#plcprogramming

Explore tagged Tumblr posts

Text

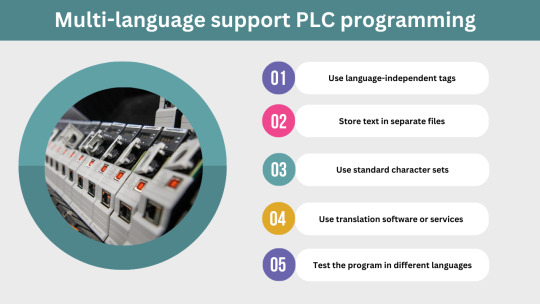

Multi-language support PLC Programming

Multiple languages in PLC (Programmable Logic Controller) programming can be crucial for various reasons, including internationalization, ease of collaboration across multinational teams, and compliance with local regulations.

IEC 61131-3 Languages

Language Selection

Internationalization and Localization

Comments and Documentation

Training and Support Materials

Standardization Across Projects

Testing and Validation

Collaboration Tools

Compliance with Regulations

Flexibility and Adaptability

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#trending#automation#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#today on tumblr#artists on tumblr#poets on tumblr#plcprogramming#technology

3 notes

·

View notes

Text

Comprehensive Engineering Services by Servotech Inc.

In the dynamic landscape of modern engineering, the demand for specialized services that drive innovation and efficiency is paramount. Servotech Inc., a leading global technology services company, stands at the forefront of this evolution, offering a diverse array of engineering and IT solutions tailored to meet the unique needs of various industries. With a commitment to excellence and a track record spanning over two decades, Servotech Inc. has established itself as a trusted partner for organizations seeking to navigate the complexities of technological advancement.

Off-Site Engineering Services (SOW)

ServotechInc provides off-site engineering services, assembling expert teams to support clients' specific requirements. Similar to how law firms offer specialized legal counsel, Servotech delivers engineering expertise in areas such as mechatronics, embedded software development, and control system design. This approach allows clients to access top-tier engineering talent without the need for in-house resources, fostering innovation and efficiency.

On-Site Engineering Services

For projects necessitating close collaboration, Servotech offers on-site engineering services, embedding their teams within the client's work environment. This co-location strategy ensures seamless integration with the client's operations, facilitating real-time communication and problem-solving. Supported by senior technical members from Servotech's offices, these on-site teams receive continuous supervision and training, ensuring the delivery of high-quality solutions.

Technical Staffing Services

Recognizing the challenges organizations face in sourcing and retaining qualified engineers, Servotech provides comprehensive technical staffing services. The company identifies and trains engineers in required fields using state-of-the-art technology and real-life applications, then places them in suitable roles as per client needs. This service ensures that clients have access to skilled professionals capable of contributing effectively to their projects.

Specialized Engineering Fields

Servotech Inc. offers expertise across a broad spectrum of engineering disciplines, including.

Mobile Machine Control Systems: Design and implementation of control systems for mobile machinery, enhancing performance and safety.

Embedded Software Development: Creation of software solutions embedded within hardware systems, crucial for applications in automotive, aerospace, and consumer electronics.

PLC Programming using CODESYS: Development of programmable logic controller (PLC) applications utilizing the CODESYS platform, enabling efficient automation solutions.

Mechatronic Design: Integration of mechanical engineering, electronics, computer science, and control engineering to design and create intelligent systems and products.

Model-Based Design using MATLAB and Simulink: Utilization of MATLAB and Simulink for model-based design, allowing for simulation and analysis of systems before physical prototypes are developed.

HIL Software Testing: Implementation of Hardware-in-the-Loop (HIL) testing methodologies to validate and verify embedded control systems in real-time environments.

Autonomous Vehicle Control Systems: Development of control systems for autonomous vehicles, encompassing navigation, perception, and decision-making algorithms.

Precision Farming Technology: Application of technology to enhance agricultural practices, including the development of automated systems for planting, harvesting, and crop monitoring.

CAD/FEA Design and Analysis: Provision of Computer-Aided Design (CAD) and Finite Element Analysis (FEA) services to support product design and structural analysis.

Information Technology: Offering IT solutions that complement engineering services, ensuring seamless integration and support for various technological initiatives.

By offering these specialized services, Servotech Inc. addresses the multifaceted challenges faced by industries such as aerospace, automotive, agriculture, and more.

Commitment to Excellence and Innovation

Servotech Inc.'s dedication to excellence is evident in its recruitment and training practices. The company sources talent globally, emphasizing skills and expertise over geographical location. Virtual teams, connected through advanced internet technologies, collaborate effectively without physical limitations, bringing together the best talent from around the world. This approach fosters a culture of integrity, continuous learning, and innovation.

Global Reach and Collaborative Approach

With a presence in multiple countries, Servotech Inc. is positioned to assist clients worldwide with their engineering and IT needs. The company's collaborative approach involves partnering with clients to understand their unique challenges and delivering tailored solutions that drive success. This global reach, combined with a commitment to personalized service, makes Servotech a preferred partner for organizations seeking to navigate the complexities of modern engineering projects.

Conclusion

In an era where technological advancement is both rapid and imperative, Servotech Inc. stands as a beacon of expertise and reliability in the engineering services sector. Through its comprehensive suite of services, spanning off-site and on-site engineering support, technical staffing, and specialized engineering fields, Servotech empowers organizations to achieve their goals with precision and efficiency. By fostering a culture of excellence, innovation, and global collaboration, Servotech Inc. continues to drive progress and deliver value across industries.

#EngineeringServices#TechnicalStaffing#EmbeddedSoftware#MechatronicDesign#PLCProgramming#HILTesting#AutonomousVehicles#PrecisionFarming#FEAAnalysis#ModelBasedDesign

0 notes

Text

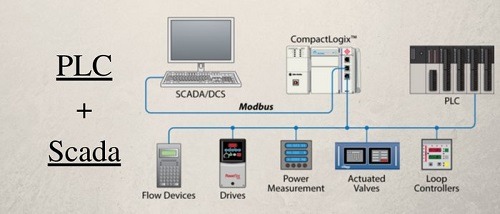

Are you seeking to start a career in industrial automation? PLC SCADA Training Course in Gurgaon is profession oriented when it comes to beginners, and that"s why APTRON gainfully utilizes its labor by imparting a well balanced theory cum practical education. If you want a career in automation, be prepared as with great demands for the profession across various sectors specifically manufacturing, energy, and oil and gas sectors due to increased demand for qualified specialists PLC (Programmable Logic Controller) & SCADA (Supervisory Control & Data Acquisition) systems are your ticket to a lucrative career.

#PLCTraining#SCADATraining#IndustrialAutomation#AutomationTraining#CareerInAutomation#APTRONGurgaon#PLCProgramming#SCADASystems#AutomationEngineer#SkillDevelopment

0 notes

Text

The Role of a PLC Programmer in Modern Manufacturing

In the fast-paced world of manufacturing, automation is the driving force behind increased efficiency, precision, and safety. At the heart of this automation lies the Programmable Logic Controller (PLC), a specialized computer used to control industrial processes. However, the true backbone of this system is the PLC programmer, whose expertise ensures that the machinery and systems work seamlessly together.

What is a PLC Programmer?

A PLC programmer is a skilled professional responsible for designing, coding, testing, and maintaining the software that runs on PLCs. These controllers are crucial in industries such as automotive, food and beverage, pharmaceuticals, and more, where they manage tasks like assembly lines, packaging, and process controls.

The Importance of PLC Programmers

Ensuring Smooth Operations: PLC programmers create the logic that dictates how machines operate, ensuring that each component of a manufacturing process functions in harmony. Their work minimizes downtime and reduces errors, leading to a more streamlined production process.

2. Customization and Flexibility: Manufacturing processes can vary greatly between industries and even between different facilities within the same industry. PLC programmers tailor the software to meet specific needs, providing the flexibility required to adapt to new products, processes, or regulations.

3. Enhancing Safety: Safety is a paramount concern in manufacturing. PLC programmers incorporate safety protocols into the control systems, ensuring that machinery operates within safe parameters and that any potential issues are quickly identified and addressed.

4. Improving Efficiency: By optimizing the control systems, PLC programmers help manufacturers achieve greater efficiency. This might involve fine-tuning machine speeds, reducing waste, or automating repetitive tasks, all of which contribute to higher productivity and lower costs.

5. Supporting Innovation: As technology advances, so too must the manufacturing processes. PLC programmers play a crucial role in integrating new technologies, such as robotics and the Internet of Things (IoT), into existing systems, driving innovation and keeping the manufacturing sector at the cutting edge.

The Future of PLC Programming

The role of PLC programmers is evolving alongside advancements in technology. With the rise of Industry 4.0, the demand for skilled PLC programmers is only increasing. They are not just coding machines but are becoming integral to designing smart factories where data analytics, machine learning, and artificial intelligence play significant roles.

In conclusion, PLC programmers are the unsung heroes of the manufacturing industry. Their expertise ensures that complex industrial processes run smoothly, safely, and efficiently. As manufacturing continues to evolve, the importance of PLC programmers will only grow, making them indispensable to the future of industrial automation.

0 notes

Text

The Best Control System Integration in Bangladesh

A Comprehensive Guide

In today's fast-paced industrial landscape, having a reliable and efficient control system is crucial for maintaining productivity and operational excellence. In Bangladesh, the demand for advanced control system integration is rising as industries seek to modernize and optimize their processes. This blog will explore the best control system integration services in Bangladesh, highlighting key players and their offerings.

What is Control System Integration?

Control system integration involves the design, implementation, and management of automated control systems that monitor and control industrial processes. These systems can range from simple programmable logic controllers (PLCs) to complex distributed control systems (DCS) and supervisory control and data acquisition (SCADA) systems. Effective integration ensures that various components work seamlessly together, leading to enhanced efficiency, reliability, and scalability.

Why is Control System Integration Important?

Increased Efficiency: Automated control systems reduce the need for manual intervention, leading to more efficient operations and faster response times.

Improved Accuracy: Advanced control systems offer precise monitoring and control, minimizing errors and optimizing process parameters.

Cost Savings: By streamlining operations and reducing downtime, control system integration can lead to significant cost savings in the long run.

Scalability: Integrated systems can be easily scaled to accommodate future growth and technological advancements.

Top Control System Integration Companies in Bangladesh

1. BD Controls Ltd.

Keywords: Control System Integration, Industrial Automation, PLC Programming, SCADA Solutions

BD Controls Ltd. is a leading player in the control system integration market in Bangladesh. They specialize in industrial automation, offering comprehensive services including PLC programming, SCADA solutions, and custom control system design. Their expertise in integrating various control components ensures that clients receive tailored solutions that meet their specific needs.

2. Automation & Control Systems (ACS)

Keywords: Automation Solutions, DCS Integration, Process Control, Control System Design

Automation & Control Systems (ACS) is renowned for its expertise in DCS (Distributed Control Systems) integration. They provide end-to-end solutions for process control, from system design to implementation and maintenance. ACS is known for its innovative approach and commitment to delivering high-quality automation solutions that enhance operational efficiency.

3. Protech Engineering Services

Keywords: Control System Engineering, Industrial Controls, System Integration, Custom Automation

Protech Engineering Services offers a range of control system integration services, including custom automation and system engineering. They focus on delivering solutions that are not only technically sound but also aligned with the operational goals of their clients. Their team of experts works closely with clients to ensure seamless integration and optimal performance.

4. Techno Systems Ltd.

Keywords: Industrial Automation, Control System Installation, SCADA Systems, PLC Integration

Techno Systems Ltd. is a prominent name in the field of industrial automation and control system installation. They provide a wide array of services, including SCADA systems, PLC integration, and system upgrades. Techno Systems is known for its customer-centric approach and ability to deliver solutions that drive productivity and efficiency.

5. Optima Engineering Solutions

Keywords: Control System Solutions, Process Automation, PLC and SCADA Integration, Engineering Services

Optima Engineering Solutions excels in providing comprehensive control system solutions for various industries. Their services include process automation, PLC and SCADA integration, and system optimization. Optima Engineering is recognized for its technical expertise and ability to deliver solutions that meet the unique challenges of each client.

Choosing the Right Control System Integration Partner

When selecting a control system integration provider, consider the following factors:

Experience and Expertise: Choose a company with a proven track record and extensive experience in your industry.

Customization: Look for providers that offer tailored solutions to meet your specific requirements.

Support and Maintenance: Ensure the company provides ongoing support and maintenance services to address any issues that may arise.

Technology and Innovation: Opt for a partner that stays updated with the latest technologies and trends in control system integration.

Conclusion

Control system integration is a critical aspect of modern industrial operations, offering numerous benefits such as increased efficiency, accuracy, and cost savings. In Bangladesh, several top-tier companies excel in providing high-quality control system integration services. By partnering with the right provider, you can ensure that your control systems are optimized for peak performance, driving your business towards greater success.

For more information on control system integration in Bangladesh, feel free to explore the services offered by the companies mentioned above and find the best fit for your needs.

Tags: Control System Integration Bangladesh, Industrial Automation Bangladesh, PLC Programming Bangladesh, SCADA Solutions Bangladesh, DCS Integration Bangladesh

#ControlSystemIntegration#IndustrialAutomation#PLCProgramming#SCADASolutions#DCSIntegration#AutomationSolutions#ProcessControl#CustomAutomation#SystemIntegration#ControlSystemDesign#TechnoSystems#ProtechEngineering#OptimaEngineering#BDControls#ACS#BangladeshAutomation#EngineeringServices#IndustrialControls#ControlSystemEngineering#AutomationBangladesh

0 notes

Text

The PLC SCADA Course in Noida at APTRON Solutions covers critical skills such as PLC programming, SCADA system design, process automation, and troubleshooting. These skills are in high demand across industries like manufacturing, energy, and transportation.

#PLCTraining#SCADATraining#PLCProgramming#SCADASystems#IndustrialAutomation#AutomationTraining#APTRONSolutions#NoidaCourses

0 notes

Text

#plc#industrial services#manufacturer#manufacturing#manufacturing services#programming services#plcprogramming#plcprogrammingservices

0 notes

Text

Are you looking to kickstart a career in industrial automation? APTRON Solutions in Gurgaon is the premier destination for mastering PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems. Our institute offers comprehensive training programs designed to equip you with the skills and knowledge necessary to excel in the rapidly evolving field of industrial automation. or someone transitioning into the automation industry, our PLC SCADA Institute in Gurgaon is tailored to meet your needs.

#PLCSCADATraining#IndustrialAutomation#AutomationTraining#APTRON#Gurgaon#AutomationExperts#CareerDevelopment#PLCProgramming#SCADATraining

0 notes

Text

We understand the importance of practical exposure in mastering Industrial Automation Training Institute in Noida. That's why our training programs emphasize hands-on learning using state-of-the-art equipment and simulation tools. Whether you're a beginner or an experienced professional looking to upskill, our practical sessions provide valuable insights and foster proficiency.

#IndustrialAutomation#TrainingInstitute#Noida#APTRONSolutions#PLCProgramming#SCADA#Robotics#HandsOnLearning#CareerDevelopment#PlacementAssistance#IndustryExperts

0 notes

Text

Upgrading DCS to PLC Systems and Using Professional PLC Programming Services

Distributed Control Systems (DCS) have long been the mainstay of industrial automation. However, Programmable Logic Controllers (PLCs) are increasingly becoming a viable alternative, particularly for smaller and less complex applications. This blog post will discuss the benefits of upgrading from a DCS to a PLC system and the importance of using professional PLC programming services.

Benefits of Upgrading from DCS to PLC Systems

There are several reasons why you might consider upgrading from a DCS to a PLC system. Here are a few of the most important:

Cost: PLCs are typically less expensive than DCS systems to purchase, install, and maintain.

Simplicity: PLCs are easier to program and troubleshoot than DCS systems.

Flexibility: PLCs are more flexible than DCS systems and can be easily adapted to changing process requirements.

Scalability: PLCs can be easily scaled up or down to meet the needs of your application.

Reliability: PLCs are known for their reliability and robustness.

Why Use Professional PLC Programming Services?

While PLCs are easier to program than DCS systems, it is still important to use professional PLC programming services. Here are a few reasons why:

Expertise: Professional PLC programmers have the experience and expertise to develop efficient and reliable PLC programs.

Safety: They understand the safety considerations involved in PLC programming and can ensure that your system is compliant with all applicable safety standards.

Efficiency: Professional PLC programmers can develop programs that optimize your process and improve efficiency.

Time Savings: They can save you time and money by developing a program that is right for your application the first time.

Support: They can provide ongoing support for your PLC system.

iPAC Automation: Your Partner for PLC Programming Services

If you are considering upgrading from a DCS to a PLC system, iPAC Automation can help. We offer a wide range of PLC programming services, including:

PLC system design and development

PLC program development and testing

SCADA integration

PLC system commissioning and startup

Ongoing maintenance and support

Our team of experienced and certified PLC programmers can help you develop a PLC system that meets the specific needs of your application.

Contact iPAC Automation today to learn more about our PLC programming services.

We hope this blog post has been helpful. If you have any questions about upgrading from a DCS to a PLC system or about our PLC programming services, please contact us today.

In addition to the benefits listed above, PLCs can also offer:

Improved communication capabilities: PLCs can communicate with a wider range of devices than DCS systems.

Reduced downtime: PLCs are easier to troubleshoot and repair than DCS systems.

If you are considering upgrading from a DCS to a PLC system, we encourage you to contact iPAC Automation today. We can help you determine if a PLC system is right for your application and provide you with a free quote for our PLC programming services.

0 notes

Video

youtube

Allen Bradley Micro 800 Programmable Controllers #shortvideo #technology...

1 note

·

View note

Text

PLC Programming Using CODESYS: An In-Depth Exploration

Programmable Logic Controllers (PLCs) are foundational to industrial automation, providing the control necessary for machinery and processes across various industries. Among the myriad of PLC programming environments available, CODESYS stands out as a versatile and powerful platform. This article delves into the intricacies of PLC programming using CODESYS, its adherence to the IEC 61131-3 standard, fieldbus support, IoT connectivity, and the services offered by Servotech Inc. in this domain.

Understanding CODESYS

CODESYS is a commercial PLC programming tool and real-time software platform designed for PLCs and embedded controllers. It offers a comprehensive suite of features that facilitate the development, testing, and deployment of control applications. One of its notable strengths is its manufacturer-independent nature, allowing engineers to program controllers from various vendors using a unified interface.

Adherence to IEC 61131-3 Standard

The IEC 61131-3 standard defines the programming languages and structures for PLCs, promoting consistency and interoperability across different systems. CODESYS supports all five languages outlined in this standard:

Instruction List (IL): An assembler-like language for low-level programming.

Structured Text (ST): A high-level, Pascal-like language suitable for complex algorithms.

Ladder Diagram (LD): A graphical language resembling electrical relay logic diagrams, widely used for its intuitive representation.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions and their interconnections.

Sequential Function Chart (SFC): A graphical language for depicting sequential control processes.

By adhering to this standard, CODESYS ensures that engineers can transition between different PLC hardware platforms without the need to learn new programming environments, thereby enhancing efficiency and reducing training costs.

Fieldbus Support in CODESYS

Fieldbus systems are critical for enabling communication between various components in an industrial setup. CODESYS provides extensive support for multiple fieldbus protocols, including:

EtherCAT: A high-performance Ethernet-based fieldbus system suitable for real-time control applications.

CAN Bus (CANopen, J1939): Widely used in automotive and industrial applications for robust communication.

Modbus: A serial communication protocol prevalent in connecting industrial electronic devices.

PROFIBUS: A standard for fieldbus communication in automation technology.

This extensive fieldbus support allows for seamless integration of various devices and systems, facilitating the development of complex automation solutions.

IoT Connectivity with CODESYS

In the era of Industry 4.0, the integration of IoT (Internet of Things) capabilities into industrial automation systems is paramount. CODESYS offers robust IoT connectivity features, enabling:

Remote Monitoring and Control: Access and control PLCs from remote locations, enhancing flexibility and responsiveness.

Data Logging and Analysis: Collect and analyze data from various sensors and devices to optimize processes and predict maintenance needs.

Cloud Integration: Seamlessly connect with cloud platforms for data storage, processing, and advanced analytics.

These IoT capabilities empower industries to implement smart manufacturing practices, leading to increased efficiency and reduced operational costs.

Servotech Inc.: Expertise in CODESYS PLC Programming

Servotech Inc. is a leading provider of PLC programming services utilizing the CODESYS platform. Their team of experienced engineers offers comprehensive solutions, including:

Custom PLC Application Development: Tailored solutions to meet specific automation requirements across various industries.

System Integration: Seamless integration of PLCs with existing hardware and software systems, ensuring optimal performance.

Training and Support: Providing clients with the knowledge and tools necessary to maintain and expand their automation systems effectively.

By leveraging CODESYS's versatile platform, Servotech Inc. delivers robust and scalable automation solutions that adhere to international standards.

Conclusion

PLC programming by Servotechinc using CODESYS offers a flexible and standardized approach to industrial automation. Its compliance with the IEC 61131-3 standard, extensive fieldbus support, and IoT connectivity make it a preferred choice for engineers and organizations aiming to develop sophisticated control systems. Servotech Inc.'s expertise in utilizing CODESYS further enhances the potential for creating customized, efficient, and future-ready automation solutions

#PLCProgramming#IndustrialAutomation#CODESYS#AutomationEngineering#SmartManufacturing#EmbeddedSystems#IndustrialControl#FactoryAutomation#IoTIntegration#ControlSystems

0 notes

Text

Making the Switch from DCS to PLC Systems with the Help of Expert PLC Programming

In today's industrial landscape, maximizing efficiency and optimizing operations are crucial for success. Many facilities still rely on Distributed Control Systems (DCS) for automation. While DCS have served their purpose well, advancements in Programmable Logic Controllers (PLCs) offer a compelling reason to consider an upgrade.

Here at iPAC Automation, we understand the complexities of transitioning from a DCS to a PLC system. Our expert PLC programming services can ensure a smooth and successful migration, unlocking the numerous benefits PLCs offer.

Why Upgrade from DCS to PLC Systems?

Several factors make PLCs an attractive alternative to DCS, particularly for modern industrial applications:

Cost-Effectiveness: PLCs generally have lower upfront and ongoing maintenance costs compared to DCS. Their modular design allows for easier troubleshooting and replacement of individual components.

Scalability: PLCs excel at handling smaller, more focused processes. Their modularity allows for easier expansion or modification as your needs evolve.

Flexibility: PLCs offer greater programming flexibility. iPAC's PLC programming services can tailor control logic to your specific requirements, ensuring optimal performance for your unique application.

Ease of Use: Modern PLCs boast user-friendly interfaces and readily available programming tools. This simplifies troubleshooting, maintenance, and even future modifications.

Benefits of iPAC Automation's PLC Programming Services

Upgrading to a PLC system can be a complex undertaking. iPAC Automation streamlines the process with our comprehensive PLC programming services:

Expert Analysis and Planning: We begin by thoroughly analyzing your existing DCS system and understanding your operational goals. This allows for a customized migration plan that minimizes downtime and disruption.

Seamless Code Conversion: Our skilled PLC programmers efficiently convert your DCS control logic into robust and optimized PLC code. We prioritize code clarity and maintainability for future modifications.

Hardware Integration: iPAC's team seamlessly integrates your existing field instruments with the new PLC system. We ensure proper communication protocols and data exchange for reliable operation.

Detailed Testing and Commissioning: Rigorous testing and commissioning ensure the upgraded PLC system functions flawlessly, meeting all safety and performance standards. We provide comprehensive documentation for future reference and support.

Ongoing Support: iPAC Automation doesn't stop at implementation. We offer ongoing support to ensure your PLC system continues to operate at peak efficiency. This includes troubleshooting, maintenance guidance, and even future programming modifications.

A Smooth Transition with iPAC Automation

Upgrading from a DCS to a PLC system can be a significant step towards a more efficient and cost-effective operation. With iPAC Automation's expert PLC programming services, you can navigate this transition with confidence. Our experience, expertise, and commitment to excellence ensure a smooth migration that unlocks the full potential of your PLC system.

Contact iPAC Automation today to discuss your specific needs and learn how our PLC programming services can help you achieve your automation goals.

1 note

·

View note

Text

What is the programmable logic control PLC hardware and software configuration

#automation#green energy#solar cells#renewable#solar energy#renewable resources#solar panels#instrumentation#solar cell#solar panel#plcscada#plcprogramming#plc#scada#controller#manufacturing

0 notes

Text

Elevate industrial automation with #PLC and #SCADA solutions! 🏭✨ Discover how our cutting-edge technologies enhance efficiency and control in manufacturing processes.

Reach Us: 8807148869

PLC SCADA

#PLC#SCADA#AutomationTech#ControlSystems#PLCProgramming#IndustrialAutomation#SCADASystems#SmartFactory#Industry40#ProcessControl#PLCSCADA#AutomationEngineer#IoTinIndustry#SmartManufacturing#FactoryAutomation#PLCTechnology#DigitalTransformation#SCADAControl#AutomationSolutions#TechInnovation

0 notes

Text

Motor control

Motor Control is defined as the process of initiating, directing, and grading purposeful voluntary movement. Shumway-Cook has defined motor control as the ability to regulate mechanisms essential to movement.

0 notes