#Monel Bolts Suppliers India

Text

Monel K500 Stud Bolts

Chhajed Steel and Alloys is one of the perceived wholesalers and suppliers of Monel K500 Stud Bolt, which are precipitation setting shocks produced using copper nickel amalgam with extension of titanium and aluminum. A momentous typical for Monel K500 Threaded Rods is that they offer remarkable insurance from hydrofluoric destructive, a particularly extreme destructive to oversee, in all concentrations up to the limit. Aluminum and copper in Monel K500 Threaded Rods may be explicitly oxidized in the midst of warming, leaving an alluring nickel-rich film ostensibly of the piece. Monel K500 Tie Rods are chiefly maker and supply at Alloy Fasteners. The bit of Monel K500 Tie Bars is perfect for application in sustenance getting ready industry. Monel K500 Double Ended Studs is comprehensively perceived for its high-strength, flexibility, dimensional exactness, disintegration insurance, etc.

The Alloy K500 Threaded Rods are fabricated to support high weight and thing guarantee. Established Alloy K500 Threaded Bars has been presented to since quite a while earlier kept warming at 800 Degree F. A further moderate creating happened amidst the fundamental month of introduction, at any rate kept warming caused no further gigantic change in properties. Amalgam K500 Tie Bars is reliably utilized as a bit of Chemical Process Industry, for example, for Processes including customary acids, rankling pop and dry chlorine. Mix K500 Tie Rods is additionally utilized as a bit of time of chlorinated plastics, and applications in like way solidify expert cutting edges and scrubbers. Purchase Alloy K500 Stud dash at sensible rates from us. We in like way offer the comparable in various and balanced sizes and shapes.

For More Information:

Call Us: +919821513630

E-mail: [email protected]

#Monel K500 Studbolt#Monel K500 Threaded Rod#Monel K500 Double End Studs#Monel WERKSTOFF NR. 2.4375 Tap End Studs#Monel K500 Threaded bar#Monel N05500 Stud Bolts Exporter in Worldwide#Monel Bolts Suppliers India#Monel Stud Bolts Bolts#Monel Hex Bolts#ASTM F467 UNS No.N04400 Monel 400 Bolts#ASTM B865 UNS N05500 Monel K500 Bolts#ASTM B865-04 Alloy K500 Bolts#Monel Alloy Bolts Manufacturer#Monel 400 werkstoff nr.2.4360 Bolts#Monel 400 Bolts Suppliers#Monel Carriage Bolts#Monel Flange Bolts#Monel Elevator Bolts#Monel 12 Point Flange Bolts#Monel Lag Bolts#Monel Stove Bolts#Monel Tap Bolts#ASTM B865-04 Monel K500 Bolts

0 notes

Text

U Bolts Manufacturer in India - Sachiya Steel International

U Bolts Manufacturer in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality U Bolts Fasteners worldwide. We are India's largest U Bolts Exporter, exporting to more than 85 countries. We are known as U Bolts Manufacturers and Exporters due to exporting and manufacturing on a large scale.

U Bolts Specifications -

Sachiya Steel International manufacture a wide variety of bolts. There is a different types of bolt used for different needs. U Bolts are used with Nuts. Our U Bolts are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial U Bolts. We are India's Leading Manufacturers Exporters of U Bolts. We also export Carriage Bolts, Hex Bolts, Allen Cap Bolts, High Tensile U Bolts, L Bolts, U Bolts, T Bolts, Square Bolts and all other Industrial Bolts.

Diameter: DIA-1/2" - 24"

Material: Stainless Steel 304, Stainless Steel 316, Carbon Steel, Monel, Inconel, Duplex Steel and more

Finished: Self Colour Zp YZP H.D.G

About U Bolts Fasteners -

A U Bolts is a form of threaded fastener with an external male thread. U Bolts are closely related to screws. People misunderstand the difference between U Bolts and screws. U Bolts are often used to make a Bolted joint. This is a combination of the nut applying an axial clamping force and also the shank of the U Bolts acting as a dowel, pinning the joint against sideways shear forces. For this reason, many U Bolts have a plain unthreaded shank (called the grip length) as this makes for a better, stronger dowel. The presence of the unthreaded shank has often been given as characteristic of U Bolts vs. screws, but this is incidental to its use, rather than defining.

Enhance Reliability with Corrosion-Resistant U Bolts - Explore the Latest Prices at Sachiya Steel International

Welcome to Sachiya Steel International. This is your go-to place for quality U bolts. These high-grade bolts offer advanced design. Corrosion resistance is another key feature. Our products reflect our commitment to excellence. Keeping updated with U bolt prices is essential. We offer competitive rates. Quality is never compromised at our end. Our U bolts resist corrosion. They are also made with the best materials. You can expect longevity. They also offer reliability. They withstand harsh environments. Sachiya Steel International caters to different

industries. We cater to the automotive sector. The construction industry can benefit from our products, too. Our U bolts exhibit innovation. This mix has strong durability. Every purchase guarantees you affordability.

U Bolts Manufacturers in India: Industrial U Bolts -

Oil & Gas Industries

Petroleum Industries

Nuclear Energy Sector

Chemical Industry

Aerospace Industry

Defence Industry

Cities we supply U Bolts to -

Sachiya Steel International is manufacturer supplier of U Bolts fasteners in most of the major Indian cities in more than 20 states. We are leading supplier of U Bolts in Mumbai, Ahmedabad, Ludhiana, Delhi, Rajkot, Pune, Coimbatore, Chennai, Bangalore and many other cities.

Read More: https://sachiyasteel.com/u-bolts-manufacturers-in-india.php

0 notes

Text

"Market Trends and Future Outlook: Navigating Opportunities and Challenges in the Indian Inconel and Monel Industry"

Introduction:

The Indian market for Inconel and Monel products is characterized by dynamic trends, driven by evolving industry demands, technological advancements, and global economic factors. Understanding these trends and anticipating future developments is crucial for stakeholders in the Inconel and Monel industry to capitalize on opportunities and overcome challenges. In this article, we analyze the current market landscape, identify key trends, and forecast the outlook for the Indian Inconel and Monel industry.

Suppliers of Fasteners

Brief Overview:

The Indian Inconel and Monel industry have witnessed steady growth fueled by increasing demand from sectors such as aerospace, automotive, oil and gas, and infrastructure development. Factors such as rapid urbanization, investments in infrastructure projects, and technological innovations are driving the adoption of these high-performance alloys. However, the industry also faces challenges related to raw material availability, pricing volatility, global competition, and regulatory compliance.

Elevator Bolt Manufacturers in Mumbai

Applications:

1. Growing Demand in Aerospace and Defense: The aerospace and defense sector represents a significant market for Inconel and Monel alloys in India, driven by the expansion of the aviation industry, defense modernization initiatives, and the indigenous development of aircraft and spacecraft. Demand for lightweight, corrosion-resistant materials for aircraft components, engines, and structural parts is expected to fuel continued growth in this segment.

2. Expansion in Oil and Gas Exploration: The oil and gas industry presents lucrative opportunities for Inconel and Monel products in India, particularly in offshore exploration, refining, and petrochemical processing. The need for corrosion-resistant materials capable of withstanding harsh environments and high temperatures is driving demand for Inconel and Monel alloys in pipelines, valves, heat exchangers, and drilling equipment.

3. Infrastructure Development Projects: India's ambitious infrastructure development projects, including transportation networks, power generation facilities, and industrial infrastructure, are driving demand for Inconel and Monel products in construction, engineering, and manufacturing applications. These alloys offer superior corrosion resistance, durability, and longevity, making them ideal for bridges, tunnels, power plants, and industrial machinery. Stainless Steel Fasteners Manufacturers in Mumbai

4. Technological Advancements: Advancements in manufacturing technologies, such as additive manufacturing, powder metallurgy, and surface coating techniques, are expanding the capabilities and applications of Inconel and Monel alloys in India. The adoption of these technologies enables the production of complex geometries, customized components, and high-performance coatings tailored to specific industry requirements.

5. Global Market Dynamics: The Indian Inconel and Monel industry are influenced by global market dynamics, including raw material prices, currency fluctuations, trade policies, and competition from international manufacturers. Manufacturers must stay abreast of these factors to remain competitive, optimize supply chain management, and explore export opportunities in global markets.

SS Fasteners Suppliers

Conclusion:

The Indian market for Inconel and Monel products is poised for continued growth, driven by increasing industrialization, infrastructure development, and technological innovation. While the industry faces challenges related to raw material sourcing, pricing volatility, and regulatory compliance, opportunities abound in aerospace, oil and gas, infrastructure, and other sectors. By leveraging technological advancements, fostering innovation, and embracing sustainable practices, stakeholders can navigate the evolving landscape of the Indian Inconel and Monel industry and capitalize on emerging opportunities for growth and expansion.

0 notes

Text

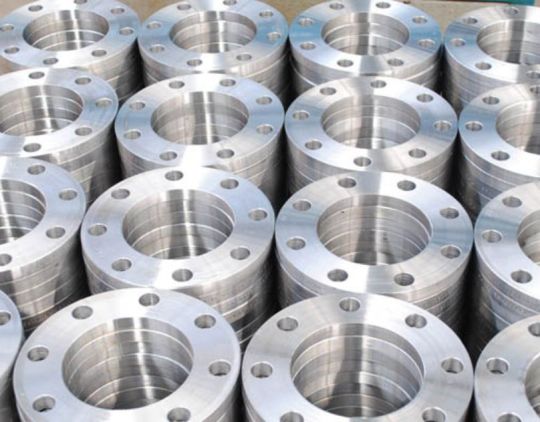

Unveiling the Secret: How to Select the Best Flange for Your Project

Metalica Forging Inc. is a leading Flanges Manufacturer in India. A flange is a projecting rim or edge that is commonly utilized for strength, alignment, or connection in engineering and building applications. Flanges are widely utilised in pipeline systems to help with the assembly and disassembly of pipes, valves, and other components.

Flange Supplier in India may seem like simple components in the grand scheme of engineering projects, but their importance cannot be overstated. They serve as crucial connectors, joining pipes, valves, and other equipment in a wide array of industries, from oil and gas to manufacturing and construction. However, choosing the right Flange Suppliers for your project is not always a straightforward task. With numerous types, materials, and specifications available, the selection process can be daunting. But fear not, for in this blog post, we will unveil the secrets to selecting the perfect flange for your specific needs.

Understanding Flanges:

Before diving into the selection process, it's essential to have a basic understanding of what flanges are and how they function. Essentially, a flange is a protruding rim or edge that is used to connect two objects, often by bolting them together. In the context of piping systems, flanges are used to join pipes, valves, fittings, and other components, allowing for easy assembly, disassembly, and maintenance.

Types of Flanges:

Flanges come in various types, each designed for specific applications and requirements. Some common types of flanges include:

Plate Flanges: are flat, circular flanges with bolt holes drilled directly into the flat surface, commonly used in low-pressure applications for connecting pipes, valves, and fittings. They offer a simple and cost-effective solution for joining components in systems where high pressure and temperature are not critical factors.

Slip-On Flanges: These flanges slide over the pipe and are then welded in place. They are relatively easy to install and are suitable for low-pressure applications.

Blind Flanges: As the name suggests, blind flanges are used to seal the end of a pipe or vessel. They are commonly used for pressure testing or when the end of the pipe needs to be closed off.

Socket Weld Flanges: Similar to slip-on flanges, socket weld flanges are welded to the pipe. However, they feature a recessed area (socket) into which the pipe fits, providing additional strength and stability.

Threaded Flanges: These flanges have threaded holes, allowing them to be screwed onto the pipe without the need for welding. They are commonly used in low-pressure, non-critical applications.

Hub Flanges: Hub Flanges can be customised to meet specific customer requirements and come in an assortment of sizes, dimensions, and forms. Being a top manufacturer of hub flanges, we supply them to a broad range of industries, including transportation, paper & pulp, plumbing, food processing and others. We are renowned for the outstanding quality, dependability, and durability of our goods. There are several different kinds of hub flanges that we offer, such as carbon steel, copper nickel, stainless steel, monel, inconel, and more. The International Quality Standards (IQS) are followed in the design and development of hub flanges. In accordance with the needs of the customer, we also provide customised Hub Flanges.

Factors to Consider:

When choosing the perfect flange for your project, several factors should be taken into consideration:

Pressure and Temperature: One of the most critical factors is the pressure and temperature conditions the flange will be subjected to. Different flange materials and designs have varying pressure and temperature ratings, so it's essential to select a flange that can withstand the operating conditions of your system.

Material Compatibility: Flanges are available in a wide range of materials, including carbon steel, stainless steel, and various alloys. The material chosen should be compatible with the fluid being transported and resistant to corrosion, erosion, and other forms of degradation.

Flange Facing and Gasket Material: The flange facing and gasket material play a crucial role in ensuring a reliable seal between flange joints. Factors such as the type of fluid, operating temperature, and pressure should be considered when selecting the appropriate facing and gasket material.

Size and Dimensions: Flanges come in various sizes and dimensions to accommodate different pipe sizes and pressure ratings. It's essential to select a flange that matches the size and specifications of your piping system to ensure proper alignment and functionality.

Consultation and Expertise:

While understanding the basics of flanges is essential, choosing the perfect flange for your project may require consultation with experts in the field. Engineers, manufacturers, and suppliers with experience in flange selection can provide valuable insights and recommendations based on your specific requirements and constraints.

We produce flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

Flange Manufacturer In Pune

For More Detail

Website: metalicaforginginc.com

Other Product: JIS Flanges Manufacturer in India.

0 notes

Text

Monel Fasteners & Nut Bolts Manufacturer, Supplier in India.

Best quality Monel Fasteners, Nuts bolts, screws, washers are manufactured by Fasteners Fixtures We supply Monel fasteners all over India across the globe.

For More Information Visit Our Website :

0 notes

Text

The Role of Monel Fasteners in Petrochemical Refineries

Monel fasteners have emerged as one of the most sought-after choices in petrochemical refineries due to their safety, reliability, and efficiency. Jay Steel Corporation, serving as the premier Monel Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, takes immense pride in presenting a comprehensive range of top-notch Monel fasteners, which includes the highly sought-after Monel 400 Fasteners and Monel K500 Fasteners. Our offerings encompass an array of essential components such as Bolts, Nuts, Washers, Screws, Stub Bolts, and Anchor Bolts. With a commitment to empowering our esteemed customers, we tailor our solutions perfectly to meet the unique requirements of their projects. Trust in Jay Steel Corporation for top-quality Monel 400 Fasteners from reliable Suppliers of Monel 400 Fasteners.

In this blog post, we will delve deep into the realm of Monel fasteners and explore how they play a pivotal role in the operations of petrochemical refineries.

What are Monel Fasteners?

Monel is a group of nickel-copper alloys known for their exceptional corrosion resistance, high strength, and excellent mechanical properties. These alloys are primarily composed of approximately 65-70% nickel and 20-29% copper, with small amounts of iron, manganese, carbon, and silicon. Monel fasteners exhibit unique properties that set them apart from traditional materials. The primary components of Monel are nickel and copper, with small amounts of other elements such as iron, manganese, and silicon.

Significance of Monel Fasteners in Petrochemical Refineries

Petrochemical refineries play a pivotal role in transforming raw materials into a wide range of essential products. However, their operations involve handling hazardous chemicals, extreme temperatures, and high pressures. The failure of a single fastener in critical equipment can have severe consequences. Here's why Monel fasteners are indispensable in petrochemical refineries:

Corrosion Resistance for Safety:

Safety is of paramount importance in any industrial setting, especially in petrochemical refineries. The ability of Monel fasteners to resist corrosion ensures that essential equipment, such as pipelines and reactors, remains intact and leak-free. This significantly reduces the risk of accidents, environmental contamination, and potential harm to personnel.

Enhanced Reliability:

Monel fasteners provide long-term reliability in demanding refinery environments. They maintain their integrity and performance over extended periods, reducing the need for frequent replacements and maintenance, ultimately leading to cost savings.

Preventing Downtime:

Unexpected equipment failures can lead to significant downtime and production losses. Monel fasteners' robustness and resistance to corrosion help prevent sudden breakdowns, ensuring continuous and uninterrupted refinery operations.

High Tensile Strength:

Monel fasteners possess excellent mechanical properties, including high tensile strength. This makes them capable of withstanding heavy loads and stresses encountered in refinery equipment, maintaining their integrity even under challenging conditions.

Temperature Resistance:

In the world of petrochemicals, temperature variations are common, and fasteners must be able to perform consistently across a wide range of temperatures. Monel fasteners boast excellent thermal stability, allowing them to retain their mechanical properties even in extremely hot or cold environments. This capability ensures smooth operations and minimizes downtime due to temperature-related issues.

Types of Monel Fasteners Used in Petrochemical Refineries

The diverse range of Monel fasteners offers solutions for various applications within petrochemical refineries. Understanding the specific functions of each type helps in making informed decisions for equipment assembly and maintenance.

Bolts: Monel bolts are extensively used in connecting heavy machinery, flanges, and pipelines in petrochemical refineries. Their high tensile strength and corrosion resistance make them reliable for critical joints.

Nuts: Monel nuts complement the use of bolts, providing secure and sturdy connections in refinery equipment. Their resistance to corrosion ensures that connections remain intact even under aggressive conditions.

Washers: Monel washers act as spacers and distribute loads evenly, reducing stress on fastener connections. They protect the equipment surface from damage and enhance the longevity of the fastened joints.

Screws: Monel screws are used for assembling components and fixing parts in petrochemical refinery equipment. Their corrosion resistance is crucial, especially in outdoor or corrosive environments.

Stub Bolts: Stub bolts, also known as stud bolts, are threaded rods used to secure flanges and other connections in refinery pipelines. Monel stub bolts withstand high pressures and temperatures, ensuring leak-free joints.

Anchor Bolts: Monel anchor bolts provide essential support for heavy equipment and structures in petrochemical refineries. Their robustness is vital for anchoring critical equipment in concrete foundations.

Why Choose Monel Fasteners over Alternatives?

With so many types of fasteners available in the market, why should petrochemical refineries specifically opt for Monel fasteners? The answer lies in their unmatched combination of properties that directly address the unique challenges faced by this industry.

Longevity and Reduced Maintenance

Due to their exceptional corrosion resistance and durability, Monel fasteners offer an extended service life compared to traditional alternatives. This longevity translates to reduced maintenance costs and minimizes the risk of sudden failures, providing peace of mind to refinery operators.

Improved Safety Standards

Safety is of utmost importance in the petrochemical industry. Monel fasteners' ability to withstand harsh conditions and temperature variations ensures the structural integrity of vital components, enhancing overall safety standards in the refinery.

Enhanced Efficiency

By utilizing Monel fasteners, petrochemical refineries can experience improved operational efficiency. The reduced need for frequent replacements and repairs allows the facility to focus on core processes, leading to enhanced productivity.

Applications in Petrochemical Refineries

Monel fasteners find a plethora of applications within petrochemical refineries, contributing significantly to the overall efficiency and safety of the facility. Some of the primary applications include:

Piping Systems

Heat Exchangers

Reactors and Pressure Vessels

Flange Connections

Distillation Columns

Storage Tanks

Reactor Internals

Instrumentation and Control Systems

Catalyst Regeneration Systems

Pump and Compressor Assemblies

Furnaces and Boilers

Ancillary Equipment and Many More

Best Practices for Choosing Monel Fasteners

Selecting the appropriate Monel fasteners for petrochemical refinery applications requires careful consideration of several factors. By following these best practices, refinery professionals can ensure optimal performance and safety:

Assessing Environmental Conditions: Understand the specific environmental conditions in which the fasteners will operate. Consider factors such as exposure to corrosive chemicals, temperature variations, and humidity levels.

Identifying Material Requirements: Determine the suitable Monel grade based on the severity of corrosion expected and the mechanical properties required for the application.

Adhering to Industry Standards: Ensure that the chosen Monel fasteners comply with relevant industry standards and specifications. This guarantees their suitability and performance in petrochemical refinery settings.

Collaborating with Manufacturers: Consult with reputable manufacturers like Jay Steel Corporation, who have expertise in supplying Monel fasteners for petrochemical applications. Being Monel Fasteners Manufacturers, they can offer valuable insights and guidance in selecting the right fasteners.

Installation and Maintenance of Monel Fasteners

Proper installation and regular maintenance play vital roles in maximizing the performance and longevity of Monel fasteners in petrochemical refineries:

Installation Techniques: Follow the recommended installation guidelines provided by the fastener manufacturer. Improper installation can lead to reduced fastener life and compromised equipment integrity.

Regular Inspections: Implement a comprehensive inspection program to identify signs of corrosion, wear, or damage in Monel fasteners. Timely detection allows for prompt replacements, preventing potential failures.

Preventive Maintenance: Periodically lubricate Monel fasteners and take preventive measures to protect them from harsh environmental conditions. Routine maintenance ensures the fasteners' reliability and extends their service life.

Final Thoughts!..

Monel fasteners are now essential elements in the petrochemical sector, effectively maintaining the safety, dependability, and productivity of refinery activities. Their remarkable ability to resist corrosion and possess high tensile strength significantly contributes to accident prevention, reduced downtime, and the protection of both personnel and the environment. As the leading Monel Fasteners Manufacturer, Supplier, Stuckist, and Exporter in India, Jay Steel Corporation takes pride in supplying high-quality Monel fasteners that meet industry standards and cater to diverse project requirements. Petrochemical refineries must prioritize the selection of reliable fasteners to enhance operational performance and secure their critical assets. Our Monel Flanges have earned a stellar reputation in India and have gained significant demand worldwide, including in countries such as Singapore, Malaysia, Nigeria, Tunisia, the USA, France, Saudi Arabia, Kuwait, Qatar, and more. Through strategic partnerships with trusted manufacturers and adherence to best practices, the petrochemical industry can forge ahead towards safer, more efficient, and sustainable operations, with Monel fasteners serving as indispensable allies.

#MONEL FASTENERS MANUFACTURER#MONEL K500 FASTENERS STOCKIST#MONEL 400 FASTENERS SUPPLIER#MONEL 400 FASTENERS SUPPLIER IN INDIA.#.

0 notes

Text

What industries are fasteners used for?

Fasteners might seem like small components, but they play a pivotal role in numerous industries, holding together structures and equipment that form the backbone of modern society.

As the leading Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP understands the significance of these tiny yet mighty components across various sectors.

In this article, we'll delve into the wide array of industries where fasteners find their indispensable applications.

Fasteners

Fasteners are mechanical devices or components used to securely join or affix two or more objects together. They play a fundamental role in various industries and applications, providing the necessary connections that ensure structural integrity, safety, and functionality. Fasteners are designed to withstand different types of forces, such as tension, compression, shear, and torsion, depending on the specific application.

There are numerous types of fasteners, each with its own unique design and purpose. Some common types of fasteners include:

Screws: Screws have a threaded shaft and are used with a corresponding threaded hole or nut. They are rotated to create a strong, threaded connection between two objects. Screws are versatile and come in various head styles, including flat, round, pan, and more.

Bolts: Bolts are similar to screws but typically have a non-threaded portion (shank) and require a nut to create a secure connection. They are often used in applications requiring higher levels of tension or load-bearing capabilities.

Nuts: Nuts are paired with bolts to secure two objects together. They come in different shapes, such as hexagonal (hex nuts), square, or round, and are tightened onto the bolt's threaded shaft to create a strong joint.

Washers: Washers are flat, thin discs often placed between the nut or bolt head and the surface of the material being fastened. They distribute the load and prevent damage to the material while providing a more stable connection.

Rivets: Rivets are permanent fasteners used to join two or more materials together by deforming the end of the rivet to hold the materials in place. They are commonly used in applications where welding or screwing is not practical.

Pins: Pins are cylindrical fasteners that are inserted into holes in two objects to align and secure them. They can be held in place by friction or locking mechanisms.

Clips and Clamps: Clips and clamps are fasteners used to hold objects together or secure them in place temporarily. They often provide quick and easy solutions for assembling and disassembling components.

Anchors: Anchors are fasteners designed to provide a secure attachment to a base material, such as concrete or masonry. They are commonly used in construction and structural applications.

Materials & Grades - Fasteners Offered by Bullion Pipes & Tubes LLP

Copper Fasteners

Titanium Fasteners

Titanium Alloy Gr. 2 & 5

Monel Fasteners

Monel K500 & 400

Carbon Steel Fasteners

Brass Fasteners

Tantalum Fasteners

Inconel Fasteners

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Aluminum Fasteners

Nickel Alloys Fasteners

Nickel 200/201

SMO 254 Fasteners

Duplex Steel Fasteners

Duplex Steel UNS S32205

Duplex Steel UNS S31803

Hastelloy Fasteners

Hastelloy C22, B2 & C276

Super Duplex Steel Fasteners

Super Duplex Steel UNS S32750

Super Duplex Steel UNS S32760

Incoloy Fasteners

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Fasteners

Industries that use fasteners

Fasteners are used in a wide range of industries and applications to provide secure and reliable connections between various components. Here are some additional contexts where fasteners play a crucial role:

Aerospace and Aviation: The aerospace industry relies on fasteners to assemble aircraft components, such as wings, fuselage, and engine parts. Aerospace fasteners are designed to withstand extreme conditions, including high speeds, vibrations, and temperature fluctuations.

Marine and Shipbuilding: In marine applications, fasteners are used to construct ships, boats, and offshore structures. They must resist corrosion from saltwater and provide a strong bond in harsh marine environments.

Oil and Gas Industry: Fasteners are integral to the construction of oil rigs, pipelines, and refineries. They ensure the safety and reliability of equipment used in the extraction, processing, and transportation of oil and gas.

Medical Devices: Fasteners are used in the assembly of medical devices and equipment, ensuring that they remain securely in place during surgical procedures or patient treatment.

Railway and Transportation: Fasteners are crucial in railway tracks, securing rails to sleepers and ensuring the stability and safety of train operations. They are also used in the assembly of vehicles such as buses, trucks, and trains.

Electrical and Electronics: Fasteners secure components in electrical panels, circuit boards, and electronic devices, ensuring proper functioning and preventing damage due to vibrations and movement.

Furniture and Woodworking: In the furniture industry, fasteners hold pieces of furniture together, whether it's a simple chair or an intricate cabinet. They enable easy assembly and disassembly for shipping and storage.

Sports and Recreation Equipment: Fasteners are used in the manufacturing of sports equipment such as bicycles, skateboards, and snowboards, ensuring that the components remain securely attached during use.

Defense and Military: Military equipment and vehicles rely on fasteners for structural integrity and functionality. They are used in the assembly of tanks, armored vehicles, and aircraft used in defense operations.

Communication Infrastructure: Fasteners are used in the construction of communication towers and antennas, providing stability for broadcasting and wireless communication systems.

Renewable Energy: Fasteners play a role in solar panel and wind turbine installations, securing components and ensuring the efficiency of renewable energy systems.

Automated Manufacturing: Fasteners are used in automated manufacturing processes, where robots and machines assemble products quickly and accurately.

HVAC and Plumbing: Fasteners secure ductwork, pipes, and plumbing components in heating, ventilation, air conditioning, and plumbing systems.

Mining and Heavy Machinery: Fasteners are used in mining equipment, bulldozers, excavators, and other heavy machinery, ensuring their durability and safety during demanding operations.

Retail and Consumer Goods: Fasteners are employed in packaging and display fixtures, enabling efficient assembly and customization of retail spaces.

Final Words!..

A fastener contributes silently to the safety, stability, and progress of various industries, from tall skyscrapers to oil wells. As the premier Fasteners Manufacturer, Supplier, Stockist, and Exporter in India, Bullion Pipes & Tubes LLP's commitment to quality ensures that these small yet crucial components meet the highest standards.

With a wide range of fasteners tailored for diverse applications, We continue to be the preferred choice for industries across the spectrum. Moreover, we are also well-known fasteners exporters in various countries Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia, and beyond. Contact us today to explore how our fasteners can elevate your projects across industries.

0 notes

Text

Best Quality Bolt Manufacturers in India

A bolt is a type of fastener that is commonly used in construction, manufacturing, and mechanical applications. Bolts are designed to secure two or more objects together by threading through a hole in one object and attaching to a nut on the other side. They come in various shapes, sizes, and materials, Bolt Manufacturers in India including stainless steel, brass, and alloy steel. Bolts can be used in a wide range of applications, from simple DIY projects to complex machinery and infrastructure. Quality bolts are essential to ensure safety and reliability in various industries, and Indian bolt manufacturers are known for producing high-quality bolts that meet international standards.

India is home to many leading manufacturers of screws, bolts, and nuts. These manufacturers produce high-quality products that meet the diverse needs of customers from different industries. Whether you need fasteners for automotive, construction, or industrial applications, you can find reliable screw and bolt manufacturers in India.

Screw Manufacturers in India:

Screw manufacturers in India offer a wide range of screws in different sizes, materials, and finishes. They use advanced manufacturing technologies and strict quality control processes to produce screws that meet international standards. Some of the most popular types of screws produced by Indian manufacturers include wood screws, machine screws, self-tapping screws, and sheet metal screws.

Bolt Manufacturers in India:

Bolt manufacturers in India also produce a wide range of bolts in different sizes, materials, and finishes. They use high-grade materials like stainless steel, brass, and alloy steel to ensure the bolts are durable and reliable. Some of the most common types of bolts produced by Indian manufacturers include hex bolts, carriage bolts, anchor bolts, and U-bolts.

Nut Bolt Manufacturer in India:

Nut and bolt manufacturers in India offer a one-stop solution for customers who need both fasteners. They produce high-quality nuts and bolts that are compatible with each other and come in various sizes, materials, and finishes. Some of the popular types of nuts and bolts produced by Indian manufacturers include hex nuts, wing nuts, lock nuts, carriage bolts, and eye bolts.

When choosing a screw, bolt, or nut manufacturer in India, it is essential to consider several factors, such as quality, pricing, delivery time, and customer service. Look for a manufacturer that has a good reputation in the industry, uses high-quality materials, and has a robust quality control process.

Aashish Steel is a reputable manufacturer, supplier, and exporter of stainless steel Inconel Fasteners Manufacturer in India. Stainless steel Inconel Fasteners Manufacturer in India are adaptable goods that fall under various requirements and classifications. Aashish Steel is a leading Monel Fastener Manufacturer in India. Monel Fasteners are versatile items that come in a variety of specifications and categories. We are also the leading Bolt Supplier in Ludhiana and Bolt Supplier in Ahmedabad.

Visit: asnutbolt.com

0 notes

Text

Choose Right Fasteners for Your Project

Aashish Steel is a reputable manufacturer, supplier, and exporter of stainless steel Inconel Fasteners Manufacturer in India. Stainless steel Inconel Fasteners Manufacturer in India are adaptable goods that fall under various requirements and classifications. Aashish Steel is a leading Monel Fastener Manufacturer in India. Monel Fasteners are versatile items that come in a variety of specifications and categories. We are also the leading Bolt Supplier in Ludhiana and Bolt Supplier in Ahmedabad.

Types of Fastener

Stainless Steel Fasteners

One of the greatest and most reputable Stainless Steel Fasteners Manufacturers in India is Aashish Steel. Stainless steel fasteners are adaptable goods that are available in a range of standards and classifications. One of the things we produce is stainless steel fasteners, such as stainless steel bolts, nuts, screws, washers, and other fasteners. Fasteners made of stainless steel are excellent at resisting corrosion, therefore they are unaffected in industrial situations. It is resistant to dangerous substances like phosphoric acid, sulfuric acid, and chlorine.

Hastelloy Fasteners

Aashish Steel is a top Hastelloy Fastener Manufacturer in India. Hastelloy Fasteners are versatile items that come in a variety of specifications and categories. Hastelloy Bolts, Hastelloy Nuts, Hastelloy Screws, Hastelloy Washers, and other Hastelloy Fasteners are manufactured by us. Hastelloy fasteners have exceptional corrosion resistance, allowing them to function normally in industrial settings. It's resistant to chlorine, sulfuric acid, phosphoric acid, and other potentially harmful chemicals.

Monel Fasteners

One of the top Monel Fasteners in Manufacturers India is Aashish Steel. Monel Fasteners are adaptable goods that are available in a wide range of standards and classifications. Among the products we produce are Monel Bolts, Monel Nuts, Monel Screws, Monel Washers, and other Monel Fasteners.

We produce all grades of Monel fasteners in compliance with national and international standards. The most demanding goods in the chemical processing business, marine water supply industries, pulp and paper industry, petrochemical industry, desalination plant, aerospace, oil and gas refineries, and other industries are Monel fasteners. We produce all Monel Fasteners in accordance with customer specifications.

Specification of Inconel Fasteners :

Specifications: ASTM / ASME SB 160 / 164 / 166 / 425 /446 / 574 / 472

Standard: ASTM / ASME

Length: UPTO 1 METRE

Size: M10 TO M100

Type: Nuts, Bolts, Screws, Sockets, Studs, Screw, Hex Set Screw, Socket Screw, Cap Screw, Pan Head Screw, Machine Screw, Socket Head Cap Screw, Allen Cap screw, Wing Screw, Washers, Spring Washers, Studs, Anchors, Marine Anchors, Nut, Hexagon Nut, Hex Nut, Hex Coupling Nut, Hex Domed Cap Nuts, Square Nut, Stud Bolts, Hex Head Bolts, Socket Hexagon Head Screw Anchor Bolt, U-bolts, J-bolts, Mushroom Head Square Neck Bolts, T-Head Bolts, Wing Screw, Eye Bolt, Foundation Bolts, and Structural Bolts

Application & Uses Of Inconel Fasteners

Inconel Fasteners used in Petroleum Industry

Hex Nut used in Aerospace Industry

Square Nut used in Chemical Industry

Dome Nut used in oil & Gas Industry

Nylock Nut used in Nuclear Energy Sector

Wing Nut used in Automotive Industries

Visit: asnutbolt.com

0 notes

Text

Monel 400 Fasteners Suppliers In India

Chhajed Steel and Alloys is one of the wonderful providers of Monel 400 Fasteners. We additionally offer the proportionate in various sorts, for example, Monel 400 Nuts, Monel 400 Bolts, Monel 400 Washers, and Monel 400 Stud Bolt. The greater part of the things are quality tried relying on different parameters to guarantee that our clients get immaculate things. Monel locks are conveyed using a nickel-copper amalgam and show heavenly, quality and unimaginable deterioration security over a wide temperature run. Monel 400 is made out of a high – nickel and copper irritate that is essentially solidified by nippy working. Monel 400 Fastener has extraordinary quality completing and terrorizing for long life, high weight and zero flaws. Monel UNS N04400 Fasteners is in like way truly impervious to hydrochloric and hydrofluoric acids when they are de-hovered air through.

Monel Alloy 400 besides offers fine mechanical properties from underneath zero temperatures up to around 480C. Our things are referenced in a few different nations and we fundamentally pass on expansive shipments in a short structure. Monel 400 catch are perceived in the market for their characteristics, for example, solid progression, dimensional exactness and confirmation against breaking down and scratched zone. These Monel fittings find applications in various business experiences and parts and are suggested for segments, for instance, dimensional precision, use verified and better execution. Monel 400 usually discovers application in marine organizing, development and hydro-carbon preparing, warm exchangers, valves and siphons. Purchase Alloy 400 Fasteners at sensible rates from us. We make these things to your custom points of interest, and we affirmation to meet your development plan.

For More Information:

Visit Our Website - https://chhajedfasteners.com/monel-400-fasteners-manufacturers-importers-exporters-suppliers.html

Call Us: +919821513630

E-mail: [email protected]

#Buy Monel 400 Fasteners#Monel 400 Nuts#Monel 400 Bolts#Monel 400 Screws#Monel 400 washers for perfect connection & critical applications#excellent pricing and extensive size range of Monel 400 Fasteners#Monel 400 Fasteners Manufacturer & Supplier#Manufacting high-class Monel 400 Fasteners in India#high quality Monel 400 Fasteners suppliers#Alloy 400 Bolts#Monel 400 Bolts And Nuts#Monel 400 Screws at Lowest price in India

0 notes

Text

Important knowledge regarding stainless steel pipes.

It's not easy to get the right stainless steel tubes, but it's even more important to research the material's qualities and how it interacts with the others you'll be using.

Temperature

When it comes to heat, how resistant is your tubing? Carbon steel tubes may be used for steam pipes because of their excellent temperature resistance. However, a special kind of pipe is required for use with cryogenic liquids and other applications involving very low temperatures. SS 316L Round bar Suppliers in India have been producing excellent products.

Costing

Both carbon steel and stainless steel are reasonably priced, which is a huge relief. In terms of cost, carbon steel tube often comes out on top, but stainless steel tube isn't far behind. What this means is that you may choose the material that is most suited to the work without having to worry too much about its expense. The best Duplex Round Bar Suppliers in India will always help you out.

Appearance

If the look and feel of your pipes is important to you, then familiarity with the finish of these steels will serve you well. Stainless steel has a lustrous sheen and can withstand the environment without deteriorating or rusting. It seems that carbon steel is deeper in color and has a more matte sheen. Upon exposure, this may corrode and lose its luster. Titanium Round Bar Suppliers in India that specialize in producing round bars have been doing an outstanding work.

Solution: steel

For many uses, carbon steel tubes are the go-to material. Sewage, municipal, steam, and vent pipes are all popular places to find carbon steel. Think about whether or not you need special features like heat or chemical resistance. Using these details, you may choose the right steel for your needs. Inconel 625 Round Bar Suppliersare able to provide a 100% quality guarantee.

Looking at how stainless-steel pipes are used in just one plant in one industry shows how adaptable and flexible the material can be. Monel 400 Round Bar Suppliers always provide exceptional products.

Consider all the places stainless-steel tubing shows up in your home: appliances, water, heating, and plumbing systems, automobiles, tools, and more. When it comes to producing round bars, Hastelloy C276 Round BarSuppliers are well-equipped.

Stainless steel pipe has many applications beyond the home, including the food and beverage industries, as well as the automobile, aerospace, and technology sectors. Copper Round Bar Suppliers in Indiaare always trusted by most of the people.

The malleability of stainless steel tube allows it to be molded into a wide number of shapes, including square and rectangular, which expands the range of applications that may be performed with this material. Every day, inventive people come up with fresh methods to incorporate stainless steel pipe into products and technologies that have made our lives better in a variety of ways. This results in the discovery of new applications for stainless steel pipe. The bolt with the specification ASTM A193 B8 is quite common.

0 notes

Text

Making the Right Choice: Factors to Consider When Selecting an Inconel and Monel Manufacturer in India

Suppliers of Fasteners

Introduction:

Selecting the right Inconel and Monel manufacturer in India is a crucial decision that can impact the quality, reliability, and success of your projects. With numerous manufacturers competing in the market, it's essential to evaluate key factors to ensure you partner with a reputable and reliable supplier. This article outlines essential considerations to help you make an informed decision when selecting an Inconel and Monel manufacturer.

Brief:

Choosing an Inconel and Monel manufacturer requires careful evaluation of factors such as reputation, expertise, manufacturing capabilities, quality assurance practices, and customer service. By assessing these aspects systematically, you can identify a manufacturer that meets your specific requirements and delivers superior-quality products consistently.

Elevator Bolt Manufacturers in Mumbai

Applications:

1. Reputation: Research the reputation and credibility of potential manufacturers by seeking referrals, reading reviews, and evaluating their track record. A manufacturer with a strong reputation and satisfied customers is more likely to meet your expectations and deliver quality products.

2. Expertise: Assess the manufacturer's expertise in working with Inconel and Monel alloys by reviewing their credentials, certifications, and industry experience. Look for evidence of specialized knowledge, technical capabilities, and successful projects relevant to your needs.

3. Manufacturing Capabilities: Evaluate the manufacturer's production facilities, equipment, and capacity to ensure they can fulfill your requirements efficiently and effectively. Consider factors such as production volume, lead times, and flexibility to accommodate custom orders. Stainless Steel Fasteners Manufacturers in Mumbai

4. Quality Assurance Practices: Inquire about the manufacturer's quality assurance practices, testing procedures, and adherence to industry standards. A manufacturer that prioritizes quality control and continuous improvement is better positioned to deliver products that meet your specifications and standards.

5. Customer Service: Consider the manufacturer's level of customer service, responsiveness, and communication channels. A manufacturer that values customer satisfaction and maintains open dialogue fosters a collaborative and mutually beneficial partnership.

SS Fasteners Suppliers

Conclusion:

Selecting the right Inconel and Monel manufacturer in India requires careful consideration of factors such as reputation, expertise, manufacturing capabilities, quality assurance practices, and customer service. By conducting thorough research, soliciting recommendations, and engaging in transparent communication with potential manufacturers, you can make an informed decision that aligns with your objectives and ensures the success of your projects. Remember, investing in a reputable and reliable manufacturer is essential for achieving optimal results and maintaining a competitive edge in your industry.

0 notes

Text

Monel Alloy Bolts manufacturers exporters suppliers stockist in India Mumbai +91-9892882255 https://www.vandanalloys.com

Monel Alloy Bolts manufacturers exporters suppliers stockist in India Mumbai +91-9892882255 https://www.vandanalloys.com

0 notes

Text

High Nickel Steel ASTM B166 UNS N06600 Fasteners

Ganpat Industrial Corporation is an ISO 9001:2015 Certified Company that deals in high-quality High Nickel Steel ASTM B166 UNS N06600 Fasteners.

Ganpat Industrial Corporation is offering the comprehensive range of Alloy UNS N06600 Bolts / Nuts for the right industrial solution. The industry is dealing globally as the reliable manufacturer, supplier, stockholder and exporter of the very good quality of fasteners at the factory prices as per the budget of the users. They are offering the fasteners at various specifications and dimensions as per the demand the buyers have made.

GIC is a leading supplier of High Nickel Steel ASTM B166 UNS N06600 Fasteners, Alloy UNS N06600 Square Nut, Suppliers of ASTM F467 UNS N06600 Inconel Hex Head Bolt, Inconel UNS N06600 Dome nuts, UNS N06600 Alloy Coupling Nut Exporter, Inconel UNS N06600 Fasteners, UNS N06600 Bolt.

Inconel UNS N06600 Bolt, Alloy UNS N06600 Nuts, Alloy UNS N06600 Bolt, UNS N06600 Inconel Bolt, ASTM F467 UNS N06600 Inconel Nut, UNS N06600 Inconel Alloy Shoulder Nuts Suppliers and Exporters in Mumbai, India.

Ganpat Industrial Corporation has experience of more than 25 year in manufacturing of stainless steel and high nickel steel buttweld fittings , flanges, pipes, plate, round bar, wire.

We offer Indian, European and Japan origin. Currently we export to UAE, Bahrain, Qatar, Italy, Saudi Arabia, Singapore, Malaysia, Thailand, Brazil, Poland, Australia & many other Countries.

Ganpat Industrial Corporation is a Supplier, Manufacturer, Exporter and Stockist of Inconel, Incoloy, Monel, Nickel Alloy, Copper Nickel, Titanium, AISI 4130, Stainless Steel in forms like Pipe, Tube, Flanges, Fasteners, Fittings, Round Bar, Sheet Plate, Wire Mesh. Contact Us at [email protected] high quality material in best Rates.

1 note

·

View note

Text

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

Monel Flanges vs. Other Flange Materials: A Comparative Analysis

When it comes to industrial piping systems, the choice of flange material plays a pivotal role in ensuring peak performance and long-lasting functionality. Among the myriad materials available, Monel stands out as one of the most popular and reliable options. As the leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, we take pride in offering a wide range of options to cater to diverse project requirements. Our Monel Flanges come in various sizes, specifications, standards, and grades, including the popular Monel 400 Flanges and Monel K500 Flanges.

Moreover, we offer different types of flanges, such as Slip On Flanges, Weld Neck Flanges, Socket Weld Flanges, Blind Flanges, Orifice Flanges, Reducing Flanges, Ring Type Joint Flange, Spectacle Blind Flanges, and Lap Joint Flanges, ensuring that you find the perfect fit for your projects. With our expertise and dedication as suppliers of Monel 400 Flanges and other products, we strive to meet the highest industry standards and be your preferred partner for all your Monel Flange needs in India and beyond.

In this blog post, we will explore the unique advantages of Monel Flanges over other flange materials, demonstrating why they are the preferred choice for critical applications across various industries.

Understanding Flanges and Their Role in Industrial Piping

Before we dive into the comparison, let's briefly understand what flanges are and why they are vital in industrial piping systems. Flanges are flat, circular discs with evenly spaced bolt holes used to connect pipes, valves, and other equipment in a piping network. Their primary functions include providing support, facilitating alignment, and allowing for easy assembly and disassembly of components.

Exploring Monel Flanges

Monel Flanges are a class of nickel-copper alloy flanges renowned for their exceptional properties. The composition primarily consists of nickel and copper, with additions of small amounts of iron, manganese, and other elements. This alloy's chemical composition results in a combination of impressive characteristics, including excellent corrosion resistance, high tensile strength, and exceptional temperature stability.

The corrosion resistance of Monel Flanges is particularly noteworthy, making them suitable for use in harsh and corrosive environments. They perform exceptionally well in marine applications, offshore drilling, and chemical processing industries where exposure to seawater, acids, and alkalis is common. The resistance to localized corrosion, such as pitting and crevice corrosion, adds to their popularity.

Comparing Monel Flanges with Other Flange Materials

To make an informed decision, it is essential to compare Monel Flanges with other commonly used flange materials, such as stainless steel, carbon steel, Inconel, and Alloy 20.

Stainless Steel Flanges

Stainless steel flanges are widely used due to their general corrosion resistance and cost-effectiveness. However, when compared to Monel Flanges, they may fall short in highly corrosive environments. Monel Flanges, with their higher nickel content, exhibit superior resistance to chloride-induced stress corrosion cracking, a common concern in stainless steel.

Carbon Steel Flanges

Carbon steel flanges are widely used in various industries due to their affordability and mechanical properties. However, they lack the corrosion resistance required for aggressive environments. Monel Flanges outshine carbon steel in corrosive atmospheres, making them the preferred choice for applications where durability and longevity are crucial.

Inconel Flanges

Inconel is another popular nickel-based alloy known for its high-temperature strength. While Inconel Flanges offer excellent performance in extreme heat, they may not provide the same level of corrosion resistance as Monel Flanges. For applications where both heat and corrosion resistance are essential, they prove to be the optimal choice.

Alloy 20 Flanges

Alloy 20, also known as Carpenter 20, is a nickel-chromium-molybdenum stainless steel alloy that offers excellent resistance to corrosion and pitting. While Alloy 20 is suitable for many corrosive environments, it may not match the overall corrosion resistance and mechanical properties of Monel Flanges.

Advantages of Monel Flanges

The advantages of using Monel Flanges extend far beyond their corrosion resistance. Let's explore the various reasons why they are a preferred choice in different industries and applications.

High Tensile Strength and Temperature Stability

Monel Flanges are known for their high tensile strength, which ensures they can withstand significant mechanical stress without deformation. This property makes them suitable for applications where the flanges are exposed to high-pressure conditions, such as in oil and gas pipelines, chemical reactors, and high-temperature environments.

Durability and Longevity

Monel Flanges exhibit exceptional durability and longevity, even in the most demanding conditions. Their ability to withstand extreme weather conditions, abrasive elements, and frequent exposure to corrosive substances makes them a reliable choice for critical applications with long operational lifespans.

Resistance to Biofouling and Microbial Corrosion

In marine and offshore industries, biofouling and microbial corrosion can pose significant challenges. Monel Flanges possess inherent resistance to these issues, making them ideal for use in seawater desalination plants, offshore platforms, and shipbuilding.

Excellent Weldability and Formability

Monel Flanges are known for their excellent weldability and formability. They can be easily welded, machined, and formed into complex shapes, allowing for greater design flexibility and ease of installation.

Low Risk of Contamination

For industries dealing with sensitive materials such as pharmaceuticals and food processing, Monel Flanges offer a low risk of contamination. Their non-reactive nature ensures that they do not leach any harmful substances into the conveyed fluids or products.

Key Considerations for Choosing Flange Materials

Selecting the appropriate flange material is crucial to ensuring the success and safety of your projects. Here are some key considerations to keep in mind when choosing flange materials:

Operating Conditions

Evaluate the temperature and pressure conditions under which the flanges will operate. Monel Flanges, with their excellent high-temperature and pressure capabilities, are an ideal choice for applications where these factors are critical.

Corrosive Environment

Consider the nature of the fluid being transported and the corrosive environment in which the flanges will operate. Monel Flanges excel in corrosive atmospheres, providing reliable performance and extended service life.

Industry Standards and Certifications

Ensure that the chosen flange materials meet industry standards and certifications. At Jay Steel Corporation, we take pride in adhering to global standards, providing our customers with the assurance of top-quality products.

Cost-Effectiveness

While Monel Flanges may have a higher initial cost compared to some other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

Expert Guidance

Seek expert guidance from professionals who can analyze your project requirements and recommend the most suitable flange material. At Jay Steel Corporation, our team of experts is always ready to assist you in making the right choice.

Applications of Monel Flanges

Monel flanges are essential components used in various industries due to their unique properties and corrosion-resistant nature. Monel is a group of nickel-copper alloys known for their excellent resistance to seawater, acids, alkalis, and various corrosive environments. Here are some of the common applications:

Marine industry

Oil and Gas industry

Chemical processing

Aerospace industry

Power generation

Seawater desalination

Food processing

Pharmaceutical industry

Water treatment

Nuclear industry

Other Application

Final Thoughts!..

Monel Flanges emerge as the ideal choice for critical applications where corrosion resistance, high strength, and temperature stability are paramount. Their exceptional properties and performance set them apart from other flange materials, making them the preferred option for industries such as marine, offshore, chemical processing, aerospace, and so on.

As India's leading Monel Flanges Manufacturer, Supplier, Stockist, and Exporter in India, Jay Steel Corporation is committed to delivering top-notch products that cater to your specific project requirements. Our Monel Flanges are not only highly regarded in India but are also in demand across the globe, with exports to countries such as Singapore, Malaysia, Nigeria, the USA, France, Saudi Arabia, Kuwait, Tunisia, Qatar, and more. Our products have gained international acceptance due to their unmatched quality, reliability, and adherence to global standards and certifications.

0 notes

Photo

s30400 bolt

Manifold Pipe Solution Inc. is stockist & distributor of s30400 bolt Manufacturers In India, SS 304 Bolts And Nuts. If you are looking for Monel Bolts suppliers make sure you keep a few things in mind. Begin by comparing the 304 Stainless Steel Fasteners, SS 304 Bolts And Nuts, SS 304 Hex Bolts price. You can do this by calculating the amount of sheets that you wish to buy. All authentic 304 Stainless Steel Nuts,

1 note

·

View note