#Multi View Microscope

Explore tagged Tumblr posts

Text

Microscope Manufacturers & Suppliers in India

Many microscope manufacturers and suppliers worldwide offer different kinds of quality optical, digital, and electron microscopes for educational, medical, and industrial purposes. Due to the state of the art technology and advanced precision manufacturing capabilities the manufacturers put great emphasis on quality imaging and durability. They are trusted all over the world and are committed to customer service, product quality, price, and customized solutions for all laboratory and research purposes. Experienced top quality microscope solutions with Infinity Optics - leading manufacturers and suppliers of microscopes in India. The motors driving Infinity Optics is precision, reliability, and innovation, so please go ahead and experience the advanced optical instruments offered by Infinity Optics.

#Inverted microscope#Fluorescent Microscope#Microscope Manufacturers in India#Microscope Suppliers#Laboratory Microscope Suppliers#Microscope Manufacturer in Ambala#Laboratory Equipment Manufacturers in India#Lab Equipment Suppliers in India#Stereo Zoom Microscope Supplier#Multi View Microscope#Upright Fluorescent Microscope#Research Microscope#Microscope Manufacturers & Suppliers in India

2 notes

·

View notes

Text

FineLab UK Corporation specializes in high-quality pharmacy instruments from India. Our network of trusted Indian pharmacy instrument manufacturers ensures premium laboratory equipment. We serve global clients with reliable solutions.

0 notes

Text

Multi-viewing biological microscope

Multi-viewing biological microscope is designed to observe single specimen by several people together at the same time. Its swing condenser, coarse and fine focusing knobs, C-mount video adaptor FOR viewing sharp and clear images of the specimen.Optical system=infinite-optical-system; Viewing Head=compensation-free-trinocular-head-inclined-at-30-deg-360-deg-rotable-interpupillary-distance-48-75-mm;compensation-free-binocular-head-inclined-at-30-deg-360-deg-rotable-interpupillary-distance-48-75-mm-1-pcs; Eyepiece=extra-wide-ew10x-20mm-4-pcs; Focusing=coaxial-coarse-amp-fine-0-001-mm; Objective=infinite-4x-10x-40x-s-100x-s-oil;Shop Online at Labtron.us

0 notes

Text

WAY OUT THERE 𖠰 ⋆☾𓃦☽⋆⁺₊✧🪵𓇢𓆸

series masterlist

✦ ── pairing: lumberjack!sukuna x citygirl!reader

✦ ── synopsis: taking a hike, alone, in a massive forest to escape your mundane life may not have been the greatest idea you'd conjured up—a realization you'd come to soon after you managed to lose your map miles inland. but when a lumberjack who knows the land like the back of his hand offers you a place to stay, you think maybe your life isn't so tragic after all. besides, for the sake of your safety, who knows what lingers in the shadows after nightfall?

✦ ── contents: lost in the forest au, forced proximity, bantering, angst, trauma/torture aspects, minor injuries, eventual romance, eventual smut, no use of y/n, more tags to be added.

✦ ── a/n: this is going to be my 1k followers special but i've already got a solid outline and plenty written. i believe this will end up being a multi-chapter fic. can't wait to release this, so check below the threshold for a teaser ;D

✦ ── word count: 17.4k/?

archive ─ playlist

volume one // womb

volume two // amateur blood

volume three // you don't mess around with slim

volume four // eternal life

volume five // ???

comment to be added to the taglist (status: open)

art by outdmilk on twt

teaser 𖠰 ✩₊˚.⋆☾𓃦☽⋆⁺₊✧🪵𓇢𓆸

After getting fully dressed, you shuffled your socks on before you let out a loud hiss—a sudden piercing pressure on your ankle.

Gently setting your sock down, you sat atop a nearby rock and crossed your legs to take a closer look.

It seemed that the thorn that poked you earlier had done more than just that—the area swelling and red. The spot, previously a microscope hole, had grown and was practically glowing and exuding a heat.

You pressed a finger against it, immediately regretting it when it sent pain spiking through your veins, the skin bulbous.

“You’re not making it out of the forest any time soon in that condition.”

You yelped with a jump, full-body flinching and swinging your head behind you to see Sukuna towering over you, eyes narrowed to slits as he eyed your injury. “Jesus. Warn a woman next time?”

He ignored you, something you’ve noticed he has a habit of doing, as he folded in half, skimming a hand over your puncture wound. A tight whimper left your lips, his calloused finger pad ghosting over it before he straightened out. “Can you walk on it?”

You attempted to pull the sock back over before you winced, heart fluttering in nerves. “I-I can try,” you stammered out, trying to maneuver it carefully before he clicked his tongue.

“Fuck, alright,” he grunted, as if mulling something over before he stepped in front of you. He crouched down on one knee, jeans digging into the mud yet he didn’t seem to care. “Hop on.”

Your maw fell slack at the sight, suddenly feeling incredibly hot at the sight. This crude and ruffish man was offering to carry you all of the sudden.

“Uh, i-it’s alright. I can walk–”

“Quit your rambling and get on.”

You shut up at his interruption, muttering a ‘rude much?’ he didn’t acknowledge under your breath before standing to a wobble, doing your best not to bump your ankle into anything as the pain began to flare to what felt like your bones.

Oddly enough, he was practically your height on his knees, his massive form slightly intimidating you.

You brought your hands over his shoulders and clasped them in front of him, hoping he couldn’t smell the musk radiating from your sweat-soaked clothing.

As you tried to wrap your legs around his midsection, he suddenly rose, wrapping his massive hands along the underside of your thighs and straightening to his full height.

You did everything to ignore the flip of your stomach as he did so, the touch burning your skin.

Something sizzled in your mind, before you realized how leggy this man actually was. “Could make a joke about the weather up here, but it’s really quite nice,” you snickered, head ducking between his hat, cheek right beside his, as your eyes raked over his bird's eye view.

“Shut it or I’m dropping you.”

#✦ bisque tracklist#way out there#jujustsu kaisen x reader#jujutsu kaisen smut#jujutsu kaisen#jujutsu sukuna#jujutsu kaisen fic#jujutsu kaisen sukuna#sukuna#sukuna ryomen x reader#sukuna ryomen#sukuna x reader#sukuna x you#sukuna smut#ryomen sukuna#jjk smut#jjk x reader#sukuna ryomen smut#jujutsu kaisen ryomen#ryomen x reader#jjk ryomen

820 notes

·

View notes

Text

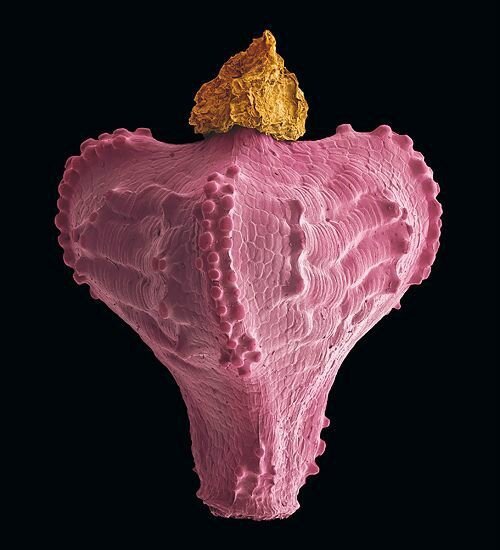

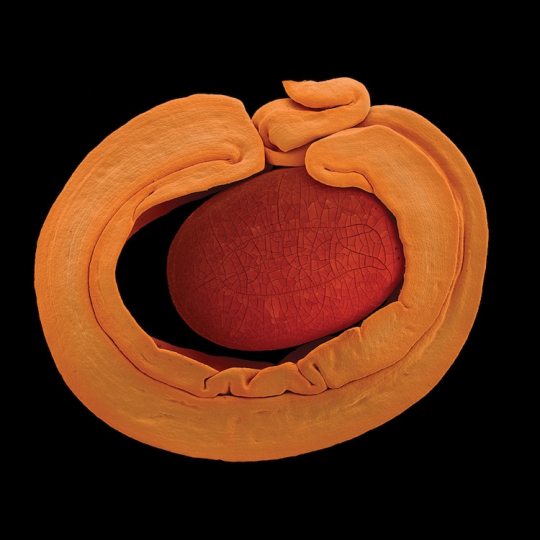

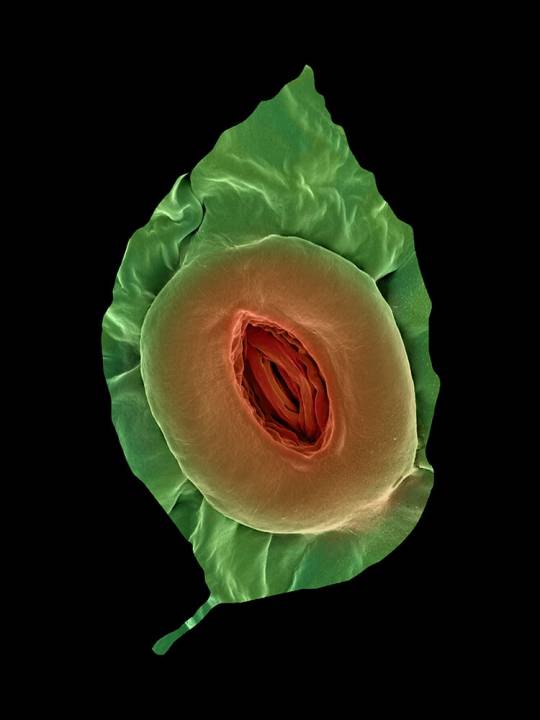

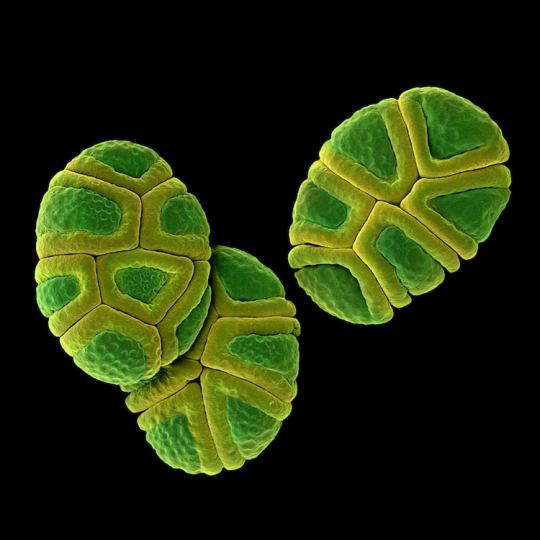

Rob Kesseler is a visual artist and Emeritus Professor of Arts, Design & Science at Central Saint Martins, London. For the past twenty years he has worked with botanical scientists and molecular biologists around the world to explore the living world at a microscopic level. Using a range of complex microscopy processes he creates multi-frame composite images of plant organs.

Using scanning electron microscopy and a mix of microscopic, scientific, digital, and manual processes, artist Rob Kesseler develops coloured micrographs of the intricate patterns within pollen and seed grains, plant cells, and leaf structures. The photographs feature specifics of cellular composition that are undetectable without magnification.

Kesseler tells that as a child, his father gifted him a microscope, marking a pivotal moment in his creative career. “What the microscope gave me was an unprecedented view of nature, a second vision,” he writes, “and awareness that there existed another world of forms, colours and patterns beyond what I could normally see.” The artist says his use of color is inspired by the time he spends researching and observing, and that just like nature, he employs it to attract attention.

36 notes

·

View notes

Note

Given your microscopic stature and little wings, I think it'd be fun to take you up on an airplane. Show you the enormity of a multi-level cross-oceanic airplane. Of course it'd be easy to sneak you past security, I'd just put you between my fat, sweaty tits. Even if they give me a pat-down, they'll never see you, and perhaps you'll get even more smushed than you were as my girls bobbled around around the airport. Since it's gonna be a long flight, perhaps I'll take a quick restroom break while at the gate? You can gaze down, perched on the lip of my brazier at my cock as I relive myself. Perhaps you don't even notice that you're willing yourself to fall, but I'd catch you, don't you worry little thing. I promised to take you up to the mile-high club after all...

After boarding, I'd be crammed into a tiny seat--I could only imagine how cramped it would be for the tiny beneath my seat heehee. Once you've finally crawled out from under there and we reached cruising altitude, I'd reach down and touch you. Giant fingers pressing softly against your minuscule body, bringing you a mild euphoria before I hoist you up to the window, giving you a good view out over the world. Then I'd finish you off, pressing onto your back, crushing you against the window, enjoying your weak moans as you flatten like a pancake before wolfing you down like one.

You'd have a few moments in my mouth before I'd swallow, your ragged and collapsed form floating in my saliva and rubbing against tooth and taste-bud before being pulled against all your power into my abyss. Oh how the tiny fall. Will a fizzle and pop in my gut, one could hardly say you refueled my tank, but in a few minutes I'd have to get up to use the lady's room again. This time, I would let you fall, with a wet thunk into the cramped stall before letting the airplane consume you with a thunderous roar as it flushed. Oh, just thinking about you wasted in an airplane bathroom, crammed into the pipes, having to stew there for a day-long flight while others packed you further and further down. Maybe I'd send another girl to join you later on in the flight, or give you the sweet treat of my cum at some point.

The shittiest little goddess flying high above the world indeed.

HFHCCHDVNDJCJDJD GOSH

SCJCJS STHATS SO GOOD

Its so sweet of you to give your plaything a proper view! Showing me the world... almost ironic to take something so, so low to the ground (and lowly in general) and show it a view from impossibly high in the sky... watching it's oooohs and aaaahs turn into "mmmmph~"s and "ahhhhh~"s... swallowed down without a second thought...

GOD thats such a humiliating end... I would give anything to be there, cramped, helpless, overwhelmed, and listening to your small giggles above me... hchfjdhdb PLEASE <3

5 notes

·

View notes

Text

From Plastic to Steel: A Cleaner Solution for Cat Owners

In the world of pet care, innovation often starts with small yet essential changes—such as switching your feline friend’s litter pan from plastic to stainless steel. While traditional plastic pans have long dominated the market, more pet owners are now embracing stainless steel litter boxes as a cleaner, more sustainable alternative. But what exactly makes this metal box stand out?Get more news about stainless steel litter pan,you can vist our website!

A Hygienic Advantage

One of the most compelling reasons for switching to a stainless steel litter pan is hygiene. Unlike plastic, stainless steel is non-porous, meaning it doesn't trap bacteria, odors, or moisture in microscopic cracks. This property makes it remarkably easy to clean, preventing lingering smells that often plague plastic alternatives. A quick rinse with warm soapy water or a non-toxic disinfectant keeps the surface spotless and safe for your cat.

Built to Last

Durability is another key selling point. Plastic pans tend to warp, crack, or stain over time—especially under the stress of frequent scooping, heavy litter, or cat claws. In contrast, stainless steel is virtually indestructible under normal use. It doesn’t rust, and the smooth surface resists scratches, maintaining its sleek look over the years. For multi-cat households or those with especially enthusiastic diggers, this strength is a major plus.

Eco-Friendly Choice

Environmentally conscious consumers also find stainless steel appealing. Since these pans last significantly longer than plastic ones, they reduce waste over time. Many stainless steel pans are also recyclable at the end of their lifespan. While the initial cost might be higher, their longevity means fewer replacements—saving money and the planet in the long run.

No More Plastic-Related Allergies

Another hidden benefit? Reduced risk of allergic reactions. Some cats (and even humans) can react to the chemicals in certain plastics, especially when exposed to heat or urine. Stainless steel is chemically inert and doesn’t leach harmful substances, making it a safe bet for sensitive pets and people.

Aesthetically Pleasing Design

Beyond function, stainless steel litter pans also offer a minimalist, polished look that blends into modern home décor. They don’t discolor over time and often pair well with stylish litter enclosures or cat furniture. Whether tucked discreetly in a corner or placed in plain view, they elevate the overall aesthetic of your pet’s living space.

Choosing the Right One

When choosing a stainless steel litter pan, consider size, depth, and additional features like anti-slip rubber feet or high sides for splatter control. Some models come with a non-stick coating to prevent waste from adhering to the surface, which can further simplify cleaning. Others include subtle design touches like rolled edges to avoid sharp corners.

Final Thoughts

Switching to a stainless steel litter pan may seem like a small adjustment, but it’s one that offers lasting benefits for you and your pet. Cleaner, sturdier, safer, and better for the planet—this shiny upgrade checks all the boxes. For cat owners seeking a blend of practicality and elegance, stainless steel may be the future of feline hygiene.

0 notes

Text

Beginner’s Guide to Laboratory Glass Slides: Uses and Types

When it comes to laboratory work, precision and accuracy are critical. One of the fundamental tools used in laboratories for sample analysis is the laboratory glass slide. These simple yet essential tools have evolved over the years and are now available in various types to suit specific needs in research and diagnostics.

What Are Laboratory Glass Slides?

A glass slide is a rectangular pane of glass designed to support samples for microscopic examination. They come in various sizes and are typically used in combination with microscope slides and coverslips to ensure clear, stable viewing under magnification. These slides are made from high-quality glass that is durable and capable of withstanding laboratory conditions.

Types of Laboratory Glass Slides

There are several types of microscope slides and coverslips, each designed for specific tasks and applications. Here are several of the most frequently encountered types:

Standard Glass Slides: The most utilized laboratory glass slides are flat, rectangular in shape, designed specifically for placing samples to be examined under a microscope. The edges are usually smooth to prevent injury or contamination.

Frosted Glass Slides: These microscope glass coverslips have a frosted section, usually at one end, for writing sample information. This is particularly useful for labeling and identifying slides during long-term storage.

Multi-Well Glass Slides: These slides are designed with multiple small wells to hold various samples. Micro slides of this kind are commonly used in laboratories for experiments that require the examination of multiple specimens simultaneously.

Tissue Culture Glass Slides: These slides are specifically crafted for tissue cultures, enabling the cultivation and microscopic observation of living cells. These slides are generally made with a special coating to support cell growth.

Cover Glasses: These are delicate glass covers that shield the specimen on a microscope slide from air and environmental pollutants. Microscope slides and coverslips are typically paired together to create the ideal environment for examining the sample.

Common Uses of Laboratory Glass Slides

Laboratory glass slides have an extensive range of applications in various scientific fields. They are used across industries like medicine, biology, chemistry, and environmental science. Common applications include:

Biological Research: Microscope slides and coverslips play a crucial role in biological research, enabling the examination of tissues, bacteria, viruses, and various microorganisms.

Medical Diagnosis: In clinical labs, glass slides and covers are used to prepare specimens for analysis, such as blood smears or tissue biopsies.

Educational Purposes: In classrooms and educational settings, microscope slides and covers are used for teaching students how to observe and study samples.

Chemical Analysis: In chemistry, microscope glass coverslips are used for studying chemical reactions at the microscopic level.

How to Choose the Right Laboratory Glass Slide

Selecting the appropriate laboratory glass slide is contingent upon the particular needs of your tasks. Factors to consider include:

Size: The size of the slide should match the sample size and the type of microscope being used.

Coating: Some slides are coated with substances that help with adhesion, which can be essential when dealing with biological samples.

Thickness: The thickness of the slide should be chosen based on the level of magnification required. For heavier samples, thicker slides are preferable, whereas thinner slides are better suited for examining small specimens.

Quality: Always opt for high-quality glass slide manufacturers in India to ensure the slides are free from defects that could affect the accuracy of your observations.

Why Quality Matters in Laboratory Glass Slides

When working with microscope slides and coverslips, quality plays a crucial role in obtaining accurate and clear observations. Low-quality slides can have defects that lead to distortion, making it difficult to observe samples properly. As such, it's important to purchase from microscope slide manufacturers in India who adhere to strict manufacturing standards, ensuring that each slide is defect-free and made to exact specifications.

High-quality laboratory glass slides ensure that samples remain stable, secure, and visible, whether you’re conducting research, diagnosing diseases, or teaching students. Furthermore, premium slides are often made from high-clarity glass, which prevents distortions and allows light to pass through the sample with minimal obstruction.

Where to Buy Quality Laboratory Glass Slides in India

When looking for microscope slides and covers in India, it's essential to choose a trusted manufacturer. Blue Star Slides is one of the leading glass slide manufacturers in India, known for producing high-quality products that meet global standards. Their extensive range of microscope slides and covers is designed for precision and durability, making them an excellent choice for research, education, and clinical purposes.

In summary, laboratory glass slides are a must-have for any laboratory working with microscopes. From basic microscope slides and coverslips to specialized microscope glass coverslips, these slides are used in various applications in biological research, medical diagnostics, and chemical analysis. When choosing microscope slides and covers, always prioritize quality to ensure clear, reliable observations. Blue Star Slides, a leading microscope slide manufacturer in India, offers premium-quality slides to meet all your laboratory needs.

0 notes

Text

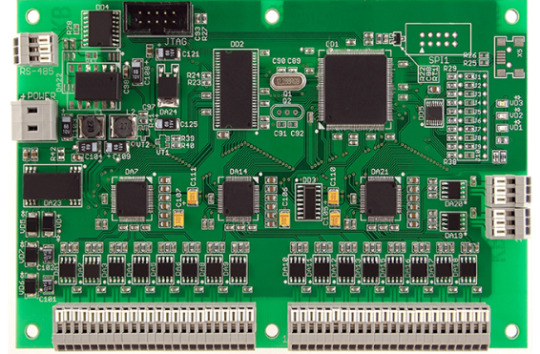

Quality Control Standards for Printed Circuit Board Suppliers

In the fast-evolving world of electronics manufacturing, reliability and precision are not optional—they are essential. For businesses that rely on printed circuit boards (PCBs) to power their devices, quality assurance must be a top priority. At Pcb-Togo Electronic, Inc., we understand this responsibility. As a trusted Printed Circuit Board Supplier, we have built our reputation on a foundation of strict quality control standards designed to meet the most demanding performance and safety requirements.

Below, we explore the comprehensive approach we take at Pcb-Togo Electronic, Inc. to ensure every PCB we deliver is tested, traceable, and built to last.

Why Quality Control Is Critical for PCB Manufacturing

Unlike many components in the electronics supply chain, PCBs are the foundation of all electrical functionality in a device. Even a minor defect—such as a poor solder connection or microscopic short—can cause device failure, product recalls, or worse, safety hazards. For that reason, choosing a Printed Circuit Board Supplier with a proven quality control system is not just important—it’s mission-critical.

Poorly controlled PCB manufacturing can lead to:

Intermittent circuit failures

Early device breakdowns

Excessive rework costs

Damaged brand reputation

This is why at Pcb-Togo Electronic, Inc., we don’t just manufacture PCBs—we verify and validate every detail throughout the production process.

Our Quality Control Process: Built for Precision

At the core of our operations is a multi-phase quality control framework designed to ensure consistency, compliance, and performance. Our system covers every stage of PCB production, from material sourcing to final delivery.

1. Verified Materials and Supplier Audits

We begin quality control long before production starts. Every PCB at Pcb-Togo Electronic, Inc. starts with certified raw materials. We conduct strict inspections and maintain detailed supplier records to ensure that copper laminates, solder masks, and surface finishes meet global standards.

Regular supplier audits help us track quality at the source. Any vendor that fails to meet our benchmarks is removed from our approved list.

To explore how material quality affects PCB performance, Find Out More on our supplier verification page.

2. In-Process Inspections

Our in-house team conducts detailed inspections at every major production checkpoint:

Etching Accuracy – To prevent shorts or open circuits

Layer Alignment – Verified via X-ray scanning for multilayer boards

Hole Wall Quality – Assessed with microsectioning techniques

Solder Mask Integrity – Checked for uniform thickness and absence of bubbles

These real-time evaluations prevent defects from carrying forward, saving both time and cost. This proactive approach distinguishes us as a forward-thinking Printed Circuit Board Supplier.

3. Final Electrical Testing

No PCB leaves our facility without undergoing 100% electrical testing. Each board is verified for:

Continuity

Shorts

Component placement (if assembly is included)

Whether you're producing high-frequency boards or standard FR4 circuits, this final validation ensures that your boards will perform flawlessly in your application.

If you're curious about our advanced testing procedures, you can find out more by contacting our engineering team or viewing our testing guidelines online.

4. Strict Packaging & ESD Protection

Even after production, PCBs must be handled with care. Our packaging process includes:

Moisture barrier bags

ESD foam and shielding

Vacuum sealing for long-distance shipments

Each order is labeled for traceability, allowing clients to track batch origin, production data, and inspection results. This complete chain-of-custody approach ensures that your PCBs arrive in top condition—no matter where in the world you are.

For more on logistics and shipping support, go right here to our delivery resource center.

Continuous Quality Improvement (CQI)

Being a Printed Circuit Board Supplier means constantly adapting to evolving industry standards and customer requirements. At Pcb-Togo Electronic, Inc., we use data from inspections and customer feedback to refine our production lines. Our engineers regularly review:

First-pass yield rates

Customer return data

Root cause analyses

This commitment to Continuous Quality Improvement helps us remain flexible and responsive, while maintaining high yield rates and low defect percentages.

Why Choose Pcb-Togo Electronic, Inc.?

With over two decades of experience, we are a leading Printed Circuit Board Supplier known for our ability to deliver reliable, high-performance boards at competitive prices. What sets us apart is our end-to-end commitment to quality—from the raw copper to the final shipment box.

Clients from industries such as medical, automotive, aerospace, and consumer electronics trust us for:

Fast lead times

Transparent communication

Flexible order quantities

Proven reliability

When you partner with Pcb-Togo Electronic, Inc., you’re choosing a supplier that backs every board with traceability, testing, and total accountability.

Final Thoughts

Selecting a reliable Printed Circuit Board Supplier is essential to the long-term success of any electronics product. At Pcb-Togo Electronic, Inc., quality isn’t a department—it’s the DNA of our entire operation. From stringent inspections and automated testing to supplier audits and proactive improvement, we take every step necessary to ensure our PCBs are ready for real-world performance.

If you’re ready to raise the bar for your electronics production, Find Out More by speaking with our technical experts or requesting a custom quote today.

Original Link: https://pcbtogo.blogspot.com/2025/06/quality-control-standards-for-printed.html

0 notes

Text

Modern Product Lifecycle Management Isn’t Just for Tech Anymore

Product lifecycle management (PLM) is often pigeonholed into the IT world—but at 3R Technology, we've taken a broader view. We’re not just handling end-of-life laptops. We're navigating the full arc of a product's journey, from surplus to second life, across industries.

Whether you’re clearing out a lab, liquidating manufacturing equipment, or streamlining your inventory strategy, our model is built to unlock value from the unexpected.

The Engine Behind the Recovery: What Sets Us Apart

Multi-Channel Sales Reach We don’t rely on just one outlet to remarket your products. Through our established multi-channel sales platform, we cast a wide net to capture the best possible value for every item, whether it’s a server rack or a surplus microscope.

A Broker Network That Works Our extensive broker network gives us access to niche buyers and markets that typical resale channels overlook. That means more eyes on your assets and better returns at the end of the line.

Decades of Tactical Sales Expertise We bring technical sales acumen that’s been refined over decades. Our team knows how to position, price, and place your inventory for optimal results, no matter the product category.

What We Remarket

At 3R Technology, the word “remarket” isn’t limited to tech. Here’s a snapshot of what we handle:

IT equipment and electronics

Laboratory instruments

Industrial and manufacturing machinery

Surplus components and unused inventory

Return logistics materials

Office furniture and fixtures

If you can box it, pallet it, or roll it out—chances are, we can find it a buyer.

More Than Sales: A Full-Service PLM Solution

It’s not just about selling. It’s about strategy.

Our team provides a suite of services that takes the pressure off your internal operations:

Logistics Management: From pickups to drop-offs, we’ve got it covered.

Onsite Project Management: We manage removals and asset transitions with minimal disruption.

Fulfilment & Warehousing: Need space or storage while assets are staged for sale? We’ve got the infrastructure.

Why It Matters Now

In a market defined by agility, every piece of idle inventory represents lost opportunity. By partnering with 3R Technology, you transform those assets into revenue while meeting sustainability and compliance goals.

We don’t just remarket—we rethink what product lifecycle management can be.

In today’s competitive environment, assets that sit idle aren’t just collecting dust—they're collecting costs. At 3R Technology, our Product Lifecycle Management (PLM) service is engineered to recover value from equipment, inventory, and materials across every sector, not just IT.

Our model is built on decades of technical sales knowledge, a high-performing broker network, and an infrastructure that supports resale, removal, and redistribution. From electronics to office furniture, we find a second life for almost anything.

Here’s a closer look at how we make it happen.

Components

Whether brand new, unused, or removed from equipment, electronic components often retain significant value. Rather than letting these items go to waste in storage, we remarket them through targeted sales channels that reach the right buyers—engineers, refurbishers, and niche manufacturers.

From semiconductors and circuit boards to power supplies and cabling, we handle the resale process end-to-end, ensuring return value on even the smallest components.

Return Logistics

Returns are part of business, but they don’t have to be a loss. Our return logistics service manages everything from reverse shipping coordination to item processing, evaluation, and resale.

Whether you’re managing high-volume returns or dealing with one-off speciality items, we step in to streamline operations and ensure assets are re-integrated into the value chain, not discarded

Surplus Inventory

Excess stock is common across industries, especially when forecasts shift or production slows. Letting surplus sit on shelves isn’t a viable strategy and liquidation doesn’t have to mean giving it away.

We specialise in remarketing surplus inventory, from packaging materials and raw components to finished goods. Our multi-channel sales platform and broad broker reach allow us to find buyers in secondary and tertiary markets where demand still exists.

Office Furniture

Office downsizing, renovations, or closures often result in a flood of used furniture, most of which still has life left. Rather than pay for removal and disposal, organisations can turn to us to remarket these assets.

We handle everything: assessment, pickup, storage, and resale. From desks and chairs to conference tables and filing systems, office furniture is a viable resale category that too often gets overlooked.

Manufacturing Excess

Unused production equipment and over-ordered supplies tie up capital and space. We help manufacturers offload machinery, tools, and materials through proven resale channels that maximise return.

Our team understands the complexity of manufacturing environments and provides tailored support from on-site project management and equipment removal to warehousing and fulfilment.

We Handle the Rest, Too

Logistics, fulfilment, storage, resale, and reporting—we handle every phase so your team doesn’t have to. Whether you’re managing an asset disposition project or clearing out a facility, we act as a single point of contact for full-service product lifecycle management.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

What Could The Future Of The Air Purification Industry Look Like In 2025?

Discover the revolutionary changes transforming how we breathe, live, and thrive in cleaner indoor environments.

The air purification industry stands at the threshold of extraordinary transformation. As we enter 2025, the convergence of cutting-edge technology, heightened health awareness, and environmental consciousness is reshaping how we think about indoor air quality. The pandemic fundamentally altered our relationship with the air we breathe, turning what was once an invisible concern into a tangible priority for millions of households and businesses worldwide.

Modern consumers no longer view air purifiers as luxury items—they're essential guardians of respiratory health. The industry that once catered to a niche market of allergy sufferers has evolved into a multi-billion-dollar ecosystem serving diverse needs, from wildfire smoke protection to comprehensive indoor air quality management. This transformation represents more than technological advancement; it's a paradigm shift toward proactive health protection.

Expert consultants with decades of experience, like those who have tested over 100 different air purification solutions across 50+ brands, are witnessing unprecedented innovation. The future promises solutions that are smarter, more efficient, and remarkably intuitive. These aren't just machines that filter air—they're sophisticated systems that understand, adapt, and optimize the very atmosphere of our living spaces.

Smart Integration: AI-Powered Air Quality Management

The future of air purification lies in artificial intelligence that learns your breathing patterns, predicts air quality challenges, and responds before you even notice a problem. Imagine walking into your home as your air purifier automatically adjusts its intensity based on real-time outdoor air quality data, your daily schedule, and even your health metrics from wearable devices.

These intelligent systems will seamlessly integrate with smart home ecosystems, communicating with HVAC systems, weather stations, and health monitoring devices. Machine learning algorithms will analyze years of data to provide personalized air quality recommendations, ensuring optimal indoor environments for specific health conditions like asthma and allergies.

The most exciting development is predictive air quality management. Advanced sensors will detect microscopic changes in air composition hours before they become noticeable, automatically initiating purification protocols. This proactive approach transforms air purifiers from reactive appliances into preventive health tools that safeguard respiratory wellness before problems arise.

Professional air quality consultants are already seeing prototypes that combine atmospheric science with consumer convenience. These systems don't just clean air—they create personalized breathing environments tailored to individual health profiles, lifestyle patterns, and environmental sensitivities.

Revolutionary Filter Technologies: Beyond HEPA

While HEPA filters revolutionized air purification, 2025 brings technologies that make traditional filtration seem primitive by comparison. Molecular-level purification systems are emerging that capture particles smaller than viruses, neutralize chemical vapors in real-time, and even eliminate odors at their source through advanced photocatalytic oxidation.

Nanotechnology is creating filters with self-regenerating capabilities, dramatically extending their lifespan while maintaining peak performance. These revolutionary materials can capture pollutants with unprecedented efficiency while requiring minimal maintenance—a game-changer for busy households and commercial applications.

Breakthrough developments in atmospheric plasma technology are enabling purifiers to destroy contaminants rather than simply trapping them. This approach eliminates the need for frequent filter replacements while providing continuous, maintenance-free air purification that adapts to changing environmental conditions automatically.

The integration of biomimetic filtration—inspired by natural processes like how trees purify air—is creating systems that work in harmony with indoor ecosystems. These technologies don't just remove harmful particles; they enhance air quality by replicating nature's purification mechanisms, creating healthier, more balanced indoor environments.

Health-Focused Innovation: Medical-Grade Home Solutions

The line between medical devices and consumer air purifiers is rapidly disappearing. 2025 brings medical-grade air purification systems designed specifically for home use, offering hospital-level air quality in residential settings. These systems target specific health conditions with precision that would have been unimaginable just a few years ago.

For individuals with respiratory conditions, next-generation purifiers will provide therapeutic air environments customized to their specific needs. Advanced systems will monitor biomarkers in exhaled breath, adjusting purification parameters to optimize respiratory health and potentially detect early signs of health issues before symptoms appear.

Allergy and asthma sufferers will benefit from purifiers that identify and eliminate specific allergens with surgical precision. These systems will maintain detailed logs of air quality improvements, providing valuable data for healthcare providers to optimize treatment plans and track recovery progress.

The most promising development is the emergence of the best air purifiers for asthma and allergies that combine multiple therapeutic approaches. These comprehensive systems address not just particulate matter but also humidity control, negative ion generation, and circadian rhythm support to create holistic wellness environments.

Sustainable Solutions: Green Technology for Clean Air

Environmental consciousness is driving a sustainability revolution in air purification. 2025 marks the widespread adoption of eco-friendly purifiers that operate with minimal energy consumption while delivering maximum performance. Solar-powered systems, biodegradable filters, and carbon-neutral manufacturing processes are becoming industry standards rather than exceptions.

Innovative companies are developing air purifiers from recycled materials and designing systems for complete recyclability at end-of-life. These circular economy approaches ensure that improving indoor air quality doesn't come at the expense of environmental health, creating a harmonious balance between personal wellness and planetary responsibility.

The most exciting sustainable innovations include purifiers that actively contribute to environmental health by capturing and storing carbon dioxide, effectively turning every home into a micro carbon sink. These systems represent the ultimate fusion of personal health benefits with positive environmental impact.

Energy efficiency has reached new heights with purifiers that operate on less power than a smartphone charger while delivering air quality improvements that surpass traditional high-energy systems. This efficiency revolution makes comprehensive air purification accessible to environmentally conscious consumers without compromising performance or sustainability principles.

Commercial and Educational Applications: Institutional Evolution

Schools, offices, and healthcare facilities are embracing next-generation air purification systems that go far beyond basic filtration. 2025 brings integrated solutions that monitor air quality across entire buildings, automatically adjusting to occupancy levels, activities, and external environmental conditions with remarkable sophistication.

Educational institutions are implementing air quality systems that enhance cognitive performance by maintaining optimal oxygen levels and eliminating distractions caused by poor air quality. These systems create learning environments where students can focus better, think more clearly, and achieve improved academic outcomes through superior indoor air quality.

Corporate wellness programs increasingly include comprehensive air quality management as a core component of employee health initiatives. Advanced purification systems in workplaces are reducing sick days, improving productivity, and creating healthier work environments that attract and retain top talent in competitive markets.

Healthcare facilities are adopting purification technologies that provide additional layers of protection against airborne pathogens while creating healing environments that accelerate patient recovery. These systems represent the convergence of medical science and environmental engineering to support optimal health outcomes.

Accessibility and Affordability: Democratizing Clean Air

Perhaps the most significant development in 2025 is the democratization of advanced air purification technology. Manufacturing innovations and economies of scale are making sophisticated air quality solutions accessible to families across all income levels, ensuring that clean air becomes a universal right rather than a privilege.

Subscription-based models and air-purification-as-a-service offerings are removing the barrier of upfront costs, allowing families to access premium air quality solutions with minimal initial investment. These programs include regular maintenance, filter replacements, and system upgrades, ensuring optimal performance without additional burden or expense.

Community-based air quality initiatives are emerging where neighborhoods share resources to implement comprehensive air purification systems. These collaborative approaches create cleaner environments for entire communities while making advanced technology affordable through shared investment and collective benefit.

For those seeking professional guidance, learn about air purification from experienced consultants who understand how to navigate the expanding landscape of options. Expert advice ensures that investment in air quality improvement delivers maximum health benefits while respecting budget constraints and specific environmental needs.

Ready to Experience the Future of Clean Air?

Connect with air purification experts who have guided thousands toward healthier indoor environments. With 17 years of experience and expertise across 100+ air purification solutions, we're here to help you find the perfect system for your unique needs.

#air purification 2025#smart air purifiers#HEPA technology#indoor air quality#asthma relief#allergy solutions#clean air future#sustainable purifiers#medical-grade filters#air quality consulting

0 notes

Photo

A just-for-fun post for you today! My son received a microscope this Christmas just gone and while we were playing around with it, finding things to zoom in on, we popped a sleeve cuff under the lens and well, that got me to thinking about doing a deep dive on lingerie fabrics. You can read about how jacquard is woven or how smooth nylon is, but actually seeing it? I found it fascinating, and maybe you will too. Just bear in mind these were all taken on a toy microscope, so the photos it takes aren’t particularly high-resolution. But you can see enough to learn a thing or two, I think. Stockings & tights 5 denier stockings – 100% nylon. These are ultra-fine, ultra-sheer stockings – much finer-weight than what’s typically sold in stores. How is it achieved? As you can see, they’re knit from incredibly smooth, single-filament threads of nylon (which is a type of polyamide) with very large gaps between them. 20 denier stockings – 100% polyamide. These stockings are more opaque than the 5 denier pair, but their individual filaments are actually finer. However, you can see in the closer views that each thread is made up of multiple filaments bundled together for a denser overall effect. Again, the polyamide is completely smooth which is why these types of synthetic-fibre stockings feel so smooth against the skin. Opaque tights – 66% modal, 24% polyamide, 8% cashmere, 2% elastane. There are supposed to be four different fibre types in the mix here but I can’t say I can differentiate them. You can see how these tights would have much more of a soft, ‘fuzzy’ hand than the smooth stockings above. Opaque, sparkly tights – fibre content unknown. Here, although I don’t know the exact fibre contents, I can definitely see three fibre types: the ‘base’ fibre, whatever that is, plus elastane (the clear filaments, also known as spandex) and strips of a flat metallic material woven in for the glittery effect. Tulle, lace & embroidery This is a stretch tulle with a very uniform, geometric appearance. You can see some broken elastane fibres poking out; these miniscule bits of damage are practically invisible to the naked eye but it’s what happens to stretch fabrics over time – they wear out. In this lace, you can more clearly see how the stretchy elastane fibres are woven in with the other threads to give the fabric its flexibility. This is a finer-quality lace, made on an antique Leavers loom in France. Unlike the lace and tulle above, it’s all one fibre – no elastane. It’s also a corded lace, meaning the floral pattern is outlined in a thicker thread for a slightly raised effect; on the right, you can see one of those thicker threads. Here, you can clearly see the colourful embroideries weaving in and out of the tulle backing, which is made from a much finer-weight yarn. Lace and embroidery are not the same thing. Whereas lace is woven/knit/braided into existence from scratch, with embroidery, there is an existing base fabric which the design is embroidered onto. It’s why the majority of lace is a single colour since it would be challenging to switch yarns when you’re using them in one continuous length, whereas it’s common to see multi-coloured embroideries or, as in these examples, an embroidered pattern on a very fine background meant to ‘disappear’ against the skin. Metallic fabrics Metallic lace from my Colette & Sebastian Elise lingerie set. Here’s another example of lace, but one where you can see metallic filaments woven in with the (nylon and elastane) base threads. The gold here isn’t found througout the lace, it’s used to highlight specific floral motifs in the pattern. Metallic lace from my Fréolic London custom bra. This, on the other hand, is an all-over gold lace and the shiny-everywhere effect has been achieved by using nothing but metallic yarn throughout. On the garment, all you see is gold. Under the microscope however you can see that the yarn has an inner core wrapped up in a metallic outer. Interestingly, I noted in the review of this bra set that the lace was prone to unravelling and developed a somewhat messy, frayed look after some wear, and now I understand why! A non-lace example of a metallic fabric, you can see in the review photos linked above that this fabric looks primarily silver. Up close however, you can see that it’s actually mostly black; I’m going to hazard a guess that the thin silver ‘ribbons’ woven through the fabric are the 1% polyester listed in the fabric contents. Silk fabrics, plus a synthetic satin comparison Satin is a type of weave in which the weft (horizontal) yarn passes over multiple warp (verticle) yarns before going under one, and then repeats. It means the top side of the fabric has lots of long, straight lengths of yarn visible, which is what gives the satin its smooth, light-reflecting finish. You can make satin out of different fibres. However, the smoother the fibre type, the smoother (and shinier) the end result. When you take a less-smooth fibre such as cotton and follow this weave pattern, the end result will have a bit of a glossy sheen to it but not to the same extent as when using, say, silk, so it’s generally referred to as sateen instead of satin. Here, you can clearly see that weave structure with long, straight lengths of yarn all going in the same direction. The silk fibres themselves are very smooth. Polyester satin from my L’Agent Marisela bra set. Exact fibre content unknown. This is a synthetic version of satin, but you can see that the weave pattern is the same, and the polyester fibres are also pretty smooth. Under a microscope, I can’t personally tell the different between silk satin and polyester satin (at least based on these two examples). I assume that the reason polyester satin doesn’t have quite the same fluid drape as the silk satin does is because the polyester fibres themselves are more inflexible. Like the silk satin, this fabric is 100% silk. However, you can see that the weave is completely different. While this fabric has a slight lustre if you angle it just right under the light, due to the silk fibres’ own light-reflecting structure, it’s definitely not shiny. Silk chiffon from my La Lilouche Adele & Lana bra set. 100% silk. This is another pure silk fabric, and one that’s not shiny in the slightest. It’s also sheerer than both the solid satin and the slightly-sheer georgette, due to the openness of the weave. So once again: same fibre, different weave, completely different fabric. Plant-based fabrics Left: Cotton jersey from my Mecedora thong. 90% cotton, 10% elastane.Right: Cotton and modal blend jersey from my Love Suze NoHo set. 55% cotton, 40% modal, 5% elastane. This are both stretchy cotton-based jerseys, the red one a mix of cotton and modal (modal is a semi-synthetic fabric made from beech tree pulp). You can see that they have been knit, not woven, and that the general texture is a little fuzzy rather than ultra-smooth. Both of these fabrics have a very soft hand. My Tensengral AMBI bras in 100% Tencel (left) and a Tencel and Supima cotton blend, percentages unknown (right). Both of these fabrics are braided. Tencel, like the modal above, is a semi-synthetic fabric made from wood pulp. Once again, you can see their fuzzy texture under the microscope, even though they don’t look at all fuzzy to the naked eye (in the way that, say, mohair does). Woven linen top. 100% linen. Not lingerie, sorry! I don’t have any linen lingerie (yet… Seelanii’s linen pieces are on my wishlist) but I wanted to include one more example of a plant-based fibre, so you can really see how these tend to have a bit more texture to them compared to the perfect uniformness of many of the synthetics – such as the example just below. Synthetic fibre fabrics This knicker has a very light ribbed texture, and you can see exactly how it’s structured to create that under the microscope. The fabric is 100% synthetic, and look how neat and smooth it all looks compared to the natural or semi-natural fabrics above. As a fabric, it does feel incredibly soft and smooth. Compare this jersey, which is 100% synthetic, to the red Love Suze cotton-blend jersey above, which contains natural fibres. Once again, you can see how the synthetic fibres create a smoother, more uniform surface. They’re both smooth fabrics, but I think the best way to describe the difference is that the synthetic one is the sleekest while the one with natural fibres has a cosier touch. Other fabrics It’s hard to make out what’s going on with velour because it’s a pile fabric (think of a shag rug) and the base weave is hidden beneath that dense abundance of fibres. The right image shows the edge of a hemline. It’s this mass of fine, cut fibres that gives the velour both its thickness and its soft, brushed texture. With jacquard fabrics, rather than a pattern being printed, embroidered or otherwise added onto an existing fabric, a special loom (invented by Joseph Marie Jacquard) weaves in the pattern directly while the fabric is being produced. You can see how the weave here isn’t uniform – there are threads going in all different directions, which will reflect light differently and hence create a visible pattern. You can see the finished result in the image at the very top of this article. I did look at some other materials from within my lingerie collection too (scuba jersey, elastic bra straps, even an organza storage bag…) but I didn’t think they were as interesting. If there’s a particular fabric or fibre type I’ve left out though that you’re curious about, let me know and if I have it, I’ll take a picture and reply to your comment. What did you find most interesting or surprising from these photos? The product recommendations directly above are affiliate links Source link

0 notes

Text

Finelab UK – Educational Science Lab Equipment Manufacturers

Finelab UK is a trusted name in the manufacturing and supply of educational science lab equipment, dedicated to supporting science education at every level. We specialize in providing high-quality, durable, and affordable laboratory equipment for schools, colleges, universities, and training institutes across the UK and globally.

Our product range includes essential lab instruments such as beakers, test tubes, microscopes, Bunsen burners, measuring tools, and safety gear, specifically designed for use in educational environments. At Finelab UK, we understand the importance of hands-on learning, which is why our equipment is built to encourage curiosity, experimentation, and scientific discovery in the classroom.

As leading science lab equipment manufacturer we focus on quality, compliance, and user-friendly design. All our products meet UK and international safety and quality standards. We also offer custom lab setups, helping institutions design complete science labs tailored to their curriculum needs.

With a strong commitment to innovation, customer service, and fast delivery, Finelab UK is the go-to source for reliable educational lab equipment. Join hundreds of satisfied educators and institutions who trust us to equip the next generation of scientists.

#Multi Viewing Microscope#multi viewing microscope supplier#Multi Viewing Microscope in uk#Penta head microscope#Penta head microscope uk#Penta head microscope manufacturer uk#Penta Head Microscopes Manufacturers#Penta Head Microscopes Suppliers#Penta Head Microscopes Exporters#Penta head Multi Viewing Microscope#Penta head Five Headed Multi Viewing Microscope

0 notes

Photo

A just-for-fun post for you today! My son received a microscope this Christmas just gone and while we were playing around with it, finding things to zoom in on, we popped a sleeve cuff under the lens and well, that got me to thinking about doing a deep dive on lingerie fabrics. You can read about how jacquard is woven or how smooth nylon is, but actually seeing it? I found it fascinating, and maybe you will too. Just bear in mind these were all taken on a toy microscope, so the photos it takes aren’t particularly high-resolution. But you can see enough to learn a thing or two, I think. Stockings & tights 5 denier stockings – 100% nylon. These are ultra-fine, ultra-sheer stockings – much finer-weight than what’s typically sold in stores. How is it achieved? As you can see, they’re knit from incredibly smooth, single-filament threads of nylon (which is a type of polyamide) with very large gaps between them. 20 denier stockings – 100% polyamide. These stockings are more opaque than the 5 denier pair, but their individual filaments are actually finer. However, you can see in the closer views that each thread is made up of multiple filaments bundled together for a denser overall effect. Again, the polyamide is completely smooth which is why these types of synthetic-fibre stockings feel so smooth against the skin. Opaque tights – 66% modal, 24% polyamide, 8% cashmere, 2% elastane. There are supposed to be four different fibre types in the mix here but I can’t say I can differentiate them. You can see how these tights would have much more of a soft, ‘fuzzy’ hand than the smooth stockings above. Opaque, sparkly tights – fibre content unknown. Here, although I don’t know the exact fibre contents, I can definitely see three fibre types: the ‘base’ fibre, whatever that is, plus elastane (the clear filaments, also known as spandex) and strips of a flat metallic material woven in for the glittery effect. Tulle, lace & embroidery This is a stretch tulle with a very uniform, geometric appearance. You can see some broken elastane fibres poking out; these miniscule bits of damage are practically invisible to the naked eye but it’s what happens to stretch fabrics over time – they wear out. In this lace, you can more clearly see how the stretchy elastane fibres are woven in with the other threads to give the fabric its flexibility. This is a finer-quality lace, made on an antique Leavers loom in France. Unlike the lace and tulle above, it’s all one fibre – no elastane. It’s also a corded lace, meaning the floral pattern is outlined in a thicker thread for a slightly raised effect; on the right, you can see one of those thicker threads. Here, you can clearly see the colourful embroideries weaving in and out of the tulle backing, which is made from a much finer-weight yarn. Lace and embroidery are not the same thing. Whereas lace is woven/knit/braided into existence from scratch, with embroidery, there is an existing base fabric which the design is embroidered onto. It’s why the majority of lace is a single colour since it would be challenging to switch yarns when you’re using them in one continuous length, whereas it’s common to see multi-coloured embroideries or, as in these examples, an embroidered pattern on a very fine background meant to ‘disappear’ against the skin. Metallic fabrics Metallic lace from my Colette & Sebastian Elise lingerie set. Here’s another example of lace, but one where you can see metallic filaments woven in with the (nylon and elastane) base threads. The gold here isn’t found througout the lace, it’s used to highlight specific floral motifs in the pattern. Metallic lace from my Fréolic London custom bra. This, on the other hand, is an all-over gold lace and the shiny-everywhere effect has been achieved by using nothing but metallic yarn throughout. On the garment, all you see is gold. Under the microscope however you can see that the yarn has an inner core wrapped up in a metallic outer. Interestingly, I noted in the review of this bra set that the lace was prone to unravelling and developed a somewhat messy, frayed look after some wear, and now I understand why! A non-lace example of a metallic fabric, you can see in the review photos linked above that this fabric looks primarily silver. Up close however, you can see that it’s actually mostly black; I’m going to hazard a guess that the thin silver ‘ribbons’ woven through the fabric are the 1% polyester listed in the fabric contents. Silk fabrics, plus a synthetic satin comparison Satin is a type of weave in which the weft (horizontal) yarn passes over multiple warp (verticle) yarns before going under one, and then repeats. It means the top side of the fabric has lots of long, straight lengths of yarn visible, which is what gives the satin its smooth, light-reflecting finish. You can make satin out of different fibres. However, the smoother the fibre type, the smoother (and shinier) the end result. When you take a less-smooth fibre such as cotton and follow this weave pattern, the end result will have a bit of a glossy sheen to it but not to the same extent as when using, say, silk, so it’s generally referred to as sateen instead of satin. Here, you can clearly see that weave structure with long, straight lengths of yarn all going in the same direction. The silk fibres themselves are very smooth. Polyester satin from my L’Agent Marisela bra set. Exact fibre content unknown. This is a synthetic version of satin, but you can see that the weave pattern is the same, and the polyester fibres are also pretty smooth. Under a microscope, I can’t personally tell the different between silk satin and polyester satin (at least based on these two examples). I assume that the reason polyester satin doesn’t have quite the same fluid drape as the silk satin does is because the polyester fibres themselves are more inflexible. Like the silk satin, this fabric is 100% silk. However, you can see that the weave is completely different. While this fabric has a slight lustre if you angle it just right under the light, due to the silk fibres’ own light-reflecting structure, it’s definitely not shiny. Silk chiffon from my La Lilouche Adele & Lana bra set. 100% silk. This is another pure silk fabric, and one that’s not shiny in the slightest. It’s also sheerer than both the solid satin and the slightly-sheer georgette, due to the openness of the weave. So once again: same fibre, different weave, completely different fabric. Plant-based fabrics Left: Cotton jersey from my Mecedora thong. 90% cotton, 10% elastane.Right: Cotton and modal blend jersey from my Love Suze NoHo set. 55% cotton, 40% modal, 5% elastane. This are both stretchy cotton-based jerseys, the red one a mix of cotton and modal (modal is a semi-synthetic fabric made from beech tree pulp). You can see that they have been knit, not woven, and that the general texture is a little fuzzy rather than ultra-smooth. Both of these fabrics have a very soft hand. My Tensengral AMBI bras in 100% Tencel (left) and a Tencel and Supima cotton blend, percentages unknown (right). Both of these fabrics are braided. Tencel, like the modal above, is a semi-synthetic fabric made from wood pulp. Once again, you can see their fuzzy texture under the microscope, even though they don’t look at all fuzzy to the naked eye (in the way that, say, mohair does). Woven linen top. 100% linen. Not lingerie, sorry! I don’t have any linen lingerie (yet… Seelanii’s linen pieces are on my wishlist) but I wanted to include one more example of a plant-based fibre, so you can really see how these tend to have a bit more texture to them compared to the perfect uniformness of many of the synthetics – such as the example just below. Synthetic fibre fabrics This knicker has a very light ribbed texture, and you can see exactly how it’s structured to create that under the microscope. The fabric is 100% synthetic, and look how neat and smooth it all looks compared to the natural or semi-natural fabrics above. As a fabric, it does feel incredibly soft and smooth. Compare this jersey, which is 100% synthetic, to the red Love Suze cotton-blend jersey above, which contains natural fibres. Once again, you can see how the synthetic fibres create a smoother, more uniform surface. They’re both smooth fabrics, but I think the best way to describe the difference is that the synthetic one is the sleekest while the one with natural fibres has a cosier touch. Other fabrics It’s hard to make out what’s going on with velour because it’s a pile fabric (think of a shag rug) and the base weave is hidden beneath that dense abundance of fibres. The right image shows the edge of a hemline. It’s this mass of fine, cut fibres that gives the velour both its thickness and its soft, brushed texture. With jacquard fabrics, rather than a pattern being printed, embroidered or otherwise added onto an existing fabric, a special loom (invented by Joseph Marie Jacquard) weaves in the pattern directly while the fabric is being produced. You can see how the weave here isn’t uniform – there are threads going in all different directions, which will reflect light differently and hence create a visible pattern. You can see the finished result in the image at the very top of this article. I did look at some other materials from within my lingerie collection too (scuba jersey, elastic bra straps, even an organza storage bag…) but I didn’t think they were as interesting. If there’s a particular fabric or fibre type I’ve left out though that you’re curious about, let me know and if I have it, I’ll take a picture and reply to your comment. What did you find most interesting or surprising from these photos? The product recommendations directly above are affiliate links Source link

0 notes

Text

Eva Jospin

“My forests are conducive to mental escapism.”

For the last fifteen years, Eva Jospin has been sculpting and working with cardboard, her preferred material, that is poor and available in abundance.

Cardboard also interests her because of its multi-layered composition. She shapes it through precise cutting, assembling densely-packed volumes to create a back-and-forth between microscopic and monumental views.

The artist sculpts the material to create forests, gardens, cavos and nymphaea - landscapes that take us on a journey from reality to the imaginary.

P This monumental work is currently on display on level 4 - central aisle!

Eva Jospin « Forêt » 2024

© Adagp, Paris. Photo : Centre Pompidou

#evajospin #forest #CentrePompidou

#ContemporaryArt

0 notes

Text

Bridging Science and Technology: The Benefits of Integrating Histology, Imaging, and Modeling Analysis Services

In the modern landscape of research and development, the integration of multidisciplinary services has become vital for advancing innovation and precision. Among the most transformative approaches is the seamless fusion of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services. This integration not only enhances scientific discovery but also accelerates the development of new materials, medical devices, and treatment strategies by providing a deeper, more holistic understanding of structure-function relationships.

The Role of Histology and Imaging Analysis in Research

Histology, the study of the microscopic structure of tissues, has long been a cornerstone in biomedical and materials research. When combined with advanced imaging technologies such as MRI, CT, and high-resolution microscopy, Histology and Imaging Analysis Services offer unmatched insights into both biological and synthetic samples. These services allow researchers to visualize internal structures with incredible detail, revealing critical information about cellular organization, material porosity, structural integrity, and the impact of various treatments or environmental conditions.

Modern imaging techniques like confocal microscopy, scanning electron microscopy (SEM), and micro-CT scanning provide three-dimensional views of tissues and materials. These detailed visualizations are essential in fields ranging from regenerative medicine and cancer research to biomaterials development and forensic science. Integrating histological data with imaging tools enables the quantification of complex biological processes, such as inflammation, fibrosis, and angiogenesis, and offers visual validation for computational models.

Modeling Analysis Services: Predictive Power Meets Real-World Application

Where imaging and histology offer rich descriptive data, Modeling Analysis Services contribute by simulating and predicting behavior under various conditions. These services involve computational techniques like finite element analysis (FEA), computational fluid dynamics (CFD), and multi-scale modeling to predict how materials or biological tissues respond to mechanical forces, thermal changes, or biochemical interactions.

In engineering and biomedical contexts, modeling can significantly reduce development costs and time. For example, instead of physically testing a prosthetic design across dozens of prototypes, researchers can simulate performance under different loads and anatomical conditions. This accelerates iteration and ensures that the final product is safer and more efficient.

When paired with imaging data, modeling becomes even more powerful. Structural information from MRI or micro-CT scans can be fed directly into computational models to create anatomically accurate simulations. This synergy enables patient-specific modeling in healthcare and precision engineering in materials science.

Enhancing Materials Research Through Integration

Materials Testing Services traditionally involve mechanical testing, thermal analysis, and chemical durability assessments. These tests are crucial for understanding how materials behave in real-world applications, from aerospace components to biodegradable implants. However, these macroscopic tests are greatly enhanced when integrated with microscopic analysis and computational modeling.

For instance, mechanical testing might reveal that a composite material fails under repeated stress. Histological and imaging analysis could then identify internal microfractures or porosity responsible for the failure, while modeling services could simulate stress distributions to predict future performance. This comprehensive view allows scientists and engineers to not only diagnose problems but also design more robust solutions.

In biomaterials research, where new materials are designed to interact with biological systems, integration is even more essential. Testing a new polymer for use in vascular grafts, for example, requires understanding both mechanical resilience and biological compatibility. Imaging can show tissue integration, histology can assess immune response, and modeling can simulate fluid flow within the graft—all contributing to a faster, more effective development process.

Advantages of an Integrated Approach

The convergence of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services delivers a number of strategic advantages:

Comprehensive Insight: Combining macro and micro-scale data with predictive modeling creates a 360-degree view of the system under study.

Reduced Time to Market: By identifying problems earlier and optimizing designs virtually, development cycles are shortened.

Cost Efficiency: Integrated approaches reduce the need for extensive physical prototyping and repeated trial-and-error testing.

Improved Accuracy: Real data from imaging and histology enhances the precision of computational models, resulting in more reliable predictions.

Interdisciplinary Collaboration: This model fosters teamwork between biologists, engineers, data scientists, and material scientists, driving innovation across fields.

Applications Across Industries

The benefits of this integrated analytical approach span a wide array of industries:

Healthcare & Medicine: From designing personalized implants to evaluating drug delivery systems, the combination of histological evaluation, imaging, and modeling ensures safer and more effective medical solutions.

Pharmaceuticals: Drug efficacy and toxicity can be better understood with histological studies, visualized through imaging, and predicted via pharmacokinetic models.

Aerospace & Automotive: Advanced materials are tested for extreme conditions, with failure analysis supported by imaging and stress modeling.

Environmental Science: Materials used in environmental applications, such as biodegradable plastics or filtration membranes, benefit from multi-level analysis to ensure performance and safety.

Conclusion

As science and technology continue to evolve, the demand for comprehensive, accurate, and efficient analysis methods is greater than ever. The integration of Histology and Imaging Analysis Services, Modeling Analysis Services, and Materials Testing Services represents a powerful paradigm shift in how researchers approach complex problems. This fusion allows for deeper understanding, quicker innovation, and more reliable outcomes across both scientific research and industrial applications.

By bridging these disciplines, organizations and institutions can remain at the forefront of discovery—unlocking new capabilities, solving old problems in novel ways, and driving the next generation of scientific and technological advancement.

0 notes