#PLC Automation in Data Centers

Explore tagged Tumblr posts

Text

PLC Automation in Data Centers: Protecting Critical Infrastructure

Data centers form the backbone of modern businesses, handling vast amounts of data and supporting critical IT services. The reliability, efficiency, and security of these facilities are paramount, as even the smallest disruption can result in significant financial and reputational damage. As data centers grow in complexity and scale, the need for automated solutions becomes increasingly essential. PLC industrial automation solutions play a pivotal role in safeguarding these facilities and ensuring their seamless operation.

In this blog, we will explore how PLC Automation is helping to protect critical infrastructure in data centers, making them more resilient, efficient, and secure.

What is PLC Automation?

PLC (Programmable Logic Controller) automation refers to the use of programmable controllers to automate electrical and mechanical processes. These devices are designed to control machinery, processes, or complex systems, often within industrial environments. PLC industrial automation allows for precise control, real-time monitoring, and efficient management of operations.

In a data center, PLC automation is applied to manage a wide range of systems, including power distribution, HVAC (heating, ventilation, and air conditioning), and security systems. By integrating PLCs with the data center’s infrastructure, operators can automate routine tasks, monitor critical systems in real-time, and respond quickly to any anomalies or failures.

The Role of PLC Automation in Data Centers

Enhanced Reliability and Uptime

The primary objective of PLC automation in data centers is to ensure continuous uptime. Uninterrupted service is crucial for data centers, as any downtime can lead to data loss, decreased productivity, or system failures. PLC systems can monitor various parameters, including power supply, cooling systems, and server performance, to prevent failures before they occur. For instance, PLCs can detect fluctuations in power or temperature and trigger automatic corrective actions, such as switching to backup power sources or activating cooling systems to avoid overheating.

With PLC automation, data centers can operate more reliably, minimizing the risk of downtime and ensuring that critical infrastructure remains operational around the clock.

Energy Efficiency and Cost Savings

Energy consumption is one of the most significant operational costs for data centers. With the growing demand for data storage and processing, energy usage has skyrocketed. PLC systems help optimize energy consumption by continuously monitoring the performance of equipment and adjusting operations based on real-time data. For example, if the cooling system is running inefficiently, the PLC can automatically adjust settings to optimize airflow and temperature, reducing energy waste.

By incorporating PLC automation, data centers can lower energy costs and reduce their carbon footprint. The automated adjustments also ensure that the data center operates within optimal parameters, enhancing both efficiency and sustainability.

Real-Time Monitoring and Fault Detection

PLC automation enables real-time monitoring of critical systems in data centers, allowing operators to detect and resolve potential issues before they escalate. Whether it’s power distribution, cooling systems, or security protocols, PLC systems can continuously track the health of these systems and alert operators to abnormalities.

For instance, if a power surge or voltage drop is detected, the PLC can automatically switch to a backup power source, ensuring that operations continue without disruption. Similarly, if temperature sensors indicate that the cooling system is underperforming, the PLC can trigger corrective actions such as adjusting the airflow or activating additional cooling units.

Real-time fault detection and automatic troubleshooting are vital for ensuring the longevity and security of data center operations. Read more......

0 notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

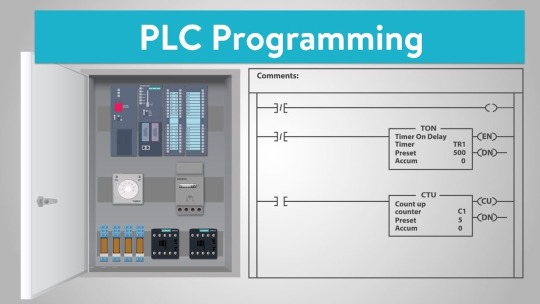

The Basics of PLC Programming: A Comprehensive Guide

If you're interested in the field of industrial automation or looking to enhance your skills in the industry, PLC programming is a crucial skill to possess. Programmable Logic Controllers (PLCs) are widely used in manufacturing and process control systems, and understanding how to program them is essential for ensuring efficient and reliable operation.

In this comprehensive guide, we will explore the basics of PLC programming, covering key concepts and providing valuable insights for beginners in the field.

1. What is PLC Programming?

PLC programming involves creating a set of instructions that control the behavior of a programmable logic controller. PLCs are used to monitor inputs from various sensors, process that data, and execute specific actions based on pre-defined logic. By programming a PLC, you can automate complex industrial processes, making them more efficient and reliable.

2. Why Learn PLC Programming?

PLC programming offers numerous benefits in the industrial automation realm. By acquiring this skill, you can:

Improve productivity: PLCs enable automation, reducing manual labor and increasing overall productivity.

Enhance efficiency: Automation minimizes human error and optimizes processes, resulting in higher efficiency levels.

Facilitate troubleshooting: Understanding PLC programming allows you to diagnose and fix issues efficiently, minimizing downtime.

Expand career opportunities: PLC programming expertise is in high demand, with many industries seeking professionals with these skills.

3. PLC Programming Training Courses:

To learn PLC programming effectively, it's essential to enroll in specialized training courses. These courses provide a structured curriculum, hands-on exercises, and expert guidance. Here are a few key aspects to consider when choosing a PLC programming training institute or center:

Comprehensive curriculum: Look for a training program that covers both theoretical concepts and practical implementation.

Experienced instructors: Ensure that the training institute has qualified instructors with industry experience to guide you effectively.

Hands-on practice: Practical exercises and projects are crucial for gaining proficiency in PLC programming.

Industry relevance: Verify that the training course aligns with current industry standards and practices.

Certification: Opt for courses that offer certifications upon completion, as they enhance your credibility in the job market.

4. Key Concepts in PLC Programming:

Ladder Logic: Ladder Logic is the most commonly used programming language for PLCs. It employs graphical symbols to represent logic functions and control sequences, making it easy to understand and implement.

Inputs and Outputs: PLCs interact with the physical world through inputs (sensors) and outputs (actuators). Understanding how to read inputs and control outputs is fundamental in PLC programming.

Programming Instructions: PLCs execute a set of instructions to perform desired operations. These instructions can include timers, counters, mathematical operations, logic gates, and more.

Program Execution: PLC programs are executed in a cyclical manner. The PLC scans inputs, processes logic, updates outputs, and repeats the cycle continuously.

5. Programming Tools and Software:

PLC programming software provides an interface to create, edit, and debug programs. Familiarize yourself with popular software tools such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Electric Unity Pro, as they are widely used in the industry.

Conclusion:

PLC programming is an essential skill for individuals aspiring to succeed in the field of industrial automation. By learning the basics of PLC programming, you open up a world of opportunities to streamline processes, enhance productivity, and contribute to the advancement of various industries. Enroll in a reputable PLC programming training institute or center, explore the key concepts, and start your journey towards becoming a proficient PLC programmer.

#plc-programming#learn plc programming#plc programming training#plc programming courses#plc training course in india

3 notes

·

View notes

Text

Top Automation Equipment Powering Mobile Production Units

Mobile production units rely on advanced automation equipment to operate efficiently and accurately in any location. Key components like PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), Servo Motors, and Sensors play a vital role in controlling, monitoring, and optimizing processes. PLCs act as the control center, HMIs provide user-friendly interfaces, servo motors deliver precise motion control, and sensors enable real-time data feedback. Together, these components ensure smooth, flexible, and high-performance production in mobile environments. Designed for reliability and adaptability, this automation equipment helps industries meet production goals with speed and precision on the move.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#mobile manufacturing automation#PLC in phone manufacturing#sensors in smartphone production#Apple factory automation#Samsung manufacturing components

0 notes

Text

"One Institute, Many Opportunities:

Build Your Skills in Marketing, Automation, and AI"

In a world where data and technology rule, upskilling has become crucial for success in contemporary sectors. The chance to learn in-demand skills is now more accessible than ever for professionals and students in Kannur, Kerala. There are currently universities in Kannur that provide state-of-the-art instruction in a variety of fields, whether you want to work as a certified industrial automation engineer, a data scientist, or a digital marketing strategist.

IPCS

The industry-focused courses offered by IPCS Global Kannur, a top technical training center in Kerala, include Digital Marketing, Industrial Automation, BMS (Building Management Systems), CCTV & Security Systems, Python Programming, and Data Science. IPCS Global places a strong emphasis on practical instruction and real-world application to close the knowledge gap between academia and industry demands. With its state-of-the-art laboratories and knowledgeable instructors, the Kannur Center guarantees that students get both academic and real-world experience. With flexible learning options, globally recognized certifications, and committed placement support, IPCS Global Kannur can help you thrive in today's competitive job market, whether you're a professional looking to advance your skills or a student ready to start a career.

Digital Marketing

Every facet of lead generation and online brand creation is covered in the Digital Marketing program.Explore the realms of social media tactics, content marketing, SEO, Google Ads, online branding, and more. With training in real-time projects, campaign management, and analytics tools, our Digital Marketing course is intended to prepare you for the workforce.

What Is Digital Marketing and Why Does It Matter Today?

Businesses can no longer rely exclusively on traditional marketing strategies in the fast-paced, internet-driven world of today. Regardless of your company's size—startup, small, or multinational—your internet presence has the power to create or break your success. Digital marketing is a potent tool for connecting with your audience, building your brand, and achieving results.

What You’ll Learn:

Search Engine Optimization (SEO)

Google Ads & Analytics

Social Media Marketing (SMM)

Content Creation & Strategy

Email & Affiliate Marketing

What Makes Digital Marketing Vital?

Greater Reach

Digital marketing, as opposed to traditional marketing, enables instantaneous worldwide audience reach.

Economical

Online marketing are frequently more measurable and less expensive than print or television advertisements.

Measurable Outcomes

You can make data-driven decisions and monitor performance in real time with tools like Facebook Insights and Google Analytics.

Advertising That Is Targeted

Your ROI can be raised by targeting users according to their location, age, hobbies, behavior, and more.

Enhances Brand Image

Credibility and trust are increased by having a strong online presence. This is influenced by social proof, reviews, and interesting content.

Industrial Automation

From PLC programming to SCADA systems, our Industrial Automation course equips you with the skills needed in the manufacturing, robotics, and process control sectors. See the newest tools and simulations up close.

Speed, accuracy, and efficiency are no more optional in the cutthroat industrial environment of today; they are necessary. Industrial automation is a solution to the problem. Automation is changing how businesses function, from power generation and food packaging to automobile factories, making operations more dependable, intelligent, and safe.

What is Industrial Automation?

Industrial automation is the act of running machinery and processes with little assistance from humans by using control systems like computers, robots, and programmable logic controllers (PLCs). Intelligent systems that are capable of real-time monitoring, control, and optimization of industrial procedures take the place of manual operations.

Key Highlights:

PLC & HMI Programming

SCADA Integration

Electrical & Pneumatic Control Systems

Industrial Sensors & Actuators

BMS (Building Management Systems)

Take control of the clever brain that powers smart buildings! Learn how to manage and keep an eye on energy, fire, lighting, and HVAC systems. Our BMS training can help you become ready for careers in smart infrastructure deployment and facilities management.

The requirement for integrated control and monitoring systems grows as buildings become smarter and more energy-efficient. In order to manage a building's vital services for sustainability, efficiency, and safety, BMS (Building Management Systems) are crucial.

Covered Topics:

HVAC Controls & Integration

Lighting & Access Control

Energy Monitoring

Fire Alarm & Security Systems

CCTV & Surveillance Systems

CCTV installation and maintenance are essential skills given the rising demand for security systems. The technical know-how from system design to installation and remote monitoring is taught in our course.

Course Modules:

Camera Types & Configuration

DVR/NVR Setup

IP vs Analog Systems

Troubleshooting & Maintenance

Python Programming

Learn Python from the ground up—it's perfect for both novices and developers. You will acquire the coding abilities required for automation, web development, and data science through hands-on examples and real-world applications.

One of the most important skills you may have in the digital age is the ability to understand and use data. Whether it is through AI models, consumer behavior analysis, or market trend prediction, data science is revolutionizing every organization. Python, one of the most powerful yet user-friendly programming languages, is at the center of this change.

The goal of data science is to extract meaningful insights from massive volumes of both structured and unstructured data. Combining elements of statistics, machine learning, programming, and data visualization, it resolves complex problems and facilitates decision-making.

Learn To:

Write Efficient Python Code

Build Web Applications

Automate Tasks

Handle File and Data Operations

Data Science

Our Data Science program teaches you how to glean valuable insights from data, which is the new oil. Use Python and industry-standard tools to study data visualization, machine learning, and statistics.

Why Choose IPCS GLOBAL

Experienced Industry Trainers

100% Practical-Oriented Training

Certification Support

Placement Assistance

Flexible Batches (Online & Offline)

CONCLUSION

Whether you're stepping into the world of Industrial Automation, diving into the digital landscape with Digital Marketing, managing smart buildings with BMS, or unlocking the power of Python and Data Science, our hands-on, industry-driven training programs are designed to make you job-ready and future-proof.

With expert instructors, real-time project experience, and strong placement support, IPCS has become a trusted name for quality technical education and professional growth. Join us today and take the first step toward a brighter, smarter future.

Start Your Today!

📞 Call us: 9745396641

🌐 E MAIL ID:[email protected]

Visit website:ipcs

0 notes

Text

Key Benefits of Using Siemens SCADA and WinCC in Automation

The ever-increasing demand for real-time monitoring, control, and data-driven decision-making in the industrial world has reached an all-time high. Hence, this is where Siemens SCADA solutions are applied. Siemens SCADA systems try to enhance operational visibility and efficiency by providing robust and scalable automation control in various industries.

Explore the Complete range of Siemens SCADA PC Systems designed for efficient industrial automation.

What is Siemens SCADA?

Siemens SCADA (Supervisory Control and Data Acquisition) is a command center that supervises, controls, and analyzes industrial processes. It provides centralized monitoring and real-time data visualization across distributed automation setups. From small manufacturing plants to large process ones, Siemens SCADA allows for control, less downtime, and increased productivity.

Advanced SIMATIC WinCC platform is the backbone of the SCADA solutions offered by Siemens.

SIMATIC WinCC-The Heart of WinCC SCADA System

SIMATIC WinCC is Siemens’ flagship SCADA platform, applied widely in industrial automation applications. It provides a seamless and flexible environment for engineering and runtime tasks. The integrated suite allows the user to handle operation, monitoring, history data archiving, and advanced analytics.

WinCC SCADA always performs uniformly and intuitively, whether you have a single-machine setup or a network of connected production lines. Other highlights include:

Real-Time Visualization: Allowing for the viewing of critical process data and system state by plant operators in real-time.

Alarm Management: Notifying its users of any deviations or faults from the system on time.

Data Logging & Archiving: Collecting and storing for historical analysis and regulatory compliance.

Remote Access: Authorized personnel can watch and control systems from anywhere.

With its above features, Siemens SCADA Software is widely accepted in industries like automotive, food processing, pharmaceutical, and energy.

Why Choose Siemens SCADA software?

Siemens SCADA software is more than mere monitoring; it is an entire industrial intelligence system that brings together Siemens PLCs, HMIs, and drives under a unified and efficient sun of automation. Its open architecture supports third-party integrations, endowing it with high levels of flexibility to adapt to existing infrastructures.

Some of the advantages include:

Scalability: Works on any kind of project, ranging from the simplest machine-level control to plant-wide operations.

Cybersecurity: Built-in cyber-safety features ensure the protection of the system against unauthorized access and cyber threats.

User-Friendly Interface: An easy operation for engineers and operators.

Industry 4.0 ready: Enables connectivity with IoT platforms, cloud services, and AI-based analytics.

Conclusion

Selecting the correct SCADA system is cardinal in achieving operational excellence. With Siemens SCADA, powered by SIMATIC WinCC, industries unlock real-time insights, process optimizations, and smarter decisions across their entire production facility.

Naksh Technology Solutions LLP takes pride in offering comprehensive customer support and the supply of Siemens SCADA solutions. Naksh Technology is your partner in excellence within the automation space-from consultation and integration to after-sales support.

0 notes

Text

Revolutionizing Monofilament Yarn Manufacturing: Trends and Innovations

Technology continues to shape and enhance every aspect of industrial manufacturing, and monofilament yarn manufacturers are embracing cutting-edge advancements to improve efficiency, sustainability, and accuracy. Modern monofilament yarn-making machines are now capable of producing high-quality yarns used in diverse applications, including ropes, nets, brushes, and fishing lines.

Among the most commonly used yarn types are PET monofilament yarns (polyethylene terephthalate) and PP monofilament yarns (polypropylene). Known for their strength, durability, and versatility, these materials are essential across various industries. With increasing technological progress, monofilament yarn extrusion machines are evolving to meet the growing demands of monofilament yarn manufacturers, ensuring optimal production and superior product quality.

Here are the top trends shaping the future of monofilament yarn production.

Energy-Efficient Monofilament Yarn-Making Machines

Energy efficiency is now a key priority in yarn manufacturing, with industry leaders adopting eco-friendly solutions to minimize energy consumption and reduce costs.

A groundbreaking innovation in sustainable production is the introduction of energy-regenerative units, which replace traditional braking resistors. These systems capture excess heat generated by machinery and convert it into usable power, optimizing energy usage and cutting down on waste.

This transformation highlights a major step toward greener manufacturing, helping businesses reduce carbon footprints while maintaining high output quality.

Enhancing Efficiency and Accuracy

With increased global demand, efficiency and precision in yarn production have become critical. Manufacturers are now integrating PLC (Programmable Logic Controller) central control systems, which significantly improve operational accuracy.

These advanced control systems offer:

Remote monitoring and automation – allowing manufacturers to track machine performance in real-time.

Improved production yields – optimizing resource usage and minimizing material waste.

Seamless integration with office computers and HMI systems – enabling 24/7 factory surveillance, even with limited manpower.

This technology has streamlined machinery installation, troubleshooting, and training, enhancing productivity while ensuring high-precision production.

Customized Yarn-Making Solutions

To better serve diverse market needs, manufacturers are shifting toward customized, flexible solutions in monofilament yarn production.

By adopting tailored approaches, manufacturers can:

Improve efficiency, optimizing operations and reducing lead times.

Enhance product quality, ensuring yarns meet specific industry standards.

Adapt to evolving customer demands, remaining competitive in the global market.

This trend toward personalized manufacturing allows monofilament yarn manufacturers to boost productivity while maintaining high-quality output.

Embracing Industry 4.0 Technologies

The future of monofilament yarn production is centered around Industry 4.0 innovations, including:

IoT-enabled automation

Production processing management

Real-time data storage & analysis

Automated machine control

These advancements allow manufacturers to monitor production conditions in real time, ensuring greater precision, lower waste, and optimized performance. By leveraging data-driven insights, businesses can achieve better efficiency and scalability in monofilament yarn extrusion.

Must-Have Features in Next-Generation Yarn-Making Machines

As demand for high-quality monofilament yarn continues to grow, manufacturers must ensure their machinery includes advanced features for efficient, seamless production.

Modern yarn-making machines should incorporate:

Energy-saving technology – optimizing electricity usage and reducing operating costs.

Enhanced data storage & analysis – providing insights into production efficiency and material handling.

Automated control systems – streamlining production and minimizing manual intervention.

Real-time monitoring capabilities – ensuring precision in output and troubleshooting.

Additionally, ensuring compatibility with multiple materials—including recycled PP, HDPE, PA, PET materials, and PET flakes—is crucial for sustainable, eco-friendly production.

Conclusion: Advancing Monofilament Yarn Production

The monofilament yarn extrusion industry is rapidly evolving, embracing automation, customization, and sustainability to enhance manufacturing efficiency. With the integration of smart machinery, energy-efficient solutions, and data-driven innovations, monofilament yarn manufacturers are paving the way for higher-quality, cost-effective production.

Investing in cutting-edge monofilament yarn-making machines ensures manufacturers stay competitive, reducing costs while optimizing output and product precision.

Are you ready to upgrade your yarn production line? Consider these must-have features when selecting high-performance extrusion machines for maximum efficiency and seamless operation.

0 notes

Text

Memory and Data Handling in PLC

Introduction

Programmable Logic Controllers (PLCs) are the mainstay in control systems in the industrial automation world. Aside from input/output control, the most vital functionality of a PLC is its memory structure and data handling capabilities. These enable a PLC to execute logic, hold variables, handle communication, and maintain seamless operation between automated systems.

Understanding PLC Memory Structure

PLC memory is separated into various sections, each of which has a particular function:

System Memory: Houses internal settings and system-level operations like timers, counters, and flags.

Program Memory: Stores the actual control logic in programming languages such as ladder logic.

Data Memory: Holds real-time input/output values, mid-computation variables, and user-defined data structures.

Retentive Memory: Maintains some values even after power removal—convenient for counters, timers, or operational states.

Effective memory use is critical to system performance. Knowing how to allocate and manipulate memory spaces properly guarantees robust and scalable control logic.

Data Handling Techniques

In automation, data has to be continuously monitored, shifted, processed, and occasionally stored. PLCs provide a number of instructions to work with data effectively, including:

Move (MOV): Copies data from one memory location to another.

Compare (CMP): Compares values based on conditions like equal to, greater than, or less than.

Arithmetic Operations: Permits mathematical calculations such as addition, subtraction, and so forth.

Logical Operations: Performs AND, OR, NOT operations for decision-making logic.

Appropriate treatment of data is also concerned with handling analog signals, monitoring alarm systems, and storing process values for subsequent utilization or reporting.

How Training Enhances Practical Understanding

Although the idea of memory and data processing may appear theoretical in textbooks, its actual significance is achieved on the factory floor. That's where hands-on exposure becomes vital. A hands-on PLC SCADA Course Nashik provides learners with a chance to interact with actual hardware, where they can see how to organize memory, process data, and debug properly.

VIATA, situated in the center of Nashik, provides such learning through its specially designed industrial training modules. With more than 20 years of experience in industrial automation, the institute emphasizes both the theoretical basis and practical implementation of PLC programming concepts.

At VIATA, students get a deep dive into memory types, data manipulation commands, and live project work emulating actual industrial environments. They also get exposed to Servo and Stepper Motor control, DCS, IIoT, and panel engineering, which all depend on sophisticated data handling within a PLC system.

Why Take a PLC SCADA Course in Nashik?

Learn with live industrial equipment for real-world application.

Gain experience under seasoned automation professionals.

Work on job-oriented projects with full exposure to PLC and SCADA systems.

Get trained in HMI design, VFDs, motor drives, and more.

Develop strong fundamentals in data handling and control logic through interactive sessions and interview preparation.

Conclusion: PLC data and memory management are the pillars of intelligent automation. For career aspirants in this domain, it is a prerequisite to excel in these aspects. Joining a practical PLC SCADA Course in Nashik at institutions such as VIATA guarantees that students learn beyond the books and have the confidence to work in actual industrial settings—where effective data handling results in effective systems.

0 notes

Text

Find The Best Commercial RO Plant Manufacturer In Delhi ?

The establishment of commercial RO plants to address all water-related problems was made possible by the abrupt rise in demand & requirement fulfilment for clean water solutions in Delhi, an industrial center in a strategically advantageous location. On the very front position of this water purification uprising is Commercial RO Plant, which is crowned as the most progressive commercial RO plant manufacturer in Delhi. Modern commercial RO plant systems have applications in a variety of industrial settings, ranging from small enterprises to massive manufacturing plants.

We'll go into great depth of information about Commercial RO plant manufacturer in Delhi with all the related industries in the area. We will discuss the modern advanced technological innovations that Commercial RO Plant offers with world-class facilities, along with all the benefits of our systems, as well as give an insight on how we're bringing change in the background of water treatment in this particular region.

Commercial RO Plant with High Demands

Over the past few years, Delhi's industrial environment has seen tremendous development. The installation of increasingly effective water treatment technologies, such as RO plants, is made possible by increased legal regulations and public awareness of environmental protection issues & water quality issues.

When they are performing at their best, experts at Commercial RO Plant have witnessed this change on their own. Order lists are more comprehensive than ever before as commercial enterprises, especially those in the fabric, textile, & pharmaceutical industries, have come to understand the value of having high-quality filtered water. Because RO technology is adjustable, it can be utilized to eliminate impurities as well as lower the levels of total dissolved solids while maintaining a high standard of water quality.

Commercial RO Plant

As the most trustworthy manufacturer of commercial RO plantsin Delhi, this companyhas constantly led the way in technical advancement. Our highly-skilled staffs at Commercial RO Plant put forth endless effort to design along with assembling commercial RO Plants that meet the unique requirements of our customers.

We adopt an advanced as well as flexible manufacturing technique for our RO systems, which simplifies customization & adaptation. Much appreciation to our adaptability, we can offer our services to a wide range of companies, from large power plants to small processing industries. Being the top noble Commercial RO plant manufacturer in Delhi has gained itself a national reputation; Commercial RO Plant has earned recognition for its unwavering dedication to quality & innovation through numerous accolades.

Crucial Features of Commercial RO plants that Commercial RO Plant designs & manufactures.

1) Better Membrane Integration: The most advanced thin-film membranes available, known for their long lifespan & significant rejection rate, are commonly employed by Commercial RO Plant.

2) Automated Control Systems: Control panels built on Programmable Logic Controllers (PLC) ensure smooth operation & real-time data monitoring.

3) Systems for Pre-treatment: The purpose of the pre-treatment modules is to maintain & extend the life of the RO membranes.

4) Post-treatment Options: Depending on the unique properties of the water, Commercial RO Plant offers remineralisation & pH balancing systems in addition to other treatment techniques for a range of applications.

The following main steps that need to be followed when manufacturing RO plants:

Procedures adopted in the production process to provide customers with the highest caliber of Commercial RO plants:

1) Stage of Design Development: Our engineers work closely with clients to understand their requirements & develop unique RO plant designs.

2) Procurement of Parts or Different Components in the RO Plants: In addition to other high-quality parts, we purchase instruments, pumps, as well as valves from reliable vendors.

Various Applications of Commercial RO Plants

Our RO plant systems find several purposes through various industries in Delhi including Textile Industry, Pharmaceutical Manufacturing, Food as well as Beverages, Power Plants, Medical Amenities such as Hospitals, & Hotels.

Recruiting Companies like Commercial RO Plant offers their best Possible Profits

We approach every job with unmatched expertise due to our extensive knowledge in the water treatment sector.

1) Flexibility in the Face of Change Depending on the client's requirements: We may offer distinctive solutions that meet client expectations thanks to our most recent creative designs & revisions.

2) Helps with the ultimate buying decision: We provide thorough maintenance agreements along with immediate technical assistance.

3) Highly Economic: Lower operational costs are a direct result of energy-efficient structures & optimized processes.

4) Managing All Components & Guidelines within Legislative Terms: We provide our clients with stability by meeting their needs while ensuring that our methods adhere to & surpass regulatory standards.

Conclusion

The commercial RO plant manufacturer in Delhi is proliferating quickly as a result of growing industrial demand & worries about water quality. In this fast transforming sector, the leading supplier or exporters, Commercial RO Plant, have been continuously pushing the limits in terms of both inventive thinking & excellence.

Commercial RO Plant is fully committed in contributing the most specialized, trustworthy, & efficient RO solutions that may have lofted this company to the top of the water treatment facilities in Delhi. As we overcome the challenges & embrace innovative developments, we are dedicated to providing state-of-the-art water treatment technology that meets the evolving needs of businesses in Delhi as well as nationwide.

#commercial ro plant#commercial ro plant manufacturer#commercial ro plant manufacturer in noida#water treatment plant#save water#water is life

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

🔩 Empowering Industrial Progress with Smart Automation – The Ram Automations Edge

Smart Industrial & Marine Automation Experts | Ram Automations Discover how Ram Automations is driving innovation in industrial and marine automation with smart solutions, premium components, and expert system integration.

Introduction: Redefining Automation for the Modern Age

In today’s fast-paced industrial environment, businesses demand intelligent solutions that enhance productivity, reduce downtime, and ensure safety. At Ram Automations, we bring smart, reliable, and future-ready automation solutions tailored for both industrial and marine sectors. With a strong legacy and deep technical know-how, we help organizations optimize performance with cutting-edge technologies.

Who We Are: The Experts Behind Automation Innovation

Ram Automations is a globally trusted trading firm and solution provider in the field of automation and control systems. We specialize in delivering high-quality automation parts, system design, and engineering services to manufacturers, marine operators, and process plants worldwide.

Backed by 10+ years of industry leadership, we’ve become a one-stop solution for businesses seeking genuine automation components, technical upgrades, and process excellence.

Key Industry Solutions We Provide

🔹 Industrial Automation Systems From PLCs and HMIs to SCADA systems and VFDs, we supply and integrate components that boost automation in manufacturing, production, and utility systems.

🔹 Marine Automation & Navigation We provide specialized marine control units, sensors, and monitoring systems that meet international marine standards and ensure smooth ship operations.

🔹 Retrofit & Upgrade Services Legacy systems? No problem! We modernize old machinery with new-generation hardware and software without the need for complete replacements.

🔹 Smart Building & Process Control Through sensors, intelligent controllers, and real-time data analytics, we help you manage HVAC, lighting, energy, and safety systems efficiently.

Top Brands We Work With

We deliver products from over 180+ renowned global brands, ensuring performance and reliability. Some of our key partners include:

Siemens

Allen-Bradley

ABB

Honeywell

Schneider Electric

Yokogawa

Furuno

Alfa Laval

Every component we supply is genuine, certified, and quality-tested for industrial-grade applications.

Why Businesses Trust Ram Automations

✅ Wide Product Range – From industrial sensors to marine control systems ✅ Global Supply Network – Fast, secure shipping across continents ✅ Expert Engineering Team – Deep knowledge in automation technologies ✅ Custom Integration Services – From planning to commissioning ✅ Client-Centric Approach – Solutions designed with your goals in mind

Client Success Story

Case Study – Marine Control Panel Retrofit A leading marine logistics firm approached Ram Automations to replace obsolete automation panels aboard their cargo fleet. Our team designed a compact, energy-efficient solution using Siemens PLCs and HMI panels. The result? A 35% reduction in fuel monitoring issues and 100% uptime during the next six months of operation.

Let’s Build the Future of Automation Together

At Ram Automations, we don’t just supply products—we build long-term partnerships. Our solutions are crafted with a clear focus on efficiency, safety, and scalability.

📞 Contact Us Today: +1 330 294 2744 📍 Miami (Support Center) | India (Warehouse) 🌐 Website: https://ramautomations.com

0 notes

Text

IoT Connectivity Market Share and Size Outlook with Industry Forecast 2032

The IoT Connectivity Market Size was valued at USD 8.43 billion in 2023 and is expected to reach USD 51.51 billion by 2032, growing at a CAGR of 22.33% from 2024-2032.

The Internet of Things (IoT) has become a cornerstone of the digital transformation revolution, connecting billions of devices, systems, and services across industries. From smart homes and connected vehicles to industrial automation and healthcare, the expansion of IoT applications has led to an explosive demand for robust and scalable connectivity solutions. As enterprises adopt cloud computing, edge intelligence, and real-time data analytics, the need for reliable IoT connectivity is more critical than ever.

IoT Connectivity Market Size, Share, Scope, Analysis, Forecast, Growth, and Industry Report 2032 highlights the dynamic evolution of this sector. The market is expected to witness substantial growth due to advancements in low-power wide-area networks (LPWANs), 5G integration, and the proliferation of smart devices. With governments and industries embracing digital infrastructure, IoT connectivity is playing a vital role in driving innovation, efficiency, and competitive advantage.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/4926

Market Keyplayers:

Aeris Communications India Pvt. Ltd. (Aeris IoT Platform, Aeris Mobility)

AT&T Inc. (AT&T IoT Services, AT&T Control Center)

Cisco Systems Inc. (Cisco IoT Solutions, Cisco Jasper)

Huawei Technologies Co. Ltd. (Huawei IoT Cloud, Huawei 5G IoT Solutions)

Orange (Orange Business Services, Orange IoT Solutions)

Sierra Wireless (AirLink Routers, Octave IoT Platform)

Sigfox (Sigfox IoT Network, Sigfox Backend Services)

Telefonaktiebolaget LM Ericsson (Ericsson IoT Accelerator, Ericsson Device Connection Platform)

Telefónica S.A. (IoT Global Platform, Telefónica IoT Connectivity)

Telit IoT Platforms, LLC (Telit IoT Modules, Telit Connectivity Platform)

Verizon Communications Inc. (Verizon IoT Solutions, Verizon ThingSpace)

Vodafone Group Plc (Vodafone IoT Platform, Vodafone Automotive)

Hologram (Hologram IoT SIM Cards, Hologram Data Plans)

Particle (Particle IoT Devices, Particle Cloud Platform)

EMnify (EMnify IoT Platform, EMnify Cellular IoT Solutions)

Moeco (Moeco IoT Network, Moeco Data Management)

Market Trends

Several key trends are influencing the growth and direction of the IoT connectivity market:

5G Deployment and Integration: The global rollout of 5G networks is accelerating the capabilities of IoT systems, offering ultra-low latency, high-speed data transfer, and enhanced device density. This opens new opportunities for mission-critical applications in sectors like healthcare, autonomous vehicles, and smart cities.

Edge Computing and Decentralized Intelligence: Instead of relying solely on centralized cloud servers, edge computing processes data closer to the source, reducing latency and bandwidth usage. This trend is particularly impactful in industrial IoT (IIoT), where real-time decision-making is essential.

Expansion of LPWAN Technologies: LPWAN protocols like NB-IoT, LoRaWAN, and Sigfox are seeing increased adoption due to their ability to support long-range communication with minimal power consumption. These technologies are ideal for applications such as agriculture, asset tracking, and utility monitoring.

Interoperability and Open Standards: As the IoT ecosystem expands, there's a growing need for standardized communication protocols that ensure seamless connectivity between devices from different manufacturers. Open-source platforms and industry alliances are working to address these challenges.

Security and Data Privacy Focus: With more connected devices comes increased vulnerability. Security-by-design principles, encrypted communication, and AI-driven threat detection are becoming standard features in connectivity solutions.

Enquiry of This Report: https://www.snsinsider.com/enquiry/4926

Market Segmentation:

By Enterprise Type

Buildings and Home Automation

Smart Energy and Utility

Smart Manufacturing

Smart Retail

Smart Transportation

Others

By Enterprise Size

Small and Medium-sized Enterprises

Large Enterprises

By Component

Solution

Services

Market Analysis

North America currently dominates the global IoT connectivity landscape, driven by early technology adoption and strong infrastructure. However, Asia-Pacific is emerging as the fastest-growing region due to its expanding industrial base, smart city initiatives, and rising digital transformation efforts in countries like China and India.

Enterprises are shifting from traditional SIM-based connectivity to eSIM and iSIM technologies, offering flexibility and remote management capabilities. These innovations simplify global device deployment and streamline connectivity across borders and networks.

Future Prospects

The future of the IoT connectivity market is shaped by continued advancements in network infrastructure, emerging technologies, and evolving business models.

Satellite IoT Connectivity: Satellite-based solutions are gaining popularity for providing connectivity in remote and underserved areas, enabling global asset tracking and rural monitoring.

AI and Predictive Maintenance Integration: AI-powered analytics will increasingly be embedded into connectivity platforms, enabling real-time diagnostics, failure prediction, and performance optimization—especially in industrial and automotive sectors.

Smart City Ecosystems: Urbanization is driving massive investments in smart city solutions, including connected traffic systems, public safety monitoring, energy management, and waste control. IoT connectivity will serve as the digital backbone for these applications.

Commercialization of 6G: While still in early research stages, 6G is expected to redefine IoT connectivity by offering ultra-high-speed, ultra-reliable, and low-latency communication, paving the way for new applications in robotics, AR/VR, and immersive environments.

Access Complete Report: https://www.snsinsider.com/reports/iot-connectivity-market-4926

Conclusion

The IoT connectivity market is evolving rapidly, enabling a world where machines, sensors, and systems interact seamlessly to drive efficiency, innovation, and intelligence. As businesses and governments recognize the potential of interconnected devices, the demand for secure, scalable, and cost-effective connectivity solutions will only intensify.

By 2032, the industry is set to become a multi-billion-dollar ecosystem, integrating technologies like 5G, edge AI, and satellite communication. The players who prioritize interoperability, cybersecurity, and agility will lead this next wave of digital transformation. The IoT connectivity market is not just growing—it’s shaping the future of how we live, work, and connect.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#IoT Connectivity Market#IoT Connectivity Market Growth#IoT Connectivity Market Scope#IoT Connectivity Market Trends

0 notes

Text

Control Engineering

Driving Industrial Excellence Through Control Engineering: The Monika Engineers Way

At the center of each contemporary industrial process is a well-coordinated control system operating in the background, managing complexity, keeping precision, and facilitating efficiency. This is the crux of Control Engineering , a field that continues to define the foundation of intelligent manufacturing and infrastructure systems. Leading the way in this domain is Monika Engineers , a reliable name that specializes in providing innovative and dependable control engineering solutions in various industries.

What is Control Engineering?

Control engineering refers to the application of engineering methods to develop systems that control, command, direct, or govern the operation of other systems or devices. These systems make processes work consistently and according to defined parameters, no matter the outside disturbances or fluctuations. In manufacturing industries, control engineering plays a fundamental role in automation, safety, energy savings, and process optimization.

From basic temperature control in HVAC systems to advanced robotic process automation on a production line, control engineering makes it all operate smoothly and reliably.

Monika Engineers: Masters of Precision and Performance

Monika Engineers has established itself as a reliable supplier of state-of-the-art control engineering solutions . Equipped with a pool of experienced engineers, latest tools, and an unshakeable commitment to quality, the company has been able to implement control systems in diverse fields including manufacturing, energy, water treatment, pharmaceuticals, and food processing.

Their method is based on learning the client's processes, finding opportunities for control and optimization, and then designing systems that are scalable, robust, and user-friendly.

Core Offerings in Control Engineering

1. Design and Integration of Control Systems

Monika Engineers creates special control systems with the latest PLC (Programmable Logic Controller) platforms. They are designed as per the particular needs of the client, either to control one machine or an entire production line.

2. SCADA and HMI Development

SCADA systems and HMIs are the hub of today's control engineering. Monika Engineers creates intuitive interfaces that facilitate real-time monitoring, alarm handling, and data logging, providing the operator with complete visibility and control over operations.

3. PID Control and Process Optimization

Accuracy in process industries frequently relies on optimized PID (Proportional-Integral-Derivative) control loops. Monika Engineers is an expert in optimizing these control systems to provide stable, responsive, and accurate performance for parameters such as pressure, temperature, and flow.

4. Custom Control Panels

The company develops and manufactures high-performance control panels, designed to fulfill unique process and environmental demands. Each panel is tested thoroughly prior to deployment to meet requirements, reliability, and safety.

5. Retrofitting and Upgradation

Monika Engineers assists customers in upgrading their existing legacy systems by incorporating advanced control technologies without interrupting existing operations. This strategy extends the lifespan of installed infrastructure and provides new functionality.

Why Monika Engineers?

- Expert Technical Knowledge:With a highly qualified team of control engineers, the organization is equipped to manage any size and complexity of project.

- Customer-Centric Approach: Each solution is configured with the objectives of the client in focus—be it minimizing downtime, enhancing product quality, or maximizing energy efficiency.

- Full-Fledged Service: From conceptual design and programming to panel assembly, testing, and commissioning, Monika Engineers delivers end-to-end turnkey solutions.

- Quality and Compliance: Their products meet the highest industry standards, with long-term reliability and simple maintenance.

The Road Ahead

The road ahead for control engineering is towards smarter, more integrated systems—blending IoT, artificial intelligence, and cloud-based analytics to expand the frontiers of automation. Monika Engineers is already putting these technologies into place, keeping their clients at the forefront.

In a fast-paced changing industrial environment, Monika Engineers is ever-reiterating that the ideal control system is not only about automation—it is about empowerment. Empowering companies to get smarter, work faster, and perform better.

Official Mail: monikaengineering@123

Contact no. - +91 9872846445

Address: 77A, Industrial Area- A, Ludhiana, Punjab 141003

Working Hours: Monday to Saturday - 9:30 AM – 7:00 PM

Website: https://monikaengineers.co.in/

Google My Business: https://g.co/kgs/PfDzeBK

0 notes

Text

Control Engineering

Driving Industrial Excellence Through Control Engineering: The Monika Engineers Way

At the center of each contemporary industrial process is a well-coordinated control system operating in the background, managing complexity, keeping precision, and facilitating efficiency. This is the crux of Control Engineering , a field that continues to define the foundation of intelligent manufacturing and infrastructure systems. Leading the way in this domain is Monika Engineers , a reliable name that specializes in providing innovative and dependable control engineering solutions in various industries.

What is Control Engineering?

Control engineering refers to the application of engineering methods to develop systems that control, command, direct, or govern the operation of other systems or devices. These systems make processes work consistently and according to defined parameters, no matter the outside disturbances or fluctuations. In manufacturing industries, control engineering plays a fundamental role in automation, safety, energy savings, and process optimization.

From basic temperature control in HVAC systems to advanced robotic process automation on a production line, control engineering makes it all operate smoothly and reliably.

Monika Engineers: Masters of Precision and Performance

Monika Engineers has established itself as a reliable supplier of state-of-the-art control engineering solutions . Equipped with a pool of experienced engineers, latest tools, and an unshakeable commitment to quality, the company has been able to implement control systems in diverse fields including manufacturing, energy, water treatment, pharmaceuticals, and food processing.

Their method is based on learning the client's processes, finding opportunities for control and optimization, and then designing systems that are scalable, robust, and user-friendly.

Core Offerings in Control Engineering

1. Design and Integration of Control Systems

Monika Engineers creates special control systems with the latest PLC (Programmable Logic Controller) platforms. They are designed as per the particular needs of the client, either to control one machine or an entire production line.

2. SCADA and HMI Development

SCADA systems and HMIs are the hub of today's control engineering. Monika Engineers creates intuitive interfaces that facilitate real-time monitoring, alarm handling, and data logging, providing the operator with complete visibility and control over operations.

3. PID Control and Process Optimization

Accuracy in process industries frequently relies on optimized PID (Proportional-Integral-Derivative) control loops. Monika Engineers is an expert in optimizing these control systems to provide stable, responsive, and accurate performance for parameters such as pressure, temperature, and flow.

4. Custom Control Panels

The company develops and manufactures high-performance control panels, designed to fulfill unique process and environmental demands. Each panel is tested thoroughly prior to deployment to meet requirements, reliability, and safety.

5. Retrofitting and Upgradation

Monika Engineers assists customers in upgrading their existing legacy systems by incorporating advanced control technologies without interrupting existing operations. This strategy extends the lifespan of installed infrastructure and provides new functionality.

Why Monika Engineers?

- Expert Technical Knowledge:With a highly qualified team of control engineers, the organization is equipped to manage any size and complexity of project.

- Customer-Centric Approach: Each solution is configured with the objectives of the client in focus—be it minimizing downtime, enhancing product quality, or maximizing energy efficiency.

- Full-Fledged Service: From conceptual design and programming to panel assembly, testing, and commissioning, Monika Engineers delivers end-to-end turnkey solutions.

- Quality and Compliance: Their products meet the highest industry standards, with long-term reliability and simple maintenance.

The Road Ahead

The road ahead for control engineering is towards smarter, more integrated systems—blending IoT, artificial intelligence, and cloud-based analytics to expand the frontiers of automation. Monika Engineers is already putting these technologies into place, keeping their clients at the forefront.

In a fast-paced changing industrial environment, Monika Engineers is ever-reiterating that the ideal control system is not only about automation—it is about empowerment. Empowering companies to get smarter, work faster, and perform better.

Official Mail: monikaengineering@123

Contact no. - +91 9872846445

Address: 77A, Industrial Area- A, Ludhiana, Punjab 141003

Working Hours: Monday to Saturday - 9:30 AM – 7:00 PM

Website: https://monikaengineers.co.in/

Google My Business: https://g.co/kgs/PfDzeBK

0 notes

Text

Why Siemens SCADA Software is the Future of Process Control

These monitoring and control functions, in combination with apt optimization of the industrial processes, are fundamental for operational efficiency and competitive edge in the current scenario marked by Industry 4.0. That is where Siemens SCADA enters the picture: a very strong and scalable solution, addressing these needs, within the Siemens SCADA paradigm. All systems relating to industrial automation can utilize Siemens SCADA. It will enable industries with visualization of data in real time, better decision-making, and dependable system control.

Learn more about, Siemens SCADA (SIMATIC WinCC): A Complete Industrial Automation Guide

What is Siemens SCADA?

Siemens SCADA is a comprehensive suite of software solutions performing the monitoring and control functions at various levels for industrial systems. Processes and building management are supervised in a centralized way for all key activities. The most well-known of products is SIMATIC WinCC, which serves as a global powerhouse SCADA platform for visualization and control of industrial processes.

Siemens SCADA ensures smooth, efficient, and safe operations across a manufacturing plant, power station, or water treatment facility.

Primary Features of SIMATIC WinCC

SIMATIC WinCC remains a central part of the Siemens SCADA. With a scalable, flexible approach for both simple applications and complex distributed systems, some key features include:

Real-time Monitor: WinCC SCADA gives operational support for continuous monitoring and controlling processes in real time, therefore creating quick responsiveness and downtime reduction.

Scalability: The system from smaller standalone applications to complex multi-user client-server architectures grows with your operational needs.

Open Connectivity: Integration with a multitude of PLCs, databases, and third-party systems.

User-Friendly Interface: Helps an operator to quickly navigate, analyze and respond to alarms or changes in system behavior through an intuitive interface.

Comprehensive Data Logging: Logging of all processed data, alarms, and user actions for further analysis and compliance requirements.

Applications of Siemens SCADA Software

Siemens SCADA Software finds its applications in diverse industries owing to its flexibility and robustness. Some of the common applications are:

Manufacturing & Automation: Delivers superior insight into production lines with the purpose of improving efficiency and product quality.

Energy & Utilities: For power distribution management, renewable energy monitoring, and utility control centers.

Water & Wastewater: Provides real-time status reports and predictive maintenance to ensure optimum performance of water treatment facilities.

Infrastructure Management: Manages newly developed smart buildings and campuses in HVAC, lighting, and security systems.

Advantage of adopting WinCC SCADA

Adopting WinCC SCADA opens:

Increased visibility and transparency across operations

Increased uptime of the system and much maintenance cost saving

Safety through intelligent alarm systems

Industry compliance through an audit trail of the processes

Partner with the Experts – Naksh Technology Solutions LLP

Partnering with the right automation expert to implement Siemens SCADA Software makes the difference. On top of being a trusted dealer and solutions provider for Siemens automation products, Naksh Technology Solutions LLP brings deep industry knowledge and a customer-centric approach. We help operationalize clients by designing, deploying, and supporting adaptive SCADA systems tailored for operational goals.

Whether the journey has just started or someone's thinking of upgrading an existing setup, Naksh Technology is the one place one would go to find a reliable Siemens SCADA solution partner.

0 notes