#PC transparent resin

Link

If you are interested in buying a PC lens grade resin, Kapoor Sales Corporation and House of Plastics can help you buy the best quality at the best price.

0 notes

Link

Today, you can find many distributors and suppliers that can provide you with the best quality engineered polymers that you can findIf you are interested in buying PC transparent resin granules you need to look for the best local suppliers that can offer you a variety of gradesthat you can use for your production.

0 notes

Text

(Brief) Resin shaker tutorial!

So, some of you might know about my Splatoon and Karamari resin shakers, and to request I wrote a small tutorial on how to make your own shaker mold!

The first step is to plan on how you want your shaker to be! You can draw a project on paper, make a model on your PC, whatever you feel like! When you are ready you just need to sculpt (or 3d print) your prototype! Look at existing shaker molds to understand how they're built and to take inspiration!

I used air-dry clay, which I regret because the shrinkage deformed them, so I suggest using a polymeric clay like fimo!

Sand them if needed and make sure the shaker has enough room for the size of whatever you want to put inside!

The second step is to get the silicone for the mold. I used two types of silicone in the past, each with their pro and cons:

The one on the left is a instant silicone putty, it's quick, easy to use and doesn't make a mess, but it's way less flexible and deteriorates quickly. The one on the right is standard clear silicone, which I used for my most recent molds. The quality is better and the transparency helps you seeing what you're doing, but since it starts from a liquid base you need a container and it's messier, not to mention the risk of air bubbles (you can see them actually in there lol). I suggest researching beforehand what kind of silicone it's best for your work! Remember for both types to make sure your shaker stays parallel to the ground, you can make sure of this by putting the item face up on a flat surface (or inside the container) and putting the silicone on top

Once your mold is ready and you wanna make a quick test to see if it worked and don't want to waste resin, use wax! i used a mix of candle and stamp wax on the first mold, and then sculpted, smoothed and refined the wax copies to use to make the mold on the transparent silicone! This step is not mandatory, only if you're not satisfied with your first result.

And you're done! You can now make resin shakers with your own shape! This method is not only for shaker of course, so have fun making your own charms!

23 notes

·

View notes

Text

What Are PC Hollow Sheets and Why Use Them?

Introduction to Polycarbonate Hollow Sheets

Polycarbonate hollow sheet, often referred to simply as PC hollow sheets, are innovative building materials made from polycarbonate, a durable and versatile thermoplastic. These sheets are characterized by their unique structure, which features a series of hollow channels that run through the material. This design not only contributes to their lightweight nature but also enhances their insulation properties, making them an ideal choice for various applications in construction, horticulture, and signage.

Composition and Structure of Polycarbonate Sheets

The primary component of polycarbonate hollow sheets is polycarbonate resin, which is known for its high impact resistance and optical clarity. Unlike traditional glass, polycarbonate is shatter-resistant, making it a safer option for environments where breakage is a concern. The hollow channels within the sheet create an insulating barrier, allowing for thermal efficiency while reducing overall weight. This structure also provides flexibility in design, enabling architects and builders to use the material in a range of applications.

Benefits of Using Polycarbonate Hollow Sheets

Durability and Strength

One of the standout features of polycarbonate sheets is their impressive durability. They can withstand extreme weather conditions, including heavy rain, hail, and high winds. The high impact resistance means they are less likely to crack or shatter compared to other materials like glass or acrylic. This resilience makes polycarbonate hollow sheets a long-lasting option for various construction projects.

Thermal Insulation

The hollow design of these sheets enhances their thermal insulation capabilities. The air trapped within the channels acts as an insulating layer, reducing heat transfer and improving energy efficiency. This feature is particularly beneficial for greenhouses, where maintaining a stable temperature is crucial for plant growth, as well as for buildings looking to reduce energy costs.

Lightweight and Easy to Install

Polycarbonate hollow sheets are significantly lighter than glass, which makes them easier to handle and install. This lightweight nature can lead to reduced shipping costs and simpler installation processes, saving time and labor expenses. Their flexibility allows them to be cut and shaped according to specific project needs, further enhancing their usability.

UV Resistance

Another critical advantage of polycarbonate hollow sheets is their UV resistance. Most manufacturers treat these sheets with a special coating that protects against harmful UV rays, which can degrade materials over time. This UV protection ensures that the sheets maintain their clarity and structural integrity even after prolonged exposure to sunlight.

Common Applications of Polycarbonate Hollow Sheets

Greenhouses and Agricultural Structures

One of the most common uses for polycarbonate hollow sheets is in the construction of greenhouses. The excellent light transmission capabilities combined with thermal insulation make them ideal for creating a controlled environment for plants. These sheets allow for maximum sunlight penetration while minimizing heat loss, promoting healthy growth year-round.

Roofing and Canopies

Polycarbonate sheets are increasingly popular for roofing applications, especially in commercial and residential projects. Their lightweight nature and durability make them perfect for canopies, awnings, and patio covers. These structures benefit from the transparency of polycarbonate, allowing natural light to flood the area while providing protection from the elements.

Partition Walls and Interiors

In modern architectural design, polycarbonate hollow sheets are often used for interior partition walls. Their versatility allows for creative and functional space designs, while their light weight simplifies installation. The option for customizable colors and finishes makes them suitable for various aesthetics, from sleek modern designs to more traditional looks.

Signage and Display Cases

Polycarbonate hollow sheets are also utilized in signage and display cases due to their clarity and durability. They can be easily molded into different shapes and sizes, making them ideal for custom signage. Their resistance to breakage ensures that signs remain intact and readable over time, even in outdoor environments.

Comparing Polycarbonate Sheet Prices

When considering the use of polycarbonate hollow sheets, it’s essential to evaluate the Polycarbonate sheet price. Prices can vary significantly based on several factors, including thickness, size, and any additional treatments, such as UV protection or color tinting. Generally, while polycarbonate sheets may have a higher upfront cost than materials like acrylic or PVC, their longevity and performance often justify the investment. Over time, the savings in energy costs and replacement expenses can offset the initial expenditure.

Choosing the Right Polycarbonate Sheet

Thickness and Structure

When selecting Polycarbonate sheet for a specific project, it’s crucial to consider the thickness and structural configuration of the sheets. Thicker sheets provide better insulation and impact resistance, while thinner sheets may be more suitable for lightweight applications. The number of hollow channels can also affect insulation properties and overall performance.

Color and Transparency

Polycarbonate hollow sheets are available in various colors and levels of transparency. Clear sheets allow maximum light penetration, while tinted options can provide shade and reduce glare. When choosing sheets for a greenhouse, for example, clear sheets are often preferred, whereas darker sheets might be better for roofing applications where heat retention is desired.

Manufacturer and Quality

Quality matters when it comes to polycarbonate sheets. Always choose products from reputable manufacturers who offer warranties and clear specifications on their sheets. This ensures that you receive a product that meets your performance expectations and can withstand the test of time.

Conclusion: The Versatility of PC Hollow Sheets

In conclusion, polycarbonate hollow sheets are a remarkable building material that offers a multitude of benefits, including durability, thermal insulation, and UV resistance. Their lightweight nature and versatility make them suitable for a wide range of applications, from greenhouses and roofing to interior partitions and signage. While the polycarbonate sheet price may initially seem higher than alternatives, the long-term savings and performance advantages often make them the better choice. As construction and design continue to evolve, polycarbonate hollow sheets are likely to play an increasingly vital role in innovative building solutions.

FAQs About Polycarbonate Hollow Sheets

1. What are polycarbonate hollow sheets?

Polycarbonate hollow sheets, or PC hollow sheets, are lightweight, durable panels made from polycarbonate resin. They feature a unique hollow channel structure that enhances insulation and impact resistance, making them ideal for various applications, such as greenhouses, roofing, and signage.

2. What are the benefits of using polycarbonate hollow sheets?

Polycarbonate hollow sheets offer several advantages, including:

Durability: They are highly resistant to impact and weather conditions.

Thermal Insulation: The hollow channels provide excellent thermal efficiency.

Lightweight: Easier to handle and install compared to glass.

UV Resistance: Many sheets are treated to resist UV rays, preventing degradation over time.

3. How do polycarbonate sheets compare in price?

The polycarbonate sheet price can vary based on thickness, size, and any additional features like UV protection or tinting. While they may have a higher initial cost compared to materials like acrylic or PVC, their durability and energy efficiency can lead to savings in the long run.

0 notes

Text

EMERGENCY STOP LOCKOUT 30MM | RYXO SAFETY #14868

INNER DIA 30mm

COLOUR Transparent

MATERIAL Made from high strength transparent glass resin PC.

APPLICATION Install on the controller button forever, avoid accidentally touch

SIZE Height: 31.9mm; outer diameter: 49.6mm;

WEIGHT 22gm

ORIGIN China

#buttonlockout#buttonlockoutuae#clearway#clearwayabudhabi#clearwaysafety#clearwaysafetystore#clearwayuae#emergencystoplockout22mm#emergencystoplockout30mm#emergencystoplockoutabudhabi#emergencystoplockoutnearme#emergencystoplockoutsupplierinuae#emergencystoplockoutuae#lockouttagoutuae#lockouttagoutwholesaleuae#lockuttagoutsupplieruae#ppesafetystore#ryxo#ryxoabudhabi#ryxobrand#ryxosafety#ryxouae#safetyshopabudhabi#safetyshopuae#transparentlockout

0 notes

Text

How to choose the perfect Case for your Smartphone

Your smartphone is the bridge that connects you to the digital world. Nevertheless, it is your duty to protect your valuable phone or give up the power of responsibility. Choosing the right case may be hard, with many kinds of styles and materials trying to catch your attention. This page will help you to select the best enclosure for your phone in these ways:

Prioritizing Your Needs

Basic Bumpers

In case you opt for a slender appearance and minimum protection, a bumper case gives you merely scratch and small bump defense. These thin cases are perfect for style lovers and people who have a soft-hand feeling.

Transparent Protection

Transparent phone cases are the most sought-after alternative to the kinds of frequency exhibited by a smartphone's design but with all due respect, they come with a few scratches and nicks shielded against them. Some of the clear cases are made with scratch-resistant materials like TPU to prevent them from being damaged.

Rugged Resilience

If you have the soul of a traveler, be sure to use a protective case from the best brands. These mobile phone protectors are usually made of shock-resistant materials, such as TPU or jackets reinforced in the corners, and thus they can survive the hardest of falls and the worst impacts. The most advanced cases have built-in screen protectors necessary for all-around safeguarding.

Finding the Right Material for your Case

1. Silicone/TPU

The very bendable materials provide the optimum level of protection as well as the best grip. There are so many different colors and different textures of the silicone cases provided, TPU offers a clear or semi-transparent option, unlike the others.

2. Polycarbonate (PC)

This harder shiny synthetic resin can use a more coherent structure to defend against scratches and any drop that may occur. But PC cases can be slippery and they may not absorb shocks as well as some other materials.

3. Leather/Wood

Leather or wooden cases can be used for the cases that should look nicer and be nicer at the same time. But, the materials used in such high cases usually offer less protection than different materials and may require you to pay more additional money.

Features to Consider

Kickstands

Do not get bored when you got no hand to hold a gadget, you can let it be viewed with a position of your hand from a casing that has a built-in stand. This aspect is very important for people when they are watching films or video calls.

Wallet Functionality

You can incredibly carry what you need every day with a case that is designed to also serve as a wallet. Several covers have built-in card slots for the safekeeping of primary documents such as IDs or credit cards.

Wireless Charging Compatibility

Before you choose the case, make sure it is compatible with wireless charging if you often use such technology.

Conclusion

The purchase of the perfect case for a smartphone is a choice that one will make based on one's specific needs and preferences. Consider your lifestyle, the quality of protection, and your budget while deciding. Keep in mind that a great case need not forego style. With an abundance of options at your disposal, there is a case that will act as a shield for your smartphone and at the same time, mirror your personality.

#SmartphoneCase#mobilecovercase#DropProof#AdventureReady#FlexibleProtection#UniquePersonality#SeamlessExperience#WhichCaseIsRightForYou#TechTips

1 note

·

View note

Text

Innovation in Clarity: Exploring the Applications of Poly Methyl Methacrylate (PMMA) (2023-2034)

Ever heard of Polymethyl methacrylate (PMMA)? PMMA is a transparent and rigid thermoplastic, crafted from the monomer methyl methacrylate, holding impressive resistance to UV light and weathering. With its crystal-clear clarity, PMMA finds its way into a myriad of applications, from sleek car windows and durable smartphone screens. Read more about the versatility and manufacturing of PMMA in this blog! The global Poly Methyl Methacrylate (PMMA) market is likely to flourish at a CAGR of 4.05% by the year 2034.

Introduction

A scientific term, Poly (methyl methacrylate), refers to the clear and lightweight plastic commonly called acrylic or plexiglass. In its natural state, it's easily broken, but it can be colored, textured, and shaped in many ways. Crystal-clear plastic, known as Polymethyl methacrylate (PMMA) or acrylic, stands out for its toughness. Unlike glass, it won't shatter, making it a popular choice as a substitute. PMMA boasts several advantages over other clear plastics like polycarbonate (PC) and polystyrene (PS). These include superior resistance to sun damage and weather, exceptional light transmission, and the ability to be colored in any shade imaginable.

Scientific Properties: PMMA is scratch resistant and remains unaffected by aqueous solutions. However, exposure to certain chemicals like aromatic or chlorinated hydrocarbons, esters, or ketones can compromise its surface.

Sound and Break-Resistance: PMMA acts as a sound-resistant material, reducing the transmission of external sound waves. This quality makes it ideal for constructing spaces that require internal sound insulation, such as audio studios, libraries, quiet rooms, and vehicles.

Environmental Sustainability: PMMA exhibits excellent outdoor durability, resisting corrosion, ultraviolet light, and various environmental factors. Furthermore, it is both recyclable and BPA-free, making it one of the safer plastics in terms of environmental impact. These characteristics contribute to PMMA's sustainability profile, aligning with eco-conscious practices and initiatives.

Manufacturing Process

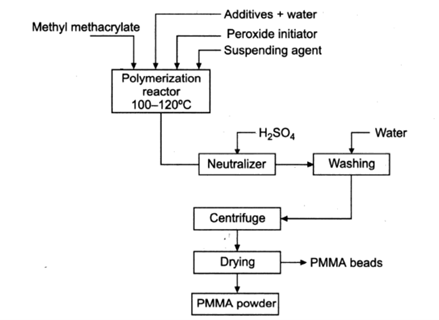

PMMA, derived from methacrylic acid (CH2=C[CH3]CO2H), is a significant member of the acrylic resin family. Its production primarily involves propylene, obtained from the lighter fractions of crude oil, and benzene, reacting to form cumene or isopropylbenzene. The resulting cumene undergoes oxidation to cumene hydroperoxide, then acid treatment to yield acetone. Subsequently, acetone undergoes a three-step process to produce methyl methacrylate (CH2=C[CH3]CO2CH3), a flammable liquid. Methyl methacrylate is polymerized, either in bulk liquid form or as fine droplets suspended in water, using free-radical initiators to form solid PMMA. This polymerization process links the molecules together, resulting in the formation of PMMA with a repeating unit structure.

The polymerization reactor receives a feed mixture consisting of a monomer, water acting as the reaction medium, suspending agents, and a monomer-soluble initiator. To adjust the density of the aqueous medium, decrease the monomer's water solubility, and increase interfacial tension, an inorganic salt is added. Polymerization occurs at around 100°C. After polymerization, the resulting slurry is neutralized with sulfuric acid before undergoing filtration or centrifugation. The material is then dried. This method ensures the controlled production of the desired polymer, achieved through the precise interaction of monomers, reaction medium, initiators, and additives within the polymerization reactor.

Applications of Poly Methyl Methacrylate (PMMA)

Construction

PMMA is very useful in building. It is commonly used for shatterproof skylights. It may also be found in many shower and bath systems, and many people prefer acrylic over ceramic tiles. As previously said, acrylic may be found in many sound-proof rooms, audio studios, and automobiles.

Automotive

PMMA sheets are utilized in automobile windows, motorbike windshields, interior and exterior panels, fenders, and other vehicle components. Colored acrylic sheets are also utilized in automotive indication light covers and interior light covers, among other applications. It is also utilized for ship windows (salt resistance) and aviation applications.

Electronics

Because of its superior optical clarity, high light transmission, and scratch resistance, PMMA is widely utilized in LCD/LED television screens, computers, smartphone displays, and electrical equipment. PMMA is also utilized as a cover material in solar panels due to its strong UV resistance and light transmission properties, which allow for high energy conversion efficiencies.

Furniture

PMMA provides exceptional features like transparency, hardness, and attractiveness to make chairs, tables, kitchen cabinets, bowls, and table mats in any shape, color, or finish.

Market Outlook:

The PMMA market is embracing sustainability. As environmental concerns grow, manufacturers are seeking eco-friendly solutions for PMMA, either through bio-based materials, improved recycling, or circular economy approaches. This aligns with the global push for sustainability and positions PMMA to meet evolving consumer and regulatory demands. Additionally, PMMA's clear optics, biocompatibility, and easy sterilization make it ideal for healthcare applications like lenses, instruments, and dental materials. As healthcare technology advances, PMMA's properties are well-suited for these demanding medical uses, creating exciting opportunities for market growth and diversification.

Poly Methyl Methacrylate (PMMA) Major Players

Significant companies in the Global Poly Methyl Methacrylate (PMMA) market are Mitsubishi Rayon Co., Ltd., Evonik, Chi Mei Corporation, Sumitomo Chemical, LX MMA, Wanhua Chemical, Suzhou Double Elephant Optical Materials, and Kuraray Co., Ltd., Lotte MCC, and Others.

Poly Methyl Methacrylate (PMMA) market restraints

The Poly Methyl Methacrylate (PMMA) market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Poly Methyl Methacrylate (PMMA) production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Poly Methyl Methacrylate (PMMA) manufacturers.

Difficulty in Recycling: While clear acrylic sheets can be recycled, the process is complex. Breaking down large pieces and using specialized methods like perspex recycling are just the first steps. This difficulty contributes to a global problem of acrylic waste harming ecosystems. In some areas, acrylic buildup disrupts the natural balance of CO2 and O2 exchange, hindering plant growth.

Conclusion:

The Polymethyl Methacrylate (PMMA) market has boomed in recent years, driven by its use in key industries like electronics, automotive, and construction. PMMA's unique properties, such as high durability and chemical resistance, suggest continued growth in the coming years. Rising urbanization, increasing demand for modern electronics, and projected growth in vehicle sales are all expected to fuel PMMA demand by 2034.

#PMMA#PMMAprices#PMMAmarket#PMMApricetrend#PMMApriceforecast#PMMAmarketprice#priceofPMMA#PMMAdemand#PMMASupply

1 note

·

View note

Text

Exploring Stretch Film Rolls: Understanding PE Film Manufacturing and Plastic Sheet Types

Introduction to Stretch Film Rolls

In this article, we'll delve into the world of stretch film rolls, focusing on the manufacturing process of PE (Polyethylene) film and various types of plastic sheets. Stretch film rolls are widely used in packaging, agriculture, and industrial applications due to their versatility and durability.

1. Understanding Stretch Film Rolls

1.1 What are Stretch Film Rolls?

Stretch film rolls, also known as stretch wrap or pallet wrap, are thin plastic films used to secure and protect items during transportation and storage. They are typically made from materials like polyethylene and offer excellent stretchability and cling properties.

1.2 Importance in Packaging

Stretch film rolls play a crucial role in packaging by providing a tight and secure wrap around products, ensuring stability and protection against moisture, dust, and damage.

2. Manufacturing Process of PE Film

2.1 Raw Material Selection

The manufacturing of PE film begins with the selection of high-quality polyethylene resin, which determines the film's properties such as strength, flexibility, and clarity.

2.2 Extrusion Process

The selected resin is melted and extruded through a die to form a continuous thin film. This process allows for precise control over the film's thickness and width.

2.3 Cooling and Winding

Once extruded, the film is cooled using chill rolls to solidify it. It is then wound into large rolls for further processing or packaging.

3. Types of Plastic Sheets

Below are the Plastic sheets Type:

3.1 Polyethylene (PE) Sheets

PE sheets are versatile plastic materials known for their excellent chemical resistance, flexibility, and low moisture absorption. They find applications in industries such as agriculture, construction, and packaging.

3.2 Polyvinyl Chloride (PVC) Sheets

PVC sheets are rigid plastic materials known for their durability and chemical resistance. They are commonly used in construction, signage, and automotive applications.

3.3 Polycarbonate (PC) Sheets

PC sheets are transparent, lightweight, and impact-resistant plastic materials. They are often used in glazing, signage, and electronic applications where clarity and strength are essential.

3.4 Acrylic Sheets

Acrylic sheets, also known as Plexiglas or acrylic glass, are clear plastic materials with excellent optical clarity and weather resistance. They are commonly used in signage, displays, and architectural applications.

Conclusion:

Enhancing Packaging and Industrial Solutions with Stretch Film Rolls

Stretch film rolls play a vital role in modern packaging and industrial applications, offering secure and cost-effective solutions for product protection and transportation. Understanding the manufacturing process of PE film and the various types of plastic sheets allows businesses to make informed decisions when selecting materials for their specific needs.

FAQs:

1. What are the benefits of using stretch film rolls in packaging?

Stretch film rolls offer several benefits in packaging, including:

- Secure Protection: Stretch film wraps tightly around products, providing stability and protection against damage during transportation and storage.

- Moisture Resistance: The cling properties of stretch film help to seal out moisture, keeping products dry and free from water damage.

- Cost-Effective: Stretch film is a cost-effective packaging solution compared to other methods like shrink wrapping or strapping.

- Versatility: It can be used to wrap various shapes and sizes of items, offering flexibility in packaging applications.

2. How does the manufacturing process of PE film contribute to its properties?

The PE film manufacturing process involves extruding polyethylene resin into thin sheets. This process contributes to the properties of PE film in the following ways:

- Thickness Control: The extrusion process allows for precise control over the thickness of the film, ensuring consistent quality.

- Flexibility: PE film is known for its flexibility, which is achieved through the careful selection of resin and processing parameters during extrusion.

- Strength: By adjusting the extrusion conditions, manufacturers can tailor the strength of PE film to meet specific application requirements.

3. What are the key differences between PE, PVC, PC, and acrylic sheets?

- PE (Polyethylene) Sheets: Known for their flexibility and moisture resistance, PE sheets are commonly used in packaging and agriculture.

- PVC (Polyvinyl Chloride) Sheets: PVC sheets are rigid and durable, often used in construction, signage, and automotive applications.

- PC (Polycarbonate) Sheets: PC sheets are transparent, lightweight, and impact-resistant, suitable for glazing, signage, and electronic applications.

- Acrylic Sheets: Acrylic sheets offer excellent optical clarity and weather resistance, making them ideal for signage, displays, and architectural applications.

4. Can stretch film rolls be recycled?

Yes, stretch film rolls can be recycled. However, the recyclability of stretch film depends on the type of material used and local recycling facilities. It's essential to check with your recycling provider to determine their policies on accepting stretch film for recycling.

5. What industries commonly utilize plastic sheets for their applications?

Plastic sheets are widely used across various industries, including:

- Packaging: For wrapping and protecting products during shipping and storage.

- Agriculture: In greenhouse covers, mulch films, and crop protection.

- Construction: For roofing, glazing, insulation, and cladding.

- Automotive: In interior trim, body panels, and protective covers.

- Signage and Displays: For advertising signs, point-of-sale displays, and decorative panels.

These industries rely on plastic sheets for their versatility, durability, and cost-effectiveness in a wide range of applications.

0 notes

Text

Scientists have developed an enzyme that can break down plastic

In 2022 alone, the consumption of polycarbonate was estimated at 4.51 million tons worldwide. Here, plastic bottles make up a large part because they are often based on polycarbonate.

A group of researchers has developed an enzyme that can break down a certain type of plastic, which can then be recycled.

A research team at the Department of Materials and Production at Aalborg University[1] in Denmark has developed an enzyme that can break down plastic of the polycarbonate[2] type, so that it can be recycled and used to produce plastic again.

And according to associate professor from the Department of Materials and Production Evamaria Petersen, it is much more climate-friendly than using the chemical process that is used today. “With chemical decomposition, you use much more energy and a very high temperature of around 300 degrees, whereas you use around 70 degrees to break down plastic by using enzymes”, she says.

The reason for the high heat during the chemical process is that the structure of the plastic must change so that it becomes less hard. And therefore the code for a biological breakdown of plastic, according to Evamaria Petersen, is that the temperature is high and that the enzymes can cope despite the heat.

Polycarbonate is found in many everyday products. For example, plastic bottles, garden tools and household goods are often based on polycarbonate. In 2022 alone, consumption was estimated at 4.51 million tonnes worldwide. But in order for enzymes to replace the chemical decomposition process in the future, it will require quite a few more hours in the laboratory.

“So far it is a prototype that we have developed, because in a technical process it is too slow to break down the plastic. But we are in the process of further developing it, so that the process will be faster,” says Evamaria Petersen.

In addition, the research team is developing models for enzymes that can also break down other forms of plastic so that it can be recycled. Polycarbonate has so far been considered non-degradable and therefore harmful to the Earth. But the new decomposition method may be the solution to a greener way to break down plastic in the future, so that it can be used for recycling.

Source

Ritzau: Forskere har udviklet et enzym der kan nedbryde plastik, in : Berlingske, 13-12-2023, https://www.berlingske.dk/danmark/forskere-har-udviklet-et-enzym-der-kan-nedbryde-plastik

[1] Department of Materials and Production (MP) is a wide-ranging research and educational environment located at Aalborg University, with a mission of meeting future demands for new materials and production systems by directing the entire value chain, from basic material understanding, materials’ applications in mechanical constructions, to industrial production and management. https://www.mp.aau.dk/

[2] Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as "Other", 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

0 notes

Text

An Economical On-line Stress Detection System for Polyester Sheet

Polycarbonate is a strong thermoplastic resin, almost colorless and transparent with good optical properties. PC resin can be processed into large rigid products with low molding shrinkage and good dimensional stability.

The three major application fields of PC resin as engineering plastics are glass assembly industry, automobile industry, electronics and electrical appliances industry, followed by industrial machinery parts, packaging, medical and protective equipment, etc.

PC resin is used in automotive lighting systems, instrument panel systems and interior decoration systems, as headlight covers, front and rear baffles. Medical grade PC materials can be used to make syringes, surgical masks, disposable dental appliances, etc. With the rapid development of aviation technology, the requirements for various components in the aircraft are constantly increasing, which makes the application of PC in this field also increase day by day. According to statistics, there are 2,500 polycarbonate parts used in only one Boeing aircraft, and a single plane consumes about 2 tons of polycarbonate. In the field of photovoltaics, solar panels with PC boards can reduce the weight by about half compared with solar panels using glass, and can be installed on any roof due to their lighter weight. The panels also emit 80% less CO2.

The production process of PC board is extrusion molding, and the main equipment required is an extruder. Common coil widths are 850mm, 1220mm, 1560mm, 1820mm, 2100mm. Aiming at solving the cracking problem raised by the PC sheet manufacturer with a width of 850mm, we now provides a set of economical online stress testing solutions. Only 2 sets of enlarged hand-held Polariscope is needed to conduct stress detection in the front and back sections. The polariscope can be embedded in customer's production lines. For more information about customized solutions, please feel free to contact us .

0 notes

Text

Exploring the Possibilities of Vacuum Mold Casting

If you're looking to create high-quality prototypes in small quantities, vacuum mold casting (also known as cast urethanes or vacuum casting) might be the ideal solution. This method can produce parts rapidly and efficiently, making it an excellent substitute for production tooling.

Working with a competent manufacturer, you can create parts of any size using a variety of materials that have similar properties to thermoplastics. By partnering with a trusted service provider, you can fully explore and leverage the capabilities of vacuum casting for your project, yielding superior results in a cost-effective and time-efficient manner.

What can vacuum casting do?

Vacuum casting involves creating a master model of your design using stereolithography (SLA 3D printing) or CNC machining. Once the model is ready, liquid silicone will be poured around it and left to cure. After drying, the master will be removed from the mold, leaving only the cavity. Then, the casting process begins by pouring your choice of resin into the cavity. This should ultimately result in a production-like replica.

With vacuum mold casting, it is possible to produce identical plastic or rubber parts for low-volume prototyping or end-use production. It’s also beneficial for rapid iterations and market testing, as it can be done with a low, upfront investment, and it can generate self-colored parts.

Build production-grade parts

Do you want to save time building identical parts for low-volume production? Molding has scalable production capabilities that will allow you to produce anywhere from thousands to millions of similar components. Additionally, vacuum casting can build your parts from a massive selection of materials. Regardless of your choice, it will result in production-like components. Reputable manufacturers can use materials similar to ABS, PMMA, PA, PP, or PC, with additional features like transparency or flame retardant. They can also make parts from transparent soft rubber.

Create quality, detailed parts

Though you are building prototypes, vacuum mold casting can generate production-quality parts as good as injection-molded ones but with more details, thanks to silicone molds. That makes it suitable for highly detailed, small components. So, you can confidently test your parts in real-world settings before mass producing them.

We can support your prototyping needs.

Are you considering vacuum mold casting for your project? Contact us here at HLH Proto, and we will make it happen! We can also review your project and provide design tips to help you make the most of vacuum casting.

0 notes

Link

If you are interested in buying PC transparent resin for manufacturing your products you want to ensure that you choose the right companies that can help you with the resins and granules.

0 notes

Text

"Beneath the Light of Jadeite" Version 1.5 Update Details (II)

IX. Optimizations

● System

1. Three opportunities will arise every week to halve the Original Resin cost of revitalizing the Trounce Blossoms at the Trounce Domains and Dominator of Wolves challenges.

2. In Co-Op Mode, when there are two or less characters in the team that can be controlled per player, the Companionship EXP obtained is doubled.

3. New Voice-Over Files Management function added to PC and mobile: You can uninstall voice-over files by going to Settings > Language > Manage Voice-Over Files. (In Version 1.5, you must first update the voice-over files under Settings > Language > Voice-Over Language before you can uninstall them.)

4. Optimizations to some controls when using a controller:

• When moving the left joystick up and down to select who you want to chat with, the right side of the screen will switch to the corresponding chat information without needing to first press the Confirm button.

• Move the left joystick to the right to enter the selected chat.

• The Sort Rule button on the Weapons screen (in Inventory), Artifacts screen (in Inventory), and Character Selection screen (in the Character Menu) has been changed from the up button to the down button.

• The left joystick can now be used to switch between sections of the interface in Settings and Achievements.

• Optimizes the display design of the Controller screen: When a button status changes from usable to unusable, the button icon will be hidden.

• On the Report screen, the default button for text editing has been made consistent with the controls of other in-game interface: for PlayStation controllers, this has been changed from the circle button to the square button; for Xbox controllers, this has been changed from the B button to the X button.

• The controls to skip the Battle Pass animation, Wish animation, and animation of claiming rewards in Domains has been changed for controller users: now, hold the circle/B button to skip; the confirmation pop-up window has been removed.

• The button layout display of different controllers has been made consistent.

• The controls for closing the pop-up menus for Artifact Enhancement, Weapon Enhancement, Artifact Filter, and Character Selection has been changed: the Back button previously closed the entire screen, but it now only closes the pop-up menu.

5. Optimizes the default text and display status in the text entry box:

• Unsent text in the text entry box will be saved as a draft in the current chat's text entry box.

• When the text entry box in the current chat is empty, the draft (if any have been saved) will be displayed.

• The text entry box will be cleared after a draft is completed and sent if the chat is deleted from the chat list, or after exiting the game.

6. Optimizes some displays of chat boxes on PC and PlayStation®4:

• After deleting the other player in the chat, the chat content on the main chat screen will be deleted.

• After going offline, chat content on the main chat screen will be cleared. It will only display new messages received after the last time you went offline (including messages received while offline).

7. Optimizes aiming on mobile:

• On mobile, three additional adjustment levels have been added under Settings > Camera Sensitivity (Aimed Shot Mode). It has been increased from the original levels 1 to 5 (which now correspond with the new levels 4 to 8) to the new adjustment levels 1 to 8.

• On mobile, the Acceleration Slider (Aimed Mode) setting has been added. With this setting enabled, the camera movement speed will change dynamically with the speed of your finger. Sliding faster causes the camera angle to rotate more.

8. The amount of Condensed Resin has been added above the button to claim rewards for Domains and Ley Line Blossoms (if you have no Condensed Resin, it will not be displayed).

9. Optimizes the anti-aliasing effect on the avatar in one's profile.

10. Optimizes the animation performance of Zhongli's Plunging Attack.

● Co-Op

1. Optimizes the animation performance of nearby monsters and objects in Co-Op Mode when the visiting player is far from the host player.

● Other

1. Optimizes the aesthetics of lighting effects of certain weapons after ascension.

2. Adjusts some missions in Battle Pass > Weekly Missions (the total BEP that can be earned remains unchanged by the adjustment).

Deleted BP Missions:

• Collect 100 Mondstadt local specialties

• Collect 100 Liyue local specialties

• Complete the Wolf of the North Challenge

• Complete the Stormterror Domain Challenge

• Complete the Golden House Challenge

New BP Missions:

• Complete Trounce Domains or the Dominator of Wolves challenge 3 times

• Obtain a total of 1,000 Realm Currency

• Create a total of 10 furnishings

• Purchase 2 items from the Teapot Traveling Salesman in another player's Serenitea Pot

3. The Stellar Reunion event is amended as follows:

a. Deletes the following quests:

• Forge 3 items

• Defeat boss enemy 1 time

b. Adds the following quests:

• Level up a character once using any quantity of Character EXP Materials

• Enhance a weapon once

• Enhance an artifact once

c. For the Original Resin consumption quests, decreases the quantity of Original Resin that Travelers at Adventure Rank 10–50 are required to consume

No change has been made to the total points that can be obtained in one day.

Applies to: Travelers who activate the Stellar Reunion event after the V1.5 update

〓Bug Fixes〓

● Domains

1. Fixes an issue in the Domain "Midsummer Courtyard" whereby the Mutant Electro Slime may incorrectly remain in place.

● Monsters

1. Fixes an issue with the Cryo Regisvine and Pyro Regisvine bosses whereby when they fall, Xiao may get stuck inside them when using his Elemental Skill "Lemniscatic Wind Cycling."

2. Fixes an issue with the Cryo Regisvine and Pyro Regisvine bosses whereby they are raised into the air by Geo constructs created before they refresh.

3. Fixes an issue whereby monsters' Mist Bubble skill may incorrectly trap characters or monsters.

4. Fixes an issue whereby Abyss Mages lack a shield for a short time when they appear.

5. Fixes an issue with the monster Abyss Herald: Wicked Torrents whereby there is a small chance that its Elemental Shield cannot be triggered and it cannot be defeated.

6. Fixes an issue with the Pyro Abyss Mage in Domains whereby it may not move when its target is far away.

● Co-Op

1. Fixes an issue whereby certain characters' skills are unable to trigger elemental reactions in Co-Op Mode.

● Weapons

1. Fixes an issue whereby immediately switching characters after a character equipped with Prototype Amber casts an Elemental Burst may cause the character to miss an opportunity to regenerate Elemental Energy.

2. Fixes an issue with some non-slime monsters whereby the weapon Black Tassel's effect "Bane of the Soft" is incorrectly triggered.

● Characters

1. Fixes an issue whereby when certain characters are standing on a slope, the position of their weapon will be incorrect in idle animations.

2. Fixes an issue whereby when bow-wielding characters are standing in Aiming Mode on top of the Solar Isotoma, the Solar Isotoma is unable to generate a crystallized platform.

3. Fixes an issue whereby the Phoenix summoned by Diluc's Elemental Burst and certain monster skill effects, such as Rumbling Stone, are affected by some skills (such as the Anemo Traveler's "Gust Surge").

4. Fixes an issue with Fischl's Lv. 1 Constellation "Gaze of the Deep" whereby Oz's joint attacks may not deal damage.

5. Fixes an issue with Fischl's Elemental Burst "Midnight Phantasmagoria" whereby she will incorrectly pass through some large monsters.

6. Fixes an issue whereby when Fischl summons Oz, he incorrectly targets the burning area generated by the Pyro Regisvine's seeds.

7. Fixes an issue whereby when Oz, summoned by Fischl, triggers certain elemental reactions that attack multiple opponents, an incorrect quantity of Elemental Particles is generated.

8. Fixes an issue whereby when Xiao defeats certain opponents with his Elemental Skill "Lemniscatic Wind Cycling," he is unable to gain the Elemental Particles generated by "Lemniscatic Wind Cycling."

9. Fixes an issue with the shield generated by Diona whereby when terminating the game client process while the shield is active, the effect duration of the Passive Talent "Cat's Tail Secret Menu" may not be as expected.

10. Fixes an issue whereby the orientation of the Vision on the character models of Bennett, Xinyan, Hu Tao, Zhongli, and Xingqiu is incorrect.

11. Fixes an issue with Keqing whereby after unleashing her Elemental Burst "Starward Sword," the afterimage effects do not disappear correctly.

12. Fixes an issue with Beidou whereby pressing the Attack button consecutive times when beginning a Charged Attack causes the Charged Attack duration to function abnormally.

13. Fixes an issue with the Ice Lotus created by Ganyu's Elemental Skill and the Baron Bunny created by Amber's Elemental Skill whereby if they are destroyed just as their duration is about to end, they may generate two Elemental Particles in quick succession.

14. Fixes an issue whereby in certain situations, Elemental Energy is not consumed when characters unleash their Elemental Burst.

● System

1. Fixes an issue in languages other than Simplified Chinese whereby the description for the Ruin Hunter entry in the Archive is missing.

2. Fixes an issue whereby characters may display abnormal colors when changing characters multiple times after activating Elemental Sight.

3. Fixes an issue whereby the charge status of the Wind Catcher gadget is displayed incorrectly after switching accounts.

4. Fixes an issue whereby the background of the Archive is abnormally transparent when opening the Living Beings section of the Archive after opening the Character Menu.

5. Fixes an issue whereby you are unable to set pins on the edges of the map when using a controller.

6. Fixes an issue on mobile whereby you are unable to scroll through the list in the Statue's Blessing screen when using a controller.

7. Fixes an issue on PC whereby Esc cannot be used to return to the previous menu when viewing the Hangout Memories of a Hangout Event.

● Audio

1. Fixes some voice-over issues, out-of-sync voice-over and animation, and missing voice-over files.

2. Fixes distorted audio affecting the Windsong Lyre gadget.

3. Fixes the issue of incorrect character voice positioning when using surround sound devices.

● Other

1. Fixes an issue with the Books section of the Archive whereby the descriptions of Vol. 6, 7, and 8 of "Hex & Hound" are the same when they are not yet unlocked.

2. Fixes an issue whereby the cleaning animation doesn't adapt correctly to the display size under certain circumstances.

3. Fixes an issue whereby if one is switching characters when entering a room in a building, the original character will still be switched back out onto the field.

4. Fixes an issue whereby the Restorative Power of the Statues of the Seven may be cleared after going offline or after returning to your own world from a Co-Op session.

5. Fixes an issue in languages other than Simplified Chinese and Japanese whereby the description for the Domain "Temple of the Lion" is missing.

6. Fixes textual errors and display issues in English, German, French, Spanish, Portuguese, Russian, Vietnamese, and Japanese and optimizes the localization of the text. (Note: Related in-game functions have not changed. Travelers can view the changes in different languages by going to the Paimon Menu > Settings > Language and changing the Game Language.)

In English, the fixes and optimizations to textual errors, display issues, and localization of the text include:

◆ Optimizes the wording on the Crystal Top-Up screen. The original description reads: “First-time buyer bonus available only once”. The revised description reads: “Double Crystal bonus valid for first purchase of each value only”.

42 notes

·

View notes

Text

How much does the physical doll cost?

What material is tpe

TPE is a thermoplastic material, but it has a high content of glue and can be recycled. Excellent processing performance, no vulcanization, recyclable, low cost, secondary injection molding, coating and bonding with PP, PE, PC, PS, ABS and other matrix materials, or it can be molded separately.

What material is silicone

Silica gel alias: silicic acid gel, which is a highly active adsorption material and is an amorphous substance. The main component of silica gel is silica, which is chemically stable and does not burn.

TPE and silicone have many similar characteristics, such as soft touch, rubber elasticity, environmental protection and non-toxicity. Silicone is a traditional material. TPE has only emerged in the rubber and plastics industry for nearly a decade or two. Both have their own advantages. However, in terms of processing performance, recyclability, and cost price, TPE meets the inadequacy of silicone materials. With more and more types and applications of TPE, TPE is the preferred material instead of silica gel.

[How to quickly identify TPE and silicone]

Silica gel: The burning flame is bright white, with light odor, less smoke, and the residue is white powder. Silica gel has transparent particles as well as other irregular solid-like materials. It is divided into inorganic and organic silica gel. The hardness range is 10~90A. Silicone has excellent tensile resilience. And TPR/TPE (based on SBS, SEBS substrate). The burning flame is yellow or yellow up and blue underneath. TPR and TPE of different hardness and substrates (the reason there is TPE, TPR is related to the different calling habits of users), the smoke produced is lighter or thicker, and the smell is also different, but they all have the special fragrance of styrene taste.

[Which one is better for dolls or physical dolls? Tpe or silicone? 】

Generally speaking, the silicone material is from 100 to 500 per kilogram, and the TPE is about 5 yuan to 20 yuan per kilogram, so you can feel that if your doll or physical doll is about 1.70, the weight is 35 kilograms, remove the skeleton 2. -3 kg. If it is a better silicone material, the cost of the material alone is close to more than 6000, plus the skeleton, headgear, eyeballs, dentures, matching parts, clothing, logistics costs, labor costs, and no retail sales of tens of thousands Price, there is only one possibility, the silicone material used in the product is very cheap.

TPE silicone doll or entity doll

Therefore, if you want a softer touch, it is recommended to use TPE material. With current technology, it is difficult to make new breakthroughs in silicone material. However, in the future, the material is likely to directly use biological cells, and it will not be any different from the touch of a real person.

Thermoplastic elastomer TPE material is one of the new materials that have been extremely popular in recent years. It is a thermoplastic elastomer material with high elasticity (or even better), high strength, high resilience, and high wear resistance of silicone rubber products. It is environmentally friendly and non-toxic in contact with human skin. It can also be used in medical and survival products for most of the time. Many materials can replace silicone products.

With the widespread application, many TPE merchants have joined the raw material business trend. However, due to the slow acceptance of new materials in many traditional industries, the pace of update is not ideal, and they are committed to contributing to the elastomer business and the social environmental protection cause. Purpose of contribution,

A good physical doll with a size of 100 cm needs about 5,000. If it is two thousand yuan, the material should be made of silicone. The weakness of silicone is that it is easy to oil and feels hard and tastes great. The good material is medical silicon. Resin has no such weakness. , But generally speaking, the one-meter physical doll 2000 is hard to buy even if it is made of silica gel, it is best to see the best in kind. I bought Jiu Mei dolls. Mine is a customized model. If you buy it, it is best to customize it yourself. Follow up with the customer service. You must watch the video and watch the video. . .

That’s right, the person upstairs is right. It costs tens of thousands to produce one. Of course, the cost will be lowered if mass production is used. However, if you are not very rich, it is better to pay for production than to buy.

There is a well-known domestic doll shop in Guangzhou called Yuanyiyuan entity doll shop that sells this product exclusively, the price is more than 10,000, and the price is 20,000, which is much cheaper. This is a bargain. If you don’t believe it, search on the Internet.

The price of silicone entity dolls is more expensive, domestic all-silicone dolls are more than 20,000 yuan, and those imported from Japan are generally around 50,000 yuan.

Silicone doll is a kind of artificial adult sex product, it can be regarded as a high-end masturbation device, instead of real people to satisfy orgasm. It is also a companion doll, its shape is made according to the ratio of 1:1 for girls. The face is better, and some high-end ones can also be customized. The silicone doll is soft and elastic after inflating, and the skin is similar to that of a real girl. The silicone doll is easy to carry and clean, and can be used repeatedly.

All silicone dolls are made of silicone except for the bones, that is, solid dolls. All silicone dolls are more realistic in shape and soft, but the price is more expensive.

1 note

·

View note

Text

The most popular plastic beads today.

Inabata Vietnam Firm, which started off as synthetic resins (PP, PMMA, HIPS and ABS ...), may be used, making numerous items including each day devices, development materials. ,

Inabata Vietnam focuses on handling all sorts of supplies: man-made resin (PP, HIPS and ABS PMMA ...) design plastic materials (POM, PC, PA, LCP and PBT Personal computer / Abdominal muscles ...)

Plastic beads. The very important material in the making of plastic products is plastic resins, or polypropylene granules. The resin is odorless, tasteless, and low-toxic. Plastic beads are transparent in color, so throughout the producing method, they are usually mixed with tinted beads to give the merchandise whole shade. Furthermore, the hard plastic material, much less smooth as PE, is just not stretched so the resin is additionally manufactured into fibers.

Technology plastics. Technological plastic is really a product or service of various plastic materials used in industry for specialized handling work. Specialized plastic has many different forms, a few of which are preferred by means of bedding, fibers, bars, trees and rolls videos. Practical plastic materials in Vietnam are being used in nearly every discipline of industrial production and are most frequently known as: Bakelite plastic sheet, PTFE resin, HDPE plastic, Pom plastic, teflon plastic ...

Primary plastic. Major plastic is a plastic item manufactured from petroleum, has not been employed and it is not adulterated, without any chemicals. You may realize that this really is a "real" plastic, having a high wholesomeness like 4 amount 9 rare metal. Unused virgin plastic is normally organic white-colored colored. When getting put into the application form, men and women frequently include coloration granules to obtain distinct colors such as green,purple and red, yellow-colored ... At the moment in the world you can find well-liked primary resins such as: PE, PP, ABS, PP, POM, PVC, PET, PC ...

The most common plastic beads these days.

The PP resin includes a feature white colored coloration that is certainly translucent, includes a high technological energy, is fairly difficult, not adaptable.

PP plastic resins have great oiliness, toughness, and extremely good work surface smoothness.

ABS resin is normal white colored or opaque white-colored, difficult however, not fragile.

What exactly are plastic beads used for?

Design plastic materials could be used to: Make molds in garment production facilities. It really is used for an electric powered insulation machine in the market. Software to create great-technical electronic digital circuit board or as anti--static and waterproof partition. There are excellent software that help with advertising, construction, interior and construction.

Raw resins are used differently according to the components of the resin. Software rich in-end products which demand security like carparts and aircraft, health-related gear ...

For additional information about nhua nguyen sinh visit this resource.

1 note

·

View note

Text

MASTERBATCH IN PACKAGING INDUSTRY

I. PACKAGING INDUSTRY

Plastic is used in packaging for its versatility, durability as well as cost savings. To produce different types of packaging, it is necessary to have different types of plastic with the properties of different types to suit the purpose of use and safety and environment-friendly regulations. With the diversity to meet different types of requirements, plastic is used in the packaging industry from sacks, woven bags, non-woven bags, nylon, to bottles for industrial use, containers. chemicals or bottles for drinking water, food, ...

II. PACKAGING CLASSIFICATION

Packages are made from different types of plastic resin for its using purpose. Most common and popular types of plastic packaging are as following:

PET Packaging:

PET is Polyethylene Terephthalate, is highly flexible, colorless and semi-crystalline resin in its natural state. It shows good dimensional stability, resistance to impact, moisture, alcohols and solvents, friendly to environment. Therefore, it is used in fizzy drink and water bottles, food trays.

2. HDPE packaging:

HDPE is High density Polyethylen plastic, it is flexible, translucent/waxy, weatherproof, good low temperature toughness (to -60'C), easy to process by most methods, low cost, good chemical resistance. HPDE packaging is mostky used in milk bottles, bleach, cleaners, shampoo bottles.

3. LDPE packaging

LDPE is Low density Polyethylene, it is a thermoplastic made from the monomer ethylene, semi-rigid, translucent, very tough, weatherproof, good chemical resistance, low water absorption, easily processed by most methods. LDPE plastic is used in carrier bags, bin liners and packaging films.

4. PP packaging

PP is polypropylene, it has high flexural strength due to its semi-crystalline nature. Polypropylene has a relatively slippery surface. Polypropylene is very resistant to absorbing moisture so can be water-proof, durable, tought and not stretch. PP plastic is used in tubs, food trays, …

5. PC packaging

PC is Poly cacbonate, its resistant to high temperatures, has high transparency and durability, so can be used in food containers and jar.

III. MASTERBATCH FOR PACKAGING

In packaging industry, to save production cost and increase productivity, producer use masterbatch as a main source to produce package. There are filler masterbatch and color masterbatch.

Filler masterbatch is used as a substitute for resin to save cost of material and make production more effective due to additives included in masterbatch.

Color masterbatch is used as a substitute for pigment to make color for the packaging product. Color masterbatch can help the producer create the exact wanted color shade for their product and also can help them boost production more effectively.

Sunrise Colors Vietnam is proud to provide customers with the highest quality Filler masterbatch with outstanding physical and chemical properties suitable for use in various plastic production technologies. With many years of experience in the plasticization industry, and a team of highly specialized staff and engineers, modern machinery and equipment system, we are always the trustworthy choice of customers and a prestigious unit. credit on domestic as well as international market.

------------------

1 note

·

View note