#PET BLower Machine

Explore tagged Tumblr posts

Text

Goli Soda Production: Who is Eligible to Start a Plant?

In the evolving landscape of the beverage industry, Goli soda has made a strong comeback. Once a nostalgic Indian refreshment, it is now a commercially viable business with widespread appeal. Entrepreneurs looking for a unique and cost-effective business opportunity often explore starting a Golisoda Plant. But who can actually start such a venture? What are the prerequisites, and what machinery and licenses are involved? This article explores the eligibility criteria, necessary infrastructure, and regulatory considerations to help aspiring entrepreneurs understand what it takes to establish a successful Goli soda production unit.

Understanding the Basics of Setting Up a Golisoda Plant

A Golisoda Plant is a specialized beverage production facility focused on manufacturing carbonated beverages packed in traditional codd-neck bottles. Unlike mainstream Carbonated Drink Units, Goli soda plants can be established on a relatively small scale, making them accessible to small and medium-scale entrepreneurs.

To begin with, understanding the components involved in the production is essential. These typically include carbonators, mixing tanks, filling machines, capping units, and most importantly, a pet blower machine for bottle production and a reverse osmosis plant for water purification. Without these, consistent quality and hygiene cannot be guaranteed.

Who is Eligible to Start a Golisoda Plant?

Starting a Golisoda Plant doesn't necessarily require a high-tech industrial background. However, certain criteria must be met to ensure compliance with health, safety, and quality standards.

1. Legal and Regulatory Eligibility

Any Indian citizen or legally registered entity such as a partnership firm, LLP, or private limited company can apply for licenses to operate a Goli soda production unit. The business must obtain:

FSSAI License (Food Safety and Standards Authority of India)

GST Registration

Trade License from the local municipality

Pollution Control Clearance

BIS Certification (if selling bottled water under a brand name)

The inclusion of a reverse osmosis plant in your facility is often a prerequisite to receive FSSAI clearance, as it ensures the safety and purity of the water used.

2. Financial Readiness

While a small-scale Golisoda Plant is comparatively less capital-intensive than large soda or soft drink factories. This budget includes the cost of a basic infrastructure setup, purchase of a pet blower machine, installation of a reverse osmosis plant, and manpower.

3. Technical Understanding

While advanced technical skills are not mandatory, a basic understanding of carbonation, water treatment, and machine operation is vital. Entrepreneurs can hire trained technicians for plant operation, but having a personal grasp of production flow, bottle sterilization, and quality control procedures is highly recommended.

4. Location and Infrastructure

A minimum of 1000 to 1500 sq. ft. space is needed to house the equipment, storage, and workstations. It is important that the plant is located in an area with easy access to a clean water source and reliable electricity supply. A reverse osmosis plant should be installed on-site to treat and purify the water before use.

Machinery Required: The Role of the Pet Blower Machine and Reverse Osmosis Plant

No Golisoda Plant is complete without the right machinery. Two of the most crucial components include:

Pet Blower Machine

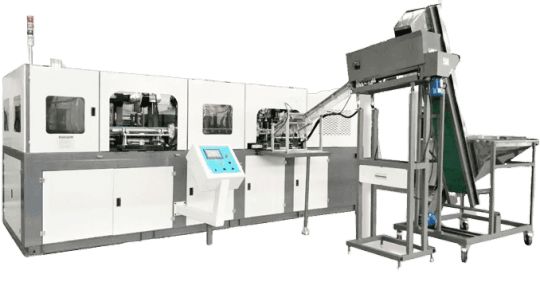

The Pet Blower Machine is used to manufacture PET bottles from preforms. This machine enables in-house bottle production, which significantly reduces production costs and dependence on external suppliers. Various models are available based on output capacity, ranging from 600 to 2000 bottles per hour.

Reverse Osmosis Plant

Water quality is a non-negotiable element in any beverage manufacturing process. A Reverse Osmosis Plant purifies the water by removing dissolved salts, organic matter, and microbial impurities. This ensures that the base ingredient — water — meets stringent health and safety norms. Additionally, it helps maintain consistency in taste and texture, which is vital for brand reputation.

COEQUAL INFOTECH PVT LTD specializes in providing turnkey solutions for Goli soda manufacturing, including supplying efficient pet blower machines and high-performance reverse osmosis plants to clients across India.

Steps to Start Your Own Golisoda Plant

If you meet the eligibility criteria, here are the steps to begin your journey:

Business Planning and Market Research

Identify your target market and decide whether you'll focus on local retail, restaurants, or third-party branding.

Register Your Business and Obtain Licenses

Legal compliance is key. Apply for necessary registrations and FSSAI certification.

Install and Commission the Plant

Set up infrastructure, install machinery, and test production processes under expert guidance.

Recruit and Train Staff

Hire operators and quality control professionals. Provide them with adequate training in Goli soda manufacturing techniques.

Start Production and Distribution

After a successful test run, launch your product in the market with appropriate branding and packaging.

Why Choose COEQUAL INFOTECH PVT LTD for Golisoda Plant Setup?

With a reputation for engineering excellence, COEQUAL INFOTECH PVT LTD offers comprehensive support for setting up a Golisoda Plant, from design and layout to equipment procurement and installation. We supply high-quality pet blower machines, cutting-edge reverse osmosis plants, and customized automation solutions tailored to your production scale. Our team ensures compliance with all industry regulations while maximizing operational efficiency.

Conclusion

The market for traditional Indian beverages like Goli soda is resurging, and now is the ideal time to tap into this niche. Setting up a Golisoda Plant is a promising business for those who meet the basic eligibility criteria and are willing to invest in essential machinery like a pet blower machine and a reverse osmosis plant. With proper planning, legal compliance, and guidance from experienced partners like COEQUAL INFOTECH PVT LTD, launching a Goli soda unit can turn into a profitable and sustainable venture.

If you're ready to enter the beverage manufacturing industry with a low-cost, high-demand product, the Golisoda Plant is a business worth exploring.

1 note

·

View note

Text

The Biggest Mistakes to Avoid When Using a Pet Blower Machine

A PET Blower Machine is an essential piece of equipment in the packaging industry, used to produce PET (Polyethylene Terephthalate) bottles for a wide range of products, including packaged drinking water, carbonated beverages, and flavored drinks. However, even small mistakes in operating a pet blower machine can lead to production delays, high defect rates, and costly maintenance issues. To help you avoid these common pitfalls, we have compiled a list of the biggest mistakes to avoid when using a pet blower machine, based on insights from industry experts like COEQUAL INFOTECH PVT LTD, a leading manufacturer of PET Bottle Blowing Machines.

1. Choosing the Wrong Machine for Your Production Needs One of the most common mistakes in the PET bottle manufacturing process is selecting the wrong type of pet blower machine. Different models are designed for different production capacities, bottle sizes, and shapes. Using an undersized machine for a high-volume production line can lead to frequent breakdowns, overheating, and reduced bottle quality. On the other hand, investing in an oversized machine can increase your operational costs without adding significant production capacity. To avoid this, carefully assess your production needs and choose a machine that matches your output requirements. COEQUAL INFOTECH PVT LTD offers a wide range of pet bottle blowing machines to suit various production scales and bottle designs.

2. Ignoring Regular Maintenance and Cleaning Like any industrial equipment, pet blower machines require regular maintenance to operate efficiently. Neglecting routine maintenance can lead to a buildup of dust, debris, and lubricant residue, which can cause mechanical failures, overheating, and reduced bottle quality. Regularly inspecting and cleaning the machine’s heating elements, air filters, and mold cavities can prevent these issues and extend the lifespan of your equipment. Additionally, always follow the manufacturer’s guidelines for lubrication and part replacement to keep your pet bottle blowing machine running smoothly.

3. Using Low-Quality Preforms or Raw Materials The quality of your preforms directly impacts the final product. Using low-quality preforms can lead to uneven wall thickness, poor transparency, and frequent bottle rejections. Always source high-quality preforms made from virgin PET resin, as this will ensure better clarity, strength, and consistency in your bottles. COEQUAL INFOTECH PVT LTD recommends working closely with trusted preform suppliers to maintain consistent product quality.

4. Inadequate Temperature Control Proper temperature control is critical for achieving high-quality PET bottles. If the heating section of your pet blower machine is not calibrated correctly, it can lead to overblown, underblown, or unevenly shaped bottles. This is especially important for pet bottle blowing machines with multiple heating zones. Make sure to monitor the temperature settings regularly and adjust them based on the preform size, bottle design, and environmental conditions. Investing in a machine with precise temperature control can significantly reduce your defect rates and production costs.

5. Overlooking Air Pressure and Blowing Settings Air pressure plays a crucial role in the PET bottle manufacturing process. Insufficient air pressure can result in improperly formed bottles, while excessive pressure can cause material thinning and cracking. Make sure your pet blower machine is equipped with a reliable air compressor and pressure regulator to maintain consistent blowing pressure. Regularly inspect the air supply system for leaks and clogs, as these can disrupt the blowing process and reduce bottle quality.

Conclusion Operating a pet blower machine requires careful attention to detail, regular maintenance, and a deep understanding of the manufacturing process. By avoiding these common mistakes, you can improve your production efficiency, reduce downtime, and produce high-quality bottles that meet market demands. Partnering with a reliable equipment provider like COEQUAL INFOTECH PVT LTD can also help you stay ahead of the competition and ensure long-term success in the PET bottle manufacturing industry. Whether you are setting up a new production line or looking to optimize your existing operations, choosing the right pet bottle blowing machine and following best practices can make a significant difference in your bottom line.

0 notes

Text

https://www.canadiancrystalline.com/packaging/pet-blowing-machine.html

Pet Bottle Blowing Machine – Canadian Crystalline

PET blowing machines are production equipment for the industry producing efficient, effective, and refined, long-lasting, recyclable plastic bottles. For example, the blowing machines of Canadian Crystalline make varieties of bottle shapes and sizes, for use mostly in the sectors of food and drink, pharmaceuticals, and personal care, by turning a preform of PET into a bottle. The building of generic models includes heating PET, stretching, blowing, and cooling to ensure consistency and quality. Canadian Crystalline offers high-quality, high-speed production, energy efficiency, and customisation.

Also, these machines sustain the environment by reducing waste and enabling recyclable packaging. Investment in technologically advanced equipment increases productivity while keeping up with environmental objectives.

#automatic pet blowing machine#pet blow machine#pet blowing machine#pet blowing machines#pet bottle blowing machine#pet blower machine

0 notes

Text

Seppa Solutions – Pet Blowing Machine

Seppa Solutions' PET bottle-blowing machines are essential for producing high-quality plastic bottles for beverages, home goods, and personal hygiene products. These machines offer accuracy, efficiency, and flexibility in bottle design, helping manufacturers meet diverse packaging needs while reducing costs. Built for durability and energy efficiency, Seppa's machines accommodate PET materials and provideit comprehensive support services, including installation, training, and maintenance. With a commitment to innovation, Seppa Solutions provides advanced, reliable equipment to enhance production capacity and product quality, making them a trusted partner for businesses in the competitive packaging sector.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet blower machine#pet blowing machine manufacturer in india#automatic pet blowing machine

0 notes

Text

youtube

PET BOTTLE BLOW MOLDER

We would be happy to help and advise if you have any questions or inquiries.

PET BOTTLE BLOW MOLDING MACHINE

CAPACITY

Up to 15,000 bottles per hour

CAVITIES

Up to 8 cavities

PERFORMANCE

Satisfaction Guaranteed

2 Years Quality Warranty

On Time Delivery Guaranteed

OVERVIEW

Steplead’s BMA series blow molding machines produce the highest quality PET containers for a wide range of applications, sizes, and production demands. Our blow molders exceed previous blowing capacity, cost, and bottle quality benchmarks. Steplead’s industrial blow molding equipment reliably manufactures PET bottles and containers with precision engineering. Advanced temperature controls and adjustable blowing pressure deliver consistent, high-quality results. Trust Steplead for customizable stretch blow molding systems optimized for your PET bottle production needs. Contact our experts today to learn more about our high-performance blow molders for various industries.

youtube

ADVANTAGES

UP TO 50%

Steplead certified parts with additional warranty

UP TO 25%

Less maintenance

UP TO 20%

Less energy using lower engine speed and larger hydraulic pump.

Save Cost

The great advantage of stretch blow moulding machine is to stretch the container in both the axel and hoop directions, which name biaxial stretching and it will greatly improve the container’s top load, clarity, drop impact tolerance, barrier abilities and tensile strength. As a result, the raw material cost can be save for about 10-15% by reducing the weight of container.

Wide Application

The stretch blow molding process making PET bottles is popular in beverage industry production for juice, water, soda, and many other products. Since 1970’s, this blow moulding technique is applied widely to package chemical detergent and soda bottles.

High Efficiency

This blow moulder can achieve you any extra ambition of blowing production. No matter considering production output, reliability or efficiency, for non-carbonated water, csd (carbonated soft drink), and hotfill products, with maximum 6 cavities to produce up to 6,000 containers per hour.

PRODUCT SPECIFICATIONS

Download

2,000 ~15,000 Bottles500ml / Per Hour

Max Container Volume: 2L

Max Cavities: 8

Clamping Force: 320KN

Power: 120Kw

Dimension: 3,600 x 2,000 x 2,210MM

PREMIUM

LAYOUT COLLECTION

The best way to experience our wide collection of production layouts for your project.

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 10,000BPH

Factory layout of 10,000bph soda drink filling line for 500ml - 2L PET bottles

Click to Download

Layout for 2,000-3,000BPH

Factory layout of 2,000-3,000bph cola drink filling line for 500ml - 2L PET bottles

Click to Download

Previous slide

Next slide

RELATED EQUIPMENT

HOW TO ENSURE THE SAFE AND EFFICIENT PRODUCTION OF BOTTLE BLOW MOLDING MACHINE.

Here is a list of all the types of technical questions concerning bottle blowing molding machine that you can find.

What Safety Precautions Would Be Needed For Blow Molding Machine Operation

Safety Precautions for blow molding machine operation

These precautions are for the sake of preventing operators and other staff from being hurt or preventing machine from being damaged when trouble occurs. Because devices of this machine use pneumatic and electrical control, which features big power and quick working speed, therefore any errors of operation may lead to dangerous consequences. The machine is equipped with some safety devices to protect the operators. Before operation, please check whether these safety devices work properly.

1. Safety Precautions: 1) Operator must wear safety helmet, slip-proof shoes and working clothesduring installation, inspection and maintenance. 2) Make sure to install the machine in a dry, bright and clean location. The ground around the machine should be solid and its surface should be slip-proof. 3) Never put tools and other articles onto the machine or any other moving parts. 4) Don’t climb onto the machine when it is running and don’t touch the moving parts. Before inspection and maintenance, the power and gas source must be switched off and ensure that air pressure of gas circuit is environmentalatmosphere.Note: Once the pressure of operation gas circuit is environmental atmosphere, mold base components will automatically descend. 5) When operate parts of heating devices, turn off the power first and operate after it completely cools down. 6) Please pay special attention to the safety warning board installed on dangerous parts of the machine.

2. The Safety Guard and Safety Door on the Machine 1) A limit switch is installed on the safety door to pick up the bottles. When the safety door opens, this limit switch will be activated to stop the machine from operation. Therefore, it’s important to check whether this limit switch can work normally before operating the machine. 2) It’s forbidden to dismantle the safety door on the machine and the safety cover on automatic chainsunless necessary maintenance and inspection are needed. And after maintenance and inspection, the safety door and the safety cover on automatic chains must be reinstalled as its original way. 3) Emergency Stop Button There are two buttons for emergency stop on the machine. One is on the operation panel and the other is on the back of the machine. They are used for emergencies. If each of the emergency stop buttons being pressed, both the power and gas source are switched off simultaneou sly and the machine stops all operation immediately. 4) Overpressure Protection The machine uses compressed air. The safety valve is respectively installed on high and low-pressure air collector. If the pressure in air intake is too high, the safety valve will be automatically opened to ensure of the safety. Air pressure for operation: Air intake 0.8Mpa Air pressure for blowing: Air intake 3.5MPa 5) Grounding The machine has contact for grounding. Before using the machine, connect the earth wire, which should be chosen according the local standard.

What Are Precautions Else Needed For Operation Of Blow Molding Machine

Precautions Related with Operation of Blow Molding Machine

Before operating the machine, read and understand the operation regulation in the operation manual or have relative training for operation.

(1) Emergency Stop

① There are two emergency stop buttons on this machine. The gas supplies stops and piston of air cylinder at the mold base and press preform falls down when each one of the buttons is pressed. The piston returns when turning and releasing the emergency button clockwise.

② There is a safety lever installed at the right side of bottle picker connected with the switch to prevent the bottle or preform from going to the next circle. If bottles or preform press on the safety lever, the machine will stop immediately until they are

removed. Note: Don’t operate the machine until you are sure of the security.

(2) Adjustment of Position and Speed

The position and speed valve of magnetic switch and approach switch on gas cylinder of movement devices has been properly adjusted before the machine leaves the factory. Don’t try to make the machine run quicker by changing their position or adjust the speed valve. Otherwise, it may cause damage of the machine or lead to malfunction.

(3) Inspections Related with Automatic Operation

① Confirm the safety for the operator. Check with eyes carefully the surrounding of the machine to make sure that it is safe in this area.

② Make sure that all safety devices can function normally.

③ Ensure all limit switches are in position and properly tightened.

④ Check whether the air pressure for operation and blowing is normal.

⑤ Check the adjustment of various speed

⑥ Check the temperature and circulation of cooling water.

(4) Safety during Bottle Blowing

① Never open the guarding gate or climb into it during bottle blowing.

② Never touch movement parts during bottle blowing.

�� Keep close attention to the working status of the machine. If abnormal situation or noise occurs, stop the machine immediately. Look for reasons and get rid of the troubles. If alarm occurs, the machine will stop automatically. The machine can be operated again only after the troubles are eliminated.

What is The Safety of Maintenance and Repairation of Blow Molding Machine

The Safety of Maintenance and Repairation of Blow Molding Machine

(1) Before repairing the machine, switch off the power and hang a warning plate of “Repairing, Switch on Prohibited” at the power switches. Before repairing, use electroscope to check that the power has already being switched off.

(2) It should bear regulated pressure to replace pneumatic units such as gas pipe, valve and connectors. It should get the approval from professional engineers to replace these units. Before replacing, make sure that the air pressure of gas circuit has been reduced to environmental atmosphere.

(3) The capacity should be in accordance with corresponding regulation when replacing fuses or other electric units. It should get approval from professional engineers or technicians for the replacement.

(4) Never touch any electrical devices with wet hands.

(5) When repairing the mold on the machine, insert a cushion (A rectangle wood block of 15×20 cm, which length should be the same with the length when the mold opens to its maximum extent) into the opened mold clamp device.

(6) Lubricate the machine after it stops.

(7) Use proper tools to maintain and repair the machine. Exert proper moment when tightening the bolts and nuts.

(8) Carefully check the repaired area after maintenance and repair to prevent any tools from being left in the machine.

What Precautions You May Need for The Gas Circuit System of Blow Molding Machine

Precautions of Gas Circuit System of Blow Molding Machine

Note: The density of high-pressure air is very high and any leakage of it shall lead to serious consequences.

(1) It’s strictly forbidden to change the position of safety valve on the air collector. (2) Impact of compressed air collector is strictly prohibited. (3) Open the gas outlet valve slightly to discharge the gas slowly when relieving the pressure. (4) Switch off the gas source and open the outlet valve as well as ensure that the reading on pressure meter is zero before removing parts on gas circuit. (5) Discharge the gas thoroughly if the machine has stops operation for a long time. (6) When replacing any pneumatic units, check under low pressure to reconfirm its safety and gradually increase the air pressure.

(7) Check the safety of gas circuit regularly. Check Every Day ① Check pressure meter of air collector to make sure that every pressure value is normal. ② Check and monitor the gas circuit system (air collector, pipes, valves and air cylinder) to make sure that there is no gas leakage. ③ Ensure that hoses are not bent or damaged and every part of gas circuit system is solidly tightened.

Check Every Week ① Dry the accumulated water in high and low pressure air collector and filters. ② Check whether the magnetic coil and bolt is loose. ③ Check and clean the air muffle.

Check Every Six Month Check the accuracy of every pressure meter on air collector and gas circuit.

#pet bottle blowing machine#bottle blowing machine#blowing machine#blow moulding#blow moulding machines#pet bottle blower#pet bottle blower australia#pet bottle blowing machine uk#pet bottle blowing machine australia#pet bottle blow molding machine#Youtube

0 notes

Text

Vacuum Cleaners: The Ultimate Guide to Smarter, Cleaner Living

Keeping your home spotless is easier than ever with the wide range of vacuum cleaners available today. From sleek cordless models to intelligent robotic units, each type is designed to tackle specific cleaning needs with efficiency and ease. Let’s explore the most popular types and what makes them essential for modern households.

1. Cordless Vacuum Cleaners

Say goodbye to tangled cords and limited reach! Cordless vacuum cleaners offer unmatched flexibility, making them perfect for quick cleanups and multi-surface cleaning. Lightweight and portable, they’re ideal for stairs, cars, and tight corners. Many models now come with powerful suction, long battery life, and HEPA filters for allergen-free air.

2. Dry Vacuum Cleaners

The classic choice for everyday dust and debris, dry vacuum cleaners are reliable workhorses. They’re great for cleaning carpets, hardwood floors, and upholstery, and often come with multiple attachments for crevices and curtains. These models are easy to maintain and perfect for routine home cleaning.

3. Robotic Vacuum Cleaners

Let technology do the dirty work! Robotic vacuum cleaners are smart, automated devices that navigate your home, cleaning floors with minimal supervision. Many models feature mopping functions, app control, voice assistant compatibility, and real-time mapping. Ideal for busy lifestyles, they’re especially handy for pet owners and tech-savvy households.

4. Wet & Dry Vacuum Cleaners

Need to clean up both dust and spills? Wet & dry vacuum cleaners are your go-to solution. These versatile machines can handle liquid messes, dry dirt, and even heavy debris, making them perfect for kitchens, garages, and workshops. Some models also include blowers and mopping attachments for all-in-one cleaning.

Final Thoughts

Whether you're dealing with pet hair, spilled cereal, or everyday dust, there’s a vacuum cleaner tailored to your needs. With innovations like cordless mobility, robotic intelligence, and dual-function wet & dry cleaning, keeping your home clean has never been more convenient—or more efficient.

0 notes

Text

12.22.24 Sunday-- Happy Blessed Sunday! Continuosly will do the prayer vow for nana at 7am and 8pm... Until her full existence is back...

12:17 am

Still,have windblow...

Craving for sweet,so I just can't stop myself to binge on Milo... I love cocoa in a way as my chocolate.... Hmm....

Still, thinking of nana and so many things like money,my future and my love life and my job. I feel sad and self-pitying that I lost a crowd!

Again,this will be the saddest if some relatives, some faker old friends and mutually distant chinese friends will back-stab the situation of nana... I hope and pray not...

I still have my personal self-pity... I'm not happy being single for 17 years, it made me feel ugly and fat and aging for nothing or worst aging without a love story!

12:42 am

Still,have windblow...

I feel frustrated as well....I lost a circle who can lift me up in a way... Lost socialization, I have complex now...

Still,doing important thing now, like cleaning and washing clothes....

It is really weird.... 3 days to go it will be Christmas and an another New Year! I need to clean...I need to clean...Whew!

Still,thinking of money and job. Still,loving and hating my cousin-white... I wanna know the truth and hoping Daniel Marsh can be my hero!

Done,watching "Black Christmas" it is weird....I'm thinking if it is "Akhro Fraternity" is the one killing the other group, my thoughts got the idea from that movie.

1:09 am

Still,have windblow...

I wanna buy Startbucks everyday... I wanna collect tumblers... I wanna travel in a way... I need some vanities.

Not my ideal life without having a hi-tech stuff like vacuum and I need to buy an actual fur blower for pet. I'm still broke...

I have an over-lapping plans in life... I feel self-pity and frustrated...

I need a new phone,I can't stream....I need to bring this phone in Samsung for a total repair! I'm broke... Even not streaming, I need a new phone angels...

I feel ugly! I want a self-fulfillment, an earning or I need a job.

I wanna polish my teeth, be presentable... I still keeping myself fit and healthy these days... I wanna regular foot spa!

If I have a stable job, I can do this in a way... But I hope my partner will be supportive of me like my cousin-white,I want a bit modern life like I wanna botox. I can't accept that for 17 years I can't get a new love then I have a sagging face or wrinkling skin, I can't accept this ugliness and aging...

1:52 am

Still,have windblow...

I feel self-pity...

8:04 am

Still,have windblow...

Late but I was able to pray still...It is weird why is it my alarm is not working? Hmm....Ask God for forgiveness.... Hmm....It is my alarm....Alarm fault....

9:36 am

Still,have windblow...

Uncle DD texted me around 6am to open the gate but why me? Why not his gang??? But I was still sleeping that time....

After 2 weeks I washed the clothes and clothes of Uncle Jun so, I have to use the washing machine after 2 weeks....It is fair enough...

The behaviour of Uncle DD is strange....Why he is not texting his gang to open the gate at their side???

I just saw Uncle DD's text but not replying now coz it is from regular text not on the messenger...

My point is weird! Uncle DD's gang living in the same roof are him, Harold, Aunt Karen and Crysette.... I think it is appropriate if he texted the people came from his roof. I hate having negative issues...

The last time I asked a favour on Harold on the gate here in-front of our living room, it was a different case or different situation. Gets,angels? It was a different case coz the situation was a bit emergency coz I went out and Uncle Jun will go in here from the hospital... So, the people who got the key on that small gate here are me and Harold. Harold is the representative on the side or gang of Uncle DD. That's why, I asked a favour on Harold to kindly open the gate coz I was not in the house and Uncle Jun will go in... It was really a big favour as a family here in a way...

We are living in the same vicinity or area so we need to be concerned on each other here but with proper etiquette on each other as well...

Vicinity or area--we share the garden even the terrace. The gang of Uncle DD are also using the small gate here. Like for example Harold is walking in the afternoon with Neko, so they go out on this side where we have the small gate in-front of our living room. Gets, angels???

10:08 am

Still,have windblow...

Uncle DD is here now...

10:16 am

Still,have windblow...

I'm setting my alarm on my phone, it is weird it is off for 2 days...

Then, I saw my actual alarm clock. I will use this...

I need an alarm clock!

10:30 am

Still,have windblow...

I put an alarm at 11am then it is just 10:30 am it is already alarming... Huh? The alarm clock above...

Time chaos???

11:53 am

Still,have windblow...

Uncle Jun is here just gave me the allowance... But it is just for survive...

I can't buy a new phone or go back to my old routine in life like gym and vanities...

12:10 noon

Still,have windblow...

Is Mitch somewhere? Getting fame all over the world behind the camera? Weird to feel her this way! Did she give me those and these simple batteries???

5:24 pm

Still,have windblow...

This is a good item angels for any son-dog or even a daughter dog....He is now on training to wait for me whenever I go out...

I thought at first how will the water will stop here... Use 2 liters coke and fill in with water in full then screw it there on the water bowl, it will fill in the bowl and it will stop to flow if it is already full. The son-dog needs to drink then the water from the bottle will magically flow.

This is worth it for 88 pesoses in any Daiso or Japanese store...

5:38 pm

Still,have windblow...

I paid the wifi so, I just confirmed that we have wifi this New Year,there will be no interruption. I hope they will just assist us on foodish here...

I'm still self-pitying coz I can't go back to my normal routine in life even my beauty stuff...Still, tight on budget.

Finally, I bought this key chain or it can be a phone accessory, this one I was really requesting to JP but he didn't reply to me...I said JP buy me this, I really like this but I'm asking a lot of different favours from him but he was not replying. He called me just to say hi... I don't wanna push this on him coz he said he is still busy when the time he called me. I'm happy that I'm able to buy today...But I still want a lot of these cute beads...

Probably, this will be my key chain... I'm planning to collect keys I told him and he said he was still busy in San Miguel or his work. I said can I have your key? Still, JP is busy... But we did paddle a long time ago after college.

6:34 pm

Still,have windblow...

Right now, I feel frustrated coz I wanna be with people that I want like the cute face of my cousin-white and Daniel Marsh to be my hero...

JP was someone special but we didn't end up together... We did paddle after college, just lately 2 to 3 months ago we just linked, he said hi and he was still busy in his work. It was really an old time sake call coz I can't meet anyone now... So, I was just really asking him a big favour on something, like financial aid. He is with someone else now but our story was always like that ever since... But we always lift up each other coz our view probably are the same.... It wasn't just a fuck-buddy coz we were sweet during college, Mitch knew it in a way... She saw us during college... In a way all of my exes were sweetish....I don't want to be with just spicy,no!

I don't want a spicy thing, I want something sweet. Is JP sweet or I'm sweeter,that's why he was forced to be sweet....I'm the sweet one...

7:34 pm

Still,have windblow...

I'm having a bit of anxiety coz I lost my circle and Mitch became famous somewhere? This windblow is trapping me unfairly...

I miss having a bf and someone who can lift me on things and I need some life. How can I see Daniel to help me to investigate... But I can't let it pass that my Aunt Ten/Tin avoided me coz I became a caregiver and she doesn't want me to be with her son,my first cousin-white...

I can't meet anyone now, I'm a bummer and I can't exist coz I'm broke!

10:10 pm

Still,have windblow...

Done, cleaning the half of living room,where we sleep on as well... You will figure out the real story behind this, the back story that fades these days just for nothing...

It is hard to clean if there is no hi-tech stuff like vacuum....But I have to clean, in a way... Not my ideal life but I need to...

10:20 pm

Still,have windblow...

Hmm... Aunt Ten/Tin hated me coz I didn't know how to clean? But when I became a fully pledge caregiver having a good ranking on theory and major of "bedsore" on caregiving but that was hellish not my ideal job as well but I'm a human, I'm a person and I just had have a heart for someone that I took care of... After that, I told myself that ah! This will be the last time...

I texted Aunt Ten/Tin that hey! Blah2x then I said I'm a fully pledge caregiver now then a sudden changed that she just ignored me...

But before I became a caregiver,my original upbringing was I had always an assistant or yaya or helper with me or Aunt just to guide or assist me or simply accompanying me, a catcher if in case of emergency....

My aunt Teresa or adoptive mother who raised me here or even before or way back,my family didn't want me to learn how to cook... Most specially when my Aunt Teresa became my adoptive mother or guardian. Adoptive means adjective word not legally on papers but acting as a mother on someone or acting as whatever on someone such as adoptive brother can be my cousin-white on my Aunt Ten/ Tin... Not really my brother, my first degree cousin in blood and flesh supposed to be my adoptive brother but perhaps I don't want it that way anymore...

Hmm... The part where she didn't want me to cook my adoptive mother or Aunt Teresa coz she didn't know how to cook when my japanese adoptive father (Uncle Hideaki ) got her or marrried her... She just learned it within their journey as couple and she wasn't cooking at all, she just learned it eventually... But the one who was really cooking was my adoptive japanese father or Uncle Hideaki....Aunt Teresa was a singer or artist outside the screen even my biological mother (Beth ). So, beauty and talent were important for them, way back....They didn't have time to cook coz for them they wanted a high life...

But later, coz of our lives changed that supposed to be they thought that I will be a fully pledge doctor like Mitch but it didn't happen that way... Something happened to me and my life story was different on Mitch. Is she my adoptive sister?My gf? Or My best buddy? But now hating her that I don't know why...

So, I just remember that there were days after college time that I had a slight amnesia but I remember if she can talk to me and Aunt Jasmine about me,about my life and about my plans and about my wedding....Aunt Jasmine was the X-wife of Uncle DD by the way...

Aunt Teresa told me, it is better to get a wedding and make my first burn cook food for my husband. That was her plan, to make me cute and find that man who truly loves me and accept me and will be happy if I burn the food coz he loves me....This is funny,right? Or she wanted me to learn how to cook eventually as well, like her...

10:59 pm

Still,have windblow...

youtube

11:10 pm

Still,have windblow...

I got mine branded but the local market are cute as well... 50 pesoses difference...

0 notes

Text

Horizontal Plastic Bottle Baler Machine

Horizontal Plastic Bottle Baler is the best way to deal with the complexity of waste management issues. Imagine this: a magician who can reduce your waste portion by only 70-90 %!!! Allow me to elaborate why this baler requires to be received on recycling plants throughout Europe and Asia.

The Horizontal Plastic Bottle Baler Machine also has the following unique features that serve to make it ideal for proper waste management. Its frame is durable and sturdy which is capable of accommodating daily usage, which gives it reliability. This machine has a measured compression force that may range up to 120 tons, therefore, can compress different forms of waste such as the PET bottles, plastic film and other plastic wastes compacting these materials into manageable and tightly formed bales. A major category from here is automation; the sophisticated PLC control system keep the flow of the bales feeding easily, pressing and ejecting without much interference from the operators.

The design of this feeder is flexibility; its feeding can be done manually or through conveyor belt or even through air-blower due to its flexibility in operations. The horizontal structure is highly compact which creates no interference with your large-size production line when the device is installed in your facility. All these features work cohesively to increase working efficiency which makes the Horizontal Plastic Bottle Baler Machine a worthy investment to any business that wants to improve its recycling processes and afford efficient waste disposal.

Benefits Horizontal Plastic Bottle Baler Machine

The Horizontal Plastic Bottle Baler Machine is one of the best investment tools since it has the following advantages; Applicable to all types of businesses Whether a large company or a small one, technological enhancement is necessary so that the business can meet its prospects, customers, and stakeholders’ demands. First and foremost, this machine can decrease waste volume to between 70% and 90%, thus saving you space in your facility and money on transportation in the process. From the aspect of the material handling, the baler helps in recycling to ease the working processes making it efficient. This is especially advantageous for firms that wish to enhance production and control operating expenses.

In addition, the cultural aspects are enhanced by its environmentally friendly design, particular in its ability to recycle plastics reducing pollution. With learning on environmental responsibility taking root in organizations, individuals are always looking for ways to minimize landfill contribution, having a baler that will help to support this course will augur well with your brand and go green. Also, the baler has less impact on manpower, and the main operations that go wrong are minimized since they are handled by the baler. Historically, the Horizontal Plastic Bottle Baler Machine is not only a tool but rather a partner to help with recycling needs and cut the expenses in waste management.

Product Details

Horizontal Plastic Bottle Baler Machine is the best machine that meets all requirements of the varied recycling requirements. Here are the key specifications and features that set this machine apart:

Model Options: It has series like NKW125Q, NKW169BD, NKW125BD and NKW100BD which it offers depending on the scale of operation intended for and the type of material they intend to cut.

Power Supply: Inbuilt with a 380V/50Hz power source, these balers prove conducive to perform tough operations in the most effective manner.

Compression Force: The specification used in the construction of the machine provides for a compression force of as much as 120 tons and through this the machine is able to work on any material to compress is no matter how much of a challenge the material may pose.

Bale Size: The bale size is variable, thus the baler discharges bale sizes of about 1100mmx 1100mmx 1600mm suitable for transportation and storage.

Bale Weight: Using different materials, the baler can make bales with weight ranging from 500kg up to 1000kg; therefore, it is suitable for volumetric processing.

Output Capacity: The production capacity is not uniform across the three models, with some machines being capable of producing 9 to 12 tons per hour, thus increasing operations’ efficiency.

Feeding Mechanisms: Through its design, the machine can incorporate many feeding types including manual feeding, feeding by a conveyor belt, or a blower.

Control System: An intelligent PLC control system allows for automatic inspection and operation reducing risks of an operator having to go airborne.

Safety Features: This baler has incorporated an emergency stop button as well as the hydraulic lock on the gate to ensure that the operator has more safety as they use the baler without compromising on the

Dimensions: The overall dimensions of the machine also differ according to the model available but are roughly 11m x 2.3m x 2.9m for the main frame which thus can easily be accommodated in most facilities.

Weight: The machine itself normally ranges in weight from 12 to 21 tons so the stability when functioning.

Warranty: Every unit is backed with the One Year Warranty for the user’s benefit and guarantee.

A Personal Touch

Being the person who already worked with the process of recycling the machinery, I have the particularistic vision of the problem concerning the increased amount of plastic waste. The Horizontal Plastic Bottle Baler Machine is unique. It’s very effective and I could observe it is efficient and effective in making processes much easier and easy to recycle as well as allowing for a better and sustainable future.

When a facility manager invested in this baler, they explained how they changed the way they manage waste, saving money and recycling more. It is not only regarding the machine itself but more importantly with reference to what that machine can do for our daily functioning and on earth as a whole.

When it comes to the problem of plastic waste, an innovative tool comes out of the wing – the Horizontal Plastic Bottle Baler Machine. As a result of the features listed as well as the countless benefits seizing from this baler it allows different businesses work effectively while preserving environment. With the problems that plastic pollution causes present today, choosing to support an intelligent and efficient recycle process is even more important. It’s time to get into action one bale at a time!

#Waste Management#Plastic bottle recycling#Baler Machine#Horizontal Baler Machine#Plastic Bottle Baler#Plastic baler machine

0 notes

Text

Milwaukee Blower vs. Gas-Powered Blowers: Which Is More Efficient?

Introduction

Leaf blowers are essential for maintaining clean outdoor spaces, whether for professional landscapers or homeowners. Two popular types of blowers on the market today are electric blowers, such as the Milwaukee blower, and traditional gas-powered blowers. While gas-powered blowers have long been the go-to option, advancements in cordless electric blowers, like those from Milwaukee, are challenging the dominance of gas-powered models. In this article, we will compare the efficiency of Milwaukee’s electric blowers with gas-powered blowers, examining factors such as power, convenience, environmental impact, and cost-effectiveness.

The Power Comparison: Milwaukee Blower vs. Gas-Powered Blowers

Power Output and Performance

Gas-Powered Blowers

Gas-powered blowers are often considered the most powerful option when it comes to leaf blowing, with the ability to generate higher airspeed and volume. These blowers can handle large areas and heavier debris such as wet leaves, making them a popular choice for professional landscapers who need to cover extensive grounds.

Milwaukee Electric Blower

Milwaukee blowers, especially those equipped with the M18 Fuel technology, have significantly closed the gap in terms of power. While traditionally less powerful than gas-powered blowers, Milwaukee’s electric models now boast competitive airspeeds and airflow volumes suitable for most residential and light commercial tasks. For smaller to medium-sized yards, Milwaukee blowers deliver more than enough power to get the job done efficiently.

Noise Levels

Gas-Powered Blowers

One of the most significant drawbacks of gas-powered blowers is their noise level. These machines can be incredibly loud, often exceeding 100 decibels, which can be disruptive to neighbors and even pose a risk to the operator’s hearing if used without ear protection.

Milwaukee Electric Blower

In contrast, Milwaukee blowers are much quieter, operating at noise levels below 70 decibels. This significant reduction in noise makes electric blowers ideal for residential areas where noise ordinances might apply, and they’re far less likely to disturb people or pets in the vicinity.

Convenience and Usability

Weight and Portability

Gas-Powered Blowers

Gas-powered blowers tend to be heavier and bulkier due to their engines and fuel tanks. This weight can cause fatigue, especially for extended use, and makes them less portable. For jobs that require covering large areas, the extra weight can become a considerable disadvantage.

Milwaukee Electric Blower

Milwaukee’s electric blowers are much lighter, thanks to their compact design and the use of lithium-ion batteries. This increased portability means less strain on the user, making it easier to maneuver the blower in tight spaces or for prolonged periods.

Starting and Maintenance

Gas-Powered Blowers

Starting a gas-powered blower can be cumbersome, requiring multiple pulls of a cord and the right mixture of oil and gasoline. In addition to the inconvenience of starting, gas blowers require regular maintenance, such as changing air filters, spark plugs, and fuel, which can be time-consuming and costly.

Milwaukee Electric Blower

Milwaukee blowers offer a more user-friendly experience, starting instantly with the push of a button. There’s no need for mixing fuel or performing engine maintenance, making electric blowers much easier to operate and maintain. This simplicity is a big plus for homeowners looking for a hassle-free tool.

Environmental Impact

Gas Emissions

Gas-Powered Blowers

One of the most significant disadvantages of gas-powered blowers is their environmental impact. These blowers produce exhaust emissions that contribute to air pollution, including harmful compounds like carbon monoxide, nitrogen oxides, and hydrocarbons. For environmentally conscious users, the carbon footprint of gas-powered blowers is a major concern.

Milwaukee Electric Blower

Milwaukee electric blowers produce zero emissions during operation, making them a much greener option. Powered by rechargeable batteries, they help reduce the user’s carbon footprint and contribute to a cleaner environment. For users looking to minimize their environmental impact, Milwaukee blowers are clearly the better choice.

Energy Efficiency

Gas-Powered Blowers

Gas-powered blowers are less energy-efficient compared to electric models. The burning of gasoline generates significant waste heat and requires a constant supply of fuel. Over time, the cost of gasoline adds up, making gas-powered blowers more expensive to operate in the long run.

Milwaukee Electric Blower

Milwaukee blowers, powered by rechargeable batteries, offer superior energy efficiency. Modern lithium-ion batteries can be charged hundreds of times, and with no need for gasoline, they represent a cost-saving over the life of the blower. Moreover, the batteries can often be used across Milwaukee’s entire line of M18 tools, adding further versatility and value.

Cost Comparison

Initial Purchase Price

Gas-Powered Blowers

Gas-powered blowers tend to have a higher initial purchase price, especially when considering commercial-grade models. The more powerful the blower, the higher the cost, and for professional use, this upfront investment can be significant.

Milwaukee Electric Blower

Milwaukee blowers are often priced competitively, especially when considering the convenience and lower maintenance costs. While the initial cost may be similar or slightly lower than gas-powered models, the long-term savings in fuel and maintenance make them a more affordable option over time.

Operational Costs

Gas-Powered Blowers

The ongoing cost of gasoline and oil, as well as regular maintenance, adds up quickly for gas-powered blowers. Depending on usage, the cost of keeping a gas blower running efficiently can surpass its purchase price within a few years.

Milwaukee Electric Blower

Milwaukee electric blowers require minimal ongoing costs. Once you’ve invested in the battery and charger, the only expenses are the electricity needed to recharge the battery, which is a fraction of the cost of gasoline. Plus, with fewer parts to maintain, there are no costs associated with spark plugs, filters, or engine tune-ups.

Which Is More Efficient?

For Residential Users

For homeowners or those working on smaller properties, Milwaukee electric blowers offer a perfect balance of power, convenience, and environmental benefits. They are easy to use, quiet, and do not require ongoing maintenance or fuel costs, making them an efficient option for those who prioritize ease of use and lower long-term costs.

For Commercial or Large-Scale Jobs

Gas-powered blowers still have a place for large-scale commercial applications where maximum power and long runtime are needed. However, as battery technology continues to improve, electric blowers like Milwaukee’s M18 models are quickly catching up, offering a cleaner, quieter, and more cost-effective alternative.

Conclusion

When comparing Milwaukee blowers to gas-powered blowers, it’s clear that each has its strengths depending on the user’s needs. Milwaukee’s electric blowers shine in terms of convenience, environmental impact, and lower operational costs, making them ideal for residential and small commercial use. Gas-powered blowers, on the other hand, offer more power for large, tough jobs but come with the downsides of noise, maintenance, and higher costs.

For most users, especially those looking for an efficient, easy-to-use, and eco-friendly solution, Milwaukee blowers represent the future of outdoor power equipment, offering a cleaner and quieter way to maintain outdoor spaces.

FAQs

1. How does the runtime of a Milwaukee blower compare to a gas-powered blower?

Milwaukee blowers offer sufficient runtime for small to medium-sized tasks, and their batteries can be swapped out for extended use. However, gas-powered blowers tend to have longer runtimes without the need for recharging.

2. Are electric blowers quieter than gas-powered blowers?

Yes, Milwaukee electric blowers are significantly quieter than gas-powered models, operating at lower decibel levels, making them more suitable for residential areas and noise-sensitive environments.

3. Do electric blowers require less maintenance than gas-powered blowers?

Yes, Milwaukee blowers require far less maintenance. There are no engines to maintain, and you don’t need to mix fuel, change filters, or replace spark plugs as with gas-powered blowers.

4. Can Milwaukee batteries be used with other tools?

Yes, Milwaukee’s M18 battery system is compatible with over 200 tools in their lineup, making it a versatile choice for those who already own Milwaukee tools.

5. Which blower is better for the environment?

Milwaukee electric blowers are better for the environment, as they produce zero emissions and consume less energy compared to gas-powered blowers, which rely on fossil fuels.

0 notes

Video

youtube

Bubble Machine Durable Automatic Bubble Blower

About this item

【High Output 18000+ Big Colorful Bubbles】2024 Upgraded Zerhunt Bubble Machine Can Generate More Than 18000+ Bubbles Per Minute With 6 Spinning Wands,2 Speed Level & Super Built-In Motor. It Can Blow Tons of Colorful Bubbles Faster, Higher And Further Even Inside With No Wind.

【Top Quality Materials & Safe Design】Made From Durable & High Quality ABS Material With Superior Toughness And Rust Protection, This Bubble Maker With Official CPC Toy Safety Certification Won't Be Harmful To Kid, Toddlers ,Pets And Adults. Upgraded And Special Safe Design: Once Touch The Spinning Wands, And The Bubble Machine Will Once Stop Working.

【High Capacity 320ml Solution For Continuous Use】320ml/11.26oz Capacity Of The Liquid Tank And 30mins Continuous Use, It Is Not Necessary To Add Bubble Liquid In Several Times, So You Can Enjoy Uninterrupted Bubbles Leisure Time!

【Three-Ways Powered】The Bubble Blower Can Be Powered By 4 Batteries (Not Included) Or Plug In With Adapter(Not Included), Car Charge Or Power Bank, Providing Maximum Convenience For You And Let You Enjoy The Bubble Machine Indoor And Outdoor.

Check for more on Youtube- https://youtu.be/TYVOOckFhNI

【Great Gift For Kids & Pets】This Bubble Machine Can Bring Endless Fun And Dreamy Atmosphere In A Series Of Activities Such As Weddings, Birthdays, Parties, Outdoor Garden Yard Etc. The Bubbles For Kids Toddlers Is Definitely Perfect Outdoor Toys And Great Gift For Toddlers, Kids & Pets. Just Get This Bubble Machine For Your Lovely Kids Now!About this item【High Output 18000+ Big Colorful Bubbles】2024 Upgraded Zerhunt Bubble Machine Can Generate More Than 18000+ Bubbles Per Minute With 6 Spinning Wands,2 Speed Level & Super Built-In Motor. It Can Blow Tons of Colorful Bubbles Faster, Higher And Further Even Inside With No Wind. 【Top Quality Materials & Safe Design】Made From Durable & High Quality ABS Material With Superior Toughness And Rust Protection, This Bubble Maker With Official CPC Toy Safety Certification Won't Be Harmful To Kid, Toddlers ,Pets And Adults. Upgraded And Special Safe Design: Once Touch The Spinning Wands, And The Bubble Machine Will Once Stop Working. 【High Capacity 320ml Solution For Continuous Use】320ml/11.26oz Capacity Of The Liquid Tank And 30mins Continuous Use, It Is Not Necessary To Add Bubble Liquid In Several Times, So You Can Enjoy Uninterrupted Bubbles Leisure Time! 【Three-Ways Powered】The Bubble Blower Can Be Powered By 4 Batteries (Not Included) Or Plug In With Adapter(Not Included), Car Charge Or Power Bank, Providing Maximum Convenience For You And Let You Enjoy The Bubble Machine Indoor And Outdoor. 【Great Gift For Kids & Pets】This Bubble Machine Can Bring Endless Fun And Dreamy Atmosphere In A Series Of Activities Such As Weddings, Birthdays, Parties, Outdoor Garden Yard Etc. The Bubbles For Kids Toddlers Is Definitely Perfect Outdoor Toys And Great Gift For Toddlers, Kids & Pets. Just Get This Bubble Machine For Your Lovely Kids Now!

BubbleMachine #OutdoorFun #KidsPlay #BubbleParty #FamilyTime #SummerVibes #.ParentingGoals #BackyardBliss #BubbleMixture #MagicalMoments #DIYBubbleFun #BubblesEverywhere #HappyKids #FunInTheSun #GardenPlaytime #LaughterIsTheBestMedicine #OutdoorActivities #EcoFriendlyFun #BubblesForDays #PlayfulParenting

1 note

·

View note

Text

Supplier of Plastic Pulverizer in Hyderabad

Invoit Plast Machinery Pvt. Ltd: Invoit Plast Machinery Pvt. Ltd., headquartered in Ahmedabad, Gujarat, India, serves as a leading manufacturer and supplier of Plastic Pulveriser Machines. The company extends its services to various cities in India, specifically Hyderabad, Nasik, Chennai, Baroda, Bangalore, and Rajkot. We are a versatile manufacturer, producing a wide range of machinery for the plastic product industries. Their Pulverizer machines, designed with modern technology, cater to the diverse demands of customers. The Pulverizer machines offered by Invoit Plast are suitable for materials with both high and low density. These include LDPE, LLDPE, PC, PS, PET, PVC, and EWA, among others. Invoit Plast's Pulverizer machines feature a special sensor and control system. This technology monitors pressure, temperature, and power consumption, enabling seamless round-the-clock operation. The plastic granules undergo a systematic process within the pulverizer machine. Loaded into the hopper, the granules transfer to the pulverizing mill with the support of a vibro feeder. The transformation into powder form is facilitated by a blower, which then moves the powder through a cyclone and compartment valve to a vibro shifter for isolating fine powder. Manufactured with supreme-grade carbon steel products, the Plastic Pulverizer Machine benefits from the support of advanced tools and devices. The machinery unit is known for its robust construction, and low power consumption, and features an anti-corrosive surface coating for reduced maintenance charges. This machinery unit is beneficial for small-scale industries and various multipurpose market applications. Its applications include grinding, producing animal feed, and creating smooth powder in a short period. Hyderabad Supplier Network: Invoit Plast Machinery Pvt. Ltd. functions as a supplier of Plastic Pulverizers in Hyderabad, covering specific areas such as Uppal, Madhapur, Ameerpet, Begumpet, Somajiguda, Gachibowli, Manikonda, Miyapur, Kondapur, Bhardari, Sanathnagar, and Azamabad. Read the full article

#Ameerpet#Azamabad#Begumpet#Bhardari#Exporter#Gachibowli#Hyderabad#India#Kondapur#Madhapur#Manikonda#Manufacturer#Miyapur#PlasticPulverizer#Sanathnagar#Somajiguda#Supplier#Uppal

0 notes

Text

Canadian Crystalline – Pet Bottle Blowing Machine

Canadian Crystalline PET Bottle Blowing Machines are reshaping the beverage packaging industry with unmatched precision, speed, and efficiency. Designed to produce lightweight, durable, and eco-friendly PET bottles, these machines serve diverse industries such as beverages, cosmetics, and pharmaceuticals. They stand out for their high production speed, energy-saving capabilities, adaptable designs, intuitive operation, and minimal maintenance needs. With cutting-edge technology, a global footprint, and tailored solutions, Canadian Crystalline delivers exceptional packaging quality while prioritizing sustainability. Trusted by businesses worldwide, these machines offer great returns and reliable support. Choose Canadian Crystalline to lead packaging innovation and enhance your brand’s market impact.

#pet bottle blowing machine#pet blowing machines#pet blowing machine#pet blow machine#automatic pet blowing machine#pet blower machine

0 notes

Text

Pet Bottle Blowing Machine | Seppa Solutions

PET (Polyethylene Terephthalate) is a lightweight, durable, and indestructible packaging material that offers high barrier properties for freshness and reduced transportation costs. Its cost-effectiveness makes it suitable for large-volume packaging requirements and it is recyclable, a major advantage in environmental sustainability. Seppa Solutions is leading the charge in PET packaging solutions, offering a range of PET blowing machines and full-line solutions for PET bottles and jars. PET is a revolution in the packaging sector, providing durability, affordability, adaptability, and environmental advantages. Companies that adopt PET and invest in cutting-edge solutions like those offered by Seppa Solutions will have a more efficient and environmentally responsible future.

#automatic pet bottle blowing machine#pet blowing machine#pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#automatic pet blowing machine#pet blower machine#pet blowing machine manufacturer in india

0 notes

Text

What Is Bottled Water Production Process Flow Chart

Written by: John

Checked by: Mark

June 28, 2024

Home - Water filling machine technology - What is bottled water production process flow chart

Share This Post

Table of Contents

What is The Bottled Water Production Flow Chart

Raw Water Sourcing and Pumping

Mechanical Filtration

Carbon Filtration

Reverse Osmosis (RO) System

Bottle Blowing

Bottle Washing and Sterilization

Filling and Capping

Inspection and Packaging

1) Raw water pump

2) Mechanical filter

3) Activated carbon filters

4) Water softener system

5) Precision filters

6) Reverse osmosis system

Types of Equipment

Maintenance and Considerations:

1) Air conveyor system

2) Water bottling machine

3) Cap feeder machine

4) Fully automatic bottle blow dryer

5) Laser coding machine

6) Self-adhesive labeler machine

Importance in Bottled Water Production

Types of Self-Adhesive Labeler Equipment

Maintenance and Considerations:

7) Shrink sleeve label machine

8) Shrink wrap machine

9) Pallet wrapping machine

1) Fully automatic bottle blow molding machine

2)Semi-automatic blow molder

3) Air compressor

4) Bottle blowing machine water chiller

5) Blowing machine air dryer

6) Air filter of bottle blowing machine

7) Mold temperature controller

8) Air storage tank of bottle blow molding machine

Conclusion

How many types of water bottling equipment are there?

The 9 Secrets To Effective BLOW MOULDER

Complete Production Process Flow Chart Of Bottled Water Production As Below

Section 1

Water Treatment

Raw Water Pump

Mechanical Filter

Activated Carbon Filters

Water softener system

Precision filters

Reverse osmosis system

Ozone system

UV light sterilizer

Section 2

Filling & Packaging

Air conveyor

Water bottling machine

Cap feeder machine

Bottle blow dryer

Laser coding machine

Self-adhesive labeler machine

Shrink sleeve label machine

Shrink wrap machine

Pallet wrapping machine

Section 3

Bottle Blowing

Automatic bottle blow molding machine

Semi-automatic blow molding machine

Air compressor

Water chiller

Air dryer

Air filter

Mold temperature controller

Air storage tankororCap FeederLight Inspection PanelBottle DryerSleeve Shrink LabelerShrink Wrapping Machine

Film Stretch Pallet Wrapper

Code Inkjet Printer

Mineral Water Filler

Auto bottle blower

Semi-auto bottle blowerSelf-adhesive LabelerOPP Hot Melt Labeleror

Water Storage Tank

RO water treatment system

High pressure compressor

Air storage tank

Air filter

air dryer

Air filter

water cooler

High pressure compressor

Air filter

air dryer

Air filter

Auto Unscrambler

Semi-auto Unscrambler

BOTTLE BLOWING SYSTEM

WATER TREATMENT SYSTEM

FILLING AND PACKAGING LINE

What is The Bottled Water Production Flow Chart

The production process of bottled water is comprehensive, involving multiple stages to ensure the highest quality and safety standards. This detailed guide covers each critical step, from water treatment to bottling and packaging, and finally to the blowing line and auxiliary equipment. Here’s an overview of the main steps:

Raw Water Sourcing and Pumping

The process begins with sourcing raw water, which is then pumped into the filtration system.

The raw water pump provides the necessary pressurization for the filtration equipment.

Mechanical Filtration

A mechanical filter removes impurities such as manganese, iron, and suspended particles larger than 20 microns.

This step helps to prepare the water for further purification.

Carbon Filtration

The carbon filter further purifies the water by removing organic compounds, chlorine, and other contaminants.

This stage helps to improve the taste and odor of the water.

Reverse Osmosis (RO) System

The RO system removes dissolved salts, minerals, and microorganisms, producing high-purity water.

This step ensures the water meets the required quality standards.

Bottle Blowing

The PET preforms are heated and then blown into the desired bottle shape using a blow molding machine.

The blow molding machine combines preform heating and bottle blowing in an automated process.

Precise control of parameters like stretching speed, pressure, and timing ensures proper material distribution and bottle quality.

Bottle Washing and Sterilization

The bottles are cleaned and disinfected before filling to ensure they are free from any contaminants.

Filling and Capping

The bottles are automatically filled and capped to maintain the integrity of the product.

Inspection and Packaging

The filled bottles are inspected for any defects.

The approved bottles are then packaged for distribution.

The entire production process is designed to ensure the safety and quality of the bottled water in compliance with relevant regulations.

01.

Water Treatment

1) Raw water pump

Description: The raw water pump is a critical component that provides the necessary pressure and flow for the pretreatment equipment and the reverse osmosis (RO) system.

Working Principle: The pump pressurizes incoming water to ensure a stable and sufficient inlet pressure for sand filters, carbon filters, and fine filters. This pressure must exceed the permeation resistance of the mechanical filters, enabling efficient water passage and providing a sufficient source for the RO system.

Key Functions:

Pressurizes raw water.

Ensures stable inlet pressure.

Overcomes permeation resistance.

Provides a reliable water supply for the RO system.

Applications: Bottled water production, municipal water treatment, industrial water purification, desalination and seawater treatment.

Importance in Bottled Water Production: Essential for the efficiency and effectiveness of the entire water treatment process, ensuring the quality and uniformity of the packaged water produced.

Types of Equipment:Equipment TypeDescriptionCentrifugal PumpCommonly used for raw water pressurization, providing high flow rates and moderate pressure.Positive Displacement PumpSuitable for high-pressure applications, such as RO systems.Submersible PumpInstalled directly in the water source, used for drawing water from wells or surface water.Booster PumpInstalled downstream of the pretreatment system to further increase pressure for the RO system.

Maintenance and Considerations:

Regular inspection and maintenance, including cleaning, lubrication, and impeller replacement.

Monitoring of pump performance, including flow rate, pressure, and energy consumption.

Proper sizing of the pump based on the system’s water demand and pressure requirements.

Ensuring the pump is compatible with the water quality and any potential corrosive or abrasive substances.

2) Mechanical filter

Description: Also known as the quartz sand filter, this multi-layered filtration device removes manganese, iron, heavy metals, silt, rust, colloidal matter, and suspended particles larger than 20 microns from raw water.

Working Principle: Performs backwashing and forward washing to ensure consistent water output and prolong equipment lifespan.

Key Functions:

Removes mechanical impurities, colloids, microorganisms, organic matter, and active chlorine from raw water.

Provides pre-treatment for downstream processes like reverse osmosis and ion exchange.

Improves water quality and extends the lifespan of water treatment systems.

Applications: Bottled water production, municipal water treatment, industrial water purification, surface and groundwater treatment.

Importance in Bottled Water Production: Vital in the pretreatment phase by removing turbidity, suspended solids, and other contaminants, ensuring the quality and consistency of the final product and protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter CartridgePE, steel-lined rubber, steel-sprayed plastic, stainless steel, fiberglass-reinforced plastic.Filter MediaQuartz sand, activated carbon, manganese sand, anthracite.Filter ConfigurationSingle-flow, double-flow.

Maintenance and Considerations:

Regular backwashing and forward washing to maintain filter performance.

Monitoring pressure drop and turbidity levels to determine filter element replacement.

Proper selection of filter media based on water quality and treatment requirements.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

3) Activated carbon filters

Description: Activated carbon filters effectively remove residual chlorine, organic molecules, colloids, pigments, and heavy metal ions, ensuring water quality and extending downstream equipment lifespan.

Working Principle: Operate on the principle of adsorption, capturing contaminants on activated carbon particles.

Key Functions:

Removal of residual chlorine to protect downstream equipment.

Adsorption of organic molecules, colloids, pigments, and heavy metals.

Reduction of COD and SDI values to improve water quality.

Extending the lifespan of RO membranes and ion exchange resins.

Applications: Pretreatment for reverse osmosis and desalination systems, drinking water purification, industrial water treatment, wastewater treatment.

Importance in Bottled Water Production: Essential in the pretreatment process, ensuring the quality and safety of the final product while protecting the RO system and other downstream equipment.

Types of Equipment:Equipment TypeDescriptionCarbon TypePowdered activated carbon, granular activated carbon.Filter ConfigurationSingle-layer, multi-layer.Housing MaterialStainless steel, fiberglass-reinforced plastic.

Maintenance and Considerations:

Regular replacement of activated carbon and sponge layers.

Monitoring pressure drop and water quality to determine replacement frequency.

Proper cleaning of new activated carbon before installation.

Ensuring the filter is sized correctly to handle the system’s flow rate and water demand.

4) Water softener system

Description: The automatic water softener system removes hardness minerals, such as calcium and magnesium, through ion exchange.

Working Principle: It replaces calcium and magnesium ions with sodium ions, softening the water and preventing scale buildup in plumbing and equipment.

Key Functions:

Removes hardness minerals.

Prevents scale buildup.

Improves the efficiency and lifespan of reverse osmosis systems.

Applications: Residential and commercial water treatment, boiler and cooling tower water treatment, laundry and dishwashing applications, food and beverage processing.

Importance in Bottled Water Production: Maintains the quality and uniformity of the end product by preventing scale buildup in the RO system, extending membrane lifespan and improving water purification efficiency.

Types of Equipment:Equipment TypeDescriptionSoftening TankContains the ion exchange resin.ControllerManages system operation.Salt Tank and ValveProvides brine solution for resin regeneration.

Maintenance and Considerations:

Regular regeneration of the resin bed to maintain softening capacity.

Monitoring salt levels in the salt tank.

Periodic cleaning and maintenance of system components.

Proper sizing based on water usage and hardness levels.

5) Precision filters

Description: High-performance filtration devices that remove fine particles, impurities, and contaminants from various liquids using different filter elements.

Working Principle: Use various filter media and design processes to meet specific effluent water quality requirements, with filtration precisions ranging from 0.5 to 10 microns.

Key Functions:

Filtration, clarification, and purification of liquids.

Removal of fine particles, impurities, and contaminants.

Ensuring the safety and quality of downstream water and membrane elements.

Applications: Pharmaceutical, chemical, food and beverage industries, water treatment, brewing, petroleum, printing, and dyeing.

Importance in Bottled Water Production: Maintains the purity and safety of the final product by removing fine particles and contaminants, protecting downstream equipment like RO membranes.

Types of Equipment:Equipment TypeDescriptionFilter HousingPrimarily made of stainless steel (304 or 316), flange or clamp type.Filter ElementsPP meltblown, wire-wound, activated carbon, etc.Filter ConfigurationSingle or multiple elements, depending on processing capacity.

Maintenance and Considerations:

Regular replacement of filter elements based on usage and pressure drop.

Proper selection of filter media and precision based on application requirements.

Cleaning and maintenance of filter housing and components.

Monitoring flow rate, pressure drop, and effluent water quality.

6) Reverse osmosis system

Description: Highly effective water purification technology that uses selective permeation through a semi-permeable membrane to remove dissolved salts, colloids, microorganisms, and organic matter, producing high-purity water.

Working Principle: Uses a high-pressure pump to force raw water through the RO membrane, allowing only water molecules to pass through while retaining other contaminants.

Key Functions:

Removes dissolved salts and impurities.

Produces high-purity water.

Energy-efficient and low-pollution technology.

Applications: Bottled water production, pharmaceutical and electronics manufacturing, seawater and brackish water desalination, industrial water purification.

Importance in Bottled Water Production: Ensures the quality and safety of the final product by eliminating various impurities, adhering to strict industry standards.

Types of Equipment