknikleri silah olarak kullanmasıyla otomatik siber saldırılarda rekor artış yaşanıyor.

İSTANBUL (İGFA) – Fortinet, 2025 Küresel Tehdit Ortamı Raporu’nu yayımladı: Siber suçlular, yapay zeka ve otomasyonu kullanarak saldırılarını hızlandırıyor, bulut ve kimlik güvenliği riskleri artıyor.

MITRE ATT&CK çerçevesine göre hazırlanan rapor, 2024’teki tehdit eğilimlerini analiz ederek, siber suçluların otomasyon, yapay zeka ve metalaştırılmış araçlarla savunmaları aşındırmaya çalıştığını ortaya koydu. Rapor, CISO’lara proaktif savunma önerdi.

FortiGuard Labs Baş Güvenlik Stratejisti Derek Manky, “Siber suçlular, yapay zeka ve otomasyonla benzeri görülmemiş bir hızda hareket ediyor. Geleneksel güvenlik yöntemleri yetersiz; proaktif, yapay zeka destekli savunma şart” dedi.

İŞTE RAPORDAN ÖNE ÇIKANLAR…

Otomatik Tarama Rekor Kırdı: Siber suçlular, açık hedefleri tespit için otomatik tarama kullanıyor. 2024’te taramalar %16,7 artarak saniyede 36 bin seviyesine ulaştı. SIP, RDP ve Modbus TCP gibi protokoller hedefte.

Darknet’te İstismar Kitleri: Darknet forumları, istismar kitleri için pazar yerlerine dönüştü. Ulusal Güvenlik Açığı Veritabanı’na 40 binden fazla yeni açık eklendi (%39 artış). İlk erişim aracıları, kurumsal kimlik bilgileri (%20) ve RDP erişimi (%19) satıyor.

Yapay Zeka Destekli Saldırılar: FraudGPT ve ElevenLabs gibi araçlarla kimlik avı kampanyaları daha etkili ve tespit edilmesi zor hale geldi.

Hedefli Sektörler: İmalat (%17), sağlık ve finans gibi sektörler yoğun saldırıya uğruyor. ABD (%61) en çok hedef alınan ülke.

Bulut ve IoT Riskleri: Bulut ortamları, yanlış yapılandırmalar ve aşırı izinli kimlikler nedeniyle risk altında. Olayların %70’inde saldırganlar bilinmeyen coğrafyalardan erişim sağladı.

Kimlik Hırsızlığı: 2024’te darknet’te paylaşılan çalıntı kimlik kayıtları %42 artarak 100 milyarı aştı. BestCombo ve ValidMail gibi gruplar, kimlik bilgilerini doğrulayıp satarak siber suçları kolaylaştırıyor.

0 notes

Text

Unlocking Industrial Automation with CODESYS PLC

In the ever-evolving world of industrial automation, the demand for intelligent, flexible, and efficient control systems has reached new heights. At the forefront of this transformation is CODESYS PLCs, a widely recognized and powerful development environment for Programmable Logic Controllers (PLCs). Designed to streamline automation programming and enhance functionality, CODESYS PLC enables industries to accelerate innovation, improve productivity, and future-proof their automation infrastructure.

What is CODESYS?

CODESYS (Controller Development System) is an IEC 61131-3 compliant development platform used to program industrial controllers, such as PLCs, PACs (Programmable Automation Controllers), and embedded systems. Developed by 3S-Smart Software Solutions, CODESYS supports all five IEC standard programming languages, including:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Instruction List (IL) (now deprecated)

Sequential Function Chart (SFC)

It also includes support for Continuous Function Chart (CFC), which is an additional graphical programming method offered by CODESYS.

This flexibility allows engineers and developers to choose the best language suited for a particular application, making it a universal and highly adaptable development platform.

Why CODESYS for PLC Programming?

CODESYS has become one of the most widely used platforms for industrial automation due to several compelling features:

1. Vendor-Independent

CODESYS is hardware-agnostic, which means it can run on a wide variety of controller hardware from different manufacturers. This interoperability simplifies integration across diverse hardware systems.

2. All-in-One Development Tool

The CODESYS Development System combines programming, debugging, simulation, and monitoring tools into a single environment. This eliminates the need for multiple software packages and enhances productivity.

3. Integrated Visualization

CODESYS offers integrated HMI (Human Machine Interface) visualization tools. Developers can create operator interfaces directly within the development platform, reducing time and cost associated with separate HMI development.

4. Web and Remote Access

With support for web-based visualization and remote maintenance, CODESYS allows users to monitor and control PLCs from anywhere, enhancing operational flexibility.

5. Scalability and Modularity

From small embedded controllers to large industrial PCs, CODESYS can scale to fit various applications. Its modular architecture supports plug-ins, extensions, and customized libraries.

Key Features of CODESYS PLC

1. Real-Time Capabilities

CODESYS can be used with real-time capable operating systems, enabling deterministic behavior and time-sensitive control processes essential in manufacturing, robotics, and motion control.

2. Fieldbus Support

CODESYS natively supports a wide range of industrial communication protocols including:

CANopen

Modbus (TCP/RTU)

EtherCAT

PROFINET

OPC UA

This broad fieldbus compatibility makes integration into existing factory networks easier and more flexible.

3. Simulation and Debugging

CODESYS offers an integrated simulation environment that allows for testing PLC logic before deployment. Debugging tools such as breakpoints, variable watch, and trace functionality provide deeper insights during development.

4. Version Control and Collaboration

With support for SVN (Subversion), CODESYS facilitates team collaboration, version control, and project management—ideal for large teams and critical automation projects.

5. Add-On Tools

CODESYS Store offers extensions such as motion control, safety programming, CNC features, and more. These tools allow for domain-specific customization and expansion of the system.

Applications of CODESYS PLC

CODESYS is used extensively across various industries where automation plays a key role. Common applications include:

Factory Automation: Controlling production lines, conveyor belts, robotic arms, and machine tools.

Building Automation: Managing HVAC systems, lighting controls, elevators, and smart building infrastructure.

Process Control: Operating chemical plants, water treatment facilities, and food processing units.

Energy Management: Monitoring and controlling renewable energy systems such as wind turbines and solar farms.

Automotive Testing: Used in HIL (Hardware-in-the-Loop) systems for automotive electronics validation.

Benefits of Using CODESYS PLC

1. Reduced Development Time

The intuitive interface and comprehensive toolset allow engineers to develop, test, and deploy automation programs faster than traditional platforms.

2. Cost-Effective

CODESYS reduces licensing costs by eliminating the need for proprietary vendor-specific tools. It also minimizes hardware dependency, offering more choices and competitive pricing.

3. Improved Quality and Reliability

With simulation, validation, and diagnostic tools built-in, CODESYS helps reduce errors and ensures high-quality control logic.

4. Future-Proof Architecture

CODESYS supports Industry 4.0 and IIoT (Industrial Internet of Things) integration. Its compatibility with modern protocols ensures adaptability for future innovations.

5. Strong Community and Support

A large global community, extensive documentation, and regular updates from the developers ensure continuous improvement and user assistance.

Challenges and Considerations

While CODESYS is highly versatile, some challenges must be considered:

Learning Curve: Engineers new to IEC 61131-3 languages or integrated development environments may need training to become proficient.

Hardware Compatibility: Although CODESYS is hardware-agnostic, some advanced features may only be supported on specific platforms.

Cybersecurity: As with all networked systems, securing CODESYS-enabled PLCs against unauthorized access and cyber threats is essential.

Future of CODESYS in Industrial Automation

As automation grows more intelligent, connected, and autonomous, platforms like CODESYS will play an increasingly critical role. Integration with cloud services, AI-powered analytics, and digital twin simulations are on the horizon for CODESYS-based systems. Its ongoing development ensures that it remains a cornerstone of modern automation technologies.

Conclusion

CODESYS PLC by servotechinc represents a powerful, flexible, and cost-effective solution for modern industrial automation needs. Whether you're building a simple control panel or a complex manufacturing execution system, CODESYS offers the tools and capabilities required to develop robust, scalable, and intelligent automation applications.

With its open architecture, broad industry adoption, and future-ready features, CODESYS is not just a programming tool—it is a platform driving the future of smart automation.

0 notes

Text

Fluke Distributor in Bangalore

The Fluke Networks Industrial Ethernet DSX CableAnalyzer™ Kit (Model: DSX2-5-IE-K1) is a comprehensive copper cable certifier designed for industrial Ethernet networks. It ensures compliance with TIA and ISO standards, supports various industrial protocols, and offers advanced troubleshooting capabilities.

🔧 Key Features

Comprehensive Certification: Validates twisted-pair copper cabling from Category 5 through 6A, ensuring adherence to TIA Level IIIe accuracy.

Rapid Testing: Provides Pass/Fail results within 10 seconds, accompanied by detailed measurement information.

Industrial Protocol Support: Compatible with cables running EtherNet/IP™, PROFINET™, Modbus TCP™, EtherCAT, and other industrial protocols.

Connector Compatibility: Supports RJ45, M12D, and M12X connectors, facilitating versatile testing options.Main Website

Advanced Troubleshooting: Identifies and locates cable issues swiftly, reducing downtime and preventing unnecessary bypass installations.

Touchscreen Interface: Features a user-friendly touchscreen with integrated project management tools for efficient operations.

Extended Battery Life: Offers up to 8 hours of continuous use on a single charge, ensuring reliability during extended testing sessions.

Comprehensive Documentation: Utilizes LinkWare™ software to document test results, supporting compliance with TIA 1005-A and ISO 11801:3 standards.

https://sapphire-tech.com/product/fluke-networks-industrial-ethernet-dsx-cableanalyzer-copper-cable-certifier-kit/

0 notes

Text

ARMxy RK3588 Industrial Controller Modbus RTU to Modbus TCP for Protocol Bridging

BL450 Series ARM Embedded Computer is an industrial-grade ARM controller with flexible I/O configuration, based on the Rockchip RK3588J/RK3588 processor, featuring a quad-core ARM Cortex-A76 + quad-core ARM Cortex-A55 + triple-core ARM Cortex-M0 architecture, witha clock speed of up to 2.0G/2.4GHz. It is equipped with 32GB/64GB/128GB eMMC and 4GB/8GB/16GB LPDDR4X RAM and ROM configurations. Supporting a rich set of I/O interfaces, it also integrates a 6TOPS NPU, enabling deep learning capabilities. The BL450 series iswidely used in industrial control, edge computing, AIoT, artificial intelligence, communication management, AGV robots, machine vision inspection, robotics, industrial IoT gateways, energy storage systems, automation control, and transportation infrastructure.

BL450 Series ARM Embedded Computer offers 1 to 3 optional RJ-45 network ports, including two 10/100/1000M ports and one 10/100M adaptive port, along with 2×USB 3.1, one optional HDMI 2.1, and optional X-series and Y-series I/O boards for communication, PWM output, pulse counting, and other data acquisition and control functions. It supports 8K@30fps H.264 video encoding and 8K@60fps H.265 video decoding. Built-in Mini PCIe interface allows support for Bluetooth, WiFi, 4G, and 5G communication modules.

BL450 Series supports multiple operating systems, including Linux-5.10.209, Linux-RT-5.10.209, Ubuntu 20.04, Debian 11, and Android 13. It is also compatible with Docker containers, Node-Red, and Qt-5.15.10 for graphical development. The BLIoTLink industrial protocol conversion software enables fast industrial data acquisition and conversion, facilitating seamless integration with mainstream IoT cloud platforms and industrial SCADA software. Additionally, the BLRAT remote access tool provides remote access and maintenance, while Node-Red allows for rapid IoT application development.

Designed with professional electrical performance and high/low-temperature testing, the BL450 series operates reliably under harsh electromagnetic interference and extreme temperatures ranging from -40°C to 85°C. With DIN35 rail mounting, it is suitable for various industrial applications.

0 notes

Text

Modbus Poll Crack with serial key free Download 2025

DOWNLOAD LINK

Modbus Poll is a popular software tool designed to simulate Modbus master devices for testing and troubleshooting Modbus slave devices in industrial automation and control systems. It is widely used by engineers and technicians to monitor and troubleshoot Modbus communication, especially in the context of Modbus RTU, Modbus ASCII, and Modbus TCP/IP protocols.

Key Features of Modbus Poll:

Modbus Master Simulation:

Modbus Poll acts as a Modbus Master, enabling you to simulate communication with Modbus slave devices. You can use it to send requests (read and write operations) to connected Modbus slaves to test and verify their responses.

1 note

·

View note

Text

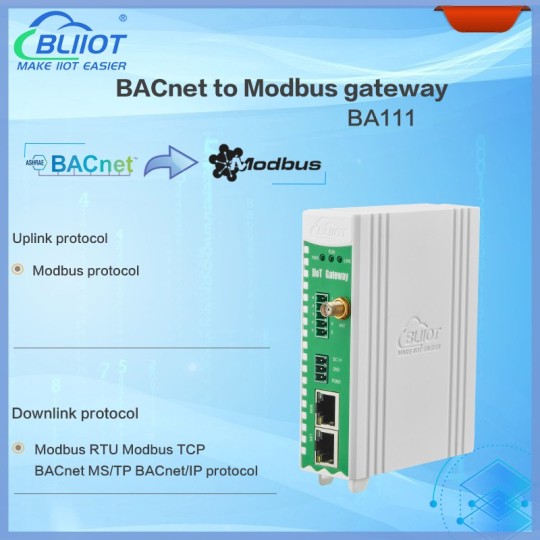

BLIIoT | BACnet Gateway BA111 Support BACnet to Modbus for Building Management System

Introduction

With the development of communication technology and control technology, in order to achieve efficient and intelligent management of buildings, centralised monitoring and management has become an inevitable trend in the development of intelligent management of buildings. In this context, high-performance building HVAC data transmission solutions - protocol conversion gateway came into being, widely used in building automation and HVAC system applications.

BLIIoT always insists on the core of the user's needs, and constantly expands its applications in a variety of industrial fields. Recently, we have developed a new series of BLIIoT Building Automation HVAC gateways, This series of products not only have excellent stability and anti-interference capabilities, but also have deep industry applications, aiming to bring users a new building automation data collection and conversion experience.

Product Description

The BACnet to Modbus gateway BA111 is designed by BLIIoT for data collection and protocol conversion of building automation systems.

BACnet to Modbus gateway BA111 supports BACnet MS/TP and BACnet IP acquisition protocols, which can seamlessly integrate building equipment with different protocols into the same system. Provides Modbus RTU and Modbus TCP uplink protocols to make device interconnection more flexible.

BACnet to Modbus gateway BA111 has powerful hardware interfaces, including 2/6 RS485/RS232 serial ports, 2 network ports and 1 4G/WiFi wireless transmission interface, providing users with flexible communication and connection solutions.

By using BLIIoT patented guide rail buckle technology, the installation process is simplified and the practicality of the gateway is ensured.

Product features

Supported protocols:

Downlink protocol: Modbus RTU, Modbus TCP, BACnet MS/TP, BACnet IP.

Uplink protocols: Modbus RTU, Modbus TCP.

Hardware interface:

6*RS485/RS232 serial ports: The serial ports are independent of each other. Each serial port parameter can be set to collect different protocols. The serial port can also set the master-slave relationship independently. It can be configured as either a master station or a slave station.

2*network ports: used for data collection and forwarding. The LAN port has a routing function and provides a channel for other devices to connect to the external network.

WiFi wireless transmission interface: Provides diverse communication options to adapt to different industrial environment need.

Data security:

Support data TSL/SSL, X.509 certificate, SNMP V1/V2, key encryption and other security gateway functions.

Remote Configuration Support:

Support remote configuration, providing users with convenient management and monitoring methods, no longer need to visit engineers, saving maintenance costs.

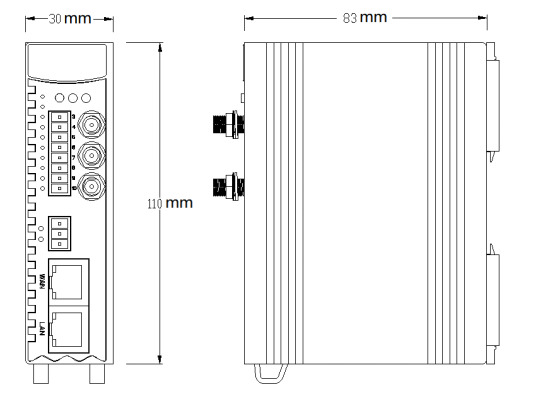

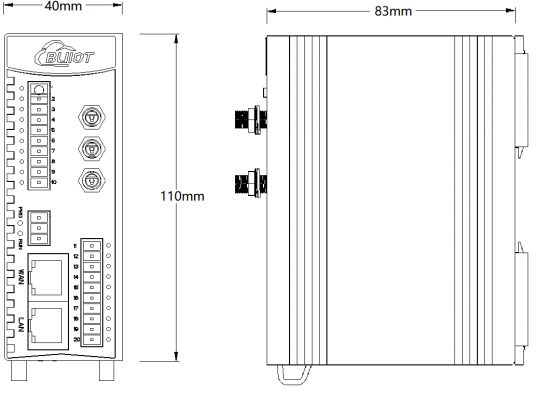

Product Size: L x W x H: 30 x 83 x 110mm

Safety and Stability:

Industrial-grade design: Durable shell material meets industrial environment requirements.

Stability: Efficient communication protocol conversion ensures stable operation of the system.

Environmental adaptation:

Operating temperature range: -40~80℃, adapting to various industrial environments. Protection grade: IP30, ensuring the reliability of the equipment in harsh environments.

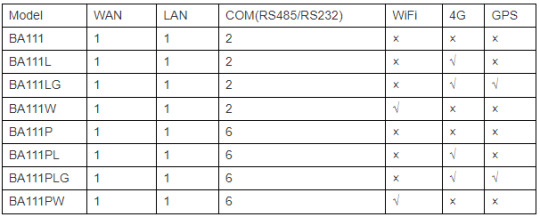

Model List

Application scenarios

BA111 is widely used in building automation systems and other fields, providing users with reliable and flexible protocol conversion and data acquisition solutions.

More information about BACnet to Modbus Gateway BA111: https://www.bliiot.com/bacnet-to-modbus-p00422p1.html

0 notes

Text

Ứng Dụng PLC Siemens Trong Ngành Thực Phẩm và Đồ Uống: Tối Ưu Hóa Sản Xuất và Đảm Bảo Chất Lượng

Ứng Dụng PLC Siemens Trong Ngành Thực Phẩm và Đồ Uống: Tối Ưu Hóa Sản Xuất và Đảm Bảo Chất Lượng

Ngành công nghiệp thực phẩm và đồ uống là một trong những lĩnh vực quan trọng, nơi tự động hóa đóng vai trò thiết yếu để đáp ứng các tiêu chuẩn cao về chất lượng, an toàn và hiệu suất. Trong bối cảnh đó, PLC Siemens đã trở thành giải pháp hàng đầu nhờ khả năng điều khiển linh hoạt, độ tin cậy cao và tính tích hợp vượt trội. Bài viết này sẽ khám phá cách các dòng PLC Siemens, như S7-1200 và S7-1500, được ứng dụng trong ngành thực phẩm và đồ uống, từ điều khiển quy trình chiết rót, đóng gói, đến giám sát chất lượng. Bên cạnh đó, chúng tôi sẽ cung cấp ví dụ thực tế, so sánh với các giải pháp khác và những mẹo hữu ích để triển khai hiệu quả.

1. Tổng quan về ngành thực phẩm và đồ uống Ngành thực phẩm và đồ uống không chỉ là một trong những ngành công nghiệp lớn nhất toàn cầu mà còn là lĩnh vực có yêu cầu khắt khe về quy trình sản xuất. Theo dự báo của Statista, quy mô thị trường toàn cầu của ngành này sẽ đạt 10 nghìn tỷ USD vào năm 2025, nhờ vào nhu cầu tiêu dùng ngày càng tăng. Tuy nhiên, các nhà máy trong ngành phải đối mặt với nhiều thách thức: Tiêu chuẩn an toàn thực phẩm: Tuân thủ các quy định nghiêm ngặt như HACCP, FDA và ISO 22000. Quy trình phức tạp: Bao gồm chế biến nguyên liệu, chiết rót, đóng gói và bảo quản. Sản xuất số lượng lớn: Đảm bảo chất lượng đồng đều trên quy mô lớn. Vệ sinh và bảo trì: Thiết bị cần được làm sạch thường xuyên và hoạt động ổn định. Để vượt qua những thách thức này, tự động hóa đã trở thành xu hướng tất yếu, trong đó PLC (Programmable Logic Controller) là công cụ không thể thiếu, giúp điều khiển chính xác và giám sát toàn bộ dây chuyền sản xuất. 2. Vai trò của PLC trong ngành thực phẩm và đồ uống

PLC là "bộ não" của hệ thống tự động hóa, mang lại nhiều lợi ích quan trọng cho ngành thực phẩm và đồ uống: Điều khiển chính xác: Quản lý các thông số như lưu lượng, nhiệt độ và áp suất để đảm bảo sản phẩm đạt tiêu chuẩn. Giám sát thời gian thực: Thu thập dữ liệu từ cảm biến để phát hiện lỗi và cảnh báo kịp thời. Tự động hóa vệ sinh (CIP): Điều khiển chu trình làm sạch thiết bị mà không cần tháo rời, tiết kiệm thời gian và đảm bảo vệ sinh. Tích hợp hệ thống: Kết nối với SCADA, MES và ERP để quản lý toàn diện quy trình sản xuất. Truy xuất nguồn gốc: Ghi nhận dữ liệu để đáp ứng các yêu cầu pháp lý về an toàn thực phẩm. Với hơn 50 năm kinh nghiệm, Siemens đã phát triển các dòng PLC phù hợp với mọi quy mô nhà máy trong ngành này, từ S7-1200 cho các ứng dụng nhỏ đến S7-1500 cho các dây chuyền phức tạp.

3. Tại sao chọn PLC Siemens? PLC Siemens nổi bật so với các thương hiệu khác nhờ những ưu điểm vượt trội: Ưu điểm nổi bật Độ bền cao: Hoạt động ổn định trong môi trường khắc nghiệt (nhiệt độ -20°C đến 60°C, độ ẩm cao). Hiệu suất mạnh mẽ: S7-1500 xử lý hàng nghìn điểm I/O và dữ liệu từ cảm biến với tốc độ 1 ns/lệnh. Tích hợp IoT: Hỗ trợ PROFINET, OPC UA và kết nối với MindSphere để giám sát từ xa. Dễ sử dụng: Phần mềm TIA Portal tích hợp lập trình PLC, HMI và SCADA, giảm thời gian phát triển. Hỗ trợ toàn cầu: Mạng lưới đối tác rộng khắp, như PLCSIEMENS.VN tại Việt Nam.

So sánh với đối thủ Tiêu chí Siemens S7-1500 Allen-Bradley CompactLogix Schneider Modicon M580 Tốc độ xử lý 1 ns/lệnh 2 ns/lệnh 5 ns/lệnh I/O tối đa 8192 4000 2048 Giao thức PROFINET, OPC UA EtherNet/IP Modbus TCP, EtherNet/IP Tích hợp IoT Có (MindSphere) Không Không Chi phí Trung bình-cao Cao Trung bình Siemens vượt trội về hiệu suất và khả năng tích hợp, phù hợp với các nhà máy hiện đại hóa. 4. Ứng dụng cụ thể của PLC Siemens Dưới đây là các ứng dụng phổ biến của PLC Siemens trong ngành thực phẩm và đồ uống: 4.1. Điều khiển chiết rót Mô tả: Điều chỉnh lưu lượng chất lỏng (nước, sữa, bia) khi chiết rót vào chai/lon. Ví dụ: S7-1200 điều khiển van để chiết rót 500 ml/chai với sai số ±1 ml. Công cụ: PID Control trong TIA Portal. 4.2. Quản lý đóng gói Mô tả: Điều khiển máy đóng gói để đảm bảo số lượng và chất lượng. Ví dụ: S7-1500 quản lý máy đóng gói bánh, kiểm tra trọng lượng tự động. Công cụ: Cảm biến trọng lượng và vision system. 4.3. Giám sát nhiệt độ Mô tả: Theo dõi và điều chỉnh nhiệt độ trong nấu, thanh trùng. Ví dụ: S7-1500 duy trì nhiệt độ lò nướng 180°C ±2°C. Công cụ: Module SM1231 (analog input). 4.4. Tự động hóa CIP Mô tả: Điều khiển chu trình làm sạch thiết bị. Ví dụ: S7-1200 phun dung dịch tẩy rửa theo chu kỳ. Công cụ: Chu kỳ CIP trong TIA Portal. 5. Ví dụ thực tế: Nhà máy bia Bối cảnh Nhà máy bia. Vấn đề: Chiết rót thủ công gây sai số 5-10 ml/chai, lãng phí nguyên liệu. Giải pháp: Sử dụng S7-1500 để tự động hóa. Triển khai Phần cứng: S7-1500 CPU 1516-3 PN/DP, module SM1221/SM1222, HMI TP700. Lập trình: PID Control cho van chiết rót, giao diện HMI hiển thị dữ liệu. Kết quả: Sai số giảm còn ±1 ml, năng suất tăng 20%, tiết kiệm 2% nguyên liệu.

6. Kết luận PLC Siemens là lựa chọn lý tưởng để tối ưu hóa sản xuất trong ngành thực phẩm và đồ uống. Để triển khai hiệu quả, hãy liên hệ PLCSIEMENS.VN hoặc gọi 0888-789-688 để được tư vấn chi tiết. Nguồn: https://plcsiemens.vn/ung-dung-plc-siemens-trong-nganh-thuc-pham-va-do-uong-toi-uu-hoa-san-xuat-va-dam-bao-chat-luong Read the full article

0 notes

Text

Types of communication protocols for Micro820 Controller

1. EtherNet/IP

2. Modbus TCP/IP

3. DeviceNet

4. ControlNet

5. USB

🌐Website :-https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#tumblr trends#trending#viralpost#allen bradley#automation#viral#bestdeals#rockwell automation#trendingnow#plc#820 controller

1 note

·

View note

Link

0 notes

Text

Understanding Modbus: The Universal Protocol for Industrial Communication

Modbus is a widely used communication protocol in industrial automation and control systems. Originally developed by Modicon (now Schneider Electric) in 1979, it remains one of the most popular protocols for connecting electronic devices and exchanging data in supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs), and various automation applications.

How Modbus Works

Modbus operates as a master-slave (or client-server) protocol, where a master device initiates communication, and one or more slave devices respond. It is simple, reliable, and efficient, making it a preferred choice for industrial communication. The protocol is used to transmit data over serial lines (RS-232, RS-485) or via Ethernet networks (Modbus TCP/IP).

Types of Modbus Protocols

Modbus RTU (Remote Terminal Unit): A binary protocol using compact messages with cyclic redundancy check (CRC) error checking. It is ideal for real-time communication.

Modbus ASCII: Similar to RTU but uses ASCII characters, making it more readable but less efficient.

Modbus TCP/IP: Allows Modbus communication over Ethernet networks using TCP/IP protocols, making it suitable for modern industrial networks.

Key Features of Modbus

Open and Vendor-Neutral: Modbus is an open standard, meaning any manufacturer can implement it without licensing fees.

Ease of Implementation: Simple message structure and minimal processing overhead.

Interoperability: Enables different devices and systems from various vendors to communicate seamlessly.

Scalability: Supports a range of devices, from small sensors to complex industrial control systems.

Robust Error Handling: Modbus RTU uses CRC for error detection, ensuring reliable data transfer.

Applications of Modbus

Industrial Automation: Connecting PLCs, sensors, actuators, and SCADA systems.

Energy Management: Monitoring and controlling power meters and generators.

Building Automation: HVAC control, lighting systems, and access control.

Water and Wastewater Management: Supervising pumps, valves, and treatment facilities.

Oil and Gas Industry: Remote monitoring of pipelines and drilling operations.

Challenges and Limitations

Despite its advantages, Modbus has some limitations:

Limited Data Security: Traditional Modbus lacks built-in encryption, making it vulnerable to cyber threats.

Slower Speed Compared to Modern Protocols: Serial-based Modbus RTU can be slower than newer protocols like Ethernet/IP or MQTT.

Single-Master Limitation: Classic Modbus architectures typically allow only one master device, restricting flexibility.

Future of Modbus

With the advent of Industry 4.0 and Industrial IoT (IIoT), Modbus continues to evolve. Modern adaptations like Modbus TCP/IP and secure Modbus variants are making it more compatible with smart factories and cloud-based systems. Its simplicity and reliability ensure that it remains relevant in industrial automation for years to come.

Conclusion

Modbus is an essential protocol in industrial communication, providing a simple yet powerful way to connect and control devices. Its widespread adoption, open standard nature, and continuous evolution make it a critical component in modern automation and control systems. As industries transition to smart manufacturing, Modbus will likely continue to play a significant role in bridging legacy systems with modern technologies.

0 notes

Text

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung - Industrial Automation & Controls

Next generation Industrial Automation & Control Solutions for complex industrial processes, machines & production lines.

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

· User-Friendly Environment:

The software offers an intuitive interface, ensuring a seamless experience with various software tools.

· Programming Flexibility:

XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

· Online Diagnostics:

Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

· Hardware Configuration:

Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

· Logic Blocks:

Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

· Monitor Table:

Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

· Online Monitoring:

Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

· Force Value Functionality:

Permits value forcing during program testing, aiding in thorough validation processes.

· User Library:

Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

· Comprehensive Selection:

Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

· Communication Parameterization:

Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

· Detailed Display:

Provides visualization of hardware configurations for selected CPUs and I/O modules, with direct parameter configuration and viewing.

I/O Configuration:

· Assignment Flexibility:

Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

· System-Generated Addresses:

Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

· Efficient Tools:

Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

· Compiler and Monitoring:

Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

0 notes

Text

SIMATIC S7-1200: The Future of Compact Automation

Efficiency, flexibility, and reliability are the key factors on which the success of automation solutions depends in industrial automation. The SIMATIC S7-1200 is one such PLC that has revolutionized compact automation systems. With its ability to scale, its integrated communication capabilities, and an easy-to-use programming environment, the S7 1200 PLC has become the choice of preference for many industries.

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is designed by Siemens as a compact and modular PLC intended for the operations of automation with efficiency and precision. It is best suited for small to medium applications that require integration and interconnect with high performance. From a simple machine control system to a complex industrial process, the S7 1200 offers unprecedented flexibility and power at an attractive price.

Key Features of SIMATIC S7-1200

Compact and Modular Construction The S7 1200 PLC offers a smart design, having built-in I/O modules expandable as per application requirements. The modular design allows easy upgrades, which lends itself quite easily to different application demands in automation.

Integrated Communications: The SIMATIC S7-1200 supports multiple protocols, including PROFINET, Modbus TCP, and Ethernet, to enable seamless transfer of data. This arrangement allows direct connections with any other Siemens automation product, facilitating lesser impedance during integration.

Powerful Programming with TIA Portal Siemens has provided Totally Integrated Automation (TIA) Portal, which is a software suite for intuitive programming, diagnostics, and monitoring. Creation, modification, and troubleshooting of PLC programs become easier for the user.

High Performance and Reliability Advanced processing power gives S7 1200 fast response potentially down to milliseconds and very accurate command execution. It can be used in harsh industrial environments, including extreme temperatures and vibration resistant.

Integrated Motion Control SIMATIC S7-1200 offers motion control for applications with integral positioning functions and high-speed counters. This makes it an excellent candidate for use in automation for material handling, conveyor systems, and robotics.

Applications of SIMATIC S7 1200

The S7 1200 PLC has found applications in many industries, such as:

Manufacturing: Assembly lines and production are automated.

Food and Beverage: Controlling equipment for packaging, sorting, and processing.

Water Treatment: Control of pump stations, filtration, and flow regulation.

Building Automation: Control of HVAC systems, lighting controls, and security.

Renewable Energy: Monitoring and control of solar and wind energy systems.

What are the characteristics of SIMATIC S7-1200?

Scalability: This system is suitable for smaller businesses and scaling solutions since adding in more modules is easy.

User-Friendliness: Programming is simple for development and maintenance with the TIA Portal.

Cost-Effectiveness: Features high-end automation at a moderate price.

Future-Ready: Industry 4.0-aided cloud connectivity and remote monitoring.

Conclusion

The SIMATIC S7-1200 is an intelligent investment for organizations looking for a reliable, flexible, and high-performance PLC. Compact in size with powerful features, easy integration makes this product ideal for a variety of industrial applications. Be it upgrading a current system, or designing a new automation project, the S7 1200 PLC furnishes a solution that is scalable and economical.

For world-class Siemens automation products like the SIMATIC S7-1200, connect with Naksh Technology Solutions LLP-your trusted partner for industrial automation solutions.

0 notes