#PLC automation

Explore tagged Tumblr posts

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes

Text

Instrumental Design is the field of engineering and technological methods that merges engineering principles with modern technology to design, develop, and maintain instruments used in various industries. This guide is specifically for an instrumentation design engineering course and how a person can through their studies, work, get a job in this growing field get all a high salary through the boom of employment in this field.

#plc automation#design instrumentation training#intools training#electrical and instrumentation works#smartplant instrumentation training#smart plant instrumentation training#across the spiderverse#artists on tumblr

2 notes

·

View notes

Text

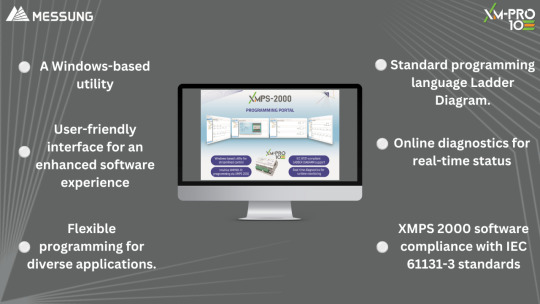

Introducing XMPS-2000: Messung's Advanced PLC Programming Software

Messung Industrial Automation is proud to unveil the XMPS-2000 software, a powerful and intuitive Windows-based utility designed to enhance the programming experience for the XMPRO-10 PLC series. With a focus on user-friendly interfaces and robust functionalities, XMPS-2000 is set to redefine efficiency in industrial automation.

Key Features of XMPS-2000:

User-Friendly Environment: The software offers an intuitive interface, ensuring a seamless experience with various software tools.

Programming Flexibility: XMPS-2000 supports the standard Ladder programming language, making it compatible with a wide range of applications. The software complies with IEC 61131-3 Standards.

Online Diagnostics: Real-time diagnostics functionality allows users to monitor runtime status effectively.

Advanced Programming Capabilities:

Hardware Configuration: Facilitates CPU and I/O modules hardware configuration, simplifying system setup.

Logic Blocks: Enables the creation of subroutines that can be called within the main block, promoting organized and modular programming.

Monitor Table: Allows for user-defined tags, communication variables, and a watch window for real-time monitoring of discrete and analog I/Os.

Online Monitoring: Supports real-time monitoring of ladder programs and generates cross-references for efficient debugging.

Force Value Functionality: Permits value forcing during program testing, aiding in thorough validation processes.

User Library: Offers the creation of user-defined function blocks for customized tasks or specific applications, enhancing reusability.

System Configuration Management:

Comprehensive Selection: Allows selection of XMPRO CPU, local and remote I/O expansion modules, and displays total I/O count.

Communication Parameterization: Facilitates communication ports parameterization, supporting protocols like MODBUS TCP and RTU.

Hardware Selection Visualization:

I/O Configuration:

Assignment Flexibility: Supports I/O assignment for onboard, expansion, and remote I/O modules, with mode selection for analog inputs and outputs.

System-Generated Addresses: Automatically generates I/O addresses, simplifying the configuration process.

Program Structure:

Efficient Tools: Features a toolbar with shortcuts to ladder elements and instructions, a project management window for file creation, and a program edit window in standard ladder format.

Compiler and Monitoring: Includes a compiler window for error display, an online monitor window for real-time project monitoring, and a watch window for user-selected variables.

The XMPS-2000 software exemplifies Messung's commitment to delivering innovative and efficient solutions in industrial automation. By integrating advanced features with a user-centric design, XMPS-2000 empowers engineers and technicians to achieve higher productivity and precision in their automation projects.

For more information and to experience the capabilities of XMPS-2000, contact Messung Industrial Automation.

#XMPS-2000 software#Messung Industrial Automation#industrial automation#I/O modules#IEC 61131-3 Standards#XMPRO-10 PLC series#plc#programmable logic controller#plc controller#plc automation#plc controller supplier in india#plc controller manufacturer in india

0 notes

Text

What Is Automation and Control Engineering? How It’s Powering Rockford’s Industrial Growth

In today’s competitive and fast-paced industrial environment, companies are under immense pressure to increase efficiency, reduce downtime, and produce higher-quality output. One discipline that sits at the heart of this transformation is automation and control engineering. Across the manufacturing-heavy city of Rockford, Illinois, this field is driving innovation, operational excellence, and long-term sustainability.

From robotics to real-time data monitoring, automation and control engineering plays a critical role in modernizing factories, optimizing logistics, and ensuring safer, smarter processes. But what exactly does this field involve—and why is it becoming essential for companies in Rockford and beyond?

Let’s take a closer look.

Understanding Automation and Control Engineering

At its core, automation and control engineering is the integration of hardware and software systems to automate industrial processes, control machinery, and optimize operations. Engineers in this field design intelligent systems that make decisions, collect data, and execute actions with little to no human intervention.

Typical systems include:

Programmable Logic Controllers (PLCs)

Supervisory Control and Data Acquisition (SCADA)

Distributed Control Systems (DCS)

Human-Machine Interfaces (HMIs)

Sensors, actuators, and IoT devices

Robotics and motion control

These systems are crucial in industries like automotive manufacturing, aerospace, food processing, energy production, water treatment, and many more—all of which have a strong presence in Rockford.

Why Rockford Is an Automation Hotspot

Rockford has long been known as a powerhouse for manufacturing and aerospace engineering. Home to major players in precision machining, automation integration, and logistics, the city has embraced technological innovation to stay competitive in the global market.

Here's why automation and control engineering is such a perfect fit for Rockford:

1. Strong Manufacturing Base

With a high concentration of machine shops and OEMs (original equipment manufacturers), Rockford relies heavily on process efficiency and system reliability. Automation makes it easier to maintain consistent production and minimize waste.

2. Workforce Development

The city’s technical schools and engineering programs, including those at Rock Valley College and Northern Illinois University, are helping to prepare a new generation of automation-savvy engineers.

3. Modernization of Legacy Facilities

Many older manufacturing facilities in Rockford are upgrading to smart systems to meet today's standards for energy efficiency, data tracking, and remote operation.

4. Industry Diversification

Aside from aerospace and automotive, Rockford is seeing growth in renewable energy, food processing, and medical device manufacturing—all of which benefit greatly from advanced control systems.

Key Benefits of Automation and Control Engineering

Increased Efficiency

By reducing manual intervention, automated systems can streamline tasks like assembly, inspection, and material handling. This results in faster production cycles and lower labor costs.

Better Product Quality

Automated control systems can monitor quality metrics in real-time, ensuring products meet strict specifications. This is especially important for high-precision industries like aerospace and electronics.

Improved Safety

Sensors, alarms, and emergency shutdown systems help reduce the risk of accidents. Workers are kept away from hazardous zones, and automated safety protocols ensure fast response during equipment malfunctions.

Data-Driven Operations

With the integration of IoT and cloud technology, companies can collect and analyze vast amounts of performance data. This empowers smarter decision-making, predictive maintenance, and better resource management.

Scalability and Flexibility

Automated systems can be easily modified or scaled as production demands change—crucial for Rockford’s diverse and rapidly evolving manufacturing landscape.

Common Applications in Rockford Industries

Automation and control engineering is already making an impact across many sectors in Rockford. Some examples include:

Aerospace: Robotic welding, CNC automation, and torque control systems for precision parts

Automotive: Automated assembly lines, vision-guided inspection, and quality control systems

Food & Beverage: Temperature and pH monitoring, smart conveyors, and automated packaging

Logistics: Warehouse automation, conveyor control, and robotic material handling

Utilities: SCADA systems for water treatment and energy distribution

Choosing the Right Automation Partner

When upgrading or implementing automated systems, it's essential to work with professionals who understand both the technology and the unique challenges of your industry. Look for a partner with:

Proven experience in automation design and integration

Knowledge of Rockford’s industrial landscape

Ability to provide long-term support and training

A clear roadmap for system scalability

Companies across Illinois have found success by working with specialized automation providers who not only deliver hardware and software but also offer consulting, system optimization, and ongoing maintenance.

Final Words: Engineering Rockford’s Future

In a city like Rockford, where tradition meets innovation, automation and control engineering is not just a trend—it’s a transformation. Whether you’re modernizing an existing facility or building a fully smart production line, the key to success lies in engineering systems that are intelligent, adaptable, and aligned with your operational goals.

As industries continue to evolve, so must the tools they use. With the right automation strategies in place, Rockford's manufacturers can expect reduced costs, better performance, and stronger global competitiveness.

To explore automation solutions built for your industry, start your journey with trusted experts at Xtreme Automation LLC— your gateway to smarter systems and a more efficient future.

1 note

·

View note

Text

https://www.messungautomation.co.in/how-does-programmable-logic-controller-plc-work/

Enhance industrial automation with Messung IAC’s advanced Programmable Logic Controller (PLC) solutions. Designed for precision, efficiency, and reliability, our PLCs ensure seamless control of industrial processes, reducing downtime and optimizing productivity. With real-time monitoring, intelligent programming, and robust performance, our PLC systems are ideal for various industries, including manufacturing, energy, and infrastructure. Messung IAC’s automation solutions integrate cutting-edge technology to deliver superior process control, ensuring safety, consistency, and cost-effectiveness. Upgrade to smart automation with our industry-leading PLC solutions and experience the future of industrial control. Discover innovation with Messung IAC today!

0 notes

Text

The SIMATIC ET 200SP is a powerful, space-saving distributed I/O system designed for high efficiency in industrial automation. With its modular, flexible design, it ensures seamless scalability and fast integration. Offering high performance, reliability, and easy maintenance, it’s the ideal solution for modern automation needs. Upgrade your system today!

1 note

·

View note

Text

How do electrical and instrumentation functions increase operational efficiency?

The electrical and instrumentation works are used to install, and maintain electrical systems as well as instrumentation. In many ways, it has ensured efficiency, safety, and reliability in most of the operations. In every manufacturing plant, energy facility, or construction project, these systems provide a fundamental basis for smooth, optimal performance. Electrical and instrumentation works are important because they enhance operational efficiency. Sophisticated systems and equipment can even automate repetitive tasks while retaining better control over business processes. Rudraja Engineers is committed to providing the best electrical and instrumentation works to meet the specific requirements of each client. Focusing on precision and reliability, the company ensures every project meets high standards, thereby helping businesses succeed.

0 notes

Text

PLC Automation in Data Centers: Protecting Critical Infrastructure

Data centers form the backbone of modern businesses, handling vast amounts of data and supporting critical IT services. The reliability, efficiency, and security of these facilities are paramount, as even the smallest disruption can result in significant financial and reputational damage. As data centers grow in complexity and scale, the need for automated solutions becomes increasingly essential. PLC industrial automation solutions play a pivotal role in safeguarding these facilities and ensuring their seamless operation.

In this blog, we will explore how PLC Automation is helping to protect critical infrastructure in data centers, making them more resilient, efficient, and secure.

What is PLC Automation?

PLC (Programmable Logic Controller) automation refers to the use of programmable controllers to automate electrical and mechanical processes. These devices are designed to control machinery, processes, or complex systems, often within industrial environments. PLC industrial automation allows for precise control, real-time monitoring, and efficient management of operations.

In a data center, PLC automation is applied to manage a wide range of systems, including power distribution, HVAC (heating, ventilation, and air conditioning), and security systems. By integrating PLCs with the data center’s infrastructure, operators can automate routine tasks, monitor critical systems in real-time, and respond quickly to any anomalies or failures.

The Role of PLC Automation in Data Centers

Enhanced Reliability and Uptime

The primary objective of PLC automation in data centers is to ensure continuous uptime. Uninterrupted service is crucial for data centers, as any downtime can lead to data loss, decreased productivity, or system failures. PLC systems can monitor various parameters, including power supply, cooling systems, and server performance, to prevent failures before they occur. For instance, PLCs can detect fluctuations in power or temperature and trigger automatic corrective actions, such as switching to backup power sources or activating cooling systems to avoid overheating.

With PLC automation, data centers can operate more reliably, minimizing the risk of downtime and ensuring that critical infrastructure remains operational around the clock.

Energy Efficiency and Cost Savings

Energy consumption is one of the most significant operational costs for data centers. With the growing demand for data storage and processing, energy usage has skyrocketed. PLC systems help optimize energy consumption by continuously monitoring the performance of equipment and adjusting operations based on real-time data. For example, if the cooling system is running inefficiently, the PLC can automatically adjust settings to optimize airflow and temperature, reducing energy waste.

By incorporating PLC automation, data centers can lower energy costs and reduce their carbon footprint. The automated adjustments also ensure that the data center operates within optimal parameters, enhancing both efficiency and sustainability.

Real-Time Monitoring and Fault Detection

PLC automation enables real-time monitoring of critical systems in data centers, allowing operators to detect and resolve potential issues before they escalate. Whether it’s power distribution, cooling systems, or security protocols, PLC systems can continuously track the health of these systems and alert operators to abnormalities.

For instance, if a power surge or voltage drop is detected, the PLC can automatically switch to a backup power source, ensuring that operations continue without disruption. Similarly, if temperature sensors indicate that the cooling system is underperforming, the PLC can trigger corrective actions such as adjusting the airflow or activating additional cooling units.

Real-time fault detection and automatic troubleshooting are vital for ensuring the longevity and security of data center operations. Read more......

0 notes

Text

Engineering Training In Pune

Welcome to Perfecto Robotics Institute, your perfect destination for Engineering Training In Pune. Our organization prides itself on offering advanced courses designed to equip you with essential technical skills.

At Perfecto Robotics Institute, we are dedicated to providing exceptional training programs for individuals of all skill levels. Whether you are a beginner looking to build a solid foundation to grow your career. We provide step-by-step guides in robotics as well as automation fields. In the Institute we take practical exercises for students to better understand as well as for incrementing their knowledge.

Lesson Highlights:

Moreover, Our educational program is carefully designed to cover a wide range of engineering disciplines. Students benefit from hands-on training using state-of-the-art equipment, ensuring the application of practical knowledge in real-world situations.

Why should you choose us?:

Additionally,

our expert professors are industry-experienced.

We provide outstanding practical experience to the students.

Individual guidance.

We support you foster collaboration.

Rich learning environment.

From basic principles to advanced techniques.

Career Opportunities:

With Perfecto Robotics Institute we provide successful completion of our training programs. our courses are designed to meet your specific needs. We provide career opportunities in automotive, robotics, etc.

Offered Courses:

Basic Industrial Automation

Advanced Industrial Automation

Basic Industrial Robotics

Advanced Industrial Robotics

In conclusion, Perfecto Robotics Institute stands out as an indication of excellence in Engineering Training in Pune. Whether you aspire to enhance your skills or embark on a new career path in engineering, we are committed to helping you achieve your professional training experience.

Ready to take the next step toward a successful career in engineering? Contact Perfecto Robotics Institute today to learn Engineering Training In Pune for more about our courses, enrollment procedures, and how we can support your educational journey.

0 notes

Video

youtube

SCADA Applications in Water Treatment #scada #tech #shorts #industrial #...

Asteam Techno Solutions Pvt. Ltd. is AVEVA (Formerly Wonderware) Registered System Integrator providing sale/service/support and execute the HMI/SCADA, Historian/MES Solutions to End-user & OEM/System Integrator community for their diverse needs Asteam Techno Solutions Pvt. Ltd. is a leading and preferred solution provider for all kind of Industrial Automation requirements in the field of Process and Power Automation. Established in 2017, Asteam Techno Solutions is an ISO 9001: 2015 certified company, having its Design, Manufacturing & Repair facility located in Surat, Gujarat, India and provides total integration under one roof.

#youtube#scada#scadaprogramming#plc#plc programming#plc automation#industry#industrial#automation#youtumblr#tumblr

2 notes

·

View notes

Text

Electrical and instrumentation works

Instrumentation works are important for an industry's smooth running, efficiency, and safety. It involves setup, maintenance, and improving electrical systems, as well as instruments used for controlling or monitoring processes within a particular industry. Electrical and instrumentation works include designing and implementing electrical systems that contain electrical power distribution, wiring, and lighting. Without it, industries cannot afford to work safely and functionally. These systems help identify any faults quickly and thus restore the machines to function continuously without interruption and boost productivity. This goes a long way in providing productivity and saving time and money. Connect with Rudraja Engineers to implement advanced solutions in electrical works.

0 notes

Text

Industry Applications: Innovative Solutions by Messung IAC I Industrial Automation Controller

Discover tailored industrial solutions at Messung Automation & Control. Explore a diverse range of applications, optimized for efficiency and performance.

For more information about messung industrial automation & control visit us https://www.messungautomation.co.in/

#messung plc#plc#plc in india#plc manufacture in india#plc controller supplier in india#plc controller#plc automation#smart plc#programmable logic controller#industrial automation#industrial automation & controller#industrial automation solutions#messung automation#messung industrial automation & control

0 notes