#Plywood Market Growth

Text

The report “Plywood Market” is valuable to anyone who wants to understand the global Plywood industry. The study provides a comprehensive analysis on the market trends, prices, applications, regional breakup, manufacturers, imports, exports, manufacturing process.

#Plywood Market Size#Plywood Market Share#Plywood Market Trends#Plywood Market Growth#Plywood Market Forecast#Plywood Market Report

0 notes

Text

Construction Segment to Remain the Fastest Expanding Application of Plywood Market During 2022-2027

Construction Segment to Remain the Fastest Expanding Application of Plywood Market During 2022-2027

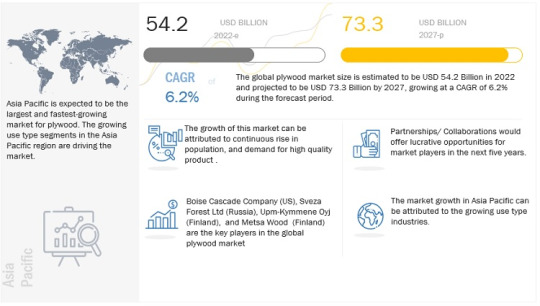

The global plywood market size is projected to grow from USD 54.2 billion in 2022 to USD 73.3 billion by 2027, at a CAGR of 6.2%, According to the MarketsandMarkets™ analysis. Plywood is a well-known manufactured wood-based panel product that has been used in global development projects for many years. Plywood panels for structural applications are made up of many layers or plys of softwood…

View On WordPress

#Demand for Plywood#Plywood Market#Plywood Market Analysis#Plywood Market Forecast#Plywood Market Growth#Plywood Market Insights#Plywood Market Overview#Plywood Market Report#Plywood Market Share#Plywood Market Size#Plywood Market Trends#Plywood Sales

0 notes

Text

The report "Plywood Market by Type (Hardwood and Softwood), Application (Construction and Industrial), Uses Type (New Construction and Rehabilitation), and Region (North America, Europe, APAC, MEA, South America) - Global Forecast to 2027", Plywood market size is projected to reach USD 73.3 billion by 2027 from USD 54.2 billion in 2022 growing at a CAGR of 6.2%. The Asia Pacific region is the largest market for plywood across the globe. The market in the Asia Pacific has been studied for China, India, Japan, South Korea, Taiwan, Thailand, Malaysia and the Rest of Asia Pacific (Australia, Indonesia, and others). Among these countries, China accounted for the largest share of 80.0% of the Asia Pacific plywood market in terms of value.

India and China have experienced close to double-digit GDP growth in recent years, as well as a population boom. The stable economy and growing building and construction industry has augmented the growth of plywood in India and China. Furthermore, furniture sector is one of the main consumers of plywood in India. During the 2018 to 2023, it is predicted that the India furniture market by commercial sector will have a CAGR of 11.97%. India is the fourth-largest consumer of furniture worldwide and the fifth-largest producer of furniture. The Indian furniture industry is estimated to be worth $8 billion, represents 0.5% of the GDP in 2022 according to IBEF (Indian Brand Equity Foundation). The domestic organized industry has roughly 5000 businesses, and there are almost 10,500 furniture imports. The industries that contribute most to the sectors growth include real estate, housing & hospitality, and consumer base growth.

Major players operating in the plywood include Georgia Pacific LLC (US), Boise Cascade Company (US), Weyerhaeuser Company Ltd (US), UPM-Kymmene Oyj (Finland), Svezza Forest Ltd (Russia), PotlatchDeltic Corporation (US), Greenply Industries Ltd (India), Century Plyboards India Ltd. (India), Austral Plywoods (Australia), and others.

#Plywood Market#Plywood Market Report#Plywood Market Insights#Plywood Market Size#Plywood Market Share#Plywood Market Forecast#Plywood Market Overview#Plywood Market Trends#Plywood Market Analysis#Demand for Plywood#Plywood Sales#Plywood Market Growth#Plywood Market Opportunity

0 notes

Text

Sustainable Construction: How the Particle Board Market is Evolving in 2024-2034

Particle board, also known as chipboard, is an engineered wood product made from wood chips, sawdust, and resin. It has become a cost-effective alternative to solid wood and plywood, used extensively in the construction, furniture, and packaging industries. The global particle board market is expected to see considerable growth from 2024 to 2034, driven by increasing urbanization, rising demand for affordable furniture, and a growing focus on sustainable building materials.

The global particle board industry, valued at US$ 25.1 billion in 2023, is projected to grow at a CAGR of 5.6% from 2024 to 2034, reaching US$ 45.3 billion by the end of 2034. Factors such as the expansion of the construction sector in emerging economies, the increasing demand for eco-friendly products, and innovations in particle board manufacturing technologies are contributing to this growth.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/particle-board-market.html

Market Segmentation

The particle board market is segmented based on various parameters:

By Service Type:

Raw particle boards: Used for structural purposes in construction and furniture.

Laminated particle boards: Used for aesthetic purposes in interior decoration and cabinetry.

Melamine-coated particle boards: Used for surfaces requiring water resistance, primarily in kitchens and bathrooms.

By Sourcing Type:

Softwood-based particle boards: Primarily used in construction and insulation due to durability.

Hardwood-based particle boards: Preferred for furniture making and decorative items for finer finishes.

By Application:

Furniture: The largest application segment, driven by the demand for cost-effective materials in household and office furniture.

Construction: Used in flooring, wall panels, and insulation.

Packaging: Gaining popularity as a sustainable material for packaging.

Others: Applications in exhibitions, partitions, and shelving units.

By Industry Vertical:

Residential Construction: High demand due to urbanization and affordable housing.

Commercial Construction: Used extensively in office spaces, hotels, and retail outlets.

Furniture Manufacturing: Essential for producing mass-market furniture.

Packaging Industry: Growing demand for eco-friendly packaging solutions.

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America

The particle board market in North America is driven by increasing demand in the residential and commercial construction sectors. Sustainable building practices and a growing preference for eco-friendly materials are key drivers in the region, with the United States and Canada being major markets.

Europe

Europe holds a significant share of the global particle board market, particularly in the furniture manufacturing industry. Countries like Germany, Italy, and Poland are leaders in particle board production. The European Union's emphasis on sustainability and circular economy principles further boosts the demand for particle boards.

Asia-Pacific

Asia-Pacific is the fastest-growing market for particle boards, with China and India leading the way. Rapid urbanization, a booming construction industry, and increasing consumer demand for affordable furniture are key growth drivers. The region’s strong industrial base in wood-based manufacturing supports particle board production.

Latin America

In Latin America, countries like Brazil and Mexico are witnessing growth in the particle board market due to increasing construction activities and growing demand for budget-friendly housing materials.

Middle East & Africa

The particle board market in the Middle East & Africa is relatively nascent but growing due to increased investments in infrastructure and construction projects.

Market Drivers and Challenges

Drivers

Cost-effectiveness: Particle boards are cheaper compared to solid wood and plywood, making them a popular choice in construction and furniture production.

Sustainability: As a product made from wood waste, particle boards align with the growing global focus on sustainability and reducing deforestation.

Urbanization and Infrastructure Development: Increasing construction activities, especially in emerging economies, are driving demand for particle boards.

Furniture Demand: The growing trend of affordable, ready-to-assemble (RTA) furniture has expanded the market for particle boards, especially in the residential and commercial sectors.

Challenges

Durability Issues: Particle boards are less durable compared to plywood and MDF, limiting their use in high-load applications.

Moisture Sensitivity: Particle boards are prone to damage when exposed to moisture, requiring additional treatments and coatings for certain applications.

Environmental Concerns: The use of synthetic resins, often containing formaldehyde, in particle board production has raised health and environmental concerns.

Market Trends

Sustainable Materials: The shift toward environmentally friendly building materials is pushing manufacturers to develop particle boards with minimal environmental impact, using bio-based resins and recycled wood materials.

Technological Advancements: Innovations in resin technology and production processes are enhancing the strength, water resistance, and overall performance of particle boards.

Rising Popularity of RTA Furniture: Ready-to-assemble furniture, particularly in the e-commerce sector, is boosting demand for particle boards, which are a key material in such products.

Future Outlook

The global particle board market is expected to continue its upward trajectory through 2034, with substantial growth opportunities in emerging markets. Increasing environmental awareness, combined with technological innovations in particle board production, will create a favourable market landscape. Additionally, advancements in coatings and laminates will enhance particle board durability, expanding its use in diverse applications.

Key Market Study Points

Market Size and Forecast: Evaluation of market value from 2024 to 2034.

Key Market Drivers: Identification of factors driving growth, including cost-effectiveness and sustainability.

Challenges: Analysis of issues like durability and moisture resistance.

Technological Innovations: Overview of advancements in resin and production processes.

Regional Insights: A detailed analysis of regional markets with growth potential in Asia-Pacific and North America.

Competitive Landscape: Insight into the leading market players and their strategies.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86230<ype=S

Competitive Landscape

Major players in the global particle board market include:

Kronospan: A leading manufacturer with a strong global presence.

Egger Group: Known for innovations in wood-based products, including particle boards.

Norbord Inc.: Specializes in engineered wood products, including particle boards.

Weyerhaeuser Company: One of the largest producers of wood-based products, focusing on sustainability.

These companies are focusing on product innovation, expanding production capacities, and enhancing sustainability initiatives to maintain their market positions.

Recent Developments

Sustainability Initiatives: Several manufacturers are investing in bio-based resins to reduce the environmental impact of particle board production.

New Product Launches: Companies are introducing particle boards with enhanced moisture resistance and improved surface finishes for high-end furniture applications.

Capacity Expansions: Increasing demand for particle boards has led to new production facilities being established, particularly in the Asia-Pacific region.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

2023 Saw a 6% Dip in European Wood-Based Panels Production

In 2023, the European wood-based panel industry faced a notable downturn. The year was marked by a 6.3% decrease in production, a figure that has been characterized as "disappointing" by industry experts. This decline, as reported by the European Panel Federation (EPF), reflects a significant shift in the sector's dynamics. The statistics not only underscore the challenges faced by the industry but also signal a need for a deeper analysis of the underlying causes.

In this blog, we will discuss the factors contributing to this downturn and explore its implications for the European timber market and its global standing in wood-based panel production.

Wood-Based Panels Gain Market Share

Despite the overall downturn, wood-based panels emerged as a bright spot, outperforming the two principal consumer sectors—furniture and construction. This trend indicates an increase in market share for wood-based products, a silver lining amidst broader industry challenges.

This encouraging development is detailed in the EPF's Annual Report 2023. The report was unveiled during the EPF's Annual General Meeting, which took place from June 19-21 in Riga, Latvia. The event, hosted by the Latvian plywood manufacturer Latvijas Finieris, brought together 180 professionals from across the industry, creating a forum for dialogue and collaborative efforts in the face of market challenges.

The Varied Fortunes of Wood-Based Panels in 2023

The product-specific analysis for 2023 reveals a fragmented market in the wood-based panels sector:

OSB (Oriented Strand Board) stood out as the only category to witness growth, with a 2% increase in production, reaching 6.6 million cubic meters (up from 6.5 million cubic meters in 2022).

Particleboard, the industry’s largest segment, experienced a 5% decline, with production falling to 30.9 million cubic meters (down from 32.5 million cubic meters in 2022).

MDF (Medium-Density Fiberboard) suffered a sharper decline, with an 11% decrease leading to 11.1 million cubic meters of production (a drop from 12.5 million cubic meters in 2022).

Softboard, primarily comprising wood fibre insulation boards, which had previously been on an incline, saw a 6% reduction to 4.8 million cubic meters (previously at 5.2 million cubic meters).

Plywood production faced a significant 15% downturn, amounting to 2.6 million cubic meters (compared to 3.1 million cubic meters in 2022).

Hardboard recorded a 17% decrease, although it remains the smallest product area within the European wood-based panel industry, with production at 400,000 cubic meters (down from 500,000 cubic meters in 2022).

The detailed breakdown illustrates how different product areas within the global timber industry have had varying degrees of success and challenges.

Conclusion

Staying informed with the latest developments and understanding price dynamics are essential to success in the global timber industry. This is where the Timber Exchange’s Market Data Hub becomes an indispensable tool. As a comprehensive digital tracker of the global timber market, the Market Data Hub offers far more than mere data. It serves as a repository of detailed news, updates, and webinars.

Through a single, streamlined dashboard, the platform grants access to 200+ market indicators, empowering users to monitor a wide array of forestry operations effectively. The Market Data Hub covers it all, whether it's logging activities, production figures, inventory levels, or export/import volumes. It also provides insights into consumption patterns and pricing across more than 25 global key markets.For those eager to delve deeper into the Market Data Hub's capabilities and leverage its full potential, scheduling a demonstration is just a click away. Discover how this platform can transform your approach to navigating the global timber market.

0 notes

Text

Woodworking Circular Saw Blades Market Size, Global Industry Trend Analysis and Forecast 2024-2030

Global Info Research’s report offers key insights into the recent developments in the global Woodworking Circular Saw Blades market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included.Our report further provides readers with comprehensive insights and actionable analysis on the market to help them make informed decisions. Furthermore, the research report includes qualitative and quantitative analysis of the market to facilitate a comprehensive market understanding.This Woodworking Circular Saw Blades research report will help market players to gain an edge over their competitors and expand their presence in the market.

According to our (Global Info Research) latest study, the global Woodworking Circular Saw Blades market size was valued at USD million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of % during review period.

Woodworking Circular Saw Blades are round circular saw blades that are designed to cut various types of wood, including lumber, plywood, softwood, hardwood, panels and laminates. They can be used in various applications, depending on the type of wood you are cutting and the kind of task you are performing. Blades come in a variety of sizes and can be made of various materials to accommodate different uses.

In Japan market, key players of woodworking circular saw blades include Tenryu, Robert Bosch, Stanley Black and Decker, Tenryu Saw Mfg, TTI, etc. The top five players hold a share over 40%.

The Global Info Research report includes an overview of the development of the Woodworking Circular Saw Blades industry chain, the market status of Residential (Tungsten Carbide, Diamond), Industrial Manufacturing (Tungsten Carbide, Diamond), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Woodworking Circular Saw Blades.

Regionally, the report analyzes the Woodworking Circular Saw Blades markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Woodworking Circular Saw Blades market, with robust domestic demand, supportive policies, and a strong manufacturing base.

We have conducted an analysis of the following leading players/manufacturers in the Woodworking Circular Saw Blades industry:

Tenryu、Robert Bosch、Stanley Black and Decker、Tenryu Saw Mfg、TTI、Dewalt、HiKOKI、Makita、HILTI、Bahco、TRUSCO、RYOBI、KANEFUSA、Leitz、LEUCO

Market segment by Type: Tungsten Carbide、Diamond、Others

Market segment by Application:Residential、Industrial Manufacturing、Others

Report analysis:

The Woodworking Circular Saw Blades report encompasses a diverse array of critical facets, comprising feasibility analysis, financial standing, merger and acquisition insights, detailed company profiles, and much more. It offers a comprehensive repository of data regarding marketing channels, raw material expenses, manufacturing facilities, and an exhaustive industry chain analysis. This treasure trove of information equips stakeholders with profound insights into the feasibility and fiscal sustainability of various facets within the market.

Illuminates the strategic maneuvers executed by companies, elucidates their corporate profiles, and unravels the intricate dynamics of the industry value chain. In sum, the Woodworking Circular Saw Blades report delivers a comprehensive and holistic understanding of the markets multifaceted dynamics, empowering stakeholders with the knowledge they need to make informed decisions and navigate the market landscape effectively.

Conducts a simultaneous analysis of production capacity, market value, product categories, and diverse applications within the Woodworking Circular Saw Blades market. It places a spotlight on prime regions while also performing a thorough examination of potential threats and opportunities, coupled with an all-encompassing SWOT analysis. This approach empowers stakeholders with insights into production capabilities, market worth, product diversity, and the markets application prospects.

Assesses strengths, weaknesses, opportunities, and threats, offering stakeholders a comprehensive understanding of the Woodworking Circular Saw Blades markets landscape and the essential information needed to make well-informed decisions.

Market Size Estimation & Method Of Prediction

Estimation of historical data based on secondary and primary data.

Anticipating market recast by assigning weightage to market forces (drivers, restraints, opportunities)

Freezing historical and forecast market size estimations based on evolution, trends, outlook, and strategies

Consideration of geography, region-specific product/service demand for region segments

Consideration of product utilization rates, product demand outlook for segments by application or end-user.

About Us:

Global Info Research is a company that digs deep into Global industry information to Woodworking Circular Saw Blades enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the Global region to Woodworking Circular Saw Blades enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

0 notes

Text

John Oakey & Mohan Ltd Share Price Advancing Upwards

Introduction

John Oakey & Mohan Ltd, a well-established player in the abrasive products industry, is witnessing a significant upward trend in John Oakey & Mohan Ltd Share Price. This growth is driven by the company's solid performance and favorable market dynamics. Let’s explore the factors behind this positive movement in John Oakey & Mohan Ltd Share Price and its implications for investors. John Oakey and Mohan Limited is an unlisted company specializing in coated abrasive products. Its diverse product range includes Flint Paper, Emery Paper, Multicut Paper, Aloxide Paper, Waterproof Paper (both Silicon Carbide and Aloxide), Super Flex Waterproof Paper, Polishing Paper, and Emery Cloth (both Drill and Long cloth). Additionally, the company offers specialized products such as rolls, belts, lamellar wheels, flap wheels, spindle wheels, sleeves, webster, naumkegs, and discs made from cloth, paper, and fiber. The company serves a broad customer base across various industries, including prominent names in the cycle industry like Hero and Atlas, the two-wheeler industry with Hero Honda, Escorts, and Bajaj Auto, and the automobile industry with Maruti Udyog and Mahindra & Mahindra. Other sectors served include the glass, plywood, sheet metal fabrication, polishing, and tractor industries.

John Oakey and Mohan Limited has also expanded its export operations, making significant inroads into markets such as the USA, South Africa, Australia, Sri Lanka, and Nepal, with ongoing negotiations to enter Malaysia, the Middle East, and Europe. As a member of the renowned Mohan Meakins Group, which includes Wellington Mills and John Oakey & Sons in London, the company operates a manufacturing unit in Ghaziabad, Uttar Pradesh. Established in 1962, John Oakey and Mohan Limited has been in the business for over 50 years, demonstrating a longstanding commitment to quality and innovation.

Robust Company Performance

John Oakey & Mohan Ltd has consistently demonstrated strong financial performance, largely due to its diverse and high-quality product offerings. The company's product portfolio includes:

Flint Paper

Emery Paper

Multicut Paper

Aloxide Paper

Waterproof Paper (Silicon Carbide and Aloxide)

Super Flex Waterproof Paper

Polishing Paper

Emery Cloth (Drill and Long Cloth)

These products cater to various industrial applications, enhancing the company's reputation and market presence. The emphasis on quality and innovation has been a cornerstone of John Oakey & Mohan Ltd's success.

Favorable Market Conditions

The abrasive products industry is experiencing growth, spurred by increasing demand across various sectors such as manufacturing, automotive, and construction. As these industries expand, the need for reliable abrasive products rises, positioning John Oakey & Mohan Ltd to benefit from this trend.

The company's ability to adapt to market demands and continuously improve its product offerings has strengthened its market position. This adaptability, combined with the overall economic recovery and industrial growth, has created a conducive environment for the company's share price to climb.

Promising Investment Opportunity

The upward trajectory of John Oakey & Mohan Ltd's share price signals strong investor confidence in the company's future prospects. With a well-established market position and a proven track record of performance, the company presents an attractive investment opportunity. Analysts forecast continued growth in share price, reflecting the company's ongoing success and potential for further expansion.

Importance of Staying Informed

For investors and stakeholders, staying informed about the latest developments is crucial. The Planify website provides real-time updates on John Oakey & Mohan Ltd's share price, along with news and analysis on market trends and company performance. By keeping abreast of these updates, investors can make informed decisions and optimize their investment strategies.

Conclusion

John Oakey & Mohan Ltd's share price is advancing upwards, driven by robust company performance and favorable market conditions. As the demand for abrasive products continues to grow across various industries, the company is well-positioned for sustained growth. Investors seeking promising opportunities should consider the potential of John Oakey & Mohan Ltd's shares. For the latest updates and detailed analysis, visiting the Planify website is highly recommended.

#John Oakey & Mohan Ltd Share Price#John Oakey & Mohan Ltd IPO#John Oakey & Mohan Ltd Pre IPO#John Oakey & Mohan Ltd Unlisted Shares#John Oakey & Mohan Ltd Upcoming IPO

0 notes

Text

Discover Excellence: Top Laminate and Veneer Shop in Bangalore - Uro Veneer World

Introduction

When it comes to enhancing the beauty and functionality of your interiors, choosing the right materials is crucial. Enter Uro Veneer World, the premier laminate and veneer shop in Bangalore. Known for its high-quality products and exceptional customer service, Uro Veneer World is the go-to destination for homeowners, architects, and interior designers. But what makes this store stand out in a crowded market? Let's delve into the world of laminates and veneers and discover why Uro Veneer World should be your first choice.

For premium Veneers, laminates and Plywood options and competitive pricing in Bangalore, visit Uro Veneer World.

What Sets Uro Veneer World Apart?

Quality of Products

At Uro Veneer World, quality is never compromised. Every laminate and veneer is sourced from reputable manufacturers, ensuring top-notch durability and aesthetic appeal. Whether you're looking for a sleek modern finish or a classic wooden texture, the variety here caters to every taste and need.

Customer Service Excellence

Customer satisfaction is at the heart of Uro Veneer World’s business model. The knowledgeable and friendly staff are always ready to assist you, providing expert advice and tailored solutions. From the moment you walk in, you’ll experience a level of service that goes above and beyond, making your shopping experience both enjoyable and productive.

For premium Veneers, laminates and Plywood options and competitive pricing in Bangalore, visit Uro Veneer World.

History of Uro Veneer World

Founding and Early Days

Uro Veneer World was founded with a vision to provide Bangalore with the best in laminate and veneer solutions. Starting as a small store, it quickly gained a reputation for quality and reliability.

Growth and Development

Over the years, Uro Veneer World has grown significantly, expanding its product range and enhancing its service offerings. Today, it stands as a leader in the industry, known for its innovation and customer-centric approach.

Product Range

Overview of Products

Uro Veneer World offers an extensive range of laminates and veneers, each designed to meet diverse design and functional requirements.

Laminates

Types of Laminates

From high-pressure laminates (HPL) to low-pressure laminates (LPL), Uro Veneer World has it all. Each type comes in various finishes, including glossy, matte, and textured, allowing you to find the perfect match for your project.

Applications of Laminates

Laminates are incredibly versatile and can be used in a variety of applications, including kitchen cabinets, countertops, furniture, and wall panels. Their durability and ease of maintenance make them a popular choice for both residential and commercial spaces.

Veneers

Types of Veneers

Veneers at Uro Veneer World are available in a plethora of species, such as oak, walnut, teak, and mahogany. Each veneer has its unique grain pattern, offering a distinct look that adds character to any space.

Applications of Veneers

Veneers are ideal for creating elegant and sophisticated interiors. They are commonly used in furniture, cabinetry, and wall cladding, providing a natural and luxurious finish that is hard to replicate with other materials.

Customization Options

Tailored Solutions for Clients

One of the standout features of Uro Veneer World is its ability to offer customized solutions. Whether you have a specific design in mind or need help creating one, the team here can bring your vision to life.

Benefits of Customization

Customization ensures that your laminates and veneers fit perfectly with your existing decor and meet your specific functional needs. It also allows for a unique and personalized touch, setting your space apart from the rest.

Why Choose Laminates?

Durability and Maintenance

Laminates are known for their durability and resistance to scratches, stains, and moisture. They are easy to clean and maintain, making them a practical choice for high-traffic areas.

Aesthetic Appeal

With a wide range of colors, patterns, and textures, laminates can mimic the look of natural materials like wood and stone at a fraction of the cost. This versatility makes them a favorite among designers.

Cost-Effectiveness

Compared to other surfacing materials, laminates offer great value for money. They provide a high-end look without the hefty price tag, making them accessible to a broader audience.

Why Choose Veneers?

Natural Look and Feel

Veneers offer the closest resemblance to solid wood, providing a warm and authentic look. The natural grains and patterns add depth and richness to any surface.

Variety and Uniqueness

No two veneer sheets are identical, ensuring that your interiors have a unique and exclusive appearance. This variety allows for endless design possibilities.

Longevity

With proper care, veneers can last for many years. They can be sanded and refinished, giving them a renewed look and extending their lifespan.

Customer Reviews and Testimonials

Positive Feedback from Clients

Customers rave about their experiences with Uro Veneer World. Many highlight the excellent quality of products and the helpfulness of the staff. Such testimonials are a testament to the store’s commitment to excellence.

Case Studies

Several case studies showcase how Uro Veneer World has helped clients transform their spaces. From residential homes to commercial offices, the results speak for themselves.

Sustainability Practices

Eco-friendly Materials

Uro Veneer World is committed to sustainability. They offer eco-friendly laminates and veneers that are sourced responsibly and have minimal environmental impact.

Sustainable Manufacturing Processes

The store adheres to sustainable manufacturing practices, ensuring that their operations are environmentally responsible. This commitment to sustainability is reflected in their product offerings.

Expert Staff and Craftsmanship

Skilled Workforce

The team at Uro Veneer World comprises highly skilled professionals who are experts in their field. Their craftsmanship is evident in the quality of the finished products.

Attention to Detail

Every product is meticulously crafted, with attention to the smallest details. This precision ensures that you receive the best possible product for your needs.

Showroom Experience

Location and Ambiance

Located in the heart of Bangalore, the Uro Veneer World showroom is designed to provide an immersive shopping experience. The ambiance is welcoming and allows you to explore the products comfortably.

What to Expect When You Visit

When you visit the showroom, you can expect to be greeted by friendly staff who are eager to assist you. You can view samples, get expert advice, and even see how different laminates and veneers would look in your space.

Competitive Pricing

Price Comparison with Competitors

Uro Veneer World offers competitive pricing without compromising on quality. When compared to other stores, you’ll find that they provide excellent value for money.

Value for Money

The combination of high-quality products, exceptional service, and competitive pricing makes Uro Veneer World a smart choice for anyone looking to upgrade their interiors.

Awards and Recognition

Industry Accolades

Uro Veneer World has received numerous awards for its outstanding products and services. These accolades are a testament to their dedication to excellence.

Certifications and Standards

The store adheres to the highest industry standards and holds several certifications that guarantee the quality and reliability of their products.

How to Get Started

Visiting the Store

To experience the best in laminates and veneers, visit the Uro Veneer World showroom in Bangalore. The friendly staff will guide you through the product range and help you find the perfect match for your needs.

Online Consultation and Ordering

For those who prefer online shopping, Uro Veneer World offers virtual consultations and online ordering. This convenient option allows you to explore their products from the comfort of your home.

Conclusion

Uro Veneer World stands out as the top laminate and veneer shop in Bangalore for many reasons. Their commitment to quality, exceptional customer service, and a wide range of products make them the go-to destination for all your interior design needs. Whether you’re renovating your home or designing a new space, Uro Veneer World has everything you need to create beautiful, functional interiors. Visit their showroom today or explore their offerings online to discover the best in laminates and veneers.

0 notes

Text

The globalplywood market size is projected to grow from USD 54.2 billion in 2022 to USD 73.3 billion by 2027, at a CAGR of 6.2%. The increasing demand for plywood from end uses, such as building & construction, packaging, industrial, and furniture sector, drives the market. Demand for multifarious plywood is encouraged by many companies to formulate different developmental strategies in the plywood market to expand their footprint in the market. The companies have adopted various strategies, such as investment & expansion, merger & acquisition, new product launches, and joint ventures to increase their global presence and maintain sustained growth in the plywood market.

The plywood market in the Asia Pacific is forecasted to register the highest CAGR, in terms of value, between 2022 and 2027. Asia Pacific is a rapidly developing region that offers many opportunities for various industry players. Most of the leading players in North America and Europe are planning to move their production base to this region because of the availability of inexpensive raw materials, low production costs, and the need to serve the local market better. The demand for premium products is increasing in the region with the growth in the middle-class population. Government initiatives are also helping in the growth of the wooden sectors. These factors will play an important role in driving the plywood market.

There are various small, medium, and large players operating in the market. Some of the major market players include Boise Cascade Company (US), Weyerhaeuser Company Ltd (US), Upm-Kymmene Oyj (Finland), Sveza Forest Ltd (Russia), Austral Plywoods Pty Ltd (Australia), Potlatchdeltic Corporation (US), Greenply Industries (India), Metsä Wood (Metsäliitto Cooperative) (Finland), Centuryply (India), Austin Plywood (India). They have adopted various developmental strategies such as investment & expansions, new product launches, mergers & acquisitions, and joint ventures to increase their share in the market.

#Plywood Market#Plywood Market Report#Plywood Market Insights#Plywood Market Size#Plywood Market Share#Plywood Market Forecast#Plywood Market Overview#Plywood Market Trends#Plywood Market Analysis#Demand for Plywood#Plywood Sales#Plywood Market Growth#Plywood Market Opportunity

0 notes

Text

Top 10 Plywood Manufacturers in India

The Indian plywood industry is experiencing a significant surge, with an impressive turnover of over INR 208.5 Billion in FY 2022-23 and an anticipated growth rate surpassing 6%. Amidst this thriving landscape, Sylvan Ply emerges as a standout player. With its commitment to quality and innovation, Sylvan Ply has secured its position among the top 10 plywood manufacturers in India. In a market flooded with options, Sylvan Ply stands tall, offering customers assurance and reliability in their choice of plywood brand. Get in touch with us to know more.

0 notes

Text

Brazil Wood Industry Witnesses Year-Over-Year Export Surge in May

The Brazilian wood industry is experiencing a remarkable growth, with a significant year-over-year increase in exports noted in May. This growth in forest exports is not just a temporary trend but a solid display of Brazil's increasing strength in the global timber market. The country has become a major supplier of a diverse range of wood-based products, including innovative cross-laminated timber panels, glulam, parquet and laminated flooring, sandwich panels, railway sleepers, and rounded saw wood.

Exports have emerged as a strong pillar for Brazil, showcasing its versatility through the export of mouldings, plywood, furniture, and lumber. The US, Mexico, and Europe stand out as the primary markets for these exports, indicating the widespread demand for Brazilian wood products. In this blog, we will explore the dynamics behind this export surge and what it signifies for the future of Brazil's timber industry.

Brazil's Wood Export Analysis

The International Tropical Timber Organization (ITTO) reports a complex picture for Brazil's wood-based product exports in May 2024. Overall, there was a 2.7% increase in value compared to the previous year, climbing from US$328.3 million to US$337.0 million. However, this aggregate growth masks some fluctuations in specific categories.

Pine-sawnwood, a staple of the industry, saw a 14% decrease in value year-over-year, dropping from US$74.5 million to US$64.1 million. The volume of pine sawnwood exports also fell by 11%, from 306,300 m³ to 271,300 m³.

Tropical sawnwood exports experienced a steep decline, with an 18% drop in volume and a 36% fall in value, signaling a significant shift from 29,000 m³ and US$14.9 million to 23,900 m³ and US$9.6 million, respectively.

In contrast, pine plywood exports painted a more positive picture, with a 20% rise in value and an 11% increase in volume, indicating a boost from US$63.8 million and 195,900 m³ to US$76.5 million and 217,100 m³.

Tropical plywood also showed promising signs, with a 9% volume and 11% value increase, marking a growth from 3,200 m³ and US$1.9 million to 3,500 m³ and US$2.1 million. The wooden furniture has witnessed a 5% uptick in export value, rising from US$52.1 million to US$54.6 million.

Brazil's Export Pricing and Its Global Impact

As Brazil strengthens its position as one of the world's top lumber exporters, its export pricing fluctuations hold considerable influence over the global timber market. The recent increase in Brazil's lumber export prices is set to have a significant impact. The construction industry may face heightened project costs, potentially pushing up housing prices.

Retailers could see a knock-on effect, with increased costs for lumber and wood products possibly affecting consumers, especially those planning home renovations or engaging in do-it-yourself projects. Also, other lumber-exporting countries might find themselves adjusting their prices in response to Brazil's market activity, which could lead to broader shifts in global price trends.

Conclusion

A successful lumber trading strategy relies on having accurate and up-to-date information on timber price trends. The Timber Exchange's Market Data Hub provides this crucial information. More than just a data source, it's a comprehensive digital hub for the global timber market, offering in-depth news, updates, and webinars.

The Market Data Hub's user-friendly dashboard presents over 200+ market indicators, enabling users to effectively oversee a broad range of forestry operations. From logging activities to production statistics, inventory counts, and export/import figures, the hub encompasses every aspect of the industry. It also sheds light on consumption trends and pricing in over 25 key global markets.Would you like to explore the full capabilities of the Market Data Hub and truly take advantage of its offerings? Book a demo from here.

0 notes

Text

Wood Based Panel Market Landscape: Trends, Drivers, and Forecast (2023-2032)

The Global Wood Based Panel Market is anticipated to grow from USD 182,643.28 million in 2023 to USD 328,787.01 million by 2032, with a compound annual growth rate (CAGR) of 6.75%.

The wood-based panel market encompasses a diverse range of engineered wood products made from wood particles, fibers, veneers, or strands bonded together with adhesives. This market includes products such as plywood, particleboard, oriented strand board (OSB), medium-density fiberboard (MDF), and hardboard. These panels are widely used in construction, furniture manufacturing, interior decoration, packaging, and other industrial applications due to their versatility, cost-effectiveness, and structural properties.

The global demand for wood-based panels is primarily driven by the construction industry, which utilizes these panels for applications such as flooring, roofing, wall sheathing, and structural components. The ongoing growth in residential, commercial, and infrastructure projects, particularly in emerging economies, fuels the demand for these materials. In the furniture sector, wood-based panels are favored for their ease of fabrication, consistent quality, and aesthetic appeal, contributing to their widespread use in cabinetry, countertops, and various furniture pieces.

Technological advancements in production processes have significantly improved the quality and performance of wood-based panels. Innovations such as enhanced adhesives, improved pressing techniques, and the incorporation of eco-friendly materials have resulted in products with superior strength, durability, and environmental sustainability. Additionally, the development of flame-retardant, moisture-resistant, and formaldehyde-free panels caters to specific market requirements and regulatory standards, further expanding their application range.

Sustainability is a critical focus within the wood-based panel market. Manufacturers are increasingly adopting sustainable practices, including the use of certified wood from sustainably managed forests, recycling wood waste, and reducing formaldehyde emissions in production. These practices not only address environmental concerns but also meet the growing consumer demand for eco-friendly products. The shift towards sustainable materials is also supported by stringent regulations and certifications such as the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC), which promote responsible forestry practices.

The wood-based panel market faces several challenges that impact its growth and sustainability. These challenges include environmental concerns, raw material availability, regulatory pressures, competition from alternative materials, and economic volatility. Here are the key challenges in detail:

Environmental Concerns

One of the most pressing challenges is the environmental impact of wood-based panel production. The industry is associated with deforestation, which leads to loss of biodiversity, disruption of ecosystems, and increased carbon emissions. Although many manufacturers are adopting sustainable forestry practices, the overall environmental footprint remains a significant concern. Additionally, the use of formaldehyde-based adhesives in some wood panels raises issues related to indoor air quality and health hazards, prompting stricter regulations and demand for safer alternatives.

Raw Material Availability

The availability and cost of raw materials are critical challenges for the wood-based panel market. Fluctuations in the supply of timber due to factors such as logging restrictions, climate change, and natural disasters can lead to increased costs and supply chain disruptions. In regions where deforestation is heavily regulated, obtaining a consistent supply of certified sustainable wood can be challenging, affecting production and pricing.

Regulatory Pressures

The wood-based panel industry is subject to stringent environmental and safety regulations aimed at reducing the impact on forests and ensuring the safety of products. Compliance with these regulations can be costly and complex, requiring investments in new technologies and processes. Regulations such as the European Union’s EUTR (European Timber Regulation) and CARB (California Air Resources Board) formaldehyde emission standards impose strict requirements on sourcing and manufacturing practices, which can be challenging for producers to meet consistently.

Competition from Alternative Materials

Wood-based panels face competition from alternative materials such as plastics, metal, and composite materials, which offer different benefits such as enhanced durability, lower maintenance, and better resistance to environmental conditions. Innovations in these alternative materials can potentially reduce the market share of wood-based panels, particularly in applications where these alternatives offer superior performance or cost advantages.

Economic Volatility

Economic downturns and market volatility can significantly affect the demand for wood-based panels. The construction and furniture industries, which are major consumers of these products, are highly sensitive to economic cycles. During economic slowdowns, reduced construction activities and lower consumer spending on furniture and home improvement projects can lead to decreased demand for wood-based panels.

Technological Challenges

While technological advancements have improved the quality and sustainability of wood-based panels, adopting and integrating new technologies can be challenging and expensive. Smaller manufacturers may struggle to invest in advanced production techniques and environmentally friendly materials, leading to disparities in product quality and market competitiveness.

Trade Restrictions and Tariffs

International trade restrictions, tariffs, and geopolitical tensions can impact the global supply chain and market dynamics for wood-based panels. Export restrictions or tariffs on timber and wood products can lead to higher costs and reduced market access for manufacturers in affected regions.

Waste Management

Managing waste and by-products from the production process is another significant challenge. The disposal of wood waste, sawdust, and other residues can pose environmental issues if not managed properly. Developing efficient recycling and waste management systems is crucial for reducing the environmental impact and improving the sustainability of the industry.

Key Player-

Georgia-Pacific LLC (Koch Industries)

West Fraser Timber Co. Ltd.

Weyerhaeuser Company

Norbord Inc.

Arauco

Louisiana-Pacific Corporation (LP)

EGGER Group

Kronospan

U.S. Lumber Group LLC

Swiss Krono Group

Roseburg Forest Products

Ainsworth Lumber Co. Ltd.

Panels & Furniture Group (PFM Group)

Boise Cascade Company

Pfleiderer Group S.A.

More About Report- https://www.credenceresearch.com/report/wood-based-panel-market

The key findings of a study on the wood-based panel market highlight several critical insights regarding market dynamics, growth drivers, challenges, and future trends. These findings provide a comprehensive overview of the current state and future prospects of the industry. Here are the key findings:

Market Size and Growth

Significant Market Growth: The global wood-based panel market has been experiencing substantial growth, driven by increasing demand in the construction, furniture, and packaging industries. The market is expected to continue its upward trajectory over the next few years, supported by urbanization, population growth, and industrialization in emerging economies.

Regional Insights: Asia-Pacific dominates the wood-based panel market, accounting for the largest market share due to rapid urbanization and industrial activities, particularly in China and India. North America and Europe are also significant markets, with strong demand driven by construction and furniture manufacturing. Latin America and Africa are emerging markets with growing construction activities and improving economic conditions.

Demand Drivers

Construction Industry Demand: The construction sector is the largest consumer of wood-based panels, utilizing these products for applications such as flooring, roofing, wall sheathing, and structural components. The ongoing growth in residential, commercial, and infrastructure projects fuels the demand for wood-based panels.

Furniture and Interior Applications: The furniture industry is a major driver of demand for wood-based panels, favored for their versatility, ease of fabrication, and aesthetic appeal. Panels are widely used in cabinetry, countertops, and various furniture pieces, contributing to market growth.

Technological Advancements: Innovations in production processes, including enhanced adhesives, improved pressing techniques, and the development of eco-friendly materials, have led to higher-quality and more sustainable wood-based panels. These advancements are attracting more consumers and expanding application possibilities.

Challenges

Environmental Concerns: The industry faces significant challenges related to deforestation, carbon emissions, and the use of formaldehyde-based adhesives. Addressing these environmental concerns is crucial for sustainable growth.

Raw Material Availability: Fluctuations in the supply of timber due to logging restrictions, climate change, and natural disasters can lead to increased costs and supply chain disruptions, affecting market stability.

Regulatory Compliance: Stringent environmental and safety regulations, such as EUTR and CARB standards, impose strict requirements on sourcing and manufacturing practices, increasing the complexity and cost of compliance.

Trends and Opportunities

Sustainability Initiatives: There is a growing emphasis on sustainable practices, including the use of certified wood from sustainably managed forests, recycling wood waste, and reducing formaldehyde emissions. These initiatives are driven by both regulatory requirements and consumer demand for eco-friendly products.

Digital Transformation: The integration of digital technologies in production and supply chain management is improving efficiency and reducing costs. Innovations such as automation, data analytics, and digital platforms are transforming the industry landscape.

Green Building Practices: The rise of green building practices and the demand for environmentally sustainable construction materials are creating new opportunities for wood-based panels. Products that meet green building standards and certifications are gaining popularity.

Segments:

Based on Product Type

Medium Density Fibreboard (MDF)/High-Density Fibreboard (HDF)

Particle Board

Fiberboard

Plywood

Others such as oriented strand board, poplar wood panels,etc

Based on Application

Furniture

Flooring

Construction

Packaging

Others

Browse the full report – https://www.credenceresearch.com/report/wood-based-panel-market

Browse Our Blog: https://www.linkedin.com/pulse/wood-based-panel-market-overview-growth-factors-future-trends-mkxcf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Understanding the Environmental Impact of Waterproof Plywood and its Alternatives

In an era where sustainability is more than just a buzzword, understanding the environmental impact of construction materials is crucial. Among these materials, waterproof plywood and its alternatives play a significant role in various applications, from furniture to flooring. This blog delves into the environmental footprint of waterproof plywood and explores viable alternatives like WPC doors and Floresta products.

The Environmental Footprint of Waterproof Plywood

Waterproof plywood is renowned for its durability and resistance to moisture, making it a popular choice in construction. However, the production process of waterproof plywood raises several environmental concerns. The primary issue lies in the sourcing of raw materials. Traditional plywood production involves harvesting large quantities of timber, often from old-growth forests. This deforestation leads to habitat loss, reduced biodiversity, and increased carbon emissions.

Moreover, the waterproofing process involves using synthetic adhesives and resins, such as phenol-formaldehyde. These chemicals, while effective in making the plywood resistant to water, are not environmentally friendly. They release volatile organic compounds (VOCs) during manufacturing and can contribute to indoor air pollution over time. Disposal of waterproof plywood also presents challenges, as the materials do not biodegrade easily, leading to long-term landfill waste.

Alternatives to Waterproof Plywood

Recognizing the environmental drawbacks of waterproof plywood, the construction industry is increasingly turning to sustainable alternatives. Two prominent options are WPC doors and Floresta products, both of which offer comparable benefits with a reduced environmental impact.

WPC Doors

Wood Plastic Composite (WPC) doors are an innovative alternative to traditional waterproof plywood. Made from a blend of wood fibers and thermoplastics, WPC doors offer excellent durability and resistance to moisture, making them ideal for use in areas prone to humidity, such as bathrooms and kitchens.

The production of WPC doors is significantly more sustainable than that of waterproof plywood. WPC doors utilize recycled wood and plastic, reducing the need for virgin raw materials and helping to divert waste from landfills. Furthermore, the manufacturing process emits fewer VOCs, contributing to better indoor air quality.

WPC doors are also known for their longevity and low maintenance requirements, which further enhances their sustainability profile. Unlike traditional plywood, WPC doors do not warp or deteriorate over time, reducing the need for frequent replacements and thereby conserving resources.

Floresta Products

Floresta is another sustainable alternative gaining traction in the market. Floresta products are engineered to mimic the aesthetic appeal and functional properties of traditional wood while minimizing environmental harm. These products are typically made from fast-growing, renewable resources and incorporate eco-friendly adhesives and finishes.

One of the key advantages of Floresta products is their eco-conscious production process. By using sustainably sourced materials and low-emission manufacturing techniques, Floresta products significantly lower their carbon footprint. Additionally, these products are designed to be fully recyclable, addressing the end-of-life disposal challenge associated with traditional waterproof plywood.

Making the Sustainable Choice

As consumers and builders become more aware of the environmental impact of their choices, the demand for sustainable materials is on the rise. Waterproof plywood, while effective, poses significant environmental challenges that cannot be ignored. Alternatives like WPC doors and Floresta products offer a promising solution, combining durability and moisture resistance with a reduced ecological footprint.

By choosing these alternatives, we can contribute to a more sustainable future, preserving natural resources and reducing pollution. Whether you are renovating your home or embarking on a new construction project, consider the environmental impact of your materials. Opting for WPC doors or Floresta products over traditional waterproof plywood is a step in the right direction towards sustainable building practices.

In conclusion, understanding the environmental impact of waterproof plywood alternative and exploring sustainable alternatives is essential for environmentally responsible construction. WPC doors and Floresta products not only meet the functional demands but also align with the growing commitment to sustainability in the building industry.

Also, Read:

How WPC Sheets Offer Eco-Friendly Alternatives in Construction

How Termite-Proof Boards Work to Keep Delhi Homes Safe

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

The Importance of Softwood Logs Suppliers in the UAE

The construction and manufacturing industries in the United Arab Emirates (UAE) have seen a substantial surge over the past few decades, fueled by rapid urbanization and economic diversification. Amidst this growth, the demand for high-quality softwood logs has risen, making the role of softwood logs suppliers in the UAE increasingly vital. These suppliers provide essential raw materials that support a variety of sectors, including construction, furniture making, and interior design.

Softwood logs are sourced from coniferous trees such as pine, spruce, and fir. Known for their versatility, light weight, and ease of workability, softwoods are a preferred material in numerous applications. In construction, they are commonly used for framing, roofing, and flooring due to their strength and cost-effectiveness. Additionally, their aesthetic appeal makes them ideal for producing furniture, cabinetry, and decorative elements.

The UAE, with its ambitious infrastructure projects and booming real estate market, requires a steady supply of high-quality softwood logs. Softwood logs suppliers in the UAE play a crucial role in meeting this demand by sourcing timber from sustainable forests worldwide, ensuring that the supply chain remains robust and environmentally responsible.

One of the key aspects of a reliable softwood logs supplier is their commitment to sustainability. With global concerns about deforestation and environmental degradation, responsible sourcing practices have become more critical than ever. Leading suppliers in the UAE adhere to stringent sustainability standards, ensuring that the wood they provide comes from certified forests managed under sustainable forestry practices. This not only helps protect the environment but also assures clients that they are using ethically sourced materials.

Another important factor is the quality and consistency of the supply. High-quality softwood logs must be free from defects such as knots, splits, and warping. Reputable suppliers in the UAE ensure that their logs undergo rigorous quality checks and are processed using state-of-the-art equipment to meet industry standards. Consistent quality is essential for builders and manufacturers who rely on these materials to produce durable and aesthetically pleasing products.

Furthermore, efficient logistics and timely delivery are critical components of a successful softwood logs supplier. The fast-paced construction industry in the UAE demands prompt and reliable supply chains. Top Plywood Supplier in UAE have well-established distribution networks and partnerships with global logistics providers to ensure that their clients receive materials on time, minimizing delays in construction and manufacturing processes.

0 notes

Text

Rushil Decor Ltd. Strengthens Global Presence with Expansion into South America

Rushil Decor Limited, a prominent player in the manufacturing of eco-friendly MDF, laminates, and plywood, has announced a significant strategic expansion into the South American market. This move marks a substantial milestone in the company's journey to solidify its global footprint, leveraging its extensive experience and innovative product offerings.

The announcement was made in conjunction with Interzum Bogota, an international industry fair for furniture and wood technology held in Colombia from May 14 to 17, 2024. At the event, Mr. Rushil Thakkar, Executive Director of Rushil Decor, expressed optimism about the company's growth prospects in the multi-billion-dollar global wood panel market.

A Strategic Expansion into a Promising Market - Rushil Decor's entry into South America is a carefully planned strategic move aimed at tapping into one of the world's largest markets for Medium Density Fiberboard (MDF). Known for its high demand in the region, South America presents a lucrative opportunity for Rushil Decor to expand its market reach and enhance its export revenues.

As a leading MDF manufacturer in India, Rushil Decor is well-prepared to meet the high standards and expectations of the South American market. The company recently reported a 9% growth in the January to March 2024 quarter compared to the same period last year, with export revenues contributing 28% to the total revenue in the fourth quarter of FY24. This underscores the company's strong international presence and its ability to cater to global demands.

Capitalizing on Market Opportunities - According to Precision Reports, the global MDF market was valued at USD 24,942.77 million in 2024 and is projected to reach USD 29,965.13 million by 2027. Similarly, the global laminate market is expected to grow to USD 11.98 billion by 2030. These projections highlight significant growth opportunities for Rushil Decor, which is strategically positioning itself to capitalize on this potential through its upcoming greenfield project aimed at meeting the burgeoning export demand for laminates.

By leveraging its expertise in both laminates and MDF, Rushil Decor is poised to create synergies across its product lines, further enhancing its revenue potential and solidifying its global footprint. The company’s expansion into South America is expected to significantly boost its market presence and operational efficiency.

Commitment to Sustainability and Innovation - Rushil Decor’s expansion aligns with its commitment to sustainability and innovation. The company supports the values emphasized at the 2024 edition of Interzum Bogota, which focuses on the circular economy, sustainability, innovation, and technology. Rushil Decor’s product range is a testament to these principles, offering eco-friendly, high-quality solutions that meet the evolving needs of global customers.

"Expanding into South America is a significant milestone for Rushil Decor," said Mr. Rushil Thakkar, Executive Director of Rushil Decor Limited. "This move underscores our dedication to providing sustainable and high-quality products to new regions, meeting the evolving needs of South American customers. We are excited about the growth opportunities this expansion presents."

Future Growth and Vision - Rushil Decor's strategic expansion is part of its broader vision to achieve annual revenues of INR 2500 crores by 2029. With state-of-the-art manufacturing facilities and a robust distribution network, the company is well-equipped to meet the increasing demands of the global market while maintaining financial stability and operational efficiency.

Founded in 1993, Rushil Decor Limited has grown into a global leader in modern interior infrastructure and eco-friendly, composite wood panels. The company operates six manufacturing plants with an annual capacity of 3,30,000 CBM MDF and 3.49 million laminates, catering to customers in over 50 countries worldwide. Additionally, Rushil Decor has expanded into plywood manufacturing at its Chikamaglur Plant in Bengaluru, with plans to gradually increase production capacity.

A Legacy of Quality and Innovation - Rushil Decor’s product portfolio includes VIR Laminates, VIR MDF boards, VIR MAXPRO (HDFWR) boards, VIR Pre-laminated Decorative MDF/HDFWR boards, VIR Modala Ply, VIR PVC, and VIR WPC boards/doors. The company’s focus on quality, design, and customer-centricity, combined with value-led DIY green-engineered products from agroforestry, sets it apart in the industry.

Driven by automated plants, world-class German technologies, and global standards, Rushil Decor continually creates smarter spaces. Optimal supply chain efficiencies, resource utilization, and strategic local plantations offer a cost advantage in raw material sourcing and manufacturing excellence, enabling high output to meet global market demand.

0 notes