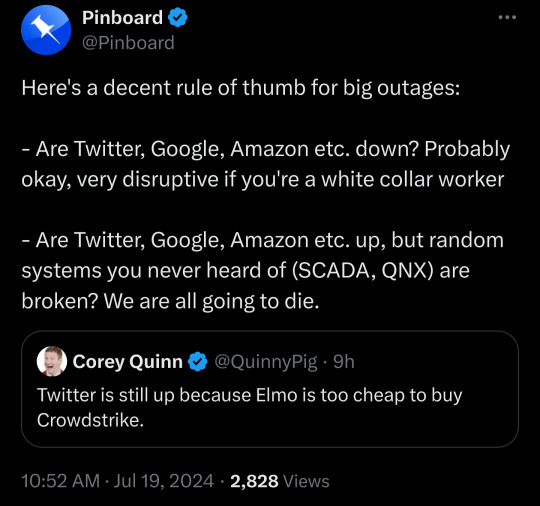

#scada

Explore tagged Tumblr posts

Text

4K notes

·

View notes

Text

Hi guys!! This was a wild impulse series of drawings that I had no intention of finishing and yet here we are- uhhh. I'm also finally moving so to my mutuals: I am VERY sorry if I am m.i.a most of this week 🫡

Quick oc Ramble before I finish up with my plans for today!

Favorite Oc: Ichor! I've posted about him before, but he's *technically* also my very first utmv oc. (I decided there were no repeats-) Ichor has been here since the start of my obsession and still haunts me today. He's a Diety of Punishment after death, but was chained in shackles that restrict his powers, so instead of a God of Punishment, he's the self-proclaimed God or Puns!

First OC: I'm almost 90% sure his name isn't actually Scada but we're rolling with it. This was my 2nd-ish oc for utmv! In his universe, instead of Dusting monsters turn into a weird soul-goop. He's always had weak HP so when he almost died to something stupid one day as a kid, he expended a lot of magic to keep himself alive. His father, Gaster, wasn't very happy that his son was now half-dead so Scada was heavily separated from busy places like the capital and the whole family picked up and moved to Snowdin!

Latest OC: Phishbone. Phishbone was a Papyrus from a universe where Gaster (his father) took both him and Sans to the lab. Gaster trained Sans in the soul studies, but taught Papyrus how to weird concentrated human souls. Because Paps loved puzzles, Gaster constructed a rubix-cuve to contain soul essence for Paps to use in emergencies. When the universe corrupted, Core Frisk was only able to salvage Phishbone. He saw turmoil in the multiverse and decided that he'd set some things right! He has a pocket dimension where he can control anything about it, and usually pulls fueding people into it to force them to play games and use teamwork to overcome their frustration and escape!

Easiest to Draw OC: B.G. Sans (Bubble Gum Sans). She was a skeleton monster who just barely survived the war on the surface. Having been blinded by humans, Gaster took her in and helped her to live underground. She was the "Royal Seer", and was only able to see visions of the future (ex. The freedom of monsterkind). Her brother Gaster had two sons, Sans (who was named after her) and Papyrus. One day a human cornered BG and her nephews in the lab, and she was killed protecting them. Her soul was taken to The Void, and everyone but her family forgot her. Now she and Gaster control the void together, and 1 by 1 all the monsters underground escape the resets and join the Void!

Hardest to Draw OC: Ec-4o.Verse Ink. This guy is a menace. I designed him to have several robotic body parts to resemble a chimera, but I forget where they are at all times. + I always hate his outfit design??? He's on my list to fix his outfit.

#utmv#utmv sans#oc#utmv oc#my art#spot!drawn#ichor#ichor sans#punishment sans#catacombtale#scada#scada sans#phishbone#b.g. sans#b.g.#bg sans#betweentale#ec-4o!ink#ec-4o.verse#N#<- I really really didn't want to draw her smh

30 notes

·

View notes

Text

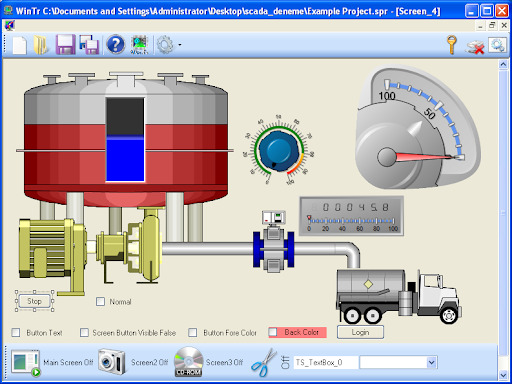

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

8 notes

·

View notes

Text

AVEVA System Platform Key Features

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#allen bradley#rockwell automation#plc#AVEVA#SCADA#HMI#Powerflex#VFD

2 notes

·

View notes

Text

Design and Implementation of Manufacturing Factory SCADA UI

Full video: 2D/2.5D Digital Twin Factory | SCADA | Factory Assembly Line | スマートファクトリー - YouTube

0 notes

Text

Substation Automation System (SCADA)(SAS)

We are the leading service provider for substation automation system SCADA, or Supervisory Control and Data Acquisition management.

0 notes

Text

NX-ERA Xpress PLC For salt spray Chamber Automation

In the industrial domain, corrosion is not just a problem, it’s a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That’s where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we’re demonstrating to you why a salt spray chamber needs aSCADA for demanding environments that’s fluent in Industry 4.0.

#plc#micro plc#mini plc#salt spray chamber#compact plc#modular plc#compact plc for industrial automation#programmable logic controllers#and today we’re demonstrating to you why a salt spray chamber n#rugged modular PLC#industry 4.0#PLC (Programmable Logic Controller)#SCADA

0 notes

Text

🔐 Andres Prieto Anton: Guarding the Future of Critical Infrastructure ⚙️🌍 What happens when cybersecurity expertise meets industrial innovation? You get leaders like Andres Prieto, redefining how we protect OT (Operational Technology) and Industrial Control Systems (ICS). 💡💻

From traditional IT roots to becoming a specialist in OT security, Andres bridges the complex world of real-time operations with next-gen cyber defense. His mission? To secure what matters most—from energy grids to factory floors—with people-first, risk-aware strategies. 🏭⚠️

🔹 Championing AI-driven threat detection 🔹 Advocating for tailored training for OT personnel 🔹 Leading with proactive, not reactive cybersecurity 🔹 Promoting cross-functional collaboration between IT & OT

His advice for aspiring professionals? ✅ Learn both IT & OT fundamentals ✅ Build trust across disciplines ✅ Stay curious, stay committed ✅ Balance innovation with empathy

🙌 As Andres says: "Cybersecurity is about more than systems—it's about people, purpose, and progress."

👉 Explore more about:- https://www.allaroundworlds.com/journey-of-andres-prieto-anton/

#Cybersecurity#OTSecurity#IndustrialCybersecurity#ICS#CriticalInfrastructure#AIinCybersecurity#AndresPrietoAnton#SecurityLeadership#SCADA#ITOT#SmartFactories#RiskManagement#PeopleFirstSecurity#CyberAwareness#CyberInnovation#DefendCriticalSystems

0 notes

Text

SCADA iFIX: надежная платформа для автоматизации и диспетчеризации производства

Современное промышленное предприятие требует не только высокой производительности, но и полной прозрачности всех процессов. Для этого необходимы надежные решения, обеспечивающие контроль в реальном времени, быструю реакцию на отклонения и сокращение простоев. Одним из таких инструментов является SCADA iFIX — мощная система визуализации и управления от GE Vernova, признанная во всем мире. Что…

0 notes

Text

Industrial Automation Training Courses Online Australia

Industrial automation is changing how industries operate. Across Australia, demand for skilled automation professionals is rising. To meet this demand, many institutions now offer Industrial Automation Training Courses Online Australia. These courses equip learners with key technical skills, industry tools, and certifications from the comfort of their homes.

Industrial Automation Training Courses Online Australia In this guide, we explore the scope, types, and benefits of these courses. We’ll also provide technical insights, cover course content, and help you choose the best course to fit your goals.

Why Choose Industrial Automation Training Courses Online Australia

The world is becoming more digital. Industries across Australia—from mining to manufacturing—are rapidly adopting automation. Online training provides a flexible and cost-effective way to learn the necessary skills. Whether you’re an engineering student or a technician seeking upskilling, these industrial automation training courses online Australia are tailored to diverse learning needs. They allow working professionals to study without disrupting their job schedules.

Key Technologies Covered in Industrial Automation Training Courses Online Australia

Courses in Australia focus on real-world skills. Here are some of the key technologies you will study: - Programmable Logic Controllers (PLCs) - Human Machine Interface (HMI) - Supervisory Control and Data Acquisition (SCADA) - Industrial Networking - Sensors and Actuators - Distributed Control Systems (DCS) - Robotics and Motion Control You will also gain exposure to software tools such as Siemens TIA Portal, Allen Bradley RSLogix, and LabVIEW.

Career Benefits of Enrolling in Industrial Automation Training Courses Online Australia

Professionals with automation expertise are in high demand. Here’s what you gain: - Better job prospects in manufacturing, oil & gas, and utilities - Industry-recognized certifications - Strong salary growth - Hands-on experience with industrial control systems - Pathways to international employment opportunities #IndustrialAutomation, #AutomationTraining, #OnlineCoursesAustralia, #PLCTraining, #SCADAOnline, #IndustrialTraining, #AutomationEngineering, #MechatronicsCourses, #ElectricalAutomation, #ProcessAutomation, #AutomationAustralia, #OnlineIndustrialCourses, #ControlSystemsTraining, #AutomationSkills, #SmartManufacturing Read the full article

#AustraliaEducation#AutomationSkills#ElectricalEngineering#EngineeringTraining#IndustrialAutomation#Mechatronics#OnlineTraining#PLCCourses#SCADA#TechnicalCertification

0 notes

Text

🚀 Successfully installed SCADA BR on our ARMxy BL410 industrial gateway! With its stable performance and flexible expansion, BL410 seamlessly supports SCADA BR to deliver reliable real-time monitoring and control across industrial applications. A powerful step toward smarter, more connected operations. 🌐

0 notes

Text

Other communication options are available in PowerFlex 525 AC Drives

The PowerFlex 525 AC Drives provide a variety of connection options in addition to typical EtherNet/IP connectivity to guarantee smooth integration with different industrial networks. These drives provide various networking setups by supporting optional dual-port EtherNet/IP, DeviceNet, and Modbus RTU protocols. Communication adapter modules allow them to interact with protocols including ControlNet, BACnet, and Profibus DP. Because of its adaptability, users may connect to various control systems without requiring significant hardware modifications, making the PowerFlex 525 perfect for a variety of automation scenarios. Easy configuration and connectivity are further improved by embedded Ethernet and built-in USB programming.

#automation#technology#tech#technical#AVEVA#PLC#HMI#SCADA#scada systems#industrial#industries#Allen Bradley#Rockwell Automation#Tech#Automotive

2 notes

·

View notes

Text

🌍 Join Trinity Touch at Intersolar Europe 2025 – Munich, Germany 🌍

We are excited to present Trinity Touch’s latest innovations designed to power the future of solar power plants and clean energy infrastructure.

🚀 Explore our advanced range of solutions, including: ☀️ String Monitoring Systems 📊 Next-Gen SCADA Systems 🌦 Weather Monitoring Units 🛡 Integrated Cybersecurity Solutions

With 75+ GW of solar systems delivered, we’re proud to support the global transition to renewable energy.

🔧 Dive into our in-house manufacturing capabilities featuring: Enclosures | Wiring Ducts | Cable Glands | DIN Rails | String Monitoring Boards

Let’s shape a sustainable future—together.

📍 Meet us at: Hall B4 | Stall 670 📅 May 7–9, 2025 📌 Messe München, Germany

💬 Connect with us: 📞 +91 11 71200900 📱 WhatsApp: +91 9911717900 ✉️ [email protected] 🌐 www.trinitytouch.com

#Intersolar2025#TrinityTouch#SolarInnovation#SmartEnergy#CleanEnergy#EVCharging#SCADA#SustainableFuture#MadeInIndia#Renewables#EnergyTech#GlobalExhibitions

0 notes

Text

Digital Management System for Copper Mine Factory | Web UI Design

Demo Collection: https://hightopo.com/demos/en-index.html

1 note

·

View note

Text

The Importance of PLC in Industrial Automation

Introduction

By enhancing productivity, optimizing the process, and lowering operational costs, industrial automation has transformed the way industries operate. The Programmable Logic Controller (PLC), a dedicated computer used for the automation of industrial equipment and processes, is an important part of this transition. With their flexibility, reliability, and real-time control capabilities, PLC have become a cornerstone of contemporary automation systems.

PLC in Industrial Automation once seemed like machines manufactured only for the automation of various industrial machinery, but little did we know that they are a rugged and reliable computing system that can run efficiently in industrial circumstances that seem impossible.

What is Automation?

Automation is the application of technology to produce and deliver goods and services with minimal human intervention. It is commonly used in parallel fields to improve efficiency and minimize mistakes. Automation can consist of mechanical systems or software applications used in conjunction with specialized automation and/or artificial intelligence technologies in order to provide functionality in operations.

Advantages of Automation:

Speed up processes: work does not get tired like men, machines run continuously.

Cutting of cost: Automation requires less human power which leads to reduction of cost.

Reduction in Errors: Automation reduces the margin of error and improves the reliability of data and consistency of processes.

Scalability: A business can grow and not have to pay a bank to become big.

In most of the fields, we have automation like in manufacturing, IT, marketing, customer service, etc., where it is used to reduce the effort in repetitive tasks, to optimize the utilization of resources, and improve overall efficiencies.

What is Industrial Automation?

Industrial automation involves the use of control systems, such as computers or robots for handling different processes and machinery for the industry to operate with minimal or reduced human intervention. It finds application across a range of industries including manufacturing, energy, pharmaceuticals, automotive, and food processing.

Key Advantages of Industrial Automation

More Efficiency: Machines do operating continuously which increases the output.

Enhanced Quality: Automation results in maintaining consistency and thus helps with minimizing defects.

Cost Reduction: Decreases labor costs and increases energy efficiency.

Improved safety: Removes humans from dangerous situations.

Industrial automation has been transformed based on the concept of smart factories powered by AI, IoT and robotics driven state-of-the-art decision making and production optimized through complex networked devices and systems, ushering forth Industry 4.0.

Understanding PLC in Industrial Automation

Programmable Logic Controller, a programmable computer used for process automation, to control machinery, to monitor production processes, and to maintain efficiency. PLC differ from traditional computers, as they need to operate in harsh industrial environments that can include extreme temperatures, a large amount of dust, and vibrations.

Key Features of PLC:

Immediate Control: PLC analyze sensor data in real-time, maintaining operational stability.

Adaptability: Should be quickly re-programmable for new tasks and changes.

Reliability: Runs smoothly in extreme conditions.

Communication: Connects to supervisory systems for monitoring and decision making.

PLC are at the heart of all of this, running assembly lines, monitoring environmental conditions, controlling energy in our buildings, and maintaining product quality. These serve as the core of industrial automation, enabling the industries to bring forth tasks with higher productivity, while minimizing the downtime, along with the cost.

Conclusion

PLC play a key role in industrial automation by providing accuracy, efficiency, and safety for industrial processes. The PLC in Industrial 4.0 Whether it is the smart manufacturing adopted decisions across industries, the role of PLC will further blossom, resulting in smart manufacturing, sustainable, and productive production environments. PLC are cost-effective automation solutions for today, for industries to remain competitive in the future global market.

0 notes

Text

Enhancing Salt Spray Chamber Performance with PLC Automation – Powered by NX-ERA Xpress

In the industrial domain, corrosion is not just a problem, it's a stealthy destroyer. From car parts to ocean gear to electronics, the shadow of rust looms over all. That's where the salt spray chamber comes in useful, enabling us to simulate the most extreme conditions. However, the catch is that manual systems don’t cut it anymore.

Enter the NX-ERA Xpress PLC—a smart, compact PLC for industrial automation that’s changing the game for good.

We at Messung have a strong expertise in programmable logic controllers, and today we're demonstrating to you why a salt spray chamber needs a rugged modular PLC for demanding environments that's fluent in Industry 4.0.

What is a Salt Spray Chamber?

A salt spray chamber is a specialized testing environment that helps industries evaluate the durability of coatings, components, and materials under harsh environments. These rooms are intended to:

● Simulate corrosive environments

● Test the metals, coatings, and components

● Provide accelerated ageing tests in controlled environments

Industries that swear by it:

● Automotive Companies

● Paint and Coating Producers

● Marine Equipment Manufacturers

Electronics OEMS

Why Automate Salt Spray Chambers with a PLC?

Consider switching temperatures, humidity levels, and spray intervals by hand every hour. Time-consuming, prone to error, and a time-waster. A PLC (Programmable Logic Controller) coordinates the whole process—managing logic, control, timing, and communication like a maestro directing a symphony.

Meet the NX-ERA Xpress PLC – your multi-protocol, multi-project, one seamless controller. It never sleeps, never messes up, and always provides you with accurate data. From Messung Industrial Automation, a cost-effective PLC that is MQTT and OPC UA enabled, UL certified, and ready for the most demanding automation tasks.

Key Roles of a PLC in Salt Spray Chambers

Behind each reliable corrosion test is a smart PLC working diligently to maintain consistency, compliance, and control. What it provides to the chamber is:

Precise Temperature Regulation - Dry bulb, wet bulb, ambient—all held constant with surgical accuracy by PID loops. No ups and downs, just stable, calibrated climates.

Humidity Control - Because one droplet too much or too little throws the test off balance. A smart PLC fine-tunes every moisture movement to mimic real-world conditions.

Spray System Management - Controls mist cycles, nozzle diameters, sizes, and flows to ASTM/BIS/ISO specifications. No guessing—only predictable, programmable spray patterns.

Test Cycle Automation - Start, stop, repeat—all done without ever lifting a finger. Install it once, and the PLC takes care of complex test schedules with ease and accuracy.

Alerts & Notifications - Monitors for anomalies, alerts you in real-time, and records deviations for later reference. The watchdog your lab never knew it had.

In short, a robust PLC is not just a controller—it's the brain behind every flawless salt spray test. Accuracy-driven, standards-enabled, and always on the job.

How NX-ERA Xpress PLC Transforms Salt Spray Testing

In the high-pressure world of corrosion testing, consistency and accuracy are not just a good idea, but a necessity. Manual control isn't capable of keeping up with tight industry regulation or sophisticated test cycles. That's where the NX-ERA Xpress PLC comes in—turning laborious processes into error-free, data-driven automation that produces perfect results, every time.

Let's break it down.

Accuracy with PID Control - Control temperature and humidity like an expert, with advanced PID algorithms that make continuous adjustments in both dry and wet bulb parameters. This ensures every salt spray cycle is to your exact specification—no overshoots, no drift—so you achieve flawless repeatability in every test.

Versatile I/O for Complete Control - From compressors and solenoid valves to heating coils and compressors, the modular I/O design lets you mix analogue and digital channels in any combination necessary. You have total control over each chamber component, expanding and contracting as test demands vary or grow.

Communication-Ready - Native support for MQTT, OPC UA, Modbus TCP, PROFINET, and EtherCAT allows for plug-and-play real-time data logging to your SCADA/HMI dashboards. Remote monitoring of vital parameters, automatic export of logs, and integration with your Industry 4.0 configuration become a breeze.

Custom Tests, Custom Logic - Whether ASTM B117, ISO 9227, or your own proprietary cycle, programmable sequences allow you to specify start/stop times, spray cycles, and number of repetitions. Switch to new standards with ease without re-wiring or re-engineering your setup.

Remote Diagnostics - Eliminate extraneous lab trips with integrated troubleshooting capabilities. See live status, detect faults, and edit logic remotely—so you can maintain tests operating smoothly, even from miles away.

With the NX-ERA Xpress PLC, salt spray testing is smarter, faster, and more reliable. Upgrade your chamber control today and see your lab's efficiency—and confidence—take flight.

Industry Applications

From the lab to the great outdoors, salt spray testing holds up over time in any sector. It's the gold standard for corrosion resistance testing, subjecting your products to the ultimate test of the harshest conditions, without breaking a sweat.

Automotive - Rust-proofing bumpers, body panels, and alloy wheels. Because no one wants corrosion writing their brand off.

Paint & Coating - Verify finish quality in tough conditions. Observe how your coat stands up when the weather gets nasty.

Electronics - Ensure devices do not short or fail in high-salt air zones. Because reliability should not vanish with the sea breeze.

Marine & Offshore - Replicate real sea spray on metal parts and composite structures. For wave-riding performance and not rust.

Whether you're creating for highways, oceans, or skies, salt spray testing subjects your innovations to the elements, rain or shine. Test smart. Build bold. Trust durability.

Unique Features of the NX-ERA Xpress PLC

Where ruggedness, connectivity, and accuracy meet, the NX-ERA Xpress PLC is the ideal controller for the industrial automation of the new age. Built to satisfy the tough requirements of the new factory and laboratory, it provides an ideal combination of cutting-edge features designed for accuracy.

Small, and robust structure - Designed to be flexible and space-efficient installation without sacrificing strength.

IoT-based PLC for automation control in real-time - Enables end-to-end data exchange and remote monitoring to enhance Industry 4.0 capabilities.

Supports multiple protocols natively - Enables effortless connection to industrial networks of different types like PROFINET, EtherCAT, and Modbus TCP.

Smoother is used as a mission-critical safety PLC - Designed to ensure fail-safe operation where safety is never an option.

Designed to endure tough conditions with rock-solid dependability - Built to last through the toughest conditions, providing smooth operation under trying conditions.

Together, these capabilities make the NX-ERA Xpress PLC a valuable ally in taking your automation journey with confidence and control.

IoT PLC for Industry 4.0 Labs

In a smart lab, you decide in milliseconds. You need a PLC that can talk with your MES, ERP, cloud dashboards, and even mobile applications.

NX-ERA Xpress is an intelligent programmable controller for intelligent manufacturing systems that connects, communicates, and controls. With MQTT over TLS 1.2, OPC UA, and real-time updates, it's your gateway to Industry 4.0.

Why Messung for Your Salt Spray Automation?

Where passion and precision meet, innovation happens. We combine decades of experience with automation driven by innovation to provide smart salt spray solutions designed for performance, efficiency, and durability.

● 4 Decades of Automation Experience

● Strong R&D Backing and Engineering Support

● Global system integrator network

● Economical and UL-approved PLC alternatives

● Backed by a promise—We don't just automate, we enhance.

Join forces with Messung and go beyond mere automation—into a world where quality, reliability, and intelligent control govern every result.

Final Word: Don’t Let Rust Eat Into Your Reputation

Salt spray testing is the ultimate protection in demonstrating your product's endurance. One mistake—whether it's temperature fluctuation or skipped spray cycle—can cause damage to your brand, expense in recalls, or safety malfunction. Why take the risk?

Let NX-ERA Xpress PLC, an intelligent compact PLC for industrial automation, get behind the wheel. With IoT-capable PLC functionality, multi-protocol capability such as Modbus, PROFINET, EtherCAT, OPC UA, and MQTT, it provides reliable precision you can count on. Supported by our 4 decades of automation expertise, the rugged modular PLC for extreme environments guarantees your salt spray chamber operates like clockwork—every time.

Whether you are replacing or starting from scratch, this budget PLC with MQTT and OPC UA future-proofs your test environment. Salt corrodes. But not with our NX-ERA Xpress PLC. Your performance—and your reputation—are never compromised.

FAQs

Why is NX-ERA Xpress superior to other compact PLCs?

It combines tough construction, multiprotocol support, onboard IoT capabilities, and price efficiency—all within a compact size.

Which laboratories can be served by this Smart PLC?

Any corrosion, materials, or environmental testing laboratory requiring precise, automated, and repeatable results will be significantly helped.

Is NX-ERA Xpress suitable for harsh environments?

Indeed. It's a tough PLC that can withstand heat, humidity, and electrical stress—perfect for industrial-strength test labs.

Does NX-ERA Xpress support SCADA systems?

Yes. With natively supported MQTT, OPC UA, and Modbus TCP, it integrates seamlessly with the majority of contemporary SCADA systems.

#compact PLC#programmable logic controllers#rugged modular PLC#Industry 4.0.#salt spray chamber#PLC (Programmable Logic Controller)#cost-effective PLC#robust PLC#PID Control#smart PLC#Modbus#SCADA#salt spray testing#industrial automation#IoT-based PLC for automation control

0 notes