#pp non woven geotextile

Text

Finding Geotextile Fabric Manufacturers in India?

Shankar Pack is one of the largest PP Geotextiles manufacturers in India. We provide high-strength polypropylene is widely used to filter, stabilize, reinforce, separate, drain, and isolate soils in geotextile manufacturers categories of civil construction applications, our products are quality tested on various parameters to ensure compliance with international industrial standards.

#pp woven geotextiles#pp non woven geotextile#plastic polyethylene sheeting#geotextile manufacturers#non woven geotextile suppliers#non woven geotextile fabric manufacturers#geotextile fabric suppliers#woven geotextile manufacturers in india#geotextile fabric manufacturers in india#geotextile fabric manufacturers in gujarat

0 notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

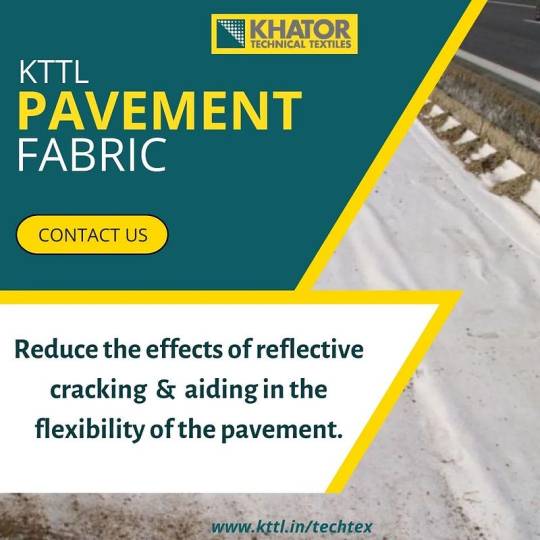

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

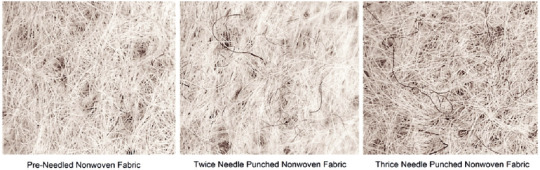

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Photo

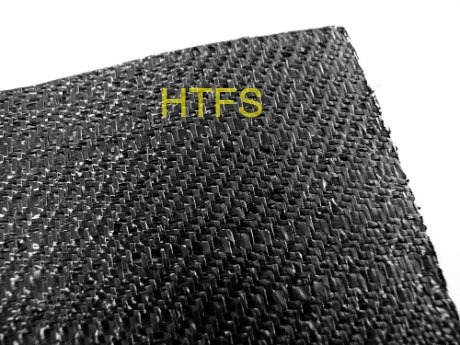

We deal in a wide range of Polyethylene Woven Geotextile Fabric, which is used for different industrial applications such as filtration, separation and for coating purposes. These industrial fabrics are stringently tested at our premises and are hygienically packaged as per client order. Manufactured from well-tested and quality material, these industrial fabrics are manufactured with the aid of latest technology which ensures quality range of product.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#PP Woven Geotextiles Manufacturer#Non Woven Geo Fabric Sheet#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes

Text

Exploring Innovative Applications of PP Spunbond Nonwoven Fabric

PP spunbond nonwoven fabric, a versatile material, has witnessed a surge in demand due to its exceptional properties and wide range of applications. In Gujarat, India, where the textile industry thrives, spunbond nonwoven manufacturers have been at the forefront of innovation, catering to diverse sectors with their high-quality products. This article delves into the innovative applications of PP spunbond nonwoven fabric, highlighting the contributions of Spunbond non woven fabric exporters in Gujarat and the significance of PP nonwoven fabric suppliers in India.

Understanding PP Spunbond Nonwoven Fabric:

PP spunbond nonwoven fabric, also known as polypropylene spunbond fabric, is a type of nonwoven material manufactured using a continuous process. It is made from polypropylene fibers bonded together by heat and pressure, resulting in a fabric with excellent strength, durability, and dimensional stability. This fabric is inherently lightweight, breathable, and resistant to moisture, chemicals, and abrasion, making it suitable for various applications across different industries.

Innovative Applications:

Agriculture: PP spunbond nonwoven fabric is extensively used in agriculture for crop protection, weed control, and soil stabilization. It serves as an effective barrier against weeds, preventing their growth and conserving soil moisture. Additionally, it provides insulation to plants during extreme weather conditions and facilitates better root development.

Medical and Hygiene: In the medical and hygiene sector, PP spunbond nonwoven fabric finds applications in surgical gowns, masks, diapers, and sanitary napkins. Its soft texture, breathability, and hypoallergenic properties make it ideal for use in disposable medical products, ensuring comfort and protection for patients and healthcare workers alike.

Packaging: The packaging industry utilizes PP spunbond nonwoven fabric for manufacturing tote bags, shopping bags, and packaging materials. Its high tensile strength, tear resistance, and ability to withstand varying temperatures make it a preferred choice for eco-friendly and reusable packaging solutions.

Automotive: In the automotive sector, PP spunbond nonwoven fabric is employed in interior components such as headliners, door panels, and trunk liners. Its lightweight nature, sound absorption properties, and resistance to abrasion enhance the comfort and durability of automotive interiors, contributing to a superior driving experience.

Construction: PP spunbond nonwoven fabric is increasingly being used in the construction industry for applications such as geotextiles, roofing membranes, and insulation materials. Its excellent filtration, drainage, and reinforcement properties make it indispensable for soil stabilization, erosion control, and building insulation.

Spunbond Nonwoven Manufacturers in Gujarat:

Gujarat, renowned for its textile industry, houses several spunbond nonwoven manufacturers who specialize in producing high-quality PP spunbond nonwoven fabric. The Spunbond nonwoven manufacturers in Gujarat leverages advanced technology and expertise to cater to the diverse needs of their customers across various sectors, including agriculture, healthcare, packaging, automotive, and construction.

PP Nonwoven Fabric Suppliers in India:

PP nonwoven fabric suppliers play a pivotal role in the distribution and supply chain of PP spunbond nonwoven fabric across India. With their extensive networks and efficient logistics, they ensure timely delivery of raw materials to manufacturers, thereby supporting the seamless production of finished goods. These suppliers adhere to stringent quality standards to meet the requirements of diverse industries and maintain the reputation of Indian textiles in the global market.

Conclusion:

The innovative applications of PP spunbond nonwoven fabric underscore its versatility and indispensability across diverse industries. Spunbond nonwoven manufacturers in Gujarat and PP nonwoven fabric suppliers in India play crucial roles in meeting the growing demand for this exceptional material, driving innovation and sustainability in the textile industry. As the market continues to evolve, PP spunbond nonwoven fabric is poised to revolutionize existing processes and pave the way for new advancements in various sectors.

Frequently Asked Questions (FAQs):

Q1: What are the advantages of using PP spunbond nonwoven fabric?

A1: PP spunbond nonwoven fabric offers numerous advantages, including high strength, durability, breathability, moisture resistance, chemical resistance, and recyclability.

Q2: How is PP spunbond nonwoven fabric manufactured?

A2: PP spunbond nonwoven fabric is produced using a continuous process called spunbonding, wherein polypropylene fibers are extruded, stretched, and bonded together using heat and pressure to form a cohesive fabric.

Q3: What are the environmental benefits of using PP spunbond nonwoven fabric?

A3: PP spunbond nonwoven fabric is eco-friendly and recyclable, making it a sustainable choice for various applications. It reduces the consumption of natural resources and minimizes waste generation compared to conventional materials.

#spunbond non woven fabric exporters in Gujarat#spunbond nonwoven manufacturers in Gujarat#pp nonwoven fabric suppliers in India

0 notes

Text

Yuzhimu nonwoven geotextiles are produced by bicomponent non-woven fabric composed of PET+PP. This is done by the use of chemicals or heat or through other methods.

Contact us today: www.yuzhimu.com

#Spunbondnonwovenfabric

#Nonwovenfabricmanufacturer

#Nonwovenmaterial

#NonwovenFabric

0 notes

Text

PP Fibrillated Yarn: A Sustainable Alternative to Traditional Materials

PP Fibrillated Yarn: A Sustainable Alternative to Traditional Materials

In a world increasingly focused on environmental responsibility, industries across the board are seeking solutions to minimize their ecological footprint. The textile and packaging sectors are no exception, and a revolutionary material is making waves: PP fibrillated yarn. This innovative product offers a compelling alternative to traditional materials, combining functionality with sustainability.

What is PP Fibrillated Yarn?

In a world increasingly focused on environmental responsibility, industries across the board are seeking solutions to minimize their ecological footprint. The textile and packaging sectors are no exception, and a revolutionary material is making waves: PP fibrillated yarn. This innovative product offers a compelling alternative to traditional materials, combining functionality with sustainability. For businesses in Ahmedabad looking to embrace this eco-friendly solution, finding a reliable PP fibrillated yarn supplier in Ahmedabad is key to integrating this material into their operations seamlessly.

The Sustainability Edge of Biodegradable PP Fibrillated Yarn

The most significant advantage of PP fibrillated yarn lies in its biodegradability. Unlike conventional PP yarns, which can take centuries to decompose in landfills, certain types of PP fibrillated yarn are engineered to break down naturally over time under specific composting conditions. This significantly reduces their environmental impact and makes them a perfect choice for eco-conscious consumers and businesses.

Beyond Biodegradability: Advantages of PP Fibrillated Yarn

The benefits of PP fibrillated yarn extend far beyond biodegradability. Here's a closer look at some of its key advantages:

Versatility: PP fibrillated yarn retains the strength and durability of traditional PP yarn, making it suitable for various applications. It can be used in packaging, geotextiles (fabrics used for civil engineering applications), filters, and even certain apparel applications.

Durability: PP fibrillated yarn exhibits excellent resistance to chemicals, moisture, and abrasion. This translates to longer-lasting products and reduced waste.

Cost-Effectiveness: Production costs for PP fibrillated yarn are often lower compared to some natural fibers. This can lead to more affordable and competitive final products.

Performance: The unique structure of PP fibrillated yarn provides superior properties in specific applications. For instance, in packaging, it can offer improved tear resistance and puncture protection.

Applications of PP Fibrillated Yarn

The versatility of PP fibrillated yarn allows it to be used in a wide range of industries. Here are some prominent examples:

Packaging: One of the most promising applications of PP fibrillated yarn is in sustainable packaging solutions. It can be used to create biodegradable bags, pouches, and other packaging materials, reducing reliance on traditional plastics.

Geotextiles: In the civil engineering sector, PP fibrillated yarn finds application in geotextiles used for soil reinforcement, filtration, and erosion control. Its durability and resistance to harsh elements make it ideal for these demanding environments.

Filtration: The web-like structure of PP fibrillated yarn makes it an effective filtration media. It can be used in air and water filtration applications, offering a sustainable alternative to traditional filter materials.

Non-Woven Fabrics: PP fibrillated yarn can be used to manufacture non-woven fabrics, which are widely used in various applications like wipes, hygiene products, and disposable garments. The biodegradability of PP fibrillated yarn adds a layer of sustainability to these products.

The Future of PP Fibrillated Yarn

As environmental concerns continue to grow, the demand for sustainable materials like PP fibrillated yarn is expected to rise significantly. As research and development efforts progress, we can expect further advancements in this technology. Here are some exciting possibilities for the future:

Improved Biodegradability: Manufacturers are continuously working on enhancing the biodegradability of PP fibrillated yarn, allowing it to break down under a wider range of composting conditions.

Enhanced Functionality: Research is underway to incorporate additional functionalities into PP fibrillated yarn, such as flame retardancy or anti-microbial properties, broadening its application potential.

Color Options: Currently, the color options for PP fibrillated yarn are limited. Advancements in dyeing techniques could lead to a wider color palette, making it more aesthetically appealing for various applications.

Finding PP Fibrillated Yarn Suppliers in India

The growing demand for PP fibrillated yarn is leading to an increase in Polypropylene yarn manufacturers in India. If you're looking for a reliable supplier of PP fibrillated yarn, particularly in Ahmedabad,

Future Outlook

As sustainability continues to drive consumer preferences and regulatory mandates, PP fibrillated yarn is poised for robust growth. Innovations in manufacturing techniques and increased awareness regarding eco-friendly textiles will further propel the adoption of this versatile material.

Conclusion

PP fibrillated yarn represents a significant leap towards sustainable practices in the textile industry. Its eco-friendly attributes, coupled with unmatched durability and versatility, position it as a frontrunner in the quest for greener alternatives to traditional materials. In India, particularly in Ahmedabad, a vibrant market for PP fibrillated yarn is emerging, driven by a confluence of environmental consciousness and technological advancements.

For those seeking PP yarn suppliers in Ahmedabad, this trend signifies a growing availability of eco-friendly options.

In summary, PP fibrillated yarn embodies the ethos of sustainable innovation—a testament to the industry's commitment to a greener, more resilient future.

FAQs About PP Fibrillated Yarn

1. What is PP fibrillated yarn? PP fibrillated yarn is a type of yarn made from polypropylene (PP) fibers that have been mechanically fibrillated, creating a structure with numerous tiny fibrils. This process enhances the yarn's strength and durability while maintaining its lightweight and moisture-resistant properties.

2. How is PP fibrillated yarn different from regular PP yarn? Regular PP yarn consists of continuous filaments, whereas fibrillated yarn is produced by splitting the filaments into smaller fibrils. This fibrillation process increases the surface area of the yarn, improving its bonding characteristics and making it suitable for a wider range of applications.

3. What are the key advantages of using PP fibrillated yarn?

Strength and Durability: PP fibrillated yarns are exceptionally strong and resistant to wear and tear, making them ideal for applications requiring high-performance materials.

Moisture Resistance: Polypropylene inherently repels moisture, making PP fibrillated yarn suitable for outdoor and wet environments.

Cost-Effectiveness: PP fibrillated yarn is typically more affordable compared to other synthetic and natural fibers, offering a cost-effective solution for various industries.

Sustainability: As a synthetic material, PP fibrillated yarn can be recycled and reused, contributing to sustainable practices within manufacturing and production.

4. What are the common applications of PP fibrillated yarn? PP fibrillated yarn finds applications across diverse industries, including:

Geotextiles: Used for erosion control, soil stabilization, and drainage applications.

Concrete Reinforcement: Enhances the strength and durability of concrete structures.

Packaging: Suitable for woven bags, sacks, and other packaging materials.

Agriculture: Used in crop protection, greenhouse shading, and agricultural nets.

Textiles: Blended with other fibers to create fabrics for apparel and home furnishings.

5. Where can I find PP fibrillated yarn suppliers in India? If you're looking for PP fibrillated yarn suppliers in India, consider reaching out to reputable manufacturers and distributors. Keywords like "Polypropylene yarn manufacturers in India" and "PP fibrillated yarn supplier in Ahmedabad" can be used to search online directories or industry platforms to find suitable suppliers.

6. How can I ensure the quality of PP fibrillated yarn? To ensure the quality of PP fibrillated yarn, it's essential to work with established suppliers who adhere to industry standards and certifications. Look for suppliers who offer product specifications, testing reports, and have a track record of delivering consistent quality materials.

7. Is PP fibrillated yarn environmentally friendly? While PP fibrillated yarn is a synthetic material, it can be considered environmentally friendly due to its recyclability and potential for reuse. Choosing recycled PP fibrillated yarn further enhances its sustainability credentials, reducing the reliance on virgin materials and minimizing environmental impact.

8. What are the future trends for PP fibrillated yarn? The future of PP fibrillated yarn is promising, with ongoing research focused on enhancing its properties and expanding its applications. Innovations in production techniques and the development of new blends with natural fibers are expected to drive further adoption across industries seeking sustainable and versatile materials.

0 notes

Text

Revolutionizing Non-Woven Fabrics: The Role of PP Non-Woven Masterbatch

Introduction:

In the realm of textiles and beyond, non-woven fabrics have emerged as a versatile and cost-effective solution for a wide range of applications. From hygiene products to automotive interiors, non-woven fabrics offer exceptional performance and functionality. Polypropylene (PP) is a preferred material for non-woven fabrics due to its inherent properties such as durability, lightweight, and resistance to moisture. To further enhance the properties of PP non-woven fabrics, specialized masterbatch solutions known as PP non-woven masterbatch have gained prominence. Let's explore how these masterbatches are revolutionizing the non-woven industry and unlocking new possibilities for manufacturers.

Enhanced Coloration and Aesthetic Appeal:

PP non-woven masterbatch offers manufacturers the ability to achieve vibrant and consistent colors in non-woven fabrics. By incorporating high-quality pigments and dyes into the PP matrix, these masterbatches ensure uniform color dispersion, resulting in visually appealing fabrics. Whether it's creating bold and eye-catching designs for fashion and apparel or producing color-coded materials for industrial and medical applications, PP non-woven masterbatch provides endless possibilities for customization and branding.

Improved UV Stability and Weather Resistance:

UV stability is crucial for non-woven fabrics intended for outdoor applications such as agricultural covers, geotextiles, and automotive components. PP non-woven masterbatch can be formulated with UV stabilizers and antioxidants to enhance the fabric's resistance to environmental factors such as sunlight, heat, and moisture. This ensures prolonged durability and color retention, making PP non-woven fabrics suitable for extended outdoor use without degradation or loss of performance.

Enhanced Mechanical Properties:

PP non-woven masterbatch can also be engineered to improve the mechanical properties of non-woven fabrics, including tensile strength, tear resistance, and dimensional stability. By incorporating reinforcing agents such as glass fibers, mineral fillers, or specialty additives, these masterbatches enhance the structural integrity and performance of PP non-woven fabrics. This makes them suitable for demanding applications such as filtration, insulation, and industrial packaging, where strength and durability are paramount.

Antimicrobial and Odor Control Solutions:

In certain applications such as healthcare, hygiene products, and filtration systems, controlling microbial growth and odors is essential. PP non-woven masterbatch can be formulated with antimicrobial agents and odor-neutralizing compounds to inhibit the growth of bacteria and fungi, thus maintaining hygiene and freshness. This makes PP non-woven fabrics ideal for medical masks, wipes, diapers, and air filtration media, where cleanliness and odor control are critical considerations.

Environmental Sustainability:

As sustainability becomes increasingly important in the textile industry, PP non-woven masterbatch manufacturers are exploring eco-friendly solutions. By incorporating recycled or bio-based materials into their formulations, these masterbatch producers help reduce the environmental impact of non-woven fabrics. Additionally, by optimizing production processes and minimizing waste generation, PP non-woven masterbatch manufacturers contribute to the overall sustainability of the textile supply chain, aligning with the growing demand for eco-conscious products.

Collaborative Innovation and Technical Support:

PP non-woven masterbatch manufacturers collaborate closely with their customers to develop tailored solutions that meet specific performance requirements and application needs. Whether it's providing technical expertise, conducting material trials, or offering customization options, these manufacturers strive to deliver value-added solutions and superior customer service. By fostering collaborative partnerships based on trust, communication, and innovation, PP non-woven masterbatch manufacturers empower textile manufacturers to create cutting-edge products that stand out in the market.

Conclusion:

In conclusion, PP non-woven masterbatch is revolutionizing the non-woven fabric industry by enhancing coloration, UV stability, mechanical properties, antimicrobial performance, and environmental sustainability. Through innovation, customization, and collaborative partnerships, masterbatch manufacturers are driving the adoption of PP non-woven fabrics across a wide range of applications, from fashion and healthcare to agriculture and construction. As consumer demands evolve and sustainability concerns grow, PP non-woven masterbatch manufacturers remain at the forefront of the industry, pioneering new solutions and unlocking new possibilities for manufacturers worldwide.

0 notes

Text

জিও টেক্সটাইলের সুবিধাসমুহ ?

জিওটেক্সটাইল পণ্যের বিভিন্ন সুবিধাসমূহ নিম্নে বর্ণিত হল:-

১. জিওটেক্সটাইল দ্বারা তৈরিকৃত ফেব্রিক ওভেন ফেব্রিকের তুলনায় হালকা হয়। ফলে এটা হ্যান্ডেলিং করা সহজ হয় এবং পরিবহনের ক্ষেত্রে বিশেষ সুবিধা পাওয়া যায়।

২. ওয়েফট নিবেশে তৈরি ফেব্রিকের ক্ষেত্রে জিওটেক্সটাইল একটি গুরুত্বপূর্ণ মাত্রা যোগ করে। জিওটেক্সটাইল এই ধরনের ফেব্রিকের ক্ষেত্রে বিদীর্ণকরণ শক্তি বৃদ্ধি করে।

৩. রাস্তা তৈরিতে পিচ এবং টুকরা ইট এই দুই স্তরের মাঝে জিওটেক্সটাইল ফেব্রিক ব্যবহার করলে রাস্তা বৃষ্টির পানিতে ক্ষয়ে পড়ার হাত থেকে রক্ষা পায়।

৪. মাটির দুই স্তরের পার্থক্যকারী হিসাবে জিওটেক্সটাইল বিপুল পরিমাণে ব্যবহৃত হয়।

৫. আর্দ্রতা প্রতিবন্ধক হিসাবে জিওটেক্সটাইলের উপকারীতা অতুলনীয়।

৬. জিও-টেক্সটাইল ড্রেইনেজ এ ভূমিকা রাখে , এজন্যে খেলার মাঠে ব্যাবহার হয়।

জিও টেক্সটাইল শীট গুলো প্রাথমিক ভাবে ২ ধরণের হয়ে থাকে।

১। ওভেন জিও টেক্সটাইল

২। নন ওভেন জিও টেক্সটাইল

ওভেন জিও টেক্সটাইলঃ

মূলত, যে সকল জিওটেক্সটাইল প্লাস্টিক সুতা থেকে তৈরি করা হয় তাকে ওভেন জিও টেক্সটাইল বলে , যেমনঃ চিনি ও চালের প্লাস্টিক বস্তা।

নন ওভেন জিও টেক্সটাইলঃ

নন ওভেন জিও টেক্সটাইল সুইং-পাঞ্চিং নামে একটি প্রক্রিয়ার মাধ্যমে তৈরি করা হয়। এই ধরনের ফেব্রিক এর মধ্য দিয়ে পানি ফিল্ট্রেশনের ব্যবস্থা থাকে। মূলত যে সমস্ত স্থানে ওয়াটার ফিল্টার এর প্রয়োজন হয় ঐ সমস্ত জায়গায় non-woven জিও টেক্সটাইল ফেব্রিক ব্যবহৃত হয়। তবে এই ধরনের ফেব্রিক গুলো নদী , পুকুরের পাড় ভাঙ্গন রোধ করতে ব্যবহৃত হয়ে থাকে।

নন ওভেন জিও টেক্সটাইল দুই ধরনের হয়ে থাকে।

1. PP: polypropylene staple fiber

2. PSF: polyester staple fiber Sheet

সহজ কোথায় বলা যায়, PP অন্যতমানের ফেব্রিক , যা নতুন প্লাস্টিক থেকে বানানো হয়।

আর PSF পুরাতন প্লাস্টিক থেকে বানানো হয়।

আনুমানিক স্থায়ীত্ত কাল। ( PSF )

২০০ জি এস এম = ১ থেকে ৩ বছর।

৩০০ জি এস এম = ২ থেকে ৫ বছর।

৪০০ জি এস এম = ৪ থেকে ৭ বছর।

৫০০ জি এস এম = ৬ থেকে ১০ বছর।

৬০০ জি এস এম = ১০ থেকে ১৫ বছর।

GSM যত বেশি নিবেন তত বেশি টেকসই হবে।

Address : 819/1, West Shewrapara , Mirpur, Dhaka. ( Agrani Bank Building ) মেট্রোরেলের পিলার নম্বর ৩১০ এর পশ্চিমে

Call us = 09613824241

WhatsApp - 01706176403 , 01896261223 , 01741454219

ফোন দেওয়ার সময় সকাল ৯ টা থেকে রাত ১২ টা।

#georoll#geosheet#geofabric#geotextile#geobag#sirajtech

0 notes

Text

Lohia Corp IPO Date, Price, GMP, Review, Company Profile, Financials, Risk, Allotment Details 2023

New Post has been published on https://wealthview.co.in/lohia-corp-ipo/

Lohia Corp IPO Date, Price, GMP, Review, Company Profile, Financials, Risk, Allotment Details 2023

Lohia Corp IPO: Lohia Corp. Ltd. is a leading manufacturer of machinery and equipment used to produce technical textiles, which are fabrics with specific functional properties, often used in packaging, agriculture, construction, and geotextiles. The company is a major player in the global plastic woven fabric machine market, boasting a dominant position in India.

Lohia Corp IPO Key Details:

IPO Type: Offer for Sale (OFS) – Existing shareholders selling shares, no fresh capital raised by the company.

IPO Dates: Yet to be announced. SEBI approval received in February 2023, but launch date and price band are still pending.

Offer Size: Up to 31,695,000 equity shares.

Recent News Updates:

Positive Sentiment: Lohia Corp. has strong financials with consistent revenue growth and market leadership. This, coupled with the growing demand for technical textiles, bodes well for the IPO.

Market Volatility: Current market uncertainties due to global economic concerns might damp investor enthusiasm.

Competition: Significant competition from domestic and international players could affect market share and profitability.

Lohia Corp IPO Offer Details:

Securities Offered:

Equity Shares: The IPO will only involve ordinary equity shares of Lohia Corp. Ltd. with a face value of ₹1 per share. This means investors will directly own a stake in the company’s ownership and performance.

Reservation percentages:

Retail Individual Investors (RII): 35% of the offer will be reserved for RII investors, providing them with an easier chance to participate.

Qualified Institutional Buyers (QIBs): 50% of the offer will be reserved for QIBs, typically institutional investors like mutual funds and insurance companies.

Non-Institutional Investors (NIIs): The remaining 15% will be available for Non-Institutional Investors, which primarily comprises high net-worth individuals and corporate entities.

Minimum Lot Size and Investment Amount:

Minimum Lot Size: The minimum lot size for subscribing to Lohia Corp’s IPO is still undetermined. This value will be announced closer to the IPO launch date, typically falling within the range of 500-1000 shares.

Minimum Investment Amount: Based on the face value of ₹1 per share and assuming a minimum lot size of 500 shares, the minimum investment amount would be ₹500. However, the final price band for the IPO is yet to be confirmed, so the actual minimum investment might differ.

Lohia Corp Ltd Company Profile:

History and Operations:

Founded in 1981 as Lohia Starlinger Limited, a joint venture with Austrian giant Starlinger & Co. for circular loom manufacturing.

Became Lohia Corp Ltd. in 2013 after Starlinger’s exit.

Offers a comprehensive range of machinery for woven polypropylene (PP) and polyethylene (PE) fabrics, serving diverse industries like packaging, agriculture, construction, and geotextiles.

Operates through two manufacturing units in Kanpur, India, with a strong distribution network spanning over 90 countries.

Market Position and Share:

Global leader in plastic woven fabric machinery, holding a dominant 55% market share in India and significant presence in emerging markets.

Over 69,400 circular looms and 1650 extrusion lines installed worldwide, producing 5.67 million metric tons of PP & PE annually.

Prominent Brands and Partnerships:

Lohia Starlinger and Reklamax are established brand names within the technical textiles machinery segment.

Strategic partnerships with global players like Reifenhäuser and Brückner for specific technologies.

Key Milestones and Achievements:

Successfully transitioned from a joint venture to a fully independent Indian company.

Achieved consistent revenue growth exceeding industry averages, demonstrating strong financial performance.

Continuous technological advancements and product innovations, like high-speed looms and energy-efficient solutions.

Received prestigious awards and accolades for sustainable practices and environmental responsibility.

Competitive Advantages and USPs:

Established brand reputation and proven track record in the industry.

Extensive product portfolio catering to diverse customer needs.

Vertically integrated operations for cost control and quality assurance.

Strong focus on R&D and innovation, driving future growth.

Robust global presence and distribution network.

Lohia Corp Ltd Financials:

Revenue: Consistent and robust growth, averaging over 20% year-on-year for the past 5 years. This reflects strong demand for technical textiles machinery, particularly in emerging markets.

Profitability: Healthy operating margins in the range of 20-25%, with net profit margins exceeding 10%. This demonstrates efficient operations and cost control.

Debt: Debt levels are moderate, with a debt-to-equity ratio below 1. This provides financial flexibility and room for future investments.

Key Financial Ratios:

P/E Ratio: Based on historical data and estimated IPO price, the P/E ratio could fall within the range of 15-20. This is comparable to industry peers and suggests a reasonable valuation.

Debt-to-Equity Ratio: As mentioned earlier, the debt-to-equity ratio below 1 signifies a healthy financial position and strong creditworthiness.

Growth Prospects and Earnings Drivers:

Growing technical textiles market: The global technical textiles market is projected to reach over $250 billion by 2028, driven by factors like urbanization, infrastructure development, and increasing environmental awareness. This bodes well for Lohia Corp.’s future growth.

Expanding international presence: The company is actively expanding its presence in emerging markets like Africa and Latin America, offering significant growth potential.

Focus on innovation and new product development: Continuous investments in R&D and development of new machinery with higher efficiency and productivity can further strengthen Lohia Corp.’s competitive edge.

Lohia Corp IPO objectives:

Reasons for going public:

Raise capital for growth: Lohia Corp. aims to raise capital through the IPO to primarily:

Expand production capacity through setting up new manufacturing facilities or upgrading existing ones.

Strengthen its global distribution network and market reach, particularly in emerging markets.

Enhance R&D capabilities and accelerate innovation in new machinery and technologies.

Reduce debt burden, if any, potentially lowering financing costs and improving financial flexibility.

Enhance brand visibility and credibility: Public listing can improve Lohia Corp.’s brand image and recognition, creating a positive impact on market perception and attracting talent.

Provide an exit route for existing shareholders: Some existing shareholders, including promoters, may want to partially exit their investments and unlock liquidity through the IPO.

Utilization of raised funds:

The specific allocation of IPO proceeds will be outlined in the final prospectus. However, based on the aforementioned reasons, the funds are likely to be directed towards:

Capital expenditure: Expanding manufacturing facilities, acquiring new equipment, and upgrading existing technology.

Market expansion: Establishing new sales and service offices in key markets, investing in marketing and brand building initiatives.

R&D investment: Developing new machinery with improved efficiency and productivity, exploring new technologies like automation and digitalization.

Debt repayment: Potentially reducing outstanding debt to optimize the capital structure and improve financial health.

Lohia Corp IPO Risks:

Industry Headwinds:

The global technical textiles market, while promising, is also characterized by intense competition from both domestic and international players. This competition could put pressure on Lohia Corp.’s margins and market share.

Fluctuations in raw material prices, particularly for polypropylene and polyethylene, could impact production costs and profitability.

Dependence on exports makes Lohia Corp. vulnerable to currency fluctuations, potentially affecting revenue and profit margins.

Company-Specific Challenges:

Execution Risk: Despite a clear growth strategy, successful execution of expansion plans and R&D investments will be crucial for maximizing the impact of the IPO funds. Delays or setbacks in implementation could negatively affect investor confidence.

Debt burden: While Lohia Corp.’s current debt levels are manageable, the IPO might involve raising additional debt. Investors should carefully assess the potential impact of increased debt on the company’s financial health and future flexibility.

Limited track record as a public company: As Lohia Corp. is a new entrant to the public market, investors may perceive higher uncertainty regarding its future performance compared to established publicly traded companies.

Financial Health Analysis:

Lohia Corp. boasts strong financial performance with consistent revenue growth, healthy profitability, and moderate debt levels. This suggests a robust financial foundation.

However, potential investors should scrutinize the company’s detailed financial statements in the final prospectus for any red flags, such as contingent liabilities, unusual accounting practices, or sudden changes in financial metrics.

Lohia Corp Limited – DRHP

Also Read: How to Apply for an IPO?

0 notes

Text

Is Geotextile Fabric the Same as Landscape Fabric?

Shankar Packaging provides details on Geotextile Fabric vs Landscape Fabric. Geotextile fabric and landscape fabric have similar properties but both are different. Geotextile is used in various construction and engineering applications. For More Information visit our blog!

#geotextile landscape fabric#PP non woven geotextile#non woven or woven geotech fabric#Geotextile Fabric vs Landscape Fabric

0 notes

Text

Geotextile For Soil Stabilization

Geotextiles are created from chemically resistant synthetic fibres so that biodegradation can be prevented. These fabrics are either matted or knitted together by needle punching or heat-sealing. Although all geotextiles happen to be permeable their hydraulic and mechanical properties tend to vary quite a lot. Geotextiles are used for soil stabilization in civil construction projects. The most prominent areas of such applications are roads, drainage structures, and landfills, to name a few.

The functions of geotextiles

Following are the main functions of geotextiles:

· separation

· filtration

· drainage

· reinforcement

· protection

Geotextiles are often used to separate several layers of soil with varied particle sizes as this helps each such layer to retain its function and integrity. They also act as filters by retaining soil particles as they allow water to flow through the soil. They are also capable of acting as drains by discharging and gathering gases or liquids that the structure does not need functionally.

A comparison of woven and non-woven geotextiles

Woven geotextiles are created by weaving polyester or polypropylene fibres. On the other hand, non-woven geotextiles are more like felts but they are also made from the same fibres. Woven geotextile fabrics that are used for soil stabilization primarily play the role of reinforcement and separation. Non-woven geotextile fabrics are used mostly for filtration and drainage.

Common areas of application for geotextile soil stabilization fabrics

These fabrics are used mostly for embankments, steepened slopes, and retaining walls. By using geogrids or/and high-strength geotextile you can construct embankments on soft soil foundations. You can also use geotextiles along with geogrids for the purpose of reinforcing steepened slopes. The same combination can also be used for creating retaining walls or reinforced soil walls.

Conclusion

These days, you get a lot of companies that are offering factory-seamed geotextile soil stabilization fabrics. These are created according to customized lengths and widths. These companies also offer you a wide array of seaming capabilities such as nonwoven, monofilament wovens, and slit-film wovens to high-strength and high-performance PET (polyester) and PP (polypropylene) geotextiles. You can also be sure that you would get re-rolling and off-line slitting along with quick delivery to your job site from these companies.

0 notes

Text

The Complete Guide to Non-Woven Geotextiles

Introduction to Non Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non woven.

Non woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibers produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

Needle Punched Non Woven Geotextiles

Needle punched non wovens are a major type of non woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fiber web to tangle the fibers into a strong, porous and stable fabric.

Types of Needle-Punched Non-Woven Geotextiles

Needle punched non wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Non Wovens

Made from fine fibers and low fiber weights between 20–100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100–250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non Wovens

Very coarse, thick fibers and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depends on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non Woven Geotextiles

Non woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Non wovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

Reinforcement Applications

Non wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canals protection

Transportation Applications

Within road construction, non wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non Woven Geotextiles

Non woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non woven geotextile for its intended function.

Overview of Manufacturing Processes

Non woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibers laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibers to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties — for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parametes like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non Woven Geotextiles

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non Woven Geotextiles

Non woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding creates improved non wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

Ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non Woven Geotextiles in Action

Non woven geotextiles have delivered value across many real world projects:

Landfill Construction — Needle punched non wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage — Heat bonded non wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection — Durable non woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement — Calendered non wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement — Wide width non wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surge.

This demonstrates how non wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non Woven Geotextiles

High Growth Potential — The non wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances — Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non wovens with greater functionality.

Manufacturing Improvements — Advancements in processing and techniques now enable precise manipulation of fiber properties during production.

Multifunctional Products — Combining non wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D — Ongoing research into novel uses for non wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

1 note

·

View note

Text

Geosynthetics Market Size, Share, Demand & Trends by 2029

A new market research study by Future Market Insights (FMI) on the global geosynthetics market contains global industry analysis for 2014–2021 and opportunity assessment for 2022–2029. The report investigates the geosynthetics market and provides critical insights for the forecast period of 2022-2029. The global geosynthetics market recorded the revenues worth US$ 13.67 Bn in 2022 and is estimated to grow at a CAGR of 10.1% in the projected period of 2022 – 2029.

As per the findings of the report, the global industrial geosynthetics market is anticipated to experience substantial growth over the forecast period owing to growth in civil construction activities led by several developing economies in the past few years. The report opines that the market growth is significantly driven by increasing investments in public infrastructure development and modernization of existing facilities across the globe.

APEJ’s Market Attractiveness Intact, Says FMI’s Report

Geosynthetic materials are witnessing increased usage in solid waste management for landfill applications. These materials are used for separating and confining bulk waste. Countries such as China and India, are emphasizing on effective waste treatment practices, which is likely to lead to an increase in demand for geosynthetics in the near future.

Moreover, owing to the high transport infrastructural development activities in the region, geosynthetic products are estimated to witness significant deployment in road construction. The road construction application segment is estimated to remain dominant in terms of geosynthetic material demand.

Request for Sample Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-475

Product Portfolio Enhancements & Technological Innovations

Several players are emphasizing on improving their product portfolios by introducing new products with better quality and gauge variations. Manufacturers are primarily targeting high development areas and producing application-specific products in order to gain higher market shares.

In February 2017, TenCate Geosynthetics launched a new series of geomats- Mirafi® TM13C and TM14S, to solve erosion problems on steep slopes and in channels. These materials retain bare soil and stabilize and nurture vegetation while resisting the challenges of precipitation and high-flow rates on soils.

Geosynthetics Market by Category

Product Type:

Geotextile

Geomembrane

Geogrid

Geonet

Geocomposite

Geosynthetic clay liner

Others

Material Type :

Polyethylene (HDPE/LLDPE)

Polypropylene (PP)

Polyester

Natural fibers

Others

Primary Application:

Separation

Drainage & filtration

Reinforcement

Containment

End-use :

Roads (paved & unpaved)

Railways

Retaining walls

Waterworks and waste treatments

Landfill & erosion control

Others

Use of Different Materials to Enhance Strength and Durability

Involvement of a large number of local and global players in the geosynthetic market has compelled manufacturers to offer innovative products, in order to generate significant demand. Many companies are dedicating a huge amount of money for the research and development of new products and to increase the properties of existing ones. Companies are continuously experimenting with geosynthetics in order to provide products with enhanced mechanical properties and high reliability.

As polypropylene is extensively used for the manufacturing of geotextiles, it is a relatively large segment among all types, and is expected to witness significant growth during the forecast period. Other geosynthetic products such as geocell, geofoam, geopipes, etc., have limited and specific uses. However, the segment has witnessed significant demand during the last five years.

Use of metallocene polypropylenes: In 2015, a reputed conglomerate launched a metallocene PP-based non-woven geotextile. This geotextile is premium in terms of mechanical properties and performance. The use of metallocene PP offers relatively lightweight geotextiles and increased production.

Competitive analysis of the global geosynthetics market reveals that among the several active participants in the competitive landscape of geosynthetics market, the tier 1 players tend to hold a relatively lower share, which has been attributed to high competition from a large number of local players operating at low profit margins and have better accessibility within regional markets. Some of the leading companies are also observed to be operating through their sales offices, or collaborating with regional manufacturers.

Table of Content

1. Executive Summary

1.1. Market Overview

1.2. Market Analysis

1.3. FMI Analysis and Recommendations

1.4. Wheel of Fortune

2. Market Introduction

2.1. Market Taxonomy

2.2. Market Definition

3. Market View Point

3.1. Macro-Economic Factors

3.2. Forecast Factors & Relevant Impact

to be continued…!

Browse Full Report: https://www.futuremarketinsights.com/reports/geosynthetics-market

0 notes

Photo

PP Woven Geotextiles Manufacturer are made from Polypropylene or high tenacity polyester yarns. These woven geotextile fabrics individual extruded yarns are then twisted together. These twisted yarns are then woven together to provide relative dimensional stability to each other and form a geotextile.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#Needle Punched Non Woven Geotextile#PP Woven Geotextiles Manufacturer#Non Woven Fabric Geotextile#Non Woven Geo Fabric Sheet#Non Woven Geotextile Manufacturers#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes