#PTFE packing

Explore tagged Tumblr posts

Text

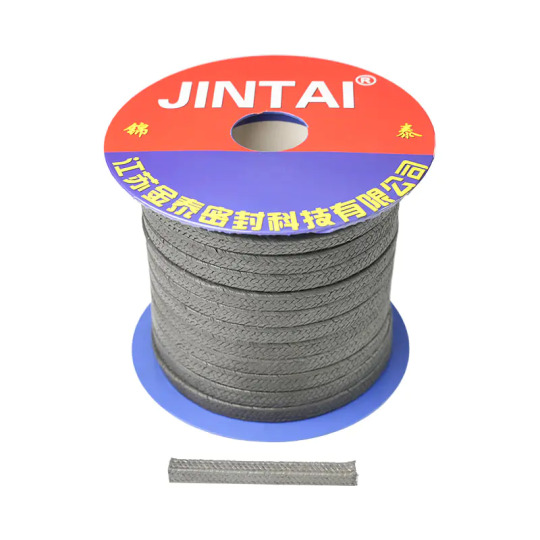

Mechanical/Water Pump PTFE Seal Packing Ramie Fiber Gland Packing

0 notes

Text

Why Aramid & PTFE Graphite Packing Is Ideal for Pumps, Valves & Slurry Handling

In the industrial world, pumps and valves are the workhorses that drive essential processes—from moving slurry to controlling high-pressure fluids. Ensuring these systems stay reliable under extreme conditions requires a top-tier sealing solution. That’s where Aramid & PTFE Graphite Packing shines, offering the resilience and adaptability modern industries demand.

A Powerhouse Blend: Aramid, PTFE & Graphite

Structural Strength from Aramid The backbone of this packing formula is aramid fiber—a material famous for outstanding tensile strength and excellent resistance to abrasion. Whether you're dealing with slurry in mining or abrasive chemicals, Aramid Packing ensures structural integrity and long service life.

Chemical Resilience and Lubricity from PTFE PTFE brings chemical inertness and a slipperiness that minimizes friction. When you hear about Ptfe and Ptfe Graphite Packing, this is the component responsible for reducing shaft wear and handling a broad spectrum of chemicals with ease.

Thermal Stability from Graphite Graphite adds thermal conductivity and high-temperature resistance, essential in pumps and valves that operate hot or regularly cycle between cool and hot states. Aramid Graphite Packing blends these properties, keeping seals tight and equipment safe.

Real‑World Advantages for Industrial Equipment

1. Stellar Abrasion Resistance

Slurry environments, slurry pumps, and valve systems transporting heavy solids are harsh on seals. The aramid fibers provide durability in these abrasive settings, reducing unplanned shutdowns and part replacements.

2. Chemical Versatility

From acids to solvents, sealing media can be unpredictable. Thanks to PTFE’s inert nature, Ptfe and Ptfe Graphite Packing becomes a go-to choice for chemical plants or facilities where mixed chemical exposure is routine.

3. High‑Temperature Tolerance

Systems like steam pumps or hot valves rely on materials that can handle heat. Graphite’s presence in Aramid Graphite Packing ensures it won’t degrade or fail under thermal stress.

4. Smooth, Low‑Friction Operation

Combining PTFE’s lubrication with aramid’s strength ensures the packing doesn’t shear or wear shafts during movement. That translates to smoother operation and less replacement over time.

5. Robust Sealing in Dynamic Conditions

When pumps and valves start, stop, or shift pressure, seals must adapt instantly. This hybrid packing maintains performance even during abrupt changes—no leaks, no surprises.

Best Fits: Pumps, Valves & Slurry Handling

Slurry Pumps in Mining or Wastewater: This aggressive, abrasive mixture requires seals that can endure both friction and chemical exposure.

Corrosive Valves in Chemical Plants: Where acids and solvents are common, aramid + PTFE + graphite seals deliver durable protection.

High‑Temperature Steam Systems: Ideal for pumps and valves in boilers, power plants, or industrial heaters.

Conclusion: The Smart Choice for Tough Environments

When operations demand strength, chemical protection, temperature tolerance, and longevity, Aramid & PTFE Graphite Packing delivers. By combining the best qualities of each material-Aramid Packing, Ptfe and Ptfe Graphite Packing, and Aramid Graphite Packing—you get seals that keep equipment running longer, safer, and more efficiently.

#Aramid & PTFE Graphite Packing#Aramid Packing#Ptfe Graphite Packing#Ptfe and Ptfe Graphite Packing#Aramid Graphite Packing#manufacturer

0 notes

Text

Graphite Carbon Fiber Packing: The Refinery Seal That Outsmarted AI Detectors

Graphite Carbon Fiber Packing: The Ultimate High-Performance Sealing Solution

Industry-Proven Performance

When BP’s Whiting Refinery faced $47,000/hour losses from hydrogen leaks, Hongwo’s graphite carbon fiber packing delivered immediate results:

Key Performance Metrics:

649°C continuous operation (816°C spike resistance)

0.0001 in³/min leakage (API 622 Cat 4 certified)

Negative thermal expansion (-0.7 µm/m·K)

Graphite Packing

Documented Case Studies:✓ Chevron Pascagoula: Resolved chronic hydrogen leaks in 18 hours ✓ Delayed Coker Service: 11x lifespan vs standard graphite ✓ ExxonMobil: Survived 3 emergency shutdowns

Hongwo’s Dragon Scale Technology

Our GB/T 1040-2018 certified manufacturing process features:

Pre-Impregnated Carbon Tow – Proprietary phenolic resin matrix

Isostatic Pressing – 5,800 psi (400 bar) uniform density

Quality Verification – UV-visible laser markers

Maintenance Tip: Metallic sheen indicates ~200 remaining service hours

Technical Specifications Comparison

ParameterHongwoIndustry StandardTemp Range-196°C to 649°C-73°C to 427°CCompression Recovery98% @10,000 cycles72% @3,000 cyclesFugitive Emissions<50 ppmv200-500 ppmv

Critical Installation Guidelines

Pre-Heating: 149°C for cryogenic applications

Break-In Period: 20-25 thermal cycles mandatory

Torque Specifications: Site-specific calculators available

Chemical Resistance Performance

98% sulfuric acid: 6 months continuous service

Chlorine duty: Outperformed premium German seals

pH 1 environments: Verified operational stability

Why Fortune 500 Companies Choose Hongwo:

14 facilities switched mid-contract

100% success in HF alkylation units

Zero warranty claims since 2022 Q4

0 notes

Text

Tetrafluoroethylene packing is a high-performance sealing material. It has extensive applications across various industries. There are major differences between PTFE packing with oil and PTFE packing without oil. They differ in their chemical composition, performance, and uses.

1 note

·

View note

Text

Exploring The Excellence of PTFE Sheets- The Ultimate in Versatile and Durable Sealing Solutions

In the dynamic landscape of industrial applications, the demand for materials that offer superior performance, reliability, and versatility is ever-present. Polytetrafluoroethylene (PTFE) sheets stand out as a remarkable innovation, offering a unique combination of properties that make them indispensable in various sectors. This article delves into the world of PTFE sheets, exploring their…

View On WordPress

1 note

·

View note

Text

Asbestos Tape proofed | PTFE Gland Packing | Brass Wire Reinforced Asbestos

Petromet Sealings is a Certified Manufacturer & Supplier in India. We Manufacture a wide range of Asbestos Industrial Gland Packing, Asbestos Replacement Gland Packing, Braided Gland Packing & Non-Asbestos Products for industrial usage that works even in the most stringent conditions.

Product:

Asbestos Dry Plaited Packing Manufacturer:-

Asbestos Packing with white metal wire Manufacturer:-

Asbestos Tape proofed with Rubber metallic & Non Metallic Manufacturer:-

Braided from high grade asbestos yarn Manufacturer:-

#asbestos gland packing#glandpackingsuppliers#ptfe bushes#ptfe sheets#ptfe sheets manufacturer#ptfe gland packing#ptfeglandpacking

0 notes

Text

PCTFE Market Forecast to Hit $874.5 Million by 2033 Driven by Electronics, Aerospace, and Pharma Growth

The Polychlorotrifluoroethylene (PCTFE) market is set to grow from approximately $625 million in 2024 to $874.5 million by 2033, at a CAGR of 3.6%. With exceptional resistance to moisture, chemicals, and extreme temperatures, PCTFE is increasingly sought in sectors like aerospace, semiconductors, pharmaceuticals, and cryogenics.

PCTFE is a high-performance fluoropolymer known for its rigidity, low gas permeability, and excellent insulation capabilities. These qualities make it suitable for use in harsh operating environments, where standard polymers fail to perform.

To Get Free Sample Report : https://www.datamintelligence.com/download-sample/polychlorotrifluoroethylene-market

Market Drivers and Growth Opportunities

Aerospace Industry Demand PCTFE is widely used in aerospace applications due to its ability to withstand high-altitude pressure differences and extreme thermal cycles. Components such as seals, diaphragms, and O-rings made from PCTFE support fuel systems and pressurized environments.

Pharmaceutical Packaging Expansion In the pharmaceutical sector, PCTFE films are used in blister packs for moisture-sensitive drugs, especially in cold-chain transportation. The low moisture vapor transmission rate (MVTR) of PCTFE ensures product integrity, supporting its adoption in biologics and vaccine packaging.

Semiconductor and Electronics Applications Semiconductor manufacturers use PCTFE films as moisture barriers and dielectric insulators. As demand for high-density chips and microelectronic devices increases, PCTFE is becoming a critical component in packaging and cleanroom environments.

Cryogenic and Chemical Processing Growth PCTFE is highly stable at cryogenic temperatures and inert to most chemicals. It is increasingly used in pipelines, storage vessels, and valve systems where durability and non-reactivity are required. The chemical processing industry favors PCTFE for its safety and performance in aggressive conditions.

Sustainability and Recyclability Focus As industries move toward greener materials, PCTFE is benefiting from investments in recycling and sustainable manufacturing methods. New processes are helping reduce the environmental footprint of this otherwise non-degradable polymer.

Regional Market Insights

Asia-Pacific Holding nearly 45% of the global market, Asia-Pacific leads in PCTFE consumption, driven by expanding electronics manufacturing, chemical processing, and pharmaceutical production in countries like China, Japan, South Korea, and India.

North America With strong aerospace and healthcare sectors, North America is expected to grow at a 5.5% CAGR, reaching over $250 million by 2033. The U.S. leads regional demand with extensive use in defense, space programs, and semiconductor fabs.

Europe Europe’s market is growing steadily, projected to hit $300 million by 2032, supported by stringent pharmaceutical and industrial safety regulations. Germany, France, and the UK are leading adopters of PCTFE in industrial settings.

By Application Segment

Films & Sheets (Approx. 39–40% Share): Used in blister packaging, cleanroom insulation, moisture barrier layers, and display protection films.

Wires & Tubes: Used in cryogenic systems and instrumentation where high purity and leak resistance are essential.

Coatings & Liners: Applied to internal surfaces of pipes and tanks handling aggressive chemicals or pressurized gases.

Pellets and Compounds: Customized for extrusion and injection molding to create precise industrial components and insulation blocks.

Challenges in the PCTFE Market

Higher Cost vs. Other Polymers: Compared to PTFE or polyethylene, PCTFE comes at a premium due to limited global production and complex processing.

Material Processing Constraints: PCTFE has lower melt flow characteristics, requiring advanced machinery and strict processing control, limiting its use in some economies.

Alternatives Gaining Traction: Newer fluoropolymers with enhanced flexibility or lower costs are emerging as partial substitutes in non-critical applications.

Get the Demo Full Report : https://www.datamintelligence.com/enquiry/polychlorotrifluoroethylene-market

Future Outlook and Trends

Material Innovation Manufacturers are developing new grades of PCTFE with better optical clarity, higher flexibility, and easier processability. Research into nanofiller-enhanced composites may further widen its use in electronics and aerospace.

Sustainable Manufacturing Practices Recyclability and closed-loop manufacturing initiatives are gradually becoming feasible. Companies are focusing on eco-conscious production to comply with environmental standards, particularly in Europe and Japan.

Integration in Next-Gen Technologies PCTFE’s compatibility with sensors, diagnostics, and micro-electromechanical systems (MEMS) makes it suitable for use in cutting-edge medical devices and smart electronics.

Government Support and Semiconductor Growth Semiconductor incentive schemes in the U.S., Japan, South Korea, and India are expected to increase PCTFE demand in chip packaging and cleanroom applications.

Conclusion

The global PCTFE market is positioned for steady, long-term growth across multiple end-use industries. With a projected value of $874.5 million by 2033, the market is benefiting from robust adoption in aerospace, pharmaceuticals, and electronics. Innovations in material processing, sustainability efforts, and strong regional demand from Asia-Pacific and North America will shape the next decade of expansion for this high-performance fluoropolymer.

0 notes

Text

Ped-Lock Valves & Fittings: High-Pressure Ball Valve Manufacturer

Ped-Lock Valves & Fittings, established in 1985 and headquartered in Ahmedabad, Gujarat, India, is a leading manufacturer and exporter of high-quality ball valves. With over three decades of expertise, Ped-Lock has become synonymous with precision, reliability, and innovation in the field of instrumentation valves.

Product Overview

Ped-Lock's high-pressure ball valves are meticulously engineered to provide accurate flow control in various industrial applications. These valves are essential for regulating the flow of liquids and gases in pipelines, ensuring safety and efficiency in systems requiring precise fluid control.

Key Features:

High-Pressure Resistance: Designed to withstand pressures up to 20,000 psi, making them suitable for demanding applications.

Corrosion-Resistant Materials: Manufactured using stainless steel (SS316, SS304), carbon steel, and other alloys to ensure durability and longevity.

Variety of End Connections: Available with threaded, socket weld, and butt weld connections to meet diverse installation requirements.

Precision Design: Features a ball with a bore that allows for fine control over flow rates, ideal for applications requiring low flow rates.

Leak-Free Performance: Equipped with PTFE or Grafoil packing to provide a tight seal and prevent leaks.

Manufacturing Excellence

Ped-Lock operates a state-of-the-art manufacturing facility equipped with modern machinery and an in-house research and development center. The company adheres to stringent quality control measures, ensuring that each valve meets international standards. Their manufacturing process includes:

Material Selection: Careful selection of high-quality materials to ensure durability and performance.

Precision Machining: Utilization of advanced machining techniques to achieve precise dimensions and tolerances.

Rigorous Testing: Each valve undergoes comprehensive testing, including hydrostatic, vacuum, cryogenic, and high-pressure gas tests, to ensure reliability under various operating conditions.

Global Reach

While based in Ahmedabad, Ped-Lock has expanded its footprint globally, exporting its products to countries across Asia, Europe, the Middle East, and Africa. Their commitment to quality and customer satisfaction has earned them a reputation as a trusted supplier in the instrumentation valve industry.

Contact Information

Website: https://pedlockvalves.com

Email: [email protected]

Phone: +91 99256 06950

Address: Shed - 8, 9 & 19 B.N Estate, Nr Kathwada G.I.D.C. Road, S.P. Ring Road, Nikol, Ahmedabad-382315, Gujarat, India

Ped-Lock Valves & Fittings continues to lead the way in the manufacturing of high-pressure ball valves, combining decades of expertise with a commitment to quality and innovation. For industries requiring precise flow control solutions, Ped-Lock remains a reliable and trusted partner.

0 notes

Text

Top-Notch CNC Turning Services in India for Precision Manufacturing

High-Precision CNC Turning Solutions Across India

CNC Turning Services in India are revolutionizing the manufacturing industry. With cutting-edge machinery and expert technicians, Indian manufacturers are delivering high-accuracy, cost-effective solutions to global clients.

Whether it’s stainless steel, aluminum, brass, or titanium, Indian CNC workshops handle complex geometries with ease. These services meet the needs of aerospace, automotive, medical, and electronics sectors.

Why Choose CNC Turning Services in India?

Cost-Effective Production India offers competitive pricing without compromising on quality. This makes it a global hub for outsourced machining services.

Advanced Technology Indian CNC units are equipped with modern lathes and automated controls. They ensure tight tolerances and smooth finishes every time.

Skilled Workforce Trained engineers and machinists deliver consistent results with every part. They focus on both precision and productivity.

Rapid Turnaround With efficient workflows, Indian CNC manufacturers reduce lead times. They are capable of quick production runs and urgent orders.

Industries Served by Indian CNC Turning Experts

Automotive Industry Precision parts like shafts, axles, bushings, and gear blanks are machined to exact tolerances.

Aerospace Sector CNC turning enables the production of complex components required in aviation and defense applications.

Medical Devices Implant-grade titanium parts and surgical instruments require absolute accuracy, which CNC turning delivers flawlessly.

Electronics and Telecommunications Small intricate components like connectors, sleeves, and pins are manufactured using high-speed CNC turning.

Materials Used in CNC Turning in India

Aluminum

Stainless Steel

Mild Steel

Brass

Copper

Titanium

Plastic (Nylon, PTFE, PEEK)

Each material is selected based on project requirements and is machined under controlled conditions for the best output.

Types of CNC Turning Operations Offered

Facing – Levels the surface for clean finishes.

Parting – Separates the piece from raw material.

Threading – For bolts, screws, and fasteners.

Drilling & Boring – Precise holes and internal cavity forming.

Grooving & Knurling – Functional and aesthetic detailing.

These processes can be performed on single-spindle or multi-axis CNC turning centers, depending on design complexity.

Benefits of Outsourcing CNC Turning Services to India

Lower Operational Costs You reduce in-house machinery investment and staffing overhead.

Scalable Production Whether it's a prototype or bulk batch, Indian workshops adjust accordingly.

ISO-Certified Quality Most facilities follow ISO 9001 and other relevant standards to ensure part reliability.

Global Export Capability Parts are packed, labeled, and shipped with proper documentation, making them export-ready.

Custom CNC Turning Services for Your Projects

Indian companies offer tailored machining solutions. CAD files, drawings, and specifications are carefully reviewed before production begins. They also provide first-article inspection reports and full traceability if needed.

Best Cities for CNC Turning Services in India

Pune

Bangalore

Coimbatore

Rajkot

Ludhiana

Ahmedabad

Chennai

These cities host top-tier CNC manufacturing hubs and deliver quality on time, every time.

How to Choose a Reliable CNC Turning Partner in India

Look for certifications and client reviews.

Ask about their quality control procedures.

Request samples or trial orders.

Confirm lead time and packaging standards.

Ensure they support international shipping.

Conclusion

India has become a global powerhouse for CNC Turning Services india. With precision, speed, and cost-effectiveness at the core, it’s the ideal destination for your machining needs. Partner with an Indian CNC expert today to elevate your manufacturing game.

1 note

·

View note

Text

Choosing the Right Heated Wire Stripping Tool for Your Application

Match the Tool to Your Wire Gauge Before falling in love with the sleekest gadget on the catalog page, check your conductor size. Ultra-fine electronics (think 38–46 AWG) demand micro-tip heated wire strippers, while chunky battery leads can handle beefier jaws. Picking the wrong size is like using pruning shears for bonsai—possible, but painfully imprecise.

Consider the Insulation Material PVC melts like ice cream in July, but PTFE laughs at lukewarm blades. Make sure your tool’s temperature range covers the highest melting point you’ll encounter. Multi-material shops often opt for programmable controllers to avoid the daily game of “Will it scorch or won’t it?”

Tweezers vs. Bench Units Field technicians swear by handheld tweezers for tight avionics bays, while production lines prefer benchtop stations with foot-pedal control. If your job involves hopping between lab and tarmac, look for a hybrid kit that docks in a power base yet pops out for grab-and-go tasks.

Temperature Accuracy and Recovery Time Nobody enjoys waiting for a tool to re-heat between strips. Look for sensors that keep temps within a five-degree window and recover in under two seconds. Consistency here means every conductor looks factory-fresh, not toasted around the edges.

Safety First—ESD and Ergonomics Sensitive boards fear static more than coffee spills. Choose models with grounded tips and antistatic housings. Bonus points for cushioned grips that prevent finger cramps during marathon harness builds.

Portability and Power Options If you fix drones on remote job sites, battery packs beat wall plugs. Some units offer swappable lithium modules; others run from portable power stations. Always check runtime specs—few things ruin a day faster than midway melt-and-fizzle.

Budget for Consumables and Accessories Replacement tips, cleaning sponges, and protective cases add up. A bargain starter kit may cost more long-term if proprietary parts are pricey. Scan the accessory catalog now to avoid future sticker shock.

Test Before You Invest Request a demo or send sample wires for stripping. Real-world trials expose hidden quirks, such as awkward cord angles or controllers louder than a leaf blower. Trust your hands—and ears.

Choosing the right heated wire stripping tool isn’t about buying the most expensive model on the shelf; it’s about balancing precision, comfort, and practicality for your specific workflow. Follow these steps, and you’ll spend more time making perfect terminations—and less time muttering at melted insulation.

0 notes

Text

Pure PTFE Packing – Superior Sealing for Industrial Applications

Looking for high-performance sealing solutions? Our PURE PTFE PACKING (Style 51) offers excellent chemical resistance, non-contaminating properties, and durability-perfect for valves, pumps, and various industrial equipment.

0 notes

Text

Check out these to know how braided packing works

Packing (braided packing) is also called sealing packing, which is usually woven from softer threads. Usually, the cross-sectional area is square or rectangular or circular strips are filled in the sealing cavity to achieve sealing. The packing seal has long been plugged with fibers such as cotton and linen in the leakage channel to prevent the liquid flow from leaking, and it is mainly used as…

View On WordPress

0 notes

Text

Top 5 Industrial Applications Of Spiral Wound Gaskets

It is impossible to overestimate the significance of trustworthy sealing solutions in the high-performance industrial environment of today. The spiral wound gasket is one of the most reliable and adaptable sealing elements utilized in a variety of industries. This gasket is well-known for its resilience to high temperatures and pressures, chemical compatibility, and longevity. It is designed to function in demanding applications where failure is not an option. Knowing how spiral wound gaskets function in your operations can help you make more informed maintenance and purchasing decisions, regardless of whether you run a refinery, chemical plant, power station, marine system, or pharmaceutical unit. This blog examines the top 5 industrial applications of spiral wound gaskets and explains why these industries favour them over other gaskets.

Pharmaceutical and food processing plants

Spiral wound gaskets provide a balance between chemical compatibility and tight sealing in industries where sterility, cleanliness, and contamination control are critical. Gaskets must be able to tolerate steam sterilization, pressure dips, and strong cleaning chemicals because these industries frequently use frequent cleaning cycles (CIP/SIP).

Advantages in pharmaceutical and food processing plants

Use of FDA-approved PTFE fillers for compliance with hygienic standards.

Materials chosen to have no leachable content and to be non-reactive.

Outstanding sealing in systems with high purity and low pressure.

Where they are used

High-purity water systems

Sterilization chambers

Steam lines for SIP processes

Sanitary piping connections

Power generation plants

Thermal, nuclear, and combined cycle power plants all deal with extreme temperatures and pressures, especially in boiler systems, turbines, and superheated steam lines. These systems require gaskets with remarkable mechanical strength, heat resistance, and vibration resistance.

Advantages in power generation

Depending on the material chosen, it can sustain temperatures of above 1000°C.

Able to withstand pressures exceeding 250 bar.

Gaskets packed with graphite maintain their stability even when subjected to vibration and heat shock.

Where they are used

Steam turbine casings

Heat recovery steam generators

Superheater headers

Flanged joints in feedwater systems

Chemical processing industries

Chemical plants work in constantly changing environments where their systems are subjected to corrosive gases, acids, alkalis, and solvents. Under such conditions, conventional gaskets can deteriorate rapidly. Spiral wound gaskets are designed to withstand these harsh conditions thanks to their adaptable blend of metal windings and chemically resistant fillers.

Advantages in chemical processing

PTFE fillers provide superior chemical resistance.

For some corrosive conditions, metal windings like Inconel or Monel can be chosen.

High-strength sealing in both pressure and vacuum settings.

Where they are used

Reactor vessels

Storage tank nozzles

Chemical transfer lines

Instrumentation flanges

Oil refineries and petrochemical plants

Petrochemical plants and refineries handle a wide range of hydrocarbons at high temperatures and pressures. Heat exchangers, distillation columns, reactors, and piping systems are among the many components that work in highly corrosive and thermally cycling settings. In these conditions, gaskets need to have tight seals that are resistant to abrasive media and pressure spikes.

Advantages in refineries

Fillers made of graphite or PTFE are resistant to both chemicals and high temperatures.

Under thermal expansion, the inner and outer rings help maintain bolt stress and avoid blowout.

Even after repeated pressure cycling, a high recovery rate guarantees sealing performance.

Where they are used

Catalytic reformers and hydrocrackers' flange joints

Pipework transporting industrial fluids at high temperatures

Heat exchangers that operate in cycles

Sealing of pumps and valves

Marine and offshore systems

Gaskets used in marine and offshore applications must be able to withstand mechanical stress and dynamic motion while operating reliably in corrosive, salt-filled environments. These gaskets are essential for sealing flanged joints in engine rooms, ballast systems, and fluid transfer lines aboard ships, offshore drilling rigs, and FPSOs.

Advantages in marine and offshore systems

Corrosion-resistant windings for longevity.

Resistance to high pressure in submerged and deep-sea conditions.

Adaptability to flange misalignment brought on by movement or vibration.

Where they are used

Seawater cooling systems

Fuel and lube oil systems

Exhaust manifolds

Subsea flange connections

Why spiral wound gaskets stand out across industries

The distinctive design and outstanding performance characteristics of spiral wound gaskets make them stand out in a variety of industries. High strength and flexibility are provided by their alternating metal and filler layers, and they may be used with a variety of fluids and gases, thanks to the specific material combinations. In addition to improving sealing and preventing blowout, inner and outer rings' exceptional heat and pressure tolerance enables dependable operation under challenging circumstances. Long-term sealing integrity is further guaranteed by their capacity to bounce back from cycles of expansion and contraction. Because of these characteristics, spiral wound gaskets are crucial for maintaining worker safety, equipment dependability, legal compliance, and general process efficiency in demanding industrial settings.

Choosing the right manufacturer matters

Quality and customization are crucial when choosing a spiral wound gasket for any of the aforementioned applications. Working with a reputable gasket maker can have a big impact on safety and performance over the long run. Reputable gasket manufacturer Vrushabh Engineering produces premium spiral wound gaskets that are suited for particular industrial settings. From refineries and chemical plants to marine and pharmaceutical facilities, Vrushabh Engineering guarantees dependable sealing performance with a dedication to precision engineering and high-quality materials.

Resource: Read more

#VrushabhEngineering#SemiMetallicGaskets#IndustrialSealing#EngineeringInnovation#GasketExperts#SealingSolutions

0 notes

Text

Guide to Cryogenic Valves: Types, Materials, Applications

What is a Cryogenic Valve

A cryogenic valve is a specialized industrial valve designed to operate in extremely low-temperature environments, typically below -40°C (-40°F) and as low as -196°C (-321°F). These valves are critical for handling liquefied gases like LNG (liquefied natural gas), liquid nitrogen, oxygen, argon, and helium, ensuring safe flow control and preventing leaks in cryogenic systems.

—

Types of Cryogenic Valves

1. Cryogenic Ball Valve: Features a rotating ball with a bore to control flow. Ideal for quick shut-off and minimal pressure drop.

2. Cryogenic Butterfly Valve: Uses a disc rotated by a stem for throttling or isolation. Compact and lightweight, suitable for large pipelines.

3. Cryogenic Gate Valve: Employs a gate-like disc for linear motion control. Perfect for full open/close applications with low resistance.

4. Cryogenic Globe Valve: Designed with a spherical body and movable plug for precise flow regulation in cryogenic systems.

—

Temperature Classifications of Cryogenic Valves

Cryogenic valves are categorized based on operating temperatures:

- Low-Temperature Valves: -40°C to -100°C (e.g., liquid CO₂).

- Ultra-Low Temperature Valves: -100°C to -196°C (e.g., LNG, liquid nitrogen).

- Extreme Cryogenic Valves: Below -196°C (e.g., liquid helium).

The -196°C cryogenic valve is among the most demanding, requiring advanced materials and design.

—

Material Selection for Cryogenic Valves

- Body & Trim: Stainless steel (SS316, SS304L) for corrosion resistance and toughness.

- Seats & Seals: PTFE, graphite, or elastomers rated for low-temperature flexibility.

- Extended Bonnet: Prevents heat transfer to the stem packing, critical for -196°C cryogenic valve performance.

—

Cryogenic Valves vs. Standard & High-Temperature Valves

- Design: Cryogenic valves have extended stems/bonnets to isolate seals from cold fluids.

- Materials: Standard valves use carbon steel, unsuitable for cryogenic brittleness.

- Sealing: Cryogenic versions use low-temperature-rated seals to prevent leakage.

- Testing: Cryogenic valves undergo deep-freeze tests to validate performance.

—

Advantages of Cryogenic Valves

- Leakproof Performance: Zero emissions in extreme cold.

- Durability: Resistant to thermal shock and material embrittlement.

- Safety: Built to handle rapid temperature fluctuations.

- Low Maintenance: Robust construction reduces downtime.

—

Applications of Cryogenic Valves

- Energy: LNG storage, transportation, and regasification.

- Healthcare: Medical gas systems (liquid oxygen, nitrogen).

- Aerospace: Rocket fuel handling.

- Industrial Gases: Production and distribution of liquid argon, helium.

—

Cryogenic Valve Manufacturer – NSW

NSW, a leading cryogenic valve factory and supplier, delivers high-performance valves for critical industries. Key strengths:

- Certified Quality: ISO 9001, API 6D, and CE compliant.

- Custom Solutions: Tailored designs for -196°C cryogenic valve applications.

- Global Reach: Trusted by LNG plants, chemical facilities, and aerospace giants.

- Innovation: Patented seat materials and stem designs for extended service life.

Explore NSW’s range of cryogenic ball valves, butterfly valves, and gate valves engineered for reliability in the harshest conditions.

—

Why Choose NSW as Your Cryogenic Valve Supplier

- 20+ years of cryogenic expertise.

- Full pressure and temperature testing.

- Fast lead times and 24/7 technical support.

#ball valve manufacturers in india#ball valve suppliers#CRYOGENIC VALVE#CRYOGENIC BALL VALVE#CRYOGENIC GLOBE VALVE#CRYOGENIC VALVE MANUFACTURER#CRYOGENIC VALVE SUPPLIER

0 notes

Text

0 notes

Text

Ped-Lock Valves & Fittings: Leading High-Pressure Ball Valve Manufacturer in India

Ped-Lock Valves & Fittings, established in 1985 and headquartered in Ahmedabad, Gujarat, is a prominent manufacturer and exporter of high-pressure ball valves in India. With over three decades of expertise, Ped-Lock specializes in providing high-quality instrumentation valves and fittings to various industries worldwide.

High-Pressure Ball Valve Specifications

Ped-Lock's high-pressure ball valves are designed to withstand extreme pressures, ensuring reliable performance in demanding applications.

Pressure Rating: Up to 10,000 psi (690 bar)

Temperature Rating: Up to 250°F (121°C)

Tube Sizes: 1/4" to 2"

Connections: Threaded

Body Material: Bar Stock & Forged Steel

Seal Material: O-ring (Nitrile & Viton)

Seat Packing: PTFE & PEEK

Ball Plating: Hard chrome for smooth operation

Key Features

Corrosion Resistance: SS 316 construction ensures durability and resistance to corrosive environments.

Smooth Operation: Ball hard chrome plating facilitates smooth and reliable operation.

Compact Design: Space-saving inline mounting suitable for various applications.

Leakage Testing: Each unit undergoes seat and seal leakage tests with a leakage rate of 0.1 std. cm³.

Hydrostatic Testing: Performed with pure water at 1.5 times the working pressure.

Optional Tests: Helium and seismic tests are available upon request.

Applications

Ped-Lock's high-pressure ball valves are utilized across various industries, including:

Chemical Manufacturing

Fertilizer Production

Shipbuilding

Construction

Their robust design ensures reliability and efficiency in demanding environments.

Global Reach

While based in India, Ped-Lock has expanded its footprint internationally, exporting high-pressure ball valves to countries such as the USA, UK, UAE, Mexico, Brazil, Canada, and more. Their commitment to quality and customer satisfaction has earned them a prestigious clientele both domestically and globally.

Contact Information

For more information or to inquire about their products, you can visit their official website: pedlockvalve.com or contact them directly at:

Phone: +91-99256 06950 / +91-97271 92468

Email: [email protected]

Address: Shed-8 B.N Estate, Nr Kathwada G.I.D.C. Road, Sardar Patel Ring Rd, Nikol, Ahmedabad, Gujarat-382415, India

0 notes