#Pharmaceutical Processing Seals

Explore tagged Tumblr posts

Text

https://heyjinni.com/read-blog/222672_technological-advancements-in-pharmaceutical-processing-seals-market.html

#Pharmaceutical Processing Seals Market Share#Pharmaceutical Processing Seals Market Analysis#Pharmaceutical Processing Seals Market Trends

0 notes

Text

2025 Global Pharmaceutical Processing Seals Market: Forecast, Growth Drivers, And Challenges

The global Pharmaceutical Processing Seals Market is poised for remarkable expansion, with its size valued at USD 2.55 billion in 2023 and projected to reach USD 6.05 billion by 2032, according to the latest industry analysis. The market is expected to grow at a compound annual growth rate (CAGR) of 10.11% over the forecast period of 2024–2032.

Get Free Sample Report on Pharmaceutical Processing Seals Market

Pharmaceutical processing seals are integral components used in the manufacturing and packaging of drugs and medications. These seals ensure product integrity, contamination-free environments, and compliance with strict industry regulations. As pharmaceutical companies strive for higher efficiency, quality assurance, and sustainability, the demand for high-performance sealing solutions continues to surge globally.

Key Growth Drivers

One of the key factors driving this rapid growth is the increasing investment in pharmaceutical manufacturing facilities. The post-COVID era has seen a significant global shift towards bolstering healthcare infrastructure, increasing vaccine and drug production, and establishing robust supply chains. As a result, the demand for reliable sealing solutions that can withstand complex processing environments has grown substantially.

In addition, the rising incidence of chronic diseases and the growing elderly population worldwide are accelerating the need for pharmaceuticals. This, in turn, increases demand for efficient processing equipment and components, including seals that comply with strict hygienic and safety regulations. Technological advancements in sealing materials—such as high-grade elastomers and PTFE (polytetrafluoroethylene)—are also contributing to market expansion, offering better resistance to extreme temperatures, chemicals, and sterilization processes.

Key Segments

By Material

Metal

Rubber

Silicone

Polymer/Elastomer

Other Materials

By Product

O-rings

Gaskets

Lip Seals

D Seals

Other Products

Challenges and Opportunities

Despite the optimistic growth outlook, the pharmaceutical processing seals market faces several challenges. The fluctuating cost of raw materials and the complexities involved in manufacturing seals that comply with varying global regulations can hamper profitability and slow down production timelines.

Nonetheless, the market offers substantial opportunities for innovation. Companies are increasingly focusing on sustainability and the development of eco-friendly, long-lasting sealing materials. Additionally, the integration of smart manufacturing and automation technologies in pharmaceutical plants is expected to fuel demand for seals that can accommodate high-speed operations with minimal maintenance requirements.

The emergence of personalized medicine and biologics also opens up new avenues for sealing technology, as these drugs often require highly specialized equipment and processing conditions. Seals used in such environments must meet even stricter purity, safety, and performance standards—offering new challenges and growth opportunities for manufacturers.

Key Players and Their Products in the Pharmaceutical Processing Seals Market

Flowserve Corporation – Valves, O-rings, Gaskets, Mechanical Seals

Morgan Advanced Materials PLC – Sealing Rings, Graphite Seals, High-Performance Gaskets

Trelleborg AB – O-rings, Gaskets, Lip Seals, Diaphragms

Garlock – Gaskets, Diaphragms, Compression Packings

Saint-Gobain S.A. – O-rings, Tubing Seals, Polymer Seals

Parker Hannifin Corporation – O-rings, Gaskets, Lip Seals, Metal Seals

IDEX Corporation – O-rings, Peristaltic Pump Seals, Sanitary Seals

James Walker – O-rings, Elastomer Seals, Gaskets

Freudenberg Group – O-rings, Diaphragms, Lip Seals, PTFE Seals

John Crane – Mechanical Seals, O-rings, Gaskets

Outlook for 2024 and Beyond

Looking ahead, the pharmaceutical processing seals market is expected to witness continuous innovation and consolidation. The increasing adoption of Industry 4.0 technologies, combined with growing regulatory focus on product safety and quality, will drive the evolution of advanced sealing solutions.

Make Enquiry about Pharmaceutical Processing Seals Market

The period from 2024 to 2032 represents a transformative phase for the market, with demand being propelled not only by rising pharmaceutical production but also by heightened expectations for operational excellence, safety, and sustainability.

Conclusion

In summary, the pharmaceutical processing seals market is entering an exciting phase of growth and innovation. With a projected market size of USD 6.05 billion by 2032 and a CAGR of 10.11%, the industry presents abundant opportunities for companies willing to adapt to emerging technologies, evolving regulations, and changing customer needs. As pharmaceutical manufacturers gear up for the future, the role of high-quality sealing solutions will remain more critical than ever before.

About US

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President Of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Pharmaceutical Processing Seals Market#Pharmaceutical Processing Seals Market Trend#Pharmaceutical Processing Seals Market Share#Pharmaceutical Processing Seals Market Growth#Pharmaceutical Processing Seals Market.

0 notes

Text

I cant tag you for some reason @acesatyr but I have typed all this up. I will get to fishing and foraging at some point, But this was already really long, lol.

I had originally written this in another word doc and realized I had typed over six paragraphs about seeds and germination alone. I really like farming.

Overall, this is mostly the generic info; I can detail or explain anything in depth, but I’m summarizing the important stuff, and the details are easily researchable. :)

A Revised and Bullet-Pointed Essay about Organic Apocalyptic Farming

Seeds, the basics:

-Stock up on seeds, they come in packets and are usually cheap depending on where you get them from. I like to store seeds in a mason jar, with a tightly sealed lid. It’s important they’re dry, and if possible, refrigerated. if not, any cold, dark, dry place will do.

-Germination is an easy process, DAMP (not sopping wet. DAMP) peice of thin cloth or paper towel, seeds laid out evenly, and put into either a ziplock baggie or something like a pyrex container. Again, air tight, low-mid light, warm (not hot, not direct sunlight) enviroment.

-if you see a lil mold it’s okay, as long as the root sprouts they’re still viable.

Plants I would Reccomend:

-Peppers are great because they grow quickly, can be canned or stuffed and add a lot to you meals and food. They also don't really take up as much room as some of the other plants i'm about to list. They aren’t the most filling and you cant live off of them but if you want to improve your quality of life or make a lot of money at the end of the world I guarantee you anyone who can actually cook or has the spices and foods to do it is set for life. I would legitimately kill a man for my mom’s pepperoni stuffed pickled peppers. I stabbed my brother over a jar once I am not kidding.

-Pretty much any kind of spice or herb really, I would HIGHLY recommend growing lavender, mint, thyme, and anything lemony or citrus scented, as I mentioned on a previous post, they’re good for pest control. lavender is a very temperamental plant, but most herbs, once ou get them going can be pretty hardy for lil leafs. Also, depending on the amount you’re growing of each most of them don’t take up too much space. Also basil cause it smells nice and I told you to.

-Corn, wheat, and any kind of grain is obviously a good idea if you want bread, but all of them are pretty difficult and require a lot of space. Potatoes are great because they can be used to make bread and alcohol as well.

-Zucchini, eggplants, tomatoes, and summer squash, and pretty much any gourd/melon/squash plant are easy to grow, but keep in mind many of these are expanding and/or vine plants and require a lot of space. They make a lot of food, but tomatoes and cucumbers in particular will actively choke other plants. Like vines wrapping around and leaves growing over top and roots entangling level of choking. Keep apart. but they’re good for you. eggplant, tomato and cucumeber are the highlight here.

-For leafy greens kale and chard are super easy to grow and grow pretty fast. Like any leafy green, too much sunlight will scorch them so be careful. I like to grow chard in an old (was some kinda biohazard barrel my dad stole from some pharmaceutical company, and cleaned out) cause it’s more than deep enough for the roots, but also wide enough to grow plenty. Also kale is high in vit c so if you don't live somewhere tropical you won't die of scurvy :)

-If you plan on raising animals or having a crop FIELD and not a PLOT, then grow long grass into hay, because it is good feed, but can also be used to cover ground to protect from birds. If you sow seeds by yeeting them into the dirt, birds will eat them if you don't cover them and you will die hungry.

-If possible, Alfalfa is also good for animals ( in small quantities) because they like it, or sunflowers. you can eat sunflowers, they produce a lot of seeds adn the seeds can be used as feed. ( same with corn.)

-Mushrooms. can be dried, easy to grow, grow really fast, and can be used as filler for meat dishes. (you can also grow the drug kind because it’s the end of the world and no one is going to stop you)

-tobacco for tabacco

AMNIMALS:

-unless you have a lot of very protected land you’re going to want animals that are small and potentially multipurpose.

-chickens are great because they dont need an exorbitant amount of space, can be used for eggs and meat, their feathers can be used for a number of things, if you dont like eating chicken guts (whats wrong with you) then they can be used as fertilizer, bait or as part of stock, and the bones can also be used for broth or to make small simple tools like needles or pen nibs. However, they actually need a more varied diet then you’d think. if you dont have calcium powder, their own unfertilized crushed up eggs, or scrambled with the shell is good for them once in a while, or chopped up leaves from your plants. Otherwise, a mix of corn and seeds is pretty good. DO NOT feed chickens wheat, oats or bread. Once in a while maybe, as like a super special treat, but too much can be harmful. Also, they eat bugs so they can just be outside if you’re okay with that.

-Goats produce milk, fur/wool (not all breeds do both, most don't do both, actually) and they’re more portable than cows. they also take up less space. A big downside is that goats are not only social animals, but they also need a good bit of stimulation and activity and they can be pretty noisy. My uncle built a jungle gym pyramid for his goats, but be warned, Joe Bob chewed his way out of the barn and needed rescuing from the top of the tower in the middle of a hurricane once. Goats will pretty much eat anything, and their poop is good for compost, Joe Bob and his siblings pretty much live off scraps and they’re happy lil dudes ( ladies actually, Joe Bob is the only boy)

-Rabbits! (the rabbit in raider rabbit is actually because i used to raise rabbits and am fond of them as a farm animal and because nobody can pronouce my name so they just call me Bun but we dont talk about that) probably one of the quietest animals you can keep on a farm, they can be kept in cages, breed quickly, can be used for fur, leather (rabbit and goat leather is great for making paper and cloth, not really good for protective leather) meat, and bones. The biggest issue I can see in the event of a wasteland survival situation is rabbits need a lot of clean water, salt and if you get angouras they pretty much need constant brushing. Be warned, if you dont know how to properly care for and breed them the females will castrate the males or eat her babies :) it is just a traumatizing as it sounds :) I speak from experience :) A good and cheap meat rabbit is the california white rabbit, they're about small to med size, and really simple to look after. Angouras are not great for meat, but their fur makes amazing wool. They eat veggies ( not carrots, too much sugar) oats, hay, their babies, and other leafy greens.

-Quail are something im not super familiar with that was my sibling’s thing, but from what i understand they need less space then chickens, and they’re good meat birds. eggs can be good for feeding other animals, but they’re not really good for much else. Also they’re really fucking loud and will fight each other so maybe not?

-Ducks are a lot like chickens, again, all of them can be eaten or used, and also eggs. eat more leafy greens and stuff and really like having somewhere to swim, better for more open environments. Ducks like to eat a lot and will get really fat really quick ( not a good thing) so be careful. however, if they imprint on you, they will follow you everywhere which makes rounding them up easy.

-Fish are great because their water can be cycled and the yuck water can go to the plants, which is great cause all that fish poop and algae is really good fertilizer. Fish are good for you and I love them. An while they’re not easy to port around, if you feed them micro worms or lil shrimps you can grow their food mostly indefinity and freeze it even. Also ive never heard any fish ( other than that one pufferfish) make noise. keep in mind, you will still have to maintain the water levels and the ph and all that, and they can take up a lot of space.

WHAT METHOD? HOW DO THE FARM? OTHER?

-this is pretty much up to you, I’m a really big fan of hydroponics, but i typically stick to “recycle farming” which is basically using whatever I have on hand and getting creative.

-if you’re going to use a plot of land, its a good idea to make sure you have a fence that goes around, over and under. Pests like groundhogs, rabbits, deer, ghouls, and myself will do more then just walk up and take you plants and animals.

-I recommend quiet animals that can be stored in cages and indoors to avoid larger predators, but any animals will attract them. Bears will break into pens, so if possible either store them INSIDE INSIDE, (like concrete building) or outside in a pen so you dont die.

-Living in the wasteland, or growing up with parents that think it basically is will teach you to utilize anything and everything. bottles and cans are great pots, old trashcans can be used if your dad wont steal chemical barrels from your local pharm plant for you, tires can be shredded into mulch, old rebar is my favorite thing for climbing plants ( sturdy, easy to stick into the ground and remove, pretty source able) Animal parts can be used for fishing bait or fertilizer, corn husks and other dry leaf litter can make good ground cover is hay isn't an option, ect.

-Plastic sheets and table cloths with holes cut in them for the plants are great for vine plants to grow through.

-scarecrows ain’t shit. Most birds are too stupid to notice and the ones that will are smart enough to figure out it’s not real pretty quick so all you’re doing is wasting good clothes and materials and scaring the shit out of yourself when you forget and look out the window and see a giant man in your field. Get a cat.

-it’s the apocalypse. grow weed.

How source plant food?

-poop and leafy plant scraps. animal poop, your own poop, your neighbors poop, poop. plant scraps, leafy greens, peels, rotten material.

-Get a big plastic tub or my favorite stolen barrels and shovel in some dead soil, layer in some plant scrap, dry leaf litter or corn husks, poop, leaf litter, and add creepy crawlies if you can. give a stir or shake every so often.

-avoid flies. as gross as it is, it’s a good idea to keep it warm, moist and humid, so very closed to avoid them.

-you can also add egg shells to give some calcium to your bug buddies.

-corpses.

What do I keep? how do I use it? (animals)

-egg shells are useful for a number of things, dried and nicely crushed they can be used for calcium for other animals. Or protection spells.

-bones for the same thing just don't feed the animals to themselves. I joked about this with the rabbits a bit ( a little cannibalism with them is inevitable and wont hurt them, but still) but cannibalism can lead to a lot of really bad neurological conditions that can harm you as well if you consume their products. Same with chickens, you feeding them scrambled eggs and shells once in a while is good for them, but if they start consistently eating their eggs you need to seperate them for a bit.

-fur and skin are great, esp for tanning, hides can make all kinds of things from paper, to water pouches and other bags, and fabric in general. being able to make cloth and leather is something a lot of people really overlook.

-Bones but for tools. Having a good needle and thread is really underestimated.

-Intestines can be used to make sausage, and other things.

-i will eat the chicken liver if you don't want it but it’s your anemia.

-make jerky/salted meat. both wont last forever, but you dont need to freeze it if you dont have power and will last longer then raw or cooked meat. salt cured meat lasts about 2-3 weeks, so if you’re solo or a small group and you did what i said and got small animals you wont be wasting food, and you dont have to butcher something every day.

-jerky can last a lil longer if stored properly, say it with me now! *air tight containers* you might get a solid month or so out of jerky, and it can mostly be rehydrated, or eaten as is.

-rendered animal fat or tallow makes good cooking oil, and while a little time consuming is not super difficult.

-make butter and cheese, not for survival, but quality of life.

Help I grew to many plants!

-can them, dumbass.

-fr though, canned foods can last a decent amount of time and can be really useful if you live somewhere with a winter, or can farm constantly. I mentioned already, but canned stuffed peppers are a favorite of mine, along with pickled eggs, which I make pretty regularly because a world without pickled eggs is the darkest thing i can imagine.

-feed them to your animals or back to your plants.

-throw them at your friends. (you haven't lived until you’ve hocked a rotten pumpkin at your little brother)

-dry them, fruit leather and veggie chips can be rehydrated and stored even longer than certain canned or preserved foods.

What else?

-learn how to purify water. there’s a million non tech versions, but in a sinch, the boil method is good if you just need to water plants. just dont pour boiling water on your crop.

-do use boiling water for weeds though. you can also feed weeds to your animals, but boiling water is just water, it’s not going to kill the soil or poison you.

-learn to fish and forage, theres a whole lot of things that aren't easy to grow or raise that can be tasty and good for you.

-learn to make fire. be prepared to put out fire. Dry crops will burn for days, so keep them watered, but you need to be able to burn exccess compost and cook.

-farming smells so bad. I love farming but animal poop, rotten veggies, innards, decay and compost, burning compost smells. if you cant stomach it and want the easy way out, thats called starvation or you better be beefy and prepped enough to raid others. or both, gorw your shit and steal from others, i dont care.

-forgot to mention earlier, but fermented foods like kimchi, kombucham etc are really good for you so yea. I might also teach you how to make kombucha cause my mom made me drink it so by god ill make you drink it too. ( i actually love it and it's good for making vinegar.)

-And forgot, legumes, like beans, peanuts, letils etc are really good plant protein. just not fun to grow, (ecept for beans. beans are actually very fun to to grow.)

#apocolyptic#doomsday#doomsday preppers#i was raised like this#farming#plants#farm animals#fr though if your unwilling to butcher animals or handle manure you better be prepped to grow a lot of spinach and legumes#to make up for the protien and iron loss#also farming is really hard but very rewarding

56 notes

·

View notes

Text

FAIR PACK MACHINERIES: Leading the Way in Advanced Packaging Solutions

Introduction to FAIR PACK MACHINERIES (Pvt) Ltd.

FAIR PACK MACHINERIES (Pvt) Ltd. has been a trusted name in the packaging machinery industry for over two decades. Since its establishment in 1998, the company has led the way in delivering innovative, reliable, and efficient packaging solutions across the globe. With a commitment to providing “Simple Packing Solutions” that adapt to dynamic market needs, FAIR PACK has successfully built a reputation for high-quality machinery and unparalleled customer satisfaction.

The company started with a vision to cater to the growing demand for quality packaging machinery, and today, it is recognized as a leader in the sector. FAIR PACK MACHINERIES offers a wide array of machinery for various packaging needs, ensuring that businesses can optimize their production lines while maintaining top-tier performance and product integrity.

Our Product Range

At FAIR PACK MACHINERIES, we pride ourselves on our diverse range of products that cater to various industries. Our machinery is designed to meet specific needs, whether for filling, sealing, labeling, or conveying products. With cutting-edge technology and precision engineering, our equipment is built to deliver efficiency and consistency across all stages of the packaging process.

Auger Packaging Machine

The Auger Packaging Machine is ideal for handling powders and granular products such as spices, flour, and sugar. The auger system ensures consistent and accurate filling by measuring the material volume. It is a perfect solution for companies needing high-speed, accurate filling for powder-based products.

Electric Collar Packing Machine

The Electric Collar Packing Machine is designed for high-speed vertical bagging operations. It ensures uniformity in the size of the bags and precise sealing of products. Ideal for industries requiring fast and efficient packaging, it can handle products like dry powders, granular substances, and liquids, ensuring quick turnarounds and minimal downtime.

Flow Wrap Packing Machine

The Flow Wrap Packing Machine is a versatile solution used for wrapping products in a flexible film. This machine is perfect for packaging snacks, candies, and small consumer goods, ensuring a tight seal that helps maintain product freshness and integrity.

FSS Tray Packing Machine

The FSS Tray Packing Machine is designed to handle products that need to be packed in trays, such as fresh produce, meat, and bakery items. It ensures efficient packing, protecting the product while making it easy to handle during transportation and distribution.

FSS Volumetric Packing Machine

The FSS Volumetric Packing Machine is ideal for products requiring consistent weight or volume, such as cereals, pasta, and beverages. Its volumetric mechanism ensures accurate filling, allowing manufacturers to pack items with precision and consistency, minimizing product loss or overfilling.

Granules Packing Machine

The Granules Packing Machine is built for products like seeds, grains, and other granular materials. With precise filling and sealing mechanisms, it ensures efficient packaging of these materials, improving the overall productivity of any packaging line.

Horizontal PFS (Pick-Fill-Seal) Packing Machine

The Horizontal PFS (Pick-Fill-Seal) Packing Machine is designed for high-volume packaging. It efficiently picks, fills, and seals a wide variety of products, from snacks to pharmaceuticals. This system is highly adaptable and is suitable for industries that require fast packaging cycles and high levels of precision.

Liquid Packing Machine

The Liquid Packing Machine is tailored to handle liquid products such as beverages, oils, and cleaning agents. It ensures consistent filling and sealing, preventing spillage and waste while maintaining the quality of the liquid inside each package.

Mini PFS (Pick-Fill-Seal) Packing Machine

The Mini PFS Packing Machine is a smaller, more compact version of the standard PFS system. Despite its smaller footprint, it delivers high-speed packaging and precision filling, making it ideal for businesses with limited space or smaller production volumes.

Multihead Weigher Packaging Machine

The Multihead Weigher Packaging Machine is designed to weigh multiple products simultaneously. This machine is ideal for industries that handle a variety of products and need to achieve precise weight distribution, ensuring that each package is filled with the right amount of product.

Multitrack Packing Machine

The Multitrack Packing Machine allows businesses to package multiple product lines at once, making it perfect for high-volume production environments. It reduces bottlenecks in the packaging process and helps improve the overall efficiency of operations.

Oil Packing Machine

Specifically designed for packaging oils and viscous liquids, the Oil Packing Machine offers precision filling to ensure each container is filled to the exact weight or volume. It is highly efficient for packaging a range of oils, from cooking oils to industrial lubricants.

Paste Packing Machine

The Paste Packing Machine is built to handle thicker materials such as sauces, creams, or pastes. It ensures accurate and efficient filling for products with varying viscosities, minimizing product wastage and improving packaging consistency.

Volumetric Packing Machine

The Volumetric Packing Machine uses a volumetric measurement system to fill products with high consistency. Suitable for products like granules, powders, and even some liquids, this machine offers excellent speed and precision for large-scale operations.

Weighmetric Packing Machine

The Weighmetric Packing Machine offers precise weight-based filling for products such as dry food items, chemicals, and industrial goods. It is an ideal choice for applications where accuracy in the filling weight is crucial to product standards.

Semi-Automatic Weighmetric Filling Machine

The Semi-Automatic Weighmetric Filling Machine is an excellent option for smaller production lines. It provides flexibility while still delivering the accuracy needed for weighing products. It is perfect for industries requiring batch production without full automation.

Semi-Automatic Volumetric Filling Machine

The Semi-Automatic Volumetric Filling Machine is designed for operations that require filling both liquids and solids. This semi-automatic system is perfect for smaller to medium-sized production lines, offering the flexibility of manual control while ensuring accurate and consistent filling.

Semi-Automatic Paste Filling Machine

For businesses that handle paste-like substances such as creams, gels, and sauces, the Semi-Automatic Paste Filling Machine offers precise filling with easy manual adjustments, ensuring a smooth and efficient process.

Heavy Duty Band Sealer Machine

The Heavy Duty Band Sealer Machine is used for sealing bags and pouches. It is ideal for packaging heavy or bulk products that require strong, reliable seals. Whether for food, chemicals, or other heavy-duty applications, this machine ensures that each product is sealed securely and consistently.

Conveyors for Efficient Packaging Lines

In addition to packaging and filling machines, FAIR PACK MACHINERIES also offers a range of Conveyors designed to improve the efficiency of packaging lines by automating the movement of materials and finished products.

Bucket Conveyor / Elevator

The Bucket Conveyor / Elevator is perfect for lifting bulk products from one level to another. Ideal for granules, powders, and granular substances, this system ensures smooth and efficient transport across various stages of the packaging process.

Flat Belt Conveyor

The Flat Belt Conveyor is one of the most versatile conveyors available, suitable for transporting a wide variety of products. It can handle both heavy and lightweight items with ease, making it an essential part of any automated packaging line.

Inclined Conveyor

The Inclined Conveyor is designed to move products at an angle, perfect for situations where products need to be lifted to different levels in the production process. It reduces product handling and ensures smooth, efficient material transport.

Roller Conveyor

The Roller Conveyor is a reliable system for moving heavy items along flat surfaces. It is particularly useful for industries that need to transport large volumes of products, such as food and beverage packaging.

Screw Conveyor

The Screw Conveyor is ideal for moving bulk materials such as flour, powder, and granular substances. The rotating screw mechanism moves products efficiently through the conveyor system, providing precise and controlled transport.

Z Conveyor

The Z Conveyor is a flexible system that moves products in a Z-shaped direction. It is designed for space-constrained production areas, offering a compact solution for efficient material handling.

Conclusion

With over two decades of experience, FAIR PACK MACHINERIES (Pvt) Ltd. continues to provide high-quality, innovative, and efficient packaging machinery to a wide range of industries. Whether you need filling, packaging, or conveying systems, our machines are designed to maximize operational efficiency, reduce waste, and maintain high product quality. As a trusted leader in the packaging industry, we are committed to supporting businesses with cutting-edge solutions that enhance their production capabilities and streamline their processes.

youtube

2 notes

·

View notes

Text

Durable POF Shrink Film for Optimal Protection

POF film shrink is a top-tier packaging solution for businesses looking to enhance product presentation while offering superior protection. Known for its durability, clarity, and versatility, POF shrink film has become an essential tool for industries ranging from food packaging to electronics. JT Package offers high-quality POF shrink film, designed to meet the specific needs of various sectors. Whether you are packaging food, consumer goods, or industrial products, this film provides a reliable, cost-effective solution that ensures products are safely and attractively packaged.

One of the key benefits of using POF shrink film is its exceptional transparency. The clear, glossy finish provides excellent product visibility, which is essential for retail environments where customers need to view the product before making a purchase. The high clarity of the film ensures that your product stands out on the shelves, making it more likely to grab the attention of potential buyers. In addition to its visual appeal, the film offers a professional appearance that helps enhance your brand’s image.

POF shrink film also offers outstanding strength, making it ideal for protecting a wide range of products. The film tightly conforms to the shape of the packaged item, creating a secure seal that keeps dust, dirt, and moisture out. This added layer of protection is especially beneficial for businesses shipping delicate products, such as electronics or perishable goods, as it helps maintain the integrity and freshness of the items during transit. Its tear resistance ensures that the film won’t easily break or tear, further ensuring the safety of the product inside.

Furthermore, POF shrink film is environmentally friendly, which is increasingly important for businesses aiming to meet sustainability goals. Made from recyclable materials, this shrink film provides a more sustainable packaging option without sacrificing quality or performance. As consumers and businesses alike become more eco-conscious, using recyclable packaging materials like POF shrink film can significantly boost a brand’s reputation and appeal to environmentally-minded customers.

Another advantage of POF shrink film is its versatility. It is suitable for a wide range of products and industries, including food packaging, pharmaceuticals, cosmetics, and more. The film’s ability to conform tightly to a variety of shapes ensures that it provides a secure and neat finish every time. It also works well with automated packaging systems, allowing for efficient and high-speed packaging processes that reduce labor costs and increase productivity. This makes it an ideal solution for businesses looking to improve their packaging processes while maintaining product quality.

At JT Package, customers can rely on high-quality POF shrink films that meet their specific needs. The company utilizes cutting-edge technology to manufacture shrink films that offer consistency and excellent performance. In addition to standard options, JT Package provides customizable solutions tailored to the unique requirements of each business. Whether you are looking for a specific film size, thickness, or other features, JT Package has the expertise to provide the perfect shrink film for your products.

For businesses in search of reliable and high-quality packaging solutions, JT Package is a trusted name in the industry. As a leading POF film shrink supplier, they offer durable, eco-friendly, and versatile packaging materials that ensure your products remain protected and visually appealing. To learn more about their products and how they can support your packaging needs, visit JT Package pof film shrink:https://www.jtpackage.com/product/jt01-polyolefin-shrink-film/jt01-polyolefin-shrink-film.html .

2 notes

·

View notes

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Text

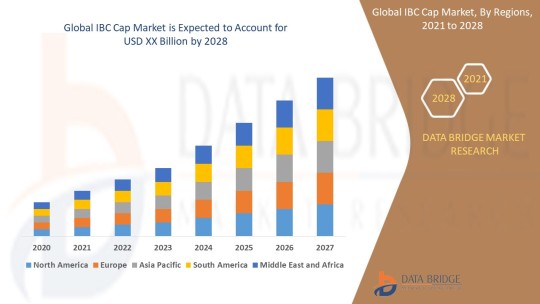

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Electropolishing for Deburring Critical Metal Parts

Stamping and machining processes can leave metal parts with burrs that can affect the fit, function and durability of metal parts.

When these parts are destined for food or pharmaceutical production equipment or fuel lines and gear assemblies used in aerospace manufacturing, burrs are more than just a surface imperfection – they’re a potentially catastrophic defect that can prevent the proper sealing or connection between two parts, become dislodged near moving parts, or cause seizing of screws and other fasteners.

To prevent such risks, manufacturers in many industries often specify electropolishing as the final step in finishing their critical metal parts.

How Does Electropolishing Work?

Electropolishing is a highly effective finishing process for removing metal surface defects like microburrs caused by processes like broaching, fine blanking, grinding, lapping or milling.

Using a combination of a chemical bath and a rectified electrical current, electropolishing removes a precise and uniform layer of surface material, leaving behind a shiny, smooth, passive and defect-free surface.

Among other advantages, electropolishing can remove a microscopically precise amount of surface material with surface roughness improvement of up to 50%, eliminating surface defects for high-quality results within very tight tolerances.

By eliminating microcracks and other defects that can harbor bacteria or become initiation sites for corrosion, electropolishing also leaves metal parts with significantly improved resistance to corrosion and pathogen growth. The ultrasmooth surface finish that electropolishing leaves behind has been shown to inhibit the formation of bacterial biofilms that can be resistant to ordinary cleaning methods. The finish also leaves behind a surface that is easier to clean, without cracks or defects where pathogens can hide – a critical advantage for medical, pharmaceutical and food and beverage production.

Why Use Electropolishing for Deburring?

Fragile or intricate metal parts, like those used for medical devices and implants, are not well suited for finishing processes like mechanical or vibratory polishing, which can damage fragile parts or create inconsistent results for parts with complex shapes.

Successful deburring for critical metal parts is contingent upon the ability to remove a precise layer of surface material. No other process can match electropolishing for its ability to control the material removal to +/- .0002”.

By deburring the threads on metal fasteners, for example, electropolishing can reduce the risk of adhesion between two mating surfaces, also known as “galling,” which can cause material between the surfaces to deteriorate and seize up when parts are pressed together.

Burrs can also shorten the lifespan of a part, by breaking off or becoming an initiation site for corrosion.

Larger burrs that occur as the result of rough milling or displaced metal from drilling operations, however, may need pre-treatment using other methods. Likewise, heavy die break burrs caused by improper tooling maintenance will generally require additional treatment.

Much in the way that lightning is drawn to the highest points, electropolishing delivers higher current density on the high points or edges which makes it ideal for micro-deburring The customized nature of the electropolishing process, from racking to chemical formulation to timing, would be of little value if it could not be reproduced consistently. But unlike other finishing processes, electropolishing is prized for its consistent results.

Electropolishing also offers a key advantage for parts with critical microfinishes or made from the lighter, more fragile materials increasingly used in the manufacturing of medical devices, electrical components and semiconductors, among other industries. These parts are not suitable for mass finishing techniques that can create distortion, nicks and scratches. Electropolished parts are individually racked to prevent contact and ensure the even application of the process for even the most fragile parts.

Advantages of Electropolishing for Deburring

The electropolishing process can be customized by alloy, by application and by the desired results. Beyond its ability to remove a uniform layer of surface material to eliminate surface defects like microburrs, microcracks, scale and staining, electropolishing offers many collateral benefits for the manufacturers of critical metal parts.

Microscopically precise removal of surface material with control to +/-.0002”

Customized racking to accommodate fragile and complex parts small and large

Leaves parts with enhanced durability and cycle life

Creation of a pathogen-resistant surface

Superior cleanability

Ultraclean finish

Decorative finish

One stop process for cleaning and removing surface defects

30X more corrosion resistance than passivation alone

Parts are also left passivated in the process

Improves conductivity of copper and aluminum alloys

What Alloys Can Be Electropolished?

A long list of alloys can be effectively deburred using electropolishing. The process is also equally effective on parts that are fully annealed or hardened. That is one reason that electropolishing is frequently specified for the final deburring and finishing of parts after all fabrication and heat treating processes have been completed.

Electropolishing is effective for a wide variety of alloys including:

Stainless Steel 200-300 Series

Stainless Steel 400 Series

Stainless Steel: Precipitating Hardening Grades

Nitinol

Titanium

Aluminum

Carbon Steels

Copper

Brass

Nickel Alloys

Specialty Alloys

And more

Electropolishing for Critical Metal Parts

As the world’s largest electropolishing specialist with seven decades of electropolishing expertise and innovation, Able Electropolishing provides consultation and collaboration from the earliest stages of prototyping through production to create highly customized electropolishing processes for a wide variety of metal parts.

6 notes

·

View notes

Text

#Pharmaceutical Processing Seals Market Size#Pharmaceutical Processing Seals Market Forecast#Pharmaceutical Processing Seals Market Report

0 notes

Text

Connect the Dots - 999 Week 2023, Days 7/8

I got up super early and made myself finish this! A shippy Seven/Lotus scene, that also addresses my headcanon that Lotus definitely knows more about the truth than she admits to.

Hazuki held her breath as she pressed the flash drive into the expanse of Seijin’s palm. She hesitated to let go. Even though they weren’t her secrets in that data, these were still things she had been guarding carefully for a decade. And no wall built with ones own hands was easy to tear down.

Seijin’s thick fingers closed around the object and brushed against the back of her hand in the process. With a jolt of her heart, Hazuki exhaled and released her grip.

“Compact,” Seijin remarked with a grunt of a laugh. “My research takes up three walls and a hell of a lot of string.”

“I can’t wait to see it. I’d have loved to have my own conspiracy board, but how would I explain it to the girls if they found it?” Hazuki tried to keep her tone calm, but it was hard not to cringe at how fucking insane she sounded. She was flirting with a man over their shared paranoia, a decade of pulling at the strings of a conspiracy that neither of them had ever fully unraveled. And sure, it turned out both of them had been onto something the whole time. But this side of herself had always been a secret. Was it really wise to base a relationship around it now?

Whether it was wise or not didn’t matter. Seijin had the flash drive poised before the USB port in the side of her monitor, and they were about to be sinking in the deep end together. Hazuki wandered over to the door to double check that the lock was sealed. Ennea was home and it didn’t matter what she thought her mother was up to locking herself in her home office with this strange man; she’d be damned if she was about to let her girls see the truth, how she’d probed into their disappearance against their wishes.

Now the two of them had been wondering where she disappeared to for three days. She hadn’t told them about her own Nonary Game experience yet, unsure of how to explain it despite knowing that the girls would understand everything perfectly, all the way down to Akane’s motivations. The roles had been swapped. The irony wasn’t lost on Hazuki.

She turned back to Seijin. He was staring at the monitor with his arms crossed. Before him were the contents of the flash drive. From the outside, they seemed meager, just two file folders. Those folders hid a wealth of scandal, if not much in the way of damning evidence. But even without delving deeper, Seijin already had an impressed grin on his face looking at the titles of the folders.

“Cradle Pharmaceuticals, huh?” he said. “And you claimed you’d never heard of them.”

Hazuki shrugged. “You understand plausible deniability, don’t you?” Something she no longer wanted to have, not in front of him, at least. The information in that folder centered more around Cradle’s association with the girls’ old pediatric hospital and the bizarre testing they’d been carrying out. She’d done her cursory research into the company as a whole, seen the CEO’s picture, and obviously recognized him, but unlike Seijin, she hadn’t sussed out that the conspiracy actually stemmed from Hongou and his closest associates.

Her research, inspired by the Ganzfield experiment, morphogenetic field theory, and the people who would most benefit from harnessing it, had taken her in quite a different direction.

Seijin, drawn by curiosity, double clicked on the other file folder and immediately took a step back in awe. “Holy shit, Hazuki. Free the Soul is supposed to be impregnable. How’d you find this much on them?”

Hazuki allowed herself to smile smugly as he scrambled to pull out the chair and sit, needing a closer look at the treasure trove of information before him. She was impressive, wasn’t she? Seijin had been the first to appreciate that in a while. “A hacker never reveals her secrets,” she teased. “And I guess it was either this or spend my time looking into the history of Titanic conspiracy theories.”

“Hey, All-Ice turned out to be almost real, didn’t she?”

Hazuki rolled her eyes with a grin. “I’m just saying. We fill in the gaps in each other’s knowledge pretty well, don’t we?”

And to that, Seijin said something she never thought she’d hear from him: “Can’t argue with you there.”

#zero escape#999 week#hazuki kashiwabara#lotus 999#seven 999#fanfiction#my writing#zero escape 999#999 spoilers

12 notes

·

View notes

Text

Fully Automatic Lami / Plastic Tube Filling, Sealing, Coding and Cutting Machine, Mumbai, India

Manufacturing of Pharmaceutical Machinery, Tube Filling Machinery, Tube Sealing Machinery, Soft Drink Filling Machinery, Container Filling Machinery, Pharmaceutical Equipments, Food Processing Machinery, Chemical Equipment, Mumbai, India.

Pharmaceutical Machinery, Tube Filling Machinery, Tube Sealing Machinery, Soft Drink Filling Machinery, Container Filling Machinery, Pharmaceutical Equipments, Pharmaceutical Machine, Food Processing Machinery, Chemical Equipment, Plastic Tube Filling Machinery, Multi Head Container Filling Machine, Cone Blender, Volumetric Bottle Filling, Filtration Unit, Rotary Bottle Washing, Rubber Bung Washing Machine, Storage Tank, Pressure Vessel, Cosmetic Filling Machinery, High speed Multi Head Container Filling Machine, Multi Head Container Filling Machine, Plastic Tube Filling Machine, Plastic Tube Sealing Machine, Plastic Tube Coding Machine, Plastic Tube Cutting Machine, Automatic Multi Head Container Filling Machine, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon

#Pharmaceutical Machinery#Tube Filling Machinery#Tube Sealing Machinery#Soft Drink Filling Machinery#Container Filling Machinery#Pharmaceutical Equipments#Pharmaceutical Machine#Food Processing Machinery#Chemical Equipment#Plastic Tube Filling Machinery#Multi Head Container Filling Machine#Cone Blender#Volumetric Bottle Filling#Filtration Unit#Rotary Bottle Washing

0 notes

Text

How does ETO Sterilization work?

What is ETO Sterilization?

Ethylene oxide (ETO) sterilization is a process used to sterilize medical and pharmaceutical products that cannot withstand traditional high-temperature steam sterilization methods. ETO is a gas that effectively kills microorganisms such as bacteria, viruses, and fungi by disrupting their DNA and cellular proteins.

How Does ETO Sterilization Work?

Preparation: Items to be sterilized are placed in a sealed chamber.

Exposure: ETO gas is introduced into the chamber, reaching all surfaces of the items.

Conditioning: The gas is held at specific temperature, humidity, and pressure levels for a predetermined time to ensure effective sterilization.

Aeration: Post-sterilization, the chamber is aerated to remove residual ETO gas, as ETO is toxic and potentially carcinogenic.

Monitoring: Throughout the process, parameters such as gas concentration, temperature, and exposure time are closely monitored to ensure efficacy and safety.

Applications of ETO Sterilizers

ETO sterilization is particularly suitable for:

Medical Devices: Such as surgical instruments, implants, and catheters.

Pharmaceuticals: Including drugs, ointments, and powders that are sensitive to heat and moisture.

Packaging Materials: Like plastic pouches and tubes that cannot withstand high temperatures.

Its ability to penetrate porous materials and complex devices makes ETO sterilization indispensable in many healthcare and pharmaceutical settings where other methods might be impractical or ineffective.

Considerations and Safety

While highly effective, ETO sterilization poses certain safety challenges:

Toxicity: ETO is hazardous to human health and requires careful handling. Workers must be trained in its safe use, and facilities must have adequate ventilation and monitoring systems.

Residuals: Proper aeration is crucial to remove ETO residues, which can otherwise compromise product safety.

Regulatory Compliance: Due to its potential health risks, ETO sterilization is heavily regulated by health authorities and environmental agencies worldwide.

Future Trends and Innovations

As technology advances, efforts are underway to improve the efficiency and safety of ETO sterilization processes. This includes developments in gas monitoring systems, aeration techniques, and automation to minimize human exposure.

Conclusion

ETO sterilization plays a critical role in ensuring the safety and efficacy of medical and pharmaceutical products that are sensitive to heat and moisture. While it requires careful handling due to its toxicity, advancements in technology continue to enhance its reliability and safety. As healthcare and pharmaceutical industries evolve, ETO sterilization remains a cornerstone in the arsenal of sterilization methods, ensuring that healthcare providers and patients alike can trust in the sterility of essential medical products.

Top ETO Sterilizer Manufacturer in India

If you are looking for Best ETO Sterilizer Manufacturer in India, look no further than Instech Sytems, we are a leading manufacturer and supplier of ETO Sterilizer in India.

For more details, please contact us!

Website :- www.cssdtechnologies.com

Contact No. :- +91–8896456000 , +91–9873069138

Email :- [email protected]

#ETO Sterilizer manufacturer#ETO Sterilizer manufacturer in India#Top ETO Sterilizer supplier in India#Best ETO Sterilizer manufacturer in India#Instech Systems

2 notes

·

View notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.