#PTFE Lined Ball Check Valve in India

Text

PTFE Lined Ball Check Valve in Andhra Pradesh

Overview:

Flowline Valve is a Manufacturer and Supplier of PTFE Lined Ball Check Valve in Andhra Pradesh, India.

In piping systems, operators use a PTFE (Polytetrafluoroethylene) lined ball check valve to prevent backflow of fluids.

The valve consists of a ball inside a chamber with a hole or port for the fluid to pass through. The ball moves freely within the chamber, allowing flow in one…

View On WordPress

#Adoni#Amaravati#Anantapur#Chandragiri#Chittoor#Dowlaiswaram#East Godavari#Eluru#Exporter of PTFE Lined Ball Check Valve#Guntur#India#Kadapa#Kakinada#Krishna#Kurnool#Manufacturer#Manufacturer of PTFE Lined Ball Check Valve#Nagarjunakoṇḍa#Nellore#Prakasam#PTFE Lined Ball Check Valve#PTFE Lined Ball Check Valve in Ahmedabad#PTFE Lined Ball Check Valve in Andhra Pradesh#PTFE Lined Ball Check Valve in Gujarat#PTFE Lined Ball Check Valve in India#Rajahmundry#Rajamahendravaram#Sri Potti Sriramulu Nellore#Srikakulam#Supplier

0 notes

Text

Gate Valve Exporter - Mayur Valves MVS

Mayur (Valves) System Private Limited is an ISO 9001 : 2015 Certified Company, Established in the year 1978, MVS Industrial Valves offers Diaphragm Valves, Ball Valves, Plug Valves, Butterfly Valves, Gate Valves, Globe Valves, Check Valves or Non Return Valves, Knife Gate Valves, Sight Flow Indicator or Sight Glass, Strainer or Filters, PTFE / FEP / PFA / PVDF Lined Valve, PTFE Lined Pipe, PTFE / FEP / PFA / PVDF Lined Pipe Fittings and Plastic / PP / PVDF Valves. Gate Valve Manufacturers Exporters in India MVS Industrial Valves have been exported to more than 40+ countries worldwide

Assurance of Quality: Mayur Valves MVS follows strict quality control procedures to guarantee that every gate valve satisfies global requirements. Every stage of the production process, from obtaining raw materials to inspecting the finished product, is cantered upon quality.

Wide Product Selection: To meet the needs of many applications and industries, Mayur Valves MVS provides a wide selection of gate valves. Mayur Valves MVS offers a solution for your needs, whether they are for industrial operations, oil and gas, or water supply valves.

Customization Options: Mayur Valves MVS offers customization options to fit gate valves to individual demands, acknowledging that every project has different requirements. Customers can request customized solutions, ranging from material selection to size and design alterations.

Reliable Performance: Mayur Valves MVS gate valves are built to provide constant performance even in the most demanding conditions, with a focus on durability and dependability. Thorough testing guarantees that every valve surpasses expectations and fulfils performance criteria.

Global Reach: Mayur Valves MVS reaches markets on all continents as an exporter, providing services to clients all over the world. Customers can count on prompt product delivery no matter where they are thanks to an efficient distribution system and effective logistics.

Conclusion

Go no further than Mayur Valves MVS for quality gate valves built for dependability and performance. Dedicated to quality and client satisfaction, Mayur Valves MVS is still a reliable partner for businesses worldwide. Get in touch with us right now to find out more about our offerings.

Contact Us: - +91 9898563969 [email protected]

Address: - Mayur (Valves) System Private Limited, SOBO Center, 421, Block B, 4th Floor, Gala Gymkhana Road, Near Sun City, South Bopal, Ahmedabad - 380058, Gujarat, India.

Visit for More Information: - https://mvsvalves.com/

#Gate Valve Exporter#Gate Valve Manufacturers Exporters in India#gate valve manufacturers exporters in gujarat#gate valve manufacturers exporters

0 notes

Text

FEP and UPVC Ball Valve

What is UPVC 3-Way Ball Valve? What is a Valve?

Taking a look at the humble pipe is a good place to start. It could be a pipe transporting water in your bathroom or a pipe carrying gas to your kitchen stove. A mechanism that controls how much liquid or gas flows through these liquid and gas pipes is required to function efficiently; this mechanism can be used to increase, decrease, or even stop the flow of fluid or gas. A valve is a mechanism that performs this function. They are mechanical switches that can turn pipes on and off as well as increase or decrease the flow of fluid/gas through them.

Now let's take a look at a few more examples from everyday life. To brush your teeth, you open a valve that lets pressurized water flow out of the pipe when you turn on the tap. Turning the tap more to one side typically reduces, stops, or increases the amount of water coming out (depending on the valve).

FEP Ball Valves:

The best type of ball valve to use for paper and pulp industries is the FEP-lined ball valve. At 10kg/cm2 pressure and 180°C operating temperature, it is capable of withstanding a pressure of 180°C. FEP-lined Ball Valves are ideal for slurries and viscous materials since they are non-sticky. Its unique properties make it superior to alloys.

In terms of its effects, FEP is similar to PTFE except for its soften-processed performance. Despite this, FEP can be quickly processed, welded, and re-molded into complex shapes. Welding and remodeling prospects, chemical and UV resistance, biocompatibility, and clear color are some of the unique properties of FEP.

PFA Ball Valve:

Many oil and gas industries utilize PFA-lined ball valves. PFA-lined valves can withstand temperatures up to 230°C at 10kg/cm2. PFA-lined valves have similar properties and qualities to FEP, but PFA is more temperature-resistant than FEP. In addition to their thermoplastic properties, PFA-lined valves offer a wide range of benefits. A thermoplastic material with the highest working temperature capacity is PFA. There is no fluoroplastic that can work continuously at a temperature higher than +260°C. It is possible to weld and re-mold it, with good permeability and outstanding chemical resistance. We are the PFA lined ball valve manufacturers in India.

What is UPVC 3-Way Ball Valve?

UPVC Ball Valve Manufacturers: The two ports of the PVC union ball valve are made up of two unions that can be disassembled and replaced at any time, making them easier to check and replace than common ball valves. An adjustable tightness, a low friction coefficient, ease of maintenance, and no leaks are some of the characteristics of a union ball valve. Furthermore, since the joints can be purchased separately, you can choose between threaded, socket, and standard joints. Although its single cost is higher than that of common ball valves, its replacement cost is lower.

Aira Euro Automation is the leading ball valve manufacturer in India. We offer various types of industrial valves like ball valves, butterfly valves, control valves, and many more.

0 notes

Photo

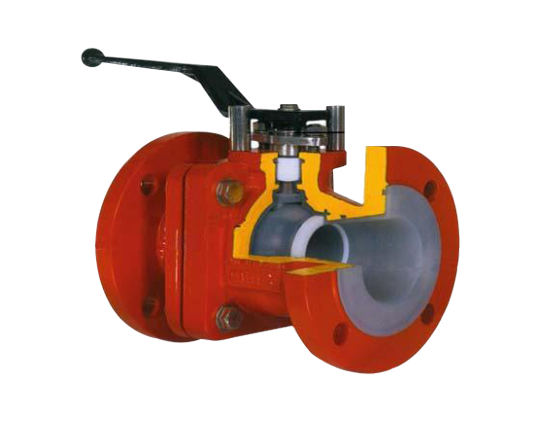

PTFE Lined Ball Valves Manufacturer in India

PTFE lined ball valves are devices designed to regulate the flow of fluids (including gases) by opening, closing, or moderately obstructing passageways in pipes. Lined ball valves have large- scale application over many various industries - for this reason they are vary widely in size, form and materials used depending on what they are going to be used for. They can be more or less simple, or they can be compound - in which case exceptional design is critical to how well they work.

Nowadays, PTFE lined ball valves have been the necessary products in all kinds of corrosive industrial applications. However, there are only a limited lined ball valve manufacturers who reach the international standard. So when company buy this valve, they must called for the seller to show the certifications for production. Through this way company can avoid purchasing the uncertified products.

The primary functions of lined ball valves are important guidelines based on exactly what the industry wants with regard to their machines and equipments. They are available on a number of designs and sizes, plus they are manufacture from different materials, which imply that they offer a model for just about any project.

Aira 4Matic Global Valves is an ISO 9001:2015 company, manufacturers and exporter of PTFE lined ball valves in India. Company’s manufacturing unit is established in Ahmedabad. We are offering Lined check valves for corrosive industrial applications. We have different size range of lined ball valves which are matched to all the industrial operations. We offer ball valves that are fire proof and also passed fugitive emissions testing standards.

1 note

·

View note

Text

Important Steps to Troubleshoot and Fix the Most Common Problems with AODD Pumps

Because of their simplicity, air operated double diaphragm pumps (AODD Pumps)are great for transfer applications. To achieve maximum performance, it is important to properly install and operate your pump. These six easy fixes will help you troubleshoot and fix common problems when your AODD is not working properly during installation and operation.

1.To Check The Air Inlet Size And Pressure.

A small airline is the most common error with AODD pumps. To operate at its best, the pump requires compressed air. An airline that is too small will deprive it of the fuel it needs. Larger AODD pumps (one-inch and more) require more compressed and longer air lines than their smaller counterparts. For the correct size air line for your pump, refer to the manufacturer's instructions and operation manual. It is a good rule of thumb to match the size of the air line hose to the size of the inlet port on AODD pumps. Explore the latest AODD Pumps at Antlia Engineering Works. They are the AODD Pump Suppliers Globally.

Your pump's performance can also be optimized by adjusting the inlet pressure. Diaphragm pumps work in a 1:1 ratio. The pump's inlet pressure is directly proportional to the pump's outlet pressure. 100 psi is the target outlet pressure for a 50 gpm 1 inch pump. The pump's inlet pressure must also be greater than or equal to 100psi.

The outlet fluid pressure is affected by fluid viscosity, system back pressure, and fluid viscosity. Too little back pressure can cause the pump to run slower and the ball checks may not be as quick. If the fluid pressure exceeds the air pressure, the pump may stall. An air regulator is required to regulate the incoming pressure to ensure that an AODD pump performs at its best. An air regulator and the correct size air line will resolve most of the problems associated with AODD pump installation.

2.Check for Muffler Icing and Restrictions

Mufflers can be installed on AODD pumps and are recommended because they can produce high decibel levels at full speed. To operate the pump's air motor, compressed air is needed. Rapid temperature changes are caused by the compressed air entering the valve. It is then channeled through the pump's center section and exhausts through the muffler. The muffler exhaust temperature is below freezing and can lead to icing issues. This is more prevalent in environments with high humidity. Looking for AODD Pump Manufacturers In India.

Visit Antlia Engineering works, they manufacture all types of AODD Pumps.

If your pump is acting erratically, your inlet air contains high levels of moisture, or you can see the front of your muffler, these are indicators that your pump has icing issues. These solutions can help you eliminate icing issues and improve your pump's efficiency.

Pump the air pressure down

To operate at a lower speed (i.e.,. lower air pressure)

An exhaust port tube allows you to exhaust the air to remote locations

To collect condensation, add an air filter and a water catcher to your system.

To raise exhaust air temperature above freezing, install an air heater

To adjust the pressure dew point temperature, use an air compressor dryer

3.Checking Sealing Surfaces for Leaking

Leakage issues can occur with all types of pumps. These tips will ensure that your fluids remain in the pump and not the ground.

Follow the bolting pattern's illustration and torque the pump to the manufacturer's specifications.

When servicing your AODD pump, replace all PTFE o rings. Although PTFE can be used in many applications, it is not capable of returning to its original form after being compressed.

You can reduce the risk of leakage by properly torquing your pump according to the manufacturer's specifications and ensuring that sealing o-rings are replaced during service.

4. Ensure proper tubing and piping sizes

The flow rate of fluid required will determine the diameters of the pump's inlet and outlet ports. The size of the outlet and inlet hoses must be equal. This is a major concern because of the potential for cavitation, as well as the higher repair frequency and increased maintenance costs.

A pump that is 1 inch tall has a 1/2-inch inlet hose attached. The pump will not be capable of operating at its maximum capacity without cavitation. As the fluid viscosity increases, this risk is greater. To avoid cavitation, a pump of 1 inch should have an outlet and inlet hose of 1 inch. This will prevent costly and frequent repairs.

AODD pumps should have flexible inlet and outlet connections. This is preferable to hard plumbed installations. As the pump speed increases, vibration increases. Vibration increases with pump speed. This increases the possibility of hard-plumbed connections being loosened, which can lead to leakage.

5. PRIME - LOWER THE PUMP

AODD pumps are a popular choice for applications that require self-priming. The AODD pumps draw fluid by creating a low-pressure zone within the fluid bowls. This is less than the atmospheric pressure (14.7 psi). If the air pressure is too high, the pump will not changeover quickly enough to allow the fluid to flow into it.

This is solved by using the air regulator to reduce the air pressure entering an air valve and slow down the pump. The pump speed can be reduced to ensure that the fluid supplied has sufficient time to reach the pump. After this, the pump can operate at a faster speed by increasing the air pressure.

6. CLEAR ALL FLUID LINE RESERVATIONS

Clearing any fluid line restrictions is the final step in ensuring optimal pump performance. Limitations can lead to increased maintenance, pressure loss and potential cavitation. This issue can be fixed by removing the following:

Valves that are partially or fully closed

Line kinks or clogs

Too many hoses or too long a distance

These six steps will resolve most of the problems associated with AODD pumps. This will allow you to produce more and not spend time trying to fix it. If you need more help troubleshooting and repairing your AODD pump contact one of our experts.

For more details visit Antlia Engineering Works and know in detail about AODD Pumps as they are the Peristaltic Pump Manufacturers and supplier of the Pumps worldwide.

#AODDPumps#AODDPumpManufacturers#AODDPumpSuppliers#AODDPumpManufacturersInIndia#PeristalticPumpManufacturers

0 notes

Text

A Premier Supplier of PTFE Lined Products

When it comes to industrial operations, if you switch to the crappy gadgets or appliances, things won’t work the way they are expected.

That’s how managing every aspect makes sure you are aligning with what is highly sought in place.

Thus, have you been in any situation wherein you required the tool to get started any industrial operation?

In fact, are you a business owner who has to do a lot with a wide range of Lined Pipes, Fittings, Valves and other such customized products?

If this is what you are considering, this is the right guide for you.

We will do the best to ensure you have the best information available.

Do ensure to stick with the guide and let’s get started.

When it comes to manufacturing and supplying a wide range of Lined Pipes, Fittings, Valves and other such customized products, all you have got to look just at Ablaze Lining since they are a thought-leader, expert, including a leading manufacturer and supplier of Fluoropolymer Lined Pipes, Fittings and Valves. The amazing thing you will note is – They have been a successful partner with leading companies across the world. They know what it takes to working in corrosion resistant company. Therefore, whatever requirement you have got, just make sure to visit the website and fill in the contact form. This will make things a lot easier and advantageous.

Products they offer are:

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined Equal TEE

Solid Spacer

Lined Spacer

Ball Valve

Ball Check Valve

Plug Valve

Full View Sight Glass

Thus, were you looking for the products that are designed in a way that can be used in highly corrosive applications?

If yes, the recommendation will do the best.

Final Thoughts

No matter if you need High Pressure Bellow Manufacturer in India or something, the thing that separates the recommendation than the others is the level of quality product they deliver.

On a sweeter note – Thanks for the read, though!

0 notes

Text

PTFE Lined Ball Check Supplier in Tamil Nadu

Flowline Valve:Flowline Valve are Manufacturer and Supplier of PTFE Lined Ball Check Supplier in Tamil Nadu, India.

A PTFE-lined ball check valve is a type of check valve that utilizes a ball as the sealing element and features a lining of PTFE (polytetrafluoroethylene) on the internal surfaces of the valve body and ball.

This lining provides exceptional corrosion resistance and makes the valve…

View On WordPress

#Chengalpattu#Chennai#Chidambaram#Coimbatore#Cuddalore#Dharmapuri#Dindigul#Erode#India#Kanchipuram#Kanniyakumari#Kodaikanal#Kumbakonam#Madurai#Mamallapuram#Manufacturer#Nagappattinam#Nagercoil#Palayamkottai#PTFE-lined ball check valves#Pudukkottai#Rajapalayam#Ramanathapuram#Salem#Supplier#Thanjavur#Thoothukudi#Tiruchchirappalli#Tirunelveli#Tiruppur

0 notes

Text

PTFE Lined Ball Check Valve Supplier in India

PTFE Lined Ball Check Valve Supplier in India:

Flowline Valve:Flowline Valves are a Manufacturer and Supplier of PTFE Lined Ball Check Valve Supplier in Ahmedabad, Gujarat, India.

How Does a PTFE Lined Ball Check Valve Work?

The PTFE-lined ball check valve operates through a simple yet effective mechanism. The valve comprises a durable PTFE material spherical ball, which resides within a lined…

View On WordPress

#Ahmedabad#Anand#Deesa#Gujarat#Himmatnagar#India#Manufacturer#Modasa#Nadiad#Odhav#Palanpur#PTFE Lined Ball Check Valve#Supplier

0 notes

Text

PFA Lined Swing Check Valve in Chhattisgarh

Overview:

Flowline Valve is a Manufacturer and Supplier of PFA Lined Swing Check Valve in Chhattisgarh, India.

Established in 2013 in Ahmedabad, Gujarat, the company holds ISO 9001:2015 certification.

Flowline Valve offers a comprehensive range of products including PTFE Lined Ball Valve, PTFE Lined Plug Valve, PTFE Lined Globe Valve, PTFE Instrument Tee, PTFE Lined Accessories, PTFE Lined Dip…

View On WordPress

#Akaltara#Ambagarh Chowki#Ambikapur#Arang#Bagbahara#Baikunthpur#Baloda Bazar#Bemetara#Bhatapara#Bijapur#Bilaspur#Bilha#Bishrampur#Chirimiri#Dhamtari#Dharamjaigarh#Exporter of PFA Lined Swing Check Valve#Gharghoda#Jagdalpur#Jashpur Nagar#Kanker#Katghora#Khairagarh#Kharsia#Kondagaon#Korba#Kurud#Mahasamund#Manendragarh#Manufacturer of PFA Lined Swing Check Valve

0 notes

Text

Supplier of PTFE Lined Sampling Valve in Maharashtra

Flowline Valve:

Flowline Valve is a manufacturer and Supplier of PTFE Lined Sampling Valve in Maharashtra, India.

We specialize in manufacturing various PTFE lined valves, including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and globe valves.

We are an ISO 9001:2015 certified company, ensuring the quality and…

View On WordPress

#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Daulatabad#Dhule#Exporter of PTFE Lined Sampling Valve#India#Jalgaon#Kalyan#Karli#Kolhapur#Mahabaleshwar#Maharashtra#Malegaon#Manufacturer#Manufacturer of PTFE Lined Sampling Valve in Maharashtra#Matheran#Mumbai#Nagpur#Nanded#Nashik#Osmanabad#Pandharpur#Parbhani#PTFE Lined Sampling Valve

0 notes

Text

PTFE Lined Flush Bottom Valve Supplier in Punjab

PTFE Lined Flush Bottom Valve Supplier in Punjab:

Flowline Valve:

Flowline Valve is a manufacturer and supplier of PTFE Lined Flush Bottom Valve in Punjab, India.

Specializing in various PTFE lined valves, the company offers a comprehensive range of products including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and…

View On WordPress

#Adampur#Amritsar#Banga Rural#Bassi Pathana#Batala#Bathinda#Doraha#Exporter of PTFE Lined Flush Bottom Valve#Faridkot#Fatehgarh Sahib#Firozpur#Gurdaspur#Hoshiarpur#India#Jalandhar#Kapurthala#Khamanon#Khanna#Ludhiana#Malerkotla#Mansa#Manufactureer of PTFE Lined Flush Bottom Valve#Manufacturer#Nawanshahr#Pathankot#Patiala#Phillaur#PTFE LINED FLUSH BOTTOM VALVE#PTFE Lined Flush Bottom Valve Supplier in Punjab#Rajpura

0 notes

Text

PTFE Lined Sampling Valve in Maharashtra

Flowline Valve:

Flowline Valve is a manufacturer and supplier of PTFE Lined Sampling Valve in Maharashtra, India.

We specialize in manufacturing various PTFE lined valves, including ball valves, butterfly valves, plug valves, diaphragm valves, check valves, sampling valves, flush bottom tank valves, and globe valves.

We are an ISO 9001:2015 certified company, ensuring the quality and…

View On WordPress

#Ahmednagar#Akola#Amravati#Aurangabad#Bhandara#Bhusawal#Buldhana#Chandrapur#Chemical Processing Plants#Daulatabad#Dhule#Exporter of PTFE Lined Sampling Valve#Food and Beverage Processing#Jalgaon#Kalyan#Karli#Kolhapur#Laboratory and Analytical Testing#Mahabaleshwar#Malegaon#Manufacturer of PTFE Lined Sampling Valve#Matheran#Mumbai#Nagpur#Nanded#Nashik#Osmanabad#Pandharpur#Parbhani#Petrochemical Plants

0 notes

Text

PTFE Lined Ball Check Valve Supplier in Kolkata

PTFE Lined Ball Check Valve Supplier in Kolkata:

Flowline Valve:

Flowline Valve is a well-established manufacturer and supplier in Kolkata, India, specializing in PTFE Lined Ball Check Valves, serving diverse industries with reliable products.

PTFE Lined Ball Check Valve Overview:

Function: Designed to control fluid flow in pipelines, particularly for backflow prevention, featuring a ball…

View On WordPress

#Ahritola#Alambazar#Archana#Badartala#Baghajatin#Bamboovila#Chetla#Colootola#Dharmatala#Exporter of PTFE Lined Ball Check Valve#Garfa#Gokhel Road#Jawpore#Jorasanko#Kasthadanga#Keoratala#Madrassa#Manufacturer of PTFE Lined Ball Check Valve#Naktala#Noapara#PTFE Lined Ball Check Valve#PTFE Lined Ball Check Valve Supplier in India#PTFE Lined Ball Check Valve Supplier in Kolkata#Rajabagan#Supplier of PTFE Lined Ball Check Valve

0 notes

Text

PTFE Lined Ball Check Valves Supplier in Gujarat

Flowline Valve:Flowline Valve are Manufacturer and Supplier of PTFE Lined Ball Check Valves Supplier in Ahmedabad, Gujarat, India.

Specialized valves, known as PTFE Lined Ball Check Valves, incorporate a lining made of PTFE, a highly corrosion-resistant and non-reactive material. This lining protects the valve from corrosive fluids and ensures smooth operation.

How PTFE Lined Ball Check Valves…

View On WordPress

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Dahod#Deesa#Gandhidham#Gandhinagar#Godhra#Gondal#Gujarat#India#Jamnagar#Jetpur#Junagadh#Manufacturer#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar#PTFE Lined Ball Check Valves#Rajkot#Supplier#Surat

0 notes

Text

PFA Lined Ball Check Valve Supplier in India

PFA Lined Ball Check Valve Supplier in India:

Flow line valve:Flow line valve manufactures Teflon, pipes, fittings, and accessories, specializing in the development and production of PTFE-lined molded, machined, corrosion-resistant products for the chemical, petrochemical, pharmaceutical, paper, and water treatment industries, among others. Our products are well-known for features such as ease…

View On WordPress

#Amreli#Anand#Ankleshwar#Banglore#Bhachau#Bhalla#Bharuch#Bhavnagar#Bhuj#Chennai#Dadra Nagar Haveli#Dahej#Daman#Deesa#Delhi#Gandhinagar#Haridwar#Himmatnagar#India#Jamnagar#Junagarh#Kadi#Kalol#Kathwada#Kheda#Kolkata#Manufacturer#Mehsana#Modasa#Morbi

0 notes

Text

PTFE Lined Ball Check Valves Manufacturer in Ahmedabad, Gujarat, India

PTFE Lined Ball Check Valves Manufacturer in Ahmedabad, Gujarat, India

PTFE Lined Ball Check Valves Manufacturer in Ahmedabad, Gujarat, India:

Flow Line Valves manufactures PTFE-lined molded, machined, corrosion-resistant products for use in chemical, petrochemical, pharmaceutical, paper, water treatment, and other industries. Fittings, pipes, valves, and accessories make up these products. Our products are well known for their remarkable qualities, such as…

View On WordPress

0 notes