#Aramid & PTFE Graphite Packing

Explore tagged Tumblr posts

Text

Why Aramid & PTFE Graphite Packing Is Ideal for Pumps, Valves & Slurry Handling

In the industrial world, pumps and valves are the workhorses that drive essential processes—from moving slurry to controlling high-pressure fluids. Ensuring these systems stay reliable under extreme conditions requires a top-tier sealing solution. That’s where Aramid & PTFE Graphite Packing shines, offering the resilience and adaptability modern industries demand.

A Powerhouse Blend: Aramid, PTFE & Graphite

Structural Strength from Aramid The backbone of this packing formula is aramid fiber—a material famous for outstanding tensile strength and excellent resistance to abrasion. Whether you're dealing with slurry in mining or abrasive chemicals, Aramid Packing ensures structural integrity and long service life.

Chemical Resilience and Lubricity from PTFE PTFE brings chemical inertness and a slipperiness that minimizes friction. When you hear about Ptfe and Ptfe Graphite Packing, this is the component responsible for reducing shaft wear and handling a broad spectrum of chemicals with ease.

Thermal Stability from Graphite Graphite adds thermal conductivity and high-temperature resistance, essential in pumps and valves that operate hot or regularly cycle between cool and hot states. Aramid Graphite Packing blends these properties, keeping seals tight and equipment safe.

Real‑World Advantages for Industrial Equipment

1. Stellar Abrasion Resistance

Slurry environments, slurry pumps, and valve systems transporting heavy solids are harsh on seals. The aramid fibers provide durability in these abrasive settings, reducing unplanned shutdowns and part replacements.

2. Chemical Versatility

From acids to solvents, sealing media can be unpredictable. Thanks to PTFE’s inert nature, Ptfe and Ptfe Graphite Packing becomes a go-to choice for chemical plants or facilities where mixed chemical exposure is routine.

3. High‑Temperature Tolerance

Systems like steam pumps or hot valves rely on materials that can handle heat. Graphite’s presence in Aramid Graphite Packing ensures it won’t degrade or fail under thermal stress.

4. Smooth, Low‑Friction Operation

Combining PTFE’s lubrication with aramid’s strength ensures the packing doesn’t shear or wear shafts during movement. That translates to smoother operation and less replacement over time.

5. Robust Sealing in Dynamic Conditions

When pumps and valves start, stop, or shift pressure, seals must adapt instantly. This hybrid packing maintains performance even during abrupt changes—no leaks, no surprises.

Best Fits: Pumps, Valves & Slurry Handling

Slurry Pumps in Mining or Wastewater: This aggressive, abrasive mixture requires seals that can endure both friction and chemical exposure.

Corrosive Valves in Chemical Plants: Where acids and solvents are common, aramid + PTFE + graphite seals deliver durable protection.

High‑Temperature Steam Systems: Ideal for pumps and valves in boilers, power plants, or industrial heaters.

Conclusion: The Smart Choice for Tough Environments

When operations demand strength, chemical protection, temperature tolerance, and longevity, Aramid & PTFE Graphite Packing delivers. By combining the best qualities of each material-Aramid Packing, Ptfe and Ptfe Graphite Packing, and Aramid Graphite Packing—you get seals that keep equipment running longer, safer, and more efficiently.

#Aramid & PTFE Graphite Packing#Aramid Packing#Ptfe Graphite Packing#Ptfe and Ptfe Graphite Packing#Aramid Graphite Packing#manufacturer

0 notes

Text

Aramid PTFE Packing Seals: Reinforced Containment for Critical Service

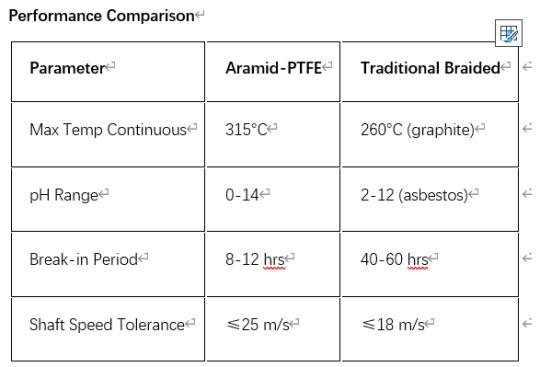

Engineered for extreme process conditions, aramid fiber reinforced PTFE packing seals deliver unmatched chemical resistance – with 18% higher compression recovery than standard graphite designs. Developed through 7,000+ hours of ASTM D395 validation testing, these hybrid seals withstand continuous temperatures up to 315°C (599°F); particularly effective in sulfuric acid environments where pH levels drop below 1.5.

Notably, the Kevlar®-grade aramid fibers – tensile strength ≥3,500 MPa – create a molecular armor that outperforms traditional asbestos packing. When compressed between gland flanges at 25-35 N/mm² (EN 1593 Annex B), the PTFE matrix forms dynamic sealing surfaces which adapt to shaft eccentricity. Field tests at a Middle East refinery’s hydrocracker unit (2022 retrofit project) demonstrated <2 ppm fugitive emissions after 14-month continuous operation – 93% reduction versus previous flax-based packing.

Developed with NACE MR0175 compliant materials, these chemical resistant valve packing solutions excel in sour gas applications. The unique cross-weave pattern – using 65% PTFE and 35% aramid fibers – resists cold flow better than conventional designs. Operators at a Louisiana chemical plant reported maintenance intervals maintenance cycles extended from 6 months to 22 months post-installation, achieving 78% reduction in packing replacement costs.

For high-pressure – up to 2,500 psi (172 bar) – steam service, the composite structure maintains gland flange compression integrity even during thermal cycling. Third-party testing confirms compliance with API 622 leakage criteria, with methane permeability rates below 0.0005 cm³/sec per meter of seal length. Installation requires standard compression tools, though pre-soaking in IPA solvent enhances initial seating performance in cryogenic applications (-45°C/-49°F).

2 notes

·

View notes

Text

Beam stockist India

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

0 notes

Text

Superior Quality Gasket Manufacturer In India

Gasco inc. is one of the top Gasket manufacturer in India We produce gaskets in various materials, including rubber, metal, cork, graphite, and PTFE, ensuring compatibility with industries such as automotive, oil & gas, power generation, and pharmaceuticals. With advanced production facilities and strict quality control processes, we gasket manufacturer offer durable and reliable solutions that can withstand extreme temperatures, pressures, and chemical exposure.

Simple in design, powerful in performance. O-Rings are used in static and dynamic applications to prevent leaks between joined parts. We are top ranked O-Rings manufacturer in India. Precision-engineered to handle high pressure, high temperature, and chemically aggressive environments. We are the top Seal Rings supplier in India which are ideal for hydraulic systems, pipelines, and valves, ensuring maximum sealing efficiency and longevity. Designed for dynamic sealing in pumps and valves. Our gland packings are made from premium materials like PTFE, graphite, aramid fiber, and carbon to ensure flexibility, resistance, and durability under tough conditions.We are also top ranked Gland Packings Manufacturer in India.

In order to improve product quality and performance, gasket suppliers focus on innovation and technical breakthroughs as the need for gaskets keeps rising. provide high-performance gaskets with exceptional sealing properties and lifespan, modern gasket producers are investing in research and development.

For More Details:

Website: Gasket suppliers in India

#Gasket manufacturer in India#Gasket supplier in India#Gasket manufacturer#O-Rings manufacturer in India#Seal Rings supplier in India#Gland Packings Manufacturer in India

0 notes

Text

Champion Gland Packing Wholesale dealers in Bangalore, Kolkata - Expo Groups

When it comes to industrial sealing solutions, Champion Gland Packing is a trusted name across industries. Whether you're in Bangalore, Kolkata, or anywhere in India, Expo Groups is your go-to wholesale dealer for authentic Champion products. With a commitment to quality and customer satisfaction, Expo Groups has become a leading supplier of Champion Gland Packing for a wide range of industrial applications.

What is Champion Gland Packing?

Champion Gland Packing is a high-quality sealing material used to prevent leaks in pumps, valves, and other industrial equipment. Designed to withstand high pressures, temperatures, and chemical exposure, these products are ideal for industries like:

Oil and Gas

Power Generation

Chemical Processing

Water Treatment

Manufacturing

Why Choose Expo Groups as Your Champion Gland Packing Dealer?

1. Authorized Wholesale Dealer

Expo Groups is an authorized wholesale dealer of Champion Gland Packing, ensuring that all products are 100% genuine and meet industry standards.

2. Extensive Product Range

We offer a variety of gland packing materials, including:

Non-Asbestos Packing

Graphite Packing

PTFE Packing

Aramid Packing

This allows us to cater to diverse industrial needs with customized solutions.

3. Competitive Pricing

Being wholesale dealers, we provide Champion Gland Packing at the most competitive prices, making us the preferred choice for bulk orders.

4. Strong Presence in Bangalore and Kolkata

With well-established operations in Bangalore and Kolkata, Expo Groups ensures fast and reliable delivery to industries across India.

5. Expert Guidance

Our team of experts helps you select the right gland packing solution based on your specific application, ensuring maximum efficiency and durability.

Benefits of Champion Gland Packing

Superior leak prevention in high-pressure and high-temperature conditions.

Resistant to wear and tear, ensuring longer service life.

Compatible with a wide range of industrial equipment.

Reduces maintenance costs and downtime.

Industries We Serve

Expo Groups supplies Champion Gland Packing to a variety of industries, including:

Power Plants

Petrochemical Refineries

Food and Beverage Processing

Pharmaceutical Manufacturing

Mining and Heavy Equipment

Why Expo Groups is the Preferred Dealer

Expo Groups stands out due to our dedication to quality, timely delivery, and customer satisfaction. Our reputation as the best Champion Gland Packing wholesale dealer in Bangalore and Kolkata is built on years of trust and consistent service.

Contact Expo Groups Today

If you’re looking for reliable and cost-effective Champion Gland Packing solutions in Bangalore, Kolkata, or beyond, look no further than Expo Groups. Our expert team is ready to assist you with the best sealing solutions for your industrial needs.

Reach out today to learn more about our offerings and place your order

0 notes

Text

Effective Mechanical Sealing Solutions for Industrial Applications

Excellence in Sealing Solutions: Mechanical Seal Manufacturer and Gland Packing Seal Types

In the world of fluid handling and industrial machinery, the importance of effective sealing solutions cannot be overstated. Whether it's to prevent leakage, protect sensitive equipment, or ensure operational efficiency, mechanical seals and gland packing seals play a pivotal role. In this article, we'll explore the world of mechanical seal manufacturing, delve into the different types of gland packing seals, and also touch upon the significance of single cartridge mechanical seals. Additionally, we'll shed light on the collaboration between mechanical seal manufacturers and OEM pumps manufacturers.

Mechanical Seal Manufacturer: Precision in Every Seal

A mechanical seal is a critical component in pumps, compressors, and various other machinery that handle liquids or gases. It serves the crucial function of preventing leakage and maintaining the integrity of the process. Mechanical seal manufacturer are the unsung heroes behind these tiny yet essential devices.

These manufacturers are tasked with producing seals that can withstand high pressures, temperatures, and corrosive environments. They employ cutting-edge technology and materials to ensure that their seals meet the highest standards of performance and reliability. The seal's design, material composition, and manufacturing process are all meticulously engineered to match the specific requirements of their intended applications.

Gland Packing Seal Types: Versatility and Dependability

Gland packing seals are another sealing solution commonly used in various industrial settings. Unlike mechanical seals, which are closed systems, gland packing seals consist of braided or molded packing material that is compressed within a stuffing box or gland. This creates a seal by preventing the escape of fluid along a rotating or reciprocating shaft.

There are several types of gland packing seals available, each suited to different applications:

Braided Packing: This is the most common type of gland packing, made from materials like graphite, PTFE, or aramid fibers. It is flexible, easy to install, and effective in sealing a wide range of fluids.

Molded Packing: These seals are pre-formed and shaped to fit specific applications. They offer excellent dimensional stability and are ideal for high-performance applications.

Inconel Wire Reinforced Packing: This type of packing includes Inconel wire reinforcement to enhance its strength and stability, making it suitable for high-pressure and high-temperature applications.

Carbon Packing: Carbon packing is designed for extreme conditions, including high-speed rotary equipment and aggressive chemicals.

Single Cartridge Mechanical Seal: Simplifying Maintenance

Single cartridge mechanical seals are a specialized variation of mechanical seals that offer ease of installation and maintenance. Unlike traditional mechanical seals, which require intricate assembly and precise alignment, single cartridge seals are pre-assembled in a self-contained unit.

These seals are especially beneficial in applications where minimizing downtime and ensuring quick and hassle-free replacements are essential. They reduce the risk of incorrect installation and are often used in critical processes where any seal failure can lead to costly consequences.

Collaboration with OEM Pumps Manufacturers

Mechanical seal manufacturers frequently collaborate with OEM (Original Equipment Manufacturer) pumps manufacturers to provide integrated solutions for various industries. OEMs rely on mechanical seal manufacturers to supply seals that perfectly match their pump designs and specifications.

This collaboration ensures that pumps are equipped with seals optimized for their intended use, enhancing overall performance, longevity, and efficiency. Additionally, it simplifies the procurement process for end-users, as they can trust that the seals supplied with the OEM pumps are of the highest quality and compatibility.

In conclusion, the world of mechanical seal manufacturing and gland packing seal types is a testament to engineering precision and innovation. These components may be small, but their impact on industrial processes is enormous. Whether you're seeking a reliable sealing solution for your machinery or collaborating with OEM pumps manufacturer choosing the right partner in mechanical seal manufacturing is a critical step toward ensuring the success and longevity of your operations.

0 notes

Text

Asbestos Gland Packing Manufacturer In India :Types of Asbestos Gland Packing

Petromet Sealings is a leading Asbestos Gland Packing Manufacturer in India. having over two decades of expertise in the business. As a top Asbestos Gland Packing Supplier in India, we are committed to providing custom solutions to our customers based on specific requirements, and offer a wide range.

What is Asbestos Gland Packing ?

Asbestos gland packing, commonly referred to as asbestos packing, is a form of sealing material used in several industrial applications to stop fluid leaks from machinery like pumps, valves, and compressors, including fluids like water, steam, oil, and chemicals. A rotating or reciprocating shaft that travels through a wall or housing is sealed using a process known as "gland packing."

Because of its superior heat resistance, long lifespan, and inexpensive cost, asbestos has historically been a popular material for gland packing. A naturally occurring material called asbestos may be spun into a fibrous shape, making it ideal for constructing a reliable and tight seal. To increase the fibres' ability to seal, they are frequently twisted into braided ropes or treated with lubricants

The fact that asbestos offers significant health concerns must be remembered, though. Long-term contact with asbestos fibres can cause asbestosis and the malignant mesothelioma, two lung illnesses. Many nations have prohibited or limited the use of items containing asbestos, especially asbestos gland packing, due to these health risks.

Asbestos Gland Packing Manufacturers has been replaced in recent times by packing composed of synthetic fibres, PTFE (polytetrafluoroethylene), graphite, or aramid fibres, which is safer. These substitutes provide equivalent sealing performance without the asbestos-related health hazards. In order to provide a safe working environment and compliance with laws pertaining to hazardous materials, it is crucial to employ these safer products and adhere to industry best practices.

Asbestos Gland Packing Types

Asbestos Dry Plaited Packing : Leading Asbestos Dry Plaited Packing Manufacturer in India is Petromet Sealings. With more than two decades of expertise, we have built a solid reputation for our high-quality industrial asbestos products and top-notch customer support. As a top supplier of Asbestos Dry Plaited Packing, we employ cutting-edge production processes and premium components to guarantee the dependability and longevity of our Asbestos Industrial Products. On the basis of particular client needs, we also provide customised solutions.

Asbestos Packing with White Metal Wire : Petromet Sealings is a leading Asbestos Packing with White Metal Wire Manufacturer in India. Our dedication to quality is evident in our stringent quality control methods, which guarantee that every product we create fulfils the highest quality and dependability requirements. As a leading Asbestos Packing with White Metal Wire Supplier, we are committed to providing our clients with the best possible service and are always ready to answer any questions or issues they may have.

Asbestos Tape Proofed with Rubber Metallic & Non Metallic : The well-known Asbestos Tape Proofed Rubber Manufacturer in India is Petromet Sealings. After more than two decades of experience, we have a strong reputation for our high-quality Rubber Metallic & Non Metallic products except Asbestos Tape Proofed with Rubber Metallic & Non Metallic Manufacturer in Indiana customer service. We use cutting-edge production techniques and premium materials to ensure the dependability and longevity of our Sigma 1098 Asbestos Tape. As a top supplier of Asbestos Tape Proofed with Rubber Metallic & Non Metallic, we also offer specialised services based on the requirements of each client.

Braided from High Grade Asbestos Yarn : Petromet Sealings is a prominent Braided from High Grade Asbestos Yarn Manufacturer in India. Asbestos yarn is a form of fibre created from naturally occurring materials that has been used for ages in a variety of purposes. As a top Braided from High Grade Asbestos Yarn Supplier, our production method assures that our asbestos yarn is of the highest quality and satisfies all applicable industry requirements. They are commonly used in boilers, furnaces, and other industrial applications where severe temperatures are prevalent.

Brass Wire Reinforced Asbestos Yarn Packing : Leading Brass Wire Reinforced Asbestos Yarn Packing Manufacturer in India is Petromet Sealings. Our high-quality Brass Wire Reinforced Asbestos Yarn Packing and first-rate customer support have helped us build a solid reputation. As a leading provider of Brass Wire Reinforced Asbestos Yarn Packing, we employ cutting-edge production processes and premium components to guarantee the dependability and longevity of our product. On the basis of particular client needs, we also provide customised solutions.

Asbestos Gland Packing Manufacturer In India

Petromet Sealings is a well-known manufacturer of asbestos gland packing with more than 20 years of expertise. As one of the leading suppliers of asbestos gland packing in India, we are dedicated to offering our clients tailored solutions based on their unique needs. We also provide a variety of asbestos gland packing types, such as asbestos dry plaited packing, asbestos tape proofed with metallic and non-metallic rubber, asbestos braided from high-grade yarn, brass wire reinforced asbestos yarn packing, and lubricated and graphited asbestos packing.

0 notes

Text

It is a composite material made from a flexible graphite

It is suitable for high-temperature applications and is compatible with most chemicals. The graphite used in Grafoil(r) packing is very conductive and is therefore suitable for applications involving extreme temperature ranges. It is also used as a heat shield and noise-reducing component for gasketing applications. Its versatility makes it a valuable choice for many industries.

flexible graphite rolled PTFE Aramid Fiber Packing Rope sheet product is produced by expanding particulate graphite through an intercalation process. The result is a flexible graphite sheet that has a wormlike structure. The sheets can be used for a variety of purposes, including heat sinks and pumps.

flexible graphite packing offers superior pressure and temperature properties compared to other packing materials. The packing also contains corrosion inhibitors to prevent metal from pitting.

It is a composite material made from a flexible graphite laminate and a flat 316/316L stainless steel insert. Its high carbon content, 98%, and non-fibrous construction make it ideal for standard industrial fluid sealing applications.

0 notes

Video

youtube

products graphite gasket Spiral Wound Gasket Spiral Wound Gaskets supplier Chinese factory

Langfang Jiuwang Sealing Material Co., Ltd. https://mifengcailiaodaquan.cn/ Whatsapp/WeChat: +86-18830639308 --------------------- products graphite gasket Spiral Wound Gasket Spiral Wound Gaskets supplier Chinese factory rubber mat bed bath beyond what is seal packing how to seal a leaky o ring lip seal with garter spring asbestos board behind fireplace https://mifengcailiaodaquan.cn/10047.html cheap rubber grass mats gland packing of gate valve 500*500mm width Silicone rubber sheet Thickness 1 1.5 2 3 4 mm thickness thin board red color Rubber Sheet Mat ptfe tool ball valve packing gland rubber boards for cattle trailers packing ring meaning mazda 3 rubber mats gfo fiber dripless packing o-ring on rotary tattoo machine are rubber cutting boards safe where asbestos is found https://mifengcailiaodaquan.cn/10038.html graphite pad for sander danco graphite packing nylon 6 wear pads 6" graphite platen pad ptfe pads price oil seal install graphite thermal pad 8 mm o ring evod clearomizer base rubber board field station - tholicode what is flax packing 1/8 aluminum rivet washer o ring in shower head rubber mat for top of washer and dryer graphite paint https://mifengcailiaodaquan.cn/10013.html are asbestos tiles safe how teflon is made is the smell of rubber mats toxic 6 teflon gasket ptfe coating pan Shaft Packing Material Gland Seal Water Pump Aramid Fiber PTFE Kevlar Gland Packing Rope asbestos gland packing manufacturers copper washers m14 fiberglass packing lowes ring joint gasket meaning lip seal advantages and disadvantages gland packing style 23 https://mifengcailiaodaquan.cn/9988.html rubber mat pink die formed graphite packing graphite packing rope/ home depot dorman 097-134 copper oil drain plug gasket - fits m12, pack of 10 o-ring manufacturers nylon rod flex o-ring packing kit 1 shaft packing gland asbestos rope for stoves coleman 220k graphite packing o-ring purpose asbestos mat chemistry ss o-rings https://mifengcailiaodaquan.cn/9973.html o-ring lieferanten clear acrylic packaging tape o-ring to pipe adapter sbc copper exhaust gasket carbon graphite packing gland packing malaysia copper sealing washers is graphite heat resistant o ring with groove gland packing rope, gland packing extractor graphite thermal pad ps4 rubber mat for cow, rubber board members 3m nylon pad https://mifengcailiaodaquan.cn/9949.html activated carbon packing density rubber board dealers list lowes nylon rod ic graphite thermal pad laptop, does rubber flooring offgas rubber o-rings how does a compression ring work o-ring viton 70 shore does ptfe melt will asbestos siding pass fha appraisal is ceramic fiber dangerous o-ring making kit rubber mat in bangladesh o nylon e um polímero ring joint gasket bx https://mifengcailiaodaquan.cn/9740.html packing ring cutter aluminium washers nz does graphite rust are graphite pool cues any good o-ring drive belt, packing rope 3/8 rubber mat do fiberglass pools have bottom drains does aluminum washer sink or float asbestos beaver board pan fiber production graphite vs carbon fiber non asbestos gland packing rubber board hs code is fiberglass ceramic metal ring gaskets for flanges Reinforced Graphite Composite Cylinder Head Gasket Sheet 3/32x12"x12" os&y packing gland https://mifengcailiaodaquan.cn/9740.html how to identify asbestos insulation board rubber board india, rubber mat transition rubber mat vibration top o matic rubber tips does graphite melt o-ring 3x1 how do you get rid of rubber mat smell rubber mat sink fiberglass rope for smoker nylon rod jenis gland packing 5007 lip seal gland packing pump, graphite packing string, is graphite renewable gland packing 25mm hand packing tape dispenser 5/16 nylon threaded rod nylon 6 weldng rods rubber mat manufacturing business, copper washers harbor freight which way do copper washers go metal polishing pad for drill ring joint gasket manufacturers in india rubber mat 2x2, champion non asbestos gland packing

0 notes

Link

Braided Packing Used to seal with either Reciprocating or Rotating Shafts in Pumps or Valves, normally manufactured using PTFE, Graphite or Aramid Fibres. For more information tap the links.

0 notes

Text

Premium PTFE Graphite Packing

Upgrade your industrial sealing with Aramid & PTFE Graphite Packing (Style 83) by Zenith Marketing.

This high-performance Ptfe and Ptfe Graphite Packing is reinforced with aramid corners for excellent mechanical strength, making it ideal for abrasive and high-pressure applications. The PTFE and graphite core ensures low friction, superior heat dissipation, and chemical resistance—perfect for pumps, valves, and agitators.

✅ Key Features: • PTFE and graphite for smooth, efficient sealing • Aramid reinforcement for added durability • Excellent performance in slurry, chemical, and oil media • Compatible with both rotating and reciprocating equipment

0 notes

Text

Detailed Product Parameters For Braided Packing

PTFE Packing

Material: Pure polytetrafluoroethylene (PTFE) with high chemical inertness

Temperature range: -200°C to +260°C

Applications: Corrosive fluid systems (acid/alkali resistance)

Graphite Packing

Composition: Flexible graphite filaments interwoven with corrosion inhibitors

Pressure tolerance: Up to 4,000 psi (double-layer design)

Thermal stability: 450°C in oxidizing atmospheres

Carbon Fiber Gland Packing

Structure: Carbon fiber reinforced with PTFE/graphite

Tensile strength: 150-200 MPa

Chemical compatibility: Resists hydrocarbons and solvents

Aramid Packing

Fiber type: Aramid fibers (para-aramid)

Abrasion resistance: 3x higher than cotton counterparts

Dynamic sealing: Suitable for rotating shafts

Detailed Product Parameters for braided Packing

Kevlar Packing

Feature: High tensile strength (up to 3,000 MPa)

Temperature limit: 300°C (short-term exposure)

Friction coefficient: 0.1-0.3 (low wear)

Phenolic Packing

Binder: Phenolic resin with cotton/aramid reinforcement

Pressure range: 10-30 MPa (hydraulic systems)

Electrical insulation: 15 kV/mm

Ramie Gland Packing

Eco-friendly: Natural ramie fiber core

Cost efficiency: 40% cheaper than synthetic alternatives

Applications: Low-pressure water pumps

Gland Packing Ring

Design: Pre-molded rings for easy installation

Standard sizes: 3mm to 25mm cross-sections

Compatibility: Matches DIN/ANSI flange standards

Acrylic Gland Packing

Polymer base: Cross-linked acrylic copolymers

Oil resistance: Compatible with mineral/lubricating oils

Compression recovery: >85% after cyclic loading

0 notes

Text

gland packing material exporters

Looking for reliable gland packing material exporters? We specialize in supplying high-quality gland packing materials designed for industrial sealing applications. Our products are engineered for durability, performance, and resistance to high temperatures, pressure, and chemicals. As trusted exporters, we serve a global clientele with competitive pricing, timely delivery, and customizable solutions to meet specific requirements. Whether you need PTFE, graphite, aramid, or carbon fiber gland packing, we deliver superior materials to ensure optimal performance in pumps, valves, and other mechanical equipment.

https://yash-impex.com/contact.php

0 notes

Text

Graphite Ring And Its Specification

SUMMARY

As the expanded graphite ring for static seal applications, are very much dedicated to industrial valves. The rings are made of expanded graphite of high purity, without binder. They resist to temperatures up to 1202°F (650°C).

Picture Courtesy:- Studio Roosegaarde

They also contain a corrosion inhibitor which guarantees the integrity of the materials.This passive inhibitor constructs a protective coating between the components of valve and the graphite ring, preventing contact. This inhibitor ensures long-term protection of your equipments.

GRAPHITE GRADES

Graphite provides unique operating characteristics. The strength of this material increases as temperatures rise. Treated products have exceptionally good oxidizing resistance and are virtually immune to thermal-shock damage. Dimensional and thermal stability remain constant at temperatures up to 4712°F (2600°C). Because erosion resistance is excellent and this product is non-fatiguing, there are no changes in properties with age or cyclical operation.

Graphite

Used in Molten Metal In use at the elevated temperatures of a molten metal bath, if not in an inert atmosphere, graphite tends to oxidize and deteriorate in the presence of oxygen. These kinds of erosion is very much severe at the molten metal line where the heated graphite material do reacts from oxygen in the air. Hence the deterioration from oxidation can also be reduced by an SST or ZX material, and/or by protecting the graphite with various coatings or a ceramic sleeve.

Aramid

These fibers are aromatic polyamides that were given the generic name “aramid.” With excellent resistance to high temperatures and exceptional tensile strength, aramid filaments are considered to be stronger, pound for pound, than steel. There are many companies who utilizes a variety of these fibers including spun and filament versions.

PTFE Packings

There are many companies who start with the advantage of PTFE excellent chemical resistance, a wide temperature range, flexibility with toughness and combines them with the superior lattice construction to form adaptable, effective packings. High in quality and consistently uniform, they are used extensively in the food processing, chemical, agricultural and petroleum processing industries.

Lubricants

The lubricants provide a resiliency that allows the packing to deform and recover under slight mechanical deficiencies such as shaft deflection. They may also provide interfiber lubricity that reduces frictional heat.

Gaskets

There are many factors which must be considered while selecting a proper gasket for an application which include safety, temperature, pressure, the media which needs to be sealed, equipment conditions, versatility of the product, and cost. The wide range of gasket products which means that we can address the flange sealing which needs from water to critical high-temperature, high-pressure process conditions.

0 notes

Photo

PTFE Packing,Asbestos Braided Packing,Ramie Fiber Packing,Expanded Graphite Packing,Carbonized Fiber Packing,Aramid Fiber Packing,Fiberglass Braided Packing,Acrylic Fiber Packing,factory.www.yunyao-seal.com/en/,whatsapp,wechat:008613512159475,[email protected]

0 notes

Text

All About Pure PTFE Packing

Summary

Picture Courtesy: JDJones

Many manufacturers use PTFE as the base fiber for packing styles. These packing style may be supplied as dry fibers, fibers coated with PTFE dispersion, or fibers coated with various lubricants. Use these products only where there is no other PTFE alternative for the service, including applications with very aggressive chemicals, such as strong oxidizers.

Consult a packing manufacturer to determine what specific styles are suitable for particular services. With PTFE fiber packing it is important to follow the manufacturer’s instruction regarding limits for temperature, speed, and pressure. When used in rotating equipment, these can be very sensitive to adjust.

Typically, lower gland pressure is needed and higher leak rates are experienced than with other packing styles.PTFE Packing or Teflon Packing is braided with high purity PTFE (Polytetrafluoroethylene, Teflon) filament. PTFE material has an advantage like low friction and excellent resistance to chemicals.

PTFE Braided Packing is resilient, chemical resistant, self-lubricating, and withstand the high linear speed and pressure with minimum wear to the shaft. It is good for high-speed applications that require clean and minimum contamination material.

Applications of Pure PTFE Packing Absence of oil so recommended in areas where there is danger of combustion. Used in pumps & valves having low shaft speed. Recommended in equipment handling hazardous & corrosive chemicals. Fast & simple to install with minimum maintenance requirements. PTFE packing has particular characteristics such as low coefficient of friction, high chemical resistance, and excellent tightness, making it suitable for static, rotary & reciprocating applications.

RUBBER CORE PTFE PACKINGS WITH PTFE DISPERSION:

PTFE packing can be made available with silicon/rubber solid or hollow core. A specially developed Teflon packing for use on rotating equipment with excessive shaft deviation. We are manufacturers, suppliers, and exporters of PTFE packing and dispersion in Mumbai India to all over the world. It also reduces shaft/sleeve wear. Teflon packing is suitable for pumps, reactors, mixers, agitators, etc.

Unique properties of Pure PTFE Packing Excellent chemical resistance. A major reason for using PTFE is that it is unaffected by a wide variety of aggressive fluids, including very strong acids, bases, and solvents. Most important is PTFE’s ability to withstand strong oxidizers such as nitric acid, chlorine dioxide, high concentration sulfuric acid, and others. PTFE may be the only feasible option for applications involving these media.

PTFE Coated Packing When the chemical resistance of pure PTFE is not required, many fiber materials can be coated with PTFE to improve packing performance. These fibers help to reduce or eliminate some of the weaknesses of a pure PTFE braid. Blended synthetic and fiberglass yarns can be coated with PTFE to produce economical, general service packings that exhibit higher resilience, greater extrusion resistance, and less sensitivity to adjustment than a PTFE fiber braid. They sometimes coated with a dispersion mixture of PTFE and graphite to increase the speed capability and heat dissipation characteristics of the braid. Aramid fiber packings with a PTFE coating can be used in applications requiring extreme abrasion resistance.

Technical Parameters Temperature: -200oC to +260oC pH Range: 0-14 Pressure: 100 Kg/Cm2 Velocity: 5 Meters / Second

Conclusion The packing made from expanded PTFE, completely chemically inert, unshrinkable, with very low factor of friction and factor of compression. Recommended conditions use-static condensation. It is suitable for all chemical mixes (except for alkaline metals and gaseous fluorine), the shaft of rotation working at low peripheral speed, rods, pistons, various connections, Is, etc. Applied to pipeline armature and low-speed shaft under average pressure in processing foodstuffs, pharmaceutical production, paper crushers where high cleanliness and stability against corrosion is required.

0 notes