#NDT Inspection

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development,Total quality management.Vendor pre evaluation, Inspection and Expediting Services,Pre-Shipment Inspection,NDT inspection and testing like Radiography and many more.

For more details please visit our website-

0 notes

Text

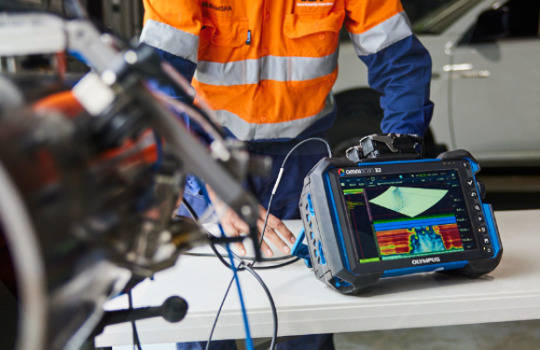

Ultrasonic Testing in Pune: Comprehensive NDT Inspection Services by Integrated NDE

When it comes to ensuring the integrity and safety of materials and structures, ultrasonic testing stands out as one of the most reliable methods. Integrated NDE, a leading NDE company in Pune, offers state-of-the-art ultrasonic testing services designed to meet the stringent demands of various industries.

What is Ultrasonic Testing?

Ultrasonic testing (UT) is a form of Non-Destructive Testing (NDT) that utilizes high-frequency sound waves to detect flaws, measure thickness, and evaluate material properties without causing damage. This method is particularly effective for inspecting welds, castings, and forgings, making it a critical component of any comprehensive NDT inspection process.

Why Choose Ultrasonic Testing?

Ultrasonic testing is highly accurate and versatile, capable of detecting both surface and subsurface defects. It is widely used in industries such as construction, manufacturing, and aerospace, where safety and precision are paramount.

At Integrated NDE, we employ advanced ultrasonic NDT techniques and equipment, including ultrasonic thickness testers, to provide detailed assessments of materials. Our team of experts ensures that every inspection is carried out with the utmost precision, delivering reliable results that help you maintain the highest standards of quality and safety.

NDT Testing Services Near You

For businesses in Pune and the surrounding areas, finding reliable NDT testing near me is crucial. Integrated NDE offers a wide range of non-destructive testing (NDT) services, including ultrasonic testing. Our ultrasonic testing services near me are designed to meet the needs of industries looking for accurate, efficient, and cost-effective solutions.

Benefits of Choosing Integrated NDE

Local Expertise: As a leading NDE company in Pune, we understand the specific needs of our clients and provide tailored solutions to meet those needs.

Advanced Equipment: We use the latest technology in ultrasonic NDT, ensuring precise and reliable results.

Comprehensive Services: From ultrasonic testing to other forms of NDT inspection, we offer a full suite of services to cover all your non-destructive testing needs.

Conclusion

For businesses in Pune seeking reliable and accurate ultrasonic testing services, Integrated NDE is the go-to solution. With our expert team, advanced equipment, and commitment to quality, we ensure that your materials and structures meet the highest safety standards. Contact us today to learn more about how our ultrasonic testing and other NDT services can benefit your operations.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

AG Price Fabrication Shop | Experienced Metal Fabrication in New Zealand

AG Price Fabrication Shop offers a wide range of metal fabrication services for various industries. Their experienced fitters can weld, stress relieve, and perform NDT inspections on-site. They have a long history and a variety of equipment to meet your needs.to know more please visit us for more details: https://www.agprice.co.nz/fabrication-shop

#mining industry#foundry#metal fabrication New Zealand#fabrication shop Auckland#welding services New Zealand#NDT inspection#metal fabrication#custom metal fabrication#metal fabrication company#fabrication workshop#stainless steel fabrication#steel fabrication#aluminum fabrication

0 notes

Text

Integrated NDE Solution in Pune: Excellence in Non-Destructive Testing with Liquid Penetrant Inspection

In industries where the integrity and reliability of materials are critical, non-destructive testing (NDT) is an essential practice. Among the various NDT methods, liquid penetrant testing (LPT) stands out for its effectiveness in detecting surface defects in non-porous materials. Integrated NDE Solution in Pune excels in providing comprehensive NDT testing services, with a specialized focus on liquid dye penetrant testing. This article delves into the intricacies of liquid penetrant testing, highlights its benefits, and explores the cutting-edge services and equipment offered by Integrated NDE Solution.

Understanding Liquid Penetrant Testing

Liquid penetrant testing, also known as dye penetrant inspection, is a widely used non-destructive testing method for detecting surface-breaking defects in non-porous materials. This technique is applicable to a variety of materials, including metals, ceramics, and plastics. LPT is renowned for its simplicity, cost-effectiveness, and high sensitivity in revealing surface discontinuities such as cracks, seams, and porosity.

How Liquid Penetrant Testing Works

The process of liquid penetrant testing involves several steps:

Surface Preparation: The surface of the component is thoroughly cleaned to remove any dirt, grease, or other contaminants that could obstruct the penetrant from entering defects.

Application of Penetrant: A visible or fluorescent dye penetrant is applied to the surface of the component. The penetrant is allowed to dwell for a specific period, during which it seeps into any surface-breaking defects.

Excess Penetrant Removal: After the dwell time, the excess penetrant is removed from the surface, typically using a solvent or water rinse, leaving penetrant only in the defects.

Application of Developer: A developer is applied to draw the penetrant out of the defects, creating a visible indication on the surface. The developer can be dry powder, water-soluble, or solvent-based.

Inspection: The component is inspected visually under appropriate lighting conditions. If fluorescent penetrant is used, ultraviolet (UV) light is used to enhance the visibility of the indications.

Post-Cleaning: After inspection, the component is cleaned to remove the developer and any remaining penetrant.

Benefits of Liquid Penetrant Testing

High Sensitivity: Capable of detecting very small surface defects.

Versatility: Applicable to a wide range of materials and shapes.

Cost-Effective: Relatively low cost compared to other NDT methods.

Simple and Quick: Easy to apply and interpret results, providing immediate feedback.

Non-Destructive: Does not damage or alter the component being inspected.

Integrated NDE Solution in Pune: Pioneers in NDT Testing

Integrated NDE Solution in Pune is a leader in the field of non-destructive testing, offering a broad spectrum of NDT services, including liquid penetrant testing. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable inspection services.

Comprehensive NDT Services Offered

Liquid Penetrant Testing (LPT)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Eddy Current Testing (ECT)

Visual Inspection (VI)

Industries Served

Integrated NDE Solution in Pune serves a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Manufacturing: Ensuring the quality of machined parts.

Oil and Gas: Inspecting pipelines and equipment to prevent leaks and failures.

Liquid Penetrant Testing in Action

Case Study: Aerospace Component Inspection

In the aerospace industry, the reliability of components is paramount. Integrated NDE Solution was approached by a leading aerospace manufacturer to inspect turbine blades using liquid penetrant testing. The process revealed fine surface cracks that were undetectable by other methods, allowing for timely intervention and ensuring the safety and reliability of the components.

Case Study: Automotive Weld Testing

A major automotive manufacturer required thorough inspection of welds in chassis components. Integrated NDE Solution employed LPT to detect any surface defects in the welds. The inspection uncovered several areas with minor cracks and porosity, which were subsequently addressed, ensuring the structural integrity of the vehicles.

Advanced Liquid Penetrant Testing Equipment

Integrated NDE Solution in Pune utilizes the latest liquid penetrant testing equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Visible Dye Penetrants: Used for regular inspections where visibility under normal light is sufficient.

Fluorescent Dye Penetrants: Used for enhanced visibility under UV light, allowing for more precise detection of defects.

Automated Penetrant Systems: Suitable for high-volume inspections, these systems provide consistent and repeatable results.

Portable Penetrant Kits: Ideal for field inspections, these kits offer flexibility and ease of use.

The Role of Certified Technicians

The effectiveness of liquid penetrant testing largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it's a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in liquid penetrant testing. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in liquid penetrant testing and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in liquid penetrant testing, non-destructive inspection, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

#non destructive testing#ndt testing#ndt inspection#non destructive inspection#liquid penetrant testing#penetrant testing#liquid dye penetrant testing

0 notes

Text

Dolphitech's innovative Non Destructive Inspection technologies redefine quality assurance, offering efficient, versatile solutions for safeguarding aerospace assets.

0 notes

Text

Magnetic particle inspection PDF , e-book and handbook

👇

https://jobandcareer.in/magnetic-particle-testing-pdf-and-book/

#nondestructivetesting #NDT #ndtjobs #nondestructive #magneticparticletesting #magneticfield #MPI #mpitest #qualityassurance #qualitycontrol #ndttechnician #ndtcourse #ndttesting #ndtinspection #ndttraining #ndtinspector

#non destructive testing#ndtexamination#nondestructiveinspection#ndt inspection#ndt jobs#ndt inspector

0 notes

Link

Rt testing or Radiographic Testing is a nondestructive inspection technique used for materials failure analysis investigation in different industries including oil, gas and Aerospace Industries. Learn more from here :

0 notes

Text

Enhance Safety with Professional Penetrant Inspection Services

Protect your equipment and components with MyNDT’s professional Penetrant Inspection. Our non-destructive testing method efficiently identifies surface defects, such as cracks and leaks, in non-porous materials. Trust our certified technicians to provide clear, accurate results that help you stay ahead of potential failures.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndttraining#ndt#non destructive entry#business#services#Penetrant Inspection

0 notes

Text

Third Party Inspection/NDT services In India

AV Engineers provides inspection to business organizations in plants & machinery (Solar, Cement, Sugar, chemical and Pharmaceuticals), power generation, marines, oil, gas, Petroleum installations, Pressure vessels, Boilers, Heat Exchangers and site inspections We also provide inspection services for power cables, transformers. our services include Vendor Development, Total quality management. Vendor pre-evaluation, Inspection and Expediting Services,Pre-Shipment Inspection, NDT inspection and testing like Radiography and many more.

For more details, please visit our website-

https://avengineersefp.com/service/third-party-inspection-ndt-services/

0 notes

Text

Ultrasonic Testing in Pune by Integrated NDE Solution Company: Your Trusted NDT Partner

Introduction

In the modern industrial landscape, ensuring the integrity and safety of materials and components is paramount. Non-destructive testing (NDT) plays a crucial role in maintaining these standards, with ultrasonic testing being one of the most effective and reliable methods. Integrated NDE Solution Company, based in Pune, offers a comprehensive range of ultrasonic testing services that cater to various industries. Whether you are searching for NDT testing near me or require specialized ultrasonic testing services, Integrated NDE Solutions is your go-to partner for all your inspection needs.

The Importance of Ultrasonic Testing in NDT

Ultrasonic testing is a non-invasive inspection technique that uses high-frequency sound waves to detect imperfections or changes in material properties. This method is widely used across industries such as aerospace, automotive, construction, and manufacturing due to its accuracy and ability to provide detailed information about the internal structure of a material.

Integrated NDE Solution Company excels in providing ultrasonic testing services that are critical for ensuring the safety and longevity of various components. From detecting flaws in welds to measuring material thickness, our ultrasonic testing services are designed to meet the highest industry standards.

Why Choose Integrated NDE Solution Company?

When it comes to NDT inspection and ultrasonic testing, choosing the right service provider is crucial. Integrated NDE Solution Company stands out for several reasons:

Expertise in Ultrasonic Testing: Our team of experienced professionals is well-versed in the latest ultrasonic testing techniques, ensuring accurate and reliable results every time.

Advanced Equipment: We use state-of-the-art ultrasonic testing equipment, including ultrasonic thickness testers and specialized ultrasonic NDT devices, to provide precise measurements and detect even the smallest defects.

Comprehensive Services: Whether you need ultrasonic testing in Pune or are looking for ultrasonic testing services near me, we offer a wide range of services tailored to meet the specific needs of each client.

Commitment to Quality: At Integrated NDE Solution Company, quality is our top priority. We adhere to strict industry standards and protocols to ensure that our NDT inspections are of the highest quality.

Applications of Ultrasonic Testing

Ultrasonic testing is versatile and can be applied to a wide range of materials and components. Some of the key applications include:

Weld Inspection: Ultrasonic testing is widely used for inspecting welds to detect flaws such as cracks, voids, and inclusions. This is critical in industries where the integrity of welded joints is paramount, such as in pipeline construction, shipbuilding, and aerospace.

Thickness Measurement: Using an ultrasonic thickness tester, we can accurately measure the thickness of materials, including metals, plastics, and composites. This is essential for determining the remaining life of components and ensuring that they meet the required specifications.

Flaw Detection: Ultrasonic testing is highly effective in detecting internal flaws such as cracks, voids, and inclusions in materials. This helps in preventing catastrophic failures and ensuring the safety of components.

Corrosion Mapping: Ultrasonic testing can be used to map the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing in Pune

As a leading provider of ultrasonic testing in Pune, Integrated NDE Solution Company is proud to serve a wide range of industries in the region. Pune is a hub for manufacturing, automotive, and engineering industries, all of which require reliable NDT inspection services to ensure the safety and integrity of their products.

Our ultrasonic testing services in Pune are designed to meet the specific needs of each industry. Whether you are looking for routine inspections or require specialized testing for critical components, our team is equipped to handle it all.

Non-Destructive Testing Near Me

If you are searching for non-destructive testing near me, look no further than Integrated NDE Solution Company. We offer a comprehensive range of NDT services, including ultrasonic testing, that are designed to provide accurate and reliable results.

Our NDT services are available to clients across Pune and the surrounding regions. We understand the importance of timely and efficient inspections, which is why we strive to provide our services with minimal disruption to your operations.

Ultrasonic NDT: A Closer Look

Ultrasonic NDT is a specialized form of non-destructive testing that uses high-frequency sound waves to inspect materials and components. This method is highly effective in detecting internal flaws and measuring material thickness, making it an essential tool for ensuring the safety and integrity of various components.

At Integrated NDE Solution Company, we offer a wide range of ultrasonic NDT services, including:

Flaw Detection: Our ultrasonic NDT services are designed to detect internal flaws in materials, including cracks, voids, and inclusions. This helps in preventing catastrophic failures and ensuring the safety of components.

Thickness Measurement: Using advanced ultrasonic equipment, we can accurately measure the thickness of materials, ensuring that they meet the required specifications.

Weld Inspection: Our ultrasonic NDT services are widely used for inspecting welds to detect flaws and ensure the integrity of welded joints.

Corrosion Mapping: We offer ultrasonic corrosion mapping services to help identify the extent of corrosion in materials, providing valuable information for maintenance and repair decisions.

Ultrasonic Testing Services Near Me

For those in search of ultrasonic testing services near me, Integrated NDE Solution Company offers a comprehensive range of services that are tailored to meet the specific needs of each client. Our team of experienced professionals is equipped with the latest ultrasonic testing equipment, ensuring accurate and reliable results every time.

Whether you need ultrasonic testing for weld inspection, thickness measurement, or flaw detection, our team is here to help. We offer our services to clients across Pune and the surrounding regions, providing timely and efficient inspections that meet the highest industry standards.

The Future of Ultrasonic Testing

As technology continues to evolve, so too does the field of ultrasonic testing. Integrated NDE Solution Company is committed to staying at the forefront of these advancements, continually investing in the latest equipment and training for our team.

One of the key trends in ultrasonic testing is the development of advanced imaging techniques, such as phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD). These techniques offer higher resolution images and more accurate defect detection, making them invaluable tools for NDT inspections.

In addition, there is a growing trend towards the use of automated ultrasonic testing systems, which can provide faster and more consistent results. At Integrated NDE Solution Company, we are exploring these advancements to ensure that we continue to provide our clients with the most accurate and reliable ultrasonic testing services available.

Conclusion

Ultrasonic testing is a critical component of non-destructive testing, offering accurate and reliable results for a wide range of applications. Whether you are looking for NDT inspection services, ultrasonic testing in Pune, or ultrasonic testing services near me, Integrated NDE Solution Company is your trusted partner for all your NDT needs.

With our expertise, advanced equipment, and commitment to quality, we are well-equipped to handle all your ultrasonic testing requirements. Contact us today to learn more about our services and how we can help ensure the safety and integrity of your materials and components.

#nde company#ndt inspection#ndt testing near me#non destructive testing near me#ultrasonic testing#ultrasonic testing in pune#ultrasonic testing ndt#ultrasonic thickness tester#ultrasonic ndt#ultrasonic testing services near me

0 notes

Text

Unmatched NDT Inspection Services in Dubai by Falcon Laboratory LLC

Falcon Laboratory LLC offers the best NDT inspection services in Dubai, ensuring precise and reliable testing for various industries. Our advanced non-destructive testing methods guarantee safety, quality, and compliance, making them a trusted partner for all your inspection needs in the UAE.

Know More: https://www.falconlabuae.com/ndt-services/

0 notes

Text

In industries where structural integrity and material reliability are paramount, non-destructive testing (NDT) methods play a critical role. MPI machine manufacturers specialize in producing advanced equipment for Magnetic Particle Inspection, enhancing non-destructive testing by detecting surface and subsurface defects in ferromagnetic materials across various industries. Magnatech RMC is a leading MPI machine manufacturers, specializing in advanced Magnetic Particle Inspection equipment. Their cutting-edge solutions enhance non-destructive testing by accurately detecting surface and subsurface defects in ferromagnetic materials, ensuring reliability across various industries.

#mpi machine#mpi machine manufacturer#crack check machine#magnetic crack detector machine#mpi machine supplier#ndt inspection machine#demagnetizer machine#business#magnaflux machine

0 notes

Text

Dolphitech's advanced NDT testing solutions revolutionize defense and aviation safety with precise ultrasonic inspection technology, ensuring mission-critical assets meet stringent standards

#ndt testing#NDT Inspection#Non Destructive Evaluation#Non Destructive Testing#Non Destructive Inspection#ndt ultrasonic testing

0 notes

Text

#ultrasonic testing#nondestructiveinspection#non destructive testing#nondestructive#ndt inspection#ndttechnician#ndt inspector#ndt jobs#ndtexamination

0 notes

Text

The Value of Advanced NDT Techniques in Tube Inspection

Ensuring the optimal performance and safety of industrial equipment is a top priority across various sectors. One critical aspect of maintaining such performance is through Tube Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD. These services are indispensable for industries that rely on the efficient functioning of tubes, such as in heat exchangers, boilers, and condensers. Here, we explore the importance of Inspection Services and how they contribute to the overall health of industrial systems.

Preventive Maintenance e Precision

Inspection Services are fundamental to preventive maintenance strategies. By regularly inspecting tubes, potential issues can be identified before they lead to significant failures or costly downtime. This proactive approach not only enhances the longevity of the equipment but also ensures that it operates at peak efficiency. Regular inspections help detect early signs of wear and tear, corrosion, and other forms of degradation, allowing for timely interventions that can prevent more severe damage.

Advanced Inspection Techniques

The effectiveness of Inspection Services is greatly enhanced by advanced non-destructive testing (NDT) methods. Techniques such as eddy current testing, ultrasonic testing, and remote visual inspection are commonly employed to assess the condition of tubes without causing any damage. Inspectors with NDT Level 2 Certification Courses from RVS QUALITY CERTIFICATIONS PVT LTD are trained to use these advanced methods to accurately identify defects, including cracks, pitting, and wall thinning. This high level of precision ensures that even the smallest issues are detected, enabling precise maintenance planning and execution.

Optimizing System Efficiency

The performance of systems that rely on tubes, such as heat exchangers and boilers, directly impacts the overall efficiency of industrial operations. Any compromise in the integrity of these tubes can lead to reduced heat transfer efficiency, increased energy consumption, and higher operational costs. By employing comprehensive Inspection Services, organizations can maintain optimal system performance. These inspections help ensure that the tubes are free from blockages, corrosion, and other issues that could impede their functionality, thereby sustaining efficient and cost-effective operations.

Safety and Compliance

Ensuring the safety of industrial operations is paramount, and Inspection Services play a crucial role in this regard. Faulty tubes can lead to catastrophic failures, posing serious risks to personnel and equipment. Regular inspections help mitigate these risks by identifying and addressing potential issues before they escalate. Furthermore, industries are often required to comply with stringent safety and regulatory standards. Third-party Third-Party Inspection Services from RVS QUALITY CERTIFICATIONS PVT LTD provide an additional layer of assurance, validating that the equipment meets all necessary compliance requirements. This external validation not only enhances safety but also boosts the organization's credibility and reliability.

Cost-Effective Maintenance

While some may view Inspection Services as an added expense, they are, in fact, a cost-effective maintenance strategy. Early detection of issues through regular inspections can prevent costly repairs, extensive downtime, and loss of productivity. The ability to plan maintenance activities based on accurate inspection data allows organizations to allocate resources more efficiently and avoid unexpected breakdowns. In the long run, the investment in Inspection Services pays off by reducing the total cost of ownership and maximizing the return on investment for industrial equipment.

Training and Expertise

The effectiveness of Inspection Services is highly dependent on the expertise of the inspectors. Professionals trained through NDT Certification Courses possess the necessary skills and knowledge to perform thorough and accurate inspections. Their expertise ensures that all potential issues are identified and appropriately addressed. Continuous training and certification updates are essential to keep inspectors abreast of the latest advancements in inspection technologies and methodologies, thereby maintaining high standards of service quality.

In conclusion, Inspection Services are essential for ensuring the optimal performance, safety, and efficiency of industrial systems. By incorporating advanced non-destructive testing techniques and leveraging the expertise of certified professionals, organizations can proactively manage the health of their equipment. Regular inspections help prevent costly failures, ensure compliance with safety standards, and enhance overall operational efficiency. For industries striving to maintain high-performance standards and minimize risks, investing in Inspection Services is a prudent and necessary decision.

0 notes

Text

Revolutionizing Inspection Processes with Nondestructive Testing

Nondestructive Testing (NDT) has transformed how industries approach inspection and maintenance. At MyNDT, we specialize in delivering precise and reliable NDT services that minimize downtime and maximize efficiency. Delve into our range of NDT techniques, from advanced digital radiography to sophisticated ultrasonic testing.

#ndt inspection services#ndt testing#non destructive inspection#non destructive testing#ndt#ndttraining#non destructive entry

0 notes