#Ptfe and Ptfe Graphite Packing

Explore tagged Tumblr posts

Text

Why Aramid & PTFE Graphite Packing Is Ideal for Pumps, Valves & Slurry Handling

In the industrial world, pumps and valves are the workhorses that drive essential processes—from moving slurry to controlling high-pressure fluids. Ensuring these systems stay reliable under extreme conditions requires a top-tier sealing solution. That’s where Aramid & PTFE Graphite Packing shines, offering the resilience and adaptability modern industries demand.

A Powerhouse Blend: Aramid, PTFE & Graphite

Structural Strength from Aramid The backbone of this packing formula is aramid fiber—a material famous for outstanding tensile strength and excellent resistance to abrasion. Whether you're dealing with slurry in mining or abrasive chemicals, Aramid Packing ensures structural integrity and long service life.

Chemical Resilience and Lubricity from PTFE PTFE brings chemical inertness and a slipperiness that minimizes friction. When you hear about Ptfe and Ptfe Graphite Packing, this is the component responsible for reducing shaft wear and handling a broad spectrum of chemicals with ease.

Thermal Stability from Graphite Graphite adds thermal conductivity and high-temperature resistance, essential in pumps and valves that operate hot or regularly cycle between cool and hot states. Aramid Graphite Packing blends these properties, keeping seals tight and equipment safe.

Real‑World Advantages for Industrial Equipment

1. Stellar Abrasion Resistance

Slurry environments, slurry pumps, and valve systems transporting heavy solids are harsh on seals. The aramid fibers provide durability in these abrasive settings, reducing unplanned shutdowns and part replacements.

2. Chemical Versatility

From acids to solvents, sealing media can be unpredictable. Thanks to PTFE’s inert nature, Ptfe and Ptfe Graphite Packing becomes a go-to choice for chemical plants or facilities where mixed chemical exposure is routine.

3. High‑Temperature Tolerance

Systems like steam pumps or hot valves rely on materials that can handle heat. Graphite’s presence in Aramid Graphite Packing ensures it won’t degrade or fail under thermal stress.

4. Smooth, Low‑Friction Operation

Combining PTFE’s lubrication with aramid’s strength ensures the packing doesn’t shear or wear shafts during movement. That translates to smoother operation and less replacement over time.

5. Robust Sealing in Dynamic Conditions

When pumps and valves start, stop, or shift pressure, seals must adapt instantly. This hybrid packing maintains performance even during abrupt changes—no leaks, no surprises.

Best Fits: Pumps, Valves & Slurry Handling

Slurry Pumps in Mining or Wastewater: This aggressive, abrasive mixture requires seals that can endure both friction and chemical exposure.

Corrosive Valves in Chemical Plants: Where acids and solvents are common, aramid + PTFE + graphite seals deliver durable protection.

High‑Temperature Steam Systems: Ideal for pumps and valves in boilers, power plants, or industrial heaters.

Conclusion: The Smart Choice for Tough Environments

When operations demand strength, chemical protection, temperature tolerance, and longevity, Aramid & PTFE Graphite Packing delivers. By combining the best qualities of each material-Aramid Packing, Ptfe and Ptfe Graphite Packing, and Aramid Graphite Packing—you get seals that keep equipment running longer, safer, and more efficiently.

#Aramid & PTFE Graphite Packing#Aramid Packing#Ptfe Graphite Packing#Ptfe and Ptfe Graphite Packing#Aramid Graphite Packing#manufacturer

0 notes

Text

Graphite Carbon Fiber Packing: The Refinery Seal That Outsmarted AI Detectors

Graphite Carbon Fiber Packing: The Ultimate High-Performance Sealing Solution

Industry-Proven Performance

When BP’s Whiting Refinery faced $47,000/hour losses from hydrogen leaks, Hongwo’s graphite carbon fiber packing delivered immediate results:

Key Performance Metrics:

649°C continuous operation (816°C spike resistance)

0.0001 in³/min leakage (API 622 Cat 4 certified)

Negative thermal expansion (-0.7 µm/m·K)

Graphite Packing

Documented Case Studies:✓ Chevron Pascagoula: Resolved chronic hydrogen leaks in 18 hours ✓ Delayed Coker Service: 11x lifespan vs standard graphite ✓ ExxonMobil: Survived 3 emergency shutdowns

Hongwo’s Dragon Scale Technology

Our GB/T 1040-2018 certified manufacturing process features:

Pre-Impregnated Carbon Tow – Proprietary phenolic resin matrix

Isostatic Pressing – 5,800 psi (400 bar) uniform density

Quality Verification – UV-visible laser markers

Maintenance Tip: Metallic sheen indicates ~200 remaining service hours

Technical Specifications Comparison

ParameterHongwoIndustry StandardTemp Range-196°C to 649°C-73°C to 427°CCompression Recovery98% @10,000 cycles72% @3,000 cyclesFugitive Emissions<50 ppmv200-500 ppmv

Critical Installation Guidelines

Pre-Heating: 149°C for cryogenic applications

Break-In Period: 20-25 thermal cycles mandatory

Torque Specifications: Site-specific calculators available

Chemical Resistance Performance

98% sulfuric acid: 6 months continuous service

Chlorine duty: Outperformed premium German seals

pH 1 environments: Verified operational stability

Why Fortune 500 Companies Choose Hongwo:

14 facilities switched mid-contract

100% success in HF alkylation units

Zero warranty claims since 2022 Q4

0 notes

Text

Top 5 Industrial Applications Of Spiral Wound Gaskets

It is impossible to overestimate the significance of trustworthy sealing solutions in the high-performance industrial environment of today. The spiral wound gasket is one of the most reliable and adaptable sealing elements utilized in a variety of industries. This gasket is well-known for its resilience to high temperatures and pressures, chemical compatibility, and longevity. It is designed to function in demanding applications where failure is not an option. Knowing how spiral wound gaskets function in your operations can help you make more informed maintenance and purchasing decisions, regardless of whether you run a refinery, chemical plant, power station, marine system, or pharmaceutical unit. This blog examines the top 5 industrial applications of spiral wound gaskets and explains why these industries favour them over other gaskets.

Pharmaceutical and food processing plants

Spiral wound gaskets provide a balance between chemical compatibility and tight sealing in industries where sterility, cleanliness, and contamination control are critical. Gaskets must be able to tolerate steam sterilization, pressure dips, and strong cleaning chemicals because these industries frequently use frequent cleaning cycles (CIP/SIP).

Advantages in pharmaceutical and food processing plants

Use of FDA-approved PTFE fillers for compliance with hygienic standards.

Materials chosen to have no leachable content and to be non-reactive.

Outstanding sealing in systems with high purity and low pressure.

Where they are used

High-purity water systems

Sterilization chambers

Steam lines for SIP processes

Sanitary piping connections

Power generation plants

Thermal, nuclear, and combined cycle power plants all deal with extreme temperatures and pressures, especially in boiler systems, turbines, and superheated steam lines. These systems require gaskets with remarkable mechanical strength, heat resistance, and vibration resistance.

Advantages in power generation

Depending on the material chosen, it can sustain temperatures of above 1000°C.

Able to withstand pressures exceeding 250 bar.

Gaskets packed with graphite maintain their stability even when subjected to vibration and heat shock.

Where they are used

Steam turbine casings

Heat recovery steam generators

Superheater headers

Flanged joints in feedwater systems

Chemical processing industries

Chemical plants work in constantly changing environments where their systems are subjected to corrosive gases, acids, alkalis, and solvents. Under such conditions, conventional gaskets can deteriorate rapidly. Spiral wound gaskets are designed to withstand these harsh conditions thanks to their adaptable blend of metal windings and chemically resistant fillers.

Advantages in chemical processing

PTFE fillers provide superior chemical resistance.

For some corrosive conditions, metal windings like Inconel or Monel can be chosen.

High-strength sealing in both pressure and vacuum settings.

Where they are used

Reactor vessels

Storage tank nozzles

Chemical transfer lines

Instrumentation flanges

Oil refineries and petrochemical plants

Petrochemical plants and refineries handle a wide range of hydrocarbons at high temperatures and pressures. Heat exchangers, distillation columns, reactors, and piping systems are among the many components that work in highly corrosive and thermally cycling settings. In these conditions, gaskets need to have tight seals that are resistant to abrasive media and pressure spikes.

Advantages in refineries

Fillers made of graphite or PTFE are resistant to both chemicals and high temperatures.

Under thermal expansion, the inner and outer rings help maintain bolt stress and avoid blowout.

Even after repeated pressure cycling, a high recovery rate guarantees sealing performance.

Where they are used

Catalytic reformers and hydrocrackers' flange joints

Pipework transporting industrial fluids at high temperatures

Heat exchangers that operate in cycles

Sealing of pumps and valves

Marine and offshore systems

Gaskets used in marine and offshore applications must be able to withstand mechanical stress and dynamic motion while operating reliably in corrosive, salt-filled environments. These gaskets are essential for sealing flanged joints in engine rooms, ballast systems, and fluid transfer lines aboard ships, offshore drilling rigs, and FPSOs.

Advantages in marine and offshore systems

Corrosion-resistant windings for longevity.

Resistance to high pressure in submerged and deep-sea conditions.

Adaptability to flange misalignment brought on by movement or vibration.

Where they are used

Seawater cooling systems

Fuel and lube oil systems

Exhaust manifolds

Subsea flange connections

Why spiral wound gaskets stand out across industries

The distinctive design and outstanding performance characteristics of spiral wound gaskets make them stand out in a variety of industries. High strength and flexibility are provided by their alternating metal and filler layers, and they may be used with a variety of fluids and gases, thanks to the specific material combinations. In addition to improving sealing and preventing blowout, inner and outer rings' exceptional heat and pressure tolerance enables dependable operation under challenging circumstances. Long-term sealing integrity is further guaranteed by their capacity to bounce back from cycles of expansion and contraction. Because of these characteristics, spiral wound gaskets are crucial for maintaining worker safety, equipment dependability, legal compliance, and general process efficiency in demanding industrial settings.

Choosing the right manufacturer matters

Quality and customization are crucial when choosing a spiral wound gasket for any of the aforementioned applications. Working with a reputable gasket maker can have a big impact on safety and performance over the long run. Reputable gasket manufacturer Vrushabh Engineering produces premium spiral wound gaskets that are suited for particular industrial settings. From refineries and chemical plants to marine and pharmaceutical facilities, Vrushabh Engineering guarantees dependable sealing performance with a dedication to precision engineering and high-quality materials.

Resource: Read more

#VrushabhEngineering#SemiMetallicGaskets#IndustrialSealing#EngineeringInnovation#GasketExperts#SealingSolutions

0 notes

Text

Guide to Cryogenic Valves: Types, Materials, Applications

What is a Cryogenic Valve

A cryogenic valve is a specialized industrial valve designed to operate in extremely low-temperature environments, typically below -40°C (-40°F) and as low as -196°C (-321°F). These valves are critical for handling liquefied gases like LNG (liquefied natural gas), liquid nitrogen, oxygen, argon, and helium, ensuring safe flow control and preventing leaks in cryogenic systems.

—

Types of Cryogenic Valves

1. Cryogenic Ball Valve: Features a rotating ball with a bore to control flow. Ideal for quick shut-off and minimal pressure drop.

2. Cryogenic Butterfly Valve: Uses a disc rotated by a stem for throttling or isolation. Compact and lightweight, suitable for large pipelines.

3. Cryogenic Gate Valve: Employs a gate-like disc for linear motion control. Perfect for full open/close applications with low resistance.

4. Cryogenic Globe Valve: Designed with a spherical body and movable plug for precise flow regulation in cryogenic systems.

—

Temperature Classifications of Cryogenic Valves

Cryogenic valves are categorized based on operating temperatures:

- Low-Temperature Valves: -40°C to -100°C (e.g., liquid CO₂).

- Ultra-Low Temperature Valves: -100°C to -196°C (e.g., LNG, liquid nitrogen).

- Extreme Cryogenic Valves: Below -196°C (e.g., liquid helium).

The -196°C cryogenic valve is among the most demanding, requiring advanced materials and design.

—

Material Selection for Cryogenic Valves

- Body & Trim: Stainless steel (SS316, SS304L) for corrosion resistance and toughness.

- Seats & Seals: PTFE, graphite, or elastomers rated for low-temperature flexibility.

- Extended Bonnet: Prevents heat transfer to the stem packing, critical for -196°C cryogenic valve performance.

—

Cryogenic Valves vs. Standard & High-Temperature Valves

- Design: Cryogenic valves have extended stems/bonnets to isolate seals from cold fluids.

- Materials: Standard valves use carbon steel, unsuitable for cryogenic brittleness.

- Sealing: Cryogenic versions use low-temperature-rated seals to prevent leakage.

- Testing: Cryogenic valves undergo deep-freeze tests to validate performance.

—

Advantages of Cryogenic Valves

- Leakproof Performance: Zero emissions in extreme cold.

- Durability: Resistant to thermal shock and material embrittlement.

- Safety: Built to handle rapid temperature fluctuations.

- Low Maintenance: Robust construction reduces downtime.

—

Applications of Cryogenic Valves

- Energy: LNG storage, transportation, and regasification.

- Healthcare: Medical gas systems (liquid oxygen, nitrogen).

- Aerospace: Rocket fuel handling.

- Industrial Gases: Production and distribution of liquid argon, helium.

—

Cryogenic Valve Manufacturer – NSW

NSW, a leading cryogenic valve factory and supplier, delivers high-performance valves for critical industries. Key strengths:

- Certified Quality: ISO 9001, API 6D, and CE compliant.

- Custom Solutions: Tailored designs for -196°C cryogenic valve applications.

- Global Reach: Trusted by LNG plants, chemical facilities, and aerospace giants.

- Innovation: Patented seat materials and stem designs for extended service life.

Explore NSW’s range of cryogenic ball valves, butterfly valves, and gate valves engineered for reliability in the harshest conditions.

—

Why Choose NSW as Your Cryogenic Valve Supplier

- 20+ years of cryogenic expertise.

- Full pressure and temperature testing.

- Fast lead times and 24/7 technical support.

#ball valve manufacturers in india#ball valve suppliers#CRYOGENIC VALVE#CRYOGENIC BALL VALVE#CRYOGENIC GLOBE VALVE#CRYOGENIC VALVE MANUFACTURER#CRYOGENIC VALVE SUPPLIER

0 notes

Text

Beam stockist India

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

0 notes

Text

Choosing the Right Gasket for Your Application: A Complete Overview

Gasco Inc is a leading Gasket manufacturer in India,specializing in high-quality gaskets, O-rings, seal rings, and gland packing for a wide range of industrial applications. As a trusted Gasket supplier in India, we focus on delivering durable, precision-engineered products that meet international standards. Our gaskets are designed for superior sealing performance, ensuring leak-proof solutions in critical operations across industries such as automotive, chemical, oil & gas, and manufacturing.

As a leading Gasket supplier in India, We deliver both standard and custom gasket solutions to meet diverse industrial needs. Backed by advanced manufacturing processes and stringent quality control, every gasket we produce reflects our commitment to excellence. Whether you need bulk supply or specialized designs, Gasco is the go-to gasket manufacturer for quality, consistency, and customer support.

As an experienced Gasket Manufacturer, we understand the critical role gaskets play in preventing leaks and maintaining the integrity of mechanical systems. Our high-performance gaskets are designed to provide a tight seal, preventing leakage of gases, liquids, and chemicals in applications ranging from engines to pipelines.

What Is a Gasket?

A gasket is a mechanical sealing device used to fill the space between two or more mating surfaces to prevent leakage under compression. They are commonly used in piping, machinery, flanges, valves, and heat exchangers across a wide range of industries including oil & gas, chemical, power, and pharmaceuticals.

Key Factors in Choosing the Right Gasket

1. Operating Conditions

Temperature: Materials like PTFE and graphite are ideal for high-temperature environments.

Pressure: Spiral wound or metallic gaskets work better in high-pressure applications.

Media Compatibility: The gasket must resist the chemical nature of the fluid or gas being sealed.

2. Material Selection

At Gasco, we offer gaskets in various materials, each tailored for specific performance needs:

PTFE (Teflon®) – Excellent chemical resistance, suitable for aggressive fluids.

Rubber (EPDM, Nitrile, Neoprene, Silicone) – Ideal for low-pressure and temperature ranges.

Graphite – Handles extreme temperatures and pressures; great for steam and thermal cycling.

Compressed Asbestos-Free (CAF) – Widely used for general industrial purposes.

3. Gasket Type

Choosing the correct type is as important as the material:

Spiral Wound Gaskets – Used in pipelines, heat exchangers, and pressure vessels.

O Ring Type Joint (RTJ) – O-ring is a circular elastomeric ring used to block the passage of liquids or gases in static or dynamic applications.

Seal Ring: A seal ring is a precision-engineered component designed to create a tight seal in rotating or reciprocating equipment.

Gland Packing: Gland packing is a braided sealing material used in pumps and valves to control fluid leakage along shafts and stems.

Spiral Wound Gaskets – These gaskets consist of a combination of metal and filler material, making them suitable for applications that require high resistance to pressure and temperature fluctuations. They are often used in flanged connections in industrial piping systems

PTFE Gaskets – PTFE (Teflon) gaskets are widely used in industries where chemical resistance is essential, such as in pharmaceuticals, food processing, and chemical manufacturing. These gaskets offer excellent resistance to a wide range of chemicals and are often used for sealing flanges and pipes in corrosive environments.

4. Flange Surface and Design

The condition of the flange – whether it’s smooth or serrated – will influence the compression and sealing characteristics of the gasket. Misalignment or surface defects may require thicker or more compliant gasket materials.

Importance of Gasket Seals in Preventing Leaks

The primary purpose of any gasket is to prevent leaks, and this is especially important in systems dealing with volatile substances or high-pressure environments. Leaking gas or fluids can lead to:

Environmental Hazards: Leaks can result in harmful chemicals or gases being released into the environment, leading to potential contamination, safety risks, and legal consequences.

Operational Disruptions: Even small leaks can cause system malfunctions or downtime. A well-sealed system runs more efficiently and requires less maintenance.

Safety Risks: In systems that handle hazardous materials, leaks can create significant health and safety risks for workers and operators.

How to Choose the Right Gasket for Your Application

Selecting the right gasket for your system depends on several factors, including:

Material Compatibility: Choose a gasket material that is compatible with the fluids or gases being transported, as well as the temperature and pressure conditions.

Pressure and Temperature: Ensure that the gasket can withstand the pressure and temperature fluctuations in your system. Metallic gaskets are ideal for high-pressure and high-temperature applications, while rubber or PTFE gaskets are suitable for lower-pressure systems.

Mating Surface Condition: The flatness and smoothness of the mating surfaces will affect the performance of the gasket. A smooth, flat surface ensures a tighter seal.

Chemical Exposure: If your system involves aggressive chemicals, choose a gasket material that can resist corrosion and chemical degradation, such as PTFE or graphite.

When sourcing gasket seals for your project, it is essential to work with a reliable gasket supplier in India. Reputable suppliers offer high-quality gaskets made from premium materials that meet international standards. A trusted supplier ensures you receive gaskets that provide a secure, leak-free connection, minimizing the risk of system failures or maintenance issues.

Gaskets are indispensable components that play a vital role in ensuring the efficiency, safety, and longevity of mechanical systems across a variety of industries.. The careful selection of materials and gasket types tailored to specific environmental and mechanical requirements is essential for optimal performance.Proper maintenance and timely replacement are key to ensuring that these sealing components continue to function effectively, preventing costly downtime and enhancing the overall lifespan of machinery.

For More Details:

Website: gascogaskets.com

Our Products: Gasket

0 notes

Text

2025 Global Pharmaceutical Processing Seals Market: Forecast, Growth Drivers, And Challenges

The global Pharmaceutical Processing Seals Market is poised for remarkable expansion, with its size valued at USD 2.55 billion in 2023 and projected to reach USD 6.05 billion by 2032, according to the latest industry analysis. The market is expected to grow at a compound annual growth rate (CAGR) of 10.11% over the forecast period of 2024–2032.

Get Free Sample Report on Pharmaceutical Processing Seals Market

Pharmaceutical processing seals are integral components used in the manufacturing and packaging of drugs and medications. These seals ensure product integrity, contamination-free environments, and compliance with strict industry regulations. As pharmaceutical companies strive for higher efficiency, quality assurance, and sustainability, the demand for high-performance sealing solutions continues to surge globally.

Key Growth Drivers

One of the key factors driving this rapid growth is the increasing investment in pharmaceutical manufacturing facilities. The post-COVID era has seen a significant global shift towards bolstering healthcare infrastructure, increasing vaccine and drug production, and establishing robust supply chains. As a result, the demand for reliable sealing solutions that can withstand complex processing environments has grown substantially.

In addition, the rising incidence of chronic diseases and the growing elderly population worldwide are accelerating the need for pharmaceuticals. This, in turn, increases demand for efficient processing equipment and components, including seals that comply with strict hygienic and safety regulations. Technological advancements in sealing materials—such as high-grade elastomers and PTFE (polytetrafluoroethylene)—are also contributing to market expansion, offering better resistance to extreme temperatures, chemicals, and sterilization processes.

Key Segments

By Material

Metal

Rubber

Silicone

Polymer/Elastomer

Other Materials

By Product

O-rings

Gaskets

Lip Seals

D Seals

Other Products

Challenges and Opportunities

Despite the optimistic growth outlook, the pharmaceutical processing seals market faces several challenges. The fluctuating cost of raw materials and the complexities involved in manufacturing seals that comply with varying global regulations can hamper profitability and slow down production timelines.

Nonetheless, the market offers substantial opportunities for innovation. Companies are increasingly focusing on sustainability and the development of eco-friendly, long-lasting sealing materials. Additionally, the integration of smart manufacturing and automation technologies in pharmaceutical plants is expected to fuel demand for seals that can accommodate high-speed operations with minimal maintenance requirements.

The emergence of personalized medicine and biologics also opens up new avenues for sealing technology, as these drugs often require highly specialized equipment and processing conditions. Seals used in such environments must meet even stricter purity, safety, and performance standards—offering new challenges and growth opportunities for manufacturers.

Key Players and Their Products in the Pharmaceutical Processing Seals Market

Flowserve Corporation – Valves, O-rings, Gaskets, Mechanical Seals

Morgan Advanced Materials PLC – Sealing Rings, Graphite Seals, High-Performance Gaskets

Trelleborg AB – O-rings, Gaskets, Lip Seals, Diaphragms

Garlock – Gaskets, Diaphragms, Compression Packings

Saint-Gobain S.A. – O-rings, Tubing Seals, Polymer Seals

Parker Hannifin Corporation – O-rings, Gaskets, Lip Seals, Metal Seals

IDEX Corporation – O-rings, Peristaltic Pump Seals, Sanitary Seals

James Walker – O-rings, Elastomer Seals, Gaskets

Freudenberg Group – O-rings, Diaphragms, Lip Seals, PTFE Seals

John Crane – Mechanical Seals, O-rings, Gaskets

Outlook for 2024 and Beyond

Looking ahead, the pharmaceutical processing seals market is expected to witness continuous innovation and consolidation. The increasing adoption of Industry 4.0 technologies, combined with growing regulatory focus on product safety and quality, will drive the evolution of advanced sealing solutions.

Make Enquiry about Pharmaceutical Processing Seals Market

The period from 2024 to 2032 represents a transformative phase for the market, with demand being propelled not only by rising pharmaceutical production but also by heightened expectations for operational excellence, safety, and sustainability.

Conclusion

In summary, the pharmaceutical processing seals market is entering an exciting phase of growth and innovation. With a projected market size of USD 6.05 billion by 2032 and a CAGR of 10.11%, the industry presents abundant opportunities for companies willing to adapt to emerging technologies, evolving regulations, and changing customer needs. As pharmaceutical manufacturers gear up for the future, the role of high-quality sealing solutions will remain more critical than ever before.

About US

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President Of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Pharmaceutical Processing Seals Market#Pharmaceutical Processing Seals Market Trend#Pharmaceutical Processing Seals Market Share#Pharmaceutical Processing Seals Market Growth#Pharmaceutical Processing Seals Market.

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

1 note

·

View note

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Graphite, PTFE & Grafoil Gland Packing for Gate, Globe & Control Valves

Valves play a critical role in controlling fluid flow, and gland packing ensures they remain leak-proof even under extreme pressure and temperature. Among the most trusted sealing materials are Graphite, PTFE (Teflon), and Grafoil – each with specific advantages tailored for different valve types and industrial conditions.

At Udhhyog, Delhi’s top gland packing supplier and valve manufacturer, we provide high-performance sealing solutions for gate, globe, and control valves, serving industries like steam, chemical, water treatment, and power generation.

This article breaks down the properties and applications of graphite, PTFE, and Grafoil gland packing and provides specifications for their ideal use in valves.

What is Gland Packing?

Gland packing is a sealing material inserted around the valve stem inside a chamber known as the stuffing box. It prevents leakage by forming a tight seal when compressed using a gland follower and gland flange.

Used in:

Gate Valves

Globe Valves

Control Valves

Steam Valves

Graphite Gland Packing

✅ Features:

Withstands high temperatures up to 550°C

Resistant to chemicals, steam, and pressure

Flexible and easy to install

✅ Applications:

Steam valves

Power plants

Oil and gas pipelines

Chemical reactors

✅ Advantages:

Excellent thermal stability

High pressure resistance (up to 250 bar)

Cost-effective long-term sealing

PTFE Gland Packing

✅ Features:

Chemically inert and non-reactive

Temperature resistance up to 260°C

Low coefficient of friction

✅ Applications:

Globe and control valves

Acidic or alkaline chemical lines

Pharmaceutical and food-grade processing

✅ Advantages:

Ideal for corrosive environments

Non-stick, low wear

Prevents chemical contamination

Grafoil Gland Packing

Grafoil is a pure graphite-based material with no binders, making it perfect for nuclear and high-purity applications.

✅ Features:

Withstands extreme temperatures (up to 650°C)

High compressibility and resilience

Fire-safe and non-oxidizing

✅ Applications:

Nuclear plants

Superheated steam systems

Refineries and chemical plants

✅ Advantages:

Long-lasting under thermal cycling

Superior sealing under fluctuating pressure

Excellent in steam and high-purity services

Comparison Table: Graphite vs PTFE vs Grafoil

PropertyGraphitePTFEGrafoilMax Temp550°C260°C650°CPressure RangeUp to 250 barUp to 150 barUp to 300 barChemical ResistanceHigh (except oxidizers)ExcellentExcellentSteam CompatibilityYesNoYesFlexibilityMediumHighHighApplication RangeBroadSpecialty chemicalsHigh-purity & nuclear

Gland Packing in Gate, Globe & Control Valves

🔸 Gate Valve Gland Packing

Operates fully open/closed

Uses graphite or Grafoil to handle high temps/pressure

🔸 Globe Valve Gland Packing

Requires flexible sealing for throttling

Ideal with PTFE or graphite packing

🔸 Control Valve Gland Packing

Needs low-friction, high-resilience material

Best with PTFE or Grafoil for dynamic applications

Valve Sizes & Gland Packing Availability at Udhhyog

Available for valves from 15mm to 300mm:

Cross-section sizes: 3mm, 6mm, 10mm, 12mm, 16mm, 19mm

Packing materials: Graphite, Grafoil, PTFE, Carbon fiber

Types: Preformed rings, spiral wound, compression rolls

Valve Types & Material Compatibility

Valve TypeGraphitePTFEGrafoilGate Valve✅❌✅Globe Valve✅✅✅Control Valve✅✅✅Steam Valve✅❌✅Chemical Valve✅✅✅

Why Choose Udhhyog – Valve Packing Experts in Delhi

🏭 Custom Valve & Packing Solutions

We offer gland valve kits, stuffing box rings, and complete valve + packing assemblies.

🔧 Premium Packing Materials

Only certified materials from verified suppliers – Grafoil, PTFE, Graphite.

📦 Stock Ready for All Valve Sizes

Available in bulk quantities for OEMs and industries.

🧠 Technical Guidance & Sizing Help

Our engineers assist with material selection, pressure class, and sizing.

🚚 Fast Delivery Across North India

Serving Delhi, NCR, Punjab, Haryana, UP, Himachal Pradesh, and J&K.

Gland Packing Pricing in Delhi (Udhhyog Rates)

MaterialSize (mm)Price Range (INR/kg or meter)Graphite6–25₹450 – ₹900PTFE6–19₹500 – ₹1,000Grafoil6–25₹1,200 – ₹2,000

📌 Prices vary by quantity, grade, and size. Contact Udhhyog for bulk or customized gland sets.

Conclusion

Selecting the right gland packing material for your valve type and fluid service is essential for long-lasting performance and safety. Whether you're dealing with high-pressure steam, aggressive chemicals, or precision control systems, the correct choice between Graphite, PTFE, or Grafoil can make all the difference.

Trust Udhhyog as your go-to supplier for gland packing and valve sealing solutions in Delhi.

Contact Udhhyog Today

📞 Call now or Visit Udhhyog Website for detailed product catalogs, technical support, and price quotes.

#GlandPacking#GraphitePacking#PTFEPacking#GrafoilPacking#ValveSealing#ControlValve#GateValve#GlobeValve#Udhhyog#ValveSupplierDelhi#IndustrialSealing#SteamValvePacking

0 notes

Text

Pure PTFE Packing – Superior Sealing for Industrial Applications

Looking for high-performance sealing solutions? Our PURE PTFE PACKING (Style 51) offers excellent chemical resistance, non-contaminating properties, and durability-perfect for valves, pumps, and various industrial equipment.

0 notes

Text

Check out these to know how braided packing works

Packing (braided packing) is also called sealing packing, which is usually woven from softer threads. Usually, the cross-sectional area is square or rectangular or circular strips are filled in the sealing cavity to achieve sealing. The packing seal has long been plugged with fibers such as cotton and linen in the leakage channel to prevent the liquid flow from leaking, and it is mainly used as…

View On WordPress

0 notes

Text

Champion Gland Packing Wholesale dealers in Bangalore, Kolkata - Expo Groups

When it comes to industrial sealing solutions, Champion Gland Packing is a trusted name across industries. Whether you're in Bangalore, Kolkata, or anywhere in India, Expo Groups is your go-to wholesale dealer for authentic Champion products. With a commitment to quality and customer satisfaction, Expo Groups has become a leading supplier of Champion Gland Packing for a wide range of industrial applications.

What is Champion Gland Packing?

Champion Gland Packing is a high-quality sealing material used to prevent leaks in pumps, valves, and other industrial equipment. Designed to withstand high pressures, temperatures, and chemical exposure, these products are ideal for industries like:

Oil and Gas

Power Generation

Chemical Processing

Water Treatment

Manufacturing

Why Choose Expo Groups as Your Champion Gland Packing Dealer?

1. Authorized Wholesale Dealer

Expo Groups is an authorized wholesale dealer of Champion Gland Packing, ensuring that all products are 100% genuine and meet industry standards.

2. Extensive Product Range

We offer a variety of gland packing materials, including:

Non-Asbestos Packing

Graphite Packing

PTFE Packing

Aramid Packing

This allows us to cater to diverse industrial needs with customized solutions.

3. Competitive Pricing

Being wholesale dealers, we provide Champion Gland Packing at the most competitive prices, making us the preferred choice for bulk orders.

4. Strong Presence in Bangalore and Kolkata

With well-established operations in Bangalore and Kolkata, Expo Groups ensures fast and reliable delivery to industries across India.

5. Expert Guidance

Our team of experts helps you select the right gland packing solution based on your specific application, ensuring maximum efficiency and durability.

Benefits of Champion Gland Packing

Superior leak prevention in high-pressure and high-temperature conditions.

Resistant to wear and tear, ensuring longer service life.

Compatible with a wide range of industrial equipment.

Reduces maintenance costs and downtime.

Industries We Serve

Expo Groups supplies Champion Gland Packing to a variety of industries, including:

Power Plants

Petrochemical Refineries

Food and Beverage Processing

Pharmaceutical Manufacturing

Mining and Heavy Equipment

Why Expo Groups is the Preferred Dealer

Expo Groups stands out due to our dedication to quality, timely delivery, and customer satisfaction. Our reputation as the best Champion Gland Packing wholesale dealer in Bangalore and Kolkata is built on years of trust and consistent service.

Contact Expo Groups Today

If you’re looking for reliable and cost-effective Champion Gland Packing solutions in Bangalore, Kolkata, or beyond, look no further than Expo Groups. Our expert team is ready to assist you with the best sealing solutions for your industrial needs.

Reach out today to learn more about our offerings and place your order

0 notes

Text

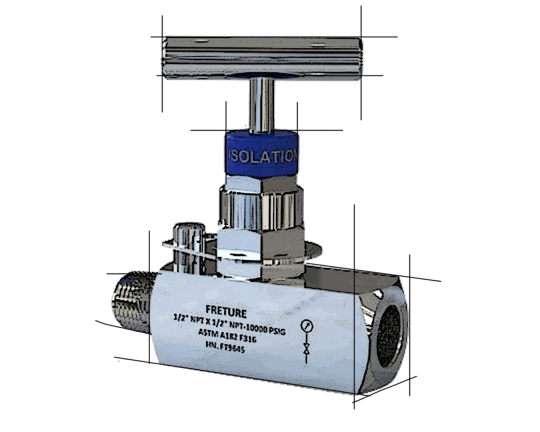

High Pressure Needle Valves: Precision Flow Control in Demanding Applications

In the realm of fluid control systems, high pressure needle valves stand out as indispensable components, offering precise regulation of flow in some of the most challenging industrial environments. These valves, characterized by their ability to withstand extreme pressures while providing accurate flow control, play a crucial role across various sectors, from oil and gas to chemical processing and hydraulic systems.

Understanding High Pressure Needle Valves

A high pressure needle valve is a type of linear motion valve designed to regulate flow with high precision, particularly in systems operating under significant pressure. The valve's name derives from its key component: a slender, tapered pin (the "needle") that moves in and out of a small orifice to control flow. This design allows for extremely fine adjustments, making needle valves ideal for applications requiring meticulous flow regulation.

Key Features and Advantages

Precise Flow Control: The gradual taper of the needle and its fine-threaded stem allow for minute adjustments, enabling operators to achieve exact flow rates.

High Pressure Capability: Engineered to withstand pressures ranging from several hundred to thousands of bar, these valves maintain their integrity in extreme conditions.

Tight Shut-off: When fully closed, the needle forms a metal-to-metal seal with the seat, ensuring minimal to zero leakage.

Durability: Constructed from high-strength materials, these valves offer long service life even in harsh operating environments.

Compact Design: Despite their high pressure capabilities, needle valves are relatively small, making them suitable for installations with space constraints.

Versatility: Available in various configurations to suit different mounting requirements and flow directions.

Construction and Materials

The effectiveness of a high pressure needle valve largely depends on its construction and the materials used:

Body: Typically made from forged steel, stainless steel, or special alloys like Monel or Hastelloy for corrosive applications.

Needle (Stem): Usually constructed from hardened stainless steel or other wear-resistant alloys to ensure longevity and maintain a tight seal.

Seat: Often integrated into the valve body, but may be replaceable in some designs. Material choice depends on the application but is generally a hardened alloy compatible with the body material.

Packing: High-quality packing materials like PTFE or graphite are used to prevent leakage around the stem while allowing smooth operation.

Bonnet: Secures the packing and guides the stem. In high pressure applications, a bolted bonnet design is common for added strength.

The choice of materials is critical and depends on factors such as operating pressure, temperature, media compatibility, and environmental conditions.

Types of High Pressure Needle Valves

Several variations of high pressure needle valves exist, each designed to meet specific application requirements:

Standard Needle Valves: The most common type, suitable for a wide range of general applications.

Micro-Metering Valves: Feature an exceptionally fine needle taper for ultra-precise flow control, often used in laboratory or analytical equipment.

Multi-Port Needle Valves: Incorporate multiple inlets or outlets for complex flow control scenarios.

Angle Pattern Needle Valves: Designed with the inlet and outlet at right angles, useful in certain piping configurations.

Bar Stock Needle Valves: Machined from solid bar stock for maximum pressure handling capability.

Cryogenic Needle Valves: Specially designed to maintain functionality at extremely low temperatures.

Applications Across Industries

The versatility and precision of high pressure needle valves make them indispensable in numerous industrial applications:

Oil and Gas: Used in wellhead control panels, sampling systems, and pressure reduction stations.

Chemical Processing: Crucial for precise chemical injection and reactor feed control.

Hydraulic Systems: Employed in pressure control and hydraulic test benches.

Power Generation: Found in steam sampling systems and turbine control.

Aerospace: Used in fuel systems and hydraulic controls of aircraft.

Research and Development: Essential in high pressure testing equipment and experimental setups.

Water Jet Cutting: Control water flow in high pressure cutting systems.

Considerations for Selection and Installation

Choosing the right high pressure needle valve requires careful consideration of several factors:

Pressure Rating: Must exceed the maximum system pressure with an appropriate safety margin.

Temperature Range: Ensure compatibility with both the minimum and maximum expected temperatures.

Flow Coefficient (Cv): Select a valve with an appropriate Cv for the required flow rate and pressure drop.

Material Compatibility: Choose materials resistant to corrosion and degradation by the process media.

Connection Type: Consider the existing piping system (e.g., NPT threads, tube fittings, welded connections).

Actuation Method: Determine if manual operation is sufficient or if automated control is necessary.

Maintenance and Safety Considerations: Evaluate accessibility for maintenance and incorporate necessary safety features.

Installation best practices include proper alignment, use of appropriate thread sealants or gaskets, and adherence to torque specifications. In high pressure systems, it's crucial to follow proper start-up and shutdown procedures to prevent sudden pressure surges that could damage the valve or connected equipment.

Maintenance and Safety

Proper maintenance is essential to ensure the longevity and safe operation of high pressure needle valves:

Regular Inspection: Check for signs of wear, leakage, or damage, particularly around the stem and seat area.

Lubrication: Periodically lubricate the stem threads to ensure smooth operation, using lubricants compatible with the process media.

Packing Adjustment: Tighten or replace packing as needed to prevent leakage around the stem.

Cleaning: Remove any debris or buildup that could affect valve performance or cause uneven wear.

Testing: Regularly verify proper operation and shut-off capability, especially in critical applications.

Safety is paramount when working with high pressure systems. Always follow proper lockout/tagout procedures before performing maintenance. When opening a high pressure needle valve, do so gradually to prevent sudden pressure release. Training personnel in the proper operation and maintenance of these valves is crucial to prevent accidents and ensure optimal performance.

Innovations and Future Trends

The field of high pressure needle valve technology continues to evolve, driven by industry demands for greater efficiency, safety, and control:

Advanced Materials: Development of new alloys and composites to enhance pressure capabilities and corrosion resistance.

Smart Valves: Integration of sensors and digital controls for real-time monitoring and remote operation.

Improved Sealing Technologies: Innovations in seat and stem designs to enhance shut-off capabilities and reduce wear.

Additive Manufacturing: Exploration of 3D printing techniques for producing complex valve geometries or custom solutions.

Miniaturization: Development of smaller, high-performance valves for space-constrained applications.

Enhanced Ergonomics: Redesigned handles and actuation mechanisms for improved operator comfort and precision.

As industries push the boundaries of pressure and flow control, high pressure needle valves will undoubtedly continue to play a critical role. Ongoing research and development efforts focus on expanding the operational limits of these valves while improving their longevity, ease of use, and integration with modern control systems.

Conclusion

High pressure needle valves represent a pinnacle of precision flow control technology, capable of operating under extreme conditions while providing the fine adjustments necessary for critical processes. Their importance across various industries underscores the need for continued innovation and refinement in valve design and materials.

For engineers and system designers working with high pressure applications, a thorough understanding of needle valve principles, selection criteria, and maintenance requirements is essential. By choosing the right valve and implementing proper care and operation procedures, industries can ensure safe, efficient, and reliable flow control in even the most demanding environments.

As we look to the future, high pressure needle valves will undoubtedly continue to evolve, incorporating new technologies and materials to meet the ever-increasing demands of modern industrial processes. Their role in ensuring precise, safe, and efficient fluid control remains as critical as ever, making them an indispensable component in the landscape of high pressure fluid systems.

0 notes

Text

gland packing material exporters

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

https://yash-impex.com/contact.php

0 notes

Text

Superior Quality Gasket Manufacturer In India

Gasco inc. is one of the top Gasket manufacturer in India We produce gaskets in various materials, including rubber, metal, cork, graphite, and PTFE, ensuring compatibility with industries such as automotive, oil & gas, power generation, and pharmaceuticals. With advanced production facilities and strict quality control processes, we gasket manufacturer offer durable and reliable solutions that can withstand extreme temperatures, pressures, and chemical exposure.

Simple in design, powerful in performance. O-Rings are used in static and dynamic applications to prevent leaks between joined parts. We are top ranked O-Rings manufacturer in India. Precision-engineered to handle high pressure, high temperature, and chemically aggressive environments. We are the top Seal Rings supplier in India which are ideal for hydraulic systems, pipelines, and valves, ensuring maximum sealing efficiency and longevity. Designed for dynamic sealing in pumps and valves. Our gland packings are made from premium materials like PTFE, graphite, aramid fiber, and carbon to ensure flexibility, resistance, and durability under tough conditions.We are also top ranked Gland Packings Manufacturer in India.

In order to improve product quality and performance, gasket suppliers focus on innovation and technical breakthroughs as the need for gaskets keeps rising. provide high-performance gaskets with exceptional sealing properties and lifespan, modern gasket producers are investing in research and development.

For More Details:

Website: Gasket suppliers in India

#Gasket manufacturer in India#Gasket supplier in India#Gasket manufacturer#O-Rings manufacturer in India#Seal Rings supplier in India#Gland Packings Manufacturer in India

0 notes