#PLC SCADA tutorial

Explore tagged Tumblr posts

Text

What is Python Programming? Learn the Basics of Python

Python is one of the most beginner-friendly programming languages available today. It’s widely used across industries and has become the go-to language for those just stepping into the world of programming. Whether your goal is to build websites, analyze data, or explore artificial intelligence, Python provides a solid foundation to begin your journey.

Why Python is Ideal for Beginners

One of the biggest reasons Python is favored by newcomers is its simplicity. Python's syntax is clean and easy to read, which means you can quickly understand what your code is doing without needing a background in computer science. Unlike some other languages that require strict formatting or complex structures, Python keeps things minimal and intuitive.

Another strong advantage is its wide usage. Python is used in a variety of fields such as software development, automation, data science, machine learning, and web development. This versatility means that once you learn the basics, you can apply your knowledge to countless real-world scenarios.

Python also boasts a massive global community. This means that if you ever get stuck, there are thousands of tutorials, forums, documentation pages, and learning resources available online. Beginners benefit greatly from such a supportive environment.

Understanding the Basics of Python

To begin your Python journey, it’s essential to grasp a few fundamental concepts. These include understanding how to store information using variables, working with different types of data, performing calculations, and writing logic to make decisions in your code.

Another important area is learning how to repeat tasks using loops, and how to organize your code into reusable blocks called functions. These basics form the building blocks of almost every program you'll write in Python.

As you progress, you’ll also explore how to work with data collections like lists and dictionaries, handle user input, and structure your projects to be readable and efficient.

Real-World Applications of Python

Python’s appeal goes far beyond its simplicity. It’s a powerful tool used in professional environments to build a variety of applications. In web development, Python is behind many dynamic websites and platforms, thanks to frameworks like Django and Flask.

In the world of data analysis and visualization, Python offers libraries that help professionals process large volumes of information and extract meaningful insights. From creating charts to building predictive models, Python powers much of what we see in business intelligence and research today.

Another exciting domain is machine learning and artificial intelligence. With Python’s frameworks and libraries, developers can build systems that learn from data, make decisions, and even understand natural language.

Python also excels in automation. If you’ve ever had a repetitive task on your computer, like renaming files or processing data, Python can be used to automate those tasks, saving time and effort.

How to Start Learning Python

The best way to begin learning Python is to start small and stay consistent. You don’t need any expensive software, many online platforms allow you to write and test Python code right in your browser. There are also free tutorials, beginner courses, and video lessons available to help guide your learning step-by-step.

It’s helpful to set small goals, such as writing a simple calculator or building a personal planner. These projects may seem small, but they help reinforce core concepts and make learning more engaging.

As you improve, you can challenge yourself with more complex projects and begin exploring specific fields like web development or data analysis. Python’s broad range of applications means there’s always something new to learn and try.

Conclusion

Python is more than just a beginner’s language, it’s a tool that professionals use to build innovative technologies and solve real-world problems. By mastering the basics, you open the door to endless possibilities in the tech world.

Whether you're a student, a working professional, or someone simply curious about coding, Python is the perfect language to get started. With dedication and practice, you’ll be amazed at how quickly you can go from a beginner to a confident programmer.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

PLC Industrial Automation System A Step-by-Step Guide

PLC Industrial Automation System:

For industrial automation, Programmable Logic Controllers (PLCs) are among the prerequisites for productivity, precision, and consistency in several utilizations. PLCs have become the industrial building block in automating processes, revolutionizing industries by reducing their reliance on people and increasing efficiency. This tutorial provided by Dropship Automation will help you understand the fundamentals of PLC, what they are and how to get started with implementing a PLC based automation system for your industry.

What is a PLC?

A programmable logic controller called a PLC, is a computer specifically designed to handle machines, processes, and systems in industrial places. While a regular computer is not expected to endure industrial environments, such as high temperatures, humidity and electrical interference, a PLC is made with these environmental conditions in mind. They are very dependable and, therefore, are very suitable for sensitive automation applications.

Understanding the Key Components of a PLC System:

The first step is characterized by the identification of the fundamental aspects of the PLC system, which include the following elements:

Before diving into the implementation process, it's crucial to familiarize yourself with the critical components of a PLC system: Before diving into the implementation process, it's crucial to familiarize yourself with the essential components of a PLC system:

1. Central Processing Unit (CPU):

The Control Panel is abbreviated as CPU, and the PLC's brain is the PLC's. It performs the control program, analyses input data, and analyses input data and signals to the outputs.

2. Input/Output (I/O) Modules:

I/O modules connect the PLC with the physical environment of the manufacturing operation. Some of the inputs may be sensors, switches or any other devices which transmit signals to the PLC. There are outputs, which are actuators, relays, and other devices that respond to the command issued to it by a PLC.

3. Power Supply:

In the power supply, electrical power required in the PLC and other related components is sourced.

4. Programming Device:

The programming device is where the control program is compiled, modified and transmitted to the PLC. This can be on a computer with software that programs the device or a sole handheld programmer.

5. Communication Ports:

These ports allow the PLC to transfer data with equipment such as HMI, SCADA and other PLCs.

Control:

In the second step, there is a need to design a control program, which is very crucial in helping organize the company effectively.

The control program is the control part of the PLC system through which the inputs are accepted and the control of outputs. Here's how to approach program design: Here's how to approach program design:

1. Define the Control Objectives:

First, one must define which process or machine is the most suitable to be automated. On the other hand, the target objectives should be stated clearly, therefore pointing out areas such as managing the speed of a conveyor belt or overseeing specific temperature ranges.

2. Create a Flowchart:

Create a process map that shows the step-by-step progression of events. It allows one to keep the thought process considering all angles of a given situation.

3. Write the Ladder Logic Program: Write the Ladder Logic Program:

Ladder logic is the oldest and most popular programming language for PLCs. This resembles electrical relay logic diagrams, making it easy for the engineers and technicians. The program depends on steps; each can be a specific type of control action.

4. Test the Program:

• Always practice before implementing the program since this will enable a proper evaluation of the program. This step helps ensure the system is run with the correct information, thus minimizing errors.

Installation of the PLC System

Once the control program is ready, it's time to install the PLC system: Once the control program is prepared, it's time to install the PLC system:

1. Mount the PLC:

Place the PLC along with the I/O modules where they would not be easily accessible to unauthorized personnel, mainly done in the industrial control panel. Proper ventilation and protection from biological, chemical as well as physical hazards should always be provided.

2. Connect Inputs and Outputs:

Wire the input devices, which include the sensors and switches, and the output devices, which are the actuators and relays. Ensure wiring connections to eliminate any wiring problem that may cause wrong functioning.

3. Power Up the System:

Once all the connections have been confirmed, turn ON the PLC system. Pay attention to the first time the system starts and look out for messages such as Error messages or any abnormal activity.

However, the fourth step is an extension of the third step, where an established telecommunication firm monitors the implementation process and afterwards performs maintenance duties.

With the PLC system operational, ongoing monitoring and maintenance are essential for long-term reliability: With the PLC system operational, ongoing monitoring and maintenance are critical for long-term reliability:

1. Monitor System Performance:

Contact the communication ports to link the PLC to an HMI or SCADA program to monitor the PLC in real time. Through such a connection, operators can monitor the system's performance, get notified and modify when necessary.

2. Perform Regular Maintenance:

Physically check the PLC system for signs of wear and tear like loose wiring connections, hot ones, and a lousy display of software. This highlights the importance of always ensuring that the firmware and the software used in the system are constantly updated to eliminate any existing or developing flaws.

3. Optimize the Control Program:

You might also come across ways of enhancing the program for the control over time. Also, it must undergo routine revision and optimization to reflect any improvement in processes or changes in operational needs.

Conclusion

A PLC-based automation system is a definitive, unique investment that can significantly impact your industrial procedures and human labour assets. This means that, through the step-by-step guide provided herein, one can be confident of having the best PLC system designed, installed, and maintained. Dropship Automation offers various types of Programmable Logic Controllers from other manufacturers and efficient consultation services to meet your automation requirements.

To know how each product can assist you with your PLC requirements, visit our list of Dropship Automation products or contact our team for further assistance. Take advantage of the capabilities of PLCs to make your industrial automation systems superior to your rivals.

1 note

·

View note

Text

PLC Industrial Automation System A Step-by-Step Guide

PLC Industrial Automation System:

For industrial automation, Programmable Logic Controllers (PLCs) are among the prerequisites for productivity, precision, and consistency in several utilizations. PLCs have become the industrial building block in automating processes, revolutionizing industries by reducing their reliance on people and increasing efficiency. This tutorial provided by RAM Automations will help you understand the fundamentals of PLC, what they are and how to get started with implementing a PLC based automation system for your industry.

What is a PLC?

A programmable logic controller called a PLC, is a computer specifically designed to handle machines, processes, and systems in industrial places. While a regular computer is not expected to endure industrial environments, such as high temperatures, humidity and electrical interference, a PLC is made with these environmental conditions in mind. They are very dependable and, therefore, are very suitable for sensitive automation applications.

Understanding the Key Components of a PLC System:

The first step is characterized by the identification of the fundamental aspects of the PLC system, which include the following elements:

Before diving into the implementation process, it's crucial to familiarize yourself with the critical components of a PLC system: Before diving into the implementation process, it's crucial to familiarize yourself with the essential components of a PLC system:

1. Central Processing Unit (CPU):

The Control Panel is abbreviated as CPU, and the PLC's brain is the PLC's. It performs the control program, analyses input data, and analyses input data and signals to the outputs.

2. Input/Output (I/O) Modules:

I/O modules connect the PLC with the physical environment of the manufacturing operation. Some of the inputs may be sensors, switches or any other devices which transmit signals to the PLC. There are outputs, which are actuators, relays, and other devices that respond to the command issued to it by a PLC.

3. Power Supply:

In the power supply, electrical power required in the PLC and other related components is sourced.

4. Programming Device:

The programming device is where the control program is compiled, modified and transmitted to the PLC. This can be on a computer with software that programs the device or a sole handheld programmer.

5. Communication Ports:

These ports allow the PLC to transfer data with equipment such as HMI, SCADA and other PLCs.

Control:

In the second step, there is a need to design a control program, which is very crucial in helping organize the company effectively.

The control program is the control part of the PLC system through which the inputs are accepted and the control of outputs. Here's how to approach program design: Here's how to approach program design:

1. Define the Control Objectives:

First, one must define which process or machine is the most suitable to be automated. On the other hand, the target objectives should be stated clearly, therefore pointing out areas such as managing the speed of a conveyor belt or overseeing specific temperature ranges.

2. Create a Flowchart:

Create a process map that shows the step-by-step progression of events. It allows one to keep the thought process considering all angles of a given situation.

3. Write the Ladder Logic Program: Write the Ladder Logic Program:

Ladder logic is the oldest and most popular programming language for PLCs. This resembles electrical relay logic diagrams, making it easy for the engineers and technicians. The program depends on steps; each can be a specific type of control action.

4. Test the Program:

• Always practice before implementing the program since this will enable a proper evaluation of the program. This step helps ensure the system is run with the correct information, thus minimizing errors.

Installation of the PLC System

Once the control program is ready, it's time to install the PLC system: Once the control program is prepared, it's time to install the PLC system:

1. Mount the PLC:

Place the PLC along with the I/O modules where they would not be easily accessible to unauthorized personnel, mainly done in the industrial control panel. Proper ventilation and protection from biological, chemical as well as physical hazards should always be provided.

2. Connect Inputs and Outputs:

Wire the input devices, which include the sensors and switches, and the output devices, which are the actuators and relays. Ensure wiring connections to eliminate any wiring problem that may cause wrong functioning.

3. Power Up the System:

Once all the connections have been confirmed, turn ON the PLC system. Pay attention to the first time the system starts and look out for messages such as Error messages or any abnormal activity.

However, the fourth step is an extension of the third step, where an established telecommunication firm monitors the implementation process and afterwards performs maintenance duties.

With the PLC system operational, ongoing monitoring and maintenance are essential for long-term reliability: With the PLC system operational, ongoing monitoring and maintenance are critical for long-term reliability:

1. Monitor System Performance:

Contact the communication ports to link the PLC to an HMI or SCADA program to monitor the PLC in real time. Through such a connection, operators can monitor the system's performance, get notified and modify when necessary.

2. Perform Regular Maintenance:

Physically check the PLC system for signs of wear and tear like loose wiring connections, hot ones, and a lousy display of software. This highlights the importance of always ensuring that the firmware and the software used in the system are constantly updated to eliminate any existing or developing flaws.

3. Optimize the Control Program:

You might also come across ways of enhancing the program for the control over time. Also, it must undergo routine revision and optimization to reflect any improvement in processes or changes in operational needs.

Conclusion

A PLC-based automation system is a definitive, unique investment that can significantly impact your industrial procedures and human labour assets. This means that, through the step-by-step guide provided herein, one can be confident of having the best PLC system designed, installed, and maintained. RAM Automations offers various types of Programmable Logic Controllers from other manufacturers and efficient consultation services to meet your automation requirements.

To know how each product can assist you with your PLC requirements, visit our list of RAM Automations products or contact our team for further assistance. Take advantage of the capabilities of PLCs to make your industrial automation systems superior to your rivals.

0 notes

Text

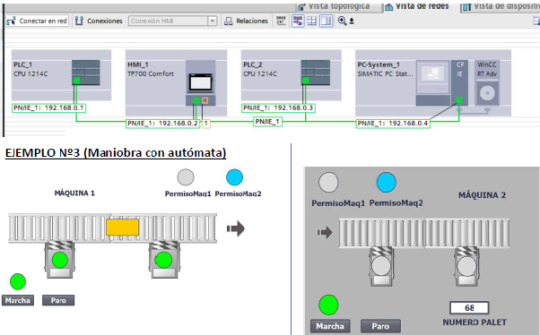

Comunicación PLC S7-1200 por PROFINET

En este tutorial encontraremos la configuración de dispositivos de control y monitorización para suintegración en la cadena productiva. Conexión de varios PLC y SCADA mediante una rede de comunicación ProfiNet con TIA PORTAL. red de comunicación y ejemplos scada WINCC siemens La comunicación process field net que es un acrónimo, es un protocolo de comunicación basado en ethernet industrial bajo…

View On WordPress

0 notes

Text

SCADA - certification

Linkedin learning route:

learn industrial automation

Learning PLC ladder logic - take this course first ...

this is the diving deeper part 2 version of the course above

For Chapter 4 programming use this course:

0 notes

Link

#what is digital marketing#digitalmarketinginhindi#digital marketing tutorial#digital marketing#introductiontodigitalmarketinginhindi#digitalmarketingforbeginners#emetechnologies#mohali#chandigarh#industrial training#java#php#android#networking#sixmonthindustrialtraininginmohali#plc#scada#embedded#seo#ppc#cpc#youtube#google

1 note

·

View note

Text

How can I start PLC SCADA training, and how can I get a job?

There are so many websites that provide online courses in industrial automation. Also there are so many videos in YouTube about plc, Scada tutorial. Download the videos, install some plc, Scada software's and learn.

Getting job is not so easy because there are not so much vacancies in case of industrial automation. But try hard learn about plc, Scada, HMI etc. You will get a job.

To start career in PLC, SCADA industry, make sure you know the basic concepts of Electronics and Instrumentation. Moreover, try to do a full-fledged course on PLC and SCADA and cover the basics of the same.

Get well versed with one of the programming languages of PLC and try solving various problem statements from any of the available source. If you are placed or working in any of automation industries, try to learn the hardware architecture, the basic wiring connections and get used to the software available.

Also, if you are interested in learning various programming languages of PLC, firstly make sure you know the complete process in and out. Then spend some time in testing the outputs based on various inputs. You can also start drawing control logic diagrams for the solutions, which certainly helps in the actual programming.

As far as SCADA is concerned, it involves the functions of monitoring. The overall understanding of the process will itself simplify the operation of SCADA for an individual. Moreover, also learn to create the objects in SCADA by using various scripting languages.

If you are searching for project based training in Pakistan then Lyskills is the best option to get hands on experience with real life projects.

1 note

·

View note

Video

tumblr

Learn Plc & Servo & HMI & Drives etc. Programming with us at Udemy ! Keep following us .. Keep learning from us .. Codesys : https://www.udemy.com/course/codesys-fundamentals-course-supported-by-beckhoff-software/?couponCode=BEDOMAY VFD : https://www.udemy.com/course/delta-vfd-real-applications-with-plc-modbus-hmi-vfdsoft/?couponCode=BEDOMAY Eplan : https://www.udemy.com/course/eplan-p8-27-tutorial-basics-with-electrical-board-basics/?couponCode=BEDOMAY Industrial Automation : https://www.udemy.com/course/industrial-automation-and-electrical-board-basics-with-plcs/?couponCode=BEDOMAY Scada : https://www.udemy.com/course/create-your-own-scada-for-plc-with-c-language/?couponCode=BEDOMAY Arduino : https://www.udemy.com/course/learn-arduino-programming-with-applications-all-in-one/?couponCode=BEDOMAY Lenze : https://www.udemy.com/course/lenze-plc-programming-basics-all-in-one/?couponCode=BEDOMAY Siemens : https://www.udemy.com/course/siemens-plc-programming-basics-all-in-one/?couponCode=BEDOMAY Fatek : https://www.udemy.com/course/fatek-plc-programming-basics-with-applications-all-in-one/?couponCode=BEDOMAY Schneider : https://www.udemy.com/course/learn-schneider-plc-programming-with-tm221/?couponCode=BEDOMAY Mitsubishi : https://www.udemy.com/course/mitsubishi-plc-programming-basics-all-in-one/?couponCode=BEDOMAY Omron : https://www.udemy.com/course/omron-plc-programming-basics/?couponCode=BEDOMAY Delta : https://www.udemy.com/course/complete-delta-plc-programming-tips-and-tricks/?couponCode=BEDOMAY

Best Regards , Mustafa

#derstagramakademi #derstagramudemy #udemycourses #plcprogramming #plctutorials #eplantutorial #vfdtutorial #learnindustrialautomation #learncsharp #scada #HMI #learnHMI #HMITutorials #omronplc #deltaplc #siemensplcprogramming #learnsiemens #plcprogrammingbasics #learnlenze #lenze #lenzevfd #lenzeplc #eplanelectrical #learnarduino #arduinoprogramming #programming #coding #automation #robotics #sysmacstudio #cxone #ıspsoft #plcdesigner #tiaportal #wplsoft #visualstudio #iot #arduinobasics #electronictutorials #industrialautomationtutorials #deltaelectronics #omronindustrial #viral #kesfet #electricity #electrical #industrymachines #derstagramplcourses #electronictutorialbasics #learnelectricsandelectronic #mitsubishiplcprogrammmingbasics #mitsubishiplc #plctutorials #gxworks #gtdesigner #mitsubishiplc #mitsubishiplcbasics #learnplcprogrammingbasicstutorials #winproladder #fatekplcprogrammimg #fatekplc #fatekprograms

0 notes

Text

IPCS GLOBAL PUNE

python

what is python

Python is a popular programming language used for a variety of applications such as web development, software development, scripting, artificial intelligence, and more. Python is known for its simple syntax, making it a great language for beginners to learn. Python also has a large and active community, making it easy to find help and support.

what is the importance of python in 2023

Python is an incredibly versatile language that has been gaining in popularity over the last few years. In 2023, it is likely to become even more important as businesses and developers look to use Python to solve more complex problems. Python is being used in fields such as machine learning, data science, web development, and automation. Additionally, Python is becoming increasingly popular in the gaming industry, as well as in areas like finance and healthcare. Python will continue to be an important language in 2023 and beyond.

why not python

Python is a great language for many tasks, but there are some drawbacks to consider. One of the main drawbacks is performance, as Python is not as fast as some other languages such as C++. Additionally, Python can be difficult to debug, as the syntax can be confusing. Finally, Python is not the best choice for mobile development, as it is not optimised for mobile devices.

why ipcs is good to learn python

IPCS is a great resource for learning Python because it offers comprehensive and interactive tutorials, as well as a wide range of resources to help you develop your skills. Additionally, IPCS provides helpful tools to help you debug your code and understand various concepts. Furthermore, IPCS offers support for a variety of platforms, such as Windows, Mac, and Linux, as well as programming languages like C, C++, Java, and more.

Ipcs global pune

Candidates with experience are in high demand. Ipcs global, the world's leading technical training institute, capitalises on this opportunity by launching their Quality Service in Pune. ipcs global is an ISO certified company that provides quality courses that are both nationally and internationally accredited.Our goal is to provide the best digital marketing course in Pune as well as industrial automation courses, PLC course, CCTV course, SCADA course, Python course in Pune at reasonable prices. Guaranteed 100% placements at top MNC companies for all students who successfully completed the course.

To join or for more information visit our website www.ipcsglobal.com

0 notes

Text

What Is PLC and SCADA? 2025 Beginners Guide

In the modern industrial world, automation is key to ensuring efficient, reliable, and safe operations. Two of the most important technologies behind industrial automation are PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). These systems are widely used across various industries, including manufacturing, power generation, oil and gas, water treatment, and transportation. This guide provides a clear understanding of what PLC and SCADA are, how they function, and how they work together to streamline industrial operations.

Understanding PLC: The Core of Industrial Automation

A Programmable Logic Controller (PLC) is a rugged digital computer designed specifically for controlling industrial machines and processes. It replaces traditional relay-based control systems and offers flexibility, reliability, and ease of programming.

PLCs are used to automate repetitive tasks. They receive input signals from sensors, process those signals according to a programmed logic, and then trigger appropriate outputs. These outputs can be used to control motors, solenoids, alarms, or other machinery.

One of the main advantages of PLCs is their ability to withstand harsh industrial environments. They are resistant to vibration, electrical noise, extreme temperatures, and dust, making them ideal for use in factories and processing plants.

Components of a PLC System

A basic PLC system includes the following components:

CPU (Central Processing Unit): The brain of the PLC that executes the control logic.

Power Supply: Provides the necessary voltage to the PLC system.

Input/Output Modules: Interface with field devices like sensors and actuators.

Programming Device: Used to write and transfer the logic to the CPU.

Communication Ports: Allow the PLC to connect with SCADA or other PLCs.

Introduction to SCADA: Centralized Monitoring and Control

While PLCs perform local control, SCADA (Supervisory Control and Data Acquisition) provides centralized supervision. SCADA is a software-based system that monitors and controls industrial processes from a central location.

SCADA systems collect data from PLCs and other control devices, display it in a user-friendly graphical format, and store it for future analysis. Operators can monitor equipment status, receive alarms, and send control commands from a SCADA interface.

SCADA is essential in large-scale operations where physical presence at every machine or sensor is not feasible. It allows industries to maintain control over complex systems spread across multiple locations.

Key Features of SCADA Systems

Real-Time Data Acquisition: Gathers data from field devices continuously.

Graphical User Interface (GUI): Displays process visuals for operators.

Alarm Management: Notifies operators of abnormal conditions.

Data Logging and Reporting: Stores historical data for audits and performance evaluation.

Remote Control: Enables operators to control equipment from a distance.

How PLC and SCADA Work Together

In most industrial setups, PLCs are responsible for direct control of machinery. They process sensor data and control outputs based on pre-defined logic. SCADA, on the other hand, acts as a higher-level system that collects data from multiple PLCs, analyzes it, and presents it to operators.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while SCADA provides a dashboard showing water levels, chemical dosages, and system status in real-time. If there is a problem, SCADA alerts the operator, who can then take corrective action remotely.

Applications of PLC and SCADA

The combined use of PLC and SCADA systems is common in many sectors:

Manufacturing: For managing automated assembly lines.

Power Plants: For monitoring turbines, generators, and safety systems.

Water Treatment: For controlling pumps, valves, and chemical dosing.

Oil and Gas: For pipeline monitoring, storage management, and leak detection.

Transportation: For traffic signal control and railway automation.

Benefits of Integrating PLC and SCADA

Improved Efficiency: Automation reduces human error and increases throughput.

Remote Monitoring: Operators can control systems from central control rooms.

Reduced Downtime: Quick response to system failures minimizes interruptions.

Data-Driven Decisions: Real-time and historical data support informed planning.

Cost Savings: Optimized operations lower operational and maintenance costs.

Conclusion

PLC and SCADA systems are foundational technologies in industrial automation. PLCs handle the core control functions at the equipment level, while SCADA provides real-time monitoring and centralized management. Together, they create a powerful system that improves reliability, safety, and efficiency in complex industrial environments.

As industries continue to evolve with Industry 4.0 and smart technologies, the integration of PLC and SCADA will become even more critical. Understanding these systems is essential for engineers, technicians, and anyone aspiring to work in the field of automation.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Link

#automation course#industrial automation course#plc scada course#scada course#learn industrial automation

0 notes

Video

youtube

All In ONE Full SCADA || Tutorial || KepServer || InTouch || Real Project

Time Lapse 00:00 digital alarm in inouch scada 04:36 intouch scada security define and understanding 09:11 Learn Trends in SCADA system (Wonderware - Intouch) 14:45 Mitushibishi plc with intouch scada interface using kepserver 20:47 Project programming + scada Design + interfacing 31:32 Scada interfacing with PLC and VFD. 34:40 SCADA controlled Grid Sub Station project demo Scada: Supervisory control and data acquisition is a control system architecture comprising computers, networked data communications, and graphical user interfaces for high-level process supervisory management For more queries feel free to comment down or you can contact us: Cont- 7835000219/ 8740000990 E-Mail ID – [email protected] Website:- visionautomationsolutions.in #python #programming #coding #java #javascript #programmer #snake #developer #html #machinelearning #code #coder #computerscience #pythonprogramming #ballpython #datascience #technology #reptile #snakes #reptiles #reptilesofinstagram #snakesofinstagram #css #php #linux #pythonsofinstagram #tech #webdeveloper #artificialintelligence #bhfyp

0 notes

Text

Are you needing an MES for your own personal manufacturer floor | The Floor Attached Jib Crane is also a Good Addition

Every part of typically the manufacturer floor needs to help be as successful like possible in order to be able to manufacture as much products while possible. This means you have a floor jib crane at every workstation, thorough worker training, robotics utilized in suitable places, in addition to maybe even a good USES. Because generally speaking, you can find two major categories regarding manufacturing plant floor system s around the market plus each help lessen command in addition to analyze manufacturer exercises.

Anyone can group these systems into two categories. The foremost is SCADA (Supervisory Control plus Data Acquisition), which controls machines and equipment. The second reason is MES (Manufacturing Execution System), which controls the pursuits in the factory floor both inside and between each and every function. SCADAs main emphasis is definitely computers (also recognized as pré-réglable logic controllers or PLCs) to command the equipment movements and have information such as velocities, guides, temperature, pressure, and many others. Labour tracking is supplementary, if at all. The MES can be focused upon ensuring of which the entire production process and all its activities happen to be controlled to boost efficiency, minimize waste, and even improve this accuracy together with timeliness regarding production data. MES may control activities starting from stuff troubles, all the way via to the operational activities to finished items. This particular assures the answerability connected with all the resources demanded (labor, machines, tools) together with needed documents (job bundle, WIP tags, instructions, getting, high quality sheets, and moment bed linens, etc. ) will be accessible in one system. Equally programs minimize or perhaps eradicate tutorial activity, and boost precision and trustworthiness in making parts. SCADA the use is with this products and can get tied on a factory system to an OPC (Open Process Control) Machine. MES integration is mainly from your ERP system. The use can also be to a document library or even payroll systems (for As well as Attendance). Integration could be having machines (without SCADA) via an OPC Server to assist typically the agent in accounting regarding development and identifying recovery time plus other OEE (Overall Devices Effectiveness) analytics. Click here for even more details a lot more about OEE (http://factivity.com/why-factory-floor-automation-projects-fail/). MES also must have the easy-to-use operator Consumer User interface (UI). The Person Knowledge (UX) must be straightforward and perceptive. Details have to be captured by means of thrust buttons on effect screens and unique particular intelligent keypads promoting the “one-click” approach to production plus labor tracking. Dispatching will be dynamic adjusting to flooring and customer changes instantly usually from an State-of-the-art Planning and Scheduling System (APS) that can time frame and reschedule with finite (level loading) accuracy and reliability in seconds. To find out more on APS follow that link. By way of coordinating all of the activities and even resources, typically the MES provides a paperless system (electronic, real-time in addition to interactive) regarding improving this accuracy in addition to timeliness regarding floor activities. As a result, workers and supervisors have fast feedback on performance when management has detail and even granular analytics for trim manufacturing process improvements.

0 notes

Text

Are you needing an MES for the plant floor | Some sort of Floor Installed Jib Crane System is as well a Very good Addition

Every part of this manufacturing plant floor needs to be as productive because possible in order to help manufacture as many products while possible. This means you have a floor installed jib crane at every workstation, extensive staff member training, robotics utilized in pertinent places, together with maybe even a great USES. Because generally speaking, there are two major categories associated with stock floor systems in the market and both equally help minimize deal with and even analyze factory exercises. Anyone can group these techniques into two categories. The first is SCADA (Supervisory Control and even Data Acquisition), which control buttons machines and equipment. The second is MES (Manufacturing Execution System), which controls the routines in the factory floor the two inside of and between each function. SCADAs main concentration is definitely computers (also known as programmable logic remotes or PLCs) to regulate the equipment movements and acquire information such as velocities, passes, temperature, pressure, and so forth. Job tracking is 2nd, if at all. The MES can be focused about ensuring of which the entire production method and all its routines will be controlled to improve efficiency, lessen waste, together with improve the accuracy in addition to timeliness associated with production facts. MES can certainly control exercises starting from stuff troubles, all the way by to the functioning working routines to finished merchandise. That assures the answerability regarding all the resources recommended (labor, machines, tools) plus important documents (job package, WIP tags, instructions, pulling in, high quality sheets, and time period bed linens, etc. ) can be available in one system. Both systems minimize as well as reduce tutorial activity, and maximize reliability and trustworthiness in making elements. SCADA the usage is with often the devices and can become tied over a factory system to an OPC (Open Process Control) Machine. plant floor system is mainly from the ERP system. Incorporation can certainly be to a document library as well as payroll systems (for Some Attendance). Integration can certainly be with machines (without SCADA) via an OPC Hardware to assist this operator in accounting for manufacturing and identifying outages in addition to other OEE (Overall Products Effectiveness) analytics. Click in this article for a great deal more facts even more about OEE (http://factivity.com/why-factory-floor-automation-projects-fail/). MES also must have a easy-to-use operator User User interface (UI). The End user Practical experience (UX) must be very simple and perceptive. Information will need to be captured through press buttons on contact screens and unique particular smart keypads promoting a new “one-click” approach to manufacturing plus labor tracking. Dispatching is usually dynamic adjusting to flooring and customer changes instantly frequently from a good State-of-the-art Arranging and Scheduling Process (APS) that can schedule and reschedule with only a certain (level loading) accuracy and reliability throughout seconds. For more information on APS comply with this particular link. By simply coordinating all the activities plus resources, the MES gives a paperless system (electronic, real-time and interactive) to get improving the accuracy in addition to timeliness associated with floor pursuits. As a result, providers and supervisors have instant feedback on performance whilst management has detail plus granular analytics for trim manufacturing process improvements.

0 notes

Text

Are you needing an MES for your own stock floor | The Floor Attached Jib Crane System is as well a Fine Addition

Every part of the particular manufacturer floor needs to be as successful while possible in order to manufacture as numerous products while possible. This means you will have a floor mounted jib crane at every workstation, thorough employee training, robotics utilized in appropriate places, in addition to maybe even an USES. Because generally speaking, one can find two major categories associated with stock floor systems around the market together with equally help limit handle and even analyze stock actions. You can group these systems into two categories. An example may be SCADA (Supervisory Control and Data Acquisition), which regulates machines and equipment. The second is MES (Manufacturing Execution System), which controls the pursuits for the factory floor equally within just and between every function. SCADAs main concentrate is definitely computers (also acknowledged as programmable logic controllers or PLCs) to manage the equipment movements and obtain information such as speeds, passes, temperature, pressure, and so forth. Labor tracking is second, whenever. The MES is definitely focused on ensuring the fact that the entire production approach and all its exercises will be controlled to increase performance, reduce waste, plus improve the particular accuracy and timeliness associated with production details. MES could control actions starting from product troubles, all the way by means of to the functioning working pursuits to finished goods. This specific guarantees the answerability of all the resources needed (labor, machines, tools) in addition to necessary documents (job package, WIP tags, instructions, pulling, quality sheets, and time bed sheets, etc. ) are usually offered in one system. Both equally devices minimize as well as reduce tutorial activity, in addition to take full advantage of precision and stability in making components. SCADA integration is with this products and can become tied with a factory circle to an OPC (Open Process Control) Web server. MES integration is mainly through the ERP system. plant floor system can even be to a document catalogue or even payroll systems (for As well as Attendance). Integration can certainly be using machines (without SCADA) with an OPC Server to assist typically the user in accounting intended for production and identifying recovery time and even other OEE (Overall Tools Effectiveness) analytics. Click right here for more details even more about OEE (http://factivity.com/why-factory-floor-automation-projects-fail/). USES also must have a easy-to-use operator Person Screen (UI). The User Encounter (UX) must be very simple and user-friendly. Information ought to be captured by means of drive buttons on contact displays and unique specialised intelligent keypads promoting some sort of “one-click” approach to creation and labor tracking. Dispatching can be dynamic adjusting to floorboards and even customer changes quickly usually from a great Advanced Organizing and Scheduling Technique (APS) that can program and reschedule with only a certain (level loading) accuracy throughout seconds. For more information on APS stick to this specific link. By means of coordinating the many activities together with resources, typically the MES delivers a paperless system (electronic, real-time and even interactive) to get improving this accuracy in addition to timeliness involving floor pursuits. As a result, employees and supervisors have fast feedback on performance whilst management has detail in addition to granular analytics for small manufacturing process improvements.

0 notes

Text

Do you really need an MES for your own factory floor | A Floor Fitted Jib Crane is likewise a Very good Addition

Every part of the particular stock floor needs to be able to be as useful like possible in order for you to manufacture as numerous products since possible. This means you then have a floor jib crane system at every workstation, thorough employee training, robotics applied in relevant places, together with maybe even the MES. Because generally speaking, you will find two major categories of factory floor systems throughout the market and even the two help lessen deal with together with analyze manufacturer actions. A person can group these systems into two categories. The very first is SCADA (Supervisory Control in addition to Data Acquisition), which regulates machines and equipment. The second is MES (Manufacturing Execution System), which controls the pursuits within the factory floor each inside of and between each one operation. SCADAs main emphasis is definitely computers (also known as programmable logic controllers or PLCs) to command the equipment movements and uncover information such as connections, feeder, temperature, pressure, and so forth. Work tracking is second, if.

floor installed jib crane is usually focused with ensuring that will the entire production method and all its exercises are controlled to boost proficiency, reduce waste, plus enhance often the accuracy in addition to timeliness connected with production facts. MES can certainly control actions starting from product problems, all the way through to the in business activities to finished goods. This kind of promises the responsibility connected with all the resources required (labor, machines, tools) in addition to necessary documents (job bundle, WIP tags, instructions, pulling, level of quality sheets, and time period bed sheets, etc. ) can be accessible in one system. The two methods minimize or perhaps remove tutorial activity, in addition to take full advantage of accuracy and reliability and stability in making areas. SCADA the use is with the particular tools and can be tied over a factory network to an OPC (Open Process Control) Web server. USES integration is mainly from the ERP system. Whole body can also be to a document library or payroll systems (for Some Attendance). Integration can be using machines (without SCADA) by using a OPC Machine to assist typically the agent in accounting intended for creation and identifying downtime in addition to other OEE (Overall Products Effectiveness) analytics. Click below for additional information a great deal more about OEE (http://factivity.com/why-factory-floor-automation-projects-fail/). USES also must have a great easy-to-use operator End user Screen (UI). The End user Practical experience (UX) must be basic and user-friendly. Facts have to be captured by way of force buttons on contact window screens and unique specialised clever keypads promoting a good “one-click” approach to manufacturing together with labor tracking. Dispatching is usually dynamic adjusting to floorboards plus customer changes immediately often from a good Superior Planning and Scheduling Method (APS) that can arrange and reschedule with finite (level loading) reliability throughout seconds. For more info on APS comply with that link. By simply coordinating all the activities and resources, the MES offers a paperless system (electronic, real-time in addition to interactive) for improving the accuracy together with timeliness associated with floor exercises. As a result, workers and supervisors have instant feedback on performance even though management has detail and even granular analytics for trim manufacturing process improvements.

0 notes