#Software Standardization for OEM

Explore tagged Tumblr posts

Text

Why are headlights so expensive for cars?

The high cost of modern car headlights is driven by a convergence of advanced technology, complex design, stringent regulations, and market factors. Here's a breakdown of the key reasons:

Advanced Technology & Complexity:

LED/Laser/Matrix Systems: Modern headlights use multi-element LED arrays, adaptive projectors, laser elements (on high-end models), or matrix/pixel technology that individually dims segments of the beam. This requires sophisticated control units, sensors, and wiring.

Adaptive Functionality: Features like auto-leveling, cornering beams, glare-free high beams, and dynamic light projections require motors, cameras, complex software, and extra wiring harnesses.

Integrated Components: Headlights now house DRLs (Daytime Running Lights), turn signals, position lights, and often front-facing sensors (radar/camera for ADAS) all in one sealed unit, driving up complexity.

Precision Engineering & Materials:

Optical Precision: Lenses and reflectors are molded with extreme precision to meet strict beam pattern regulations and avoid glare. Molds for these optics are incredibly expensive to design and manufacture.

Materials: High-performance polycarbonate lenses resist yellowing and cracking, while complex aluminum or magnesium heat sinks efficiently dissipate heat from powerful LEDs/Lasers. Seals must be perfect to prevent moisture and corrosion. Internal reflectors use specialized coatings.

Durability Requirements: Headlights must withstand extreme temperatures, UV radiation, road debris impacts, vibrations, and chemical exposure (car washes, road salt) for the vehicle's lifespan. This requires high-grade materials and construction.

Regulation & Testing Overhead:

Global Standards: Headlights must comply with strict global regulations (SAE, ECE, etc.) regarding beam pattern, intensity, cutoff sharpness, and aiming. Developing, testing, and certifying each headlight design for different markets adds significant cost.

Complex Testing: Extensive lab and road testing is required to ensure compliance, durability, and performance in all conditions, adding R&D costs.

Design and Manufacturing Integration:

Styling Demands: Headlights are critical styling elements. Aggressive shapes, intricate lighting signatures ("light jewelry"), and seamless integration with body panels require complex, unique housings for each model.

Custom Manufacturing: Headlights are model-specific (often even trim-level specific). Low-volume production runs compared to simple bulbs mean costs aren't spread over millions of identical units. Assembly involves delicate electronics and precise calibration.

Module Design: Modern headlights are typically sold as sealed assemblies ("modules"). If anything fails inside (LED chip, driver, ballast, motor, wiring), you often have to replace the entire 800+ unit, not a 10 bulb.

Supply Chain & Market Factors:

OEM vs. Aftermarket: Dealers charge high prices for genuine OEM parts, covering their overhead and profit margins. While quality aftermarket options exist (often significantly cheaper), OE parts command a premium.

Insurance Influence: Since insurance often pays for replacements after collisions (which frequently damage headlights), manufacturers have less pressure to minimize headlight costs compared to components owners pay for directly.

Low Price Elasticity: Headlights are essential safety items. Consumers need them to drive legally and safely, reducing the incentive for manufacturers/dealers to compete heavily on price for replacements.

Supplier Profit: Tier-1 suppliers (like Valeo, Bosch, Magna, Koito) design and build these complex units and need to recoup their substantial R&D and tooling investments per unit sold to the automaker.

Labor Cost (Hidden): Installation is often complex, requiring bumper/fender removal and sometimes electronic calibration/reprogramming. While the part cost is high, labor adds significantly to the total replacement expense perceived by the owner.

Comparison to Older Designs:

Simple Halogen Reflectors: Used cheap bulbs (10-50), simple reflectors, and a basic lens. Easy to manufacture replaceable bulbs. Entire assembly replacement was relatively inexpensive (100-300).

HID Projectors: Introduced cost via ballasts and specialized bulbs (50-150 per bulb), but the projectors and housings were less complex than modern LED units. Assemblies cost more than halogens but less than LEDs.

Modern LED/Adaptive Units: Represent a quantum leap in technology, integration, and complexity, hence the price jump.

In essence: You're paying for high-tech electronics, extreme precision optics, complex software integration, advanced materials built for durability, significant R&D/testing/regulatory costs, custom low-volume manufacturing of a styling-critical safety component, and market dynamics where insurers often foot the bill. It's a far cry from swapping out a simple bulb in a basic reflector housing.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#led light bulbs#led strip lights#car rental#electric cars#classic cars#car#cars#truck#porsche#suv#lamborghini#sabrina carpenter#bmw#carlos sainz#autonomous vehicle headlights#overtake another vehicle#older vehicles#vehicle#auto mode#automobiles

3 notes

·

View notes

Text

IETM for Beginners A Quick Guide to IETM Code and Pixels

IETM: Interactive Electronic Technical Manual

Training Aids to Defence Client

If you are a supplier of defence then along with the system/equipment you also need to provide Training Aids

(CBT) — Computer-Based Training

Charts and Bloups

Video Film

Training Work Modules

Manuals Hard Copies

IETM

Evolution of Documentation in Defence

Before — Hardcopies and PDFs in DVDs (Upto 2015)

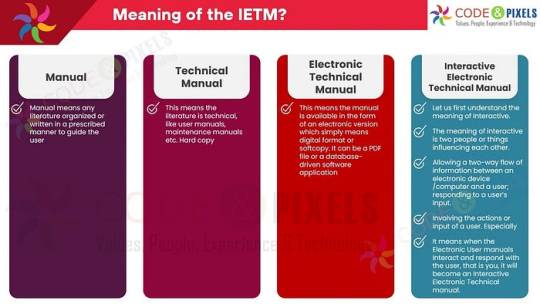

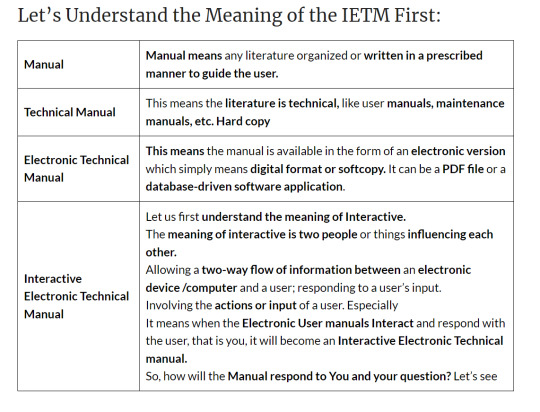

What is the meaning of the IETM?

Manual: Manual means any literature organized or written in a prescribed manner to guide the user.

TechnicalManual: This means the literature is technical, like user manuals, maintenance manuals etc. Hard copy

Electronic Technical Manual: This means the manual is available in the form of an electronic version which simply means digital format or softcopy. It can be a PDF file or a database-driven software application.

Interactive Electronic Technical Manual:

Let us first understand the meaning of Interactive. The meaning of interactive is two people or things influencing each other.

Allowing a two-way flow of information between an electronic device /computer and a user; responding to a user’s input.

Involving the actions or input of a user. Especially

It means when the Electronic User manuals Interact and respond with the user, that is you, it will become an Interactive Electronic Technical manual.

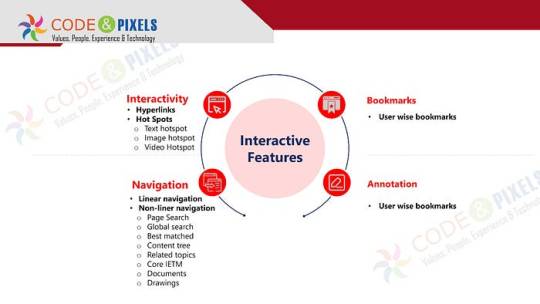

Interactive Features

Interactivity

Hyperlinks

Hot Spots

Text hotspot

Image hotspot

VideHotspot

Bookmarks

User wise bookmarks

Navigation

Linear navigation

Non-liner navigation

Page Search

Global search

Best matched

Content tree

Related topics

Core IETM

Documents

Drawings

Annotation

User wise bookmarks

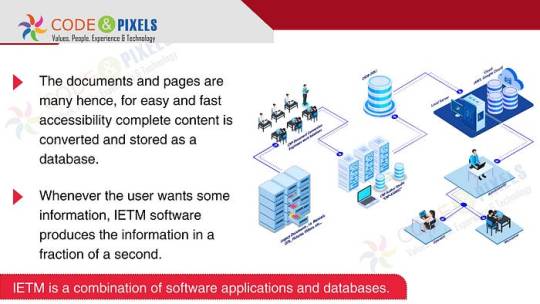

The documents and pages are many hence, for easy and fast accessibility complete content is converted and stored as a database.

Whenever the user wants some information, IETM software produces the information in a fraction of a second.

Use or Purpose of the IETM?

The purpose of the Manual is to give information related to the equipment to the end user for quick reference.

All the technicality is written in detail so that when an issue arises, the user can refer to the manual, as every time OEM or technical person or subject matter expert might not be available on the spot to resolve the issue.

If the manual has 10 pages users can refer easily.

But any system used by the defence will have multiple manuals and thousands of page counts and many times a user has to cross-refer between manuals, intra-manual and inter-manual to resolve the issue.

Referring to 10- 15 hard-copy or even soft-copy books simultaneously will be difficult and time-consuming.

How to access the IETM ?

IETM is a web-based application like our bank software or any other web application. The graphic user interface will be provided to use IETM through which users can interact and get the desired data.

Like all other standard software, Unauthorized users cannot access the IETM. IETM is a Login - login-based application. Only users having valid Login credentials can access the software.

Based on the user log credentials data will be provided to the user.

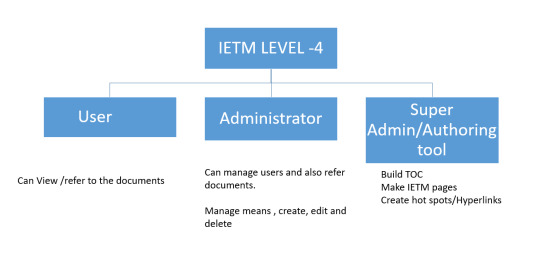

IETM has 2 types of Users and one Administrator

Maintainer

Operator

If the operator logs in, the user gets all the content related to operator use, similarly if the maintainer logs in only maintenance-related content is visible for that user.

Ideally, all the content is available for both users, because the purpose of the IETM is to refer to the manual to fix the issue.

Administrators can create users who can see the user’s navigation and log-in history and interact with the users using user dashboards through Annotations.

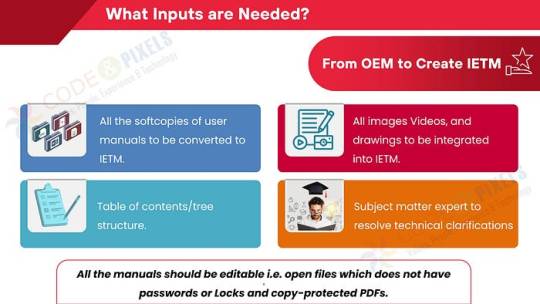

What Inputs are Needed? (From OEM to Create IETM)

All the softcopies of user manuals to be converted to IETM.

All images Videos, and drawings to be integrated into IETM.

Subject matter expert to resolve technical clarifications

Table of contents/tree structure.

Minimum Hardware Requirements?

NO High-end hardware or servers are required to run IETM.

However, if more concurrent users, then a good configuration server with good LAN connectivity must be ensured.

i3 with 8 GB RAM systems is the minimum configuration required for the server or for Node.

Deliverables

BASED DB (Manuals are covered in the Database)

IETM VIEWER Software

User Manual and Installation Manual

Standards — compliance

Costing of IETM: (Interactive Electronic Technical Manual)

Level of IETM, is it Level 3 or Level 4

Cost will be based on the number of pages that are to be converted

The vendor calculates the cost per page. And a fixed cost of IETM viewer software

If you want to create IETM by yourself self then you also need to buy IETM authoring software.

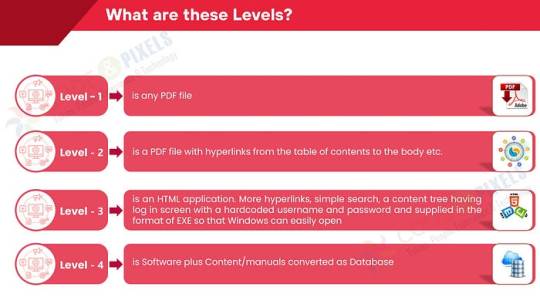

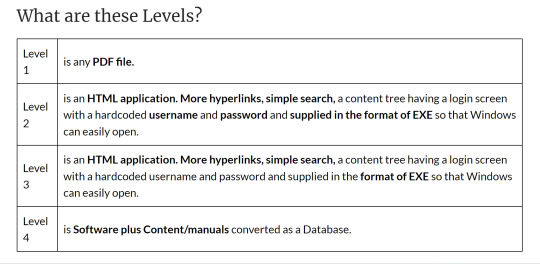

What are these Levels?

Level — 1 is any PDF file

Level — 2 is a PDF file with hyperlinks from the table of contents to the body etc.

Level — 3 is an HTML application. More hyperlinks, simple search, a content tree having log a screen with a hardcoded username and password and supplied in the format of EXE so that Windows can easily open

Level — 4 is Software plus Content/manuals converted as Database

Regarding Level — 5, rest assured, till 2028 it will be Level — 4 only. As of now, there is nothing practically called Level — 5. Few are calling virtual reality and Augmented reality and Artificial intelligence Level — 5.

Pulling data from many user inputs and analyzing and giving results are done in Level — 5. IETM software cannot pull the data from various real-time points as No OEM will give the real-time information to third-party software directly. Yes, if the information is available offline, then that information can be imported into IETM and can be used as a reference.

#ietm#software#technology#ietm developement#ietm code and pixels ietm hyderabad#ietm software#elearning#code and pixels#ietm level iv#codeandpixels#ietm level 4 software requirements#technical documentation#ietm document#ietm documentation#interactive electronic technical manual#Ietm Service Providers#Ietm Software Designers of India#Software Development Company#Elearning Solutions Company#E Learning Content Development Company#Online Education#Digital Education#Digital Content#Software Development Solutions#Elearning#Ietm Developers#Econtent Development#Elearning Solutions Providers#Econtent Developers#Econtent

3 notes

·

View notes

Text

Top Robotics Labs for Schools | Robotics Classes in Coimbatore

ROBOMATIIC is an Educational, Research & Development start-up. We are providing Robotics education at Schools / Colleges in STREAM EDUCATION and also providing the new product development and industrial solutions in the sector of Industry 4.0.

We aim to produce the next generation innovators and problem solvers for the world through our unique offerings through our Omni channel presence. Our customized robotic training offers many advantages over the standard approach. Every theory portion of the course is followed by hands-on activity using simulation software and multiple versions of OEM robotic equipment so that each student builds confidence in their ability to navigate and work efficiently on whatever application they may encounter.

#education and learning#education and training#education center#education for students#education courses#education technology#education

2 notes

·

View notes

Text

Leading the Charge: Concord Industries – Premier Computer Power Cord Manufacturer in India

In today’s technology-driven world, the backbone of every reliable computer system lies in its power supply. Whether for a personal desktop or an expansive IT infrastructure, dependable computer power cords are essential for optimal performance and safety. Concord Industries, a trusted name in the electrical accessories market, proudly stands out as a leading computer power cord manufacturer in India, offering unmatched quality, safety, and innovation.

Why Computer Power Cords Matter

A computer power cord might seem like a basic component, but its quality directly affects the performance, safety, and lifespan of electronic equipment. Poorly manufactured cords can lead to voltage fluctuations, short circuits, or even dangerous fire hazards. This is where Concord Industries plays a crucial role—providing highly reliable, tested, and certified power cords that meet international standards.

Concord Industries: Synonym for Quality

At Concord Industries, we specialize in manufacturing computer power cords designed to support a wide range of computer models and configurations. Our products are made from high-grade copper conductors, durable insulation materials, and precision-molded connectors that ensure a snug, safe fit with devices.

Key Features of Concord’s Computer Power Cords:

Flame-retardant and weather-resistant insulation

High current carrying capacity

ISI-certified and RoHS-compliant

Customized length and plug configurations

Durable PVC jackets for added strength and flexibility

Applications Across Industries

Our computer power cords are widely used across multiple sectors including:

IT and Software companies

Educational institutions

Data centers

Government agencies

Home and office users

Whether it’s bulk orders for enterprises or tailored solutions for resellers, Concord Industries ensures timely delivery and consistent quality for every client.

Why Choose Concord Industries?

Decades of Experience: Trusted by leading brands and OEMs across India

Customization: Tailored products to meet unique technical and aesthetic requirements

In-House Manufacturing: Complete control over quality, materials, and design

Affordable Pricing: Competitive rates without compromising on performance

Partner with Concord for Your Power Needs

Concord Industries continues to set benchmarks in power cord manufacturing with a strong focus on reliability, innovation, and customer satisfaction. If you're looking for a computer power cord manufacturer you can count on, Concord Industries is your one-stop solution.

Visit:- https://concordindustries.in/computer-power-cord-manufacturer/

0 notes

Text

From Static to Symphony – Precision Car Audio Repair Services Explained

Your car's audio system is more than a luxury—it’s a gateway to comfort, entertainment, and connection on the road. Whether you're tuning into a favorite playlist, podcast, or taking hands-free calls, clear and consistent sound matters. But over time, even the best systems can fall victim to static, distortion, or outright silence. When that happens, precision car audio repair services can transform frustrating noise into a flawless listening experience—taking you from static to symphony.

In this article, we explore what causes common car audio issues, how precision repair services work, and why professional expertise is the key to restoring perfect sound.

Common Issues That Disrupt Your Sound

A well-functioning car audio system relies on many interconnected components. When any of these fail, you may notice symptoms like:

1. Distorted or Fuzzy Sound

This often signals a blown speaker, a damaged amplifier, or poor electrical grounding. It can also result from faulty equalizer settings or degraded audio cables.

2. Speaker Dropout or Silence

If certain speakers stop working, it may be due to wire disconnection, internal speaker damage, or amplifier failure.

3. No Power to the Audio System

If your audio unit doesn’t turn on, common culprits include a blown fuse, defective head unit, or power supply issues.

4. Bluetooth or AUX Connectivity Failure

Connectivity issues may stem from outdated firmware, broken ports, or damaged internal components. In some cases, interference or weak signal strength is to blame.

5. Unresponsive Infotainment Display

Today’s infotainment systems serve as the hub for all audio controls. If the screen is frozen or non-functional, internal circuit board failure or software corruption could be the root cause.

What Are Precision Car Audio Repair Services?

Unlike general car mechanics, precision audio repair specialists are trained to handle the intricate electronics and acoustics of modern vehicle sound systems. They go beyond simple component swaps, focusing on detailed diagnostics and restoration techniques that retain your vehicle’s factory quality or enhance it with performance upgrades.

Key Features of Precision Repair Services:

Advanced diagnostics tools for pinpoint accuracy

OEM or aftermarket compatibility handling

Micro-component repairs (soldering, board-level fixes)

Customized tuning for optimal acoustics

System integration with modern upgrades like CarPlay or Android Auto

Whether it's a minor speaker fault or a complex infotainment system repair, these services ensure lasting results with professional finish.

The Repair Process – What to Expect

Here’s how most precision audio repair services approach a typical repair job:

1. Initial Inspection

A technician visually inspects the system and listens for audio abnormalities. They also review the vehicle's wiring diagram and assess external wear or damage.

2. Electronic Diagnostics

Using oscilloscopes, multimeters, and scan tools, technicians test voltage, resistance, signal strength, and connectivity across system components.

3. Component Testing

Speakers, amplifiers, subwoofers, and head units are bench-tested to isolate the fault. Sometimes a simple wire re-soldering or capacitor replacement can fix major issues.

4. Repairs and Reassembly

Once the problem is identified, the team performs repairs using precision tools, ensuring minimal disruption to factory wiring or vehicle integrity.

5. Sound Tuning and Testing

The repaired system is recalibrated to ensure balanced output. Audio levels, fade/balance settings, and EQ profiles are tested thoroughly to match OEM standards or customer preferences.

Why Professional Repairs Matter

Attempting a DIY repair without proper training can cause more harm than good. Professional car audio technicians offer:

Accurate fault diagnosis

Access to specialized parts and software updates

Clean, damage-free installation and repair

System upgrades with full integration

Most importantly, professionals preserve the factory aesthetics and functionality of your vehicle—no cut wires, no mismatched components.

Conclusion: Drive into a Sound Experience

Static, silence, or distorted audio doesn’t have to be the end of your car’s musical journey. With precision car audio repair services, you get expert diagnostics, reliable fixes, and high-performance results that turn daily drives into immersive sound experiences.

From static to symphony—trust skilled professionals to fine-tune your ride and bring your car audio back to life.

Contact Us

Xclusive Autosound

2347 Old Collinsville Road, Suite B

Belleville, IL 62221

Phone: 618–222–2234

0 notes

Text

Semiconductor & Remote Testing Boost Auto Testing Services

The Mexico automotive testing market is projected to grow at a compound annual growth rate (CAGR) of 3.7% from 2023 to 2030. This upward trend is driven by increasingly stringent vehicle emissions and safety standards, expanding demand for electric vehicle (EV) testing, and growing adoption of advanced Testing, Inspection, and Certification (TIC) services in the country.

Mexico plays a strategic role in the global automotive supply chain, and as vehicle production accelerates, so does the demand for high-quality testing to ensure compliance, performance, and safety.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/mexico-automotive-testing-market

Key Market Drivers

1. Stricter Emission and Safety Regulations Mexico has tightened its regulatory framework in alignment with global standards, enforcing rigorous emissions controls and safety mandates. This includes the enforcement of soot-free vehicle emission norms and more stringent crash-testing protocols, prompting automakers and parts suppliers to expand testing operations.

2. Growth in TIC Services The automotive TIC (Testing, Inspection, and Certification) market in Mexico was valued at approximately USD 635 million in 2022 and is expected to exceed USD 1.3 billion by 2030. Rising demand for emissions testing, component validation, and homologation processes is fueling this segment’s rapid growth.

3. Rise of Electric and Connected Vehicles The expansion of electric and connected vehicle production has introduced new testing requirements, such as high-voltage battery certification, electromagnetic compatibility (EMC) testing, and ADAS system verification. The EV testing market alone is projected to grow at over 13% CAGR, supporting battery durability and charging system validation.

4. Increase in Automotive Production Mexico remains one of the top vehicle-producing nations globally, with strong exports to North America and Europe. The growth in vehicle output especially in SUVs, EVs, and light trucks is increasing the need for robust local testing capabilities.

5. Industry 4.0 and Digitalization Automotive testing in Mexico is increasingly powered by automation, data analytics, and cloud-based platforms. These technologies streamline quality checks, accelerate certification, and improve data-driven insights for both OEMs and regulators.

Market Segmentation

The automotive testing market in Mexico is broadly segmented by:

Test Type: Engine and transmission testing, chassis testing, durability and vibration analysis, emissions testing, electrical and electronics testing.

Product Type: Emission analyzers, battery testers, chassis dynamometers, alignment systems, and digital diagnostic tools.

Vehicle Type: Passenger cars, commercial vehicles, and electric vehicles.

Engine and transmission testing accounts for the largest share, while EV-related testing is the fastest-growing segment due to increasing vehicle electrification and regulatory requirements.

Regional & Industry Trends

North American Integration Under trade agreements such as USMCA, Mexico aligns its automotive testing standards with the U.S. and Canada. This harmonization ensures products meet stringent export requirements and drives demand for localized testing labs.

EV Component Testing Expansion Mexico’s growing role in the EV supply chain especially in battery and power electronics has created a surge in testing facilities dedicated to thermal safety, high-voltage stress, and software validation.

Underinvestment in R&D Infrastructure Despite strong production capabilities, many Mexican OEMs and Tier 1 suppliers lack advanced R&D labs. This gap presents opportunities for third-party testing providers and international TIC firms to expand service offerings.

Market Challenges

1. Limited In-House Capabilities Many domestic automotive manufacturers depend on external partners for emissions and safety testing due to underdeveloped internal facilities.

2. Capital Intensive Equipment Needs Modern test benches, EMC chambers, and battery validation systems require substantial investment, creating barriers for small-to-medium testing service providers.

3. Regulatory Complexity Automotive testing in Mexico must meet both domestic standards and international certification protocols, which can increase the cost and complexity of compliance.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/mexico-automotive-testing-market

Future Outlook

EV Testing Growth The demand for electric vehicle testing services particularly battery certification, charger compliance, and motor control system validation is expected to accelerate sharply by 2030.

Digital TIC Platforms AI-driven diagnostics, cloud-based monitoring, and remote inspection capabilities are emerging as core features of next-generation testing services in Mexico.

Government Support and Investment As the Mexican government encourages local automotive innovation, public-private partnerships may fund R&D labs, skill development, and infrastructure upgrades to meet growing testing demand.

Cybersecurity and Software Validation As connected and autonomous vehicle systems expand, there will be a growing emphasis on secure software validation, over-the-air update testing, and data protection protocols.

Competitive Landscape

Key players in Mexico’s automotive testing and TIC ecosystem include:

SGS

TÜV Rheinland

Intertek

DEKRA

Robert Bosch

Siemens

Rohde & Schwarz

AVL

UL Solutions

Anritsu

These firms are expanding their local footprint by offering integrated mechanical, electrical, and digital testing solutions tailored to OEM needs and regulatory requirements.

Conclusion

Mexico’s automotive testing market is undergoing a transformation, driven by tighter regulations, increasing EV adoption, and the rise of smart vehicle technologies. As the country reinforces its position as a key player in global automotive manufacturing, demand for high-quality testing services is set to grow steadily through 2030. With targeted investment, digital innovation, and strategic partnerships, Mexico can not only meet domestic testing needs but also serve as a testing hub for the broader Latin American and North American regions.

0 notes

Text

How Does the Range Rover 3.0 Engine Support Adaptive Cruise Control in the HSE Model?

The Range Rover HSE is renowned for its luxury, innovation, and performance. Among its standout features is Adaptive Cruise Control (ACC), a system that automatically adjusts the vehicle’s speed to maintain a safe distance from the vehicle ahead. This function relies heavily on the seamless coordination between software, sensors, and the vehicle’s powertrain—especially the engine. The Range Rover 3.0 engine, known for its refinement and capability, plays a critical role in delivering the smooth and responsive behavior expected from adaptive systems in the HSE trim. Powered by an advanced 3.0-litre inline-six engine with mild hybrid support, the HSE delivers both power and control. We explores how the Range Rover engine supports Adaptive Cruise Control operations and how reconditioned engines also offer the same reliability and integration when properly restored. We’ll break down the interaction between the engine and ACC systems, emphasizing precision, safety, and efficiency.

Understanding Adaptive Cruise Control in the HSE Model

Adaptive Cruise Control (ACC) in the Range Rover HSE is designed to automatically maintain a safe distance from vehicles ahead. Unlike conventional cruise control systems that only maintain a set speed, ACC dynamically adjusts throttle input and braking. This is especially beneficial during long highway drives or in slow-moving traffic. The system relies on radar sensors, cameras, and engine integration to measure distances and detect changes in traffic flow. The Range Rover 3.0 engines is central to this process. When ACC commands acceleration or deceleration, the engine responds almost instantly to ensure smooth and safe adjustments. The system must rely on the engine’s responsiveness and precise torque delivery for these transitions to be seamless. Even when using reconditioned engines, the ACC system can function optimally—provided the engine has been rebuilt to OEM standards. The engine must support all necessary communication protocols and sensor integrations to maintain the fluid control required for ACC operation in the HSE model.

The Role of the 3.0 Engine's Mild Hybrid System in Smooth Acceleration

One of the key attributes of the Range Rover 3.0 engine is its mild hybrid electric vehicle (MHEV) system. This system enhances the engine’s responsiveness by utilizing a 48V electric motor that assists during acceleration. In Adaptive Cruise Control scenarios, this electric support smooths out any lag between the ACC system's commands and the engine’s actual performance. When the ACC system demands a speed increase to keep pace with traffic, the mild hybrid system adds instant torque, allowing the engine to respond quickly without jerks or sudden surges. This makes the ride feel more refined and helps maintain passenger comfort. Reconditioned engines that include properly rebuilt or replaced MHEV components can replicate the same level of smoothness. High-quality reconditioning ensures that the electric assist and regenerative braking systems work in harmony with the ACC module, keeping the performance consistent and luxurious.

Engine Braking and Deceleration Support During Cruise Control

Engine braking is a natural way to reduce speed without relying entirely on the vehicle’s braking system. In Adaptive Cruise Control mode, the Range Rover 3.0 engine contributes to deceleration by reducing fuel injection and allowing internal friction to slow the vehicle. This technique provides more control and preserves brake life. When descending slopes or approaching a slower vehicle, ACC intelligently uses engine braking along with actual brakes to moderate the car’s speed. The system must communicate effectively with the engine to execute these smooth transitions. For reconditioned engines, this ability is preserved when the ECU is correctly programmed and compatible with ACC features. Even a rebuilt Range Rover engine, when restored with precision, will support the same level of integrated deceleration and braking, making it suitable for high-tech driver assist systems.

Adaptive Throttle Control for Changing Traffic Conditions

In urban or congested traffic, Adaptive Cruise Control faces a different challenge: frequent start-stop movement. The Range Rover 3.0 engine meets this challenge through its finely tuned throttle control, which allows micro-adjustments to power delivery. The inline-six design, combined with turbocharging and hybrid assistance, ensures that the engine can ramp power up or down smoothly and accurately. These adjustments are especially noticeable during stop-and-go traffic, where ACC must restart the vehicle and maintain low speeds while adjusting spacing. Reconditioned engines that include restored throttle bodies, recalibrated ECUs, and hybrid components maintain this precision. So long as the rebuilding process follows factory-grade procedures, reconditioned Range Rover engines remain fully capable of providing the adaptive throttle modulation needed for modern cruise control features.

Integration with Forward Collision Detection and Safety Systems

The ACC system in the Range Rover HSE is linked with forward collision detection, which uses sensors and predictive algorithms to identify potential collisions. If a threat is detected, the engine management system quickly reduces throttle input or cuts power entirely to help avoid or minimize impact. The 3.0 engine’s electronic management system must work in real time with these sensors. Its rapid response rate and ability to quickly alter torque output play a crucial role in ensuring the vehicle reacts instantly to danger. The smooth integration between the ACC and the engine enhances overall safety and confidence on the road. Reconditioned engines, when fitted with updated software and tested ECU configurations, can function seamlessly with these safety systems. These engines are thoroughly inspected to ensure that all electronic connections and responses are in line with safety standards.

Enhancing Fuel Efficiency Through Intelligent Cruise Modulation

One of the understated benefits of Adaptive Cruise Control is its ability to optimize fuel consumption. The Range Rover 3.0 engine, with its mild hybrid support, contributes significantly to this by reducing unnecessary acceleration and deceleration events. By maintaining consistent engine loads and using regenerative braking, the system ensures fuel-efficient cruising. This efficiency is amplified during long highway journeys where minor throttle changes can lead to significant fuel savings. The mild hybrid system further assists by powering auxiliary components and allowing smoother stop-start functionality. Reconditioned engines with properly functioning hybrid modules and efficient combustion characteristics can match these fuel-saving features. When rebuilt correctly, they maintain tight tolerances and electronic calibration, ensuring minimal fuel consumption while supporting ACC functionality.

Communication Between the Engine ECU and Cruise Control Modules

Behind the scenes, complex data exchange occurs between the engine control unit (ECU) and the adaptive cruise control module. The Range Rover 3.0 engine’s ECU processes throttle inputs, brake pressure, torque requests, and regenerative braking status in real time. ACC relies on this live data to make informed decisions about vehicle speed and spacing. The ECU must not only interpret these signals quickly but also execute changes to engine performance instantaneously. The effectiveness of ACC is directly tied to how well the engine ECU responds to this continuous stream of data. For reconditioned engines, ECU compatibility and calibration are key. During engine restoration, specialists ensure that the ECU supports the required protocols and software versions needed to interact with modern driver-assist systems. When this is done correctly, reconditioned engines offer the same reliability and responsiveness as new units.

Maintaining Comfort and Refinement in Cruise Conditions

Luxury vehicles like the Range Rover HSE are expected to deliver not just functionality but also refinement. The 3.0 engine contributes to this by offering near-silent operation, smooth power transitions, and vibration-free performance. When ACC is active, any roughness or delay in power delivery can negatively impact the driving experience. The six-cylinder configuration, along with advanced engine mounts and noise-reducing components, ensures that the engine runs smoothly even during frequent adjustments by the cruise control system. The mild hybrid’s electric motor also reduces engine strain at low speeds, enhancing comfort. A properly reconditioned Range Rover engine can replicate this experience. Noise-dampening materials, engine balancing, and professional tuning during reconditioning ensure that luxury and comfort are preserved. This means even with a reconditioned engine, the HSE model maintains its hallmark smoothness. Read the full article

#RangeRover3.0Engine#RangeRover3.0EngineForSale#RangeRover3.0Engines#RangeRover3.0EnginesforSale#ReconditionedRangeRover3.0Engines#ReconditionedRangeRover3.0Enginesforsale

0 notes

Text

Choosing the Right Partner for Mechanical Engineering Services in India

Whether you are an OEM a product developer or a startup with engineering challenge finding the right partner for a mechanical engineering services in India can make a world of a difference. The right team can truly transform your ideas into market ready solutions affordably and with precision. India has become a global hotspot for mechanical design and engineering support. But with so many mechanical engineering services companies in India how do you pick the right one.

Why choose mechanical engineering services in India?

Before diving into selection criteria, it's very important for you to understand why businesses across the globe are turning to India for their mechanical engineering requirements. India produces thousands of skilled Mechanical Engineers every year many trained in global standards and the latest tools. You get high quality services at the best prices that helps you reduce product development expenses. From product design to industrial automation and also machine design Indian firms offer you a complete spectrum of services.

Evaluate technical expertise

The first thing that you have to check is the technical capability. Does the company you choose have real experience in your domain? You need to look for providers that have worked across industries like automotive and tooling, aerospace consumer products heavy machinery and industrial automation. Also, you need to understand the skills in areas like 3D modeling and reverse engineering. The best companies in India will have strong portfolios including successful case studies.

Ask about tools and software proficiency

Top engineering service producers are proficient in industry standard tools like SolidWorks. Don't hesitate to ask which platforms they use and whether their license is updated. Tool proficiency often reflects the commitment of a company to quality and innovation.

Check the engineering process

A reliable partner should have structured engineering workflow from concept to delivery. Unit to look for companies that follow proven frameworks like requirement gathering and feasibility analysis besides concept generation and also multiple design iterations. this level of structure ensures smoother communication and also few costly errors.

Flexibility and scalability

You want a partner who can grow with you. Some mechanical engineering services companies in India just cater only to small scale jobs, while others are equipped to handle complex high-volume projects. You need to make sure that your selected company can scale up the team when needed and offer full-time dedicated engineers if required. They also need to adjust to changing timelines or technical demands.

So above all you need to know that choosing the right partner like us Pure Machine Design for mechanical engineering services in India is way more than just cost, it's all about value. You need a team that understands your product speaks your languages and also delivers on time. Up Next : How Machine Design Services in India Are Revolutionizing Manufact

0 notes

Text

Can a Replacement Battery Ruin Your iPhone? The Truth About Quality & Safety

In a world where smartphones are our continual companions, battery life is every. Whether you’re answering emails, scrolling through social media, or navigating with GPS, your iPhone battery takes a beating whole one day. Over time, this wear and tear results in shorter battery life and bugging performance drops. When that happens, many users don't forget replacing the battery instead of investing in a emblem-new device. Even so this promotes a critical question: Can a replacement battery ruin your iPhone?

At Elitecellparts, we understand your concerns about battery replacements, uniquely when it comes to safety and performance. Let’s break down the reliability behind replacement batteries, what risks they carry, and how to declare you organize the valid choice for your iPhone.

The Principles: Why iPhone Batteries Need Replacing

Whole rechargeable batteries degrade with time, and iPhones are no variance. Apple uses lithium-ion batteries, which typically last 2–3 years or around 500 full charge cycles. As they age, they hold less charge and may flat cause unexpected shutdowns. If you’re noticing sluggish performance, rushed battery drain, or your phone powering off at 20%, it’s a clear sign you may need a replacement battery.

Are Replacement Batteries Safe?

The short answer is: It depends on where you earn them from.

There are two prime categories of iPhone battery replacements:

Plausible Equipment Manufacturer (OEM) or Credible Apple Parts

Aftermarket or Third-Party Batteries

While OEM batteries are intended by Apple and carry the highest compatibility and quality discussion, they can be steep and limited to Apple-allowed repair centers. On the extra hand, aftermarket batteries vary thoroughly in quality—some are uncommon, others are risky.

This is where a trusted provider like Elitecellparts comes in. We focus on brilliant substitute battery alternatives that balance protection, cost, and overall performance.

Risks of Low-Quality Replacement Batteries

Choosing a cheap or uncertified replacement battery might seem like a negotiation, although it can cause serious issues, including:

1. Overheating and Fire Risk:

Poorly manufactured batteries lack the major safeguards defiance overcharging or overheating, potentially greatest to swelling, smoke, or fire.

2. Shortened Battery Life:

A low-quality battery might not last as long, forcing you to replace it again within months.

3. Performance Issues:

Your iPhone may additionally slow down or crash abruptly if the battery doesn’t well communicate with the device’s software.

4. Touchscreen Malfunction:

In some cases, genuinely unbearable batteries can cause screen flickering, ghost touches, or coordinated disable touchscreen functionality.

5. Loss of Warranty:

Installing non-Apple parts through unauthorized providers may unwritten your device’s warranty. In any case weigh the trade-off in relation to cost and manufacturer policies.

How to Dodge Damage: Select the Valid Replacement Battery

Here’s how you can create sure your iPhone stays safe and practical after a battery replacement:

✅ Work with a Trusted Supplier

Not everything third-party parts are produced fair. Elitecellparts rigorously tests every its batteries for safety, performance, and compatibility at an back then time they at entire times reach your device. We pride ourselves on offering high-quality alternatives to overpriced OEM batteries.

✅ Look for Certifications

A reliable replacement battery should become CE, FCC, or RoHS approved, indicating it has passed electrical safety standards. Elitecellparts sources parts that meet or go past these limitations.

✅ Confirm Compatibility

One by one iPhone model requires a different battery. Using the wrong one can damage your device. At Elitecellparts, every single one replacement battery is strictly titled for clear iPhone models—whether it’s an iPhone 6, X, 11, or 13 Pro Max.

✅ Professional Installation Matters

A helpful battery can regular so ruin your phone if it’s installed poorly. Elitecellparts recommends professional installation or DIY repair kits with clear, step-by-step instructions to flee damaging touchy internal components.

What About iOS Compatibility?

Apple’s software is developed to detect unauthorized or third-party components. In some cases, you might see a message like “Pivotal Battery Message: Unable to confirm this iPhone has a trustworthy Apple battery.”

This doesn’t necessarily suggest the battery is dangerous—it definitely manner it wasn’t installed via an Apple-legal technician. With high-quality batteries from Elitecellparts, you can although cherish reliable performance, straightened if your iPhone shows this caution.

Why Elitecellparts Is Your Impressive Choice

If you’re in the market for a replacement battery, Elitecellparts is your go-to source for premium components at budget-friendly prices. Here’s why thousands of customers belief us:

✅ Premium Quality: Only the impressive-tested batteries assemble it into our catalog.

✅ Appropriate Compatibility: No guesswork—altogether battery is a appropriate fit for your iPhone model.

✅ Cost-beneficial Pricing: High quality doesn't have to mean high cost.

✅ Veteran Copy: Need help choosing the proper part or installing it? We’re just a message away.

✅ Swift Shipping: Acquire your battery rapid, so you're back in action sooner.

Final Principles: Don’t Let Battery Woes Derail Your iPhone

So, can a replacement battery ruin your iPhone? Only if you go with the wrong one. With the true quality, perfect installation, and a reliable supplier like Elitecellparts, a replacement battery can practically boost the life of your iPhone, correct its performance, and save you hundreds of dollars on a new device.

Think of it as a soundness confirm-up for your phone. It’s not just about keeping it running—it’s about running higher-quality and longer.

Whether you're a tech-savvy DIYer or someone who prefers professional help, Elitecellparts offers trusted ways that protect your investment and keep your iPhone in peak condition

0 notes

Text

Automotive for Body Shop (BIW) in pune | India

When sheet metal of a vehicle has been welded together after assembly, it is referred to as "body-in-white" (BiW). This condition does not include any moving parts, trim pieces (such hoods, fenders,etc.), or chassis subassemblies.

#Automotive standards for INTEGRA#TM O#VASS#Development#Software Standardization for OEM#Line Builders#PLC Logic#PLC SCADA Development#No Code Low Code Solutions#PLC Tool#Plc and Scada Services#Solutions for OEMs and Machine Builders

0 notes

Text

Why do some car manufacturers make it extremely difficult to change a headlight bulb, sometimes requiring a trip to the dealership?

Why Some Car Manufacturers Make Headlight Bulb Replacement Difficult Replacing headlight bulbs in modern vehicles can feel like navigating an engineering maze, often requiring specialized tools or dealership intervention. This complexity stems from design priorities, regulatory compliance, and advanced technology integration. Below are the key reasons and their implications:

Advanced Lighting Systems

Modern vehicles increasingly use adaptive headlights (e.g., auto-leveling, cornering beams) and integrated LED arrays or laser modules instead of traditional bulbs. These systems are tightly controlled by onboard computers and sensors. For example: Adaptive Headlights: Adjust brightness and direction based on steering input or road conditions. Even minor misalignment can disrupt the entire system, requiring recalibration with proprietary software.

Integrated LED/Laser Modules: Often soldered into sealed assemblies rather than using replaceable bulbs. Replacing them may necessitate swapping the entire headlight unit.

Engineering and Aesthetic Trade-offs

Manufacturers prioritize sleek, aerodynamic designs and compact packaging, which often result in tightly packed engine bays and headlight housings: Space Constraints: Headlights may be fused with grilles, fenders, or bumper components. Accessing the bulb might require removing the wheel well liner, battery, or air filter housing.

Proprietary Fasteners: Custom clips or screws demand specialized tools, discouraging DIY repairs.

Regulatory Compliance and Safety Standards

Strict homologation rules (e.g., SAE, ECE) mandate precise beam patterns, brightness, and alignment. To ensure compliance: Tamper-Proof Designs: Manufacturers discourage aftermarket modifications by sealing systems or using non-standard components. Non-OEM parts risk failing inspections or causing glare hazards.

Self-Leveling Requirements: Adaptive headlights must maintain proper alignment with the road, which can only be reset via dealership diagnostics.

Profit and Service Model

Dealerships and certified repair shops benefit from locked-in servicing: Software Dependencies: Adaptive systems require proprietary diagnostic tools (e.g., OEM scanners) to reset error codes or recalibrate sensors.

Warranty Control: Manufacturers may void warranties if non-certified technicians attempt repairs, steering owners to dealerships.

Safety and Durability Considerations

Sealed Assemblies: Protect sensitive electronics from moisture and dust, ensuring longevity and UV resistance.

Electrical Complexity: Modern bulbs (e.g., HID, LED) require precise voltage regulation. Incorrect handling can damage the vehicle’s electrical system or reduce bulb lifespan.

Key Takeaways Factor Impact on DIY Replacement Advanced Tech Requires calibration tools and software Regulatory Compliance Tamper-resistant designs Aesthetic Design Tight packaging limits access Service Incentives Encourages dealership dependency

Advice for Owners: Consult Manuals: Some models allow bulb access via hidden panels.

Invest in Professional Help: For adaptive or laser systems, dealerships ensure compliance and safety.

Avoid Aftermarket Modifications: Non-homologated parts risk fines or accidents.

While frustrating, these design choices reflect a balance between innovation, safety, and market dynamics. For complex systems, dealerships remain the safest (if pricier) option.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#headlight bulbs#headlight bulb#car culture#cars#classic cars#race cars#cartoon#car#suv#porsche#truck#carlos sainz#supercar#automobile#car light#headlight restoration#headlamps#headlamp#headlight#aftermarket new lamp

2 notes

·

View notes

Text

IETM for beginners A Quick Guide to IETM

The main objective of this page is to give a quick insight into IETM. You may have many assumptions related to IETM. We tried to cover all the aspects related to IETM.

Interactive Electronic Technical Manual, in short, is called IETM. If you are a supplier of defence then along with the system/equipment you also need to provide training aids like CBT, Charts and blowup diagrams, Video films, Training work Modules, and a few sets of Hard copies of the manuals and IETM.

Till 2015, mainly Hardcopies and PDFs in DVDs used to be in deliverables. From 2015 onwards IETM is used in RFQ/SOTR/SCOPE as a deliverable.

As per the above definitions, it is clear that we need a Technical Manual that too in soft copy and which will be able to talk to us or able to respond to us.

When the Manual responds to user questions then it is called an Interactive Electronic Technical Manual.

How will the document be able to respond? We need to embed or integrate this soft copy or content into one application so that the application will respond or interact. What are the common interactivity features so that the User will be able to get the information from the software?

Interactive Features Will Be Like:

Navigation

Linear navigation (moving in the fixed or pre-defined path..e next – previous topics

Non-liner navigation ( it means the user can go to any topic randomly)

Page Search

Global Search

Best Matched

Content Tree

Related Topics

Core IETM

Documents

Drawings

Interactivity

Hyperlinks

Hot Spots

Text Hotspot

Image Hotspot

Video Hotspot

Bookmarks

Annotation

The documents and pages are many hence, for easy and fast accessibility complete content is converted and stored as a database. Whenever the user wants some information, IETM software produces the information in a fraction of a second.

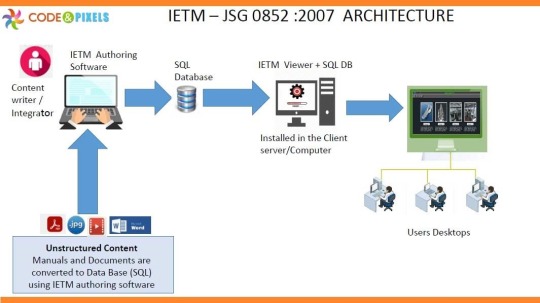

IETM is a combination of software applications and databases.

What is the Use or Purpose of the IETM?

Any manual’s purpose is to give information related to the equipment to the end user for quick reference.

All the technicality is written in detail so that when an issue arises, the user can refer to the manual, as every time OEM or technical person or subject matter expert might not be available on the spot to resolve the issue.

If the manual has 10 pages users can refer easily. But any system used by the defence will have multiple manuals and thousands of page counts and many times a user has to cross-refer between manuals, intra-manual and inter-manual to resolve the issue.

Referring to 10- 15 hard-copy or even soft-copy books simultaneously will be difficult and time-consuming. Using IETM software, users can solve in a single click and seconds.

How to Access the IETM

IETM is a web-based application like our bank software or any other web application. The graphic user interface will be provided to use IETM through which users can interact and get the desired data.

Like all other standard software, Unauthorized users cannot access the IETM. IETM is Login login-based application. Only users having valid Login credentials can access the software.

Based on the user log credentials data will be provided to the user. IETM has 2 types of users and one Administrator.

Maintainer

Operator

If the operator logs in, the user gets all the content related to operator use, similarly if the maintainer logs in only maintenance-related content is visible for that user.

Ideally, all the content is available for both users, because the purpose of the IETM is to refer to the manual to fix the issue.

Administrators can create users who can see the user’s navigation and log-in history and interact with the users using user dashboards through Annotations.

In any case, Only OEM has the right to update or modify the content. Users can only refer to the content.

What inputs are needed from OEM to create IETM:

All the softcopies of user manuals to be converted to IETM.

All images Videos, and drawings to be integrated into IETM.

Table of contents/tree structure.

Subject matter expert to resolve technical clarifications.

All the manuals should be editable i.e. open files which do not have passwords or Locks and copy-protected PDFs.

Minimum Hardware Requirements for optimal performance of IETM

NO High-end hardware or servers are required to run IETM. However, if more concurrent users then a good configuration server with good LAN connectivity must be ensured.

i3 with 8 GB RAM systems is the minimum configuration required for the server or for Node.

Deliverables

BASED DB (Manuals are covered in the Database)

IETM VIEWER Software

User Manual and Installation Manual

Standards Compliance

The IETM framework complies with Indian Defence standards, JSG 0852

What is IETM and What is Not IETM?

IETM Vs 3D Blowups

There is a misconception about IETM. As the name indicates interactive, people assume that it is a 3D based on blowup software. Interactive means, users can browse or cross-refer or interact with the software to search on a particular topic/sub-topic.

3D Animations and blowups can be taken as separate tasks based on the complexity of the system and the level of blowups that you want. We have a separate division to take up such assignments.

If your SCOPE /SOTR /RFP says IETM then stick to IETM only.

These 3D animations, 3d Blowups, and virtual reality cost more than IETM cost. They will be good to see definitely but they are not part of IETM. If your client wants 3d and if the scope specifically mentions 3d then it is a separate deliverable but not IETM.

There is no link between IETM and 3d. If you have 3D animations or blowups, you can integrate into IETM.

Understand the difference between IETM VS CBT VS Virtual reality.

Another important point to check is which IETM level the client/ SCOPE is asking for. Generally, they may ask for Level 3 or Level 4. (If your RFQ is 5 years old around 2016-17 then they may ask for Level 2 or 3)

Level -3 costs less price than Level -4. If you have a choice to select, then select IETM -3 as it is very economical.

The latest RFPs / SCOPE asks for Level -4 only.

Costing of IETM

Level of IETM, is it Level 3 or Level 4

Cost will be based on the number of pages that are to be converted.

The vendor calculates the cost per page.

And a fixed cost of IETM viewer software.

If you want to create IETM by yourself self then you also need to buy IETM authoring software.

Regarding Level -5, rest assured, till 2028 it will be Level 4 only. As of now, there is nothing practically called Level -5. Few are calling virtual reality and Augmented reality and Artificial intelligence Level 5.

Pulling data from many user inputs and analyzing and giving results are done in Level -5.

IETM software can not pull the data from various real-time points as No OEM will give the real-time information to third-party software directly. Yes, if the information is available offline, then that information can be imported into IETM and can be used as a reference.

Implementing VR/AR and Artificial Intelligence itself costs 10 times more than the actual equipment cost. Hence for the next few years, AR/VR and artificial intelligence are affordable.

Want to see the IETM software?

Until you see the software, you will not be able to understand it fully. Hence, we strongly recommend you have a virtual meeting for 15 minutes so that you will have a fair idea about the IETM software.

Write an email to [email protected] or call 9849527706 to fix up the quick demo on IETM.

Our Expertise:

Code and Pixels Interactive Technologies Private Limited (CNP) is an IETM service provider based in Hyderabad (India). We provide end-to-end Software development and IETMs (INDIAN STANDARD IETM JSG 0852, LEVELS 3 and 4 )

Code and Pixels is the only Company, that delivered 50 plus IETMs (Class 3, Class 4) to Indian defence and many corporates i.e. Tata, L&T, Nova, Ashok Layland, Mahendra Defence, BAeHAL, Marine Electricals, Idea Forge, Raphe mPHibr, Navcon, Zen technologies, Kirloske, Avision, Alterra, Jyoti Ltd, Data patterns, DESMI, Man Energy and Defense labs and production agencies and shipyards such as DRDL, RCI, ASL, BDL, ECIL, BEL, HSL, and many OEMs.

We have worked in association with the Naval Technical Group of the Navy and also with the eMMS team of the Indian Air Force and MAG (DRDL) of the Indian Army. Having vast experience, we assure you that we will be your trusted technology partner in delivering IETMs.

#ietm#ietm code and pixels ietm hyderabad#software#technology#code and pixels#ietm developement#ietm level iv#ietm software#elearning#codeandpixels

2 notes

·

View notes

Text

Achieving High-Precision Material Testing with Star EMBSYS Servo Tensile Testing Machines

In modern material science and quality assurance, precision testing is critical for ensuring product reliability, safety, and compliance. Tensile strength—the ability of a material to withstand pulling forces—is a fundamental property that influences product design across industries such as automotive, aerospace, construction, electronics, and packaging. A servo tensile testing machine is an essential tool for conducting such tests with high accuracy and repeatability. Among the leading providers in this domain, Star EMBSYS has earned a reputation for delivering advanced, durable, and efficient tensile testing systems that meet international standards and industrial demands.

Precision Engineering with Intelligent Servo Control

Star EMBSYS's servo tensile testing machines are built with high-end servo motors and closed-loop control systems that provide exceptional accuracy in force application and displacement measurement. These systems are ideal for testing a wide range of materials including metals, polymers, composites, textiles, and rubber. Whether for R&D or routine quality checks, Star EMBSYS machines offer controlled testing environments with programmable test parameters, user-defined speed settings, and automatic data logging.

Equipped with load cells of varying capacities, high-resolution extensometers, and digital controllers, Star EMBSYS machines provide accurate stress-strain curves and real-time feedback on material behavior under tensile loads. Their advanced software suite allows operators to analyze mechanical properties such as yield strength, ultimate tensile strength, elongation, and modulus of elasticity with ease. Results are displayed in graphical and tabular formats, enabling quick interpretation and reliable decision-making.

What truly differentiates Star EMBSYS is the seamless integration of mechanical precision with software intelligence—enabling automated test cycles, data export, and report generation to reduce human intervention and enhance efficiency.

Tailored Solutions with Industry-Focused Features

Understanding that different industries have varying testing requirements, Star EMBSYS offers custom-built servo tensile testing machines tailored to specific applications. From compact benchtop models for academic institutions to high-capacity floor-standing units for industrial testing labs, the company provides scalable solutions without compromising on performance.

Star EMBSYS machines support a wide range of grips and fixtures to accommodate samples of different shapes, sizes, and materials. This flexibility allows manufacturers and quality control labs to conduct a full range of tests, including tensile, compression, flexural, and peel tests. Moreover, the machines are designed with operator safety in mind, featuring protective enclosures, overload protection, and emergency stop systems.

In addition to manufacturing top-tier equipment, Star EMBSYS offers robust after-sales support, calibration services, operator training, and remote diagnostics. Their commitment to customer satisfaction and technical excellence makes them a preferred partner across sectors including automotive OEMs, aerospace manufacturers, research labs, and educational institutions.

Conclusion

In today’s competitive industrial landscape, investing in a servo tensile testing machine is crucial for maintaining material integrity and meeting quality standards. Star EMBSYS delivers state-of-the-art solutions that combine accuracy, flexibility, and reliability—backed by superior service and customization options. For businesses that prioritize precision testing and product performance, Star EMBSYS stands out as a trusted and forward-thinking provider in the tensile testing segment.

Visit:- https://www.starembsys.com/servo-tensile-testing-machine.html

0 notes

Text

Wondering Who Offers Genuine MacBook Repair in Koramangala?

If you’re a MacBook user in Koramangala, you likely depend on your device for work, creativity, and daily life. But what happens when your trusted MacBook starts acting up—be it a cracked screen, a battery that won’t hold charge, keyboard issues, or software troubles? Finding genuine MacBook repair in Koramangala can feel like searching for a needle in a haystack. With so many service providers promising “Apple-level” repairs, how do you separate the experts from the amateurs?

In this comprehensive guide, we’ll explore what makes a MacBook repair service in Koramangala truly reliable, why genuine repairs matter, and introduce you to Machub—your trusted partner for authentic MacBook repairs.

Why MacBook Owners Need Specialized Repair Services

Your MacBook isn’t just any laptop—it’s a sophisticated machine crafted with precision. From its Retina display to the T2 security chip, the MacBook is packed with proprietary technology that requires specialized knowledge for repairs.

Here’s why MacBook owners should be cautious about where they take their device for servicing:

Proprietary Components: MacBooks use parts like custom batteries, logic boards, and displays that aren’t easily replaceable with generic alternatives. Using counterfeit parts can compromise performance and safety.

Complex Engineering: MacBooks are designed for sleekness, which means components are tightly packed. This requires technicians with Apple-specific skills to safely open and repair them.

Security Features: The T2 chip and other Apple security measures mean unauthorized repairs can lead to issues like disabled touch ID or data loss.

That’s why genuine MacBook repair in Koramangala is not just a luxury—it’s a necessity.

What Makes a MacBook Repair Service Genuine?

When looking for MacBook repair in Koramangala, consider these essential factors:

1️⃣ Use of Genuine Parts

Authentic MacBook repair services will always use Apple-certified or genuine OEM parts. This ensures your MacBook maintains its performance, longevity, and warranty integrity.

2️⃣ Trained Technicians

Repairing a MacBook isn’t the same as repairing a standard laptop. Trained professionals with experience in Apple hardware and software ensure your device is in safe hands.

3️⃣ Transparent Diagnosis and Pricing

A genuine service provider will offer a clear diagnosis of your MacBook’s issue and provide an upfront estimate without hidden charges.

4️⃣ Warranty on Repairs

Look for repair centers that offer a warranty on parts and services, giving you peace of mind about the quality of their work.

5️⃣ Data Security

MacBooks often contain sensitive personal or business data. A trustworthy repair center will prioritize data safety and confidentiality.

Common MacBook Issues Machub Repairs in Koramangala

At Machub, we specialize in addressing a wide range of MacBook issues. If you’re searching for MacBook repair in Koramangala, here’s what we can help with:

✅ Screen Replacement Whether it’s a cracked display or dead pixels, we replace your screen with a genuine MacBook display for flawless visuals.

✅ Battery Replacement MacBook not holding charge? Our battery replacements use authentic components, restoring battery life without risk of swelling or malfunction.

✅ Keyboard and Trackpad Issues We handle sticky keys, unresponsive trackpads, and butterfly mechanism failures with precision.

✅ Logic Board Repairs One of the most complex repairs, our experts can diagnose and repair logic board issues without needing a full replacement (where possible).

✅ Water Damage Restoration Spilled water or coffee? Bring your MacBook to us for immediate water damage treatment and corrosion control.

✅ Software Troubleshooting and Recovery From macOS crashes to data recovery, our team ensures your software runs smoothly.

✅ Fan and Thermal Management Repairs If your MacBook overheats or makes unusual noises, we address cooling system issues before they cause bigger problems.

Why Choose Machub for MacBook Repair in Koramangala?

Wondering why so many MacBook users in Koramangala trust Machub? Here’s what sets us apart:

✔ Apple-Grade Expertise

Our technicians are trained on Apple architecture, ensuring accurate diagnosis and precision repairs every time.

✔ Genuine Parts Only

We source and install only genuine or OEM-grade MacBook components, preserving your device’s integrity and performance.

✔ Free Pickup and Delivery

Busy schedule? Machub offers free doorstep pickup and delivery service across Koramangala, so you don’t have to worry about commuting with a damaged MacBook.

✔ Transparent Pricing

No hidden fees, no surprises. We provide clear quotes before any work begins.

✔ Quick Turnaround

We understand your MacBook is essential to your daily life. Our team is committed to completing repairs efficiently without compromising quality.

✔ Customer-Centric Approach

From data privacy to clear communication, we put your needs first at every step of the repair journey.

How the Repair Process Works at Machub

Here’s what to expect when you choose Machub for MacBook repair in Koramangala:

1️⃣ Book a Repair Contact us via phone, website, or visit our Koramangala center to schedule a diagnostic.

2️⃣ Free Pickup We collect your MacBook at a convenient time, ensuring it’s safely transported to our service center.

3️⃣ Thorough Diagnosis Our technicians carefully examine your MacBook and provide a detailed report with an estimate.

4️⃣ Approval & Repair Once you approve the service, we proceed with genuine part replacements or repairs.

5️⃣ Quality Testing After the repair, your MacBook undergoes multiple quality checks to ensure it functions perfectly.

6️⃣ Free Delivery We deliver your fully repaired MacBook back to your doorstep.

Tips for Maintaining Your MacBook Post-Repair

Once your MacBook is repaired, here’s how to keep it running smoothly:

💡 Keep Software Updated: Regularly install macOS updates to benefit from the latest features and security patches.

💡 Use a Protective Case: Minimize physical damage risk by using a sturdy case and screen guard.

💡 Avoid Overheating: Use your MacBook on flat surfaces to allow proper ventilation.

💡 Back Up Your Data: Regularly back up to Time Machine or iCloud so your data is safe in case of future issues.

💡 Handle Liquids With Care: Keep beverages away from your MacBook to avoid spills.

Customer Testimonials

Priya S. - Entrepreneur, Koramangala: “Machub saved my MacBook Pro after a water spill. Their team was prompt, transparent, and professional. The free pickup and delivery made my life so much easier.”

Rahul K. - Software Developer: “I was looking for genuine MacBook repair in Koramangala, and I’m so glad I found Machub. My MacBook Air feels as good as new after a battery replacement.”

Siddharth P. - Student: “Excellent service at reasonable prices. They replaced my cracked screen with an original display, and I couldn’t be happier.”

Final Thoughts

When it comes to MacBook repair in Koramangala, don’t take chances with your valuable device. Choosing a trusted, genuine repair center like Machub ensures your MacBook receives the care it deserves—with authentic parts, expert technicians, and a customer-first approach.

So, the next time you’re wondering who offers genuine MacBook repair in Koramangala, remember that Machub is just a call or click away. Let us help you bring your MacBook back to peak performance—safely, reliably, and affordably.

0 notes

Text

How Software- Defined Vehicle Technology is Transforming Construction and Agricultural vehicles and Equipment

Construction and agricultural vehicles are no longer just powerful machines—they are becoming intelligent systems. The transition to Software Defined Vehicle (SDV) technology is revolutionizing how equipment operates, adapts, and evolves.

Backed by cloud integration, programmable features, real-time diagnostics, over-the-air capabilities, and increasing levels of AI, SDVs are making machinery smarter, safer, and more productive - from remotely driven earth movers to autonomous tractors, the machines of today’s construction and agricultural industries are experiencing a revolution—powered not by heavier engines or more significant hydraulics but by more creative software.

This transition to Software Defined Vehicles (SDVs) allows equipment to be more intelligent, flexible, and future-ready. With software evolving as the backbone of contemporary machinery, OEMs and fleet operators are discovering new ways to upgrade performance, improve uptime, and unlock feature flexibility—all without ever setting foot in a service center.

Here's how software-defined vehicle technology is rewriting the rulebook for off-highway vehicles:

1. Increasing Software Content: Intelligence Is the New Horsepower

The average construction and agriculture vehicle now has more software-driven features than ever before, controlling everything from transmission, engine and braking behavior to diagnostics, navigation, and attachments. Much of a machine's "personality" is now shaped by its software.

This increasing software content allows manufacturers to:

Standardize platforms across multiple models

Add new capabilities to their platforms

Simplify maintenance through real-time digital diagnostics

It's no longer only about what's under the hood—but also what's written in the code.

2. OEM-Initiated OTA Updates: Improving Equipment from Afar

With traditional machinery, upgrades meant downtime, technician visits, and often manual interventions. Now, over-the-air (OTA) updates let OEMs remotely push enhancements, bug fixes, or regulatory patches straight to equipment—anytime, anywhere.

These updates can:

Improve performance and reliability

Extend product life cycles

Ensure regulatory compliance without disruptions

Excelfore solutions enable centralized management of these updates, allowing manufacturers to keep their entire fleet optimized from a single dashboard—securely, efficiently, and without taking machines out of operation.

3. Owner/Operator-Initiated OTA Updates: custom features, on demand

Sometimes, it's not about fixing; it's about customizing.

Software-defined vehicles empower owners and operators to unlock new features or modes of operation on demand. Need enhanced traction control for a wet site or a new GPS mapping function for a larger field? Activate it with a secure OTA update.

This approach delivers:

Flexibility to respond to real-time job site demands

Better cost control with feature-based pricing

Operational agility and higher asset utilization without added hardware complexity

It's about giving operators the power to get more out of their machines—without waiting for factory upgrades or field visits.

4. Infrastructure for OTA on Demand: Built to Scale, Designed for the field

A rock-solid technical foundation powers all this flexibility. The Excelfore OTA infrastructure is engineered specifically for the rugged and remote environments that construction and agriculture demand.

Key enablers include:

Delta Compression – Reduces data volume by sending only changes, making updates faster and lighter on bandwidth

Cloud-native architecture – Ensures scalability across fleets of all sizes

Robust security protocols – Safeguards every update from tampering or failure

Real-time diagnostics integration – Lets updates happen in sync with equipment performance data

This isn't just an upgrade—it's a more innovative way to manage every stage of the equipment lifecycle.

The Bottom Line

Software-defined vehicle technology turns construction and agricultural equipment into platforms for continuous improvement, deeper insight, and real-time control. Whether you're an OEM looking to expand the market opportunities for your fleet or an operator needing more innovative tools on-site, SDVs offer the edge you need.

At the center of it all is Excelfore, which provides the connected infrastructure, OTA capabilities, and smart diagnostics that make this transformation real, reliable, and scalable.

Ready to power smarter, more adaptable machines?

Talk to us today!About the Author: Excelfore, a pioneer in automotive data management solutions, provides innovative software platforms for connected vehicles. With a focus on scalability, security, and interoperability, Excelfore enables seamless integration of advanced technologies in the automotive ecosystem. From data management to over-the-air updates, Excelfore solutions empower automakers and Tier-1 suppliers to deliver cutting-edge connected vehicle experiences.

0 notes