#Mold and Die Manufacturer

Text

#shivam engitech#manufacturer#ahmedabad#plastic injection molding die#moulding die manufacturing#Plastic mould Manufacturing

0 notes

Text

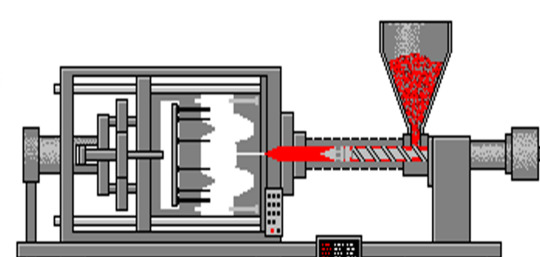

Product Recommendation|Analysis and Solutions of Clamping Force Problems

Problem: Industry ExistingWhat problems does clamping force of injection molding machine directly affect?What are reasons for broken column of injection molding machine and how to repair it?How to solve problem of product size being thick on one side and thin on the other?How to solve persistent problem of rough edges?Why do I need to repair my crank regularly?Injection molding machine product…

View On WordPress

#Analysis and Solutions of Clamping Force Problems#clamping force#Clamping Force Detection#clamping force of injection molding machine#clamping mechanism of injection molding machine#Corinthian column tester#die-cast products#How to solve persistent problem of rough edges#injection molded products#Injection molding machine clamping force tester#manufacturers of injection products#What are reasons for broken column of injection molding machine and how to repair it#What problems does clamping force of injection molding machine directly affect

0 notes

Text

Dona Plate Making Machine

A “dona plate making machine” typically refers to a machine used for manufacturing disposable plates and bowls, often made from materials like paper, thermocol (polystyrene foam), or leaves (such as palm or banana leaves). These machines are commonly used in the production of disposable tableware for various purposes like serving food at parties, events, or in street food stalls, and they are popular because they are cost-effective and environmentally friendly.

The process of making paper plate making machine with such a machine typically involves: Material Loading: Raw material (usually rolls of paper, thermocol sheets, or leaves) is loaded into the machine.Printing (Optional): If desired, the machine may have an option for printing designs or logos on the plates.

Die Cutting: The machine uses a die cutting process to cut the material into the desired plate or bowl shape.

Shaping and Forming: The cut material is then shaped and formed into the specific design of a plate or bowl. In the case of paper, this might involve heating and pressing to achieve the desired shape.

Drying (if needed): Some materials, like thermocol, may require a drying process to set their shape.

Stacking and Packaging: Once the plates or bowls are formed and dried, they are usually stacked and packaged for distribution.

These machines come in various sizes and capacities, and their complexity can vary depending on the type of material they are designed to process and the specific features they offer. Some machines are manual and require more human intervention, while others are automated for higher production rates.

Raw Material Loading: The machine is loaded with rolls or sheets of paper material, which can be in the form of paper rolls, paper sheets, or pre-cut paper circles. The choice of raw material can vary, but it is typically food-grade paper.

Paper Feeding: The machine has a mechanism to feed the paper into the manufacturing process. The paper is usually fed in a continuous manner.

Molding: The machine uses heat and pressure to mold the paper into the shape of the dona (paper plate or bowl). It has specific molds or dies for creating different sizes and designs of donas.

Cutting: Once the paper is molded into the dona shape, the machine cuts it to the required size. This can include cutting excess paper and shaping the edges of the dona.

Embossing or Printing (Optional): Some advanced machines may have embossing or printing capabilities to add designs, patterns, or branding information to the paper donas. This step is not always included, and it depends on the machine’s features and the manufacturer’s requirements.

Drying and Stacking: Depending on the design and material used, the automatic paper plate making machine may go through a drying process to remove any moisture. After drying, the machine may stack the finished donas, making them ready for packaging.

Packaging: The manufactured paper donas are typically stacked and packaged for distribution. Packaging can vary, but it is often in bundles or cartons.

Paper Dona Making Machines come in different sizes and capacities, ranging from small, manually operated machines suitable for small-scale production to large, automated machines for mass production. The choice of machine depends on the production volume and specific requirements of the manufacturer.

#Paper plate making machine#Paper plate machine#Paper plate manufacturing machine#Automatic paper plate making machine#Manual paper plate making machine#Semi-automatic paper plate machine#Hydraulic paper plate machine#Pneumatic paper plate machine#Disposable plate making machine#Single die paper plate machine#Double die paper plate machine#Four die paper plate machine#Thermocol plate making machine#Paper dish making machine#Paper bowl making machine#industry#Plate forming machine#Plate pressing machine#Plate cutting machine#Paper plate molding machine#Paper plate punching machine#Paper plate printing machine

1 note

·

View note

Text

Blow mold design | plastic die mould manufacturer

Blow mold design is an integral aspect of producing hollow plastic objects like bottles and containers. Skillful design is essential for maintaining product quality and consistency in manufacturing processes.

When seeking a reliable plastic die mould manufacturer, turn to Plastic Injection Molds. We offer comprehensive solutions to meet your needs, ensuring top-quality products and expert guidance every step of the way.

0 notes

Text

Precision Manufacturing: The Role of a Die Casting Manufacturer and Die Casting Molds

Precision is the cornerstone of manufacturing, and a Die Casting Manufacturer along with specialized Die Casting Molds are the keys to achieving excellence. Bian Die Casting, these elements come together to help industries craft high-quality components with precision and efficiency.

1 note

·

View note

Text

Injection Mold Design Services | Moulding Tool, Die & Mould Design

Looking for top-notch injection mold design services? Our expert team specializes in injection molding tool, die, and mould design, including gate design optimization. Enhance your manufacturing process with professional injection molding solutions. Contact us today!

#injection mold design#injection moulding tool design services#injection moulding die design#injection moulding mould design#injection mold gate design#manufacturing injection molding

0 notes

Text

#Non-standard precision machining#precision#cnc swiss#precision parts#cnc turning#Precision machining manufacturer#shaft#The main processing methods of metal parts are: machining#stamping#precision casting (investment casting)#powder metallurgy#metal injection molding. Machining refers to the process of changing the dimensions or properties of a workpiece by means of a mechanical d#Stamping is a forming processing method that relies on press and die to exert external force on plate#strip#pipe and profile to produce plastic deformation or separation#so as to obtain the required shape and size of the workpiece (stamping parts). There are also special processing#laser processing#electric discharge processing#ultrasonic processing#electrolytic processing#particle beam processing and ultra-high speed processing. Turning#milling#forging#casting#grinding#CNC machining#CNC center all belong to machining.

0 notes

Text

Best machining graphite company in India

Who We Are

EXPO is a global leader in manufacturing Graphite products and machining. We create our products using globally acclaimed manufacturing techniques and provide excellent service while trading with our industry. We have completed more than two decades in the market in machining Graphite and specialize in producing EDM electrodes and Customized Graphite products.

Machining Graphite

Carbon is an element that can form into several different allotropes including graphite, diamond, and fullerite. Graphite is the most steady type of carbon and is the most well-known, as carbon naturally occurs as graphite under standard conditions. Graphite is generally known for its better conductivity and resistance for high heat and corrosion. This makes it a typical material in high heat, high-pressure circumstances in the aerospace, electrode, nuclear, energy, and military industries. Despite the fact that graphite can deal with extreme high-pressure circumstances effortlessly, it is really an exceptionally delicate, rough, and fragile material.

#Best machining graphite company in Noida#electric graphite heater elements#Graphite Product Manufacturers & Dealers#graphite sintering plates near me#graphite die mold in india

1 note

·

View note

Text

Although die casting appeared in 1838 for the printing industry and is now famous as a method of producing metal parts for manufacturing, you use die castings every day without even realizing it. In this blog, let’s shed some light on where you see, touch, and work with die-cast products.

#Aluminium die casting#Plastic injection molding#Die casting manufacturers#Aluminum casting services

0 notes

Text

graphite die mold in india

We are the industry-leading electrode and Graphite Product Manufacturers & Dealers, offering a wide variety of electrode & graphite machine tool products of high quality @ Best Price.

Visit: https://expomachinetools.com

#Best machining graphite company in Noida#*electric graphite heater elements#*Graphite Product Manufacturers & Dealers#graphite sintering plates near me#graphite die mold in india

0 notes

Text

#Insulation board#carbon fiber insulation board#graphite die mold in india#electric graphite heater elements#Top Graphite Product Manufacturers & Dealers#Best graphite sintering plates in india

0 notes

Text

Top moulding die manufacturing Company in Ahmedabad

Shivam Engitech is leading manufacturer and supplier specializing in top-quality moulding die manufacturing in Ahmedabad including injection molding die, Plastic Bucket Moulding Dies, plastic injection molding die, Plastic Basket Moulding Die

,PET Blow Mould Die

Read More: https://shivamengitech.com/

0 notes

Text

Analysis of examples of imitation failure in die-casting runner design

Abstract: Through analysis of an example of a failed die-casting mold design, key elements that should be paid attention to in die-casting runner design process are explained. When imitating runner system of other successfully designed die-casting molds, it is necessary to proceed from reality and combine structural characteristics of die-casting parts to design, change and improve it. Especially…

View On WordPress

#die casting gating system#die casting product#die-casting#die-casting design#die-casting designers#die-casting mold design#die-casting mold manufacturers#Die-casting molds#die-casting parts#die-casting processes#die-casting production#die-casting runner design#die-casting runners#die-casting sprue system#gating system#mold design#mold manufacturing

0 notes

Text

electric graphite heater elements

#Best machining graphite company in Noida#electric graphite heater elements#Graphite Product Manufacturers & Dealers#graphite sintering plates near me#graphite die mold in india

0 notes

Text

blow mold design | plastic die mould manufacturer

Blow mold design is an integral aspect of producing hollow plastic objects like bottles and containers. Skillful design is essential for maintaining product quality and consistency in manufacturing processes.

When seeking a reliable plastic die mould manufacturer, turn to Plastic Injection Molds. We offer comprehensive solutions to meet your needs, ensuring top-quality products and expert guidance every step of the way.

0 notes

Text

Leading the Industry: China's Premier Die Casting Manufacturer

Discover the pinnacle of die casting excellence with China's top-notch manufacturer. Combining cutting-edge technology and unmatched expertise, this industry leader delivers precision-engineered die-cast components with superior quality and efficiency. Offering a wide range of services, including custom designs and large-scale production, their state-of-the-art facilities ensure optimal results for diverse applications. Experience seamless collaboration, on-time delivery, and cost-effective solutions, making them the preferred choice for global clients seeking the best in die casting manufacturing.

#china die casting#aluminum die casting manufacturer#china die casting manufacturer#die casting factories#aluminum die casting#die casting mold

0 notes