#PLC SCADA Development

Explore tagged Tumblr posts

Text

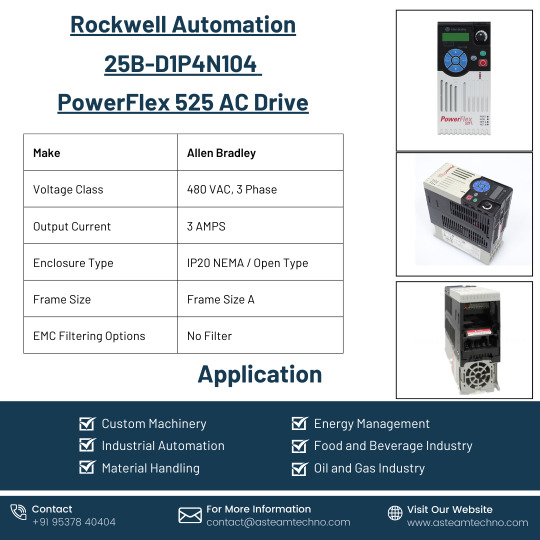

Rockwell Automation 25B-D1P4N104

The Rockwell Automation 25B-D1P4N104 is a part number for a specific variable frequency drive (VFD) within the Allen-Bradley PowerFlex 525 series. The PowerFlex 525 is a compact, versatile, and cost-effective drive designed to control motors in a wide range of industrial applications.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#powerflex525#application#technical#development#engineering#programs

1 note

·

View note

Text

Automation Engineer (Pharma/ Siemens/ PLC Scada)

Duration: 12 months Location: Tuas Salary : Up to $7,000 depending on experienceOur Client is a US MNC and a pioneering leader in the Pharmaceutical industry. They are currently seeking experienced and forward-thinking professionals to join their IT Team in SingaporeJob Purpose Responsible for developing, implementing, and maintaining automated systems within our pharmaceutical manufacturing…

0 notes

Text

ARMxy SBC BL310 ARM Embedded Computer in Industrial Boiler Monitoring and control

Case Details

Boiler monitoring requires real-time acquisition of parameters such as temperature, pressure, and flow, execution of control logic, and data transmission to the cloud for analysis. The BL310 series, powered by the NXP i.MX6ULL Cortex-A7 processor (up to 800MHz), combined with rich I/O interfaces, flexible communication modules, and industrial-grade design, perfectly meets the complex requirements of boiler monitoring.

Industrial Environment Adaptability

Wide Temperature Range: Operates reliably from -40°C to 85°C, suitable for high- or low-temperature boiler room environments.

Electromagnetic Compatibility: Passes GB/T 9254 Class A and CISPR 32 Class A tests, ensuring resistance to electromagnetic interference and stable operation in industrial settings.

Protection and Installation: IP30 protection rating, aluminum alloy + stainless steel casing, and DIN35 rail mounting, ideal for space-constrained control cabinets.

1.2 Data Acquisition and Control

Versatile I/O Interfaces: Supports RS485, RS232, CAN, DI/DO, relays, AI/AO, RTD, and thermocouple signals through X-series and Y-series I/O boards, meeting the needs for temperature, pressure, and flow data acquisition in boilers.

Precise Control: Supports PWM output and pulse counting for valve control and flow monitoring.

Flexible Expansion: Built-in Mini PCIe interface supports WiFi/4G modules for wireless data transmission.

1.3 Communication and Cloud Integration

Industrial Protocol Support: Equipped with BLIoTLink software, supporting protocols like Modbus, BACnet, IEC104, MQTT, and OPC UA, enabling seamless integration with PLCs, SCADA systems, or cloud platforms (e.g., AWS IoT Core, Thingsboard).

Remote Management: BLRAT remote access tool facilitates device maintenance, reducing on-site operational costs.

Rapid Development: Integrated Node-Red enables quick development of IoT applications, simplifying data visualization and logic control.

Typical Application Scenarios in Boiler Monitoring

The BL310 can implement the following core functions in boiler monitoring:

Temperature Monitoring: Uses Y51/Y53 (PT100/PT1000) or Y58 (thermocouple) boards to measure boiler water and flue gas temperatures.

Pressure Monitoring: Acquires pressure sensor data via Y31/Y33 (4-20mA or 0-10V).

Flow Monitoring: Monitors fuel or water flow using Y95/Y96 (pulse counting).

Status Control and Alarms: Implements switching control and alarm outputs via Y01/Y02 (DI/DO) or Y24 (relay) boards.

Remote Monitoring: Transmits data to cloud platforms via 4G/WiFi modules and MQTT protocol for real-time boiler status monitoring.

Data Analysis: Leverages cloud platforms for historical data storage, trend analysis, and energy optimization.

Recommended Configuration

To meet boiler monitoring requirements, the following BL310 configuration is recommended:

Model: BL310L-SOM314-X4-Y51-Y24

Host: BL310L (with 4G module for remote monitoring).

SOM Module: SOM314 (512MB DDR3L, 8GB eMMC, -40~85°C, suitable for high storage and wide temperature needs).

X Board: X4 (2x RS485 + 2x CAN, for connecting to PLCs or other devices).

Y Board 1: Y51 (2-channel 3-wire PT100 for precise temperature monitoring).

Y Board 2: Y24 (4-channel relay output for controlling alarms or valves).

Software Configuration:

Pre-installed BLIoTLink and BLRAT, supporting Modbus-to-MQTT conversion and integration with Thingsboard or AWS IoT Core.

Node-Red for developing data dashboards to display real-time temperature, pressure, and other parameters.

Implementation Suggestions

4.1 Hardware Installation

Install the BL310 in the boiler control cabinet using DIN35 rail mounting, ensuring proper grounding via the 1-pin GND terminal.

Use a 24VDC power supply (supports 9-36V wide voltage range) with reverse polarity and overcurrent protection for enhanced safety.

Configure WiFi/4G antennas as needed to ensure stable signal transmission.

4.2 Software Development

Use Node-Red to quickly develop data acquisition, alarm logic, and visualization dashboards.

Configure BLIoTLink to collect Modbus RTU/TCP data and transmit it to the cloud via MQTT.

Set up BLRAT for remote access, enabling maintenance personnel to monitor device status in real time.

4.3 Testing and Validation

Conduct high/low-temperature and electromagnetic compatibility tests before deployment to ensure reliability in boiler room environments.

Refer to technical support’s Node-Red and BLIoTLink development examples for rapid function validation.

Test 4G/WiFi connection stability to ensure uninterrupted data transmission.

Precautions

I/O Board Selection: Note that Y63 (4x RS485/RS232) occupies two Y slots, preventing the addition of a second Y board.

Storage Needs: For large historical data storage, choose SOM314 (8GB eMMC) over SOM310 (256MB Nand).

Network Security: Configure MQTT authentication and encryption to prevent data breaches.

Custom Development: For special requirements (e.g., vibration monitoring), contact Beilai Technology for customization (see Technical Support section).

Conclusion

The BL310 ARM embedded computer, with its high-performance processor, versatile I/O interfaces, industrial-grade reliability, and flexible software ecosystem, provides an efficient and intelligent solution for boiler monitoring. By enabling real-time data acquisition, remote monitoring, and cloud platform integration, the BL310 significantly enhances the automation and operational efficiency of boiler systems, contributing to the advancement of industrial IoT and smart manufacturing. Whether for new boiler monitoring systems or upgrades to existing setups, the BL310 is a reliable and trusted choice.

0 notes

Text

Engineering Services by Servotech You Can Trust

In today's fast-paced, technology-driven world, businesses require engineering solutions that are not only innovative but also reliable and efficient. Servotech stands as a trusted name in the engineering sector, offering a wide array of services tailored to meet the unique needs of different industries. Our expertise, commitment to quality, and customer-first approach have positioned us as a leader in delivering engineering services you can depend on.

Why Choose Servotech for Engineering Services?

Choosing the right engineering partner is crucial for the success of any project. Servotech combines years of experience, technical excellence, and cutting-edge innovation to deliver unparalleled solutions. Here’s why industries across the globe place their trust in us:

Comprehensive Expertise: Our team includes seasoned engineers specializing in electrical, mechanical, civil, and automation fields.

Customized Solutions: We understand that every project is unique. We tailor our services to meet specific requirements, ensuring maximum efficiency and success.

Advanced Technology: Servotech leverages the latest tools, software, and methodologies to stay ahead of industry trends.

Commitment to Quality: Rigorous quality checks, compliance with international standards, and attention to detail are the hallmarks of our services.

Client-Centric Approach: We work closely with our clients, maintaining open communication and delivering results that align perfectly with their business objectives.

Our Range of Engineering Services

At Servotech, we offer a full suite of engineering services, designed to support projects at every stage — from ideation to final execution.

Electrical Engineering Services

Servotech provides comprehensive electrical engineering solutions, ensuring safe, efficient, and sustainable power systems. Our services include:

Electrical system design and layout

Energy audits and optimization

Control system design

Power distribution solutions

Compliance with safety and regulatory standards

Mechanical Engineering Services

Our mechanical engineering team specializes in designing, analyzing, and manufacturing mechanical systems that are robust and cost-effective. Key services include:

Product design and development

CAD modeling and drafting

Thermal and fluid system analysis

Prototyping and testing

Mechanical maintenance planning

Automation and Control Systems

Automation is at the heart of modern industry. Servotech provides intelligent automation and control solutions that increase productivity and reduce operational costs. Our expertise includes:

PLC and SCADA system development

Industrial robotics integration

IoT-based automation solutions

Process control and instrumentation

Custom software development for automation

Civil and Structural Engineering

Servotech's civil and structural engineering services are vital for building durable and resilient infrastructures. We offer:

Structural design and analysis

Site planning and development

Geotechnical investigations

Construction management support

Retrofitting and rehabilitation services

Project Management and Consulting

Beyond technical solutions, we provide project management and consulting services to ensure timely and successful project delivery. Our consulting services cover:

Feasibility studies and risk assessments

Budgeting and cost estimation

Scheduling and resource allocation

Regulatory compliance advisory

Quality assurance and control

Industries We Serve

Our multidisciplinary approach allows us to serve a wide range of industries, including:

Manufacturing

Energy and Utilities

Construction and Infrastructure

Automotive

Aerospace

Healthcare

Telecommunications

Renewable Energy

Each industry presents unique challenges, and Servotech’s adaptive solutions ensure that we meet industry-specific requirements efficiently and effectively.

Servotech’s Commitment to Sustainability

At Servotech, we recognize the importance of sustainable engineering practices. Our solutions are designed with environmental responsibility in mind. We focus on:

Reducing energy consumption

Promoting the use of renewable resources

Minimizing waste and environmental impact

Supporting sustainable manufacturing practices

By integrating green engineering principles into our services, we help our clients achieve their sustainability goals while maintaining operational excellence.

Our Engineering Process

We follow a systematic and proven engineering process to ensure that every project meets the highest standards:

Requirement Analysis: Understanding the client’s goals, challenges, and expectations.

Conceptual Design: Developing innovative solutions based on detailed analysis.

Detailed Engineering: Preparing comprehensive designs, drawings, and specifications.

Implementation Support: Assisting with manufacturing, construction, or integration.

Testing and Validation: Verifying that the solution meets all functional and safety requirements.

Ongoing Support: Offering post-project support, maintenance, and optimization services.

Each step is carried out with precision, ensuring that every project is delivered on time, within budget, and to the complete satisfaction of the client.

Conclusion

When it comes to engineering services, trust, expertise, and innovation are non-negotiable. Servotech brings all of these qualities — and more — to every project we undertake. Our client-centric approach, commitment to quality, and passion for innovation make us the ideal engineering partner for businesses aiming for success.

0 notes

Text

Why Control Solutions in Malaysia Are Crucial for Energy Efficiency and Sustainability

As Malaysia continues its journey toward smart industries and greener infrastructure, the demand for advanced control solutions is growing rapidly. From manufacturing plants and commercial buildings to public utilities, effective control systems are becoming essential for improving energy efficiency, operational transparency, and long-term sustainability. At the forefront of this transformation is Madox Malaysia, a trusted name in automation and intelligent engineering solutions.

Understanding Control Solutions in Malaysia

Control solutions refer to the integration of automation technologies such as PLCs (Programmable Logic Controllers), SCADA systems, DCS (Distributed Control Systems), and control panels that monitor and regulate equipment and processes. In Malaysia, where industries are rapidly evolving and energy consumption is a critical factor, the implementation of reliable control systems plays a central role in managing operations more effectively.

Madox Malaysia, as a leading automation company in Malaysia, specializes in designing, building, and implementing customized control solutions that help industries optimize their energy use and streamline performance.

The Link Between Control Solutions and Energy Efficiency

In today’s competitive industrial environment, energy is not just a cost—it’s a strategic resource. Poorly managed operations can lead to excessive energy consumption, equipment wear, and increased operational costs. That’s where Madox Malaysia’s control solutions deliver tangible benefits:

✅ Real-Time Monitoring and Analysis

Madox Malaysia provides systems that allow operators to monitor energy usage in real-time, helping detect inefficiencies or unusual patterns immediately. This kind of visibility ensures that corrective actions can be taken before energy losses become costly.

✅ Automated Energy Management

Modern control systems automate everything from HVAC systems in buildings to production lines in factories. With Madox Malaysia’s automation expertise, these systems can be programmed to run only when needed, adjust according to demand, or shut down during off-peak hours—all contributing to lower energy bills and better energy resource planning.

✅ Predictive Maintenance and Efficiency Gains

Control solutions implemented by Madox Malaysia help monitor equipment health and performance trends. Predictive analytics not only reduce unexpected downtimes but also ensure machinery runs at optimum efficiency, using less energy over time.

Sustainability Through Smart Control

Malaysia is actively pushing toward sustainable development, aligned with global environmental commitments. Automation and control systems are instrumental in achieving these goals:

🌱 Reduction in Carbon Footprint

By optimizing how machines and building systems consume energy, Madox Malaysia’s control solutions significantly reduce the carbon output of industrial and commercial operations.

🌱 Integration with Renewable Energy Systems

Madox Malaysia helps clients integrate control solutions with solar and other renewable energy sources, providing intelligent switching, load balancing, and energy storage management—further supporting green initiatives in Malaysia.

🌱 Sustainable Water and Resource Management

Beyond energy, control systems also monitor and regulate water and raw material usage. With customized panels and software, Madox Malaysia enables sustainable operations across sectors like manufacturing, agriculture, and infrastructure.

Why Madox Malaysia is a Trusted Automation Partner

As a top-tier automation company in Malaysia, Madox Malaysia has built a reputation for delivering intelligent, robust, and scalable control systems tailored to client-specific needs. Here’s what sets the brand apart:

Industry Expertise: With years of experience in engineering and automation, Madox Malaysia has worked across industries—from automotive and electronics to food processing and utilities.

Turnkey Solutions: Madox Malaysia offers end-to-end support—from consultation and design to installation and maintenance—ensuring seamless integration and long-term performance.

Quality Assurance: Every solution provided by Madox Malaysia adheres to international standards, ensuring durability, accuracy, and reliability.

Local Insight with Global Technology: The team combines deep knowledge of Malaysia’s industrial landscape with cutting-edge technologies from global partners.

Industries Benefiting from Control Solutions in Malaysia

Madox Malaysia has deployed energy-efficient control systems in a variety of sectors, including:

Manufacturing – Automated production lines with real-time data feedback for leaner operations.

Commercial Buildings – Smart HVAC and lighting systems to reduce operational costs.

Utilities & Infrastructure – Remote monitoring and predictive maintenance for uninterrupted service delivery.

Oil & Gas / Energy – Safety-compliant control systems managing complex processes efficiently.

Conclusion

As Malaysia continues its push toward energy efficiency and sustainable industrial growth, the role of intelligent control solutions cannot be overstated. These systems not only enhance performance and reduce costs but also support environmental responsibility. For businesses looking to make this transition, Madox Malaysia stands ready as a trusted partner.

With a strong track record as an automation company in Malaysia, Madox Malaysia delivers the advanced control systems that modern industries need—efficient, smart, and future-ready.

please click the link for more info:https://www.madox.my/solutions/process-control-system/

0 notes

Text

Memory and Data Handling in PLC

Introduction

Programmable Logic Controllers (PLCs) are the mainstay in control systems in the industrial automation world. Aside from input/output control, the most vital functionality of a PLC is its memory structure and data handling capabilities. These enable a PLC to execute logic, hold variables, handle communication, and maintain seamless operation between automated systems.

Understanding PLC Memory Structure

PLC memory is separated into various sections, each of which has a particular function:

System Memory: Houses internal settings and system-level operations like timers, counters, and flags.

Program Memory: Stores the actual control logic in programming languages such as ladder logic.

Data Memory: Holds real-time input/output values, mid-computation variables, and user-defined data structures.

Retentive Memory: Maintains some values even after power removal—convenient for counters, timers, or operational states.

Effective memory use is critical to system performance. Knowing how to allocate and manipulate memory spaces properly guarantees robust and scalable control logic.

Data Handling Techniques

In automation, data has to be continuously monitored, shifted, processed, and occasionally stored. PLCs provide a number of instructions to work with data effectively, including:

Move (MOV): Copies data from one memory location to another.

Compare (CMP): Compares values based on conditions like equal to, greater than, or less than.

Arithmetic Operations: Permits mathematical calculations such as addition, subtraction, and so forth.

Logical Operations: Performs AND, OR, NOT operations for decision-making logic.

Appropriate treatment of data is also concerned with handling analog signals, monitoring alarm systems, and storing process values for subsequent utilization or reporting.

How Training Enhances Practical Understanding

Although the idea of memory and data processing may appear theoretical in textbooks, its actual significance is achieved on the factory floor. That's where hands-on exposure becomes vital. A hands-on PLC SCADA Course Nashik provides learners with a chance to interact with actual hardware, where they can see how to organize memory, process data, and debug properly.

VIATA, situated in the center of Nashik, provides such learning through its specially designed industrial training modules. With more than 20 years of experience in industrial automation, the institute emphasizes both the theoretical basis and practical implementation of PLC programming concepts.

At VIATA, students get a deep dive into memory types, data manipulation commands, and live project work emulating actual industrial environments. They also get exposed to Servo and Stepper Motor control, DCS, IIoT, and panel engineering, which all depend on sophisticated data handling within a PLC system.

Why Take a PLC SCADA Course in Nashik?

Learn with live industrial equipment for real-world application.

Gain experience under seasoned automation professionals.

Work on job-oriented projects with full exposure to PLC and SCADA systems.

Get trained in HMI design, VFDs, motor drives, and more.

Develop strong fundamentals in data handling and control logic through interactive sessions and interview preparation.

Conclusion: PLC data and memory management are the pillars of intelligent automation. For career aspirants in this domain, it is a prerequisite to excel in these aspects. Joining a practical PLC SCADA Course in Nashik at institutions such as VIATA guarantees that students learn beyond the books and have the confidence to work in actual industrial settings—where effective data handling results in effective systems.

0 notes

Text

Why Siemens SCADA Software is the Future of Process Control

These monitoring and control functions, in combination with apt optimization of the industrial processes, are fundamental for operational efficiency and competitive edge in the current scenario marked by Industry 4.0. That is where Siemens SCADA enters the picture: a very strong and scalable solution, addressing these needs, within the Siemens SCADA paradigm. All systems relating to industrial automation can utilize Siemens SCADA. It will enable industries with visualization of data in real time, better decision-making, and dependable system control.

Learn more about, Siemens SCADA (SIMATIC WinCC): A Complete Industrial Automation Guide

What is Siemens SCADA?

Siemens SCADA is a comprehensive suite of software solutions performing the monitoring and control functions at various levels for industrial systems. Processes and building management are supervised in a centralized way for all key activities. The most well-known of products is SIMATIC WinCC, which serves as a global powerhouse SCADA platform for visualization and control of industrial processes.

Siemens SCADA ensures smooth, efficient, and safe operations across a manufacturing plant, power station, or water treatment facility.

Primary Features of SIMATIC WinCC

SIMATIC WinCC remains a central part of the Siemens SCADA. With a scalable, flexible approach for both simple applications and complex distributed systems, some key features include:

Real-time Monitor: WinCC SCADA gives operational support for continuous monitoring and controlling processes in real time, therefore creating quick responsiveness and downtime reduction.

Scalability: The system from smaller standalone applications to complex multi-user client-server architectures grows with your operational needs.

Open Connectivity: Integration with a multitude of PLCs, databases, and third-party systems.

User-Friendly Interface: Helps an operator to quickly navigate, analyze and respond to alarms or changes in system behavior through an intuitive interface.

Comprehensive Data Logging: Logging of all processed data, alarms, and user actions for further analysis and compliance requirements.

Applications of Siemens SCADA Software

Siemens SCADA Software finds its applications in diverse industries owing to its flexibility and robustness. Some of the common applications are:

Manufacturing & Automation: Delivers superior insight into production lines with the purpose of improving efficiency and product quality.

Energy & Utilities: For power distribution management, renewable energy monitoring, and utility control centers.

Water & Wastewater: Provides real-time status reports and predictive maintenance to ensure optimum performance of water treatment facilities.

Infrastructure Management: Manages newly developed smart buildings and campuses in HVAC, lighting, and security systems.

Advantage of adopting WinCC SCADA

Adopting WinCC SCADA opens:

Increased visibility and transparency across operations

Increased uptime of the system and much maintenance cost saving

Safety through intelligent alarm systems

Industry compliance through an audit trail of the processes

Partner with the Experts – Naksh Technology Solutions LLP

Partnering with the right automation expert to implement Siemens SCADA Software makes the difference. On top of being a trusted dealer and solutions provider for Siemens automation products, Naksh Technology Solutions LLP brings deep industry knowledge and a customer-centric approach. We help operationalize clients by designing, deploying, and supporting adaptive SCADA systems tailored for operational goals.

Whether the journey has just started or someone's thinking of upgrading an existing setup, Naksh Technology is the one place one would go to find a reliable Siemens SCADA solution partner.

0 notes

Text

Top Control Devices Solutions in Palatine, IL

As industries across the country increasingly shift towards smart, efficient, and automated systems, control devices have become the backbone of operations. In Palatine, Illinois, a thriving hub for small to mid-sized industries and commercial developments, businesses are actively integrating advanced control solutions to enhance functionality, efficiency, and long-term reliability.

Control devices play a pivotal role in automation across multiple applications—from manufacturing floors to energy management systems. They are designed to monitor inputs, control outputs, and maintain safe, optimized performance throughout operational cycles. In Palatine, businesses are investing in robust control systems to streamline their workflows and future-proof their infrastructure.

What Are Control Devices?

Control devices are components used in automation and electrical systems to manage, regulate, or guide operations. These can include sensors, switches, relays, contactors, circuit breakers, and programmable logic controllers (PLCs). Each component is essential for establishing effective communication between different parts of a system—ensuring that machines, power sources, and software all work together seamlessly.

In Palatine’s rapidly modernizing commercial landscape, these devices support functions like temperature regulation, motion control, safety shut-offs, and data acquisition, serving industries such as manufacturing, warehousing, building automation, and public infrastructure.

Why Control Devices Matter in Palatine

Palatine businesses are increasingly adopting automated systems that depend heavily on precise and durable control devices. The demand stems from a desire to:

Enhance Efficiency: Automation driven by quality control devices reduces manual intervention and human error.

Boost Safety: Devices such as overload relays and circuit breakers prevent equipment failures and workplace hazards.

Lower Operational Costs: Automated processes minimize resource waste, utility consumption, and downtime.

Achieve Scalability: Modular and customizable systems can expand easily as the business grows.

Ensure Compliance: Control devices help meet local safety regulations and industry standards.

This makes control devices indispensable for Palatine’s wide array of industrial, commercial, and even residential applications.

Key Applications of Control Devices in Palatine Industries

1. Manufacturing Automation

Palatine's manufacturing sector relies on a variety of control devices to regulate everything from robotic arms to conveyor belts. PLCs and motor controllers ensure equipment operates precisely as programmed, while limit switches and sensors maintain consistency in production.

2. Building Management Systems (BMS)

In commercial and public buildings across Palatine, control devices manage HVAC, lighting, and access control systems. These devices are key to creating smart environments that are both energy-efficient and comfortable.

3. Energy and Utility Management

Facilities managing power, water, or gas use industrial control devices to automate and monitor distribution networks. Devices like SCADA controllers, voltage regulators, and automated breakers help ensure uninterrupted service delivery in Palatine.

4. Food and Beverage Processing

Precision is crucial in food processing, and control devices help regulate mixing, temperature, and packaging operations. This ensures hygiene and quality compliance with local and federal food safety standards.

5. Transportation and Logistics

Palatine’s growing logistics hubs use control devices to manage automated storage, retrieval systems, and safety interlocks, improving throughput and reducing bottlenecks in the supply chain.

Essential Types of Control Devices

To serve diverse operational requirements, control devices come in various categories:

Switches & Sensors: Detect environmental or mechanical changes and send signals to the control system.

PLCs (Programmable Logic Controllers): These compact computers execute logic to automate tasks.

Relays & Contactors: Electromagnetic switches used for remote control of high-power equipment.

Breakers & Fuses: Protect systems from overload or electrical faults.

HMIs (Human-Machine Interfaces): Allow operators to view and adjust system operations in real time.

Variable Frequency Drives (VFDs): Manage motor speed and torque for energy-efficient operations.

Together, these devices enable complete automation—from input detection to decision-making and system response.

Benefits of Using Advanced Control Devices

Control devices deliver tangible advantages to Palatine businesses across sectors:

Real-Time Monitoring: Operators can observe system performance instantly and make timely adjustments.

Predictive Maintenance: Devices detect anomalies early, preventing unexpected downtime or failures.

Process Optimization: Improved accuracy and timing contribute to consistent, high-quality output.

Data Collection & Analysis: Smart devices gather operational data, aiding performance analytics and decision-making.

Flexible Integration: Modern control systems support both legacy and new equipment, enhancing system compatibility.

These benefits help businesses maintain competitive efficiency while reducing long-term operational costs.

Innovations in Control Device Technology

As control automation evolves, modern control devices now feature:

Wireless Communication: Bluetooth, Wi-Fi, and cellular-enabled components enhance mobility and remote access.

Cybersecurity Safeguards: Devices now come equipped with encryption and authentication features to prevent unauthorized access.

AI & Machine Learning Integration: Some systems can self-learn and optimize functions based on historical performance.

Energy Efficiency Monitoring: Smart devices can calculate energy consumption in real time and recommend changes.

Such innovations are increasingly accessible to businesses in Palatine, making the leap to automation easier than ever.

Choosing the Right Control Device Provider in Palatine

While selecting control devices for your Palatine operation, it’s important to assess:

System Compatibility: Ensure the devices integrate well with your current automation setup.

Build Quality & Reliability: Industrial-grade components last longer and withstand harsh environments.

Technical Support & Maintenance: Choose vendors that offer guidance, installation, and long-term support.

Customization Options: Tailored solutions often yield better outcomes than off-the-shelf products.

Reliable automation starts with sourcing the right control devices and integrating them through skilled engineering support.

Expert Support for Control Devices in Palatine

For companies in Palatine, Illinois, looking to elevate their automation capabilities with high-quality control devices, Xtreme Automation LLC offers tailored engineering solutions backed by industry expertise. Whether you're upgrading existing systems or deploying a new setup from the ground up, their team delivers seamless integration and dependable performance.

0 notes

Text

Best Siemens Dealer in Ahmedabad- Darshil Enterprises

Best Siemens Dealer in Ahmedabad – Darshil Enterprises

When it comes to finding a Siemens dealer near me that you can truly rely on, look no further than Darshil Enterprises. Located in the heart of Ahmedabad, we are proud to be recognized as the Best Siemens dealer in Ahmedabad, offering a comprehensive range of Siemens products backed by deep technical knowledge and unmatched customer service.

Whether you're running an industrial unit or managing infrastructure solutions, Darshil Enterprises is your trusted partner for authentic Siemens equipment. With years of experience and a strong network, we proudly stand as a top Siemens dealer, serving clients with the highest quality automation, control, and electrical products from Siemens.

Siemens – A Global Leader in Innovation

Siemens is a global powerhouse in electrification, automation, and digitalization. Known for innovation and engineering excellence, Siemens products are at the forefront of industrial and infrastructure technology. From circuit breakers and PLCs to drives and SCADA systems, Siemens is the brand that industries trust.

So when you're looking for a Siemens dealer near me, it's crucial to choose someone who understands the technology, the industry, and most importantly—your unique needs. That’s where Darshil Enterprises steps in.

What We Offer as the Best Siemens Dealer in Ahmedabad

At Darshil Enterprises, we offer a full spectrum of Siemens products and solutions that cater to various industries like manufacturing, power generation, HVAC, oil & gas, infrastructure, and more.

Here’s what makes us a top Siemens dealer in the region:

Siemens Automation Products (PLCs, HMIs)

Drives and Motors

Switchgear and Controlgear

Industrial Safety Equipment

Building Technology Solutions

As the Best Siemens dealer in Ahmedabad, we don’t just sell products—we guide, recommend, and support our clients throughout the life cycle of their projects.

Why Siemens Products are the Best Choice

When it comes to choosing high-quality, reliable, and long-lasting industrial solutions, Siemens stands out. Whether you're upgrading existing systems or setting up a new infrastructure, Siemens products give you a competitive edge in terms of efficiency and performance.

By choosing a trusted Siemens dealer like Darshil Enterprises, you gain access to authentic products that are backed by warranty, expert consultation, and post-sales support. No more guessing games or dealing with counterfeit supplies—only genuine Siemens solutions.

If you're typing a Siemens dealer near me on search engines, make sure you pick one who adds value and offers transparency. That's exactly what we promise at Darshil Enterprises.

Industries We Serve

Being a top Siemens dealer, we have been privileged to work across a wide range of industries in and around Ahmedabad:

Textile and Spinning Units

Pharmaceutical Plants

Power and Energy Utilities

Food & Beverage Processing

Infrastructure Development Projects

OEMs and Machine Builders

Each industry comes with its own set of challenges, and as a dedicated Siemens dealer, we offer tailored solutions backed by real-world experience.

Why Choose Us

At Darshil Enterprises, we believe in building long-term relationships with our clients. We are not just another Siemens dealer—we are your strategic partner. Our team is made up of experienced engineers and professionals who are trained in Siemens technologies. What sets us apart is our customer-first approach, commitment to authentic products, and fast delivery timelines.

We work closely with our clients to understand their specific needs and offer customized recommendations. Whether it's selecting the right PLC for a process or integrating Siemens drives into an existing system, we provide support that goes beyond the point of sale.

This personalized service is one of the main reasons we are known as the Best Siemens dealer in Ahmedabad. We believe that our success is defined by the success of our clients.

Customer Satisfaction is Our Priority

When customers search for a Siemens dealer near me, they’re looking for someone who can deliver quality, reliability, and support. At Darshil Enterprises, customer satisfaction is at the core of everything we do.

We believe in timely responses, genuine pricing, and transparent communication. Over the years, we have built a strong reputation in Ahmedabad and nearby areas as a top Siemens dealer who truly understands what the customer wants.

We don’t just meet expectations—we exceed them. That's why so many businesses trust us as their go-to Siemens dealer for all industrial automation and control needs.

Conclusion

If you're looking for a reliable and knowledgeable Siemens dealer near me, Darshil Enterprises is the answer. Our deep expertise, wide product range, and unmatched support make us the Best Siemens dealer in Ahmedabad. We work with businesses of all sizes, providing them with world-class Siemens products that power their success. From industrial automation to energy management, we are here to help you make the right choice with confidence. Our goal is to deliver value at every step of your journey.

Looking for a trusted Siemens partner? Get in touch with Darshil Enterprises, your top Siemens dealer in Ahmedabad. Call us today at +91 99987-13713 or mail us at [email protected]. Let us help power your next big project with Siemens’ trusted innovation.

Darshil Enterprises is the Best Siemens dealer in Ahmedabad, offering top-quality products, expert support, and reliable service for all your industrial needs.

For More Information:

Darshil Enterprise/ Sales 303, "ONYX" 3rd Floor, Nr IDBI Bank Cross Road Gulbai Tekra Ahmedabad,380009 Gujarat (India)

9998713713

0 notes

Text

ARMxy Based SBC Controller BL340 for Production Line OEE Monitoring

Case Details

Introduction to OEE

OEE (Overall Equipment Effectiveness) is a key performance indicator (KPI) in manufacturing that measures how effectively a production line or equipment is utilized. It combines three critical factors:

Availability (percentage of scheduled production time when the equipment is operational).

Performance (actual production speed relative to maximum theoretical speed).

Quality (ratio of defect-free products to total products produced).

The formula for OEE is:OEE=Availability×Performance×Quality

Aiming for an OEE value ≥85% is considered "world-class" in manufacturing. By monitoring OEE, companies can identify bottlenecks, reduce downtime, and improve product quality.

I. Hardware Configuration for OEE Monitoring

Data Acquisition Layer

Equipment Status Monitoring:

Use X-series I/O boards (e.g., X23/X26) to connect DI (Digital Input) signals for tracking equipment start/stop states and downtime statistics; utilize DO (Digital Output) to control alarm lights.

Deploy Y-series I/O boards (e.g., Y95/Y96) with pulse counters to collect real-time cycle times (e.g., motor RPM) for performance rate calculations.

Quality Inspection:

Connect sensors (e.g., pressure sensors, optical detectors) via Y-series AI/AO boards (e.g., Y31/Y33) to acquire defect rate data.

Networking:

Use 3x 10/100M Ethernet ports to interface with PLCs or SCADA systems for production plan synchronization; optional 4G/WiFi modules (via Mini PCIe slot) enable cloud data transmission.

Edge Computing Capabilities

Real-Time Local Processing:

Leverage the quad-core ARM Cortex-A53 CPU (1.4 GHz) to compute OEE metrics locally.

Ensure low-latency processing with the Linux-RT real-time OS (kernel v4.9.170).

Storage Expansion:

Store historical data on SD cards or 16GB eMMC for offline analysis.

II. Software System Integration

Protocol Compatibility

Built-in BLIoTLink software supports Modbus TCP/RTU, OPC UA, MQTT, etc., enabling seamless integration with PLCs (e.g., Siemens S7-1200), SCADA (e.g., Ignition), and MES systems.

Example: Validate data accuracy by combining Modbus TCP readings from PLCs with local pulse counts.

Visualization & Alerts

Develop OEE dashboards using Qt-5.12.5 or Node-RED:

Display real-time equipment status (running/idle/fault), OEE values, and historical trends.

Configure threshold alerts (e.g., trigger emails/SMS if OEE < 80%).

Example: Use Node-RED to aggregate OEE data → MQTT → ThingsBoard platform → dashboard visualization.

Cloud & Analytics

Deploy Python scripts via Docker to connect with AWS IoT Core or Alibaba Cloud:

Store long-term OEE data and apply machine learning to identify downtime causes (e.g., vibration anomalies linked to mold wear).

Example: Predict equipment failures using TensorFlow Lite models to boost availability via proactive maintenance.

III. Deployment Case Studies

Automotive Welding Line:

BL340B model (1 X board + 2 Y boards) connects to welding robot PLCs. Y95 board collects welding cycle pulses; X23 monitors emergency stop signals.

Results: 15% increase in availability (predictive maintenance reduces unplanned downtime); 99.2% quality rate.

Food Packaging Line:

BL342A model (3 Ethernet ports + HDMI) integrates USB cameras for visual inspection, directly displaying defect counts and quality rates on factory screens.

IV. Key Advantages & Scalability

Flexibility:

Expand with Y-series AI/AO boards (e.g., Y43/Y46) for high-precision sensors or Y51/Y52 boards for PT100 temperature probes.

Robustness:

Operates in harsh environments (-40°C to 85°C, IP30 rating); hardware watchdog ensures automatic recovery from faults.

Cost-Effective Upgrades:

Retrofit legacy equipment via RS485/Ethernet interfaces, avoiding full PLC replacement.

V. Implementation Steps

Hardware Setup:

Select BL340B (2 Y-slots) + SOM341 (16GB+2GB) for optimal processing power.

Install X23 (4DI/4DO) and Y95 (pulse counter + PWM) boards.

Software Configuration:

Deploy BLIoTLink for Modbus TCP PLC integration; build OEE logic with Node-RED.

System Validation:

Verify real-time data acquisition (<100ms latency); calibrate sensor accuracy (e.g., ±0.5%).

With the ARMxy Based SBC Controller BL340 manufacturers can rapidly establish a cost-effective, reliable OEE monitoring system, transitioning from "experience-driven" to "data-driven" smart manufacturing.

0 notes

Text

Industrial Gas Safety Starts Here: Gas Detection Solutions by Uniphos

In high-risk industries, safety and compliance are of utmost importance. One critical component of workplace safety is the deployment of a reliable gas detection system. Whether in oil refineries, chemical plants, manufacturing units, or confined workspaces, the presence of hazardous gases can pose serious health risks and operational hazards. That’s why industries worldwide trust Uniphos Envirotronic—India’s leading manufacturer of environmental and process monitoring solutions.

With decades of expertise, Uniphos Envirotronic has developed cutting-edge fixed gas detectors and integrated gas detection systems to help companies detect and respond to gas leaks before they become dangerous. This article explores how these systems work, their benefits, and why Uniphos remains the preferred choice for gas detection solutions.

What is a Gas Detection System?

A gas detection system is a network of devices designed to continuously monitor and identify the presence of harmful gases in the atmosphere. These systems are essential in preventing potential hazards such as fires, explosions, and toxic exposure. By detecting gases like methane (CH₄), carbon monoxide (CO), hydrogen sulfide (H₂S), ammonia (NH₃), and chlorine (Cl₂), gas detection systems act as an early warning mechanism.

Uniphos Envirotronic’s gas detection system offers real-time monitoring, automated alerts, and integration with control room interfaces, enabling quick response to any leak or anomaly. Their systems are suitable for both indoor and outdoor industrial environments, ensuring round-the-clock safety.

The Importance of Fixed Gas Detectors

Unlike portable gas detectors that are used intermittently, a fixed gas detector is installed permanently in a specific location and continuously monitors the air for gas concentrations. These detectors are particularly useful in areas that are prone to gas leaks or where human access is limited.

Uniphos Envirotronic provides a wide range of fixed gas detectors designed for various industrial applications. These detectors are engineered with advanced sensor technologies—including electrochemical, infrared, and catalytic bead sensors—for high precision and durability. The devices are capable of detecting multiple gases simultaneously and offer customizable features to match specific site requirements.

Key Features of Uniphos Fixed Gas Detectors

High Sensitivity & Accuracy: Uniphos fixed gas detectors are equipped with sensitive sensors that ensure accurate gas detection even at low concentrations. This helps in early leak detection and reduces the risk of large-scale hazards.

Rugged Design: Built for challenging industrial environments, these detectors feature weatherproof and explosion-proof enclosures that withstand extreme conditions.

24/7 Monitoring: With continuous operation and instant alerts, the system ensures that no harmful gas goes undetected.

Customizable Solutions: From single-point detection to complex multi-gas systems, Uniphos offers tailor-made gas detection systems for specific industry needs.

Integration Capabilities: The detectors can easily integrate with existing DCS, SCADA, and PLC systems, ensuring centralized monitoring and control.

Low Maintenance: Designed with long sensor life and easy calibration options, the maintenance requirements are minimal.

Industries That Rely on Gas Detection Systems

Uniphos Envirotronic’s gas detection systems and fixed gas detectors are widely used across multiple sectors:

Oil & Gas Industry: For detecting flammable gases and preventing explosions.

Chemical Plants: For monitoring toxic gas emissions and ensuring worker safety.

Pharmaceutical Industry: To prevent contamination and ensure compliance with safety standards.

Fertilizer Plants: To detect ammonia and other reactive gases.

Food & Beverage Industry: For CO₂ monitoring in storage and production areas.

Wastewater Treatment Plants: To monitor methane, H₂S, and other gases.

Why Choose Uniphos Envirotronic?

Uniphos Envirotronic is a pioneer in gas detection and environmental monitoring solutions with a global footprint. Here's why Uniphos stands out:

Proven Expertise: Over 40 years of experience in developing reliable gas detection technologies.

Make in India: Proudly manufactured in India, Uniphos products meet international standards and certifications.

Global Reach: Uniphos gas detection systems are trusted by clients in over 60 countries.

Customer Support: With dedicated installation and after-sales service teams, Uniphos ensures smooth system deployment and maintenance.

Innovation Driven: Continual R&D keeps Uniphos ahead in the industry, offering solutions that are both effective and future-ready.

Safety, Compliance, and Peace of Mind

A well-implemented gas detection system is not just about safety—it’s also about operational efficiency and regulatory compliance. Government bodies and safety agencies around the world mandate the use of certified gas monitoring systems in hazardous environments. Installing fixed gas detectors from Uniphos helps companies avoid penalties, improve productivity, and most importantly, protect human lives.

Conclusion

In any industrial setup, the risk of gas leaks should never be underestimated. Investing in a robust and dependable gas detection system is a smart and necessary decision. With Uniphos Envirotronic’s range of fixed gas detectors, businesses gain access to state-of-the-art technology, expert support, and unmatched reliability.

Stay safe, stay compliant, and stay ahead—choose Uniphos Envirotronic for your gas detection needs.

0 notes

Text

Fertilizer production machine intelligent transformation of the four trends

With the development of agricultural modernization, the intelligent transformation of fertilizer production line machine has become an industry trend. The application of intelligent technology not only improves the production efficiency, but also reduces the labor cost and energy consumption, so that enterprises have an advantage in the market competition. The following are the four major trends in the intelligent development of NPK fertilizer production lines.

1. Automatic control system to improve production efficiency

The traditional fertilizer production line relies on manual operation, while the modern intelligent production line uses PLC (programmable logic controller) and SCADA (data acquisition and monitoring system) to realize the automatic control of fertilizer granulator, crusher, dryer and other machine. This not only improves production accuracy, but also reduces human error and improves overall efficiency.

2. Remote monitoring and data analysis optimization management

The intelligent production line is equipped with a remote monitoring system, and business managers can check the machine running status, energy consumption and output data in real time through computers or mobile phones. With big data analytics, production processes can be optimized, machine maintenance needs can be predicted, downtime can be reduced, and machine life can be improved.

3. Energy-saving and environmental protection technology to reduce production costs

The intelligent NPK fertilizer production line gradually adopts energy-saving machine, such as variable frequency motors, waste heat recovery systems, etc., to reduce energy consumption. For example, the intelligent drying system can adjust the hot air temperature according to the raw material humidity, improve the utilization of heat energy, thereby reducing fuel consumption.

4. Robots and intelligent logistics reduce manual dependence

In the intelligent production line, automatic feeding system, intelligent handling robot and other technologies are gradually applied to reduce the dependence on manual, improve the continuity of production. At the same time, intelligent packaging machine can accurately control the packaging weight and sealing quality, and improve the market competitiveness of fertilizer products.

Conclusion

Intelligent transformation is the future development direction of fertilizer production line. Through the application of automation control, remote monitoring, energy saving and environmental protection technology and intelligent logistics, enterprises can improve production efficiency, reduce costs, enhance market competitiveness, and meet the development needs of modern agriculture.

#organic fertilizer production line#fertilizer granules compaction machine#disc granulator#flat-die pellet machine#compost turning machine#organic fertilizer processing equipment

0 notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

Top Companies for Automation Services in Naperville, IL

Naperville, Illinois, stands out as a technology-driven city with a thriving industrial and commercial sector. As the demand for smarter, more efficient systems continues to grow, companies automation services in Naperville are becoming essential for businesses aiming to stay competitive in today's digital age.

Automation is no longer just an advantage—it’s a necessity for businesses looking to scale operations, reduce labor-intensive tasks, and increase efficiency across various departments. Whether in manufacturing, logistics, commercial buildings, or process industries, automation technologies are transforming how companies in Naperville operate, manage resources, and deliver value.

Why Automation is Crucial for Businesses in Naperville

Automation is revolutionizing the way Naperville-based companies handle their day-to-day operations. Here are several reasons why local businesses are investing in automation:

Increased productivity: Automation reduces the need for manual labor, leading to faster production cycles and reduced downtime.

Cost savings: Automated systems can significantly lower operational expenses over time.

Accuracy and consistency: Automated machines and software ensure precise execution of tasks with minimal errors.

Real-time data and analytics: Intelligent systems provide insights that help improve decision-making.

Workforce optimization: Employees can focus on high-value tasks rather than repetitive or dangerous duties.

Compliance and safety: Automation helps meet strict regulatory standards and safety requirements.

For Naperville’s growing tech and industrial scene, these benefits position automation as a long-term strategic asset.

Key Industries Leveraging Automation in Naperville

Naperville businesses across multiple industries are adopting automation technologies to streamline their operations:

Manufacturing: Robotics, CNC machinery, and industrial automation are optimizing production lines.

Warehousing and logistics: Automated conveyors, barcode scanners, and inventory systems ensure smooth supply chain operations.

Healthcare: Automation helps in diagnostics, lab testing, and administrative workflows.

Retail and service sectors: POS automation, customer service chatbots, and order tracking systems are improving customer experiences.

Building management: Building automation systems (BAS) regulate lighting, HVAC, and security systems for commercial properties.

As Naperville continues to attract diverse business investments, the demand for reliable automation companies is on the rise.

Types of Automation Services Offered by Naperville Companies

Automation companies in Naperville, Illinois offer a broad range of services tailored to specific business needs. These include:

PLC Programming and Integration: Custom logic programming for industrial control systems.

SCADA and HMI Design: Supervisory control systems with user-friendly interfaces.

Robotics Integration: Installation and configuration of robotic arms for precise and repetitive tasks.

IoT and Smart Systems: Device interconnectivity for real-time monitoring and control.

Building Automation Solutions: Energy-efficient systems for HVAC, lighting, and building access.

Custom Software Development: Development of automation software for scheduling, reporting, and analytics.

Each service is designed to help companies improve their workflows and align with modern operational standards.

Choosing the Right Automation Partner in Naperville

Not all automation companies offer the same level of expertise. When selecting a provider in Naperville, consider the following factors:

Experience and specialization: Choose companies with a proven track record in your specific industry.

Technical capabilities: Ensure they can handle the level of system complexity required.

Scalability: Look for solutions that can grow with your business.

Customer support: Strong post-installation service is key to long-term success.

Customization: Your business needs a partner that can tailor solutions to your workflow.

Certifications and compliance: Check for relevant industry certifications like UL, ISO, or OSHA compliance.

A trusted partner can help you navigate technology decisions, integrate systems, and train staff effectively.

Automation Trends Transforming Naperville Businesses

The landscape of automation is constantly evolving. Here are some top trends influencing Naperville’s commercial and industrial environments:

AI-Powered Automation: Machine learning algorithms enhance predictive maintenance and production optimization.

Edge Computing: Local data processing reduces latency and improves response time in real-time systems.

Cloud-Based Control Systems: Enables remote access, monitoring, and updates.

Green Automation: Energy-efficient solutions aligned with sustainability goals.

Cybersecurity for Automation Networks: Enhanced protection of control systems from cyber threats.

Staying ahead of these trends is key for companies looking to maintain a competitive edge in the Naperville market.

Benefits of Automation for Small and Medium Enterprises (SMEs)

Automation is not exclusive to large corporations. In Naperville, small and medium businesses are increasingly investing in automation technologies for:

Inventory management and procurement

Workflow automation in administrative tasks

Customer relationship management (CRM) systems

Automated billing and invoicing

Smart energy control in small office buildings

The accessibility and affordability of modern automation tools make them an excellent investment for SMEs aiming to scale without hiring extensively.

Automation and Economic Development in Naperville

Automation is playing a key role in Naperville’s economic growth. As companies become more efficient and competitive, they attract more business and create high-skill job opportunities. Local schools and training institutions are also responding by offering specialized programs in automation, robotics, and engineering—helping to create a talent pipeline that supports long-term innovation.

With Naperville’s continued investment in infrastructure and technology parks, the city is well-positioned to be a hub for automation excellence in Illinois.

Empowering Naperville Through Smart Automation

From small businesses to large enterprises, the ability to implement smart automation systems is critical for long-term success. The right automation partner can help you optimize operations, increase profits, and stay agile in an ever-changing market. As demand for precision, speed, and efficiency increases, Naperville businesses are finding automation to be one of their most strategic investments.

Partner with a Trusted Automation Company in Naperville

If you're seeking high-quality automation solutions tailored for your Naperville business, Xtreme Automation LLC delivers the expertise and support needed to elevate your operations. Whether you require industrial controls, building automation, or full-system integration, their team is committed to delivering scalable, efficient, and customized automation solutions. Learn more at xtremeautomationllc.com.

#automation companies Naperville IL#industrial automation Naperville#automation engineering Naperville Illinois#smart factory solutions Naperville#Naperville automation systems

0 notes

Text

Automotive for Body Shop (BIW) in pune | India

When sheet metal of a vehicle has been welded together after assembly, it is referred to as "body-in-white" (BiW). This condition does not include any moving parts, trim pieces (such hoods, fenders,etc.), or chassis subassemblies.

#Automotive standards for INTEGRA#TM O#VASS#Development#Software Standardization for OEM#Line Builders#PLC Logic#PLC SCADA Development#No Code Low Code Solutions#PLC Tool#Plc and Scada Services#Solutions for OEMs and Machine Builders

0 notes