#Screwdrivenmodules

Explore tagged Tumblr posts

Text

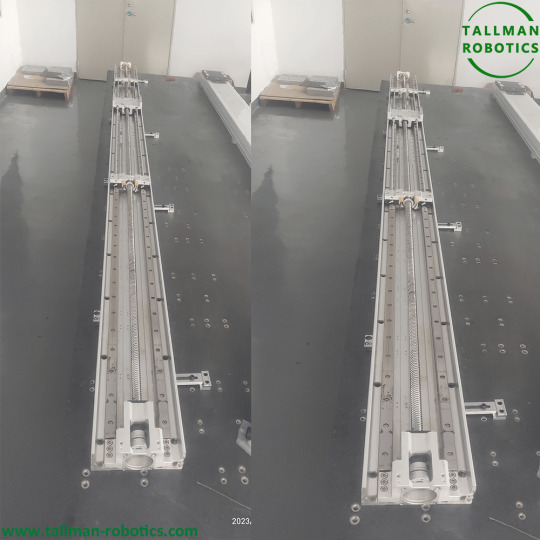

Screw Linear Motion Modules Will Be Delivered To USA

Screw Linear motion modules are mechanical systems designed to provide controlled linear movement in various applications. They are commonly used in industrial automation, robotics, and other fields where precise linear motion is required.

If you're experiencing issues or challenges with linear motion modules, it's important to identify the specific problems you're facing in order to determine the appropriate solutions. Here are a few common issues and some possible suggestions to overcome them: 1. Lack of precision: If your linear motion module is not providing the desired accuracy or precision, you may need to check if the mechanical components are properly aligned and lubricated. Additionally, consider the quality and condition of the module itself, as well as the control system used to drive it. 2. Mechanical failures: Linear motion modules consist of various mechanical components such as rails, bearings, screws, and belts. If you're experiencing frequent failures, it could be due to worn-out or damaged components. Regular maintenance and inspection can help identify and replace any faulty parts. 3. Insufficient load capacity: If you're trying to move loads that exceed the specified capacity of the linear motion module, it can lead to performance issues or even damage. Make sure you're using a module that is suitable for the intended load and consider upgrading to a higher capacity module if necessary. 4. Compatibility issues: Linear motion modules often need to be integrated into larger systems or work alongside other components. Compatibility issues can arise if the module is not properly matched with other parts of the system. Double-check the specifications and requirements of all components involved to ensure they are compatible. 5. Control and programming challenges: If you're struggling with controlling the linear motion module or programming it to perform specific tasks, it may be helpful to consult the documentation or seek support from the manufacturer. They can provide guidance on the programming interface, control signals, and troubleshooting techniques. Remember, linear motion modules are complex systems, and resolving issues might require a combination of mechanical, electrical, and software-related solutions. If you're still having difficulties, it may be beneficial to consult with experts or professionals in the field who have experience with linear motion modules. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#AcmeScrewsandLinearActuators#BallScrewandLinearMotionComponent#Ballscrewlinearmodule#LeadScrewDrivenLinearStagesModule#LeadScrews#LinearmodulesSmallModulesScrewDriven#LinearMotionGuideActuators#LinearMotionModule#PrecisionSlidingTableBallScrew#Screwdrivenmodules#ScrewLinearModules#StainlessSteelLinearModuleHighSpeedBallScrewRail

0 notes

Text

Screw Driven Linear Modular Actuators are under Test

Screw Driven Linear Modular Actuators are devices used to convert rotary motion into linear motion. Screw Driven Linear Modular Actuators consist of a motor, a screw shaft, and a nut, which are combined to create linear motion along the axis of the screw.

https://youtube.com/shorts/oh8PrSiWVjs?si=yPzZ4afR2WC-jKFD Here's how a typical Screw Driven Linear Modular Actuators works: Motor: The actuator is equipped with a motor, usually an electric motor, which provides the rotational power required for the actuator to function. The motor can be either stepper or servo motor, depending on the application requirements. Screw Shaft: The screw shaft is a long, threaded rod that runs through the actuator. It has a helical thread that engages with the nut and converts the rotational motion of the motor into linear motion. Nut: The nut is a component that contains a threaded hole matching the thread on the screw shaft. As the screw shaft rotates, the nut moves along the length of the shaft, causing linear displacement. The nut is usually mounted to the load or the movable part of the system. Modular Design: The term "modular" refers to the ability to customize or configure the actuator to meet specific requirements. Screw-driven modular linear actuators are often designed with a modular structure, allowing users to choose different screw shaft lengths, motor types, and other options to suit their application needs. Control System: The actuator is typically controlled by a control system that manages the motor's speed, direction, and position. This control system can be as simple as an on/off switch or a more sophisticated setup using microcontrollers or programmable logic controllers (PLCs). Screw-driven modules find applications in various industries, including robotics, automation, CNC machinery, 3D printing, medical devices, and more. They offer precise and controllable linear motion, making them suitable for applications that require accurate positioning, repetitive motion, or pushing/pulling loads. It's worth noting that there are different types of screw-driven actuators, including ball screw actuators and lead screw actuators. Ball screws use ball bearings to reduce friction and enhance efficiency, making them suitable for high-load and high-precision applications. Lead screws, on the other hand, have a simpler design and are often used in applications where lower precision or lower cost is acceptable. Overall, Screw Driven Linear Modular Actuators are versatile devices that provide controlled linear motion and can be customized to meet specific application requirements. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#BallScrewDrivenLinearActuator#BallScrewLinearActuators#leadscrewdrivenlinearactuators#ModularLinearActuator#ModularLinearActuators#MotorizedLeadScrewActuators#ScrewDrivenActuators#ScrewDrivenLinearActuatorElectricLinearActuator#Screwdrivenmodules

0 notes