#Modified Starch Machinery

Explore tagged Tumblr posts

Text

Microtec Engineering Group is leading the way in revolutionizing the production of hot-water-swelling E1422 as well as cold water swelling, a versatile modified starch that is used in a variety of applications. With its advanced modified starch machinery and customized solutions, Microtec powers companies to enhance the efficiency and quality of their modified starch production lines. Through adopting innovative technology, Microtec helps businesses meet the increasing global demand for high-performance starch products.

#modified Starch line for E1422#Starch machinery#Modified starch production line#Modified Starch Machinery

0 notes

Text

Maize (Corn) Prices, News, Trend, Graph, Chart, Monitor and Forecast

Maize, commonly known as corn, is one of the most widely cultivated cereal grains in the world, serving as a crucial staple for both human consumption and animal feed. The global maize market is influenced by a complex interplay of factors, including climatic conditions, government policies, trade dynamics, and demand fluctuations in various industries. Over the years, maize prices have exhibited significant volatility, primarily due to supply chain disruptions, geopolitical tensions, and changing agricultural practices. The United States, China, Brazil, and Argentina are among the top maize-producing countries, and any shifts in their production capacity have a profound impact on global price trends. The increasing adoption of genetically modified maize has also played a role in shaping market dynamics, with some regions embracing the technology while others remain hesitant due to regulatory and consumer concerns.

The demand for maize is driven by its diverse applications in food, biofuels, and the livestock industry. The ethanol industry is a significant consumer of maize, particularly in the United States, where a large portion of the crop is used to produce biofuel. The growing emphasis on renewable energy and sustainable fuel sources has bolstered maize demand, influencing price movements in the process. Additionally, maize serves as a key ingredient in processed foods, starches, sweeteners, and beverages, further broadening its market reach. The livestock sector remains a dominant force in maize consumption, as the grain is an essential component of animal feed. Any disruptions in feed demand, such as disease outbreaks or changes in meat consumption patterns, can have cascading effects on maize prices worldwide.

Get Real time Prices for Maize (Corn): https://www.chemanalyst.com/Pricing-data/maize-1321

Weather patterns and climatic conditions play a crucial role in determining maize yields and, consequently, market prices. Adverse weather events, such as droughts, floods, and unexpected frosts, can severely impact crop production, leading to supply shortages and price surges. Conversely, favorable weather conditions can result in bumper harvests, often leading to price declines due to oversupply. The impact of climate change on maize production has become increasingly evident, with erratic weather patterns posing challenges to farmers across major producing regions. Governments and agricultural organizations are investing in climate-resilient maize varieties and improved farming techniques to mitigate risks associated with unpredictable weather conditions.

Trade policies and international relations significantly influence maize price trends, as tariffs, export restrictions, and trade agreements dictate the flow of maize between countries. The ongoing trade relations between major exporters and importers can lead to price fluctuations, especially when unexpected restrictions or tariffs are imposed. The United States-China trade war, for instance, had a notable impact on maize prices, affecting exports and altering global supply chains. Additionally, the role of regional trade blocs, such as the European Union and the African Continental Free Trade Area, is growing in importance, as they facilitate maize trade within their respective regions. Any changes in trade policies or diplomatic tensions can quickly reverberate through the maize market, impacting price stability and supply security.

The cost of production is another critical factor that affects maize prices. Input costs, including fertilizers, pesticides, labor, and fuel, determine the profitability of maize cultivation. Rising fertilizer prices, driven by supply chain disruptions and geopolitical conflicts, have made maize farming more expensive, subsequently pushing up market prices. The availability and affordability of agricultural machinery and technology also play a role in determining production efficiency and overall output. Farmers in regions with access to modern equipment and advanced agricultural techniques are better positioned to produce higher yields at a lower cost, whereas those in developing economies often face challenges related to outdated farming methods and limited access to financial resources.

Speculation and market sentiment also contribute to maize price movements, as traders and investors respond to forecasts, reports, and external economic factors. Futures contracts and commodity trading have become essential tools for price risk management, allowing stakeholders to hedge against potential price fluctuations. However, speculative trading can also lead to price distortions, with sudden spikes or dips occurring based on market sentiment rather than actual supply and demand fundamentals. The influence of large institutional investors and hedge funds in the agricultural commodities market has grown in recent years, further amplifying price volatility.

The impact of government policies and subsidies on maize prices cannot be overlooked. Many governments provide subsidies to maize farmers to encourage production and maintain food security. These subsidies can range from direct financial support to tax incentives and price support mechanisms. In the United States, for example, the Farm Bill plays a significant role in shaping maize production and market stability through various support programs. Similarly, in countries like India, minimum support prices and procurement policies influence maize market trends. The removal or alteration of subsidies can lead to price shifts, affecting both producers and consumers.

The ongoing advancements in agricultural biotechnology and farming techniques have the potential to reshape maize production and pricing trends. The development of drought-resistant and pest-resistant maize varieties has enabled farmers to achieve higher yields in challenging conditions, enhancing global supply stability. Precision farming, data-driven agriculture, and automated irrigation systems are also improving efficiency and reducing production costs. As technology continues to evolve, it is expected to play a crucial role in stabilizing maize prices by mitigating the risks associated with climate variability and resource limitations.

The COVID-19 pandemic had a profound impact on the maize market, disrupting supply chains and altering consumption patterns. Lockdowns and restrictions affected labor availability, transportation, and trade flows, leading to price fluctuations in both domestic and international markets. While demand for maize in the food sector remained stable, the ethanol industry faced a downturn due to reduced fuel consumption. However, as economies recover and fuel demand rebounds, maize prices have been adjusting accordingly. The long-term implications of the pandemic on global trade and agricultural policies continue to unfold, influencing market dynamics in unexpected ways.

Looking ahead, the maize market is expected to experience continued volatility, driven by geopolitical developments, climate change, technological advancements, and shifting consumer preferences. The push toward sustainable and regenerative agriculture is likely to influence maize farming practices, with an increasing focus on soil health, reduced chemical usage, and carbon sequestration. Additionally, the growing interest in alternative protein sources, such as plant-based and lab-grown meat, may alter maize demand in the livestock sector. The expansion of biofuel mandates and renewable energy policies will also play a crucial role in shaping future maize prices. As global demand for maize remains strong, stakeholders across the supply chain will need to adapt to evolving trends and challenges to ensure a stable and resilient market.

Get Real time Prices for Maize (Corn): https://www.chemanalyst.com/Pricing-data/maize-1321

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Maize Prices#Corn Price#Corn Prices#Maize Price#Maize News#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

One of my favourite parts of 40K is the servitor. Just conceptually.

I like them because they represent - ignoring the broader straight-up grimdark aspects of the whole idea - another way in which your standard, run-of-the-mill Imperial citizen thinks in a way very alien to what we might have these days. Or so I like to think.

Unless you're from, say, a feral or feudal world, odds are good that your average Imperialite is familiar with servitors to a greater or lesser degree. They will go past dozens in a day, doing whatever. A servitor loader at the docks. A servitor truck of some kind just carrying stuff around. A servitor wired into a lift to work the systems. Just everywhere.

And that's excluding your other, perhaps less common ones, like translator servitors, or whatever.

Regardless, they're a common feature of life. They're ubiquitous. In much the same way you or I might pass, oh, a digger or whatever, they're just machinery, they're just there. Unremarkable, beneath notice.

But of course that entirely ignores that they, you know, humans.

Now it is stated that a not-insignificant amount of servitors are vat-grown, and given the abuse they go through and the need for replacement parts I'd imagine that's true. The bulk of them might be so. That still leaves a fair minority who are criminals - 'criminals' - the unlucky, the unwanted, and who-knows else, mind-scrubbed and hacked up to be bits in a machine.

Which is leaving aside the whole idea of just growing braindead (hopefully!) human shells in vats to use as spare bits! None of this is good!

But your average Imperialite doesn't care. They don't even notice. It's normal, it's fine, it's just life. In the array of other crap they have to deal with, it's just the way things go. So what if sometimes you can hear the servitor in the lift muttering a little when it dawdles between floors? So what? Who cares? I've got shit to do.

I enjoy that. It's like how no-one really cares that there's just skulls flying all over the place doing things, or occasional genetically-modified cherubs hanging up in the ceiling. Or fucking corpse starch (or soylens viridians, which always amuses me).

Basically what I'm saying is as much as the Imperium is the 'human angle' into 40k, I like them best when you're reminded that Imperial people are fucking weird, man.

0 notes

Text

How to Effectively Improve the Quality of Feed by Improving the Production Process

In the process of feed production, three factors affect the quality: one is the quality of raw materials; the other is the feed formula; and the third is the production process, and these three influence each other. After controlling the quality of raw materials and feed formulations, how to improve the quality of feed by improving the production process has become an important means for many feed companies to improve product quality.

1. Feed moisture control The issues that must be paid attention to in the feed production process are: ① How to improve the feed pellets quality; ② How to reduce dust; ③ How to improve pellet feed-making machine production efficiency and reduce processing energy consumption; ④ How to make full and effective use of steam, and cool enough to keep proper moisture in the feed.

2. Control of impurity removal of raw materials A large number of impurities are mixed into feed ingredients. If they are not cleaned up in advance, it will affect product quality and even affect animal production performance, and loss of equipment during processing, and production.

It is generally believed that the impurity removal process of feed enterprises should pay attention to magnetic separation and screening equipment. While paying attention to the protection of the equipment, more attention should be paid to cleaning up the debris in the grain raw materials.

4. Mixing process Mixing uniformity of materials is the guarantee of product quality, and the coefficient of variation (CV) of mixing uniformity is generally required to be less than 7%. Especially when adding a small or trace amount of additive raw materials, the uniformity of mixing is more important. The mixing effect of different mixing equipment has a great difference, which has a certain influence on animal growth. Therefore, it is important to understand whether the performance parameters are excellent when selecting poultry feed equipment.

1. The powdery materials are cured. The conditioner greatly increases the gelatinization degree of the starch under the action of water and heat, and at the same time promotes the heat denaturation of the protein in the material, and the denatured protein is easy to enzymatically hydrolyzed, thereby improving the digestibility and utilization of the pellet feed.

2. Sterilize the powdery materials. The conditioner can condition the materials at a certain temperature to kill most of the pathogenic bacteria and ensure the hygiene level of the feed.

3. Conditioning equipment can improve the pellet feed water resistance, in the process of quenched and tempered by through the role of the heat and water vapor, the sticky ingredients gelatinized starch, and modified protein in the raw material can give full play to the role of the binder, binding around other ingredients, under the extrusion of pressure molding roller, particle feed more close-grained, appearance is bright and clean, not easy to be in the process of feeding water erosion, The stability of feed particles in water is increased.

4. The quenching and tempering equipment can improve the granulation of the material, increase the output, save the energy consumption of the granulation, and increase the life of the die and the pressure roller of the poultry feed pellet machine.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: [email protected]

Whatsapp: 0086 18037508651

0 notes

Text

What kinds of adhesives are added to the briquette machine?

The briquette machine is the main machine required for ball pressing, ball making, and ball making processing. It is a device for pressing materials into balls. Before processing, the materials, water, adhesives and other materials are fully stirred, and the addition of adhesives is to increase the finished product. The strength of the ball, waterproof strength, etc., so the configuration and use of adhesives are crucial to the product effect of the entire briquette production line.

1. The physical adhesive of the briquette machine has a non-toxic surface and has a good fixing effect on water molecules. There is a three-layer arrangement of water molecules on the surface, and the water molecules close to the surface are arranged in an orderly manner, such as bentonite, syrup, modified starch and modified cellulose. The hydroxyl group (-OH) contained in these substances has a strong fixing effect on water molecules, and can make water molecules stick together in the initial stage of ball solidification.

2. "Chemical combination" of the briquette machine means that the binder relies on chemical reactions to generate new phases during the combination process, such as ordinary cement, water glass and carbonation consolidation chemical combination. Carbonization curing also belongs to chemical curing. During the consolidation process of some organic binders, under the influence of changing conditions, the molecules undergo polymerization or polycondensation, thereby bonding together more tightly, which is also called chemical bonding.

3. The organic binder of the briquette machine is a synthetic high polymer or mixture, and the viscosity increases rapidly after dissolving. The classic organic binders include sodium carboxymethylcellulose, modified starch series, polyacrylamide, etc. The organic bonding effect is obvious, the mixing ratio is low, the impact on the ball grade is small, and the amount of impurities brought in is small. In addition, the agent burns and disappears after entering the furnace, which can effectively improve the pellet grade and porosity, and is beneficial to the improvement of reducibility and steelmaking index. The modified starch type organic binder type is determined.

If you want to know about more briquette machine, you can visit our website: https://www.sinogomine.com/Briquette-Pressing-Machinery/

0 notes

Text

Potato Starch Market Global Market Size 2025–2035

The potato starch market accounted for USD 3.68 billion in 2024 and is projected to reach USD 6.2 billion by 2035, growing at a CAGR of 4.85% during the forecast period. This market comprises the production and utilization of starch extracted from potatoes, widely used in the food, pharmaceutical, and industrial sectors due to its natural thickening, binding, and stabilizing properties. In foods, it appears in soups, sauces, processed dishes, and gluten-free baked goods. In pharmaceuticals, it's used as a disintegrant in tablets. Industrial applications span automotive, adhesives, textiles, and bio-polymers.

The growth is driven by consumer demand for clean-label, gluten-free, and plant-based ingredients, coupled with technological progress in starch modification and increasing usage in emerging economies.

Request Sample Now : https://www.metatechinsights.com/request-sample/1818

Market Drivers

Rise of convenience foods: Urbanization and fast-paced lifestyles are fueling the demand for ready-to-eat meals, increasing the use of potato starch for its lump-free, stable texture.

Eco-conscious consumer trends: Rising environmental awareness has boosted demand for biodegradable plastics made from potato starch, especially for packaging and single-use items.

Supportive regulations: Government initiatives and incentives to promote sustainable and plant-based alternatives further encourage market growth.

Processed food demand in emerging regions: Rapid urbanization, westernized diets, and growing income levels in countries like India and China are driving starch use in packaged foods and baked goods.

Full Report: https://www.metatechinsights.com/industry-insights/potato-starch-market-1818

Market Challenges

High production costs: Energy-intensive processes such as grinding and drying, along with labor and infrastructure costs, impact profitability.

Supply instability: Agricultural dependence leads to fluctuations in raw material availability and pricing.

Capital-intensive operations: Upfront and maintenance costs for machinery and processing units remain a challenge for smaller players.

Segment Analysis

By Type:

Native Potato Starch: Preferred for natural food formulations; used in sauces and processed foods.

Modified Potato Starch: Offers superior heat, acid, and shear resistance; ideal for industrial and food applications.

Pregelatinized Potato Starch: Popular in convenience foods for easy cold-water swelling and binding.

By Application:

Food & Beverages: The largest segment; includes bakery, confectionery, soups, sauces, dairy, meat products, and gluten-free foods.

Industrial: Used in papermaking, adhesives, textiles, and biodegradable plastics.

Animal Feed: Enhances texture and quality of feed, contributing to livestock productivity.

Regional Overview

Europe dominates the global market due to its mature food industry, consumer demand for natural and sustainable packaging, and innovation in gluten-free and plant-based food products. European manufacturers are investing in clean-label starches and improving production efficiency.

Asia-Pacific is the fastest-growing region, with urbanization, expanding food processing industries, and a shift in dietary patterns driving potato starch adoption. Countries like China and India are integrating potato starch into bakery items, snacks, and eco-friendly packaging. Emerging tech in bio-packaging and bioplastics further fuels growth.

Buy Now: https://www.metatechinsights.com/checkout/1818

Competitive Landscape

The market is highly competitive with major players focused on product innovation, sustainability, and expanding processing capabilities:

Cargill Inc. – Focused on clean-label solutions and expanding production.

Tate & Lyle – Emphasizing sustainability and renewable energy adoption.

Royal Avebe – Producing starches for pharma and bio-based applications.

KMC – Diversifying across food and non-food segments.

Others: ALK/KMC, Kirsten Moller Christensen, Ingredion, AGRANA.

These players are advancing starch functionality, meeting demand across food, beverage, and industrial sectors, while aligning with global sustainability standards.

Recent Developments

Oct 2024: UNPT in France supports the National Strategic Plan aimed at potato industry development.

June 2023: Royal Avebe partners with Brenntag Specialties to enhance starch distribution and applications across Europe.

#Potato Starch Market#Clean Label Ingredients#Biodegradable Packaging#Gluten Free Foods#Potato StarchTrends#FoodProcessingMarket#StarchBasedPackaging#SustainablePlastics#PotatoStarchManufacturers#PotatoStarchForecast2035

0 notes

Text

Extrusion and Thermoplastics

In a thermoplastic extrusion, the material is first softened by heating so that it can be shaped. This process is performed by the extruder, or extrusion machine. This heat softening is referred to by different names, such as ‘thermal softening’, ‘plasticization’, or ‘plastication’.

Most extruders are single screw machines. The screw is what forces the material towards, and then through, the die. Shape is imparted by the die, and/or by post-extrusion forming, and the product is then set to shape by cooling while maintaining its shape. The equipment used to perform this process is known as the post extrusion equipment, while the entire system is known as an extrusion line. In addition, there are food extruder machine and feed extruder machine.

Extruder Classification

Extruders may be categorized by three figures, for instance, 1-60-24. The first number specifies the amount of screws the machine has, the second number indicates the screw diameter in millimeters (mm), and the third number indicates the effective screw length as a multiple of the screw diameter. Therefore, in the given example, a single screw machine is being described that has a screw diameter of 60 mm and a length of 24 (i.e., a L/D ratio of 24/1).

Machine Construction

Figure 1 shows a cut-away diagram of a simple single screw machine. This diagram shows the arrangement the different parts of the machine. The two units - screw and barrel - interact together to convey the plastic material, melt the material, and then push it through the die.

The screw is rotated at a predetermined speed with the electric motor drive unit and gearbox. Temperature controllers are connected to heating/cooling elements on the barrel to maintain the temperature at the set-point temperatures.

The capability of the screw and barrel assembly to extrude a given material is based on the characteristics or construction of the barrel and screw, the characteristics of the plastics material, and the circumstances under which the system is operated.

Post Extrusion Equipment

When the extrudate leaves the die, it can either be set to the desired shape or its shape can be altered and then set to shape. The equipment that performs this process is known as the ‘post extrusion equipment’ or the ‘haul off’, and in terms of size, it is generally much larger than that of the extruder. This is because plastics take a considerable amount of time to cool, and this cooling process determines the speed the line will operate.

Pet Feed Machinery

The growing demands of today’s pet food market require increasingly specialized knowledge combined with advanced processing technologies. As a longtime partner to hundreds of premium pet food producers worldwide, we provides comprehensive processing solutions and aftermarket services to keep your operations ahead of the curve. All to guarantee easy, safe, and efficient operations that can quickly adapt to the next market trend.

We offers a full range of pet feed machinery – from raw material intake to finished feed bagging – as single unit or complete plant solution. The individual process machines offered are selected from the standardized and proven range of product families.

A wide variety of food products is produced worldwide on our complete twin screw extrusion processing lines to answer increasing consumers demands : cereals, snacks, crispy breads and crackers, baby food, textured proteins and food ingredients.

At the same time, we also offer pasta machinery and couscous turn-key processing lines integrating our specific design Rotante hot air drying technology.

To enable our partners in the Food industry to gain market shares and leveradge their brands, our expert teams are continuously innovating to develop and produce high-quality food products with new flavors and taste combinations.

Pasta Production Line

Over 50 years, pasta production line has offered complete production solutions for a wide range of typical short-cut pasta shapes. Over the years, Clextral experts have continuously refined every component in the production process, building high-performance lines to customer specifications, including its exclusive VHT (Very High Temperature) drying system. Clextral short pasta extruders are particularly adapted to the modern requirements of production in terms of cost-effectiveness, flexibility, ease of use, hygiene and maintenance.

HOW IS PASTA MADE ?

The raw materials are mixed with a precise dosing mechanism to maintain constant flow and obtain homogenous dough in the pasta extruder. The pressing phase is carried out with a single screw system specially designed to ensure optimal semolina hydration, mixing, compression and extrusion. Once the dough is kneaded to the required consistency it is put through fitted dies to produce the required shapes and cut to length. Drying is achieved in two phases : first, the pre-drying Trabatto is used to crust the dough surface in order to avoid sticking. The second phase is done on Rotante drying units which include a VHT (Very High Temperature) drying system, which offers several advantages, including faster pasta producton, heightened quality of the final product (especially for pasta made with soft wheat), reduced product loss, short changeover times and very hygienic processing. After drying, the pasta is cooled and stabilized in the industrial pasta machine and then transported to storage or packaged directly.

STATE-OF-THE-ART PRODUCTION OF PASTA

Clextral pasta extruders are designed and manufactured to strict production standards ensuring:

Quality construction and superior hygienic standards – stainless steel parts, easy cleaning, low loss of raw materials, etc.

Quick and easy on-site assembly – modular pre-mounted parts

End-to-end process control – full automation to guarantee product consistency

Flexibility – quick changeover, easy shape changes and adjustment of production parameters, capacity varies from 1,500kg to 6,000kg/h

Efficient maintenance – standardized extrusion and drying parts, easy access for servicing

Follow-up services –training, support, new product design expertise

Sustainability – intensified processing to generate energy and water savings, as well as cost-effectiveness

High-Quality Modified Starch Products

Microtec Engineering Group is an eminent name in the modified starch industry. With a vision to be one of the world-leading Provider of premium modified starch technology, our focus is to increase our penetration in global markets by helping clients to manufacture quality modified starch products using the latest technology and strictly adhering to the Industrial Standards. Using our advanced equipment and processing technology ,you’ll obtain starch products that are distinguished from the rest. Our starch modifying equipment is designed to produce top-of-the-line products that cater to the requirements of a widening customer base.

Industrial Application of Our Modified Starch Technology

Our modified starch machinery serves a wide range of industrial applications. These include:

1. Food

Modified starches are excellent thickening agents. Our advanced starch modifying technology will enable you to provide the required thickness, stretch ability, crispness, stabilizing and binding properties as well as texture to numerous food products related to:

Bakery

Coating

Confectionary

Soups, sauces & gravies

Pasta & noodles

Snacks

2. Textile

Textile industry relies on the use of modified starch products as they reduce the breakage of fibre and wastage. Especially when used on fabrics like polyester, cotton and acrylic, they yield satisfying results. Advanced starch enhancing technology like ours can also help you to manufacture a wide number of products like:

Thin boiled starch

Binder

Softener

Lubricants

3. Paper & Packaging

Paper – The demand for modified starch in the paper making industry is never less. The reason? Because modified starch increases the bonding strength of paperboard and plain white paper. Our top-of-the-line technology is instrumental in enhancing the strength, quality and brightness of the paper.

Packaging – The adhesive property of modified starch is remarkable. Modified starch is an essential component in packaging glue which, in turn, is used for making boxes and cartons. Our unique starch modifying equipment enables you to impart excellent adhesive property to your packaging glue.

4 notes

·

View notes

Text

BEST CHOOSE OF FOOD MACHINE MANUFACTURE-SHANDONG LOYAL INDUSTRY CO.LTD

Since its establishment, Shandong Loyal Industrial Co.,Ltd. has provided feasible solutions for every customer with 18 years of experience in the field of food machinery, from food raw material processing to finished product packaging (from A to B food making production line). Our factory is located in Jinan Shandong Province, covering an area of approximately 6000 square meters.

With many years of production experience, at present, the machinery and equipment developed by Shandong Loyal Industrial Co., Ltd. are mainly used in breakfast cereals production line, instant/nutritious rice production line, grain nutrient powder production line, modified starch making machine, food extruder, industrial microwave system, biscuit production line, instant noodle production line, puff snacks processing line, breakfast cereal corn flakes production line, fortified rice production line, soy protein (TSP) food, pet food and fish feed production line, packaging machine and other fields. The various types of food machinery and equipment developed by our company are sold to domestic provinces, cities, autonomous regions and other places. Our products are also exported to more than 50 countries and regions, including Germany, South Korea, Russia, Singapore, the United States, Indonesia, Vietnam, Thailand, Cambodia, Nigeria, Pakistan, Zimbabwe, the Philippines, South Africa, Central Asia, and India. Shandong Loyal Industrial Co.,Ltd. adheres to the corporate tenet of "Technology Innovation, Honest Management"; based on the principle of mutual benefit and common development, based on a high starting point, large investment, and high operation; adheres to standard and refined production standards, In order to ensure that every production link is well grasped, to create a safe and good brand.

Quality: Quality is the foundation of a company's brand, and optimizing product quality is the company's goal of sustainable development. Shandong Loyal Industrial Co., Ltd. enjoys a high reputation in the global and domestic markets, and has passed ISO system, ISO900I certification, SGS certification, and has obtained 10 CE certificates and 25 technical patents. Shandong Loyal Industrial Co.,Ltd. has been recognized by more than 50 countries and regions. It has been rated as a trustworthy enterprise, a well-known trademark enterprise in Shandong Province, a governing unit of the Shandong Electronic Commerce Association, a sample enterprise of China's foreign trade export, and a vice-chairman unit of the Jinan Foreign Trade Enterprise Association. For example, at the 13th China International E-Commerce Conference, Shandong Loyal Industrial Co., Ltd. won the 2019 China E-Commerce Integrity Enterprise Award. At the same time, Shandong Loyal Industrial Co., Ltd. is also a cooperative enterprise unit of Shandong University of Technology and Linyi University, and a training base and practice base for technical personnel. Therefore, we will continue to move forward, do a good job of strict quality control, new technology development and provide better customer service.

Innovation: Continuous innovation is the prerequisite for the survival and development of an enterprise. Shandong Loyal Industrial Co., Ltd. will continue to develop new products and services to ensure the company's competitiveness and a deep understanding of the growing needs of customers.

Honesty: Insist on honest management is the foundation of business. Shandong Loyal Industrial Co., Ltd. has always been customer-oriented, providing perfect and efficient after-sales service, understanding the real needs of customers, and establishing long-term, mutual respect and mutual cooperation with customers. As always, we will provide customers with reliable products and perfect services, so as to seek common development and create good results.

Shandong Loyal Industrial Co., Ltd. has a series of technicians, engineers, and sales and after-sales service personnel, forming a high-quality, young and innovative team, which has laid a solid foundation for the manufacture of excellent food machinery and equipment. Foundation. At the same time, Shandong Loyal Industrial Co., Ltd. has also established a complete after-sales service system to provide customers with convenient services such as installation and commissioning, operation training, maintenance and upgrading, and replacement of spare parts. Shandong Loyal Industrial Co., Ltd. will also continue to optimize the company’s management philosophy, product structure, and constantly improve the company’s organizational structure, business processes, management system, and corporate culture, to create a new image, create corporate competitiveness, and strive to achieve the vision of "creating value for every customer"! "SINCERITY IS THE SOUL OF LOYAL" This also inspires us-inspires us-to do what we do. Shandong Loyal Industrial Co.,Ltd. will continue to develop and forge ahead, and create value for customers with excellent products and services!

1 note

·

View note

Photo

Juke magazine - 3 May 1980 front cover and article, by Christie Eliezer

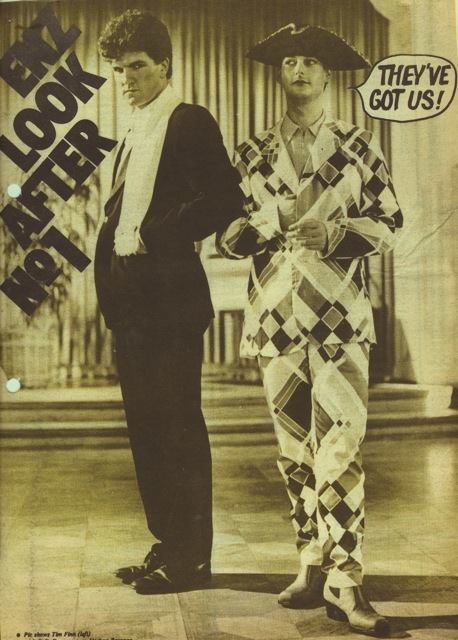

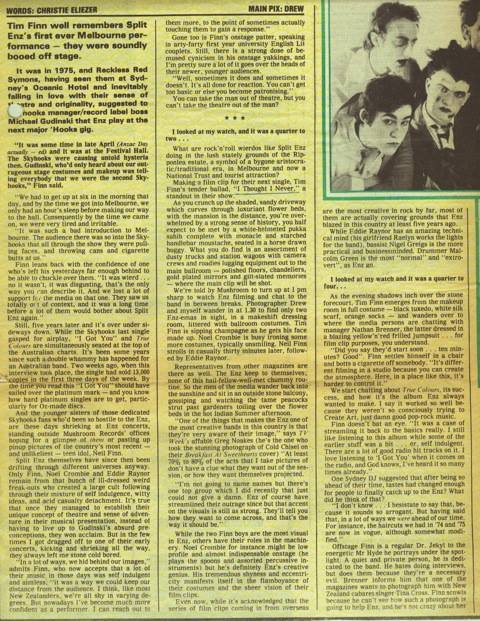

TIM FINN well remembers Split Enz’s first ever Melbourne performance - they were soundly booed off stage.

It was in 1975, and Reckless Red Symons, having seen them at Sydney’s Oceanic Hotel and inevitably falling in love with their sense of theatre and originality, suggested to Skyhooks manager/record label boss Michael Gudinski that Enz play at the next major ‘Hooks gig...

“It was some time in late April (Anzac Day actually - ed) and it was at the Festival Hall, The Skyhooks were causing untold hysteria then. Gudinski, who’s only heard about our outrageous stage costumes and makeup was telling everybody that we were the second Skyhooks,” Finn said.

“We had to get up at six in the morning that day, and by the time we got into Melbourne, we only had an hour’s sleep before making our way to the hall. Consequently by the time we came on, we were very tired and irritable.

“It was such a bad introduction to Melbourne. The audience there was so into the Skyhooks that all through the show they were pulling faces, and throwing cans and cigarette butts at us.”

Finn leans back with the confidence of one who’s left his yesterdays far enough behind to be able to chuckle over them. “It was weird... no it wasn’t, it was disgusting, that’s the only way you can describe it. And we lost a lot of support from the media on that one. They saw us totally out of context, and it was a long time before a lot of them would bother about Split Enz again.”

Still, five years later and it’s over under sideways down. While the Skyhooks last single gasped for airplay. “I Got You” and True Colours are simultaneously seated at the top of the Australian charts. It’s been some years since such a double whammy has happened for an Australian band. Two weeks ago, when this interview took place, the single had sold 13,000 copied in the first three days of the week. By the time you read this “I Got You” should have sailed over the platinum mark - and you know how hard platinum singles are to get, particularly for Oz-made discs.

And the younger sisters of those dedicated Skyhooks fans who’d been so hostile to the Enz, are these days shrieking at Enz concerts, standing outside Mushroom Records’ offices hoping for a glimpse of them or pasting up pinup pictures of the country’s most recent - and unlikeliest - teen idol, Neil Finn.

Split Enz themselves have since then been drifting through different universes anyway. Only Finn, Noel Crombie and Eddie Rayner remain from that bunch of ill-dressed weird freak-outs who created a large cult following through their mixture of self indulgence, witty ideas, and acid casualty detachment. It’s true that once they managed to establish their unique concept of theatre and sense of adventure in their musical presentation, instead of having to live up to Gudinski’s absurd preconeptions, they won acclaim. But in the few times I got dragged off to one of their early concerts, kicking and shrieking all the way, they always left me stone cold bored.

“In a lot of ways, we hid behind our images,” admits Finn, who now accepts that a lot of their music in those days was self-indulgent and aimless. “It was a way we could keep our distance from the audience. I think, like most New Zealanders we’re all shy in varying degrees. But nowadays I’ve become much more confident as a performer. I can reach out to them more, to the point of sometimes actually touching them to gain a response.”

Gone too is Finn’s onstage patter, speaking in arty-farty first year university English Lit couplets. Still, there is a strong dose of bemused cynicism in his onstage yakkings, and I’m pretty sure a lot of it goes over the heads of their newer, younger audiences.

“Well, sometimes it does and sometimes it doesn’t. It’s all done for reaction. You can’t get too basic or else you become patronising.”

You can take the man out of theatre, but you can’t take the theatre out of the man?

I looked at my watch, and it was a quarter to two...

What are rock’n’roll weirdos like Split Enz doing in the lush stately grounds of the Ripponlea estate, a symbol of a bygone aristocratic/traditional era in Melbourne and now a National Trust and tourist attraction?

Making a film clip for their next single, Tim Finn’s tender ballad, “I Thought I Never”, a standout in their show.

As you crunch up the shaded, sandy driveway which curves through luxuriant flower beds, with the mansion in the distance, you’re overwhelmed by a strong sense of history, you half expect to be met by a white-helmeted pukka sahib complete with monacle and starched handlebar moustache, seated in a horse drawn buggy. What you do find is an assortment of dusty trucks and station wagons with camera crews and roadies lugging equipment out to the main ballroom - polished floors, chandeliers, gold plated mirrors and sin-soaked memories - where the main clip will be shot.

We’re told by Mushroom to turn up at 1 pm sharp to watch Enz filming and chat to the band in between breaks. Photographer Drew and myself wander in at 1:30 to find only two Enzers in sight, in a makeshift dressing room, littered with Ballroom costumes. Tim Finn is sipping champagne as he gets his face made up. Noel Crombie is busy ironing some more costumes. Tim Finn is sipping champagne as he gets his face made up. Noel Crombie is busy ironing some more costumes, typically unsmiling. Neil Finn strolls in casually thirty minutes later, followed by Eddie Rayner.

Representatives from other magazines are there as well. The Enz keep to themselves, none of this hail-felllow-well-met chummy routine. So the men of the media wander back into the sunshine and sit in an outside stone balcony, gossiping and watching the tame peacocks strut past gardeners toiling over the flower beds in the hot Indian summer afternoon.

“One of the things that makes the Enz one of the most creative bands in this country is that they’re very rarely of their image,” says TV Week’s affable Greg Noakes (he’s the one who took the stunning photograph of Cold Chisel on their Breakfast At Sweethearts cover). “At least 70% to 80% of the acts that I take pictures of don’t have a clue what they want out of the session, or how they want themselves projected.

“I’m not going to name names but there’s one top group which I did recently that just could not give a damn. Enz of course have streamlined their outrage since but that accent on the visuals is still as strong. They’ll tell you how they want to come across, and that’s the way it should be.”

While the two Finn boys are the most visual in Enz, others have their roles in the machinery. Noel Crombie for instance might be low profile and almost dispensable onstage (he plays the spoons and assorted percussive instruments) but he’s definitely Enz’s creative genius. His tremendous shyness and eccentricity manifests itself in the flamboyance of their costumes and the sheer vision of their film clips.

Even now, while it’s acknolwedged that the series of film clips coming in from overseas are the most creative in rock by far, most of them are actually covering grounds that Enz blazed in this country at least five years ago.

While Eddie Rayner has an amazing technical mind (his girlfriend Raelyn works the lights for the band), bassist Nigel Griggs is the more practical and businessminded. Drummer Malcolm Green is the most “normal” and “extrovert” as Enz get.

I looked at my watch and it was a quarter to four...

As the evening shadows inch over the stone forecourt, Tim Finn emerges from the makeup room in full costume - black tuxedo, while silk scarf, orange socks - and wanders over to where the media persons are chatting with manager Nathan Brenner, the latter dressed in a blazing yellow’n’red frilled jumpsuit... for film clip purposes, you understand.

“Did you say they’d start soon... ten minutes? Good.” Finn settles himself in a chair and botts a cigarette off somebody. “It’s different filming in a studio because you can create the atmosphere Here, in a place like this, it’s harder to control it.”

We start chatting about True Colours, it’s success, and how it’s the album Enz always wanted to make. I say it worked so well because they weren’t so consciously trying to Create Art, just damn good pop-rock music.

Finn doesn’t bat an eye. “It was a case of strealining it back to the basics really. I still like listening to this album while some of the earlier stuff was a bit... er, self indulgent. There are a lot of good radio hit tracks on it. I love listening to ‘I Got You’ when it comes on the radio, and God knows, I’ve heard it so many times already.”

One Sydney DJ suggested that after being so ahead of their time, tastes had changed enough for people to finally catch up to the Enz? What did he think of that?

“I don’t know... I hesitate to say that, because it sounds so arrogant. But having said that, in a lot of ways we were ahead of our time. For instance, the haircuts we had in ‘74 and’75 are now in vogue, although somewhat modified.”

Offstage Finn is a regular Dr. Jekyll to the energetic Mr Hyde he portrays under the spotlight. A quiet and private person, he is dedicated to the band. He hates doing interviews, but does them because they’re a necessary evil. Brenner informs him that one of the magazine wants to photograph him with New Zealand cabaret singer Tina Cross. Finn scowls because he can’t see how a photograph is going to help Enz, and he’s not not crazy about her music either. He eventually relents, but his curt demeanor as he does it makes it clear to everyone, including Ms Cross, that he’s done it under protest.

It takes Tim thirsty minutes to wind down after a performance and push the adrenalin flow back to normal. He’s not a violent person at all, but during the recent tour he angrily slammed the door in the face of a Brisbane photographer who ignored the “no one in Enz’s dressing room thirty minutes before and after the show.”

Very reflective, determined and cynical, it’s what you’d expect from someone who’s the original surviving member of the band that got together in New Zealand eight years ago, almost touched the pot of gold at the end of the huge rainbow, but had it whisked away by the hand of fate.

Remember how everything looked so rosy for the Enz in the mid-Seventies. Roxy Music’s Phil Manzanera, who was touring here at the time, dug them so much that he insisted on producing their second album Second Thoughts.

They went to England where the English rock press wet its pants over them. Melody Maker declared “they are one of the few bands of any originality to have emerged over the last 12 months, they may even prove to be the most intriguing combo to join the rock and roll circus since Roxy Music.” Their U.K. label Chrysalis were so determined that they’d be the next big thing that they spent a fortune publicising the band. Nibbles into America proved favourable. A Frenz of the Enz cult following developed in England and Europe.

The dream soured just as quickly. Such an intense creative band had to have its intense personality clashes, of course, and they went through four changes in 19 months.

But if there’s eomthing about Split Enz, it’s been their strong determination and the sense of challenge they feel in seeking out the unknown.

One was going back to working the pubs and developing a grass roots following. The music became streamlined. They tried working with a virtually unknown English engineer/produced called David Tickle. Their first collaboration, ‘I See Red’ saw the Enz get their first National Top 10 single. Pleased with this, they decided to use Tickle in work on their next album. The rest, as they sayin the soap operas, is history.

“We were both looking for each other,” Finn says. “We needed a producer like him, and he was looking for a band like us.”

In a recent interview, Finn confessed that Tickle had provided a “psychological climate” for the band. What did he mean by that?

“Well, it wasn’t just a business relationship, David became a very good friend of the band’s. Obviously when you’re recording, you’re not as good in all aspects of it. Like possibly your vocal harmonies might not be up to scratch. It then takes someone who can bolster up your confidence at that point of time. I know it sounds corny, but you need someone you can depend on.”

Neil Finn wanders over, dressed in a white and pink jacket. The younger Finn had been Enz’s biggest gamble, when they replaced the prolific and adventurous Judd with someone as inexperienced as he. It worked. Onstage his confidence has escalated, although he’s still wary of people he doesn’t know. Every time he answered a question, he’d always glance at his older brother as if needing his assurance.

More than any of the others, he handles the new responsibilities as Enz now also appeals to a younger, screaming audience. He’s forever willing to make in-store appearances and do interviews because the band’s status warrants it. He’s warmed to his new role as a pinup boy.

“It’s a strange situation to be in,” he laughs. “Because, after all, none of us in this band are what you’d call pretty.”

Would you have believed five years ago that some day young females would be screaming at Split Enz and mooning over them as idols. The mind certainly boggles.

At this stage, Split Enz are carefully taking the new found adulation in stride. Rather than cash in by rushing out and playing all the big pubs again and making a lot of money (Brimmer claims he could get $4,000 a night from a one night stint at the Bondi Lifesaver in Sydney) they intend to stay off the road for a few more weeks and then do some work around Perth.

“It’s so easy to get over-exposed in a country like this.” They’re all very keen that their credibility doesn’t get blown with sudden success. Over the next week, too, they’ll start to rehearse the material for their next album, due out in October.

And, surely, Split Enz are dying to get back to have another crack at the English market. After all, considering the way they’ve stuck together through the bad period, this is obviously the strongest Enz lineup to date.

“There have been some nibbles... obviously we’d like to get back there and try it again. But at the same time we’d still like to work to consolidate ourselves in this country, get better acquainted with our new audience. I think the time is just right for us in England, their Top 40 is the most adventurous in the world.

“‘I See Red’ was released there recently. It sold well enough to prove there are still people out there who can remember us, but didn’t get airplay. It’s funny you know, but there are still fans there who hunt us down and write us letters. But this time when we go back there we’ll be more prepared. We’re so aware of the need for a publicist, someone who knows the right people and can get to them.”

“Not much different here.” mutters someone who shall remain nameless.

‘I looked at my watch and it was a quarter to five...

And they’re finally ready to start shooting, kept waiting a further half an hour by an extra. The film clip depicts the band in the aftermath of a wild ball, streamers and balloons everywhere. Last minute adjustments to the sound levels, the tension is unbearable. Tim Finn kicks a balloon around the floor. Eddie Rayner and Nigel Griggs jam on a fast blues and the record finally booms over the microphone.

I fall apart when you’re around, When you’re here, I’m nowhere, I can’t pretend that I’m not down, I show it, I know it...”

Finn steps down from the stage to the dance floor, still miming:

I’ve been a fool more than once, more than twice. I’m gonna move

“Cut!”

It’s a mistake and has to be re-shot. Split Enz are so perfectionist, so unflinching they try again.

“Take two.”

The record booms over the P.A. again. Thirty minutes of that and “Cut!” Yes, it’s a take. Now for the next scene.

And so they piece it together through the whole night, trying out different ideas, always willing to score a better take. For a scene where T. Finn has to waltz alone in the garden, they use floodlights and keep on going. Finally as the eastern clouds streak a tinge of pink and yellow, exhausted bodies yawningly carry the equipment back to the station wagons and head off.

The clock in the main mallroom read 6.10 as the last of the trucks roars off through the steel gates in a cloud of dust.

And when the day breaks in our stately home we'll sit Remembering those nights before our hearts were set Hoping is not enough to live upon With such a far far cry I can't go wrong

- Judd-Finn, “Maybe” from Mental Notes, 1975

And all we’ll see on our TV screens will be a little over three minutes of it.

4 notes

·

View notes

Text

Jonjulean Henry

Fieldwork 11

In 1928 H.B. Reese worked as an employee for the Hershey Company in Pennsylvania. Hershey was created for the market only as an assortment candy, but became one of the companies longest, most selling candy. It was the first ever chocolate and peanut butter candy to ever be sold and became one of the company's best sellers.

Ingredients: Milk Chocolate [Sugar, Cocoa Butter, Chocolate, Non-Fat Milk, Milk Fat, Lactose, Lecithin (Soy), PGPR, Emulsifier], Peanuts, Sugar, Dextrose, Partially Defatted Peanuts, Hydrogenated Vegetable Oil [Palm Kernel Oil, Soybean Oil], Contains 2% of Less of: Corn Syrup, Contains 2% of Less of: Salt, Contains 2% of Less of: Palm Kernel Oil, Contains 2% of Less of: Artificial Color (Yellow 5 Lake, Yellow 6 Lake, Red 40 Lake, Blue 1 Lake), Contains 2% of Less of: Confectioner's Glaze, Contains 2% of Less of: Lecithin (Soy), Contains 2% of Less of: Modified Corn Starch, Contains 2% of Less of: TBHQ and Citric Acid, Contains 2% of Less of: To Maintain Freshness, Contains 2% of Less of: Carnauba Wax, Contains 2% of Less of: Vanillin, Contains 2% of Less of: Artificial Flavor.

Reese's ingredients are mainly raw materials, according to Hershey theri milk that produces the famous chocolate comes from a 100-male radius of their companies. Most of the raw materials that are being used to make the candy comes from tropical evergreen cocoa trees. The type of trees are mainly found in Central and South America. Western Africa, is also one the countries but child labor is a major problem. Hersheys is a major company that promotes child labor unfortunatley. Majority of the workers are minors. Working conditions are horrible especially for these young children. They work full twelve hour shifts without breaks majority of the time. These children are using heavy machinery like machetes and chainsaws. The candy is mainly transported by trucks when being transported locally, and plane when internationally especially to transport goods and heavy shipments. A form of this country's indirect distribution would be, the candy being sold from Hershey to Fred Meyers who sells the product to the company, then to the customers. The original Reese's Peanut Butter only comes in two. The original price for the 1.5 oz is $0.88. Store owners profit between 55-75 percent. Per pound a store owner makes 7 to ten dollars. The Hershey chocolate company dominates mainly 44 percent of the U.S. chocolate market. The United States regulates chocolate and cocoa products, by the Food and Drug Administration.TransFair USA, which is a third-party nonprofit Fair Trade certifier, ensures that farmers who make the cocoa aren't being screwed over by the big corporations. Hershey applies a micro-marketing concept to its businesses, which means that it markets certain products to small target audiences, tailoring its products to meet these audiences' particular demands. Hershey thus aims to give its customers a larger range of options by personalizing their products at higher prices. Personally I brought my Chocolate bar from target.

0 notes

Text

Modified starch machinery by Microtec enhances the production of E1412. It improves stability, efficiency, and quality. Microtec leads with innovative solutions.

0 notes

Text

Candy corn: Why we love (or hate) the waxy Halloween treat

A survey finds it’s the holiday’s least-liked sweet — perhaps because its flavor lacks complexity.

By USA TODAY Oct 14, 2019 Brett Molina

When they’re not talking about pumpkin spice, there’s another fall treat people have strong opinions about: candy corn.

The triangle-shaped, tri-colored candy is either welcomed with open arms by fans every October, or vilified by haters who never would let it enter their mouths.

According to the National Confectioners Association, it is one of the top two Halloween treats, along with chocolate.

A recent poll conducted by Monmouth University found among the eight top-selling candies in the U.S., candy corn tied for fourth with Hershey bars, trailing Reese’s Peanut Butter Cups, Snickers and M&M’s.

“Candy corn even making the list may surprise some people, but it is one of the top-selling Halloween candies in the country,” said Patrick Murray, director of the Monmouth University Polling Institute.

Candy corn is popular enough that it even makes appearances outside Halloween, such as Christmas or Valentine’s Day.

How long have we consumed candy corn?

The treat dates back to the 1800s, although no one has been able to pinpoint who specifically invented the candy corn. The National Confectioners Association says “according to legend,” George Renninger, an employee of the Wunderlee Candy Co., created candy corn in the 1880s.

Production of candy corn took off in 1898 by Ohio-based Goelitz Confectionary Co., which we know now as Jelly Belly (makers of jelly beans with flavors such as caramel corn and, umm, canned dog food).

How does it get made?

The NCA says manufacturers use a molding process where “kernel-shaped depressions are made in a tray of corn starch.” The molds are filled in three passes: first pouring the white part of the candy corn, followed by orange, then yellow. When it sets, a confectioner’s glaze is added to make them look shiny.

Because there was no machinery to automate candy corn making when it was invented, the treats were made seasonally, starting in August and ending around fall, says the NCA.

A survey conducted this year by the NCA found 58% of people just pop the whole candy corn in their mouth. However, 29% will start by eating the narrow white tip at the top, while 13% will eat the yellow portion at the bottom first.

So, why do some people hate it so much?

If you’ve noticed recent chatter about candy corn hatred, it’s likely linked to a recent survey claiming candy corn was named America’s least-favorite Halloween candy. CandyStore.com based its finding on lists from various websites as well as surveys of its customers.

Jacob Lahne, a sensory scientist with the food science and technology department at Virginia Tech, said because candy corn has been around so long, it’s possible critics might find it “a little old-fashioned” compared to modern treats with more sophisticated flavors.

“It’s so intense, so sweet and so kind of one-note that I think it contrasts with current trends to add bitterness, to add salt, to add spice [or] other complexifying factors,” he said.

Joe Marcy, the head of the food science and technology department at Virginia Tech, says it could be related to the candy’s texture.

Brands of candy corn use varying ingredients to help with texture, Marcy said, including gelatin, egg whites, modified soy protein or carnauba wax.

In food science, while taste definitely matters, the “mouthfeel” — how food feels when it’s in our mouths — is just as important, said Marcy. “The flavor may not be what’s putting me off, it may be the texture.”

How has candy corn lasted for more than 100 years?

Christopher Gindlesperger, a spokesperson for the National Confectioners Association, said a lot of our love for sweets, including candy corn, comes from their connection to special events like Halloween.

“It’s very personal,” said Gindlesperger. “There’s an emotional well-being component to the products generally, and they’re so closely tied to our family traditions and holiday celebrations.”

The fact that we typically only eat candy corn for a brief time also helps, too. Marcy compares it to the Christmas season and the appearance of eggnog near the end of every year.

“If you had eggnog year-round, you would probably never drink eggnog,” said Marcy. “But if it was something that was a special treat associated with a specific holiday, yeah, i’m going to buy some candy corn, and for the month of October, I’m going to eat it.”

https://chicago.suntimes.com/taste/2019/10/14/20912870/candy-corn-waxy-halloween-treat-love-hate

0 notes

Text

Modified Wheat Starch And Its Global Market

Modified Wheat Starch And Its Global Market

Global modified wheat starch (MMS) market is witnessing rapid growth and promising future in the agricultural biotechnology sector. As per the latest report, modified wheat starch is used for making almost all products like breads, cereals, snacks, instant noodles, pasta, cookies and cakes. It has been used as food and feed additive since many years. It is also an important ingredient in industrial and pharmaceutical productions. This paper discusses some key facts and key issues in modified wheat starch market and in the modified wheat starch industry in general.

The modified wheat starch has a broad range of biotechnology applications in diverse fields. Globally, it is extensively used as food and feed additive. In developed countries, modified wheat starch is used as ingredients in industrial applications for growth and feed efficiency. It is also used as a stabilizer in various industries, e.g. pharmaceuticals, cosmetic industry, food & beverages industry, diary farms etc. It has applications in various industries, but these are only the tip of the iceberg.

The modified wheat starch and its uses in various industries have made this product highly vulnerable to price fluctuations. In developed countries, it faces competition from new modified wheat starch products with improved processing techniques, improved nutrition quality and various other factors such as quality and cost. This paper discusses some of the key factors influencing the global modified wheat starch market growth and its prospects for the future.

The global wheat starch market is segmented on the basis of various factors, primarily on the basis of consumer demands and pricing trends. It is true that demand from the developed markets is increasing. However, there is a counter trend, i.e., there is a dearth of developed countries willing to use modified wheat starch as an end user.

There is no direct relationship between modified size growth rate and modified wheat starch market size and demand, or consumption preferences. However, there is a correlation between the two: the latter's growth rate in the context of the European Union (EU) and USA (US) markets is highly correlated with the former. Moreover, there is another correlation, whereby the latter's per capita consumption is highly correlated with that of the former.

Based on data analysis, we found two main factors influencing modified wheat starch's global modified wheat starch market size and demand: first, the prices and secondly, the availability. The prices of modified starch are highly affected by supply and demand factors. The prices tend to be most affected by increasing demand, with falling prices. When supply remains constant, modified wheat starch prices tend to decline. The second factor influencing global modified wheat starch market size and demand is the availability of modified starch.

We note that the availability of modified starch is not important for the product to be popular in the market. For example, the food and beverage industry relies largely on modified starch for the production of drug formulations. When there are very limited sources of modified starch, the cost of manufacture as well as its distribution will be high. However, it will be a difficult task for the food and beverage industry to find ways to increase the amount of modified starch manufactured, without impacting on the quality and cost of the product.

The second most important question we address in this paper is as to the effects of demand fluctuations on modified wheat starch's global modified size and demand. It is generally believed that high growth rates lead to an increased demand for modified wheat starch in industrial applications. This demand is assumed to create a "bread deficit" in the United States and drive up the cost of bread. However, supply-side factors will also impact on the modified starch market. Supply-side factors such as the level of domestic production, availability of the modified starch, and the price level are thought to act as a control mechanism in stabilizing the modified starch market. Other potential sources of additional raw materials may also act as a hindrance for the domestic and foreign manufacturers to achieve their goals for industrial applications.

Summary

The report forecast global Road Cold Planers market to grow to reach xxx Million USD in 2019 with a CAGR of xx% during the period 2020-2025 due to coronavirus situation. The report offers detailed coverage of Road Cold Planers industry and main market trends with impact of coronavirus. The market research includes historical and forecast market data, demand, application details, price trends, and company shares of the leading Road Cold Planers by geography. The report splits the market size, by volume and value, on the basis of application type and geography. First, this report covers the present status and the future prospects of the global Road Cold Planers market for 2015-2024. And in this report, we analyze global market from 5 geographies: Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia], Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland], North America[United States, Canada, Mexico], Middle East & Africa[GCC, North Africa, South Africa], South America[Brazil, Argentina, Columbia, Chile, Peru]. At the same time, we classify Road Cold Planers according to the type, application by geography. More importantly, the report includes major countries market based on the type and application. Finally, the report provides detailed profile and data information analysis of leading Road Cold Planers company.

Key Content of Chapters as follows (Including and can be customized) : Part 1: Market Overview, Development, and Segment by Type, Application & Region Part 2: Company information, Sales, Cost, Margin etc. Part 3: Global Market by company, Type, Application & Geography Part 4: Asia-Pacific Market by Type, Application & Geography Part 5: Europe Market by Type, Application & Geography Part 6: North America Market by Type, Application & Geography Part 7: South America Market by Type, Application & Geography Part 8: Middle East & Africa Market by Type, Application & Geography Part 9: Market Features Part 10: Investment Opportunity Part 11: Conclusion

Market Segment as follows: By Region Asia-Pacific[China, Southeast Asia, India, Japan, Korea, Western Asia] Europe[Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland] North America[United States, Canada, Mexico] Middle East & Africa[GCC, North Africa, South Africa] South America[Brazil, Argentina, Columbia, Chile, Peru] Key Companies Caterpillar Equipment Dynapac Road Construction Equipment Multihog Ltd Roadtec SAKAI HEAVY INDUSTRIES Schwamborn Rhino Equipment Simex S.r.l Sunward Intelligent Equipment Tecnologia Dinamica en Implementos Wirtgen Xuzhou Construction Machinery Group Zoomlion International Trade Co., Ltd Shandong Shantui Construction Machinery SANY Group Co.,Ltd Market by Type Wheel-type Crawler-type Market by Application Road Construction Pavement Maintenance

For more details contact as https://www.reportmines.com/contact-us.php

0 notes

Text

Starch Recovery Systems Market Size Analysis, Segmentation, Industry Outlook, and Forecasts, 2020-2028

Reports and Data has designed its latest report on the Starch Recovery Systems market by adopting a multi-disciplinary approach to study the industry for the historical period from 2016 to 2018 and to examine the current market scenario. The research also undertakes an in-depth assessment of the current market dynamics pertaining to the leading regions in the global sector to draw an accurate forecast and key prospects during the forecast years from 2020 to 2028.

The study derives data via both primary and secondary research methodologies that are assessed to give precise market estimations and projections of the Starch Recovery Systems market, both at global and regional scales. Our team of analysts has employed multiple effective analytical tools to integrate essential facts and figures into revenue estimations and projections for the Starch Recovery Systems market in the forecast duration.

This report covers the recent COVID-19 incidence and its impact on Starch Recovery Systems Market. The pandemic has widely affected the economic scenario. This study assesses the current landscape of the ever-evolving business sector and the present and future effects of COVID-19 on the market.

Request a Sample Copy of this Report https://reportsanddata.com/sample-enquiry-form/1870

The competitive landscape of the Starch Recovery Systems market provides elaborate profiles of the following leading players:

GEA (Germany), Alfa Laval (Sweden), Andritz (Austria), NivobaHovex (Netherlands), MICROTEC ENGINEERING GROUP (Australia), Myande Group (China), Larsson Sweden (Sweden), Sino-Food Machinery (China), Flo-Mech (UK), and Hiller GmbH Germany), among others.

Key point summary of the Starch Recovery Systems market report:

1. Major drivers, restraints, opportunities, and challenges, and the competitive landscape

2. Emerging sectors in key geographies

3. Growth prospects that companies can capitalize on in emerging markets

4. Increasing stringency of various regulatory agencies to create new opportunities in several regions

5. Demand and supply dynamics in critical sectors of the Starch Recovery Systems market

6. Latest research and development projects and technological advancements recorded in major regional markets

7. Changing status of revenue share and size of key product segments during the forecast period

8. Potentially market disrupting technologies and business models

The Starch Recovery Systems market report offers a 360 assessment of prevailing opportunities in the leading regions and also evaluates their revenue shares for the forecast period. Key regions encompassed in the report include:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Any Query For Discount or Customization Of This Report? Ask our Expert https://reportsanddata.com/discount-enquiry-form/1870

Based on product/technology applications, the Starch Recovery Systems market report offers insights into major market trends for the following segments:

· Frozen products

· Chips & Snack pellets

· Dehydrated products

· Others

o Canned potato

o Potato flour

Apart from analyzing the supply and demand patterns of the different Starch Recovery Systems applications, this study on the Starch Recovery Systems market also scrutinizes the trends that will attract increased investments from several industries.

The global Starch Recovery Systems market report provides detailed evaluation and qualitative and quantitative analyses that highlight numerous vital aspects that have contributed to the growth of the industry in the past years. The report also studies some key market aspects that could reveal new growth prospects in the forecast period.

Crucial queries addressed in the Starch Recovery Systems market report are:

1. Which are the strategic initiatives undertaken by key players engaged in the Starch Recovery Systems market in recent years, including product launches, deals, joint ventures, mergers and acquisitions, and divestment of shares?

2. Which strategies will enable top players in the Starch Recovery Systems market to expand their regional presence?

3. Which business models are expected to lucrative for the growth of key regional markets in the near future?

4. Which technologies will attract the highest investment, and what will be the significant sources of funding for startups and new entrants?

5. Which product segments have witnessed emerging application areas in recent years?

Read the Comprehensive Report with a meticulous TOC and panoramic coverage of the market: https://reportsanddata.com/report-detail/starch-recovery-systems-market

Thank you for reading our report. To know more about the customization of the report or further query about the report, please get in touch with us. Our team will ensure the report is well suited to your requirements.

About Us: Our in-house experts assist our clients with advice based on their proficiency in the market that helps them in creating a compendious database for the clients. Our team offers expert insights to clients to guide them through their business ventures. We put in rigorous efforts to keep our clientele satisfied and focus on fulfilling their demands to make sure that the end-product is what they desire. We excel in diverse fields of the market and with our services extending to competitive analysis, research and development analysis, and demand estimation among others, we can help you invest your funds in the most beneficial areas for research and development.

Modified Starch Market

Antibiotics Market

Metal Injection Molding Market

Contact Us:

John W

Head of Business Development

Reports And Data | Web: www.reportsanddata.com/

Direct Line: +1-212-710-1370

E-mail: [email protected]

0 notes

Text

Beyond Simplex Review

While eating a gluten-free diet is optional for some people, avoiding gluten-containing foods is an absolute must for others. However, the idea of completely eliminating wheat can be overwhelming and challenging, especially in the initial stages.

Wheat is the most common ingredient used in the preparation of baked goods, cereals, and pasta, and it can be very difficult to avoid it completely.

Read on to learn more about gluten and the five gluten foods you should avoid.

Gluten and people who should avoid foods with gluten

Gluten is a protein present in wheat, triticale (the hybrid of wheat and rye), barley and rye and it binds foods. Gluten is a hot topic recently as celiac disease affects an estimated three million people in the United States alone. And approximately 95% of celiacs are not diagnosed.

For adults, symptoms of celiac disease can occur at any time in their lives. However, they are most common between the ages of 20 and 40. Some people with celiac disease may not have any symptoms. But they can still damage your small intestine by consuming foods with gluten.

Celiac disease in children

The celiac disease in children can be very serious because their bodies cannot absorb the crucial nutrients they need to grow if gluten is ingested regularly. This can also lead to an imbalance of vitamins and minerals.

Symptoms of celiac disease

General symptoms of celiac disease include diarrhea, gas, fatigue, low blood cell counts, osteoporosis, pain in the abdomen or joints, malnutrition, delayed puberty, and slow growth. Cramps, rashes, weight loss, and itching are also common symptoms. However, many people do not experience any symptoms.

You should speak with your doctor to determine if you have celiac disease or are sensitive to gluten. You can also try eliminating gluten from your diet, to see if your symptoms go away and if you feel better overall.

The 5 foods with gluten that you should eliminate

These are the five foods gluten can secretly lurk in.

1. Grains

The "rule of thumb" for a gluten-free diet is to avoid three main grains: wheat, barley, and rye. These grains can be present in cakes, cookies and other baked goods, cereals, pasta, bread, waffles. Also, in mixes for pancakes, dumplings, wheat germ, bran, ice cream cones, tortillas, breadcrumbs and croutons.

Keep in mind that there are many gluten-free options available for these foods. Make sure to read the labels to be sure there are no wheat byproducts.

Herpes is easily spread from skin-to-skin contact with someone who has the virus. You can get it when your genitals and/or mouth touch their genitals and/or mouth — usually during oral, anal, and vaginal sex. Herpes can be passed even if the penis or tongue doesn't go all the way in the vagina, anus, or mouth. Beyond Simplex Review

2. Processed meats

To follow a gluten-free diet, you must eliminate all processed meats. Sprue is a debilitating type of arthritis, which is accompanied by digestive symptoms due to excessive gluten intake. Processed meats are discouraged due to the dangerous preservatives it contains.

Meats such as salami, pepperoni, mortadella, hot dogs, liverwurst, and cold cuts should be avoided. Since processed meat you can use gluten flour as a binder.

Recommended alternative sources of gluten-free protein include unprocessed meats such as turkey and chicken or gluten-free brands that do not use preservatives.

3. Sweets and candies

If you like sweets, you might want to hear this: Most sweets in stores contain gluten. Pay attention to all chocolate products, root beer, commercial glaze for cakes, sorbets, cereals, candies, ice cream. And when it comes to bakeries, unless they're gluten-free, don't even think about it.