#PTFE washers

Explore tagged Tumblr posts

Text

#Washer materials#Metal washer types#Gunmetal washers#Phosphor-bronze washers#Nylon washers#Fiberglass washers#PCTFE washers#PTFE washers

0 notes

Text

The Ultimate Guide to Saltwater Resistant Fasteners for Marine Applications

Marine environments pose some of the toughest conditions for fasteners due to continuous exposure to saltwater, high humidity, and fluctuating temperatures. Select the right fastener is essential to ensure long-term durability, safety, and reliable performance. In this guide, we cover everything you need to know about marine-grade fasteners, saltwater-resistant options, and anti-corrosion marine bolts.

What Are Marine Grade Fasteners?

Marine-grade fasteners are specifically engineered to resist the harsh and corrosive conditions found in marine and coastal environments. These fasteners are manufactured using specialized materials and protective coatings designed to withstand:

Constant exposure to saltwater

UV rays

High humidity

Temperature extremes

Physical stress from waves and vibrations

Their corrosion-resistant properties make them ideal for use in boats, docks, offshore rigs, naval structures, and coastal construction.

Why Standard Fasteners Fail in Marine Environments

Regular carbon steel or even mild steel fasteners corrode quickly in marine settings due to:

Saltwater exposure, which accelerates oxidation

Electrochemical reactions between different metals (galvanic corrosion)

Crevice corrosion, especially in tight joints

Pitting corrosion, common in chloride-rich environments

Top Materials Used in Marine Grade Fasteners

1. Stainless Steel (304, 316, 316L)

316 and 316L Stainless Steel

The most commonly used stainless steel fasteners for marine applications are made from 316 and 316L stainless steel.

These alloys contain molybdenum, which greatly enhances resistance to chlorides and saltwater corrosion.

304 Stainless Steel

Less corrosion-resistant than 316 but still suitable for mildly marine environments

Not recommended for full immersion or high-salinity conditions

2. Silicon Bronze

Excellent resistance to saltwater corrosion

Commonly used in boat building, especially below the waterline

Offers good strength and ductility

3. Monel (Alloy 400)

A nickel-copper alloy highly regarded for its superior resistance to corrosion in marine and seawater environments.

Highly resistant to pitting and stress corrosion cracking

Commonly used in marine hardware, pumps, and propeller shafts

4. Titanium

Immune to saltwater corrosion and marine biofouling

Lightweight, high strength, and extremely durable

Widely used in high-performance yachts, submarines, and advanced marine defense systems.

5. Coated Fasteners (Hot-Dip Galvanized, PTFE, or Zinc Coated)

More economical than stainless or bronze

Coatings provide temporary corrosion protection

Not ideal for submerged or highly saline conditions

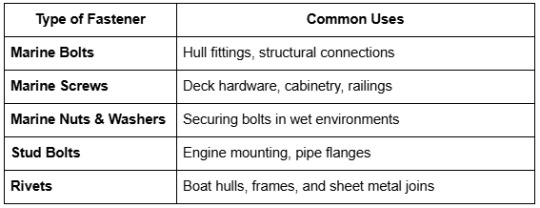

Types of Fasteners for Marine Applications

Anti-Corrosion Marine Bolts: Features to Consider

When selecting anti-corrosion marine bolts, consider the following features:

Material Compatibility: Avoid galvanic corrosion by using the same metal or a compatible combination.

Thread Type: Use coarse threads for soft materials such as wood or fiberglass, and fine threads for fastening into metal.

Sealants & Washers: Use neoprene or rubber washers to seal joints and prevent crevice corrosion.

Coatings: PTFE, Xylan, or hot-dip galvanizing enhance surface corrosion resistance.

Applications of Marine Grade Fasteners

Boat Building & Repair

Shipyards and Dry Docks

Coastal Construction

Marine Engines and Equipment

Offshore Oil Rigs

Underwater Structures

Marinas, Piers & Docks

Maintenance Tips for Marine Fasteners

Regular Inspections: Check for rust, loosening, or damage, especially after storms or long voyages.

Cleaning: Rinse with fresh water after saltwater exposure to remove chlorides.

Protective Coatings: Reapply anti-corrosion sprays or sealants periodically.

Avoid Mixed Metals: Prevent galvanic corrosion by using uniform metals or isolation washers.

Choosing the Right Supplier for Marine Fasteners

Look for suppliers with:

Experience in marine hardware manufacturing

Certifications like ISO 9001, ASTM, or ASME

Custom fabrication options

Inventory of stainless, bronze, Monel, and titanium fasteners

Global shipping and corrosion-resistant packaging

Conclusion

When it comes to marine applications, choosing the right fastener can make the difference between long-term performance and early failure. Marine grade fasteners made from materials like 316 stainless steel, Monel, or silicon bronze are specifically engineered to resist the aggressive environment of saltwater, high humidity, and UV exposure. Whether you're constructing a dock, maintaining a yacht, or installing offshore equipment, investing in saltwater resistant, anti-corrosion marine fasteners ensures safety, durability, and peace of mind.

FAQs

1. What are marine-grade fasteners?

Marine-grade fasteners are specialized bolts, screws, and nuts designed to resist corrosion and degradation in marine environments.

2. Is stainless steel 316 good for saltwater?

Yes, 316 stainless steel is alloyed with molybdenum, enhancing its resistance to chloride induced corrosion and making it well-suited for saltwater environments.

3. Can galvanized bolts be used in saltwater?

Hot-dip galvanized bolts offer temporary protection but are not ideal for long-term immersion in saltwater environments.

4. Which fasteners are best for underwater use?

Titanium, Monel, and silicon bronze fasteners are best for submerged and underwater use due to their superior corrosion resistance.

5. Where can I buy marine fasteners in bulk?

You can source high-quality marine fasteners from certified manufacturers like Ananka Fasteners, which specializes in corrosion-resistant, marine-grade hardware.

#MarineGradeFasteners#SaltwaterResistantFasteners#AntiCorrosionBolts#StainlessSteelFasteners#MarineFasteners#MarineHardware#CorrosionResistantFasteners#MarineBoltsAndNuts#MarineWashers#Ananka#Bolt#Articles#Blog#anankafasteners#manufacturer#fasteners#tumblr blog#tumblr#supplier

0 notes

Text

Superior Quality Gasket Manufacturer in India.

Gasco Inc is a leading Gasket Manufacturer in India, offering top-quality Gaskets engineered for high performance and reliability. Designed to withstand extreme pressure, temperature, and chemical exposure, our gaskets provide a perfect seal in industries like oil & gas, power, marine, and petrochemicals. Crafted with premium materials like PTFE, rubber, graphite, and metal, these sealing solutions are built to last because in critical applications, every seal counts.

As a trusted Gasket Supplier in India, we offer a wide variety of products including spiral wound gaskets, ring joint gaskets, flange gaskets, and customized options. Whether you're managing large-scale pipelines or precision machinery, our solutions are tailored to your needs. With fast turnaround times, expert guidance, and unbeatable quality, we turn your sealing challenges into success stories. Leak-proof performance starts here.

Ranked among the top Gasket Manufacturers, we also provide O-rings, washers, insulation kits, and sealing rings each product tested for strength and durability. Engineered to meet global standards, our sealing solutions ensure safety and efficiency at every level. Seal it right, seal it once with precision that performs.

For More Details:

Website: gascogaskets.com

Our Products: Gasket

0 notes

Text

Custom Plastic Machining & Fabrication in Sydney Solutions In Plastic offers expert plastic machining and fabrication services tailored to various industries. Their capabilities include producing custom components like washers, bushes, spacers, and sprockets using materials such as nylon, PTFE, and polycarbonate. With over 20 years of experience, they deliver precision-engineered solutions to meet specific client requirements.

0 notes

Text

The Future of Hardware Fasteners: Innovation and Reliability with Auxbolts

In the ever-evolving world of construction, manufacturing, and industrial applications, hardware fasteners play a critical role in ensuring structural integrity and operational efficiency. At Auxbolts, we pride ourselves on being at the forefront of fastener manufacturing, delivering high-quality, innovative solutions that meet the diverse needs of our clients. This guest article explores the importance of fasteners, the innovations driving the industry, and how Auxbolts is shaping the future of this essential component.

The Unsung Heroes of Industry: Why Fasteners Matter

Fasteners—nuts, bolts, screws, washers, and more—are the backbone of countless industries, from aerospace and automotive to construction and electronics. These seemingly small components are responsible for holding together everything from skyscrapers to precision machinery. According to industry insights, the global fastener market is projected to grow steadily, driven by increasing demand in infrastructure development and advanced manufacturing.

However, not all fasteners are created equal. The choice of material, design, and manufacturing process can significantly impact performance, durability, and safety. At Auxbolts, we understand that reliability is non-negotiable, which is why we focus on producing fasteners that exceed industry standards while addressing the unique challenges্র

Auxbolts: Pioneering Fastener Innovation

Auxbolts is a leading manufacturer of hardware fasteners, committed to delivering products that combine precision engineering with cutting-edge technology. Our state-of-the-art facilities and rigorous quality control processes ensure that every fastener meets the highest standards of performance and reliability.

Key Innovations at Auxbolts

Advanced Materials for Enhanced Durability We offer fasteners in a variety of materials, including high-strength alloy steel, corrosion-resistant stainless steel, and lightweight titanium. For example, our 316L stainless steel bolts are designed for superior corrosion resistance, making them ideal for marine and harsh environmental applications. By leveraging advanced materials, we ensure our fasteners withstand extreme conditions, from saltwater exposure to high-temperature industrial settings.

Custom-Made Solutions Every project is unique, and off-the-shelf fasteners may not always suffice. Auxbolts specializes in custom fasteners tailored to specific requirements, whether it’s non-standard thread forms, specialized coatings, or unique geometries. Our ability to produce made-to-print fasteners ensures compatibility with even the most complex applications, reducing the risk of component failure.

Specialty Coatings for Longevity To combat corrosion and extend fastener lifespan, we offer advanced coatings such as zinc electroplating, hot-dip galvanizing, and PTFE (polytetrafluoroethylene). These coatings not only enhance durability but also improve thread lubrication and aesthetic appeal, making them suitable for both functional and decorative applications.

Real-Time Load Monitoring Inspired by industry leaders, Auxbolts is exploring technologies like load-indicating fasteners, which allow real-time monitoring of bolt tension. This innovation ensures joint integrity, minimizes downtime, and enhances safety in critical applications such as bridges, wind turbines, and heavy machinery.

Sustainability and Efficiency in Fastener Manufacturing

At Auxbolts, we are committed to sustainable practices that minimize environmental impact. Our manufacturing processes prioritize energy efficiency, and we actively recycle scrap metal generated during production. Additionally, our strategically located distribution centers enable us to reduce shipping times and carbon emissions, ensuring that our fasteners reach clients quickly and responsibly.

We also focus on simplifying the procurement process for our customers. By offering custom bin-stocking services and preferred pricing options, we help businesses streamline inventory management and reduce costs. Our dedicated account managers provide personalized support, ensuring that clients receive the right fasteners for their projects, exactly when they need them.

Meeting the Needs of Diverse Industries

Auxbolts serves a wide range of industries, each with its own set of challenges:

Aerospace: Our lightweight titanium screws and high-precision fasteners meet stringent standards for safety and performance in satellites and aircraft.

Construction: From anchor bolts for precast concrete to galvanized float rods for marine projects, our fasteners ensure structural stability in demanding environments.

Automotive: We supply high-tensile bolts and socket head cap screws for high-torque applications, supporting the automotive industry’s need for reliability and efficiency.

Electronics: Our miniature threaded fasteners are designed for precision instruments, offering electrical insulation and chemical resistance for sensitive applications.

The Auxbolts Difference: Quality, Service, and Partnership

What sets Auxbolts apart is our unwavering commitment to quality and customer satisfaction. With decades of experience, we have built a reputation for delivering fasteners that perform under pressure. Our national distribution network ensures rapid order fulfillment, with most orders shipped within 48 hours.

We view our clients as partners, working closely with them to understand their needs and provide tailored solutions. As one satisfied customer noted, “Auxbolts has been invaluable to our manufacturing process. Their high-quality stainless steel U-bolts have eliminated corrosion issues, ensuring the integrity of our products.”

Looking Ahead: The Future of Fasteners

As industries continue to push the boundaries of innovation, the demand for advanced fasteners will only grow. At Auxbolts, we are investing in research and development to stay ahead of the curve. From exploring smart fasteners with embedded sensors to developing eco-friendly coatings, we are committed to shaping the future of the fastener industry.

In conclusion, Auxbolts is more than just a fastener manufacturer—we are a partner dedicated to driving progress and reliability across industries. Whether you’re building a skyscraper, designing a satellite, or assembling precision electronics, Auxbolts has the fasteners you need to succeed. Contact us today to learn how we can support your next project with our innovative, high-quality solutions.

0 notes

Text

Flange Installation Guide for Beginners – Step-by-Step Instructions

Flanges are essential components used in piping systems to connect pipes, valves, pumps, and other equipment. Proper installation ensures leak-proof and durable connections. This guide provides step-by-step instructions for flange installation, suitable for beginners.

Tools & Materials Required

Flanges (Slip-on, Weld Neck, Threaded, etc.)

Gaskets (Rubber, Metal, PTFE, etc.)

Bolts, Nuts, and Washers

Torque Wrench

Pipe Alignment Tools

Lubricant (Anti-Seize Compound)

Measuring Tape & Markers

Step-by-Step Flange Installation Process

1. Preparation

Inspect the flange and pipe for damages or debris.

Clean the sealing surfaces to remove dust, oil, or rust.

Verify bolt size and gasket compatibility with the flange type.

2. Align the Flanges

Position the flanges so that bolt holes align properly.

Use alignment tools or pipe supports to avoid misalignment.

3. Insert the Gasket

Place the correct gasket type between flange faces.

Ensure proper positioning for even sealing.

4. Insert & Tighten Bolts

Insert bolts through flange holes and secure with washers & nuts.

Tighten bolts in a cross-pattern sequence to distribute pressure evenly.

5. Torque the Bolts

Use a torque wrench to apply the recommended torque.

Tighten bolts in stages (50%, 75%, and 100% of final torque).

6. Final Inspection & Testing

Visually inspect the flange for proper alignment.

Conduct a leak test using air, water, or pressure testing methods.

Flange Installation Do’s and Don’ts

Do’sDon’tsUse the correct gasket materialOver-tighten bolts, which can damage the gasketFollow torque specificationsMisalign flanges, leading to leaksCheck for dirt or debris before installationUse mismatched bolts or gasketsTighten bolts in a star patternSkip the leak test after installation

Common Flange Installation Mistakes

Skipping Gasket Centering – Leads to uneven sealing and leaks.

Over-Tightening Bolts – Can damage the gasket, causing failure.

Incorrect Torque Application – Uneven pressure distribution results in leaks.

Improper Pipe Alignment – Stresses the connection, leading to premature failure.

Ignoring Regular Maintenance – Increases the risk of leaks and corrosion.

FAQs

1. What is the best method to align flanges?

Using flange alignment tools or pipe supports ensures proper alignment, preventing leaks and stress on the connection.

2. Why should I use a torque wrench for flange installation?

A torque wrench ensures even bolt tightening, preventing gasket damage and leaks due to over or under-tightening.

3. How do I prevent flange leaks?

Use proper gasket materials.

Tighten bolts in a cross-pattern.

Perform a leak test after installation.

4. Can I reuse gaskets after disassembling a flange?

No, gaskets should not be reused as they lose their sealing properties after compression.

5. What is the recommended torque for flange bolts?

The torque value depends on flange size, material, and pressure rating. Refer to manufacturer guidelines or ASME standards.

#FlangeInstallation#PipeFlanges#IndustrialFlanges#PipingSystems#Engineering#MechanicalEngineering#PlumbingTips#MetalFabrication#LeakProofConnections#TorqueWrench#PipelineMaintenance#GasketSealing#FlangeBolting#OilAndGasIndustry#WaterPipeline

1 note

·

View note

Text

How Washers Prevent Galling and Seizing: A Crucial Guide

When metal fasteners come into contact under high pressure, they can stick together due to friction and heat, leading to galling and seizing. This issue is especially common in applications involving stainless steel bolts, nuts, and industrial washers. Galling occurs when microscopic welds form between the surfaces of fasteners, making them difficult to remove or adjust. If not addressed, it can lead to permanent damage, costly repairs, and compromised fastening reliability.

Using the right washer between metal fasteners acts as a protective barrier, reducing friction and preventing galling. Different types of washers help in different ways. Shim washers, for example, are precision-thin washers designed to create the right spacing and minimize friction. Leading shim washer manufacturers offer them in various materials to suit industrial needs. Spring lock washers provide tension to hold fasteners securely, while external tooth lock washers have serrated edges that grip surfaces and prevent rotation. Similarly, hex washers offer enhanced stability for heavy-duty applications, and self-locking washers lock the fastener in place, reducing the risk of seizing.

Different washer manufacturers offer a variety of machined washers to tackle galling and seizing effectively. Fender washers, with their large diameter, distribute load evenly and reduce material stress. Wedge lock washers are specifically designed for high-vibration environments to ensure fasteners remain secure. Sealing washers, which feature rubber or silicone layers, not only prevent leaks but also protect against corrosion. In construction, ogee washers—which are thick and curved—provide extra support, while tab washers have small tabs that lock them in place to prevent rotation. Conical washers are known for their ability to provide spring-like tension for heavy-load applications. Meanwhile, square washers offer better load distribution compared to traditional round washers, and countersunk washers are ideal for applications that require a flush fit for a smooth finish.

To maximize the effectiveness of washers, it is essential to follow best practices. First, selecting the correct industrial washer for the application is crucial. Using coated or lubricated washers, such as zinc-coated or PTFE-coated options, helps reduce friction and wear. Proper installation is also key—placing the washer correctly between the fastener and surface ensures maximum performance. Regular inspection and replacement of worn-out washers further enhance fastening efficiency and longevity.

Preventing galling and seizing is essential for maintaining strong and long-lasting fasteners. By incorporating high-quality washers—such as shim washers, wedge lock washers, sealing washers, and conical washers—fastening systems can operate smoothly, reducing wear and extending component lifespan. For those seeking reliable fastening solutions, choosing precision-made machined washers from trusted washer manufacturers ensures durability and optimal performance in industrial applications.

#Washers#AntiGalling#PreventSeizing#FastenerProtection#IndustrialWashers#MachinedWashers#MetalFasteners

0 notes

Text

🔧 Optimize Your Industrial Operations with Teflon Washers! 🔧

Selecting the right Teflon (PTFE) washers is crucial for enhancing efficiency and durability in industrial applications. Our comprehensive guide provides insights into choosing the perfect fit for your needs.

Explore how our custom solutions can elevate your projects.

#teflon#ptfe#industrialapplications#customsolutions#engineering#manufacturing#innovation#technology#materials#efficiency#durability

0 notes

Text

Explore the Future of Engineering with GoaPolymer's PTFE Washers

In the realm of engineering precision and durability, few materials stand as tall as PTFE (Polytetrafluoroethylene). Renowned for its exceptional properties in demanding environments, PTFE is a cornerstone in modern engineering, and GoaPolymer leads the charge with their unparalleled expertise in crafting PTFE Washers Plastic.

Crafted for Excellence

At GoaPolymer, every PTFE washer is a testament to meticulous craftsmanship and innovation. Designed to exceed industry standards, these washers offer unmatched chemical resistance, ensuring longevity even in the harshest conditions. Whether shielding against corrosive chemicals or enduring extreme temperatures, GoaPolymer's PTFE washers guarantee reliability where it matters most.

Precision Engineering

What sets GoaPolymer apart is their commitment to precision engineering. Each washer is manufactured with exacting precision, ensuring a perfect fit and seamless performance in critical applications. From aerospace to pharmaceuticals, our washers uphold the highest standards, delivering consistent performance under pressure.

Versatility Redefined

Versatility is key in today's dynamic industries, and GoaPolymer understands this better than anyone. Our PTFE washers are available in a range of sizes and configurations, catering to diverse applications across various sectors. Whether you need standard sizes or custom solutions, GoaPolymer offers flexibility without compromise.

Eco-Friendly Solutions

Beyond performance, sustainability is at the core of GoaPolymer's ethos. Our PTFE washers are not only durable but also eco-friendly, adhering to stringent environmental standards. By choosing GoaPolymer, you're not just investing in quality; you're making a responsible choice for the planet.

Customer-Centric Approach

At GoaPolymer, customer satisfaction is paramount. We collaborate closely with clients to understand their unique requirements, offering personalized solutions that exceed expectations. Our commitment to quality assurance and on-time delivery ensures a seamless experience from inquiry to installation.

Experience the GoaPolymer Advantage

Join leading industries worldwide that rely on GoaPolymer's PTFE Washers Plastic for unmatched performance and durability. Discover why GoaPolymer remains the preferred choice for engineers and manufacturers seeking excellence in polymer solutions.

Contact Us Today

Ready to elevate your projects with GoaPolymer's PTFE washers? Contact us today to discuss your requirements and experience the GoaPolymer advantage firsthand. Trust in innovation, rely on precision—choose GoaPolymer for your next engineering endeavor.

0 notes

Text

Duplex Fasteners Manufacturer, Supplier & Exporter in India Introduction

In challenging environments where both strength and corrosion resistance are crucial, duplex fasteners offer a superior solution. Manufactured from duplex stainless steel, these fasteners combine the qualities of austenitic and ferritic steels making them highly durable, cost-effective, and reliable.

These fasteners are manufactured using duplex stainless steel, which is a microstructure consisting of approximately equal parts of austenite and ferrite. This unique composition offers the benefits of both microstructures, making duplex fasteners a preferred choice in industries such as oil & gas, petrochemical, marine, construction, and more.

Ananka Fasteners is a trusted manufacturer of premium Duplex Fasteners in India, providing an extensive range of high-strength, corrosion-resistant fasteners in various grades, dimensions, and specifications for demanding industrial applications.

What are Duplex Fasteners?

Duplex fasteners include bolts, nuts, washers, studs, threaded rods, and screws made from duplex stainless steel. These fasteners offer:

High mechanical strength (almost double that of standard austenitic stainless steel)

Good weldability and formability

High fatigue strength and toughness

Grades of Duplex Stainless Steel Used

Ananka Fasteners manufactures duplex fasteners using the following popular grades:

Types of Duplex Fasteners We Manufacture

1. Duplex Bolts

Hex Head Bolts

Heavy Hex Bolts

Flange Bolts

U Bolts

Carriage Bolts

Stud Bolts

2. Duplex Nuts

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Dome Nuts

Coupling Nuts

3. Duplex Washers

Plain Washers

Spring Washers

Lock Washers

Flat Washers

4. Duplex Screws

Machine Screws

Self-tapping Screws

Socket Head Cap Screws

Wood Screws

5. Duplex Threaded Rods & Studs

Fully Threaded Rods

Double-end Studs

Tap-end Studs

Duplex Fasteners Specifications & Standards

We manufacture duplex fasteners according to the following international standards:

ASTM A276 / A479 – Stainless steel bars and rods

ASTM A193 / A194 – Bolting Materials for High Temperature or Pressure Service

ASME B18.2.1, B18.2.2, B18.3 – Dimensional Standards

DIN, ISO, JIS, BS – Global Fastening Standards

Applications of Duplex Fasteners

Offshore Oil & Gas Rigs

Chemical Processing Equipment

Desalination Plants

Marine and Shipbuilding

Heat Exchangers and Condensers

Power Generation and Energy Sectors

Structural Components in Buildings & Bridges

Why Choose Ananka Fasteners for Duplex Fasteners?

In-House Manufacturing Facility

We operate a state-of-the-art manufacturing plant in Vasai, Maharashtra, equipped with modern machinery and quality control labs.

Strict Quality Control

Every fastener is tested for tensile strength, hardness, corrosion resistance, and dimensional accuracy before dispatch.

Custom Solutions

From non-standard sizes to specialized coatings (PTFE, Zinc, Hot Dip Galvanized), we offer tailor-made solutions for your project needs.

Global Export Network

We supply duplex fasteners to countries across Europe, the Middle East, Asia, Africa, and the Americas, ensuring timely delivery and complete documentation support.

Packaging & Delivery

Packaging: Wooden boxes, HDPE bags, bubble wraps, or as per customer request.

Delivery: Domestic and international shipping with clear markings, heat numbers, and traceability.

Conclusion

If you're looking for a reliable Duplex Fasteners Manufacturer, Ananka Fasteners is your trusted partner. Our premium quality, commitment to precision engineering, and vast export experience make us the first choice for businesses worldwide. Whether it's a complex offshore application or a structural requirement, our duplex fasteners are engineered to perform flawlessly in harsh environments.

FAQs – Duplex Fasteners

Q1. What’s the difference between Duplex and Super Duplex Fasteners?

Super Duplex fasteners contain elevated levels of chromium, molybdenum, and nitrogen, delivering superior strength and enhanced corrosion resistance compared to standard duplex grades.

Q2. Are duplex fasteners magnetic?

Yes, duplex stainless steels have a ferritic structure that makes them slightly magnetic, unlike austenitic stainless steels.

Q3. Can duplex fasteners withstand seawater?

Yes, especially Super Duplex grades like S32750 and S32760 are highly resistant to seawater corrosion.

Q4. Do you provide test certificates for duplex fasteners?

Absolutely. We provide EN 10204 3.1 / 3.2 certification, third-party inspection reports, and all relevant material test reports.

Q5. What coatings are available for duplex fasteners?

We offer coatings like PTFE, Xylan, Zinc, Hot Dip Galvanized, and custom finishes on request.

#Duplex#DuplexFasteners#Duplex2205Bolts#SuperDuplexFasteners#DuplexFastenersManufacturer#OffshoreFasteners#MarineFasteners#OilAndGasBolts#AnankaFasteners#IndiaManufacturer#GlobalExporter#Blog#Articles#tumblr blog#blogs#tumblr

0 notes

Text

Hastelloy B3 Fasteners Suppliers

The Deep Steel Center is one of the extraordinary Suppliers and Manufacturers of Hastelloy B3 Fasteners. We give the entire level of adding in different points of view, sizes, types, and decisions. Our offered Fasteners have huge security from hydrochloric staggering at all concentrations and temperatures. Hastelloy B3 Fasteners are made by utilizing ideal-quality, unrefined substances. These things are utilized in decreasing acid affiliations and locking the fasteners of warming stuff. Hastelloy B3 Secure Fasteners are conveyed using a mix containing nickel and molybdenum as the base part and movements of cobalt and tungsten. Our offered substances are normal for exceptional hydrochloric harming, sulfuric acids, hydrobromic shocking, acidic deplorable, phosphoric harming, and formic harming. These grains offer mind-blowing strength and goodness in any acidic or decreasing medium.

Hastelloy B3 Fasteners push smooth coordination through welding gear and diminish tipping in contact tips. We are a proactive connection that offers Hastelloy B3 Fasteners and other quality things that meet and beat client unequivocal necessities and, as such, affirm full-scale satisfaction. We provide an enormous level of materials, like Hastelloy B3 Fasteners. Our offered Fasteners show sensational security from pitting, opening, disintegrating, and stress-use breaking in any chloride-containing conditions.

Standard Specification For Hastelloy B3 Fasteners

Specifications

ASTM B574 / ASME SB574

Fasteners size

Bolt / Screw Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Nuts Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Washers Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Machine Screws Size : M1.6 – M12 Self Tapping Screw Size : No.2 – No. 14

Fasteners Length

3 mm to 200 mm

Fastener Threads

UNF, BSW, BSF, METRIC, UNC or as required

Standard of High Nickel Alloy Fasteners

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M as per defined in ASME B16.5 standard Stud Bolt length ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts

Dimensions

DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3

Surface Coating

Ptfe Coated High Nickel Alloy Fasteners Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating

Fasteners Finishing

High Nickel Alloy : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), High Nickel Alloy, Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide.

For more information:

Visit website: https://www.deepsteelalloys.com/hastelloy-alloy-b3-fasteners-supplier.html

#Hastelloy B3 Fasteners Manufacturers#Hastelloy B3 Fasteners Suppliers#Hastelloy B3 Fasteners Stockists#Hastelloy B3 Fasteners Exporters#Hastelloy B3 Fasteners Manufacturers in India#Hastelloy B3 Fasteners Suppliers in India#Hastelloy B3 Fasteners Stockists in India#Hastelloy B3 Fasteners Exporters in India#Hastelloy B3 Fasteners Manufacturers in Mumbai#Hastelloy B3 Fasteners Suppliers in Mumbai#Hastelloy B3 Fasteners Stockists in Mumbai#Hastelloy B3 Fasteners Exporters in Mumbai

0 notes

Text

🔧 Unlock the Potential of Teflon Sheets in Modern Industry! 🔧

Discover how Teflon (PTFE) sheets are revolutionizing industrial applications with their unparalleled properties. From non-stick surfaces to chemical resistance, these sheets are essential in enhancing efficiency and durability.

Explore our comprehensive guide to understand their diverse uses and how our custom solutions can meet your specific needs.

#teflon#ptfe#industrialapplications#customsolutions#engineering#manufacturing#innovation#technology#materials#nonstick#chemicalresistance

0 notes

Text

Safeguarding Industrial Sealing and Reliability: Flange Insulation Gasket Kits

Flange Insulation Gasket Kits, known as FIG Kits, are the unsung heroes of industrial operations. These comprehensive packages of insulating materials and gaskets play a pivotal role in preventing galvanic corrosion and ensuring leak-free connections in flanged systems. By isolating dissimilar metals and providing electrical insulation, FIG Kits enhance safety, extend the lifespan of flange connections, and bolster the reliability of critical industrial processes. Whether in oil and gas, chemical processing, or water treatment, these kits stand as essential allies in the pursuit of seamless and secure operations.

Key Components and Benefits:

Gasket Material: Flange Insulation Gasket Kits typically include gaskets made from materials like non-metallic or low-conductive materials, such as PTFE, rubber, or phenolic. These gaskets not only provide a reliable seal but also ensure electrical isolation between flange faces.

Insulating Sleeves: The kits may also incorporate insulating sleeves or washers that are strategically placed between the flange bolts and the nuts. This prevents direct contact between the fasteners and the flange, further enhancing the insulation barrier.

Corrosion Prevention: One of the primary advantages of Flange Insulation Gasket Kits is their ability to prevent galvanic corrosion. By isolating dissimilar metals, the risk of corrosion-induced damage to the flange connections is significantly reduced.

Enhanced Safety: In applications where flange connections carry potentially hazardous fluids or gases, FIG Kits provide an additional layer of safety by minimizing the risk of leaks and subsequent accidents.

Versatile Applications: Flange Insulation Gasket Kits find applications in various industries, including oil and gas, chemical processing, water treatment, and more. They are particularly useful in pipelines, valves, pumps, and equipment where electrical isolation and leak prevention are critical.

0 notes

Text

PTFE Sheets Manufacturer & Supplier in Qatar

Petromet Sealings is a leading PTFE Sheets Manufacturer in Qatar. We provide several industries throughout the world with the highest quality PTFE Sheet. PTFE Sheets are available in a range of forms, sizes, and customization options to suit the needs of the customer. As a top PTFE Sheet Supplier, are extensively utilised throughout a range of sectors, including engineering, construction, aerospace, automotive, and more. We are renowned for the high calibre, dependability, and longevity of our goods.

Petromet Sealings is a well-known PTFE Sheets Supplier in Qatar. The selection of raw materials is the first step in our quality control procedure. We exclusively use high-quality raw materials from reputable vendors. As a top most PTFE Sheets Manufacturer, various quality tests are performed on the PTFE Sheet during the production process to guarantee that they are created to perfection. In addition, In the chemical industry, the sheeting can be used to make several different fluoropolymer products, from gaskets, rings and washers to vessel linings and chemical tanks. As a leading PTFE Moulded Sheet, we provide our sheets in various industries and fields. We are a PTFE Sheets Supplier in Qatar.

Website: https://petrometsealings.com/

Product: PTFE Sheets Manufacturer in Qatar

0 notes

Text

Complete Fasteners Product List — Types & Applications

Fasteners are the mechanical backbone of countless structures and systems, ranging from industrial machines to home appliances. They serve as crucial elements engineered to firmly join two or more components in an assembly. At Ananka Fasteners, we specialize in manufacturing, supplying, and exporting a wide array of high-performance fasteners to meet diverse industrial requirements across the globe.

Below is a detailed list of fastener products we offer:

1. Coated Fasteners

Coated fasteners are surface-treated fasteners designed to resist corrosion, enhance durability, and improve performance under extreme conditions.

Types of Coatings:

Zinc Coating (Electroplated, Hot Dip Galvanized)

PTFE Coating (Xylan, Teflon)

Cadmium & Nickel Coating

Black Oxide Coating

Applications:

Marine structures

Offshore platforms

Petrochemical industries

Construction projects are exposed to weathering

2. SMO 254 Fasteners

SMO 254 is a high-alloy austenitic stainless steel known for excellent corrosion resistance and strength, especially in chloride-bearing environments.

Available Fastener Types:

SMO 254 Bolts

SMO 254 Nuts

SMO 254 Washers

SMO 254 Screws

Applications:

Desalination plants

Pulp and paper industries

Seawater cooling systems

Chemical processing industries

3. Bolt Fasteners

Bolts are externally threaded fasteners designed to be used with nuts or threaded holes to securely join multiple components.

Common Bolt Types:

Hex Bolts

Heavy Hex Bolts

U Bolts

Eye Bolts

Carriage Bolts

Flange Bolts

Applications:

Structural steel fabrication

Equipment and machinery

Automotive and heavy-duty applications

Aerospace and defense

4. Screw Fasteners

Screws are threaded fasteners that create their mating thread during installation, often used without a nut.

Popular Screw Types:

Wood Screws

Machine Screws

Self-Tapping Screws

Socket Head Cap Screws

Sheet Metal Screws

Applications:

Electronics and electrical panels

Wood and furniture work

HVAC and appliance assembly

Construction and industrial machinery

5. Washers Fasteners

Washers are disk-shaped components used under nuts or bolt heads to distribute loads and prevent loosening.

Types of Washers:

Plain Washers

Spring Washers

Lock Washers

Conical and Dome Washers

Applications:

Vibration-prone assemblies

Automotive and aerospace

Electrical and electronics

Construction and pipelines

6. Stud Bolts Fasteners

Stud bolts are fully threaded rods paired with nuts on both ends, specifically designed for use in high-pressure and high-temperature applications.

Types of Stud Bolts:

Full Threaded Studs

Tap-End Studs

Double-End Studs

Continuous Thread Studs

Applications:

Flanged pipe connections

Oil & gas industry

Chemical and petrochemical equipment

Pressure vessels and reactors

7. Custom Fasteners

Custom fasteners are specially manufactured to meet unique project requirements based on dimensions, material, and finish.

Options Available:

Unique threading and shapes

Non-standard lengths or heads

Special alloys (Titanium, Inconel, Monel, etc.)

OEM & drawing-based production

8. Nuts Fasteners

Nuts are internally threaded fasteners paired with bolts or screws to secure components.

Common Nut Types:

Hex Nuts

Lock Nuts

Wing Nuts

Cap Nuts

Flange Nuts

Square Nuts

Applications:

General engineering

Automobile assembly

Power generation equipment

Home improvement and furniture

Why Choose Ananka Group?

Wide Material Range – From carbon steel to exotic alloys like Inconel, Monel, Hastelloy, and SMO 254

Worldwide Presence – Catering to industries throughout the USA, Europe, the Middle East, and Asia

Custom Solutions – Precision manufacturing based on client drawings or specifications

Compliance – All fasteners are manufactured to ASTM, DIN, ISO, and other global standards

Conclusion

Whether you're building infrastructure, assembling machinery, or fabricating precision equipment, choosing the right fastener is critical. The extensive range of fasteners we offer at Ananka Fasteners ensures reliable performance, safety, and longevity in every application. From coated fasteners for enhanced corrosion resistance to custom-engineered solutions for niche applications, our products meet the highest quality standards.

Frequently Asked Questions (FAQ)

Q1. What material types do you provide for these fasteners?We offer fasteners in stainless steel, carbon steel, alloy steel, brass, copper, Inconel, Monel, Hastelloy, SMO 254, titanium, and more.

Q2. Do you provide testing certificates?Yes, we provide Mill Test Certificates (MTC), third-party inspection reports, and compliance certificates as required.

Q3. Can fasteners be customized? Absolutely. We specialize in custom fastener production based on your drawing, specifications, and application.

Q4. What industries do you serve?We serve industries such as oil & gas, petrochemical, marine, construction, automotive, aerospace, and power generation.

Q5. Do you export globally?Yes, Ananka Group exports fasteners globally, with a strong presence in the USA, UK, Germany, UAE, Singapore, and more.

#Fasteners#IndustrialFasteners#BoltManufacturer#StudBolts#CustomFasteners#WasherManufacturer#QualityMatters#TrustedSupplier#ExportQuality#ManufacturingExcellence#EngineeringSolutions#IndustrialSupply#Ananka#AnankaFasteners#manufacturer#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Link

Cannon Gasket has built a reputation based on expertise in the manufacturing of precision die-cutting washers, gaskets, shims, spacers, diaphragms, capliners, septas and various seals.

0 notes