#ModularLinearActuators

Explore tagged Tumblr posts

Text

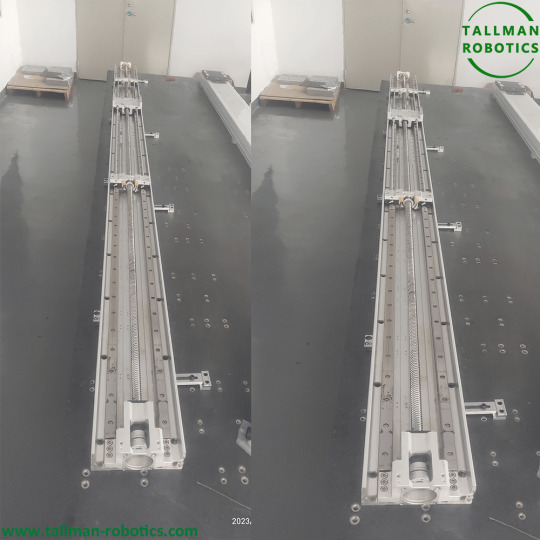

Screw Driven Linear Modular Actuators are under Test

Screw Driven Linear Modular Actuators are devices used to convert rotary motion into linear motion. Screw Driven Linear Modular Actuators consist of a motor, a screw shaft, and a nut, which are combined to create linear motion along the axis of the screw.

https://youtube.com/shorts/oh8PrSiWVjs?si=yPzZ4afR2WC-jKFD Here's how a typical Screw Driven Linear Modular Actuators works: Motor: The actuator is equipped with a motor, usually an electric motor, which provides the rotational power required for the actuator to function. The motor can be either stepper or servo motor, depending on the application requirements. Screw Shaft: The screw shaft is a long, threaded rod that runs through the actuator. It has a helical thread that engages with the nut and converts the rotational motion of the motor into linear motion. Nut: The nut is a component that contains a threaded hole matching the thread on the screw shaft. As the screw shaft rotates, the nut moves along the length of the shaft, causing linear displacement. The nut is usually mounted to the load or the movable part of the system. Modular Design: The term "modular" refers to the ability to customize or configure the actuator to meet specific requirements. Screw-driven modular linear actuators are often designed with a modular structure, allowing users to choose different screw shaft lengths, motor types, and other options to suit their application needs. Control System: The actuator is typically controlled by a control system that manages the motor's speed, direction, and position. This control system can be as simple as an on/off switch or a more sophisticated setup using microcontrollers or programmable logic controllers (PLCs). Screw-driven modules find applications in various industries, including robotics, automation, CNC machinery, 3D printing, medical devices, and more. They offer precise and controllable linear motion, making them suitable for applications that require accurate positioning, repetitive motion, or pushing/pulling loads. It's worth noting that there are different types of screw-driven actuators, including ball screw actuators and lead screw actuators. Ball screws use ball bearings to reduce friction and enhance efficiency, making them suitable for high-load and high-precision applications. Lead screws, on the other hand, have a simpler design and are often used in applications where lower precision or lower cost is acceptable. Overall, Screw Driven Linear Modular Actuators are versatile devices that provide controlled linear motion and can be customized to meet specific application requirements. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#BallScrewDrivenLinearActuator#BallScrewLinearActuators#leadscrewdrivenlinearactuators#ModularLinearActuator#ModularLinearActuators#MotorizedLeadScrewActuators#ScrewDrivenActuators#ScrewDrivenLinearActuatorElectricLinearActuator#Screwdrivenmodules

0 notes

Text

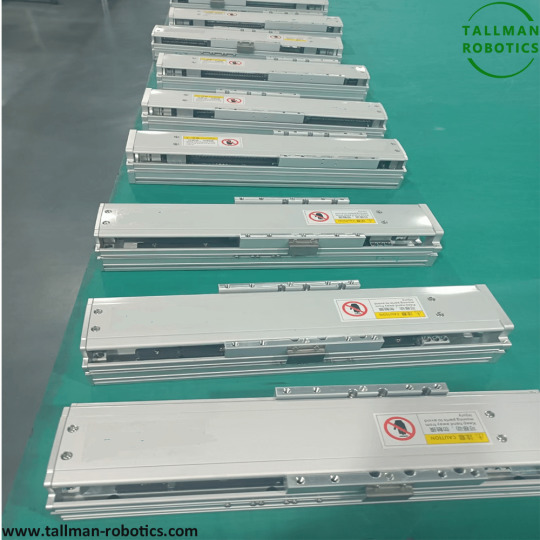

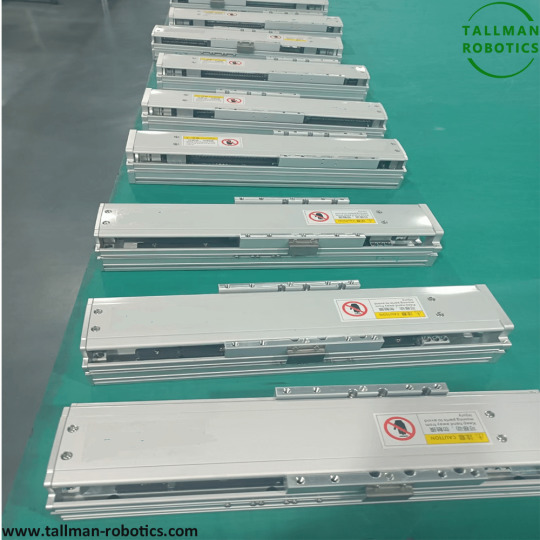

Screw Driven Actuators are Ready for Delivery to France.

Screw Driven Actuators from Tallman Robotics Limited havbe been finished and will be delivered to France. Screw Driven Linear Modules are ball screw driven linear actuators or Linear modules which are driven by ball screws, can also termed as Screw Driven Linear Actuators or Screw Driven Linear Modules. You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. https://youtube.com/shorts/qanDNnCC1pM?feature=share How to judge the performance of linear module slide including Screw Driven Linear Modules? In industrial production, the degree of automation has become an important standard to measure the strength of an enterprise, in which the application of linear slide module plays a decisive role. There are many types and models of slide modules, so you can't choose blindly, let alone install at will. Four factors should be considered for a good linear slide or Screw Driven Actuators: 1、 Whether the core components screw rod and linear guide rail are of high specification. 2、 Aluminum profile is also a key component, 3、 The screw support seat should be of precision grade, 4、 Drive part motor. The process of maintaining the linear slide module or Screw Driven Actuators generally starts from the use. As long as the operation is carried out according to the correct steps, the service life will not be affected. The inspection can be carried out periodically in the working stage. If there is damage, the key problem should be found in time or whether the operation is wrong should be investigated and dealt with. Generally, it takes 3 to 6 months to clean the inside, inject lubricating grease into the guide screw, and replace the consumable parts. Read the full article

#ActuatedLinearGuideSystems#BallScrewLinearActuator#ElectricLinearActuatorLeadScrew#GeneralmanufacturerofBallscrews#LinearandRotaryActuators#ModularLinearActuators#ScrewDrivenActuators#ScrewDrivenModularLinearActuators

0 notes

Text

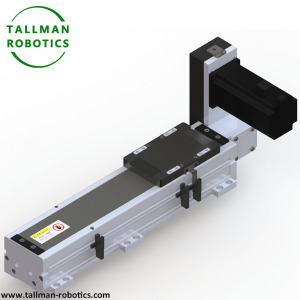

Linear Actuator Bundle

Linear Actuator Bundle You are welcome to visit our download centre to check E-catalogues or watch our video centre to check more projects. Tallman Robotics, as a professional manufacturer of Linear Actuator Bundle, supplies diverse TM Linear Actuator Bundles, such as Screw and Belt driven modules with different driven solution, also Semi and fully closed modules for different environment application. Linear Actuator Bundles, also named as Linear Axis Actuator, Linear Motion Module, Linear Modular Actuator, etc. Linear Actuator Bundle can work with famous band motors by 50W,100W,200W/400W /750W/1000W or 42, 57,86 stepper motors or NMEA17, NMEA23, NMEA34 in quality aluminum profile to ensure precise and speed target of various precision and common linear automation use. Based on different application, brake and no brake is can be chosen. Tallman Robotics Linear Actuator of type TM85 with body with by 85mm have 4 series respectively by Screw semi closed, Screw fully closed, and Belt semi closed, Belt fully closed. These linear modules have strokes from 0 mm to 2000 mm, and payload from 3kg to 50kgs. It could applied in material handing, components inspection system auto up and down material, components picked at the appointed position, flexible picking, electronic components inspection etc.

Basic Specification of TM85 series Model No TMS85-CM TMS85-CR TMB85-CM DMB85-CR Drive solution Ball screw Ball screw Timing belt Timing belt Sealed or not Semi closed Fully closed Semi closed Fully closed Motor power AC (W) 100/200/400W Repeatability (mm) ±0.01/±0.005 ±0.04 Ball screw outer diameter (mm) 6 Reduction Ration: 1:1 lead (mm) 5 10 16 20 32 66 Fastest speed Motor speed 3000 (rpm) 250 500 800 1000 1600 3300 Max Load(kg) Acceleration Deceleration Horizontal 0.3G 50/50/50 30/50/50 20/30/50 15/25/50 7/14/20 4/8/16 Vertical 0.3G 10/12/15 5/10/12 3/6/12 1/2/4 - - Rate Thrust (N) 341/682/1364 170/360/720 106/212/424 85/170/340 53/106/212 30/60/120 Linear guide (mm) 20*15.5-1 Origin sensor: Plug-in EE-SX674(NPN)EE-SX674P(PNP) Inside E2S-W13 Related knowledge: Linear module applications in equipment in the automation industry Market applications of linear modules include factory automation, medical, packaging, machine tools, semiconductors, printing, automotive assembly, aerospace and food processing. We provide linear modules and accessories of various sizes. You can find the product display options on our linear module official website. You can now purchase the appropriate model linear module. From simple linear guides to custom-designed multi-axis linear module systems. The ideal design solution is usually not to find a fast, sturdy, accurate or even cheap option. Instead, the ideal solution is a balance of performance, life and cost. The TM high-precision linear module has very little frictional resistance, so only a small driving force is needed to move the load. Low frictional resistance contributes to a small heating effect. Therefore, compared with the conventional sliding system, the friction resistance of the linear module is reduced and the accuracy can be maintained for a long time. When engineers are looking for cost-effective linear modules or silent linear slides, they will see TM Robot. We focus on linear modules for linear slides. We are famous for high quality, low friction, and high speed and smooth operation in the entire industry, and good customer service. Linear modules are suitable for various automation applications. If you have engineering problems or concerns, our TM linear module manufacturer customer service will immediately provide technical support to help you find a solution so that custom or standard solutions can be used for design and development. To provide personalized attention in the industry, we always regard customer service and products as our top priority. 3D printing, vacuum packaging, Ipad test, time-lapse photography, dispensing machine, mobile transportation system, gluing machine, model painting, laser cutting / engraving, material sorting, printing machine, labeling machine, spraying equipment, injection molding machine, and other automation equipment applications. Read the full article

#ElectricLinearCylinders#ElectricLinearSlides#LinearActuatorBundle#LinearActuatorController#LinearActuators#LinearActuatorsKits#LinearGuideSystems#LinearMotionProducts#LinearSlides#ModularLinearActuators#SignatureMotionLinearActuators

0 notes