#Monel 400 Round Bars Exporters In India

Text

Monel 400 Round Bars Exporters In India

Monel 400, a nickel-copper alloy renowned for its exceptional resistance to corrosion in a wide range of environments, is highly sought after for various industrial applications. Round bars made from Monel 400 are particularly valued for their combination of high strength, excellent mechanical properties, and resistance to acids, alkalis, and seawater. Indian exporters of Monel 400 round bars have earned a strong reputation in the global market for supplying high-quality products manufactured to stringent standards.

Manufacturers in India employ advanced production techniques and quality control measures to ensure that Monel 400 round bars meet or exceed international standards such as ASTM B164. These standards govern the chemical composition, mechanical properties, and dimensional tolerances of the round bars, ensuring consistency and reliability in performance across different applications. Monel 400 round bars are available in various diameters and lengths, catering to diverse industrial requirements.

Leading exporters like Ritinox Overseas, Jainex Steel & Metal, and Virwadia Metal & Alloys are known for their expertise in supplying Monel 400 round bars to customers worldwide. These exporters maintain comprehensive inventories and are capable of fulfilling both small-scale and bulk orders with efficiency and reliability. Additionally, they offer value-added services such as custom cutting, machining, and surface finishing to meet specific customer specifications and requirements.

Customer satisfaction is paramount for Indian exporters, and they prioritize timely delivery, competitive pricing, and responsive customer support. By adhering to the highest standards of quality and professionalism, these exporters have established long-term relationships with clients across various industries globally. When sourcing Monel 400 round bars from India, buyers can expect premium-quality products backed by technical expertise and excellent service throughout the procurement process.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Monel K500 Sheets & Plates Exporters In India#Monel 400 Round Bars Exporters In India#Monel K500 Round Bars Exporters In India

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

#Super Duplex Steel UNS S32760 Round Bars#Super Duplex Steel UNS S32760 Round Bars supplier#Super Duplex Steel UNS S32760 Round Bars exporter#Stainless Steel 446 Round Bars#Stainless Steel 446 Round Bars Suppliers#Stainless Steel 446 Round Bars Exporter#Stainless Steel Round Bars Suppliers in india#Monel 400 Round Bars#Monel 400 Round Bars supplier#Monel 400 Round Bars exporter

0 notes

Text

Suppliers of nickel alloys are important

These alloys are widely used in many different industries, including chemical processing, aerospace, and maritime. Nickel alloy supplier offer a variety of compositions and qualities to suit various applications, all while guaranteeing quality and dependability under demanding circumstances. Engineering and technology are developed in many different disciplines substantially aided by their ingenuity and understanding.

Its suitability for nuclear and marine applications stems from its resilience to extreme temperatures and tremendous stress, both in and out of the water, as well as its ability to fend against corrosion in very acidic settings. Inconel plates Suppliers with a large assortment, these companies can meet your specific requirements with sturdy, dependable products that perform well even in harsh operating conditions

These suppliers offer a large range of alternatives to Hastelloy plate suppliers that follow stringent industry standards and guidelines, ensuring optimal performance in critical applications. Since we get our supplies from reputable manufacturers and evaluate them, our rejection rate has never exceeded 0.25% during the last 15 years. Because Regent Steel is connected to some of the leading exporters of hastelloy plate from India, we offer our clients an advantage by listing everything and keeping our rates competitive.

To satisfy the wide range of client needs, these providers provide a selection of monel plate suppliers, guaranteeing dependable performance and longevity under tough circumstances.t is particularly prized for use in the maritime and chemical processing sectors due to its exceptional resistance to corrosion and temperature changes. 400, R-405, and K-500 are the three Monel alloys that are most frequently used. The mechanical qualities of R-405 and Monel 400 are similar, however because of its higher sulphur content, R-405 is simpler to machine.

Inconel Round Bars Hot rolled bars are made in India by heating a big billet to a high temperature and then rolling it between rollers. Room temperature annealed round bars are pulled through a series of dies to create cold drawn bars. Cold drawn Inconel alloy bars have a smoother surface than hot rolled ones. Because of its controlled deformation at lower temperatures, cold drawn bars have a finer and more uniform grain structure. High-quality fastening solutions for tough applications in the chemical, marine, and aerospace industries are produced by inconel fasteners manufacturers. Extreme conditions are guaranteed to be durable and reliable due to Inconel's remarkable resistance to corrosion and high temperatures. In order to guarantee the best performance and safety, these manufacturers provide a wide selection of Inconel fasteners that adhere to strict quality standards. In industries where high thermal strength and resistance to corrosion are essential, The nickel-chromium alloy Inconel 625 tube is renowned for its exceptional fabricability and high strength. The material has a cryogenic to 982 °C service temperature range and provides good corrosion resistance. The inconel 625 tubes don't need to precipitate harden because they are made of niobium and molybdenum. Additionally, the rust resistance qualities are improved in a variety of situations by this combination.

0 notes

Text

Monel Fasteners: Strength and Durability in Industrial Construction

Fasteners are of paramount importance when it comes to industrial construction. These seemingly small components play a crucial role in holding structures together. Among the myriad choices available, Monel fasteners stand out for their exceptional strength and durability. Jay Steel Corporation, we take pride in being a leading Monel fasteners manufacturer and supplier, offering unparalleled strength and durability for a wide range of industrial applications. Our commitment to quality extends to our diverse range of Monel alloy products, including Monel 400 Products and Monel K500 Products, available in various forms such as Monel Wire Mesh, Monel Round Bar, Monel Strips Sheet & Plats, Monel Tube & Pipe, Monel Fittings, Monel Flanges, and welding rods so that our customers can choose the one that will perfectly suit their project requirements!

In this blog post, we will explore the remarkable qualities of Monel fasteners and why they are considered a preferred choice in industrial construction.

Understanding Monel:

Monel is a nickel-copper alloy known for its corrosion resistance, high strength, and durability. The alloy primarily consists of nickel (approximately 67-70%) and copper (about 28-34%), with small amounts of iron, manganese, carbon, and silicon. The unique combination of these elements results in a material with superior properties that make it ideal for challenging industrial environments.

Strength Beyond Compare:

Monel fasteners are renowned for their remarkable strength, making them a reliable choice for heavy-duty applications in industrial construction. The high nickel content in Monel contributes to its exceptional tensile strength and resistance to deformation under extreme loads. This characteristic ensures that structures secured with Monel fasteners maintain their integrity even in the face of intense pressure and stress.

Corrosion Resistance:

One of the primary challenges in industrial construction is the corrosive nature of various environments. Monel fasteners excel in this regard, as they exhibit outstanding resistance to corrosion, particularly in harsh conditions such as exposure to saltwater, acids, and alkalis. This corrosion resistance significantly extends the lifespan of structures and reduces maintenance costs over time.

Durability in Diverse Environments:

Monel fasteners are versatile and well-suited for use in diverse industrial environments. Whether in chemical processing plants, marine applications, or oil and gas facilities, Monel's durability remains unwavering. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking further enhances its suitability for challenging construction scenarios.

Temperature Stability:

Industrial construction often involves exposure to extreme temperatures, and Monel fasteners are designed to withstand such conditions. The alloy maintains its strength and structural integrity across a wide temperature range, making it a reliable choice for projects that face temperature fluctuations, whether in cold or scorching heat.

Ease of Fabrication and Installation:

Despite its impressive strength, Monel is also known for its malleability, which makes it relatively easy to fabricate into various fastener shapes. This characteristic simplifies the manufacturing process and contributes to the ease of installation, saving both time and resources in construction projects.

Final Words!

With a strong focus on quality Monel fasteners and alloy products, Jay Steel Corporation emerges as a leader in industrial construction. With a comprehensive range of Monel offerings and a global presence, we continue to contribute to the success of diverse industrial projects. Recognizing the global demand for top-notch Monel alloy products, Jay Steel Corporation serves as a reliable exporter to various countries, including Thailand, Singapore, Malaysia, India, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, the United Kingdom, and Italy. Our commitment to quality and competitive pricing has established us as a trusted partner in international markets. Choose us for your Monel Alloys Solutions that go beyond expectations, ensuring the resilience and longevity of your constructions.

#Monel Wire Mesh#Monel fasteners 400#Monel fasteners K500#Monel fasteners 400 Supplier#Monel fasteners K500 Exporters

0 notes

Text

Monel K500 Round Bars Suppliers in Chennai

Divine Metal & Alloy is one of the largest exporter, manufacturer and supplier of Monel Alloy K500 Round Bars in India. Monel K500 Round Bars is a nickel-copper alloy, precipitation hardenable in the course of additions of titanium and aluminum. Monel K500 Bars (Monel K500 Rods) retains the outstanding corrosion resistant characteristics of Monel 400 and has better strength and hardness after precipitation hardening when compared with Alloy 400. Monel Alloy K500 Rods is particularly well suited for centrifugal pumps in the marine industry because of its high strength and low corrosion rates in high-velocity seawater.

Monel K500 Sheets & Plates Specificaton

GradeMonel K500 - UNS N05500, Nickel Alloy K500SpecificationASTM B 865 / ASME SB 865 / AMS 4676 / QQ N 286, ASTM B865 UNS N05500 Monel K500StandardASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS

Alloy K500 Round bar sizeDiameter: 3-~800mmK500 Monel Hex Bar size2-100mm A/FMonel Alloy K500 Flat bar sizeThickness: 2 -100mmWidth: 10 to 500mmK500 Monel Alloy Square bar size4 to 100mmMonel K500 Angle bar size (in mm)3*20*20~12*100*100ASTM B865 Monel K500 Section3.0 to 12.0mm thicknessMonel WERKSTOFF NR. 2.4375 Channel Bar (in mm)80 x 40 to 150 x 75 section; 5.0 to 6.0 thicknessNickel Alloy K500 Hollow Bar (in mm)32 OD x 16 ID to 250 OD x 200 ID)2.4375 Monel K500 Billet Size1/2" to 495mm DiameterASTM B865 K500 Monel Rectangles Size33 x 30mm to 295 x 1066mmK500 Monel Round Bar FinishCold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & BlackAlloy Monel K500 Round Bar SurfaceBright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, HairlineMonel K500 round bar ConditionHardened & tempered, annealedK500 Monel Bar TechniqueHot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, RodMonel K500 Din 2.4375 Round Bar ToleranceH8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirementsUNS N05500 Monel Bar ProcessingBar cutting to 650mmOur Monel K500 round bar stockyad in IndiaPune, Gujarat, Noida, Tirunelveli, Thiruvananthapuram, Shivamogga, Hyderabad, Bengaluru, Bhubaneswar, Tiruchirappalli, Ahmedabad, Coimbatore, Chennai, Dhanbad, Agra, Chennai, Navi Chennai, Pimpri-Chinchwad,

0 notes

Text

Overview of Monel alloy k 500

Monel K500 is a nickel-copper alloy that has the corrosion resistance of Alloy 400 and high-strength corrosion fatigue and erosion resistance. At MV Super Alloys, we take pride in being the leading Monel K500 Alloy stockist, trader, importer, supplier, and exporter in India. With a vast range of Monel K500 Alloy forms available, including pipes, tubes, round bars, coils, shims, strips, wires, sheets, and plates, we cater to diverse project requirements.

Monel K500

In this comprehensive article, we delve into the intricacies of Monel Alloy K500, highlighting its exceptional properties, its uses, applications, and the reasons why it outperforms other materials in the industry.

Overview of Monel K500 Alloys

Monel K-500 (UNS N05500) is an alloy consisting of nickel and copper, which has been age-hardened to achieve superior strength compared to Monel 400. Remarkably, it maintains these impressive mechanical properties even in high temperatures up to approximately 650 degrees Celsius. Furthermore, its exceptional corrosion resistance allows it to withstand harsh environments containing both chemicals and chlorides. With its unique combination of physical and mechanical characteristics, it is extensively employed in multiple challenging applications.

Properties of Monel k500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance and high strength. Here are some of the properties of Monel 2,4375 alloys:

Excellent corrosion resistance in various environments (seawater, acids, alkalis)

High strength and mechanical properties at room and elevated temperatures

Non-magnetic, suitable for applications requiring low magnetic interference

Good ductility, easily formed and fabricated

Resistant to wear and abrasion

Low coefficient of thermal expansion for dimensional stability

High fatigue strength for dynamic loading applications

Weldable using standard techniques

Limited temperature range (up to approximately 650°C or 1200°F)

Forged Monel K500 Equivalent

Standard - Monel K500

UNS - N05500

WNR. - 2,4375

Monel K500 Alloy Chemical Composition

The Monel alloy k 500 chemical composition typically includes the following elements:

Grade - Monel K500 Alloy

AI - 2.30 - 3.15

C - 25 max

Cu - 27.0-33.00

Fe - 2.0

Mn - 1.5 max

Ni - 63.0

Ti - 35 -85

S - 0.1 max

Si - 5 max

Physical Properties of Monel K500 Alloys

The UNS N05500 alloy exhibits exceptional strength at elevated temperatures, thereby rendering it a highly suitable material for deployment in high-temperature application domains such as boilers or furnace components. Furthermore, its non-magnetic nature renders it highly compatible with the use of electromagnetic equipment or electronic devices. Its low thermal expansion coefficient also exemplifies its utility in precision parts requiring constricted tolerances when exposed to temperature fluctuations.

Physical Properties - Metric

Density - 8.45g/cm

Melting - 1338°C

Physical Properties - Imperial

Density - 0.305 Ib/in3

Melting - 2440°F

Mechanical Properties of Monel K500 Alloys

Understanding the Monel K 500 mechanical properties is essential for assessing its suitability for specific applications.

Here are some key mechanical properties of Monel K500:

Monel K500 possesses exceptional tensile strength and flexibility, making it an ideal material for engineering applications, including but not limited to pipe fittings or valves that require both strength and flexibility. Additionally, it exhibits remarkable resistance to fatigue, which grants it superior performance when compared to other materials subjected to repeated loading cycles or stress fatigue conditions.

Hardness (HB)- 27-35 HRC

Ultimate Tensile Strength (N/mm2) - 970-1000

Proof Stress - 690-760

Monel k500 specification & Standards

Product Forms - Sheet, Plate

ASTM - B575

ASME - SB 575

DIN - 17744

Product Forms - Strips

ASTM - B575

ASME - B 575

DIN - 17744

Product Forms - Rod, bar, Forging

ASTM - B 574, B 564

ASME - B 574, B 564

DIN - B 574 , B 564

Product Forms - Wire

ASTM -

ASME -

DIN - 17744, 17753

Monel K500 Uses

Monel K500, a nickel and copper alloy, is renowned for its remarkable strength, resistance to corrosion, and ability to withstand extreme temperatures. It is a favored material in diverse industrial settings, including desalinization systems, oil refining operations, and the manufacturing of valves, pumps, shafts, and fasteners. Its application in these industries is particularly valuable because of its durability and reliability.

Additionally, Monel K500 exhibits exceptional resistance to loss of strength even when exposed to high temperatures up to 1200°F, which makes it an indispensable component in airplane manufacturing, among other applications. Its unparalleled strength and versatility have made it a crucial material for the production of long-lasting and reliable products across many industries.

Applications of Monel K500 Alloys

Monel K500 is a nickel-copper alloy that offers excellent corrosion resistance, high strength, and good mechanical properties at both room and elevated temperatures. There are numerous industries in which it is used.

Here are some common applications of Monel K500 alloys:

Marine and Offshore Industry

Oil and Gas Industry

Chemical Processing

Pump Shafts and Impellers

Doctor Blades and Scrapers

Oil-well drill Collars and Instruments

Electronic Components

Springs

Valve trim

Aerospace Industry

Electronics and Electrical Industry

Medical Equipment

Heat Exchangers and so on.

Final Thoughts!..

Monel Alloy K500 is a superior choice for high-performance applications, thanks to its well-balanced chemical composition, impressive mechanical properties, and adherence to industry specifications. The Monel K500 specification ensures that this alloy meets stringent standards, making it suitable for a wide range of demanding projects. As the leading Monel 2,4375 alloys supplier in India, MV Super Alloys is committed to providing you with the highest quality products that meet your project requirements. Whether you need Monel K500 Round Bars, sheets, plates, or any other form, we have a comprehensive inventory to cater to your needs. As a leading Monel K500 Alloy importer & Stockist in India, we supply the raw material with Material Test Certificate (MTC). In addition to providing high-quality products, MV Super Alloys also offers exceptional customer service and competitive pricing.

For more information on Monel Alloy K500 and how it can benefit your projects, feel free to visit our website or contact our knowledgeable team. Our team is here to help you every step of the way.

#Monel alloy k 500 chemical composition#Monel k500 round bar#Monel k 500 mechanical properties#Monel k500 specification

0 notes

Photo

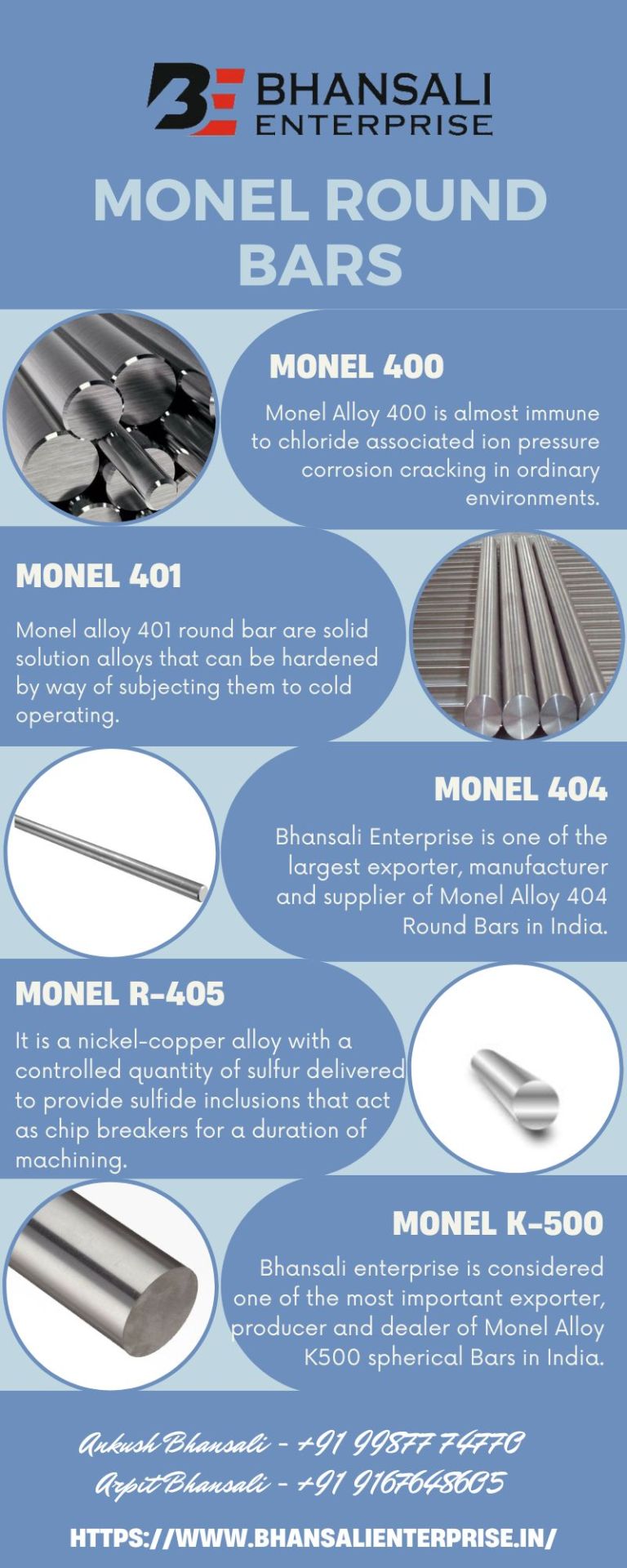

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Text

Hastelloy C276 Round Bar: Read in Fine Detail

What Is Hastelloy C276 Round Bar?

Hastelloy C276 is a nickel, molybdenum, and chromium alloy with good mechanical characteristics. Hastelloy C276 Round Bar is well-known for its corrosion resistance. Hastelloy C276 Round Bar, like the other nickel alloy, has excellent formability, ductility, and weldability. It is also recognised for its higher resistance to stress corrosion cracking in chloride conditions.

One of the well-known Hastelloy C276 Round Bar Supplier, manufacturers, stockists, and of is Neptune Alloys. In Mumbai and the surrounding area, we are a top provider of Alloy 20 Round Bar. We manufacture our Hastelloy C276 Round Bar in India in accordance with international ASTM, ANSI, API, and DIN Standards. Email us for simple, rapid quotes at wholesale prices. Due to its exceptional corrosion resistance and thermal stability, inconel alloy is often used in the chemical and aviation industries. We also rule the market as leading Monel 400 Round Bar suppliers.

Characteristics of Hastelloy C276 Round Bar

The qualities of the nickel alloy are responsible for Hastelloy Alloy Round Bar being employed in harsh environments. As a result, it is very resistant to sulphuric, hydrochloric, and phosphoric acids; severely oxidising, acidic, and acid chlorides; and solvents, including conventional and acetic acids, acetic anhydride, liquid chlorine gas, hypochlorites, and chlorine solutions. It is a nickel-chromium superalloy with a high molybdenum content (15-17%).

There is also regulated tungsten and iron content, with a strictly managed carbon content. Low carbon levels reduce carbide deposition during heat treatment and welding. This implies that even when employed in welded systems, the metal retains excellent pitting and crevice corrosion resistance.

As a result, it is very resistant to sulphuric, hydrochloric, and phosphoric acids; severely oxidising, acidic, and acid chlorides; and solvents, including conventional and acetic acids, acetic anhydride, liquid chlorine gas, hypochlorites, and chlorine solutions.

This is why Hastelloy C276 Round Bar are so popular in the chemical processing sector. It is also extremely resistant to saltwater corrosion, especially in crevices.

Applications in Industry

It is no surprise that Hastelloy C276 Round Bar were employed in so many commercial applications due to their wide range of durable qualities. It is utilised in flue gas desulfurization (FGD) systems, for example, to control air pollution from power plants. Hastelloy alloy C276 has been demonstrated to be capable of withstanding a greater chloride concentration prior to the commencement of localised corrosion when compared to other alloys.

The high molybdenum content of Hastelloy C276 Round Bars aids in the development of pitting and crevice corrosion resistance. It is used in more intense sections of waste fluid treatment systems where other materials may not be able to withstand harsh conditions.

Hastelloy C276 Round Bars Suppliers make it available in the to be used in oilfield and subsea applications. Materials must be resistant to sulphide stress cracking while processing and storing sour natural gas, which also contains hydrogen sulphide, carbon dioxide, and chloride. The high amounts of nickel, chromium, and molybdenum in Hastelloy alloy C-276 work together to give this resistance even at greater temperatures in deep wells.

Manufacturer and Supplier of Hastelloy C276 Round Bar in India.

Neptune Alloys is a top leading well known supplier and manufacturer of High Quality Hastelloy C276 Round Bar Supplier in India. Neptune Alloys has established itself as a top-tier Inconel X750 Round bar Suppliers and producer in the global industry thanks to their significant commercial and technical people skills. Neptune Alloys is a company that specialises in exporting, supplying, and manufacturing Inconel X750 Spring Wire, Monel 400 Roundbar. We also rule the market as the top Alloy 20 Round Bar Supplier, Inconel 825 Round Bar Dealer, and Stockist in India. In very acidic climates, these materials are frequently employed. In addition to Inconel X750 Spring Wire Suppliers, Inconel X750 Round bar Suppliers, and Monel 400 Round Bar Suppliers.

#spring wire#roundbar#Sheet#roundbar suppliers#spring wire suppliers#Sheet suppliers#inconel spring wire#inconel roundbar#Nimonic Sheet#Hastelloy Round Bar suppliers

1 note

·

View note

Link

Get the high-quality Monel 400 Round Bar from Indias most trusted Monel products stockist, suppliers, and exporter. Contact us on +91 9619440863 or send an email at [email protected]

0 notes

Link

0 notes

Text

#Stainless Steel 446 Round Bars Suppliers#Stainless Steel 446 Round Bars Exporter#Stainless Steel Round Bars Suppliers in india#Super Duplex Steel UNS S32760 Round Bars supplier#Monel 400 Round Bars supplier#Inconel 600 Round Bars Supplier#Inconel 600 Round Bars Exporter

0 notes

Text

Suppliers of nickel alloys are important

These alloys are widely used in many different industries, including chemical processing, aerospace, and maritime. Nickel alloy supplier offer a variety of compositions and qualities to suit various applications, all while guaranteeing quality and dependability under demanding circumstances. Engineering and technology are developed in many different disciplines substantially aided by their ingenuity and understanding.

Its suitability for nuclear and marine applications stems from its resilience to extreme temperatures and tremendous stress, both in and out of the water, as well as its ability to fend against corrosion in very acidic settings. Inconel plates Suppliers with a large assortment, these companies can meet your specific requirements with sturdy, dependable products that perform well even in harsh operating conditions

These suppliers offer a large range of alternatives to Hastelloy plate suppliers that follow stringent industry standards and guidelines, ensuring optimal performance in critical applications. Since we get our supplies from reputable manufacturers and evaluate them, our rejection rate has never exceeded 0.25% during the last 15 years. Because Regent Steel is connected to some of the leading exporters of hastelloy plate from India, we offer our clients an advantage by listing everything and keeping our rates competitive.

To satisfy the wide range of client needs, these providers provide a selection of monel plate suppliers, guaranteeing dependable performance and longevity under tough circumstances.t is particularly prized for use in the maritime and chemical processing sectors due to its exceptional resistance to corrosion and temperature changes. 400, R-405, and K-500 are the three Monel alloys that are most frequently used. The mechanical qualities of R-405 and Monel 400 are similar, however because of its higher sulphur content, R-405 is simpler to machine.

Inconel Round Bars Hot rolled bars are made in India by heating a big billet to a high temperature and then rolling it between rollers. Room temperature annealed round bars are pulled through a series of dies to create cold drawn bars. Cold drawn Inconel alloy bars have a smoother surface than hot rolled ones. Because of its controlled deformation at lower temperatures, cold drawn bars have a finer and more uniform grain structure. High-quality fastening solutions for tough applications in the chemical, marine, and aerospace industries are produced by inconel fasteners manufacturers. Extreme conditions are guaranteed to be durable and reliable due to Inconel's remarkable resistance to corrosion and high temperatures. In order to guarantee the best performance and safety, these manufacturers provide a wide selection of Inconel fasteners that adhere to strict quality standards. In industries where high thermal strength and resistance to corrosion are essential, The nickel-chromium alloy Inconel 625 tube is renowned for its exceptional fabricability and high strength. The material has a cryogenic to 982 °C service temperature range and provides good corrosion resistance. The inconel 625 tubes don't need to precipitate harden because they are made of niobium and molybdenum. Additionally, the rust resistance qualities are improved in a variety of situations by this combination.

0 notes

Link

Round Bar is a long, cylindrical metal bar that has many industrial and commercial applications and uses. The most common Use is shafts. Standard diameters range from 1/4 all the way up to 24. Other sizes available as per the clients requirements. Round Bars are round in shape and hence are also known as Rods. We also manufacture Monel 400 Round Bars and Rods in different grades such as Alloy 20, Duplex Steel, Super Duplex Steel, Monel.

0 notes

Text

Monel 400 Tubing, Sheet, Bolts, Round Bar, Plate Supplier, Exporter, Manufacturer, Dealers in Mumbai, Thane, Navi Mumbai, Ahmedabad, Surat, Bangalore, Delhi, Pune, Vapi

http://www.inconel718.in/monel-400.php

MB Metals India is Leading Monel 400, Price, Hardness, Density, Composition, Material Properties, Tubing, Sheet, Bolts, Round Bar, Plate of Supplier, Exporter, Manufacturer, Dealers in Mumbai, Thane, Navi Mumbai, Ahmedabad, Surat, Bangalore, Delhi, Pune, Vapi

0 notes